Page 1

We understand water.

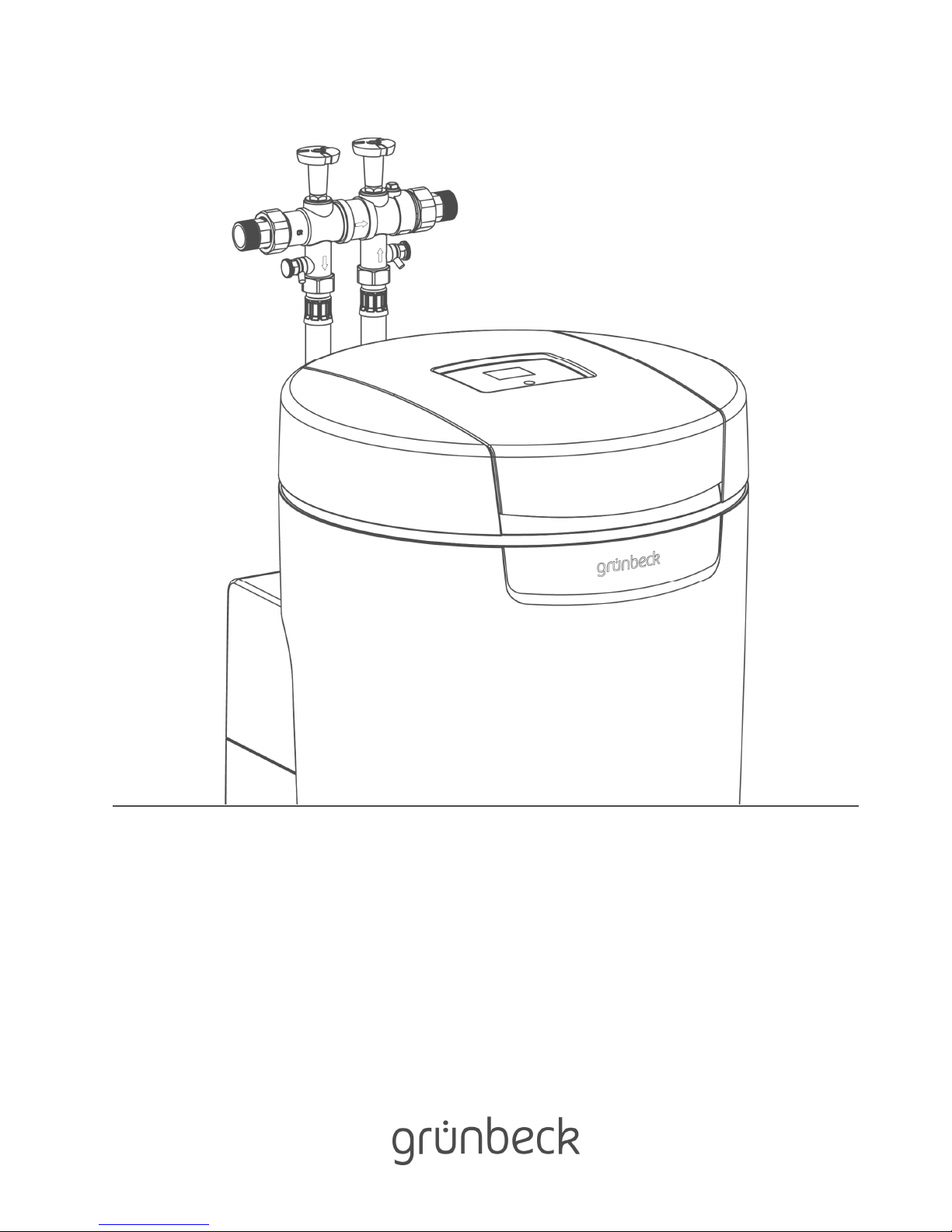

Water Softener | softliQ:MC

Operation manual

Page 2

Central Contact

Germany

Sales

Phone +49 9074 41-0

Technical Service

Phone +49 9074 41-333

Fax +49 9074 41-120

Availability

Monday to Thursday

7:00 am – 6:00 pm

Friday

7:00 am – 4:00 pm

Your local point of contact: see

accompanying list of

representatives

Copyright

The manufacturer reserves the copyright to this manual. No part of this manual may be reproduced

in any way without the written permission of Grünbeck Wasseraufbereitung GmbH, nor may any part

be processed, duplicated or disseminated using electronic systems.

Violations of the aforementioned requirements shall be subject to compensation.

We reserve the right to modifications.

© by Grünbeck Wasseraufbereitung GmbH

Translation of the original operation manual

Edition of the operation manual: August 2018

Order no.: TD3-BM000en_064

Page 3

Table of contents

3 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

Table of contents

1

About this manual ............................................... 4

1.1Other applicable documents ................................ 4

1.2Target group ........................................................ 4

1.3Storage of documents .......................................... 4

1.4Symbols used ...................................................... 4

1.5Typographical conventions .................................. 5

1.6Validity of the manual .......................................... 6

1.7Type plate ............................................................ 7

2Safety ................................................................... 8

2.1Safety measures .................................................. 8

2.2Technical safety instructions ................................ 9

2.3Regulations .......................................................... 9

2.4Responsibilities of the specialist installer and/or

the specialist company ...................................... 10

2.5Responsibilities of the owner/user ..................... 10

2.6Permitted regenerant ......................................... 10

3Product description .......................................... 11

3.1Intended use ...................................................... 11

3.2Product components .......................................... 11

3.3Functional description ........................................ 12

3.4Features ............................................................. 13

3.5Product registration ............................................ 14

3.6Accessories ....................................................... 15

4Control unit ........................................................ 17

4.1Overview ............................................................ 17

4.2Displays ............................................................. 17

4.3Navigating the control unit ................................. 19

4.4Menu structure ................................................... 20

4.5Code-protected levels ........................................ 22

4.6"myGrünbeck" app ............................................. 24

4.7Peer-to-peer connection .................................... 25

4.8Connection via Wi-Fi router ............................... 26

4.9Sending an email if there is a malfunction ......... 31

5Installation ......................................................... 33

5.1Requirements in relation to the installation site . 33

5.2Checking the scope of supply ............................ 35

5.3Installing the product .......................................... 35

6Start-up .............................................................. 40

6.1Starting up the product ...................................... 40

6.2Hand over the product to the owner/user togehter

with the operation manual ..................................44

7Operation ............................................................45

7.1Retrieving information .........................................45

7.2Starting a manual regeneration ..........................46

7.3Settings ...............................................................47

7.4Select regeneration time .....................................48

7.5Setting the current date and time .......................48

7.6Setting the time of the fixed regeneration ...........48

7.7Determining and entering the water hardness ....49

7.8Refilling salt tablets .............................................51

8Cleaning, inspection, maintenance ..................52

8.1Cleaning .............................................................52

8.2Inspection ...........................................................53

8.3Maintenance .......................................................53

8.4Consumables ......................................................55

8.5Spare parts .........................................................55

8.6Wearing parts .....................................................56

9Troubleshooting .................................................57

9.1Display messages ..............................................57

9.2Other observations .............................................61

10Shut-down and restart .......................................62

10.1Shut-down ..........................................................62

10.2Restart ................................................................62

11Dismantling and disposal .................................63

11.1Dismantling .........................................................63

11.2Disposal ..............................................................63

12Technical specifications ...................................65

13Other information ...............................................67

13.1Explanation of terminology .................................67

13.2Sodium content in the water ...............................67

13.3Hardness ranges ................................................68

14Operation log ......................................................69

Page 4

About this manual

4 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

1 About this manual

1.1 Other applicable documents

The following documents shall be deemed as applicable documents for the softliQ:MC:

● For Grünbeck's technical service/authorised service company:

Technical service manual for softliQ:MC water softener

Order no.: TD4-BM000en

● In addition, the manuals of all accessories used do apply.

1.2 Target group

This manual is intended for specialist installers and owners/users.

1.3 Storage of documents

Keep this manual and all other applicable documents, so that they are available when

needed. Make sure that your specialist installer enters the proper start-up and annual

maintenance in the operation log in chapter 14 .

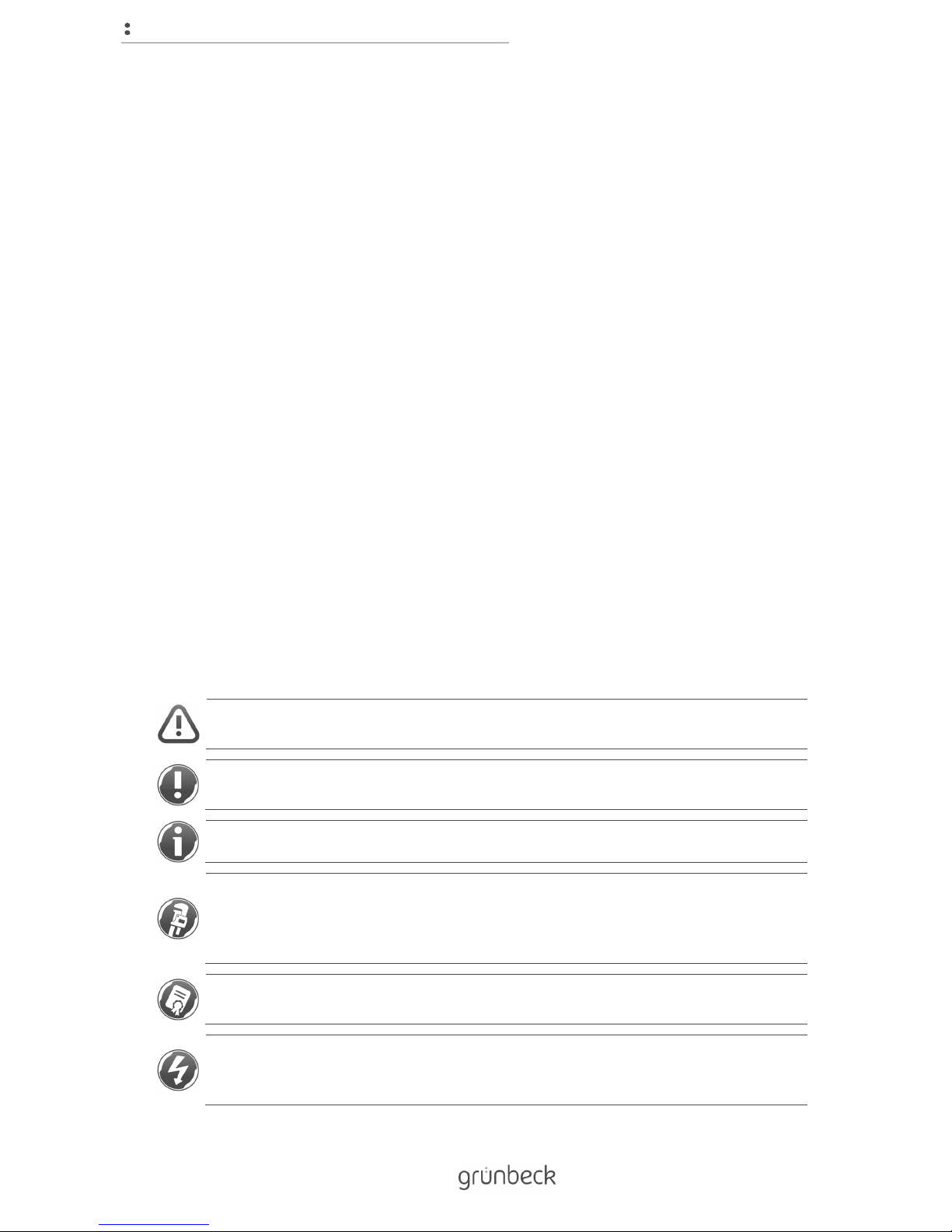

1.4 Symbols used

This symbol identifies information and instructions and that you must comply with for your

personal safety as well as to avoid damage to property.

This symbol identifies information and instructions that you must comply with in order to

avoid damage to property.

This symbol identifies important information about the product or its handling.

This symbol identifies work that may only be carried out by a specialist installer. In

Germany, the installation company must be registered in an installation directory of a water

supply company acc. to §12(2) AVB Wasser V (German Ordinance on General Conditions

for the Supply of Water).

This symbol designates tasks that may only be performed by Grünbeck's technical

service/authorised service company or by specialist installers trained by Grünbeck.

This symbol identifies work that may only be performed by electronically trained personnel

in accordance with the VDE guidelines or according to the guidelines of similar local

institutions.

