Page 1

We understand water.

Filter | GENO-backwash filter MXA 1"- MXA DN 100

Operation manual

Page 2

General Contact

Germany

International Sales

Phone +49 9074 41-145

Technical Service

Phone +49 9074 41-333

Fax +49 9074 41-120

Availability

Monday to Thursday

7:00 am - 6:00 pm

Friday

7:00 am - 4:00 pm

Copyright

The manufacturer reserves the copyright to this operation manual. Without the written consent of

Grünbeck Wasseraufbereitung GmbH, no part of this manual may be reproduced in any way, nor

may any part be processed, duplicated or distributed using electronic systems.

Non-compliance with the aforementioned stipulations shall be subject to compensation for damages.

We reserve the right to technical modifications.

© by Grünbeck Wasseraufbereitung GmbH

Translation of the original operation manual

Edition of the operation manual: July 2019

Order no.: TD3-AM000en_014

Page 3

Table of contents

3 | 72

Table of contents

1 About this manual ..................................................... 4

1.1 Other applicable documents ...................................... 4

1.2 Target group .............................................................. 4

1.3 Storage of documents ................................................ 4

1.4 Symbols used ............................................................ 4

1.5 Typographical conventions ........................................ 5

1.6 Validity of the manual ................................................ 5

1.7 Type plate .................................................................. 6

2 Safety ......................................................................... 7

2.1 Safety measures ........................................................ 7

2.2 Technical safety instructions ...................................... 8

2.3 Regulations ................................................................ 8

2.4 Responsibilities of the specialist installer and/or

the specialist company .............................................. 8

2.5 Responsibilities of the owner/user ............................. 9

2.6 Product-specific safety instructions ........................... 9

2.7 Packaging, shipping and storage ............................... 9

3 Product description ................................................ 10

3.1 Intended use ............................................................ 10

3.2 Foreseeable misuse ................................................ 10

3.3 Product components ................................................ 11

3.4 Functional description .............................................. 12

3.5 Accessories ............................................................. 14

4 Installation ............................................................... 15

4.2 Requirements regarding the installation site ............ 17

4.3 Checking the scope of supply .................................. 18

4.4 Installing the product ................................................ 19

5 Control unit GENO-RS-tronic ................................. 28

5.1 Components of the control unit ................................ 28

5.2 Overview of display .................................................. 30

5.3 Navigating the control unit ....................................... 33

5.4 Menu structure ......................................................... 36

5.5 Programming levels ................................................. 36

6 Start-up .................................................................... 38

6.1 Preparations .............................................................38

6.2 Starting up the product .............................................39

6.3 Handing over the product to the owner/user ............39

7 Operation ..................................................................40

7.1 Information in the basic display ................................40

7.2 Setting parameters in the User level.........................41

7.3 Setting parameters in the Programming level ..........42

8 Cleaning, inspection, maintenance ........................46

8.1 Cleaning ...................................................................46

8.2 Intervals ....................................................................47

8.3 Inspection .................................................................47

8.4 Maintenance .............................................................48

8.5 Spare parts ...............................................................53

8.6 Wearing parts ...........................................................53

9 Troubleshooting .......................................................54

9.1 Display messages ....................................................54

9.2 Other malfunctions ...................................................57

9.3 Manually closing the filter’s suction nozzle ...............59

10 Disposal ....................................................................62

10.1 Packaging .................................................................62

10.2 Product .....................................................................62

11 Technical specifications .........................................63

11.1 Pressure loss curves ................................................65

12 Operation log ............................................................67

12.1 Start-up log ...............................................................67

12.2 Maintenance .............................................................68

EU Declaration of Conformity ..........................................69

Index ...................................................................................70

Page 4

About this manual

4 | 72

BA_TD3-AM001en_014_MXA.docx

1 About this manual

1.1 Other applicable documents

The following documents shall be considered as applicable documents for the GENO

backwash filter as well:

● For Grünbeck's technical service/authorised service company:

Technical service manual GENO-backwash filter MXA

Order no.: TD4-AM001en

● The manuals of all accessories used.

1.2 Target group

This manual is intended for specialist installers and owners/users.

1.3 Storage of documents

Keep this manual and all other applicable documents, so that they are available when

needed. Make sure that your specialist installer enters the proper start-up and annual

maintenance in chapter 12 of the operation log.

1.4 Symbols used

This symbol identifies instructions that you must comply with for your own personal safety

as well as to avoid damage to property.

This symbol identifies instructions that you must comply with in order to avoid damage to

property.

This symbol identifies important information about the product or its handling.

This symbol identifies work that may only be carried out by a specialist installer. In

Germany, the installation company must be registered in an installation directory of a water

supply company acc. to §12(2) AVB Wasser V (German Ordinance on General Conditions

for the Supply of Water).

This symbol identifies work that may only be carried out by Grünbeck's technical

service/authorised service company or by specialist installers trained by Grünbeck.

This symbol identifies work that may only be carried out by electronically trained personnel

according to the VDE guidelines or according to the guidelines of similar local institutions.

Page 5

About this manual

5 | 72

BA_TD3-AM001en_014_MXA.docx

1.5 Typographical conventions

The following typographical conventions are used in this manual:

Designation

Depiction

Instruction

Single-step instruction or chronological

sequence of steps does not matter

► Action

Instruction

Multi-step instruction and chronological

sequence of steps is important

1. First action

a first step

b second step

2. Second action

Result following an instruction

» Result

Lists

● Listed item

• Listed sub-item

Menu paths

Status level>Menu level>Submenu

Display texts

Display text

Operating elements

Button/key

1.6 Validity of the manual

This manual applies to the following products:

● GENO-backwash filter MXA 1" (DN 25)

● GENO-backwash filter MXA 1¼" (DN 32)

● GENO- backwash filter MXA 1½ (DN 40)

● GENO-backwash filter MXA 2" (DN 50)

● GENO-backwash filter MXA DN 65

● GENO-backwash filter MXA DN 80

● GENO-backwash filter MXA DN 100

Page 6

About this manual

6 | 72

BA_TD3-AM001en_014_MXA.docx

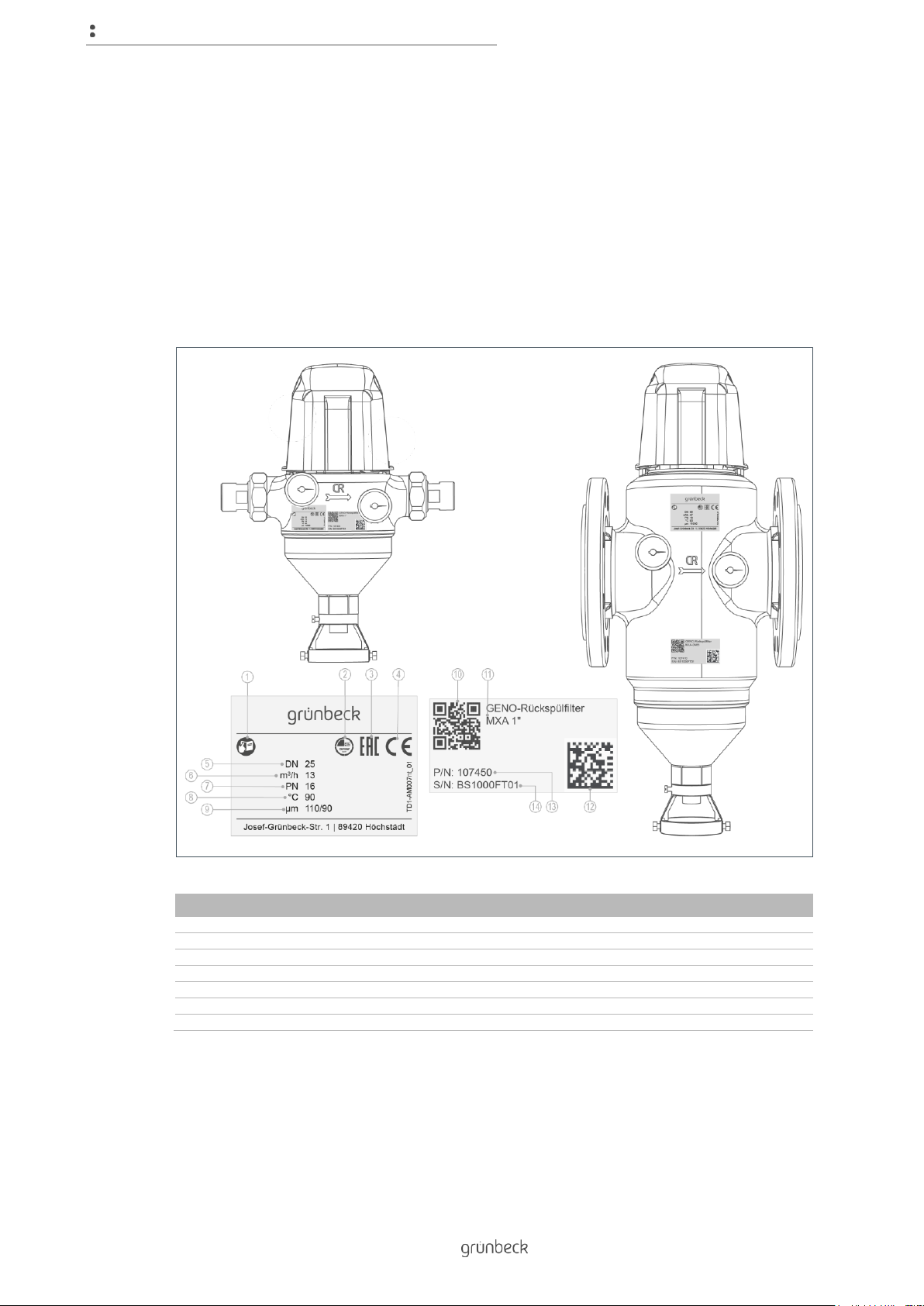

1.7 Type plate

The type plate is located on the front of the filter housing.

Please specify the data shown on the type plate in order to speed up the processing of your

inquiries or orders.

► Therefore, add the serial number in order to have the necessary data available at

all times.

