Page 1

We understand water.

Filters | Automatic filters pureliQ:A,

pureliQ:AD

Operation manual

Page 2

Central Contact

Germany

Sales

Phone +49 9074 41-0

Technical Service

Phone +49 9074 41-333

Fax +49 9074 41-120

Availability

Monday to Thursday

7:00 am - 6:00 pm

Friday

7:00 am - 4:00 pm

Your local point of contact: see

accompanying list of

representatives

Copyright

The manufacturer reserves the copyright to this manual. Without the

written consent of Grünbeck Wasseraufbereitung GmbH, no part of

this manual is allowed to be reproduced in any way, nor is any part

allowed be processed, duplicated or distributed using electronic

systems.

Contraventions of the aforementioned requirements shall be subject to

compensation in damages.

We reserve the right to modifications.

© by Grünbeck Wasseraufbereitung GmbH

Translation of the original operation manual

Edition of the manual: May 2018

Order no.: TD3-AA000en_025

Page 3

Table of contents

3 | 44

-AA000en_025

Table of contents

1 About this manual .......................... 4

1.1 Other applicable documents ........... 4

1.2 Target group ................................... 4

1.3 Storage of the documents ............... 4

1.4 Symbols used ................................. 5

1.5 Typographical conventions ............. 6

1.6 Validity of the manual ..................... 7

1.7 Type plate ....................................... 8

2 Safety .............................................. 9

2.1 Safety measures ............................. 9

2.2 Technical safety instructions ......... 10

2.3 Regulations ................................... 11

2.4 Responsibilities of the specialist

installer ......................................... 11

2.5 Responsibilities of the owner-user 12

3 Product description ..................... 13

3.1 Intended use ................................. 13

3.2 Product components ..................... 14

3.3 Functional description ................... 15

4 Installation .................................... 16

4.1 Requirements in relation to the

installation site .............................. 17

4.2 Checking the scope of supply ....... 18

4.3 Installing the product ..................... 19

5 Start-up ......................................... 22

5.1 How to start up the product .......... 22

5.2 Operating the backwash unit ........ 23

5.3 Setting the month display ............. 24

5.4 Setting pressure reducer (only

pureliQ:AD) ................................... 25

5.6 Handing over the operation manual

to the operator .............................. 26

6 Cleaning, inspection,

maintenance ................................. 27

6.1 Cleaning ....................................... 27

6.2 Inspection and maintenance ......... 27

6.3 Wearing parts ............................... 28

6.4 Service kits ................................... 29

6.5 Spare parts ................................... 31

7 Faults ............................................ 32

8 Disposal ........................................ 33

9 Technical specifications ............. 34

9.1 Automatic filter pureliQ:A .............. 34

9.2 Automatic filter pureliQ:AD ........... 36

10 Other information ......................... 38

10.1 Explanation of terminology ........... 38

11 Operation log ................................ 39

Page 4

About this manual

4 | 44

-AA000en_025

1 About this manual

1.1 Other applicable documents

The following documents also apply in the case of the automatic

filters pureliQ:A und pureliQ:AD:

● The manuals of all accessories used shall apply.

1.2 Target group

This manual is intended for specialist installers and owners/users.

1.3 Storage of the documents

This manual and all other applicable documents must be kept so

as to be available if required. Make sure that your specialist

installer enters the proper start-up in chapter 11 the operation log.