Page 5

About this manual

5 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

1.5 Typographical conventions

The following typographical conventions are used in this manual:

1.5.1 Menu paths

Menu paths are shown in a different font. The sequence of the menus is indicated by the ">"

sign.

Status level>Menu level>Manual regeneration

1.5.2 Menu items

Menu items, e.g. within a software menu, are highlighted in grey.

Menu item

1.5.3 Buttons

Buttons are depicted with a dotted frame.

Button

1.5.4 Instructions

Single-step instructions or instructions where the sequence of the actions is unimportant are

indicated as follows:

► Action

Multi-step instructions where the sequence of the steps must be observed are indicated as

follows:

1. First step (level 1)

a - First subdivision of the step (level 2)

b - Second subdivision of the step (level 2)

2. Second step (level 1)

Results of an instruction are indicated as follows:

» Result

Page 6

About this manual

6 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

1.5.5 Lists

Bullet points used:

● First bullet point (level 1)

• First bullet point (level 2)

• Second bullet point (level 2)

● Second bullet point (level 1)

1.6 Validity of the manual

This manual applies to the following products:

● Water softener softliQ:MC32

● water softener softliQ:MC38

Page 7

About this manual

7 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

1.7 Type plate

The type plate is located under the lid of the brine tank.

Please specify the data shown on the type plate in order to speed up the processing of your

inquiries or orders. Therefore enter the necessary information in the table below to have it

readily available whenever necessary.

Item Designation Item Designation

1 Brine tank lid 2 Pre-alarm salt supply

3 Observe operation manual 4 Disposal information

5 SVGW test mark 6 DVGW test mark

7 EAC mark 8 CE mark

9 Nominal pressure 10 Ambient temperature

11 Power supply 12 Power input

13 Protection class 14 Product designation

15 QR code 16 Data matrix code

17 Order no. 18 Serial no.

● Product designation: Water softener softliQ:MC__

● Order no.: 187___

● Serial no.: ________________

2

3 8

9

16

14

13

15

10

12

18

17

1 76

5

4

11

Page 8

Safety

8 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

2 Safety

WARNING: Contamination of drinking water due to improper handling.

● Risk of infectious diseases.

► Have the installation, start-up and annual maintenance carried out by specialist

installers only.

2.1 Safety measures

● Carefully read this manual before operating your product.

● Install the product in a frost-free room. Otherwise, the system may suffer

irreparable damage. Water damage may occur as a result.

● Only use genuine spare parts for maintenance or repair. If unsuitable spare parts

are used, the warranty for your product will be void.

● Do not use products which have a damaged power supply cable. This can lead to

injuries due to electric shock. Have damaged power supply cables replaced without

delay.

● Mains cables may only be replaced by the manufacturer or by authorised

personnel.

● Comply with the hygiene instructions in chapter 8. Failure to comply can result in

microbiological contamination of your drinking water installation.

● Only have persons working on your system that have read and understood the

present manual and that are qualified to do such work based on their vocational

training.

● Only operate the product if all components are installed properly.

● Safety devices must never be removed, bridged or otherwise tampered with.

● This product can be used by children over 8 years of age and persons with limited

abilities or lack of experience if they are supervised or instructed in the safe use of

the product and do understand the resulting hazards.

● Cleaning and maintenance must not be carried out by children.

● Keep the product away from children.

Page 9

Safety

9 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

2.2 Technical safety instructions

This manual contains information and instructions that you must comply with for your

personal safety as well as to avoid damage to property. The information and instructions are

highlighted by a warning triangle and have the following structure:

CAUTION: Type and source of danger.

● Possible consequences

► Preventive measures

The following signal words are defined according to the degree of danger, and may be used

in this document:

● DANGER means that serious or fatal injuries will occur if the corresponding

precautionary measures are not taken.

● WARNING means that serious or fatal injuries may occur if the corresponding

precautionary measures are not taken.

● CAUTION means that damage to property may occur if the corresponding

precautionary measures are not taken.

● NOTE (without a warning triangle) means that damage to property may occur if the

corresponding safety measures are not taken.

2.3 Regulations

When installing and starting up the system, amongst others, comply with the following

regulations and guidelines:

● Statutory regulations on environmental protection

● Provisions of the employers' liability insurance company

● DIN EN 806 Specifications for installations inside buildings conveying water for

human consumption

● VDI 6023 Parts 5 to 7

Page 10

Safety

10 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

2.4 Responsibilities of the specialist installer and/or the

specialist company

Comply with the following instructions to ensure the proper and safe functioning of the

product:

● Only perform activities described in this manual.

● Perform all activities in accordance with all applicable standards and regulations.

● Brief the owner/user on the function and operation of the product.

● Advise the owner/user of the maintenance of the product.

● Inform the owner/user about possible dangers that can arise during operation of

the product.

2.5 Responsibilities of the owner/user

Comply with the following instructions to ensure the proper and safe functioning of the

product:

● Arrange for a specialist installer to carry out installation, start-up and maintenance.

● Have the product explained to you by the specialist installer.

● Only perform activities described in this manual.

● Do not carry out any activities that are explicitly marked for a specialist installer.

● Only use this product as intended.

● Make sure that the required inspection and maintenance work is carried out.

● Keep this manual.

2.6 Permitted regenerant

The softliQ:MC water softener may only be operated with the following regenerant:

● Salt tablets according to EN 973 type A

Other regenerants are not allowed.

Page 11

Product description

11 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

3 Product description

3.1 Intended use

● The softliQ water softener may only and exclusively be used for the softening and

partial softening of cold drinking water.

● The softliQ water softener protects water pipes and connected water-carrying

systems from scaling or from malfunctions and damage caused by scaling.

● The softliQ:MC32 water softener is designed for the continuous supply of houses

of 1 up to 8 units (max. 20 persons) with soft water.

● The softliQ:MC38 water softener is designed for the continuous supply of houses

of 3 up to 12 units (max. 30 persons) with soft water.

3.2 Product components

Item Designation Item Designation

1 Connection block 2 Shut-off valve for raw water

3 Shut-off valve for soft water 4 Control unit

5 Brine valve 6 Housing of technical equipment, lower part

7 Exchanger 2 8 Exchanger 1

9 Housing of technical equipment, upper part 10 Water test kit "total hardness“

11 Sieve bottom 12 Brine tank

13 Illuminated LED ring 14 Brine tank lid

15 Control valves

2 3

1 4

5

67

15

9 10

11

12

14

13

8

Page 12

Product description

12 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

3.3 Functional description

3.3.1 Ion exchange process

The softliQ water softener works according to the ion exchange process. The exchange of

calcium and magnesium ions for sodium ions causes the water to become soft.

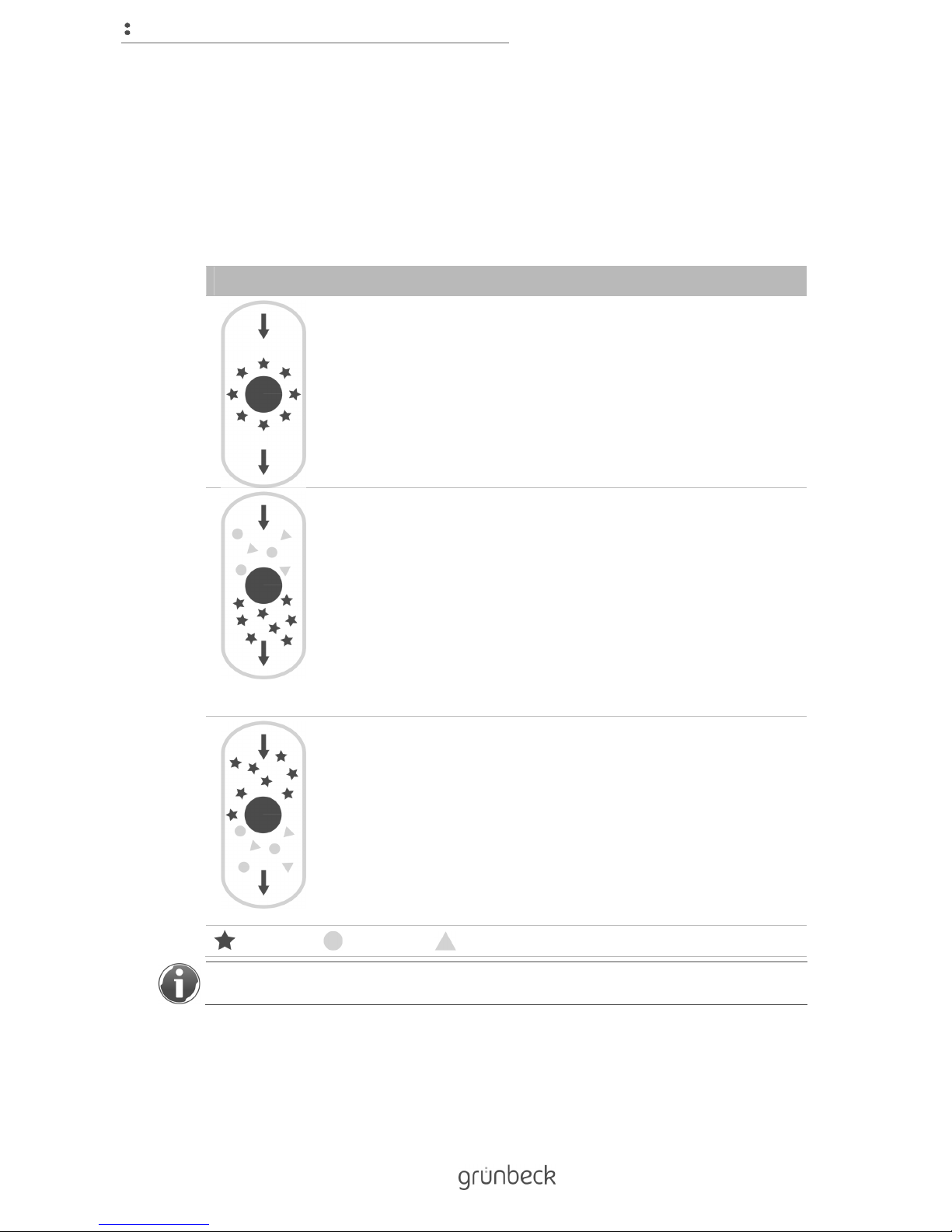

Figure Explanation

The exchanger contains ion exchanger resin in the form of small resin

beads.

Sodium ions adhere to each resin bead.

Hard water containing lots of calcium and magnesium ions flows through

the exchanger.

The ion exchanger resin absorbs calcium and magnesium ions from the

water in exchange for sodium ions.

This reaction is called ion exchange.

The calcium and magnesium ions are retained in the exchanger.

Soft water without calcium and magnesium ions, but containing sodium

ions, leaves the exchanger.

This process continues until no more sodium ions are available. The ion

exchanger resin is exhausted.

The exchange can be reversed if a large amount of sodium ions is

added.

The exchanger is rinsed with brine (water containing salt).

By their sheer number, sodium ions displace calcium and magnesium

ions on the ion exchanger resin.

This water containing calcium and magnesium ions is discharged to the

drain.

The initial condition is restored.

The ion exchanger resin is regenerated, and thus ready for operation.

Sodium ion Calcium ion Magnesium ion

Your dishwasher works according to the ion exchange process, too.

Page 13

Product description

13 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

3.3.2 Intelligence of the softliQ:MC water softener

Based on the consumption values of the past four weeks, the system capacity is

automatically adjusted to the individual water consumption of the owner/user.

A regeneration is released, if at least 50 % of the current system capacity is used up. The

point of regeneration automatically is placed in a time period where usually little water is

consumed. The point of regeneration can also be set at a fixed time.

During each regeneration, only the used-up system capacity is regenerated and only as

much salt is used as necessary. No later than after four days without regeneration, the

system releases a complete regeneration, as required by DIN standard 19636-100, for

hygienic reasons.

The intelligence of the softliQ water softener allows for an efficient operation at the lowest

salt and power consumption possible.

3.3.3 Function

The softliQ:MC water softener features four modes (selections):

● Eco

Minimum use of resources in case of normal consumption.

● Power

Maximum performance for highest demands.

● Comfort

Optimum use of resources and system performance.

● Individual

To enter your own user profile.

3.4 Features

3.4.1 Electronically controlled blending unit

The electronically controlled blending unit automatically regulates the ratio between fully

softened water and raw water. The regulation is subject to the raw and soft water hardness

programmed in the control unit.