Item

Designation

Item

Designation

1

Observe operation manual

2

DVGW test mark

3

EAC mark

4

CE mark

5

Nominal connection diameter

6

Nominal flow

7

Nominal pressure

8

Max. water temperature

9

Max./min. pore size

10

QR code

11

Product designation

12

Data matrix code

13

Order no.

14

Serial no.

● Product designation: GENO-backwash filter MXA_______

● Order number: 107 ______

● Serial no.: ________________

Page 7

Safety

7 | 72

BA_TD3-AM001en_014_MXA.docx

2 Safety

WARNING: Contamination of drinking water due to improper handling.

● Risk of infectious diseases.

► Have the installation, start-up and annual maintenance carried out by specialist

installers only.

2.1 Safety measures

● Carefully read this manual before operating your product.

● Install the product in a frost-free room. Otherwise, the system may suffer

irreparable damage. Water damage may occur as a result.

● Only use genuine spare parts for maintenance or repair. If unsuitable spare parts

are used, the warranty for your product will be void.

● Do not use any products which have a damaged mains cable. This can lead to

injuries due to electric shock. Have damaged mains cables replaced without delay.

● Keep your product permanently connected to the power and water supply.

● Comply with the hygiene instructions in chapter 8. Failure to comply can result in

microbiological contamination of your drinking water installation.

● Only have persons working on your product that have read and understood the

present manual and that are qualified to do such work due to their vocational

training.

● Only operate the product if all components are installed properly.

● Safety equipment must never be removed, bridged or otherwise tampered with.

● Observe the maintenance intervals (refer to chapter 8.2). Failure to comply can

result in microbiological contamination of your drinking water installation.

● This product can be used by children over 8 years of age and persons with limited

abilities or lack of experience if they are supervised or instructed in the safe use of

the product and understand the resulting hazards.

● Cleaning and maintenance must not be carried out by children.

● Keep the product away from children.

Page 8

Safety

8 | 72

BA_TD3-AM001en_014_MXA.docx

2.2 Technical safety instructions

This manual contains information and instructions that you must comply with for your own

personal safety as well as to avoid damage to property. The information and instructions are

highlighted by a warning triangle and have the following structure:

CAUTION: Type and source of danger.

● Possible consequences

► Preventive measures

The following signal words were defined subject to the degree of danger and may be used in

the present document:

● DANGER means that death or serious injury will result.

● WARNING means that death or serious injury may result.

● CAUTION means that minor bodily injuries may occur.

● NOTE (without warning triangle) means that damage to property may occur.

2.3 Regulations

When installing and starting up the system, amongst others, comply with the following

regulations and guidelines:

● Statutory regulations on environmental protection

● Provisions of the employers' liability insurance companies

● DIN EN 806 Specifications for installations inside buildings conveying water for

human consumption

● VDI 6023 Part 5 - 7 Specifications for installations inside buildings conveying water

for human consumption

● Low Voltage Directive 2014/35/EU, Appendix IV

2.4 Responsibilities of the specialist installer and/or the

specialist company

Comply with the following instructions to ensure the proper and safe functioning of the

product:

● Only perform activities described in this manual.

● Perform all activities in accordance with all applicable standards and regulations.

● Brief the owner/user on the function and operation of the product.

● Advise the owner/user of the maintenance of the product.

Page 9

Safety

9 | 72

BA_TD3-AM001en_014_MXA.docx

● Inform the owner/user about possible dangers that can arise during the operation

of the product.

● Fill in the operation log (refer to chapter 12).

2.5 Responsibilities of the owner/user

Comply with the following instructions to ensure the proper and safe functioning of the

product:

● Arrange for a specialist installer to carry out installation, start-up and maintenance.

● Have the product explained to you by the specialist installer.

● Only perform activities described in this manual.

● Do not carry out any activities that are explicitly designated for a specialist installer.

● Only use this product as intended.

● Make sure that the required inspection and maintenance work is carried out.

● Keep this manual.

2.6 Product-specific safety instructions

WARNING: If the intervals for inspection and backwash are not observed, the filter element

will become excessively polluted.

● Health risk due to contamination of the drinking water.

► Observe the intervals and recommendations for inspection and backwash of the

filter element.

2.7 Packaging, shipping and storage

Transport

► Transport the filters only in their original packaging.

Storage

► Protect the product from:

● Damp, moisture, environmental impacts such as wind, rain, snow, etc.

● Frost, direct sunlight, severe heat exposure

● Chemicals, dyes, solvents and their vapours

Page 10

Product description

10 | 72

BA_TD3-AM001en_014_MXA.docx

3 Product description

3.1 Intended use

● GENO-backwash filters MXA are designed for the filtration of drinking and

industrial water.

● The filters are suitable for the filtration of process, boiler feed, cooling and air

conditioning water – only in partial flow.

● The filters are suitable for water temperatures up to 90 ºC.

● The filters can be used in the pressure range.

● The filters are designed according to the stipulations of DIN EN 13443-1 and

DIN 19628 and are intended for installation into drinking water pipes according to

DIN EN 806-2 (installation immediately downstream of the water meter).

● The filters protect the water pipes and connected water-carrying system parts from

disturbances and corrosion damage due to undissolved impurities (particles), such

as rust particles, sand, etc.

3.2 Foreseeable misuse

● The filters cannot be used in the negative pressure range.

● The filters are not suitable for circulation water that has been treated with

chemicals.

● The filters are neither suitable for oils, greases, solvents, soaps and other

lubricating media, nor for the separation of water-soluble substances.

● Do not install the filters in vertical water pipes.