Page 5

About this manual

5 | 44

-AA000en_025

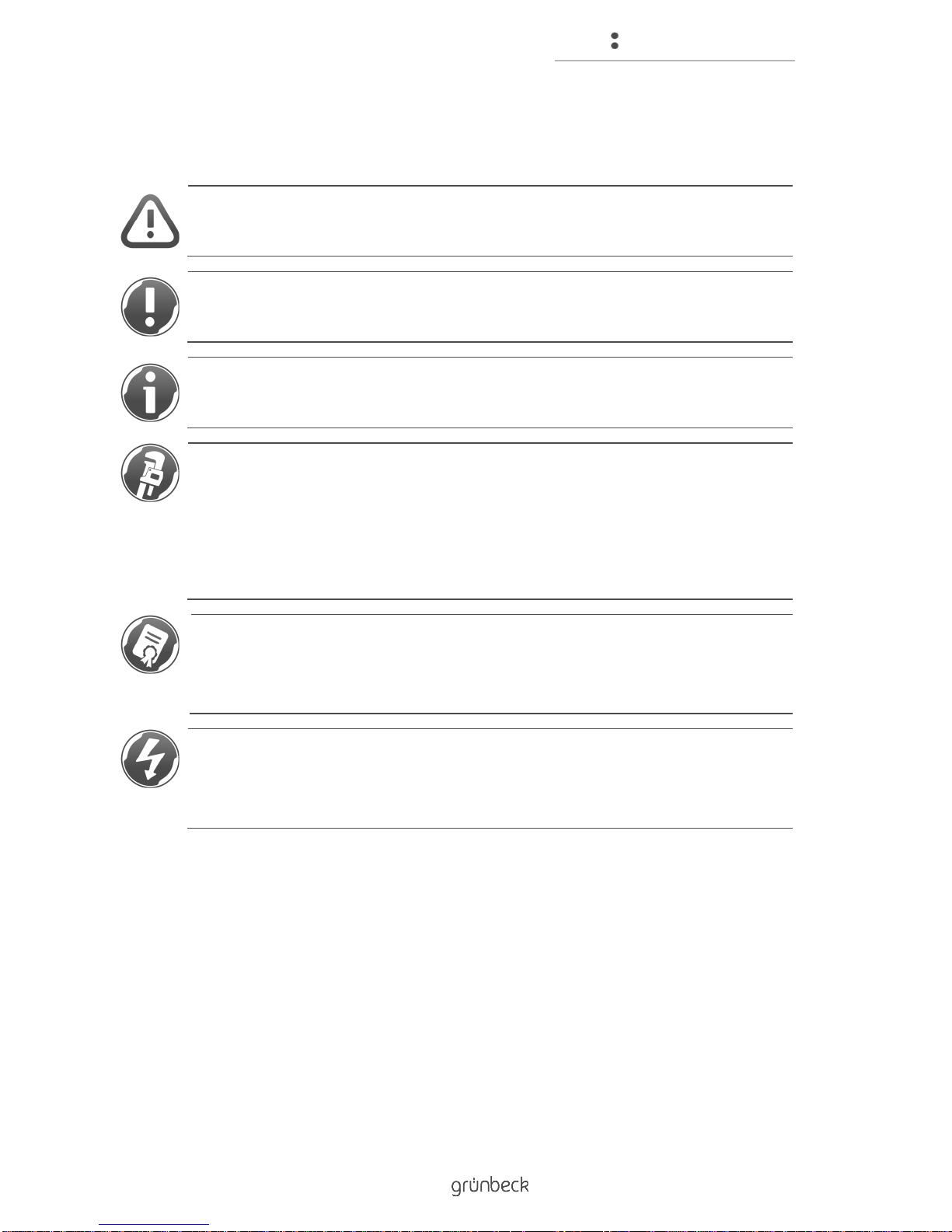

1.4 Symbols used

This symbol identifies instructions that you must comply with for

your personal safety.

This symbol identifies instructions that you must comply with in

order to avoid damage to property.

This symbol identifies important information about the product or

its handling.

This symbol identifies work that is only allowed to be carried out

by specialist installers. In Germany, the installation company

must be registered in an installation directory of a water supply

company acc. to §12(2) AVB Wasser V (German Ordinance on

General Conditions for the Supply of Water).

This symbol designates tasks that are only allowed to be

performed by Grünbeck’s technical service/authorised service

company or by specialist installers trained by Grünbeck.

This symbol identifies work that is only allowed to be carried out

by qualified electronics experts according to the VDE guidelines

or according to the guidelines of similar local institutions.

Page 6

About this manual

6 | 44

-AA000en_025

1.5 Typographical conventions

The following typographical conventions are used in this manual:

1.5.1 Instructions

Single-step instructions or instructions where the sequence of the

actions is unimportant are indicated as follows:

► Action

Multi-step instructions in which the sequence must be complied

with are indicated as follows:

1. First step

a First action in the first step

b Second step of the first action

2. Second action

Results of an instruction are indicated as follows:

» Result

1.5.2 Lists

Bullet symbols used:

● First list point (level 1)

• First bullet point (level 2)

• Second bullet point (level 2)

● Second list point (level 1)

Page 7

About this manual

7 | 44

-AA000en_025

1.6 Validity of the manual

This manual applies to the following products:

● Automatic filter pureliQ:A

● Automatic filter pureliQ:AD

Page 8

About this manual

8 | 44

-AA000en_025

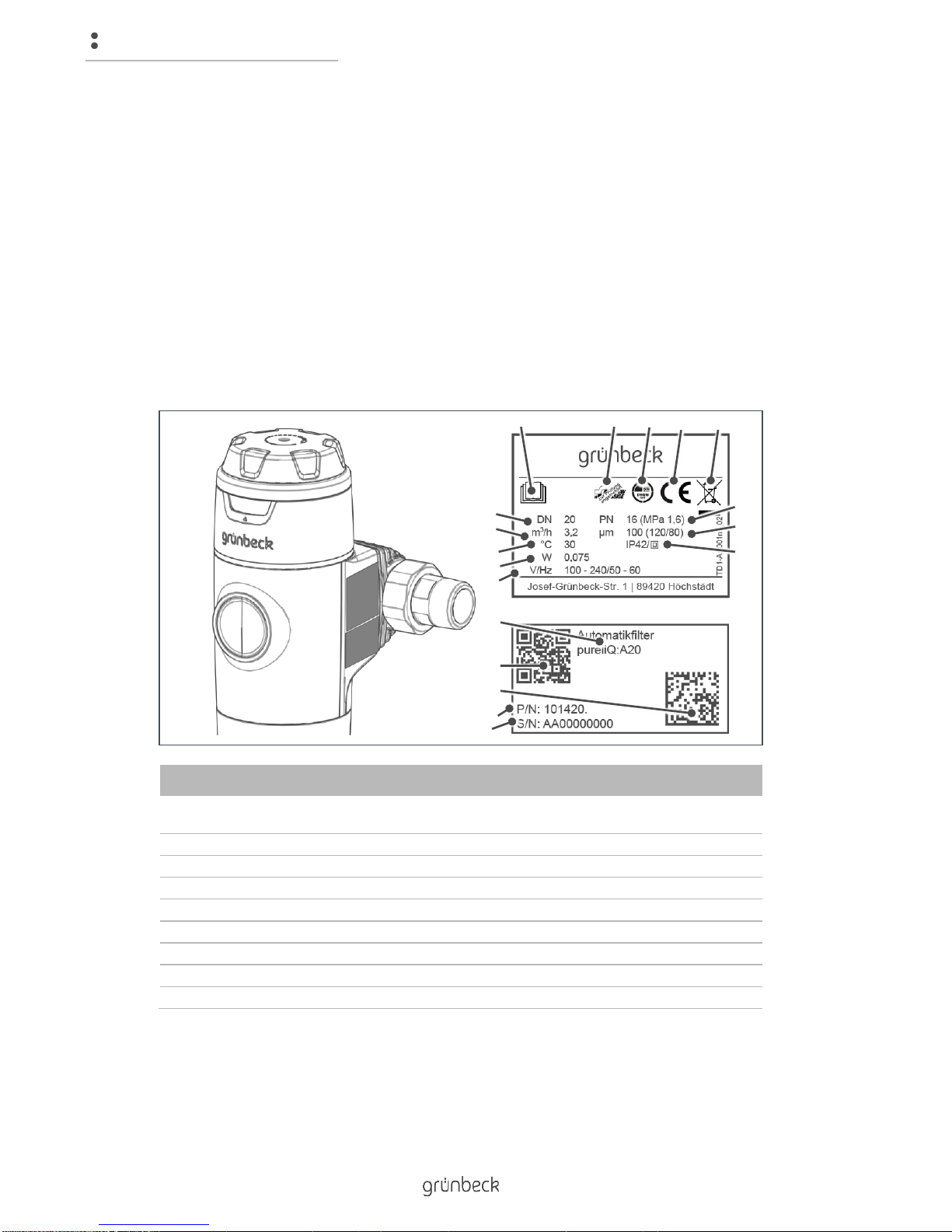

1.7 Type plate

Type plate is located on the right side of the housing as seen from

the front.

Please specify the data shown on the type plate in order to speed

up the processing of your enquiries or orders. Please enter the

serial number below in order to have the necessary data handy

whenever necessary.

Item

Designation

No.

Designation

1

Observe operation manual

2

SVGW mark of conformity

(registered)

3

DVGW test mark

4

CE mark

5

Disposal information

6

Nominal pressure

7

Pore size

8

Protection/protection class

9

Serial no.

10

Order no.

11

Data matrix code

12

QR code

13

Product designation

14

Power supply

15

Max. electrical power input

16

Max. water temperature

17

Nominal flow rate

18

Nominal connection diameter

● Product designation: Automatic filter pureliQ:____

● Order number: 101 ___

● Serial no.: ________________

2

3

6

7 8 14

9

10

12

11

1

13

15

16

17

18

4

5

Page 9

Safety

9 | 44

-AA000en_025

2 Safety

WARNING: Contamination of drinking water due to improper

handling.

● Risk of infectious diseases.

► Only have installation and start-up carried out by a

specialist installer.

2.1 Safety measures

● Carefully read this manual before operating your product.

● Install the product in a frost-free room. Otherwise, the

system may suffer irreparable damage. The consequence

can be a water damage.

● Only use genuine spare parts for maintenance or repair. If

unsuitable spare parts are used, the warranty for your

product will be void.

● Do not use products which have a damaged power supply

cable. This can lead to injuries due to electric shock. Have

damaged power supply cables replaced without delay.

● Mains cables are only allowed to be replaced by the

manufacturer or authorised personnel.

● Comply with the hygiene instructions in chapter 6. Failure

to comply can result in microbiological contamination of

your drinking water installation.

● Only have persons working on your system that have read

and understood the present manual and that are qualified

to do such work due to their vocational training.

Page 10

Safety

10 | 44

-AA000en_025

● Only operate the product if all components are installed

properly.

● Safety device must never be removed, bridged or

otherwise tampered with.

● Children are not allowed to play with the product.

● This product can be used by children over 8 years of age

and persons with limited abilities or lack of experience if

they are supervised or instructed in the safe use of the

product and understand the resulting hazards.

● Cleaning and maintenance must not be carried out by

children.

2.2 Technical safety instructions

This manual contains information and instructions that you must

comply with for your own personal safety as well as to avoid

damage to property. The information and instructions are

highlighted by a warning triangle and have the following structure:

CAUTION: Type and source of danger

● Possible consequences

► Preventive measures

The following signal words were defined subject to the degree of

danger and can be used in the present document:

● DANGER means that serious or fatal injuries will occur if

the corresponding precautionary measures are not taken.