Page 14

Product description

14 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

3.4.2 Pre-alarm salt supply

Once per regeneration, a light sensor checks the filling level of the regeneration salt. If the

filling level of the regeneration salt is low, the control unit provides feedback in the form of a

warning message. This is shown by a yellow symbol in the control unit. If the level falls below

the minimum filling level, the control unit calculates how many days the salt supply is

expected to last and indicates this value in days.

The days the salt supply is expected to last are calculated based on the water consumption

of the past days. In case of fluctuating water consumption, the indicated range of the salt

supply also fluctuates.

3.4.3 Illuminated LED ring

The illuminated LED ring illuminates the brine tank and is a visual signal to indicate operating

states. The illuminated LED ring may be programmed to the following functions:

● Is illuminated during water treatment

● Is illuminated during operation of the control unit

● Intermittent flashing in case malfunctions do occur

● Intermittent flashing in case of pre-alarm salt supply

If desired, the illuminated LED ring can be set to continuous illumination or be deactivated

completely (refer to chapter 4.4).

3.5 Product registration

If you register your product, the warranty for this product will be extended by one year.

You have the following options to register your product:

● Registration on Grünbeck's website (www.gruenbeck.com).

● Registration using the myGrünbeck app (refer to chapter 4.6).

Page 15

Product description

15 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

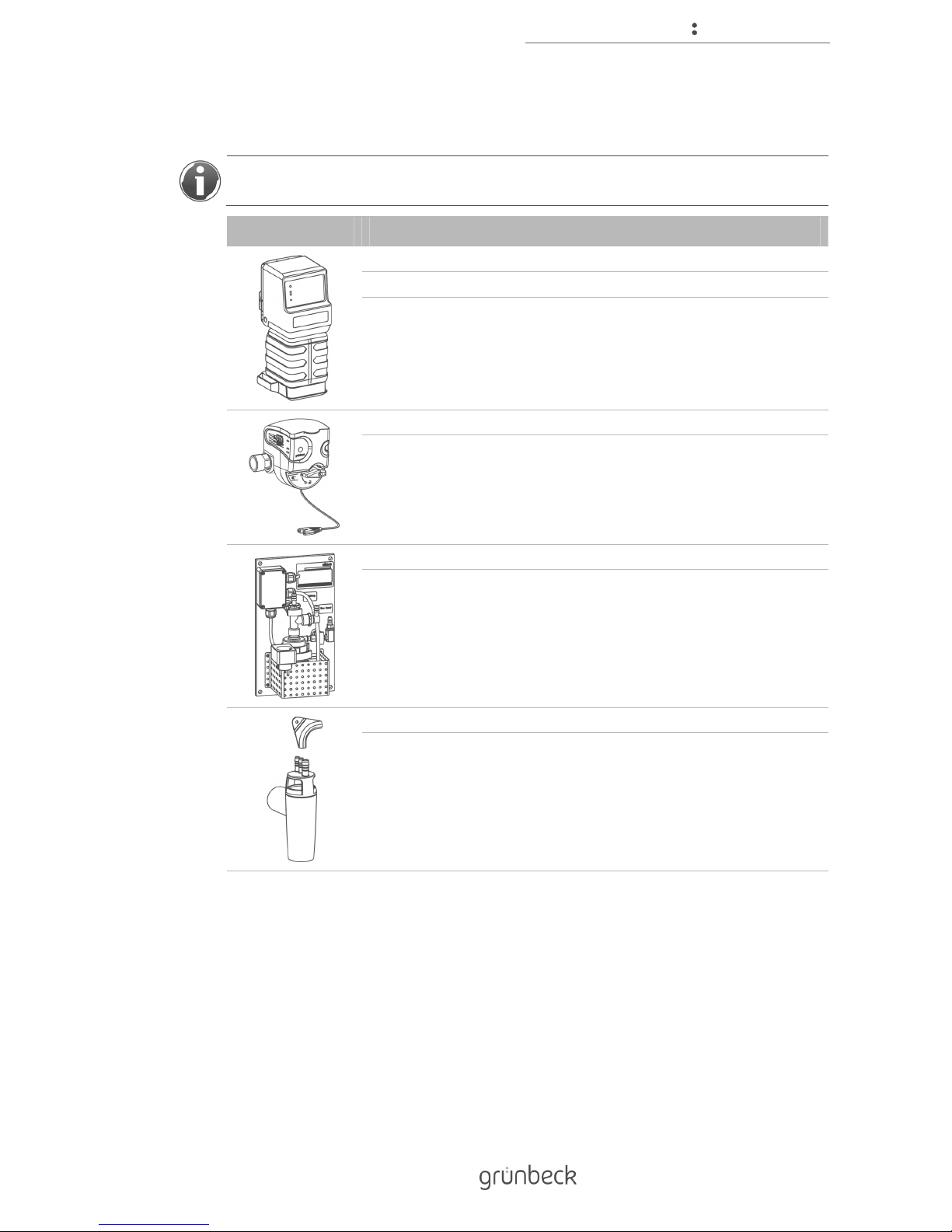

3.6 Accessories

You can retrofit your product with accessories. Please contact your local Grünbeck

representative or Grünbeck’s headquarters in Hoechstaedt for details.

Figure Product Order no.

EXADOS dosing computer EK 6 softliQ:MC 115 570

EXADOS dosing computer ES 6 softliQ:MC 115 580

Electronically controlled dosing technology for corrosion protection or

to stabilise the total hardness.

Safety device protectliQ:A20 126 400

Product for protection against water damage in one- and two-family

homes.

For other sizes, please inquire.

Regeneration water delivery pump 188 800

To discharge the regeneration water into drain pipes located at a

higher level.

Drain connection DN 50 188 875

For professional installation acc. to DIN EN 1717.

Page 16

Product description

16 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

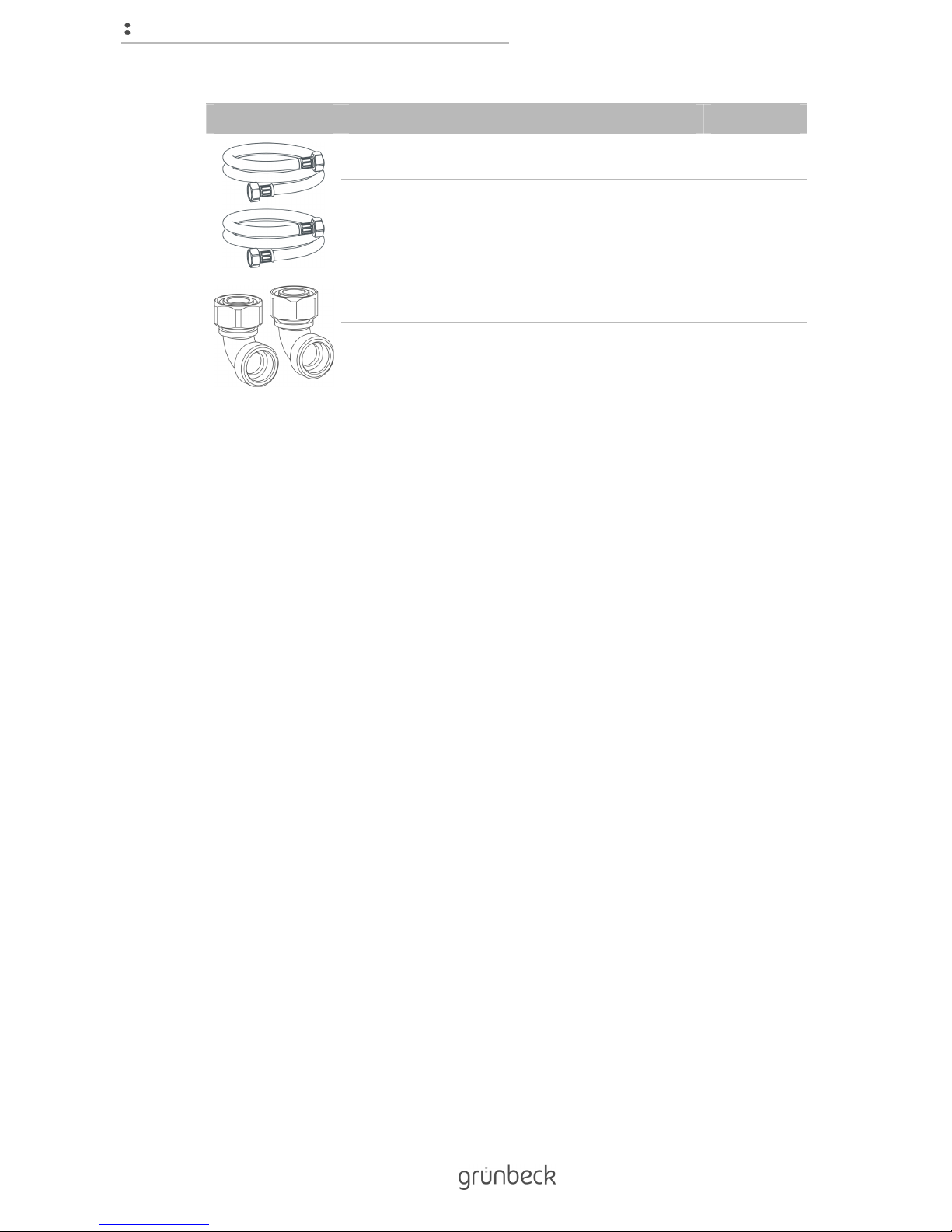

Figure Product Order no.

Extension kit for connection hoses DN25

(MC32)

187 660e

Extension kit for connection hoses DN32

(MC38)

187 680e

To extend the hose to 1.6 m.

90° connection angle – 1" (2x)

(MC32)

187 865

To direct the connection hoses closer along the softliQ in case of

confined installation conditions.

Page 17

Control unit

17 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

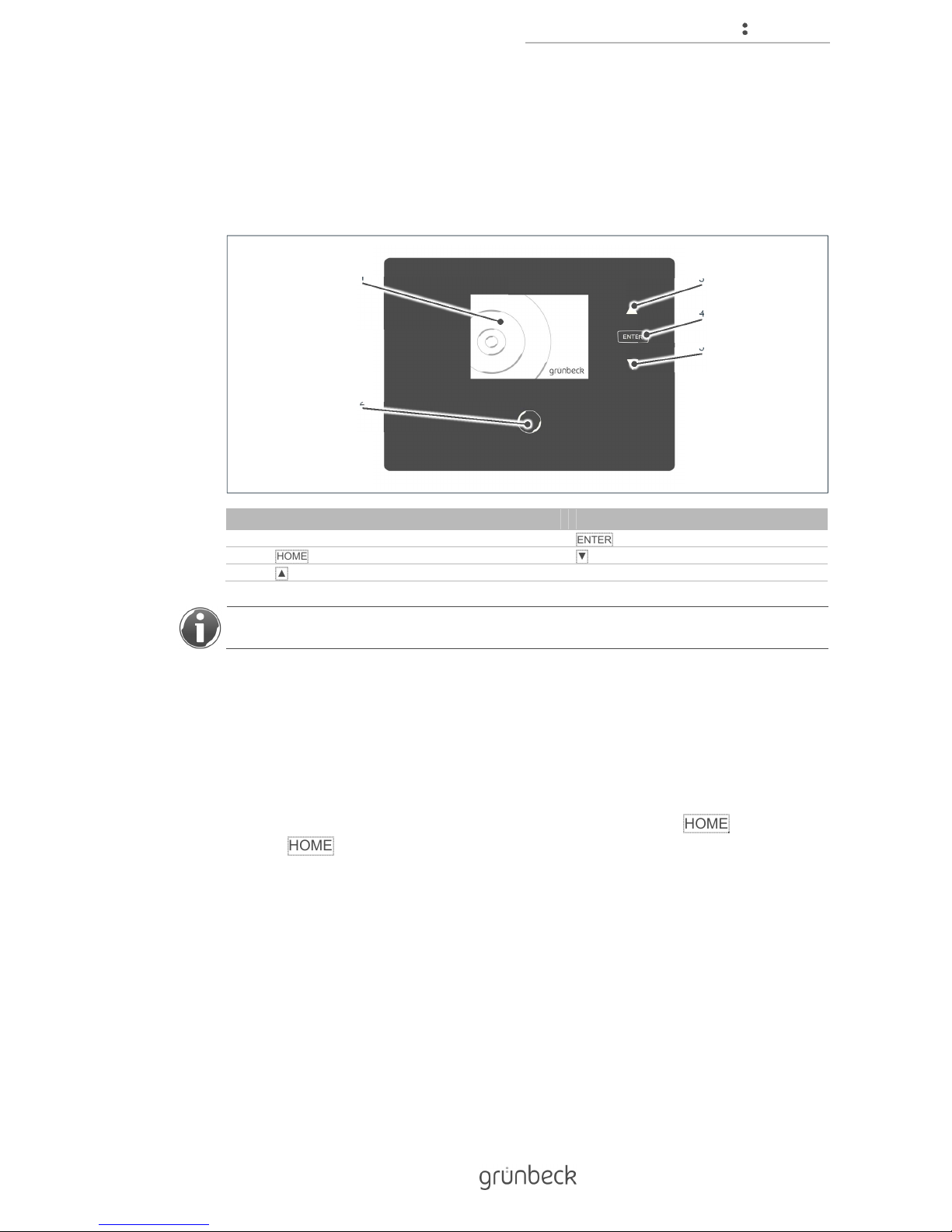

4 Control unit

4.1 Overview

Item Designation Item Designation

1 Display 4

ENTER key

2

HOME button

5

▼ Down arrow key

3

▲ Up arrow keys

Only those keys light up, which currently have a function assigned.