Page 11

Product description

11 | 72

BA_TD3-AM001en_014_MXA.docx

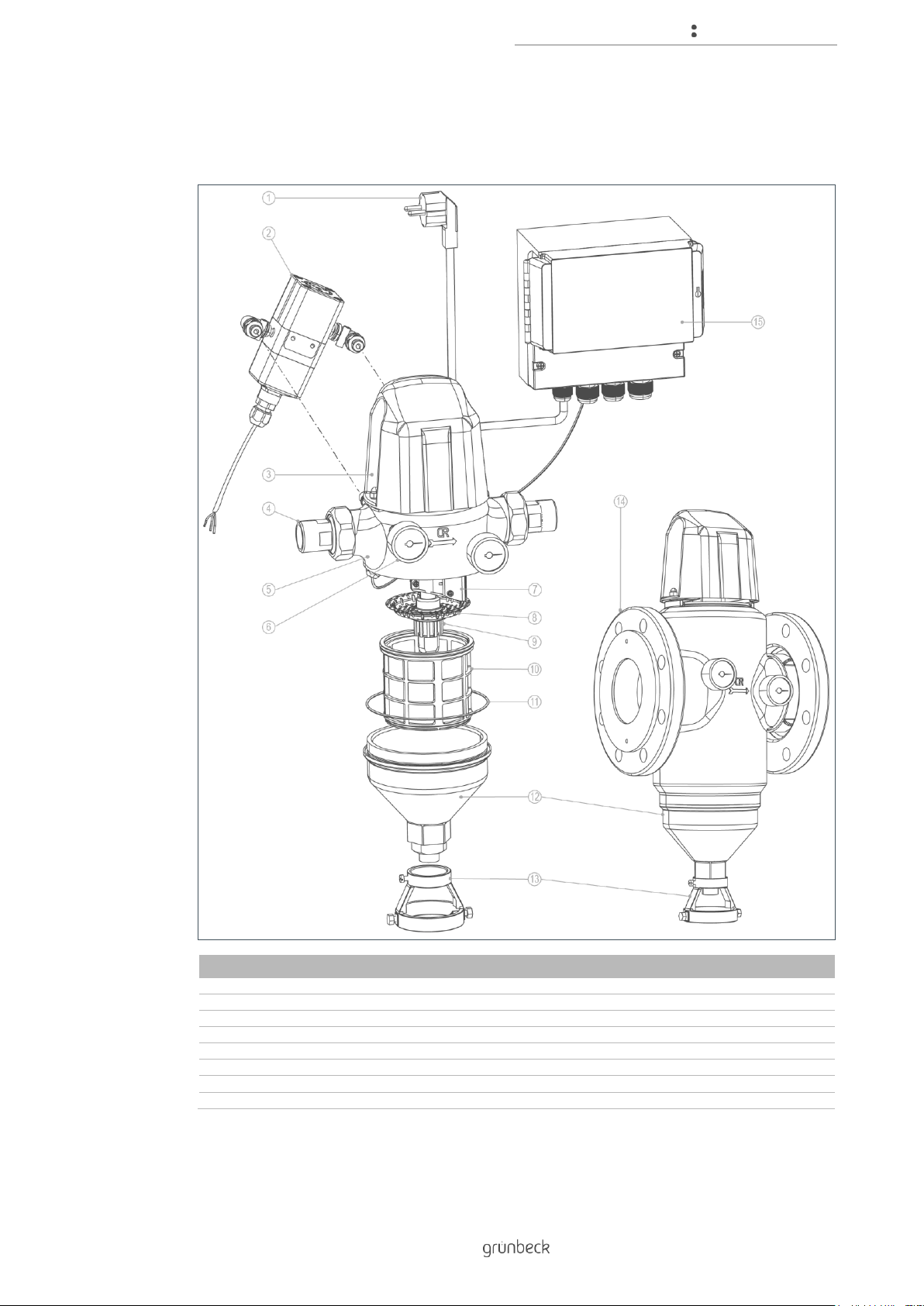

3.3 Product components

Item

Designation

Item

Designation

1

Shock-proof plug, 1.5 m cable

2

Differential pressure sensor

3

Cover

4

Water meter screw connection

5

Filter housing

6

Pressure gauge

7

Brush

8

Sieve bottom

9

Suction nozzle

10

Filter element

11

Gasket

12

Filter funnel

13

Backwash water connection

14

Flange connection

15

Control unit GENO-RS-tronic

Page 12

Product description

12 | 72

BA_TD3-AM001en_014_MXA.docx

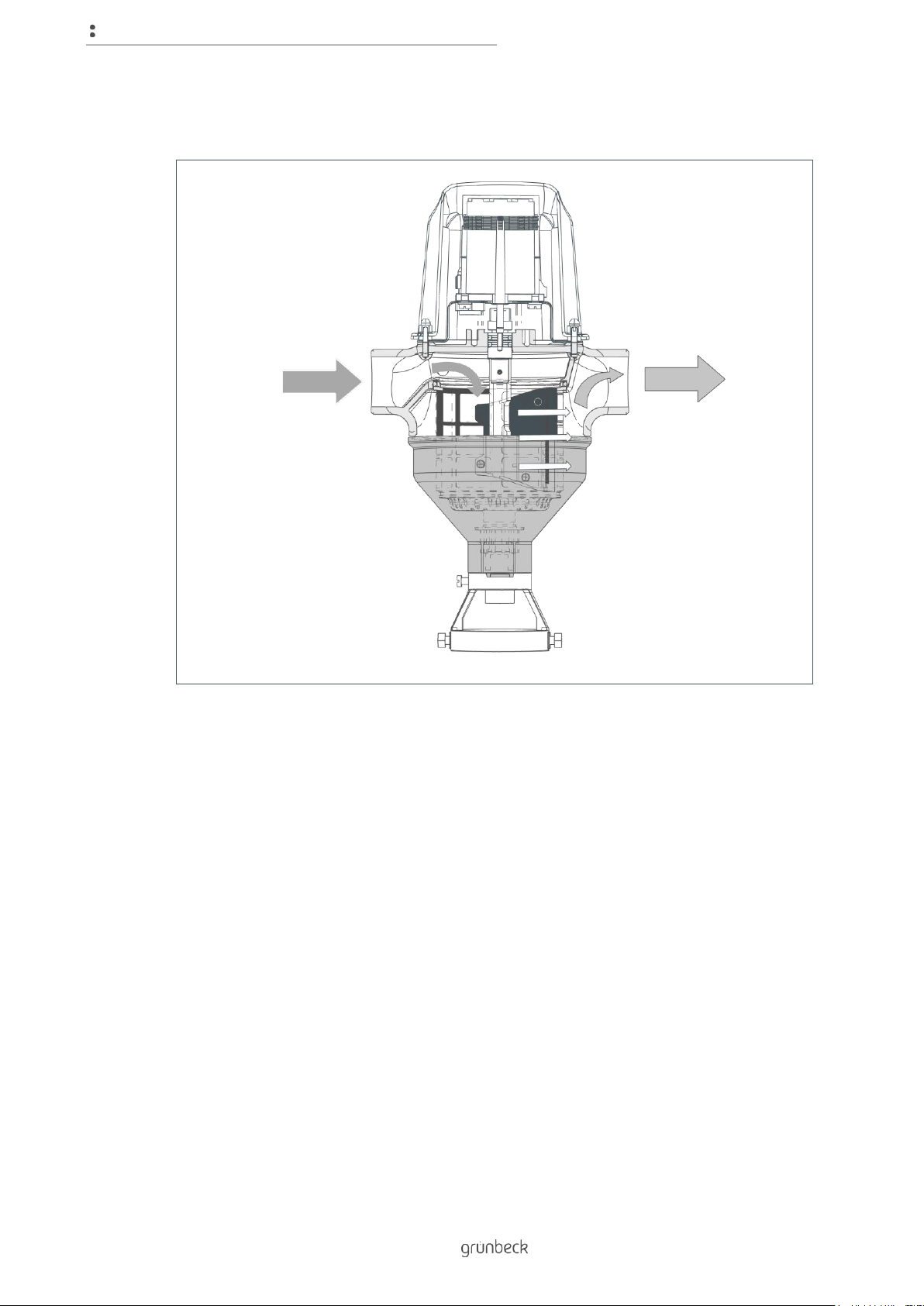

3.4 Functional description

The unfiltered raw water flows into the filter from the inlet side and then from the inside out

through the filter element and to the pure water outlet.

Thus, foreign particles of a size > 100 µm are retained.

Depending on their size and weight, the foreign particles stick to the filter element or they fall

straight down into the filter funnel.

The backwash process is activated by the GENO-RS-tronic control unit and carried out by

the drive unit on the filter head. The lower suction nozzle is lifted and the drain outlet is open.

During the rotating motion, the brush brushes over the filter surface of the filter element. The

filter element is cleaned.

The impurities are removed by the brush and the suction nozzle sucks them into the drain

outlet.

Page 13

Product description

13 | 72

BA_TD3-AM001en_014_MXA.docx

3.4.1 Backwash with the GENO-RS-tronic control unit

The GENO-RS-tronic control unit activates time and differential pressure controlled

backwash processes.

Apart from a time interval for the activation of a backwash, an off-period during which no

backwash processes may take place can also be defined.

An actuator opens the backwash water outlet. Initially, in clocked operation and then with

continuous rotation.

The rotation triggers the contact of a microswitch via a cam disc. The microswitch sends

pulses to the control unit. After several pulses, the control unit reverses the direction of

rotation and closes the backwash water outlet.

If the rotary motion is blocked by dirt or wear and tear, the control unit detects this and

responds automatically.

If the control unit cannot resolve the issue independently, a corresponding error message is

displayed (refer to chapter 9).

The control unit features a voltage-free fault signal contact and a voltage-free contact for

remote monitoring. A backwash in progress is signalled via the voltage-free contact.

The control unit monitors the number of backwashes. It provides - sometimes in conjunction

with a timed maintenance interval - information on the remaining number of backwashes in

the current maintenance interval via a bar graph in the display.

Page 14

Product description

14 | 72

BA_TD3-AM001en_014_MXA.docx

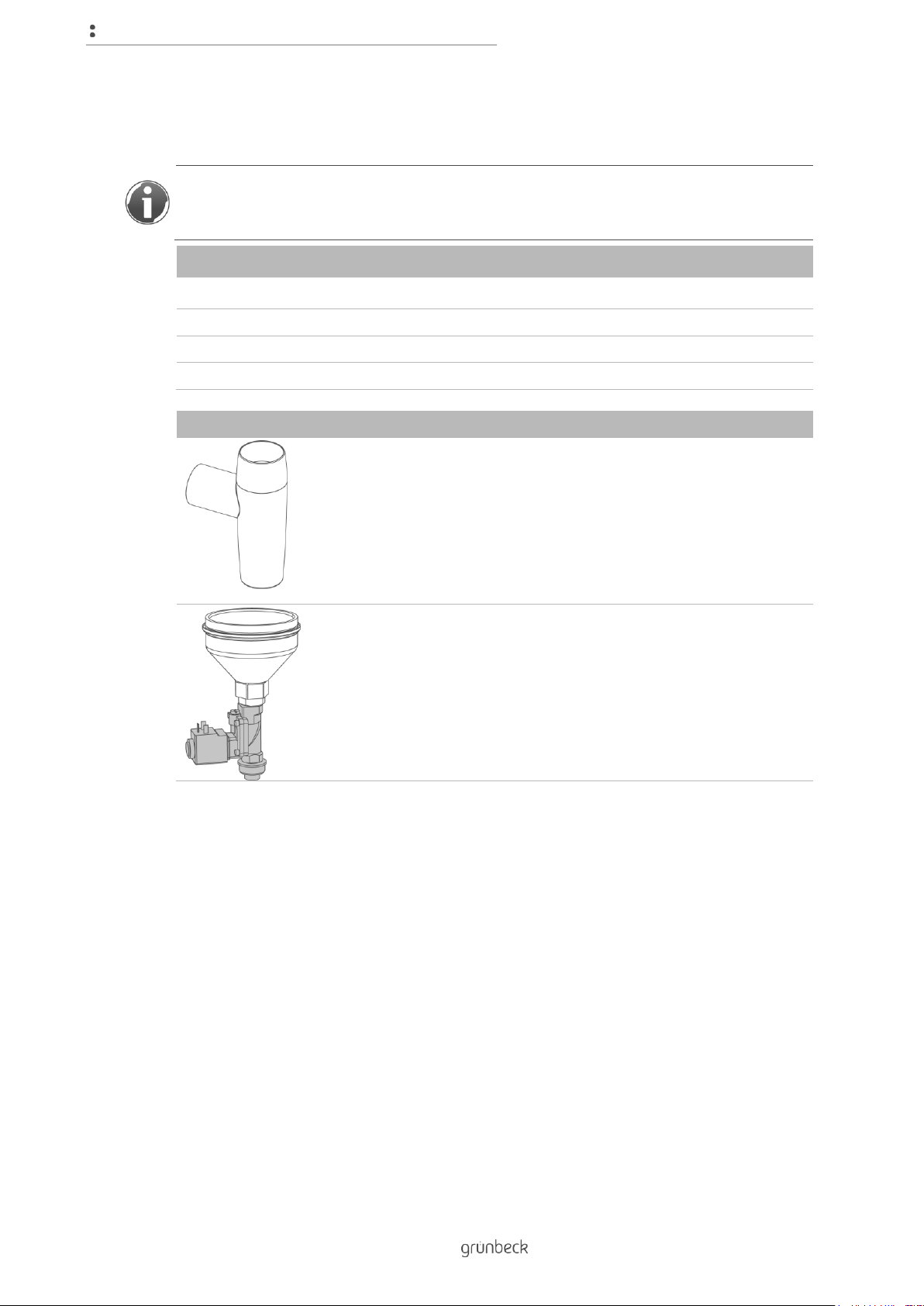

3.5 Accessories

You can retrofit your product with additional accessories. Please contact your local

Grünbeck representative or Grünbeck’s headquarters in Hoechstaedt for more details (refer

to www.gruenbeck.com).

Designation

Order no.

1" / 1¼"

1½" / 2" / DN 65

DN 80 / DN 100

50 µm filter element

107 052

107 053

107 054

200 µm filter element

107 072

107 073

107 074

500 µm filter element

107 082

107 083

107 084

Illustration

Product

Order no.

Drain connection DN 50 acc. to DIN EN 1717

with integrated siphon

188 875

Safety valve for MXA

GENO-RS-tronic-controlled, normally closed

solenoid valve.

Is installed at the backwash water outlet and

prevents inadmissible water leakage during a

backwash process, e.g. in case of a power

failure.