● WARNING means that serious or fatal injuries may occur if

the corresponding precautionary measures are not taken.

Page 11

Safety

11 | 44

-AA000en_025

● CAUTION means that minor injuries may occur if the

corresponding precautionary measures are not taken.

● NOTE (without a warning triangle) means that damage to

property may occur if the corresponding safety measures

are not taken.

2.3 Regulations

During installing and start-up of the system, amongst other things

comply with the following regulations and guidelines:

● Statutory regulations on environmental protection

● Provisions of the employers' liability insurance associations

● DIN EN 806 Specifications for installations inside buildings

conveying water for human consumption

● VDI 6023 section 6

2.4 Responsibilities of the specialist installer

Comply with the following instructions to ensure the proper and

safe functioning of the product:

● Only perform activities described in this manual.

● Perform all activities in accordance with all applicable

standards and regulations.

● Brief the owner/user on the function and operation of the

product.

● Advise the owner/user of the maintenance of the product.

● Instruct the owner-user about possible dangers that can

arise during operation of the product.

Page 12

Safety

12 | 44

-AA000en_025

2.5 Responsibilities of the owner-user

Comply with the following instructions to ensure the proper and

safe functioning of the product:

● Assign the installation and start-up to a specialist installer.

● Have the product explained to you by the specialist

installer.

● Only perform activities described in this manual.

● Do not carry out any activities that are explicitly marked for

a specialist installer.

● Only use this product as intended.

● Make sure that the required inspection and maintenance

work is carried out.

● Keep this manual.

Page 13

Product description

13 | 44

-AA000en_025

3 Product description

3.1 Intended use

● The automatic filters pureliQ:A and pureliQ:AD are

designed for the filtration of drinking and industrial water.

● The automatic filter pureliQ:AD with pressure reducer in

addition is suitable for the adjustment of the after-pressure

on the withdrawal side.

● The filters can be used for positive pressure- and negative

pressure applications. A backwash and the adjustment of

the after-pressure on the withdrawal side, however, are

only possible when applied in the positive pressure range.

● The filters are not suitable for circulation water that is

treated with chemicals.

● The filters are neither suitable for oils, greases, solvents,

soaps and other lubricating media, nor for the separation of

water-soluble substances.

● The filters are designed according to DIN EN 13443-1,

DIN 19628 and DIN EN 1567 (only applies to the automatic

filter pureliQ:AD) and are intended for installation in

drinking water systems according to DIN EN 806-2

(installation directly after the water meter system).

● The filters protect the water pipes and connected water-

carrying system parts from disturbances and corrosion

damage due to undissolved impurities (particles) such as

rust particles and sand.