4.2 Displays

4.2.1 Status level

The status level is the basic display of your water softener. It provides you with information

on the current status. As standard, the display is switched off and only HOME is illuminated.

Pressing HOME briefly activates the display.

If the menu level is selected but no button is pressed for more than 2 minutes, the control

unit returns to the status level and the display turns off. Parameters that have not been

saved are discarded.

2

1

3

4

5

Page 18

Control unit

18 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

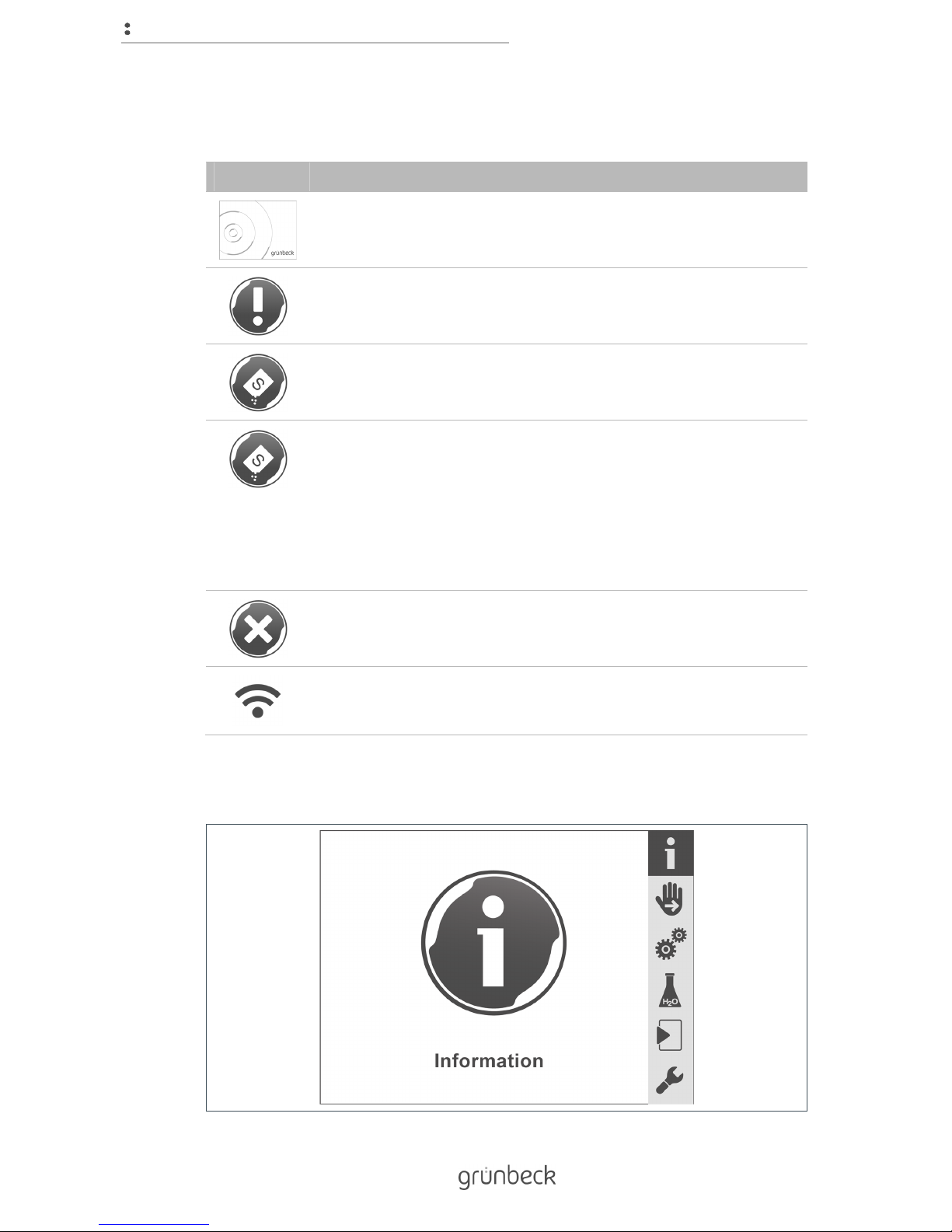

The following messages are displayed in the status level:

Figure Explanation

The water softener is working properly.

Yellow symbol

Service due!

Notify Grünbeck's technical service/authorised service company.

Yellow symbol

Salt supply low! Please refill! Still sufficient for xy days

Red symbol

Salt supply used up! Refill immediately!

The water softener is not working properly.

1. Refill salt.

2. Wait for 10 minutes.

3. Perform a manual regeneration (refer to chapter 7.2).

Red symbol

The water softener is not working properly. A malfunction has occurred

(refer to chapter 9.1).

Wi-Fi symbol

This is displayed when there is a Wi-Fi connection with a router.

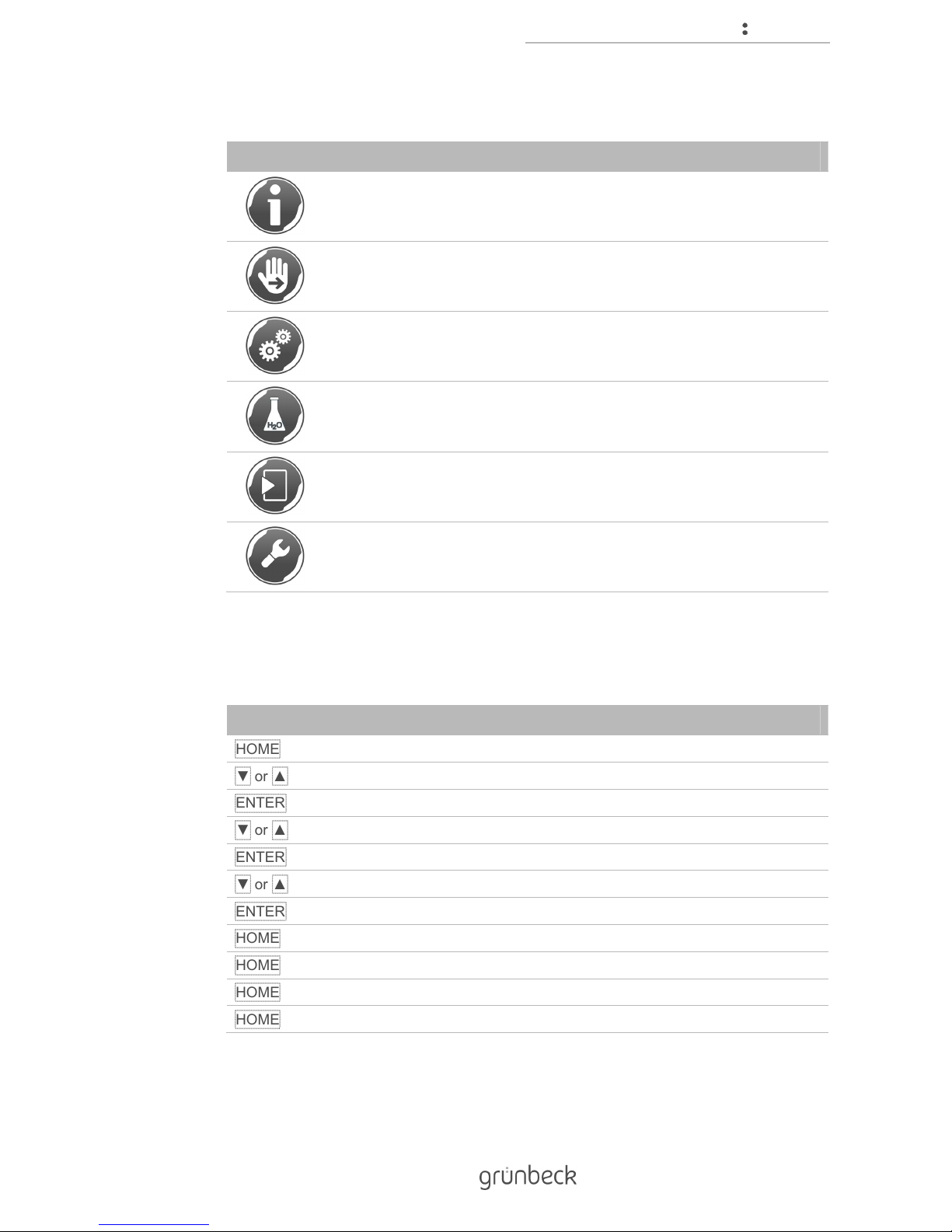

4.2.2 Menu level

Page 19

Control unit

19 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

In the menu level, you may select the following submenus:

Figure Explanation

Information

This menu offers useful information on the water softener (refer to

chapter 7.1).

Manual regeneration

In this menu, you can manually release a regeneration (refer to

chapter 7.2).

Settings

In this menu, you can adapt your water softener individually (refer to

chapter 7.3).

Water hardness

In this menu, you can enter the values of the prevailing raw water and the

desired soft water hardness (refer to chapter 7.7).

Start-up

In this menu, you can start the automatic start-up program (refer to

chapter 6.1).

Technical service

The technical service menu is reserved for Grünbeck's technical

service/authorised service company and is protected by a code.

4.3 Navigating the control unit

Step Designation

HOME

Call up the menu level from the status level

▼ or ▲

Scroll through the menu level

ENTER

Select submenu

▼ or ▲

Scroll to the menu items

ENTER

Activate value or selection

▼ or ▲

Change values or select setting

ENTER

Accept value or setting

HOME

Do not save value or setting (cancel procedure)

HOME

Back to the menu level

HOME

Back to the status level

HOME

Call up the menu level from the status level

Page 20

Control unit

20 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

4.4 Menu structure

For more information about the contents of the menu level, refer to chapter 7.