107 850

Page 15

Installation

15 | 72

BA_TD3-AM001en_014_MXA.docx

4 Installation

The installation of a filter represents a major intervention into the drinking water system and

may only be performed by a specialist installer.

In accordance with DIN EN 806-2 and DIN EN 1717, the product is installed in the water pipe

downstream of the water meter and upstream of distribution pipes or the systems to be

protected.

NOTE: Significant temperature differences occurring when the product is moved from one

location to another can lead to moisture forming on electronic components within the

control unit.

● Possible malfunction of the control unit during initial start-up.

► We recommend unpacking the product prior to installation and allowing it to rest

at the installation site for 1 hour without being used.

» Possible moisture formation on electronic components inside the control unit can

dry off.

Page 16

Installation

16 | 72

BA_TD3-AM001en_014_MXA.docx

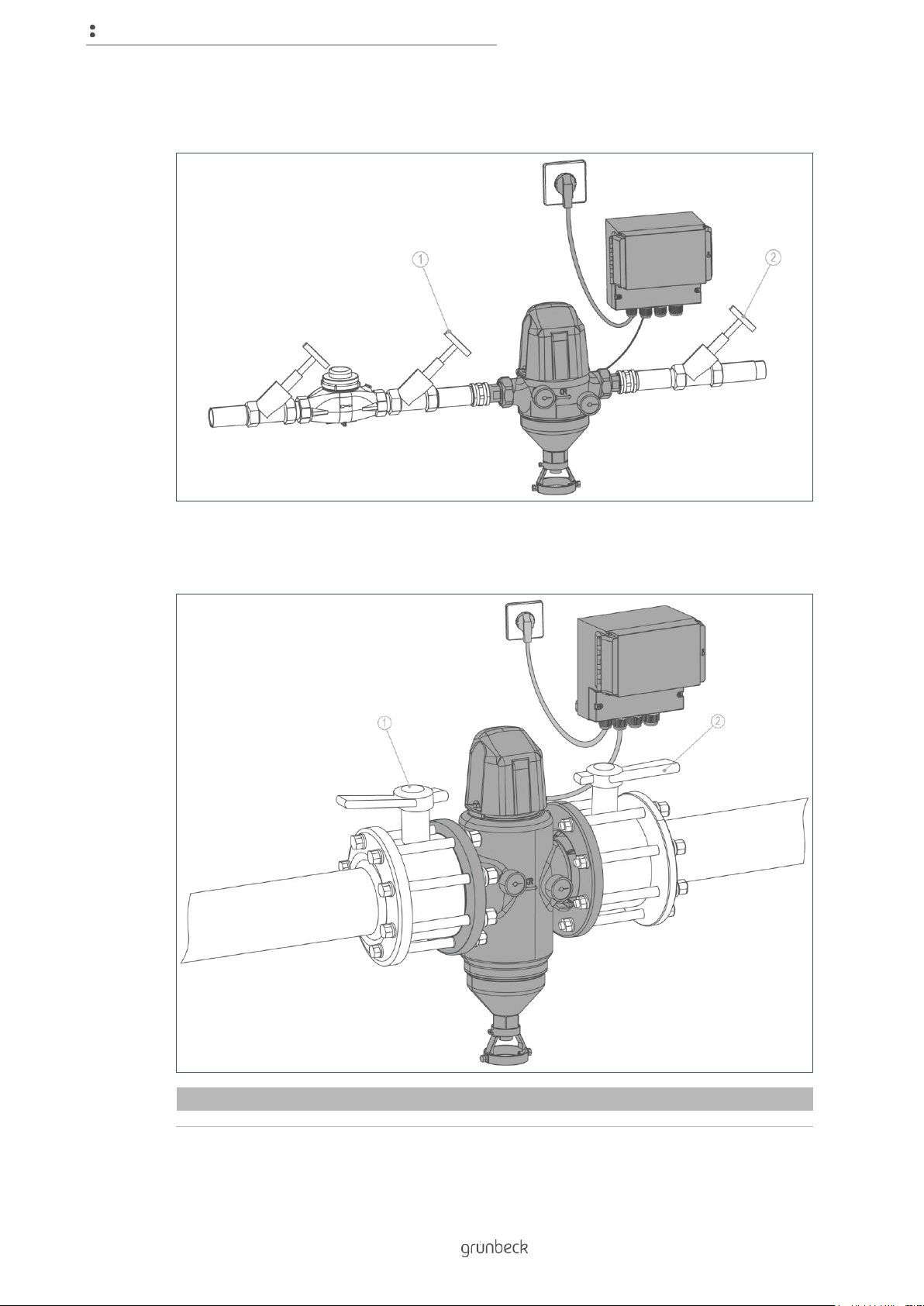

GENO-backwash filter MXA with screw connections

GENO-backwash filter MXA with flange connections

Item

Designation

Item

Designation

1

Inlet shut-off valve

2

Outlet shut-off valve

Page 17

Installation

17 | 72

BA_TD3-AM001en_014_MXA.docx

4.2 Requirements regarding the installation site

Observe local installation directives, general guidelines and technical specifications.

● The installation site must be frost-proof and ensure the filter's protection from

chemicals, dyes, solvents, vapours and direct sunlight.

● A drain connection (DN 50) must be available to discharge the backwash water.

● The installation room must provide a floor drain. If no floor drain is available, an

appropriate safety device must be installed in order to prevent water damage. We

recommend using a protectliQ:A.

● The installation site must be easily accessible for maintenance purposes.

● A shock-proof socket is required within a distance of approx. 1.2 m of the system.

NOTE: Power failure during the backwash process.

● Backwash will not be completed if the electrical power supply is interrupted.

● The backwash process continues until it is terminated manually.

► Do not connect the socket with light and heating switches.

Page 18

Installation

18 | 72

BA_TD3-AM001en_014_MXA.docx

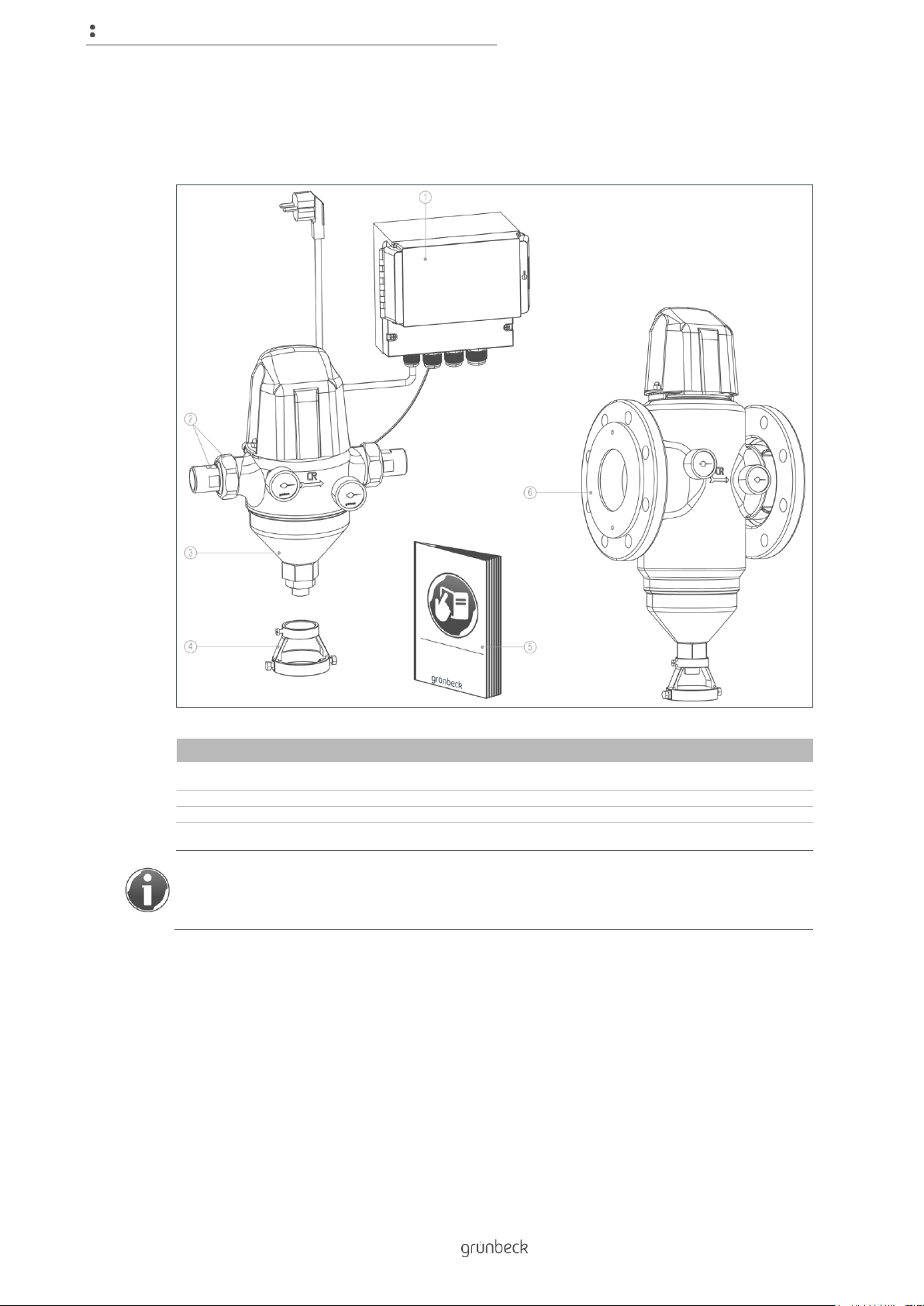

4.3 Checking the scope of supply

Item

Designation

Item

Designation

1

Control unit GENO-RS-tronic

2

Water meter screw connection with gasket,

union nut

3

Filter with screw connections

4

Backwash water connection

5

Operation manual

6

Filter with flange connections

The filter is available with screw connections for sizes: 1" (DN 25), 1¼" (DN 32),

1½" (DN 40), 2" (DN 50)

The filter is available with flange connections for sizes: DN 65, DN 80, DN 100

► Check the scope of supply for completeness and possible damage.