Page 14

Product description

14 | 44

-AA000en_025

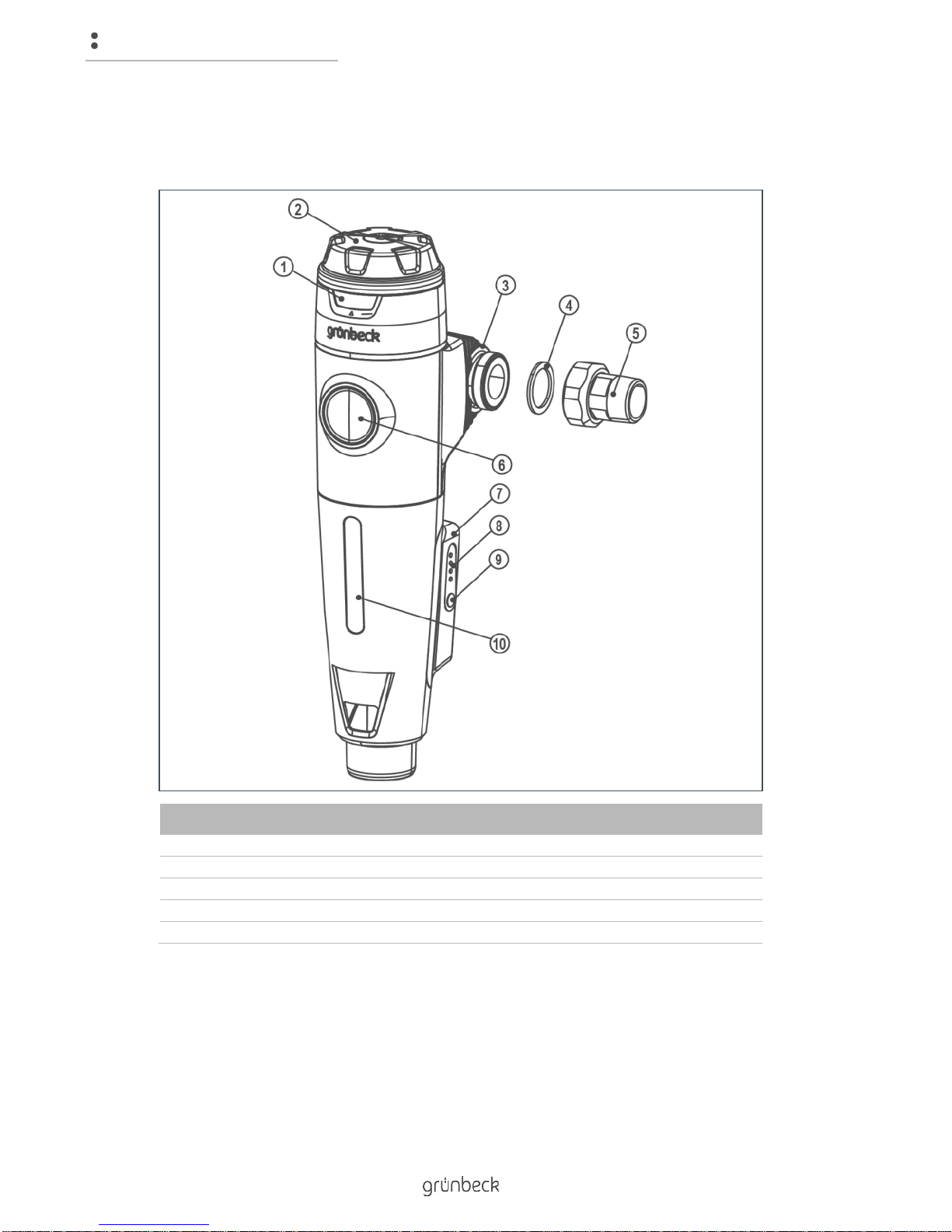

3.2 Product components

No.

Designation

No.

Designation

1

Month display

2

Pressure reducer handwheel

3

Click connection flange

4

Seal

5

Water meter screw connection

6

Pressure gauge

7

Automatic unit

8

LEDs backwash intervals

9

Push-button

10

Inspection window

Page 15

Product description

15 | 44

-AA000en_025

3.3 Functional description

The unfiltered drinking water flows into the filter from the inlet side

and then from the outside in through the filter element and to the

pure water outlet. Thus, foreign particles of > 100 µm in size are

retained.

Depending on their size and weight, the foreign particles either

stick to the filter element or they fall straight down into the filter

cylinder.

The controller automatically releases the backwash as per the

setting. Possible settings for the backwash intervals are 7, 30, 60

and 90 days. A backwash can be initiated manually at any time.

The drain is opened by triggering a backwash. The water flows

through the primary screen to the filter element and then flows

through the filter element in reverse direction of standard filtration.

Particles adhering to the filter element are freed and rinsed out to

the drain.

The backwash process takes about 50 seconds. In case some

particles still remain on the filter element, the backwash must be

triggered again manually. Grünbeck recommends a backwash

interval of 60 days.

In the automatic filter pureliQ:AD, the flow-optimised pressure

reducer, which is designed according to DIN EN 1567, enables

the after-pressure on the withdrawal side to be set to 1 – 6 bar

(factory setting: 4 bar).

Page 16

Installation

16 | 44

-AA000en_025

4 Installation

The installation of a filter represents a major intervention into the

drinking water system and may only be performed by a

specialist installer.

The pureliQ filters are installed in accordance with DIN EN 806-2

and DIN 1988-200 in the cold water line downstream of the water

meter and upstream of distribution lines or the devices to be

protected.

Pos.

Designation

No.

Designation

1

Inlet shut-off valve

2

Outlet shut-off valve

3

Drain connection

Page 17

Installation

17 | 44

-AA000en_025

4.1 Requirements in relation to the installation

site

Observe local installation directives, general guidelines and

technical specifications. The installation site must be frost-proof

and ensure the filter's protection from chemicals, dyes, solvents,

vapours and direct sunlight.

The installation location must be away from heat sources (e.g.

washing machines, boilers and hot water pipes).

A drain connection DN 50 must be available to discharge the

flushing water.

There must be push socket with earthing contact in the

installation area.

The installation room must be provided with a floor drain. If none

is available, an appropriate safety device has to be installed to

avoid water damage. We recommend using a protectliQ:A.

The installation site must be well accessible for maintenance

purposes.

Page 18

Installation

18 | 44

-AA000en_025

4.2 Checking the scope of supply

No.

Designation

No.

Designation

1

Water meter screw fittings

2

Gaskets

3

Automatic filters pureliQ:A or

pureliQ:AD

4

Operation manual

► Check the scope of supply for completeness and possible

damage.

Page 19

Installation

19 | 44

-AA000en_025

4.3 Installing the product

In order for the water line on both sides of the filter to be

properly connected to the protective-equipotential bonding, we

recommend establishing a corresponding electrical bypass

according to DIN VDE 0100-540.

Use suitable tools for assembly and be careful not to scratch the

housing with your tool.

The transparent plastic film serves as transport and dirt

protection. We recommend leaving it on the device during

assembly and the construction phase to prevent soiling of the

white housing.