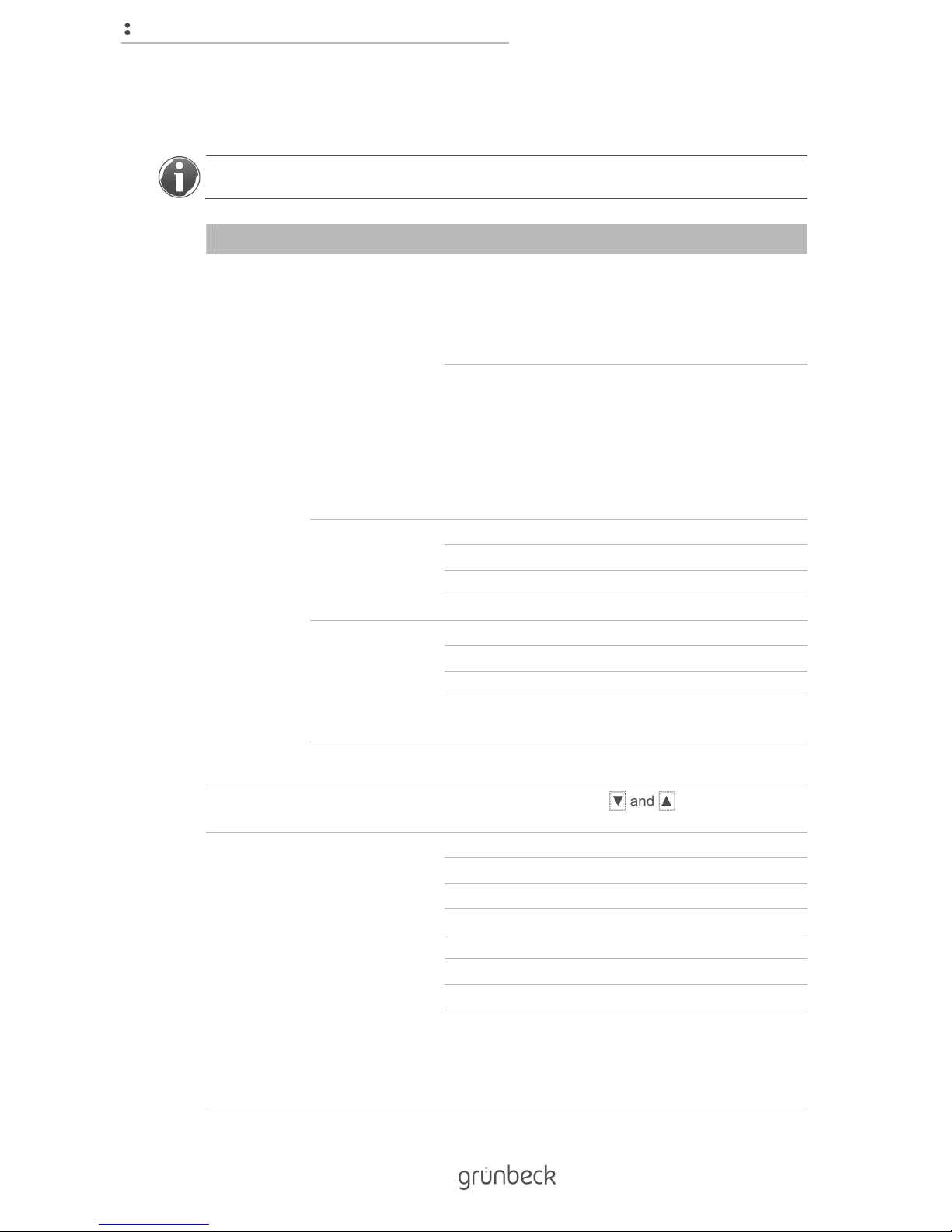

Menu level Menu items Values/settings

Information Information 1 During operation

Graphic depiction of the system capacity of each

exchanger (two blue symbols).

Indication of operating mode

Eco/Power/Comfort/Individual

During regeneration: Graphic depiction of the

operating state of each exchanger

Grey symbol: Exchanger is being regenerated

Blue symbol: Exchanger is in operation

Current regeneration step

Fill brine tank/salting/slow rinse/

backwash/washing out

Information 2 System flow rate

Days the salt supply is expected to last

Raw water hardness

Actual soft water hardness

Information 3 Regeneration counter

Soft water volume meter (0 °dH)

Password for app connection

Perform maintenance in xx days

(only if activated)

Information 4 Contact data,e.g. of your installer

Name/phone number/e-mail address

Manual

regeneration

-

To start, press and hold ▼ and ▲ for 2 seconds.

Settings Change language German

English

French

Italian

Dutch

Russian

Spanish

Chinese

Page 21

Control unit

21 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

Menu level Menu items Values/settings

Change hardness

unit

°dH

°f

°e

ppm

mol/m³

Date/time Setting the time

Current date

Automatic switch-over from DST to ST

Configure Wi-Fi Release of Wi-Fi module (activated/deactivated)

Configure Wi-Fi

Search for Wi-Fi (start/back)

Display of Wi-Fi networks found

Display of Wi-Fi network connected to

Enter password

Wi-Fi network status

App network status

Select

regeneration time

Automatic

Fixed

Function Eco

Power

Comfort

Individual

Display in standby Activated

Deactivated

Set maintenance

interval

Setting in days

Illuminated LED

ring

function

Illuminated LED ring function

During water treatment, operation, malfunction

During operation, malfunction

During malfunction

Deactivated

Illuminated continuously

Illuminated LED ring is flashing in case of pre-alarm

salt supply (yes/no)

Water

hardness

Water hardness Set raw water hardness

Setpoint of soft water hardness

Start-up Start-up Follow the instructions indicated in the display of the

softliQ:MC

Technical

service

Code-protected

area

The settings described here may only be made by

Grünbeck's technical service/authorised service

company.

Page 22

Control unit

22 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

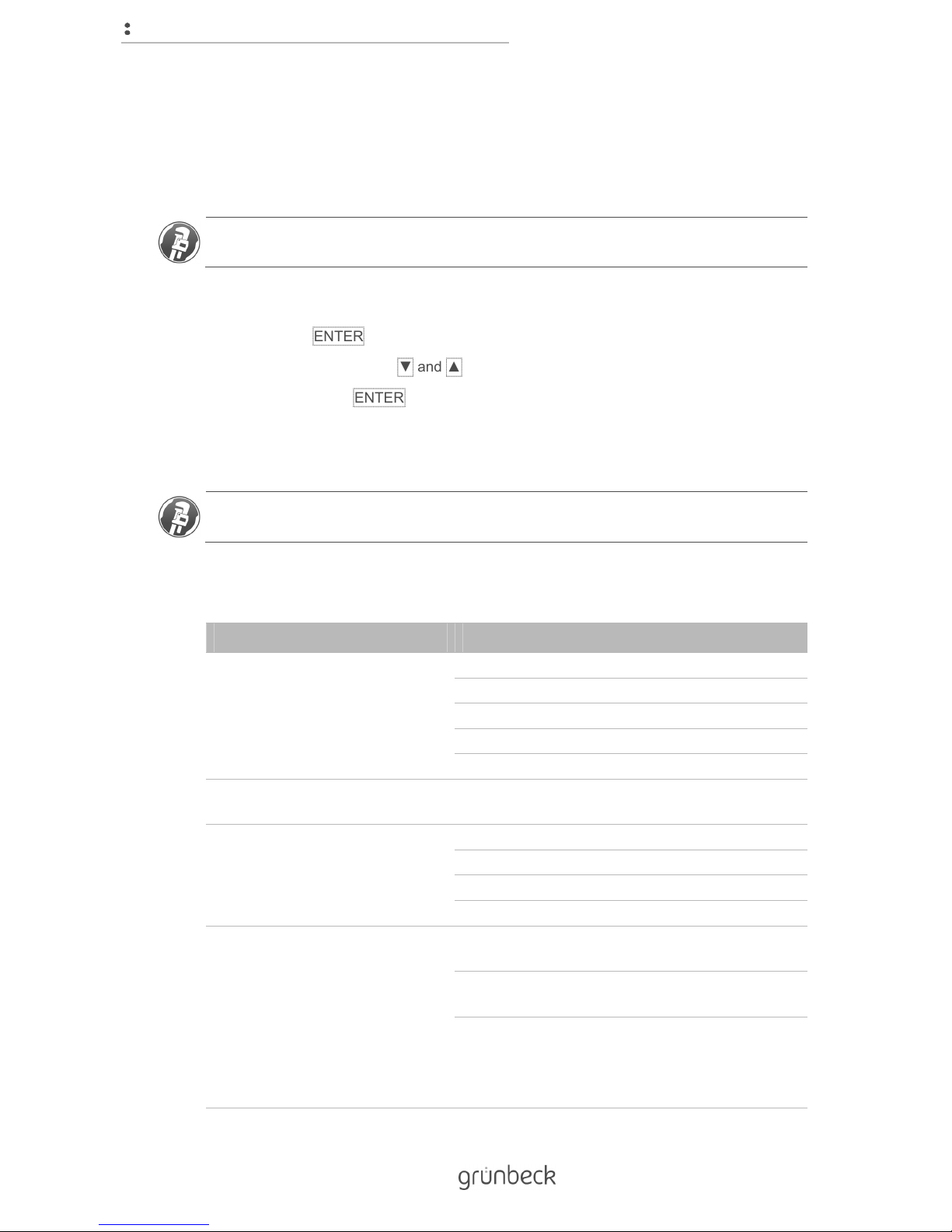

4.5 Code-protected levels

The settings described here may only be made by Grünbeck's technical service/authorised

service company.

Status level>Menu level>Technical service

1. Touch ENTER briefly.

2. Enter the code with ▼ and ▲.

3. Confirm with ENTER.

4.5.1 Installer level (code 005)

The settings described here may only be made by Grünbeck's technical service/authorised

service company.

In the extended installer Level, additional parameters and values can be modified:

Menu items Settings/remarks

Information

exchanger 1

(indication only) Current flow [m³/h]

Capacity figure [m³ x °dH]

Remaining capacity [m³]

Regeneration step [min.] or [l]

Last regeneration [date/time] over [%]

Information

exchanger 2

(indication only) As for exchanger 1

Blending

information

Current flow [m³/h]

Setpoint of soft water hardness [°dH]

Actual soft water hardness value [°dH]

Actual raw water hardness value [°dH]

Flow rates (indication only) Parallel operation

Peak value x.xx [m³/h] for xxxxx [min.]

Exchanger 1

Peak value x.xx [m³/h] for xxxxx [min.]

Exchanger 2

Peak value x.xx [m³/h] for xxxxx [min.]

Page 23

Control unit

23 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

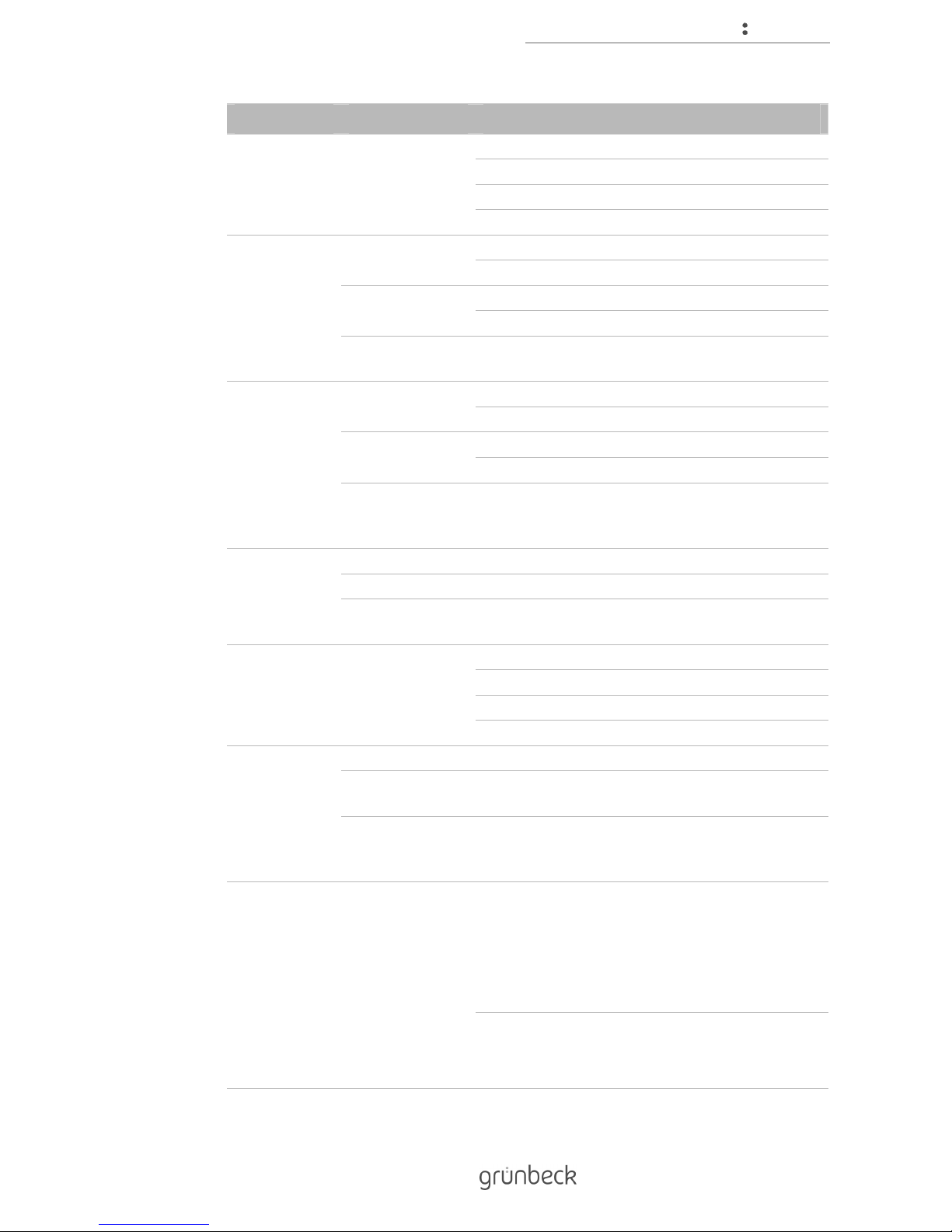

Menu items Settings/remarks

Water volumes Soft water exchanger 1 [m³]

Soft water exchanger 2 [m³]

Raw water blending [m³]

Make-up volume [l]

Soft water

sample

Exchanger 1 0 – Factory setting

1 – Carry out function

Exchanger 2 0 – Factory setting

1 – Carry out function

Perform soft water sampling for selected exchanger. After completion,

the factory setting is activated again.