Page 19

Installation

19 | 72

BA_TD3-AM001en_014_MXA.docx

4.4 Installing the product

Only install the GENO-backwash filter MXA horizontally and without mechanical stress.

Please note the following points before installation:

● Installation only possible in horizontal position

● Free outlet and discharge of the backwash water without backpressure

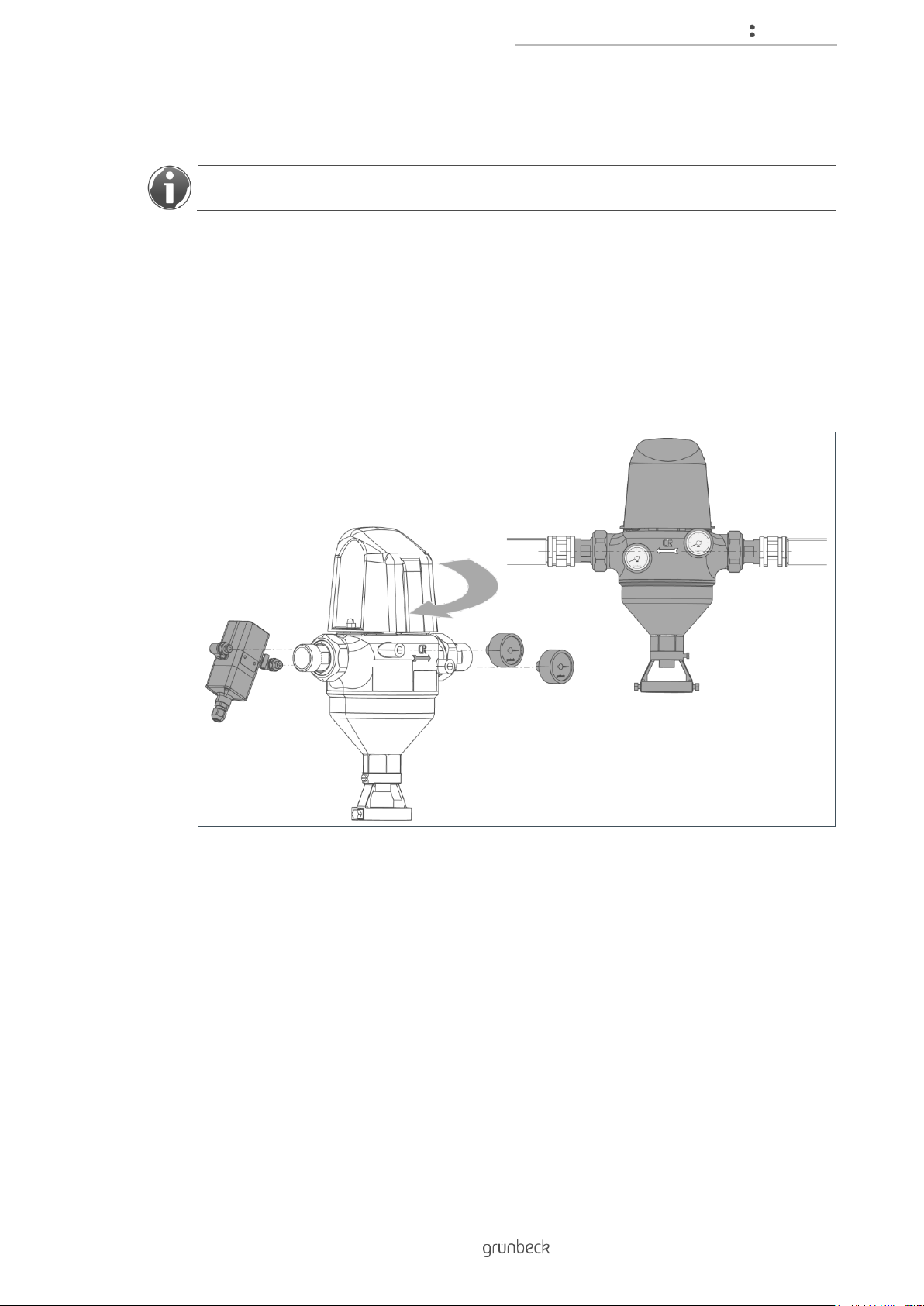

4.4.1 Changing the direction of flow

► Check the flow direction given on site.

► If necessary, remount the filter as follows:

1. Unscrew the differential pressure sensor and the pressure gauges.

2. Rotate the filter by 180°.

3. Mount the differential pressure sensor and the pressure gauges.

» The filter has been modified for flow direction to the left.

Page 20

Installation

20 | 72

BA_TD3-AM001en_014_MXA.docx

4.4.2 Installing the GENO-backwash filter MXA with screw connections

1. Install the pipe fitting into the pipe (the installation dimension must be:

190 mm for sizes 1", 1¼" and 206 mm for sizes 1½", 2").

2. Position the filter (note the marking for the flow direction on the filter).

3. Tighten the filter at the pipe fittings using an open-ended wrench without applying

mechanical stress

» The filter is mounted.

Page 21

Installation

21 | 72

BA_TD3-AM001en_014_MXA.docx

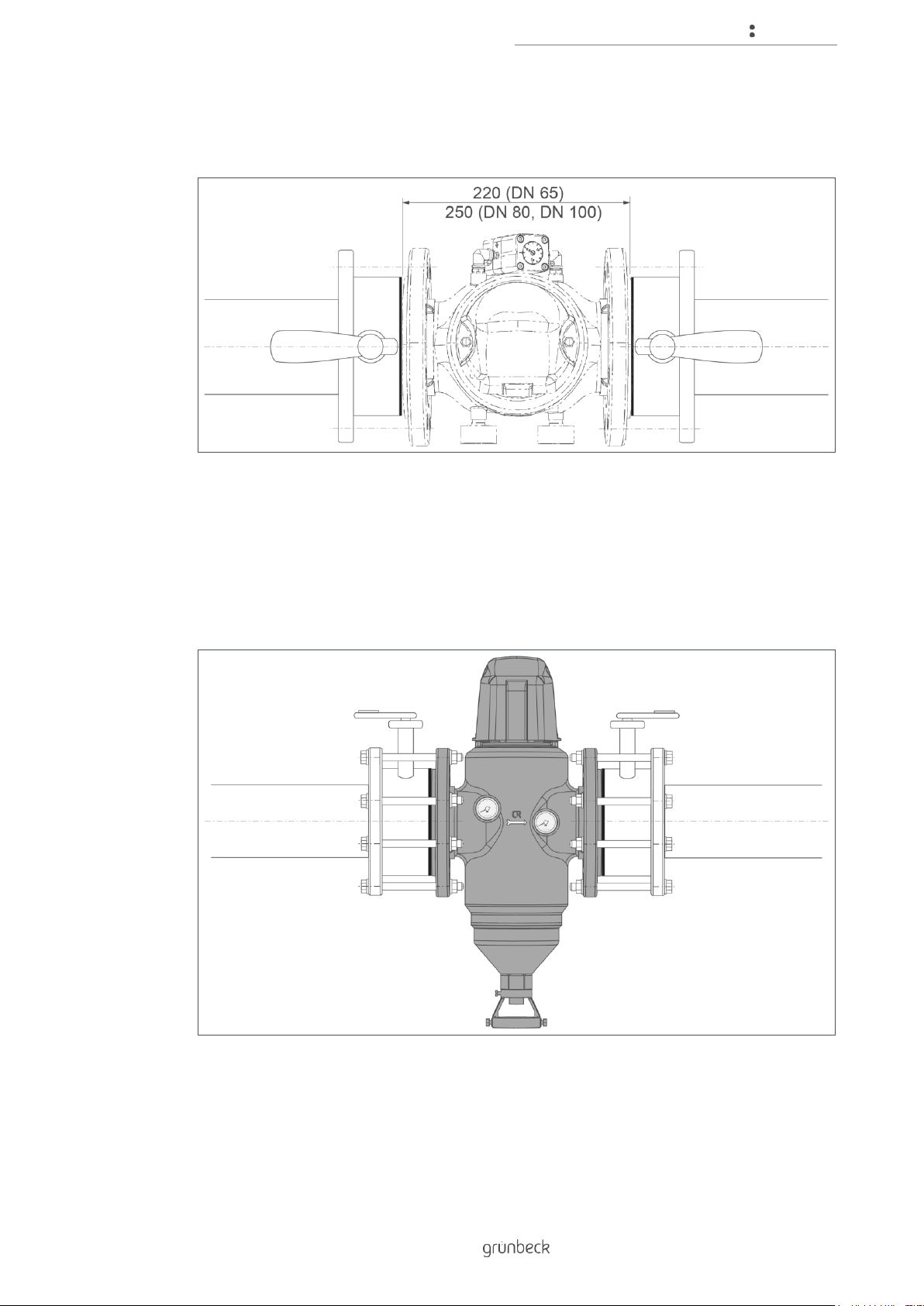

4.4.3 Installing the GENO-backwash filter MXA with flange connection

1. Prepare the pipe with flange connection in accordance with DIN EN 1092-1 (the

distance between the two gaskets must be: 220 mm for DN 65 and 250 mm for

DN 80 and DN 100).

2. Position the filter (note the marking for the flow direction on the filter).

3. Tighten the filter at the flanges by means of the screw connections without applying

mechanical stress.

» The filter is mounted.