4.3.1 Installing the filter

1. Install the water meter screw connection in the pipe (the

distance between the two seals must be 100 mm).

2. Leave the protective caps on the threads.

The rotatable click-type connection flange allows the filter to be

adapted to any flow direction given on site.

Page 20

Installation

20 | 44

-AA000en_025

3. Check the flow direction given on site.

4. Rotate the click-type connection flange to the position

suitable for your flow direction (marking on click-type

connection flange).

5. Remove the protective caps.

6. Install the filter without stress and tighten the union nuts.

Page 21

Installation

21 | 44

-AA000en_025

4.3.2 Attaching the backwash connection

Discharge of backwash water with drain and trap

► Install the drain connection (not included in the scope of

supply) at the lower outlet of the filter.

The free outlet is already integrated in the filter.

Page 22

Start-up

22 | 44

-AA000en_025

5 Start-up

The start-up is only allowed to be carried out by a specialist.

5.1 How to start up the product

1. Open the shut-off valves.

2. Open the nearest tap after the filter as far as it will go.

3. Check the filter for leaks.

4. Connect the mains plug to the socket.

» LED 60d lights up (factory setting).

» The filter is in operation

The filter does not automatically backwash during the initial

start-up, but waits until the set interval is reached. We therefore

recommend triggering a backwash manually.

The interval counter is then set to zero. The next backwash

takes place at the set interval.

5. Trigger a backwash manually (refer to chapter 5.2.2).

» The filter is vented by backwashing.

Page 23

Start-up

23 | 44

-AA000en_025

5.2 Operating the backwash unit

The filters pureliQ:A and AD automatically trigger backwashes at

the set intervals.

5.2.1 Setting the backwash interval

Pos.

Designation

No.

Designation

1

LED element 90d

2

LED element 60d

3

LED element 30d

4

LED element 7d

5

Push-button

► Press the button repeatedly until the desired backwash

interval is set.

» The corresponding LED lights up.

» The filter automatically backwashes at the set interval.

Page 24

Start-up

24 | 44

-AA000en_025

5.2.2 Triggering a backwash manually

► Press the button for 3 seconds.

» A backwash is initiated.

If the electrical power supply is interrupted, the filter

automatically completes any backwash that may be in progress.

During the initial start-up or after a longer interruption of the

electrical power supply, the backwash protection will only be

available again after approx. 5 minutes.

5.3 Setting the month display

In order not to miss a check date, you can set the next date for

checking by turning the month display.

► Turn the ring above the month display until the desired

month is shown in the month display.

Page 25

Start-up

25 | 44

-AA000en_025

5.4 Setting pressure reducer (only pureliQ:AD)

The factory setting for the pressure reducer is 4 bar. You can

change this value as follows:

1. Open the withdrawal point.

2. Set the desired after-pressure on the handwheel for

pressure reducer by turning it.

3. Read off the measured actual after-pressure at the

pressure gauge on the front of the housing.

4. Close the withdrawal point.

Page 26

Start-up

26 | 44

-AA000en_025

5.6 Handing over the operation manual to the

operator

When handing over the product, proceed as follows:

1. Inform the owner/user how the filter works.

2. Hand over all documents to the owner/user for keeping.

3. Use the manual to brief the owner/user, and answer any

questions.

4. Inform the owner/user about the need for inspections and

maintenance.

Page 27

Cleaning, inspection,

maintenance

27 | 44

-AA000en_025

6 Cleaning, inspection,

maintenance

6.1 Cleaning

NOTE: Do not clean the filter with alcohol or cleaning agents

containing solvents.

● These substances will damage components made of

plastic.

► Use a mild soap solution for external cleaning and flush

the parts well.

6.2 Inspection and maintenance

Inspection and maintenance are not necessary for automatic

filters.

We recommend checking the filter every six months.

1. Check the filter for leaks

2. Trigger a backwash manually.

3. Check the mains cable for damage.

Mains cables are only allowed to be replaced by the

manufacturer or authorised personnel.

4. Enter the work performed into the operation log in chapter

11.

5. Set the date for the next check (6 months) by setting the

month display.

Page 28

Cleaning, inspection, maintenance

28 | 44

-AA000en_025

6.3 Wearing parts

NOTE: Danger of damaging the system if unsuitable wearing

parts are used.

● Risk of functional impairment, malfunctions and loss of

warranty.

► Only use genuine wearing parts.

Seals are wearing parts.

Although these parts are wearing parts, we grant a limited

warranty period of 6 months for them.

Page 29

Cleaning, inspection,

maintenance

29 | 44

-AA000en_025

6.4 Service kits

6.4.1 Service kits for automatic filter pureliQ:A

Pos.

Designation

No.

Designation

1

Backwash valve incl. seals

2

Fastening nut incl. seal

3

Automatic drive

4

Filter cylinder

5

Cylinder O-ring

6

Filter element

Designation

consisting of:

Order no.