Find reference

position

regeneration

valve

Regeneration

valve exchanger 1

0 – Factory setting

1 – Carry out function

Regeneration

valve exchanger 2

0 – Factory setting

1 – Carry out function

Move to reference position of the selected exchanger. Ongoing

regenerations are aborted. After completion, the factory setting is

activated again.

Fill operating

water volume

into brine tank

Deactivated – factory setting

Activated – Carry out function

Fill the brine tank to a minimum water level (e.g. after cleaning the brine

tank). After completion, the factory setting is activated again.

Start test

regeneration

0 – Factory setting

both – both control valves in succession

2 – only exchanger 2

1 – only exchanger 1

Select

regeneration

time

Automatic Factory setting

Fixed Programming of 1 – 3 fixed regeneration times.

Regeneration only takes place, if required.

Weekly timer

regeneration time

1/2/3

Mon ... Sun

Time of the regeneration on each day of the week

(factory setting: Mon – Fri at 7:00 am)

Inputs and

outputs

Voltage-free

contact function

Regeneration water delivery pump (factory setting)

Contact closed during the regeneration steps

salting, slow rinse, backwash and washing out.

This setting must be made in connection with the

regeneration water delivery pump available as an

accessory (refer to chapter 3.6).

Regeneration message

Contact closed during the entire regeneration.

Page 24

Control unit

24 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

Menu items Settings/remarks

Configuration of

fault signal

contact

N. C. (factory setting)

Contact closed if mains voltage is applied and there

is no malfunction.

N. O.

Contact closed in the event of a malfunction.

Programmable

input function

Release of regeneration (factory setting)

Start of a complete regeneration if the contact at the

programmable input closes.

Regeneration lock

The regeneration lock is active as long as the

contact at the programmable input is closed;

manually released and automatic regenerations

after a power failure take priority.

Fault signal forwarding

When the contact opens, a text stored using the

myGrünbeck app is sent as an e-mail.

If (in conjunction with the function voltage-free

contact>forwarding of fault signals)

additional devices are connected, the text stored for

sending e-mails can be modified in the myGrünbeck

app accordingly.

4.6 "myGrünbeck" app

1. You can find the "myGrünbeck" app in Google Play, the App Store or any other

marketplace.

2. Install the myGrünbeck app.

The myGrünbeck app supports IOS from version 5.0 onwards and Android

from version 4.0. Refer to the instructions of your mobile device for more

detailed information about installing an app.

You can register your product conveniently using the myGrünbeck app. In the

myGrünbeck app, call up the "Product registration" function in the "User"

menu. Scan the data matrix code on the type plate (refer to chapter 0).

Registering your product will earn you a follow-on warranty for your product.

Page 25

Control unit

25 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

4.7 Peer-to-peer connection

You can connect Wi-Fi devices such as smart phones, tablets or laptops directly to the

control unit of the softliQ and thus permit access to the control unit.

This connection is particularly convenient for specialist installers for the start-up and

maintenance of the softliQ.

A peer-to-peer connection is also possible if there is an existing connection via Wi-Fi

router. Up to 5 connections can be established simultaneously.

1. Search for available Wi-Fi connections in the settings of your Wi-Fi- device.

For information about connecting your Wi-Fi device (e.g. smart phone or

tablet) to a Wi-Fi network, refer to the instruction manual of your device.

2. Select the SSID of your water softener (softliQ:MC_XXXXXX).

3. Enter the 8-digit password.

The password that you need for your connection can be found here:

Status level>Menu level>Information>

Information3>Password for app connection

» You are connected to the softliQ's control unit.

Once the connection has been established, it is possible to access the water softener via the

internal webpage or using the myGrünbeck app. The connection will only be established

after the password has been entered.

Page 26

Control unit

26 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

4.8 Connection via Wi-Fi router

You can connect the control unit of the softliQ to a Wi-Fi router, and thus integrate it into an

existing network. You will then be able to access the control unit of the softliQ via your Wi-Fi

network. This connection is particularly suitable for the owner/user of the softliQ water

softener.

The control unit of the softliQ has 4 buttons. These must be used for making all entries.

Therefore, we recommend establishing the connection via the internal webpage or the

myGrünbeck app.

It may happen that the connection is dropped if your router changes to the economy mode

with reduced transmission power. Refer to the instruction manual of your router to learn

how to switch off the economy mode.

NOTE: Invisible SSIDs are not detected by the control unit.

● The control unit cannot be integrated into an existing Wi-Fi network with an

invisible SSID.

► Activate transmission of the SSID temporarily.

Note: The connection may be dropped if the DHCP function of your router is active.

● The system cannot be operated via an external device.

► In the settings of your router, set the connection to "static DHCP". Refer to the

instruction manual of your router to learn how to set this function.

Page 27

Control unit

27 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

4.8.1 Connect the softliQ to Wi-Fi using the myGrünbeck app

In order to be able to configure the water softener using the myGrünbeck app, you must

already have an existing peer-to-peer connection (refer to chapter 4.7).

1. Open the menu of the myGrünbeck app.

2. Select Settings.

3. Choose Wi-Fi configuration.

» You will see a screen with "Wi-Fi network status" and "Access point network

status".

» Under "Access point network status", you will see the SSID, IP address and status

of an existing peer-to-peer connection.

If there is no connection, no information will be displayed under "Wi-Fi

network status".

4. Activate Search for networks.

» Available networks are displayed.

5. Select your network.

6. Enter the password of your network.

7. Confirm the entry.

» If the Wi-Fi connection was established successfully, the Wi-Fi symbol () will

appear in the top left-hand corner of the display.

4.8.2 Connect the softliQ to the Wi-Fi network by using the internal Webpage.

NOTE: Access to the internal webpage is not possible if an unsuitable browser is used and

if JavaScript is not activated.

● You will not be able to configure your product using the internal webpage or read

out data.

► Install a current version of Internet Explorer (IE10 or higher) and activate

JavaScript.

You must already have a peer-to-peer connection so that the water softener can be

configured using the internal webpage (refer to chapter 4.7).

You can find the IP address of the internal webpage here:

Settings>Configure Wi-Fi >App network status

Page 28

Control unit

28 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

1. Enter "http://192.168.0.1/" in the address bar of your brower.

2. Confirm the entry.

3. Select Wi-Fi configuration in the menu bar on the left-hand side.

4. In the table on the right-hand side, next to the Search for Wi-Fi item, activate Start.

The search can take up to one minute.

» All available networks are displayed under "Connect to Wi-Fi network". These are

named as "Wi-Fi network 1" to "Wi-Fi network X".

5. Activate Connect next to the SSID of your router.

6. Enter the Wi-Fi password of your router.

The login can take up to one minute.

Page 29

Control unit

29 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

» If the login has been successful, "Connected" is displayed under "Wi-Fi network

status". The Wi-Fi symbol ( ) will appear in the top left-hand corner of the display

of the softliQ:MC control unit.

If the connection process takes longer than two minutes, disconnect the Wi-Fi

connection of your Wi-Fi device. Start the connection process again as

described in chapter 4.8.

4.8.3 Connecting the softliQ to the Wi-Fi network via the control unit

Status level>Menu level>Settings>Configure Wi-Fi>Wi-Fi module

1. Check whether "activated" was selected.

2. If "deactivated" was selected, press ENTER.

3. Select "activated".

4. Confirm with ENTER.

5. Press ▼.

Status level>Menu level>Settings>Configure Wi-Fi>Configure Wi-Fi

6. Press ENTER.

7. Select "Start".

8. Confirm with ENTER.

» All Wi-Fi networks within range are displayed.

9. Confirm with ENTER.

10. Select the SSID of your Wi-Fi .

The selected Wi-Fi is indicated by "-" next to the SSID.

11. Confirm with ENTER.

12. Press ▼.

» SSID of the selected Wi-Fi network is displayed.

13. Press ▼.

Status level>Menu level>Settings>Configure Wi-Fi>Enter password

14. Confirm with ENTER.

15. Enter the Wi-Fi password of your router.

Page 30

Control unit

30 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

The characters appear in this sequence when ▼ is pressed:

!"#$%&'()*+,-/0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ

[\]^_`abcdefghijklmnopqrstuvwxyz{|}~

Press ▼ again if the letters cease to change. If you entered a position

incorrectly, you may return to the beginning with HOME.

16. Confirm each position with ENTER.

17. Complete the entry by pressing ENTER for at least 5 seconds.

The login can take up to one minute.

18. Press ▼.

» Wi-Fi network status is displayed. The Wi-Fi symbol ( ) will appear in the top left-

hand corner of the display.

4.8.4 Checking the connection to your Wi-Fi router

If there are other Wi-Fi capable Grünbeck products in the vicinity, an unintended connection

to your Wi-Fi router may be established.

Status level>Menu level>Settings>Configure Wi-Fi

1. Press ▲.

Status level>Menu level>Settings>Configure Wi-Fi>App network status

2. Write down the SSID of your water softener.

softliQ:MC_ _ _ _ _ _ _

3. Check that this matches the SSID displayed on your router.

Refer to the instructions of your router for more detailed information on the

procedure for displaying the devices that are connected to your router.

Page 31

Control unit

31 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

4.9 Sending an email if there is a malfunction

The control unit of your softliQ water softener can notify you via email if there is a

malfunction. You can use an email service provided by Grünbeck or your own email account

for this purpose.

4.9.1 Using the e-mail service provided

If you would like to use the email service provided by Grünbeck, proceed as follows:

1. Go to www.gruenbeck.de/myaccount.

2. Follow the instructions.

» You will receive an email containing all necessary data.

The email will be sent by "noreply@prodreggb.de" and its subject is "Confirmation of user

agreement". You can search for it in your inbox. If you do not find the email in your inbox,

check your spam folder.

The email function can only be set up using the myGrünbeck app or the internal webpage.

4.9.2 Using your own email account

To configure the email sending function, you require the following data of your e-mail

account:

● Email address from which you are sending

● SMTP server

● Port

● Account

● Password

4.9.3 Configuring the email function

The following steps cannot be carried out unless there is an existing Wi-Fi connection as

described in chapter 4.8.

If you have concluded a maintenance contract, you can have an e-mail sent directly to your

specialist installer. Please discuss that with him/her.

Page 32

Control unit

32 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

CAUTION: Incorrect e-mail settings will prevent you from being notified if there is a

malfunction.

● Malfunctions that are not remedied can lead to hygiene problems.

► Once you have completed the e-mail configuration, send a test email to check the

settings.

Data required for e-mail configuration

● Data from the email of the email service provided by Grünbeck or of your email

provider:

• Email address from which you are sending

• SMTP server and port

• Account (user name)

• Password

● Personal data:

• Email address to which the email should be sent (up to 3)

• Telephone number and last name of the owner/user

There is no need to enter a telephone number and last name. If entered, the

data will appear in the subject line of the email, and this will make it easier for

the recipient (installer, caretaker) to make the correct categorisation.

• Email text for subject line

The email text for the subject line is only used if the malfunction to be

transferred is triggered by the programmable input (refer to chapter 4.9).

Using the myGrünbeck app:

1. Open the menu of the myGrünbeck app.

2. Select Settings.

3. Select Email configuration .

4. Enter the necessary data.

5. Send a test email to make sure it is working.

Using the internal webpage:

1. Enter "http://192.168.0.1/" in the address bar of your brower.

2. Confirm the entry.

3. Select "Networks" in the menu bar on the left-hand side.

4. Enter the required data in the table under Email configuration.

5. Send a test email to make sure it is working.

Page 33

Installation

33 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

5 Installation

The installation of a water softener represents a major intervention into the drinking water

system and may only be performed by a specialist installer.