Page 22

Installation

22 | 72

BA_TD3-AM001en_014_MXA.docx

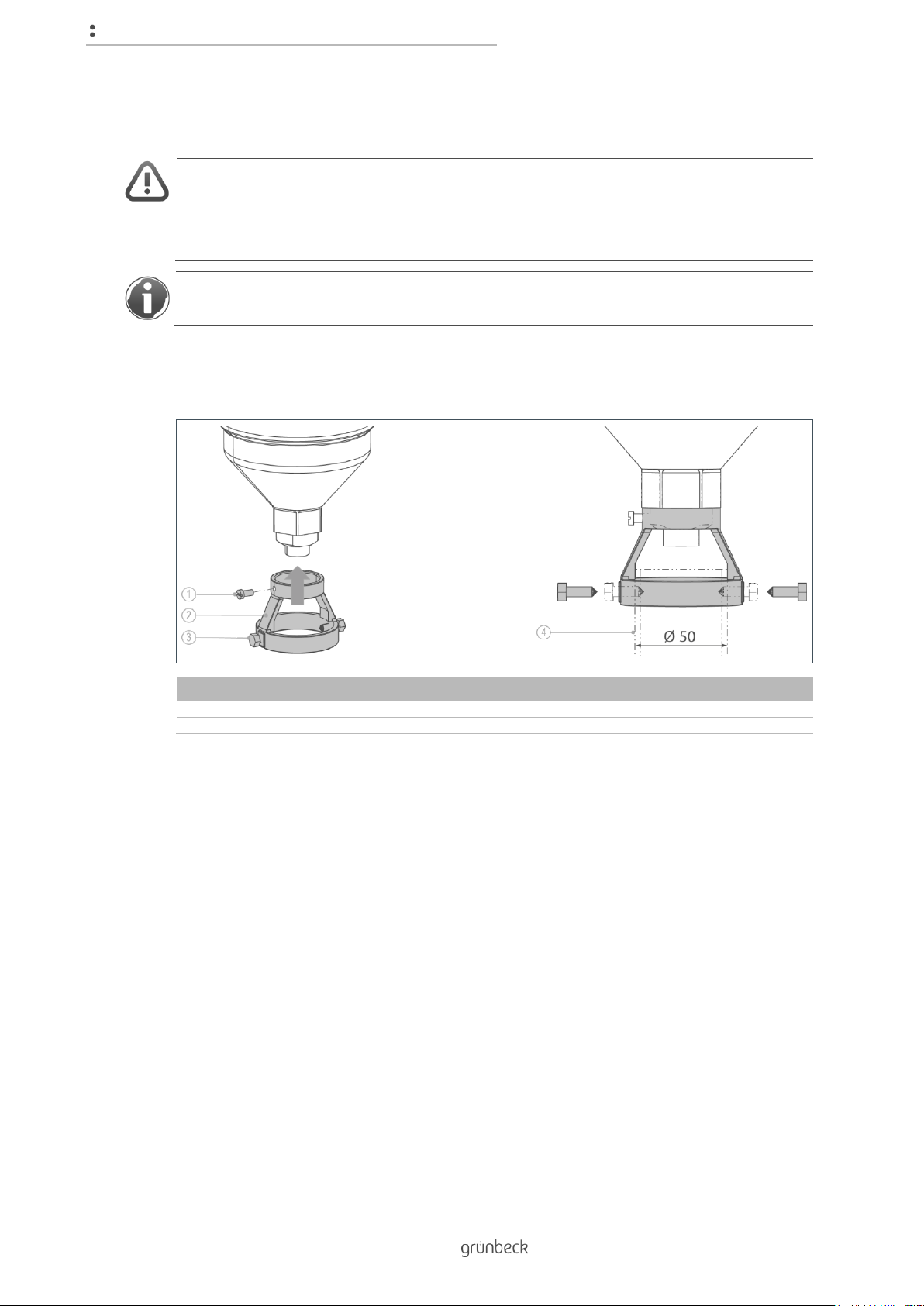

4.4.4 Installing the backwash water connection

CAUTION: Splashing hot water at the drain outlet during backwash.

● Danger of scalding in case of hot water filtration without waste water pipe.

► For hot water filtration, install a fixed waste water pipe at the drain connection.

If it is not possible to install a waste water pipe, the backwash water can be collected in a

bucket/container.

► Install a waste water pipe (not included in the scope of supply) at the pre-installed

drain connection with free outlet.

Item

Designation

Item

Designation

1

Clamping screw

2

Backwash water connection

3

Pointed screw

4

Waste water pipe (HT pipe DN 50)

1. Push the backwash water connection onto the collar of the filter funnel.

2. Fix the backwash water connection by means of the clamping screw.

3. Push the waste water pipe into the backwash water connection as far as it will go.

4. Fix the waste water pipe with the pointed screws.

Page 23

Installation

23 | 72

BA_TD3-AM001en_014_MXA.docx

5. Install a waste water pipe towards the drain connection.

» The backwash water connection is installed.

The drain connection is available as an option (refer to Accessories, chapter 3.5).

To install the drain connection, follow the mounting instructions TD5-BS002.

Page 24

Installation

24 | 72

BA_TD3-AM001en_014_MXA.docx

4.4.5 Electrical installation

DANGER! Live components!

● Risk of electric shock when working on the electrical system.

► Make sure that the mains voltage is disconnected and that the plug is unplugged.

► Do not connect to mains until the connection work has been completed and the

control unit is closed.

The electrical installation may only be carried out by a skilled craftsman.

► Unscrew the cover of the connections at the control unit.

Page 25

Installation

25 | 72

BA_TD3-AM001en_014_MXA.docx

Fastening the control unit

The control unit must not be installed in the immediate vicinity of heat sources with high

radiation temperatures.

► Fasten the control unit on the wall.

NOTE: Securely fasten the control unit.

● Precarious and unsound fastening can cause the control unit to crash.

► Prior to fastening the control unit, check the wall type present.

► Select fasteners on site which are suitable for the respective wall type.

► Position the control unit while taking the length of the connecting cable into

consideration - connecting cables must not be extended.

► Fix the control unit with three screws.

Page 26

Installation

26 | 72

BA_TD3-AM001en_014_MXA.docx

Wiring diagram of the control unit

Wiring diagram of GENO-backwash filter MXA

Item

Designation

Item

Designation

A

Safety solenoid valve

K

Connecting line to filter

B

Backwash valve Open

L

Brown

C

Backwash valve Closed

M

Motor, 24 V~

D

Cam N Blue E Ext. input

O

Black

F

Illuminated LED: Voltage supply, cam-operated

switch, programmable input and differential pressure

switch OK

P

Safety device solenoid valve, 24 V ~,

order no. 107 850

G

Differential pressure switch

Q

Backwash signal

H

Do not connect wire 3

R

Collective fault signal active, contact rating:

250 VAC/3A each

I

Programmable input

M

Mains 230 VAC/50 Hz

J

Cam-operated switch

T

System fuse, T2A

General electrical installation

► Make the electrical connection according to the wiring diagram.

1. Connect the differential pressure cable to the control unit.

2. Connect the connecting lines to the filter with the control unit.

3. Connect additional accessories according to the wiring diagram.

4. Screw on the cover after the connection has been completed.

» The general electrical wiring is completed.

Connection to mains voltage will only take place during start-up (refer to chapter 6).

Page 27

Installation

27 | 72

BA_TD3-AM001en_014_MXA.docx

4.4.6 Additional inputs and outputs

Activation of backwash at external input

In addition to the general electrical wiring, you can install the control unit for external

activation of the backwash.

► Connect the connecting line at the external input E, terminals 17 and 18.

This control unit input is designed for wiring with a voltage-free contact.

If it is closed for more than 1 second, a backwash will be carried out.

The prerequisites for the activation of a backwash at the external input are:

● No backwash active

● No error Er 3 or Er 5 active

● No backwash lock active

Backwash lock at external input

As an alternative, the input can be used for an external backwash lock (refer to

chapter 5.5.1, Parameter “d”).

Combined operation of two GENO-backwash filters MXA

By means of these two inputs and outputs, two control units can be operated in combination,

so that the two filters are not backwashed at the same time.

To do so, the external input is programmed for external backwash lock on both control units

and connected to the signal output backwash of the respective other control unit:

Filter 1

Filter 2

Terminal 17

to

Terminal 8

Terminal 18

to

Terminal 9

Terminal 8

to

Terminal 17

Terminal 9

to

Terminal 18

The collective fault signal is designed as active, voltage-free change-over contact.

Page 28

Control unit GENO-RS-tronic

28 | 72

BA_TD3-AM001en_014_MXA.docx

5 Control unit GENO-RS-tronic

5.1 Components of the control unit

Item

Designation

Item

Designation

1

Shock-proof plug, 1.5 m cable

2

Cover

3

Operating / Menu level

4

Release button

5

Connection level

NOTE: Incorrect setting/operation of the control unit

● Dangerous operating conditions/functional impairments may occur health/personal/property damage possible

► Only make the settings described in this chapter.

► Have additional settings made by specialist installers or trained personnel only -

refer to the technical service manual “GENO-RS-tronic”.

Page 29

Control unit GENO-RS-tronic

29 | 72

BA_TD3-AM001en_014_MXA.docx

5.1.1 Releasing a backwash

With the GENO-RS-tronic, a backwash can be activated in:

1. Automatic release by time interval

● The time interval is adjustable from 1 hour - 99 days.

● The time interval is generally active.

● From an interval period >= 1 day, the start time can be programmed as well.

● An off-period during which no backwash will be released can be activated.

● Automatic backwash before and after the off-period.

2. Automatic activation after a differential pressure is reached

● The differential pressure sensor detects the differential pressure between the raw

water side and the pure water side.

● The differential pressure sensor triggers a backwash when approximately 0.4 bar is

exceeded. Default setting = 0.4 bar; adjustable from 0.16 – 1.6 bar.

● The differential pressure evaluation can be deactivated.

3. Activation by external signal

The backwash can be triggered by means of an external voltage-free contact.

If the contact is closed for more than 1 second, a backwash will be carried out.

Prerequisites for activation via the external contact are:

• No backwash lock is active

• No backwash is active

• No error Er 3 or Er 5 is present

The input can be reprogrammed for an external backwash lock.

4. Manual activation

The backwash can be activated manually by way of the button on the control unit (refer

to chapter 7.2.2). No backwash lock must be active. The basic display (time) must be

indicated.

Behaviour of the backwash filter if there is a power failure

From software version V3.2 on, the time is retained for a maximum of 180 min in the event of

a power failure. The number of the software version can be retrieved via Code level “999”

(refer to chapter 5.5.2).

If a power failure interrupts the backwash process for a maximum of°180°min, it will be

terminated correctly afterwards.