Recommended

replacement

interval

Service kit I

• Filter element 100 µm

incl. seal

• Cylinder O-ring

• Backwash valve

incl. seals

• Fastening nut incl.

seal

101 694e

5 years

Service kit II

• Service kit I

• Filter cylinder

• Automatic drive

101 696e

10 years

Tools required

Strap wrench

105 805

Allen key 10

Page 30

Cleaning, inspection, maintenance

30 | 44

-AA000en_025

6.4.2 Service kits for automatic filter pureliQ:AD

Pos.

Designation

No.

Designation

1

Backwash valve incl. seals

2

Fastening nut incl. seal

3

Automatic drive

4

Filter cylinder

5

Cylinder O-ring

6

Pressure gauge

7

Pressure reducer

8

Filter element

Designation

consisting of:

Order no.

Recommended

replacement

interval

Service kit III

• Service kit I

• Pressure

reducer

• Pressure gauge

101 697e

5 years

Service kit IV

• Service kit III

• Filter cylinder

• Automatic drive

101 698e

10 years

Tools required

Strap wrench

105 805

Allen key 10

Pipe socket wrench

104 805

TORX T8 (pressure gauge)

TORX T10 (pressure reducer adjusting

cap)

Page 31

Cleaning, inspection,

maintenance

31 | 44

-AA000en_025

6.5 Spare parts

NOTE: Risk of damage to the system if unsuitable spare parts

are used.

● There is a risk of functional impairments, malfunctions

and loss of warranty.

► Only use genuine spare parts.

Page 32

Faults

32 | 44

-AA000en_025

7 Faults

WARNING: Risk of contaminated drinking water due to

unintentional, strong reduction of pressure.

● Risk of infectious diseases.

► Remedy this malfunction immediately.

Fault

Explanation

Remedy

The water pressure at the

withdrawal point is too low

(pressure loss too high).

The shut-off valves are not

open completely.

Open the shut-off valves

completely .

The filter element is fouled.

Carry out a backwash.

Taste of the treated water

negatively affected.

Inappropriately long period

of non-use (standstill).

Draw off water for a few

minutes.

Carry out a backwash.

Solids in the filtered water.

Inappropriately high flow

rate through the filter.

Contact the specialist

installer or Grünbeck's

technical service.

Filter element damaged or

not properly installed.

Contact the specialist

installer or Grünbeck's

technical service.

Water loss from the

system.

Faulty joint.

Check the filter housing for

damage or leaks.

Contact the specialist

installer or Grünbeck's

technical service.

All four LEDs flash

• Timeout during the

backwash procedure

(> 115 s)

• Timeout when starting

the backwash

Valve blocked

Carry out a backwash. If

this does not remedy the

fault, contact the specialist

installer or Grünbeck's

technical service.

Motor defective

Timing belt defective

Defect of the microswitch

during the backwash

Uppermost LED 90d

flashes

Defect of the microswitch

Carry out a backwash. If

this does not remedy the

fault, contact the specialist

installer or Grünbeck's

technical service.

Page 33

Disposal

33 | 44

-AA000en_025

8 Disposal

This symbol indicates products or product components

that must not be disposed of as household waste. The

labelled product or product components must be collected

separately and recycled in an environmentally sound

manner.

Do not dispose of the packaging, the product and/or the

accessories with the domestic waste.

► Comply with the applicable national regulations for

disposal.

► Make sure that the packaging, the product and the

accessories are disposed of properly.

The product and accessories must be returned to a

suitable collection point for the recycling of electronic and

electrical appliances.

Page 34

Technical specifications

34 | 44

-AA000en_025

9 Technical specifications

9.1 Automatic filter pureliQ:A

Dimensions and weights

A Installation height up to

centre of connection

[mm]

285

B Installation length

with/without screw

connection

[mm]

185/100

182/100

191/100

C Min. distance to wall

[mm]

50

D Installation depth up to

centre of connection

[mm]

135

135

145

E Total height

[mm]

385

Empty weight

[kg]

1.8

2.0

2.2

Operating weight, approx.

[kg]

2.3

2.5

2.7

Connection data pureliQ:A

Nominal connection

diameter

DN 20

DN 25

DN 32

Connection diameter

¾“

1"

1¼"

Drain connection DN 50

Power supply

[V]/[Hz]

100 – 240/50 – 60

Page 35

Technical specifications

35 | 44

-AA000en_025

Connection data pureliQ:A

Electrical power

consumption

Operation = max./standby

[W]

2/0.075

Protection/protection

class

IP42/

Performance data

Nominal flow at

p 0.2 (0.5) bar

[m³/h]

3.2 (5.1)

4.2 (6.7)

5.0 (8.0)

KV value

[m³/h]

7.2

9.5

11.3

Pore size

[µm]

100

Largest/smallest pore

size

[µm]

120/80

Operating pressure

[bar/MPa]

2 – 16/0.2 – 1.6

Nominal pressure PN 16

General

Backwash water volume at

4 bar inlet pressure

[l]

approx. 14

Water temperature

[°C]

5 – 30

Ambient temperature

[°C]

5 – 40

DVGW registration number

NW-9301CT0031

SVGW certificate number

pending

Order no.