Item Designation Item Designation

1 Safety device protectliQ 2 Drinking water filter pureliQ

3 Garden water pipe 4 Water withdrawal point

5 EXADOS dosing computer 6 Drain connection DN 50 acc. to DIN EN 1717

5.1 Requirements in relation to the installation site

Observe local installation directives, general guidelines and technical specifications. The

installation site must be frost-proof and ensure the system's protection from chemicals, dyes,

solvents and vapours.

Always install a drinking water filter and, if required, a pressure reducer (e.g. fine filter

pureliQ:KD) upstream of the system. A shock-proof socket is required within a distance of

approx. 1.2 m of the system. For the discharge of the regeneration water, a drain connection

(DN 50) must be available.

NOTE: The system will not function without continuous power supply.

● No soft water will be available if the system is operated without power.

► Do not interconnect the socket with a light switch, heating emergency switch or

the like.

2

5

4

6

1

3

Page 34

Installation

34 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

NOTE: The valves of the system are electrically operated.

● Water can flow to the drain unchecked if there is a power failure during

regeneration.

► If there is a power failure, check your product and shut off the water supply, if

necessary.

The installation room must be provided with a floor drain. If none is available, an appropriate

safety device has to be installed to prevent water damage. We recommend using a

protectliQ safety device (refer to chapter 3.6).

If the softened water is intended for human consumption within the meaning of the German

Drinking Water Ordinance, the ambient temperature must not exceed 25 °C. For applications

that are purely technical, the ambient temperature must not exceed 40 °C.

NOTE: Malfunction of the lifting system if there is a power failure.

● Water damage in case the lifting system fails.

► Secure your water installation against inadvertent water leakage if there is a

power failure.

NOTE: Functional failure if lifting systems are not resistant to salt water.

● Water damage in case the lifting system fails.

► Use a salt water-resistant lifting system, or our regeneration water delivery pump

(refer to chapter 3.6).

Page 35

Installation

35 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

5.2 Checking the scope of supply

Item Designation Item Designation

1 Water softener completely pre-assembled 2 2 Connection hoses

3 Connection block incl. 2 inserts, union nuts, gaskets

each

4 Water test kit "total hardness“

5 Operation manual

► Check the scope of supply for completeness and possible damage.

5.3 Installing the product

WARNING: Danger of contaminated drinking water due to stagnation.

● Risk of infectious diseases.

► In accordance with VDI 6023, do not connect your product to the drinking water

installation until directly before start-up.

5.3.1 Fitting the connection block into the pipe

1. Pay attention to the sieve insert and the flow direction.

2. Install the connection block into the pipe with inserts, union nuts and gaskets.

2

534

1

Page 36

Installation

36 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

5.3.2 Installing the connection hoses

1. Unscrew both the screws on the sides of the upper part of the housing of the

technical equipment.

2. Remove the upper part of the housing of the technical equipment.

3. Mount the connection hoses.

NOTE: Mix-up of connection hoses and insufficient tightening torque of union

nuts possible.

● Functional failure and/or leaks at the system.

► Observe the flow direction marked by arrows.

► Tighten the union nuts with approx. 4 Nm.

Page 37

Installation

37 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

5.3.3 Establish waste water connection as per DIN EN 1717

The drain connection DN 50 as per DIN EN 1717 for small-scale water softeners makes it

easier to connect according to the DIN standard (refer to chapter 3.6).

NOTE: Backing up of wastewater due to kinked hoses.

● Risk of water damage.

► Run the hoses to the drain with a downward slope and without kinks and bends.

Page 38

Installation

38 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

1. Shorten the flushing water hose (outside diameter 12 mm) to the required length.

2. Fasten the flushing water hose (regeneration water flows out under pressure).

3. Shorten the overflow hose (outside diameter 16 mm) to the required length.

4. Run the overflow hose to the drain with a downward slope.

5. Fasten the overflow hose.

6. Make sure there is a free outlet to the drain.

If a water flow pressure of at least 3.0 bar is available, the flushing water

hose can be laid up to max. 2.2 m above the floor level. Then, the connection

of the overflow hose of the brine tank is not possible.

» This completes the installation.

After completion of the installation, slide the protective cover from the packaging over the

water softener. This protects the water softener from contamination until it is started up.

Page 39

Installation

39 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

5.3.4 Inputs and outputs of the control unit

The control unit features a voltage-free input and output. These are configured in the installer

level (refer to chapter 4.5).

Item Designation Item Designation

1 Programmable input DigIN 3 Voltage-free fault signal contact Pot.f.S. (NO)

max. 230 V/max. 1 A

2 Voltage-free contact Prog.Out

max. 230 V/max. 1 A

Use the following connection cables tor connection to the programmable input or voltagefree output of the control unit:

● Flexible cables of quality H03xx F 2x0.5 mm² or comparable for connecting the

programmable input (no. 1), because only voltage-free contacts may be connected.

● Flexible cables of quality H05xx F 2x0.75 mm² or comparable for connecting the

voltage-free output (no. 2), because consumers operated with mains voltage may

be connected.

3

1

2

Page 40

Start-up

40 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

6 Start-up

6.1 Starting up the product

The softliQ control unit is operated using keys (refer to chapter 4.3).

The start-up program assists you with starting up the softliQ water softener. You are guided

through the start-up procedure step-by-step on the display.

There are dots on the right of the display. These provide orientation and show you where in

the program you are at present. The current position is shown in a darker colour. Values can

only be changed if the corresponding dot is shown in green. Use the ▲ or ▼ keys to

navigate through the program. Open menus with ENTER.

6.1.1 Initial start-up and automatic start of the start-up program

1. Keep salt tablets (refer to chapter 2.6) handy.

2. Remove the protective film from the display.

3. Plug in the mains plug.

4. Select the required language with ▲ or ▼.

5. Confirm with ENTER.

6. Select the desired hardness unit with ▲ or ▼.

7. Confirm with ENTER.

8. Enter your app password.

You only need your app password if you want to put the product into

operation using the myGrünbeck app. Otherwise, skip this step.

Page 41

Start-up

41 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

9. Select Start-up START.

10. Confirm with ENTER.

11. Continue with chapter 6.1.3.

6.1.2 Manual start of the start-up program

If required, start the start-up program manually from the menu level.

Status level>Menu level>Start-up

1. Confirm with ENTER.

2. Press and hold ▲ and ▼ for 2 seconds.

6.1.3 Program flow of the start-up program

There may be wait periods during the start-up program. These are indicated in the

control unit by means of an hourglass symbol. Continuing with the program is only

possible upon completion of the wait period and the disappearance of the symbol.

Use the ▲ or ▼ keys to navigate through the program.

1. Do not fill any water into the brine tank.

2. Confirm with ▼.

3. Fill salt tablets into the brine tank (refer to chapter 7.8).

4. Confirm with ▼.

5. Set the current time and the current date.

a Set the desired value using▲ and ▼.

b Confirm with ENTER.

The system moves to its reference point. In case the reference point has not

been reached until after the entry of the time, the remaining time will be

indicated in the display.

6. Determine the raw water hardness. You have the following options to do so:

• Contact your water supply company and ask them what the value is.

• Determine the value by using the water test kit supplied with the system (refer

to chapter 7.7).

7. Use ▲ and ▼ to set the value for the raw water hardness.

8. Confirm with ENTER.

Page 42

Start-up

42 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

Confirmation is only possible if the system has completed the previous step.

This is the case when the ENTER key lights up. The value can be changed

later (refer to chapter 7.7).

Item Designation Item Designation

1 Shut-off valve for raw water 2 Shut-off valve for soft water

3 Sampling valve for raw water 4 Sampling valve for soft water

9. Open the raw water shut-off valve at the connection block.

10. Confirm with ▼.

11. Check for leaks.

12. Confirm with ▼.

Water flows through the flushing water hose to the drain. This is completely

normal during start-up.

13. Press ENTER to start the venting program.

2

3

4

1

Page 43

Start-up

43 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

» The display indicates "Remaining time 22:00 min". The counter counts down to

00:00 min. If this is completed, the next display message will be indicated.

In exceptional cases, start-up may be aborted (remaining time runs down to

00:00 minutes and nothing else happens). In this case, proceed as follows:

► Disconnect the mains plug.

► Wait for 5 seconds.

► Start again from point 6.1.1.

Should, after some time, "raw water shut-off valve at connection block still

closed" appear in the display, open the shut-off valve for raw water.

14. Open the soft water shut-off valve.

15. Confirm with ▼.

16. Check the water hardness on exchanger 1 as described in chapter 7.7.

» Upon confirmation with ENTER, exchanger 1 is put out of operation and exchanger

2 is put into operation.

17. Check the water hardness on exchanger 2 as described in chapter 7.7.

18. Confirm with ▼.

With these tests, the function of the exchangers is checked. The water

sample must have a hardness of less than 1 °dH.

19. Use ▲ and ▼ to set the desired value for the soft water hardness.

• Recommendation for Germany: Soft water hardness 3 - 6 °dH.

• Recommendation for Austria: Soft water hardness at least 8.4 °dH.

Take the maximum admissible sodium concentration of your drinking water

into consideration (refer to chapter 13.2).

20. Press ENTER to start the test regenerations.

» The remaining time will be indicated in the display. The remaining time for the

regeneration of both exchangers is counted down.

The test regenerations take approx. 33 minutes for both exchangers.

In exceptional cases, a malfunction may be indicated at the end of the test regeneration. In

this case, proceed as follows:

► Confirm with ENTER.

► Restart the start-up program.

► Call Grünbeck's technical service/authorised service company if the malfunction

occurs again.

Page 44

Start-up

44 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

6.2 Hand over the product to the owner/user togehter with the

operation manual

When handing over the product, proceed as follows:

1. Inform the owner/user how the water softener works.

2. Hand over all documents to the owner/user for storage.

3. Use the manual to brief the owner/user, and answer any questions.

4. Inform the owner/user about the need for inspections and maintenance.

5. Inform the owner/user about the influence of the water hardness on the dosage of

detergents and cleaning agents.

Page 45

Operation

45 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

7 Operation

7.1 Retrieving information

Status level>Menu level>Information

7.1.1 Information 1

Here, you see a graphic display of the current system function.

Figure Explanation

Both exchangers are in operation. The system capacity

declines from the top downwards. One bar corresponds to 20

%. The light bars show the available system capacity.

Below the symbols, the current mode is indicated:

Eco/Power/Comfort

One exchanger is in operation, the other is being regenerated.

The bars of the grey symbol correspond to the following

regeneration steps from the bottom upwards:

Fill brine tank (lowermost bar)

Salting

Slow rinse

Backwash

Washing out (highest bar)

Below the symbols, the regeneration step is indicated.

Explanation of symbols:

Blue symbol

Grey symbol

7.1.2 Information 2

Display Explanation

System flow rate Indicates the current flow rate of the system. The value is

displayed in m³/h.

Days the salt supply is

expected to last

Indicates for how long the salt supply is estimated to last. The

value is displayed in days.

Raw water hardness Indicates the set raw water hardness. The value is displayed in

the selected hardness unit.

Actual soft water

hardness

Indicates the set soft water hardness. The value is displayed in

the selected hardness unit.

Page 46

Operation

46 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

7.1.3 Information 3

Display Explanation

Regeneration counter Indicates how many regenerations have been performed.

Soft water volume

meter

Indicates in m³ how much soft water has been withdrawn from

the system.

Password for app

connection

Indication of the password to establish the connection between

the control unit and the myGrünbeck app installed on a mobile

device

Perform maintenance

in xx days

(only if activated)

Indicates in how many days the next maintenance is due.

7.1.4 Information 4

Display Explanation

Contact data Indication of contact data, for instance, of your installer

(name, phone number, email address).

Entry only possible via app or website.

7.2 Starting a manual regeneration

Status level>Menu level>Manual regeneration

A manual regeneration is necessary in the following cases:

● The product resumes operation after a longer period of standstill.

● After maintenance and repair work has been performed.

● If the raw water hardness has changed or has been altered.

● After a longer power failure.

Both exchangers will be regenerated one after the other with the maximum capacity figure.