Page 30

Control unit GENO-RS-tronic

30 | 72

BA_TD3-AM001en_014_MXA.docx

5.2 Overview of display

Item

Designation

Item

Designation

1

Display

2

Connection data of the control unit

3

Button I for information

4

Button R for backwash

5

Button P for program

6

Explanation of manual backwash

7

Explanation of symbols displayed

Page 31

Control unit GENO-RS-tronic

31 | 72

BA_TD3-AM001en_014_MXA.docx

5.2.1 Display indication

First line

Illustration

Explanation

Wrench

• Displayed with error messages

• If the maintenance interval has elapsed or when more backwash

processes were carried out per maintenance interval than permitted.

Clock

Indicates an interval-controlled backwash:

• Statically - when the interval-controlled backwash is active

• Flashing - when an interval-controlled backwash is in progress

• Switched off - when a backwash lock is active

Differential pressure

Indicates a differential pressure controlled backwash:

• Statically - when the differential pressure evaluation is activated

• Flashing - when a backwash triggered by differential pressure is in

progress

• Switched off - when a backwash lock is active

External trigger active

Indicates a backwash triggered by an external control signal:

• Statically - when the programmable input is set for activation of an

external backwash

• Flashing - when a backwash triggered by the external signal is in

progress

• Switched off - when a backwash lock is active

Second line

Illustration

Explanation

Unit

Indicates the unit of the adjacent numerical value:

● Seconds

● Minutes

● Hours

● Days

Page 32

Control unit GENO-RS-tronic

32 | 72

BA_TD3-AM001en_014_MXA.docx

Second line

Standard operation

● Indicates the time (basic display)

Information menu level

● Indicates the operating parameters

User menu level

● Indicates the numerical value of the parameter in the menu

• Open parameters are flashing

Parameter number (small figure)

● In all menus, indicates the number of the parameter in the

current menu level

Additionally, and depending on the situation:

• “H” flashes during manual backwash and backwash after

acknowledgement of an error

• “A” flashes during automatic backwash 5 minutes before and at the

end of an off-period

• “E” flashes if the programmable input is set as backwash lock and the

external signal is present

• “c” flashes if the filter is moved to the “CLOSED” position after the

system voltage has been switched on

• “C” is displayed statically if a programming level is to be opened and

the code no. is displayed

Third line

Illustration

Explanation

Maintenance display

Indicates the lesser of the two values by percentage:

• Remaining days of the current maintenance interval

• Remaining number of backwash processes in the current

maintenance interval

Page 33

Control unit GENO-RS-tronic

33 | 72

BA_TD3-AM001en_014_MXA.docx

5.3 Navigating the control unit

► Press the release button on the side.

» The cover of the control unit is unlocked and can be opened.

5.3.1 Buttons

Illustration

Designation

Function

Program

Button P

In standard mode:

● Switches to User menu level.

In the User menu level:

● Opens parameters

● Saves the settings and closes parameters

Backwash

Button R

In standard mode:

● Starts the manual backwash

In the User menu level:

● Switches to previous parameter

● Decreases numerical values

During start-up:

● Closes the filter

Info

Button I

In standard mode:

● Calls up the Info level

● Switches the display to the next position

In the User menu level:

● Switches to the next parameter

● Increases numerical values

Page 34

Control unit GENO-RS-tronic

34 | 72

BA_TD3-AM001en_014_MXA.docx

5.3.2 Selecting menu levels

Objective

Step

Status level

► Press the buttons and at the same time.

Information level

► Press the button in the status level 1x - 6x, rotating

through the display and back to the basic display.

User menu level

► Press the button in the status level for more than

2.5 s.

Programming menu

level

► Press the buttons and in the status level at

the same time for more than 1 s.

» The display switches from the time to three flashing

digits “000” and the parameter no. changes to “C”.

1. Press the or the button to select Code 113.

2. Press the button to confirm your selection.

Menu level Software

Version

► Press the and the button in the status level

at the same time for more than 1 s.

» The display switches from the time to three flashing

digits “000” and the parameter no. changes to “C”.

1. Press the or the button to select Code 999.

2. Press the button to confirm your selection.

Page 35

Control unit GENO-RS-tronic

35 | 72

BA_TD3-AM001en_014_MXA.docx

5.3.3 Setting the parameters

Objective

Step

Selecting

parameters

In every menu level, the button switches to the next

parameter and the button switches to the previous parameter.

Opening

parameters

When the desired parameter is displayed:

► Press the button.

» The value of the parameter flashes.

Changing

parameters

When the open parameter flashes:

► Press the button for lower and the button for

higher values.

Closing parameters

without saving

If you want to exit the setting of the open parameter without making

any changes:

► Press the and the button at the same time.

» The parameter will be closed, and the unchanged value is

displayed continuously.

Saving parameters

When the right value flashes in the display:

► Press the button to save the value.

» The parameter will be closed, and the set value is

displayed continuously.

Exiting the

menu level

If you have made the desired settings:

► Press the and the button at the same time.

» The display shows the basic display (time) in the status

level.

Automatic return to

the basic display

The system also returns to the basic display if no entry is made for

more than 1 minute.

» Entries which had not been saved are lost.

Page 36

Control unit GENO-RS-tronic

36 | 72

BA_TD3-AM001en_014_MXA.docx

5.4 Menu structure

Menu level

Menu items

Values/settings

Status level

Acknowledgement of

malfunctions

Press one of the three buttons.

Manual backwash

Press the button for more than 5 s

Select the menu

level

Refer to chapter 5.3.2

Information

1

Current configuration of the backwash.

2

Active backwash interval, [hh:mm]

3

Status of backwash lock

4

Start time of backwash lock, when active,

[hh:mm]

5

Current configuration of microswitch

6

Return to basic display

User

Set the time

Hours and minutes separately, [hh:mm]

Programming /

Code-protected

levels

For settings and displays (refer to chapter 5.5).

5.5 Programming levels

5.5.1 User programming level via Code 113

Status level>Code-protected level 113

Parameters

Meaning

Factory

settings

Setting range

0

Evaluation of the

differential

pressure signal

The GENO-RS-tronic utilises the differential

pressure switch to detect independently

when a backwash is required

1

0 = Differential pressure signal is not

evaluated

1 = Differential pressure signal is

evaluated

1

Backwash

interval

Time after which a backwash takes place

automatically

30 d

1 – 23 h (hours), here, a backwash

always takes place at the full hour

1 – 99 d (days), here, the time can be

programmed in the parameters that

follow as well

2

Start time of the

intervalcontrolled

backwash

(hours)

When the backwash interval, parameter “1”,

is set in range 1 - 99 d

01:

00: - 23:

3

Start time of the

intervalcontrolled

backwash

(minutes)

When the backwash interval, parameter “1”,

is set in range 1 - 99 d

:00

:00 -:59

4

Activation of a

timed backwash

lock

The timed backwash lock can be used to

suppress any backwash for a programmable

period of time

0

0 = Timed backwash lock deactivated

1 = Timed backwash lock active

Page 37

Control unit GENO-RS-tronic

37 | 72

BA_TD3-AM001en_014_MXA.docx

If the backwash lock is activated, a backwash is performed automatically 5 min before the

start and after the end of the backwash lock.

A minimum of 1 hour must be scheduled between the start and the end of a backwash lock.

The interval-controlled backwash must be scheduled at a time outside of an active

backwash lock.

Parameters

Meaning

Factory

settings

Setting range

5

Start time of the

timed backwash

lock (hours)

If the timed backwash lock, parameter 4,

is activated

01:

00: - 23:

6

Start time of the

timed backwash

lock (minutes)

If the timed backwash lock, parameter 4,

is activated

:00

:00 -:59

7

End time of the

timed backwash

lock (hours)

If the timed backwash lock, parameter 4,

is activated

01:

00: - 23:

8

End time of the

timed backwash

lock (minutes)

If the timed backwash lock, parameter 4,

is activated

:00

:00 -:59

9

Maintenance

responsibility

Maintenance work must be carried out by

either the owner/user or Grünbeck's

technical service/authorised service

company

1

0 = Maintenance work is carried out

by the owner/user

1 = Maintenance work is carried out

by Grünbeck's technical

service/authorised service company

A

Acknowledgement

of maintenance

The owner/user notifies the

GENO-RS-tronic that maintenance was

carried out

0

0 = Basic mode

1 = Programming to perform the

function

b

Operating mode of

GENO-RS-tronic

Operation of the control unit on a

Grünbeck-backwash filter of model series

MXA or MSA.

Major differences between the two

operating modes: In case of MXA, the

rotation is monitored via microswitch

pulses; direction of rotation during

backwash

0

0 = MXA

1 = MSA

Only change the factory settings of the following parameter “C” if special motors or special

gear boxes are used.

Parameters

Meaning

Factory

settings

Setting range

C

Gearing

MXA: Gearbox output speed

MXA:

8 min-1

MXA: 1.0 - 15.0 min-1

MSA: Gear ratio

MSA:

46:1

MSA: 31:1, 46:1, 62:1

d

Programmable

input

For wiring and application refer to chapter

4.4.6.

0

0 = external activation of backwash

1 = external backwash lock

5.5.2 Software version via Code 999

Status level>Code-protected level 999

Parameters

Meaning

Factory

settings

Setting range

C

Software version

Software version of control unit

0

-

Page 38

Start-up

38 | 72

BA_TD3-AM001en_014_MXA.docx

6 Start-up

6.1 Preparations

NOTE: Upon delivery, the drain outlet of the GENO-backwash filters MXA is open.

► Close the open drain outlet for 1.5 min:

1. Press and hold the button.

2. Plug the mains plug into the socket.

3. Release the button.

NOTE: Faulty connection/installation

● Filter is not closing, or the green lamp above terminal 20 only lights up dimly or

not at all.

► Disconnect the mains plug and check the installation of the product.

Page 39

Start-up

39 | 72

BA_TD3-AM001en_014_MXA.docx

6.2 Starting up the product

► Carry out the following steps after installation and after every maintenance.

1. Set the time (refer to chapter 7.2.1).

2. Set other operating parameters, if necessary (refer to chapter 7.2).

3. Open the shut-off valves.

4. Open the closest water withdrawal point downstream of the filter to the maximum.

5. Apply the maximum operating pressure.

» The filter is vented.