101 420

101 425

101 430

Automatic filter pureliQ:A pressure loss curve

Pos.

Designation

No.

Designation

1

Differential pressure [bar]

2

Flow rate [m³/h]

Page 36

Technical specifications

36 | 44

-AA000en_025

9.2 Automatic filter pureliQ:AD

Dimensions and weights

A Installation height up to

centre of connection

[mm]

285

B Installation length

with/without screw

connection

[mm]

185/100

182/100

191/100

C Min. distance to wall

[mm]

50

D Installation depth up to

centre of connection

[mm]

135

135

145

E Total height

[mm]

405

Empty weight

[kg]

2.0

2.2

2.4

Operating weight, approx.

[kg]

2.5

2.7

2.9

Connection data pureliQ:AD

Nominal connection

diameter

DN 20

DN 25

DN 32

Connection diameter

¾“

1"

1¼"

Drain connection DN 50

Power supply

[V]/[Hz]

100 – 240/50 – 60

Electrical power

consumption

Operation = max./standby

[W]

2/0.075

Protection/protection

class

IP42/

Page 37

Technical specifications

37 | 44

-AA000en_025

Performance data

Flow rate as per DIN

EN 1567

[m³/h]

2.3

3.6

5.8

Pore size

[µm]

100

Largest/smallest pore

size

[µm]

120/80

Nominal pressure PN 16

General

Backwash water

volume at 4 bar inlet

pressure

[l]

approx. 14

Water temperature

[°C]

5 – 30

Ambient temperature

[°C]

5 – 40

DVGW registration

number

NW-9311CT0032

SVGW certificate

number

pending

Order no.

101 470

101 475

101 480

Page 38

Other information

38 | 44

-AA000en_025

10 Other information

10.1 Explanation of terminology

Filter element

Part of the filter that ensures the retention of the particles.

Pore size

The filter's ability to retain particles and suspended matter of

a certain size range, regardless of the type of filter material.

It is defined by the upper and lower filtration fineness

Nominal flow rate

Flow rate at which, with a clean filter, either the pressure

loss does not exceed 50 kPa (0.5 bar) or the filter surface

loading does not exceed the maximum specified value

(whichever value is lower)

Upper filtration fineness

the number indicates the particle size of a material in μm

which passes through the filter under test conditions with a

mass fraction of 10%

Drinking water

Drinking water is any water that is intended to be used in the

domestic environment for drinking and all other food

preparation purposes, for personal hygiene and cleaning as

well as for cleaning objects that do not only temporarily

come into contact with foodstuffs or the human body.

Lower filtration fineness

the number indicates the particle size of a material in μm

which passes through the filter under test conditions with a

mass fraction of 90 %

Page 39

Operation log

39 | 44

-AA000en_025

11 Operation log

● Product designation: Automatic filter pureliQ:____

● Order no.: 101 ___

● Serial no.: ________________

Date

Work performed

Signature

Page 40

EC Declaration of Conformity

40 | 44

EC Declaration of Conformity

In accordance with the EU Low-Voltage Directive 2014/35/EU, Appendix IV

This is to certify that the system designated below meets the safety and health requirements

of the applicable European guidelines in terms of its design, construction and execution.

This certificate will become invalid if the system is modified in a way not approved by us.

Automatic filter pureliQ:A / AD

Serial no.: See type plate

The aforementioned system also complies with the following directives and provisions:

• EMC (2014/30/EU)

The following harmonised standards have been applied:

• DIN EN 61000-6-2:2006-03

• DIN EN 61000-6-3:2011-09

• DIN EN 60335-1

•

The following standards and regulations have been applied:

• DIN EN 13443-1:2007-12

• DIN 31000/VDE 1000:2017-04

• DIN 19628:2007-07

Responsible for documentation:

Dipl.-Ing. (FH) Markus Pöpperl

Manufacturer

Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Str. 1

89420 Hoechstaedt

Germany

Hoechstaedt; Germany, 16 November 2017

Dipl. Ing. (FH) Markus Pöpperl

Head of Department for Product Implementation and Product Launch

Page 41

Notes

41 | 44

-AA000en_025

Notes

Page 42

Index

42 | 44

Index

B

Backwash .............................. 15, 32

C

Cleaning ................................ 27, 38

D

Disposal ..................................... 33

F

Fault ........................................... 32

Faults ......................................... 32

Filter element ...... 15, 29, 30, 32, 38

Filtration ................................ 13, 15

I

Inspection ................................... 27

Installation ................... 9, 11, 12, 16

M

Maintenance ............ 4, 9, 11, 12, 27

P

Pressure reducer . 13, 14, 15, 25, 30

S

Service kit..............................29, 30

Spare parts ............................. 9, 31

T

Technical specifications .............. 34

W

Wearing parts ............................. 28

Page 43

Page 44

Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Str. 1

89420 Hoechstaedt

Germany

For more information. go

to www.gruenbeck.com

+49 9074 41-0

+49 9074 41-100

info@gruenbeck.com

www.gruenbeck.com

Loading...

Loading...