Page 47

Operation

47 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

7.3 Settings

Status level>Menu level>Settings

You can change the following values:

Menu item Setting options

Change language German (factory setting)

English

French

Italian

Dutch

Russian

Spanish

Chinese

Change hardness unit °dH (factory setting)

°f

°e

ppm

mol/m³

Date, time Set the time

Current date

Automatic switch-over from DST to ST

Configure Wi-Fi Refer to chapter 4.8

Select regeneration time Automatic (factory setting)

Fixed

Function Eco

Power

Comfort (factory setting)

Individual

Display behaviour in standby Activated

Deactivated (factory setting)

Set maintenance interval 000 days (factory setting)

Page 48

Operation

48 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

Menu item Setting options

Illuminated LED ring function Illuminated LED ring function

During water treatment, operation, malfunction

(factory setting)

During operation, malfunction

During malfunction

Deactivated

Illuminated continuously

Illuminated LED ring is flashing in case of pre-alarm

salt supply

yes

no (factory setting)

7.4 Select regeneration time

Status level>Menu level>Settings>Select regeneration time

1. Press ENTER.

2. Use ▲ and ▼ to select the desired setting.

a Automatic (factory setting)

b Fixed

3. Confirm with ENTER.

7.5 Setting the current date and time

Status level>Menu level>Settings>Date, time>Set current time

1. Press ENTER.

2. Use ▲ and ▼ to set the time.

3. Confirm with ENTER.

7.6 Setting the time of the fixed regeneration

Status level>Menu level>Settings>Select regeneration time>Set

regeneration time

1. Press ENTER.

2. Use ▲ and ▼ to set the time.

3. Confirm with ENTER.

Page 49

Operation

49 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

7.7 Determining and entering the water hardness

7.7.1 Water test kit

The water test kit is designed for the determination of the water hardness in °dH or in °f.

The unit mol/m³ (= mmol/l) can be determined from °f.

Item Designation Item Designation

1 Test tube 2 Titration solution

7.7.2 Taking a water sample

NOTE: If the flow rate is too low during the sampling, the result will be falsified.

● The system will be programmed with incorrect values for the raw water hardness.

● The required soft water value will not be attained.

► Fully open the water withdrawal point for cold water or the sampling valve. A flow

rate between 0.4 m³/h and 0.6 m³/h must be attained.

► When taking a soft water sample, the flow rate can be read in information level 2.

1. Open a water withdrawal point for cold water or a sampling valve at the connection

block.

a In order to take a raw water sample, use a water withdrawal point for cold water

upstream of the system or the raw water sampling valve.

b In order to take a soft water sample, use a water withdrawal point for cold water

downstream of the system or the soft water sampling valve.

NOTE: The water exits the sampling valves at high pressure.

● The product and its vicinity might be sprinkled with splash water.

► Keep a sufficiently dimensioned collecting vessel, e.g. a bucket with

a volume of least 5 l, handy.

2

1

Page 50

Operation

50 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

2. Let the water flow for at least 30 seconds.

3. Take a water sample with the test tube:

a Fill the test tube up to the °dH mark to determine the water hardness in °dH.

b Fill the test tube up to the marking °f (x 0.1 = mol/m³) in order to determine the

water hardness in °f, mol/m³ or mmol/l.

7.7.3 Determining the water hardness in °dH/°f

1. Add one drop of titration solution (1 drop = 1 °dH = 1 °f).

2. Shake the test tube until the titration solution is mixed with the water.

3. In case of red colouring, repeat steps 2 and 3 and count the drops until the colour

changes to green.

» If the colour changes to green, the water hardness has been determined.

The number of drops corresponds to the degree of hardness in °dH or °f.

Example:

Test tube filled up to the °dH mark: 6 drops = 6 °dH.

Test tube filled up to the °f mark: 6 drops = 6 °f.

7.7.4 Determining the water hardness in mol/m³ (mmol/l)

1. Determine the water hardness in °f as described.

2. Divide the °f measured by 10.

The water hardness in °f divided by 10 corresponds to the degree of

hardness in mol/m³ (= mmol/l). Example:

6 drops = 6 °f = 0.6 mol/m³ = 0.6 mmol/l.

7.7.5 Entering the water hardness

Status level>Menu level>Water hardness

1. Press and hold ▼ and ▲ for 2 seconds.

2. Enter the value of the raw water hardness with ▼ and ▲.

3. Confirm with ENTER.

4. Enter the setpoint of the soft water hardness with ▼ and ▲.

Page 51

Operation

51 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

NOTE: The maximum soft water hardness that can be programmed is

approx. 50 % of the raw water hardness present.

● Error message “Check soft water hardness” indicated in the display.

► Select a lower soft water value.

5. Confirm with ENTER.

7.8 Refilling salt tablets

The level of salt tablets in the brine tank must always be higher than the water level.

1. Open the brine tank lid.

The sensor for the low-salt alarm is located in the lid of the brine tank. This

sensor does not work with laser light, so it is safe for the eyes. The function of

the low-salt alarm is explained in chapter 3.4.2.

2. Fill in salt tablets.

3. Close the brine tank lid.

Page 52

Cleaning, inspection, maintenance

52 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

8 Cleaning, inspection, maintenance

WARNING: Risk of contaminated drinking water if the work is not carried out properly.

● Risk of infectious diseases.

► Pay attention to hygiene when working on water softeners.

Inspection and maintenance of a water softener is prescribed in the DIN EN 806-5 standard.

Regular maintenance ensures trouble-free and hygienic operation. At least once a year, the

water softener must be serviced by Grünbeck's technical service/authorised service

company or by specialist installers trained by Grünbeck. Proper operation and maintenance

of the system are essential for trouble-free and hygienic operation.

A maintenance contract ensures that all the required maintenance work will be performed

in due time.

8.1 Cleaning

1. Only clean the outside of the product.

2. Do not use any strong or abrasive cleaning agents, because they can damage the

surface.

3. Wipe the housing with a damp cloth.

Page 53

Cleaning, inspection, maintenance

53 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

8.2 Inspection

Regular inspection increases the operating reliability of your product. Therefore, conduct an

inspection at least every 2 months.

To conduct an inspection, proceed as follows:

1. Visually check the system for leaks

2. Check the soft water hardness (refer to chapter 7.7)

3. Check that there are sufficient salt tablets in the brine tank.

The level of salt tablets in the brine tank must always be higher than the

water level.

4. Check the control valve to the drain for leaks.

No water must drip from the flushing water hose during parallel operation.

The system is in parallel operation when two blue symbols are displayed in

information level 1 (refer to chapter 7.1).

8.3 Maintenance

Some regular work is necessary in order to ensure proper functioning of the product in the

long term. For this purpose, DIN EN 806-5 recommends a semi-annual and an annual

maintenance.

8.3.1 Six-monthly maintenance

Proceed as follows to carry out the semi-annual maintenance:

1. Visually check the system for leaks

2. Check the soft water hardness (refer to chapter 7.7).

3. Check that there are sufficient salt tablets in the brine tank.

The level of salt tablets in the brine tank must always be higher than the

water level.

4. Check the control valve to the drain for leaks.

5. Evaluate the salt consumption subject to the water volume consumed.

6. Check the salt condition (salt must not be lumpy).

Break up incrustations with a suitable tool.

Page 54

Cleaning, inspection, maintenance

54 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

8.3.2 Annual maintenance

Carrying out annual maintenance work requires specialist knowledge. This maintenance

work may only be performed by Grünbeck's technical service/authorised service company

or by specialist installers trained by Grünbeck.

The maintenance work to be performed for the annual maintenance complete the tasks that

have to be carried out in the course of the semi-annual maintenance. The maintenance work

is divided into reading and documenting operating values, general maintenance work and

maintenance work to be carried out per exchanger. In addition to the semi-annual

maintenance, the following work needs to be done:

Operating values

7. Measure the raw water hardness.

8. Match the measured raw water hardness to the setting in the control unit.

9. Measure the soft water hardness.

10. Match the measured soft water hardness to the setting in the control unit.

11. Read off the water and flow pressure.

12. Read off the residential water meter reading.

13. Read off the regeneration counter (Information 3).

14. Read off the soft water volume meter (Information 3).

15. Read out the error memory (Code 245).

Preliminary maintenance work

16. Check the hose connections for leaks and damage.

17. Check all cables and connections for damage and a firm seat.

18. Check the salt tablets for impurities.

19. Clean the brine tank.

20. Check the brine valve and the level electrodes and clean them if necessary.

Maintenance work on the exchangers

The work described below needs to be carried out on each of the

exchangers. Starting from “Release manual regeneration”, we recommend

carrying out the work in parallel.

21. Check the soft water meter for pulse output (Code 005).

22. Check injectors and injector sieves for dirt and clean them if necessary.

23. Check the brine filling orifices in the brine connection angles (red).

24. Move to the reference positions (Code 005).

25. Initiate a manual regeneration.

26. Check the suction power of the injectors.

Page 55

Cleaning, inspection, maintenance

55 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

27. Check the chlorine currents during salting (regeneration step 2) (Code 245).

28. Check the function of the regeneration counter in any regeneration step (Code

005).

29. Check the control valves at the drain outlet in operational position for leaks

(flushing water hose Ø 12 mm).

30. Check the filling and suction hoses to the brine valves for leaks.

31. Check the flushing water hose for leaks.

32. Initiate a double regeneration (Code 005).

33. After cleaning the brine tank, fill it with the operating water volume (Code 005).

Final maintenance work

34. Reset the service interval, if activated.

35. Record data and work performed, including repair work, in the operation log and

checklist.

36. Hand over the water softener and the operation log to the owner/user.

8.4 Consumables

NOTE: Danger of damaging the system if unsuitable consumables are used.

● There is a risk of functional impairments, malfunctions and loss of warranty.

► Only use genuine consumables.

Product Order no.

Regeneration salt tablets (25 kg) acc. to EN 973 type A. 127 001

Water test kit "Total hardness“ 170 187

8.5 Spare parts

NOTE: Risk of damage to the system if unsuitable spare parts are used.

● There is a risk of functional impairments, malfunctions and loss of warranty.

► Only use genuine spare parts.

You can order spare parts and consumables from your local Grünbeck representative (refer

to the internet at www.gruenbeck.com).

Page 56

Cleaning, inspection, maintenance

56 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

8.6 Wearing parts

NOTE: Risk of damaging the system if unsuitable wearing parts are used.

● There is a risk of functional impairments, malfunctions and loss of warranty.

► Only use genuine wearing parts.

Wearing parts are listed below:

● Control valve: Gaskets, set of discs, injector and chlorine cell.

● Brine valve: Gaskets and electrodes.

Page 57

Troubleshooting

57 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

9 Troubleshooting

WARNING: Danger of contaminated drinking water due to stagnation.

● Risk of infectious diseases.

► If malfunctions do occur, have them remedied immediately.

The water softener softliQ indicates malfunctions on the display. If malfunctions do occur that

cannot be remedied by the instructions given below, contact Grünbeck's technical

service/authorised service company.

► Have your equipment data (refer to chapter 0) handy.

9.1 Display messages

1. Acknowledge the malfunction or warning with ENTER.

2. Observe the display.

3. Compare the display message with the following table if the malfunction reoccurs.

9.1.1 Warning messages (yellow symbols)

Display shows Explanation Remedy

Maintenance due!

Notify Grünbeck’s technical

service

Only displayed if

maintenance interval is

activated.

Notify Grünbeck's technical service/

authorised service company.

Salt supply low! Please refill!

Sufficient for: xy days

(order no. 127 100)

Salt supply low. Refill salt tablets (refer to

chapter 7.8), acknowledge the

malfunction with ENTER.

If the error message reoccurs, notify

Grünbeck's technical service/

authorised service company.

Page 58

Troubleshooting

58 | 80

BA_TD3-BM000en_064_softliQ-MC.docx

9.1.2 Error messages (red symbols)

Display shows Explanation Remedy

Power failure > 5 minutes

Only displayed if detection

is activated.

If there is a power failure,

any regeneration in

progress at the time is

stopped and then

continued afterwards.

Check the electrical power

connection.

Reset the clock of the water softener

if there is a power failure> 3 days

(only in case of "fixed" regeneration

time, refer to chapter 7.5).

Initiate a manual regeneration (refer

to chapter 7.2).

Salt supply used up! Refill

immediately!

(Order no. 127 100)

Salt supply used up. Refill salt tablets into the brine tank

(refer to chapter 7.8)

Acknowledge the malfunction with

ENTER.

If the error message reoccurs, notify

Grünbeck's technical service/

authorised service company.

Cavity under the salt. Loosen incrustations with a suitable

tool.

Water pressure too low. Increase flow pressure to at least 2.0