6. Check the filter for tightness.

7. Carry out a backwash.

» The filter is in operation.

6.3 Handing over the product to the owner/user

► Explain to the owner/user how the product works.

► Use the manual to brief the owner/user and answer any questions.

► Inform the owner/user about the need for inspections and maintenance.

► Hand over all documents to the owner/user for keeping.

► Enter the initial start-up in the operation log (refer to chapter 12.1).

Page 40

Operation

40 | 72

BA_TD3-AM001en_014_MXA.docx

7 Operation

7.1 Information in the basic display

Status level

The display continuously gives information on the operating state of the system.

Indicating parameters in the basic display:

● Functions that are activated to trigger a backwash.

● Function by which the current backwash was triggered.

● Whether a backwash lock is active.

● Time until the next maintenance and/or the remaining number of backwash

processes until the next maintenance.

● Time stored.

7.1.1 Retrieving information

Status level>Information level

Press the button to call up information about other parameters:

Button

pressed

Indication

Explanation

1 x

0

Backwash function with differential pressure signal OFF

(deactivated)

1

Backwash function with differential pressure signal ON

(active)

2x

± XX %

Active interval for backwashing in hours or days

3 x

0

Backwash lock function deactivated

1

Backwash lock function active

Page 41

Operation

41 | 72

BA_TD3-AM001en_014_MXA.docx

Button

pressed

Indication

Explanation

4x

-

Go to 5x if backwash lock function is deactivated

XX:XX

Start time of backwash lock

YY:YY

End time of backwash lock

5x

XX:YY

Number of microswitch pulses during the last backwash

process. The displayed value is only updated during the

ongoing backwash

XX

Upon opening, factory setting 36

YY:

Upon closing, factory setting 34...40

6x

XX:XX

Display is reset to basic display (time)

7.2 Setting parameters in the User level

7.2.1 Setting the current time

Status level>User level

► Set the current hour and minutes:

1. Press the button to open the parameter for the hours.

» The display for hours flashes.

2. Press the or the button to set desired value.

3. Press the button to save the setting.

» The current hour is saved.

Page 42

Operation

42 | 72

BA_TD3-AM001en_014_MXA.docx

4. Press the button to switch to the display for minutes.

5. Press the button to open the parameter for the minutes.

» The display for minutes flashes.

6. Press the or the button to set desired value.

7. Press the button to save the setting.

» The current time is set.

7.2.2 Starting a backwash manually

Status level

► Press and hold the button for more than 5 s.

» A manual backwash is carried out.

7.3 Setting parameters in the Programming level

Settings deviating from the factory settings may only be carried out by trained technical

service personnel.

Status level>Programming level

Page 43

Operation

43 | 72

BA_TD3-AM001en_014_MXA.docx

7.3.1 Entering the Code

► Press the buttons and in the status level for more than 1 s.

» The display switches from the time to the three flashing digits “000” and the

parameter no. switches to “C”.

1. Press the or the button to select code 113.

6. Press the button to confirm the selection.

7.3.2 Evaluation of the differential pressure signal

7. Press the button to switch to the evaluation of the differential pressure signal.

Page 44

Operation

44 | 72

BA_TD3-AM001en_014_MXA.docx

7.3.3 Setting the backwash interval

The example below shows you how to work in the programming level/code-protected level.

The interval-controlled backwash is always active and set to 30 d in the factory setting.

You can choose between two configurations:

Period

Range

Explanation

Hours

[h]

1 - 23

Backwash at the full hour every h

hours

Days + Hours

[d] + [h]

(1 – 99) + (1 – 23)

Backwash every d days and, in the

next menu, h hours.

Setting the backwash interval:

1. Press the button to switch to parameter „1“.

» In the factory setting, the following is displayed:

• “1” for the selected parameter

• The value “30” for the days set

• The unit “d” for days

2. Press the button to open the parameter.

» The value of the parameter flashes.

3. Press the or the button to set the desired value of the parameter.

4. Press the button to save the value.

» The value of the parameter stops flashing.

» The days are set.

5. Press the button to switch to the display of the value for the hours.

6. Press the button to open the parameter for the hours.

Page 45

Operation

45 | 72

BA_TD3-AM001en_014_MXA.docx

7. Press the or the button to set the desired value of the parameter.

8. Press the button to save the value.

» The value of the parameter stops flashing.

» The hours are set.

► Press the and the button at the same time to return to the status level

(basic display).

Programming further parameters is done in an analogous manner.

Page 46

Cleaning, inspection, maintenance

46 | 72

BA_TD3-AM001en_014_MXA.docx

8 Cleaning, inspection, maintenance

WARNING: Danger of contaminated drinking water if the work is not carried out properly.

● Risk of infectious diseases.

► Pay attention to hygiene when working on the installation.

Inspection and maintenance of a filter is prescribed in the DIN EN 806-5 standard.

Regular maintenance ensures trouble-free and hygienic operation.

A maintenance contract ensures that all the required maintenance work will be performed

in due time.

► Only use genuine spare and wearing parts from Grünbeck.

8.1 Cleaning

WARNING: Damp cleaning of live components

● Risk of electric shock! Sparking possible due to short circuit.

► Disconnect the mains plug prior to cleaning work.

► Make sure that no voltage is applied to the systems.

► Only clean the outside of the product.

► Do not use any strong or abrasive cleaning agents.

► Wipe the housing with a damp cloth.

NOTE: Do not clean the filter with cleaning agents that contain alcohol or solvents.

● These substances will damage components.

► Use a mild/pH-neutral soap solution.

Page 47

Cleaning, inspection, maintenance

47 | 72

BA_TD3-AM001en_014_MXA.docx

8.2 Intervals

Task

Interval

Execution

Inspection

2 months

Visual/functional check

Maintenance

6 months

Manual backwash

Annually

Check O-rings, flat gaskets and brush for wear and

tear, check tight fit, backwash

Maintenance

5 years

Recommended: changing filter element, gaskets,

suction nozzle unit

8.3 Inspection

According to DIN EN 806-5, the owner/user must inspect the filters every 2 months.

1. Check the installation for leaks.

2. Open several water withdrawal points (generate max. flow).

3. Read the inlet and outlet pressure at the pressure gauges.

4. If the system’s differential pressure cannot be relieved by means of one or several

backwash processes, a malfunction has occurred (refer to chapter 9).

We recommend performing a backwash every 2 months.

Page 48

Cleaning, inspection, maintenance

48 | 72

BA_TD3-AM001en_014_MXA.docx

8.4 Maintenance

WARNING: Non-regular backwash of the filter element

● Health risk due to contamination of the drinking water.

► Observe the intervals for inspection and backwash of the filter element.

8.4.1 Semi-annual maintenance

Manual backwash of the filter

During the backwash process, filtered pure water is still available.

► Press and hold the button for more than 5 s.

» A manual backwash is carried out.

Page 49

Cleaning, inspection, maintenance

49 | 72

BA_TD3-AM001en_014_MXA.docx

If the raw water is heavily contaminated, the standard backwash water outlet can be

increased from Ø 6.5 mm to max. Ø 7.5 mm. This increases the cleaning effect and the

amount of backwash water per backwash.

This measure may only be carried out by a specialist installer. Refer to technical service

manual TD4-AM001 for GENO-backwash filter MXA.

8.4.2 Annual maintenance

Carrying out annual maintenance work requires specialist knowledge. This kind of

maintenance work may only be carried out by Grünbeck's technical service/authorised

service company or by specialist installers trained by Grünbeck.

In addition to the semi-annual maintenance, the following work needs to be done:

1. Check the O-rings for wear and tear.

2. Check the filter for tight fit and leaks.

3. Check the brushes for wear and tear.

Page 50

Cleaning, inspection, maintenance

50 | 72

BA_TD3-AM001en_014_MXA.docx

Opening and checking the filter

1. Close the inlet and outlet shut-off valves.

2. Initiate a manual backwash.

» Backwash water exits via the drain valve.

3. Disconnect the system’s mains plug after 5 s.

» The suction nozzle stops in its position and the water can flow out of the filter.

4. Unscrew the filter funnel – turn anti-clockwise.

5. Unscrew the lower suction nozzle from the pipe nozzle.

6. Remove the sieve bottom.

7. Check the thread coating and the O-ring for wear and tear.

If the thread is worn, the complete suction nozzle unit must be replaced.

8. If the thread and O-ring are not worn:

Clean the thread and O-ring and apply food-safe grease, e.g. UNI-Silicon L641;

order no. 128 619.

Page 51

Cleaning, inspection, maintenance

51 | 72

BA_TD3-AM001en_014_MXA.docx

9. Remove the filter element.

10. Check the filter element for impurities and damage.

11. Check the O-rings of the filter element (outside and inside) for wear and tear.

Depending on the filter size, different filter elements are combined. If one filter element is

damaged, you can either replace one filter element or a complete set of filter elements. The

individual filter elements are detachably connected by means of a snap connection.

Page 52

Cleaning, inspection, maintenance

52 | 72

BA_TD3-AM001en_014_MXA.docx

Closing the filter

1. Fit the O-rings to the filter elements. Slide the filter elements with the larger Ø

pointing forward over the suction nozzle into the housing of the filter.

2. Position the sieve bottom between the pipe nozzle and the lower suction nozzle.

3. Screw the lower suction nozzle onto the pipe nozzle until the O-ring is just not

visible any longer.

4. Slide the filter funnel onto the suction nozzle – the two flat faces of the filter funnel

must be parallel to the wrench flat at the suction nozzle.

5. Screw on the filter funnel clockwise.

6. Put the filter into operation – refer to chapter 6.

» The filter is ready to use.

Page 53

Cleaning, inspection, maintenance

53 | 72

BA_TD3-AM001en_014_MXA.docx

8.5 Spare parts

For spare parts and consumables please contact your local Grünbeck representation which

you can find on the internet at www.gruenbeck.de/Service/Ersatzteilkatalog.

Use of filter elements with pore sizes: 50 µm, 200 µm and 500 µm only after consultation

with Grünbeck Wasseraufbereitung GmbH – refer to accessories on page 14.

Designation

Order no.

1" / 1¼"

1½" / 2" / DN 65

DN 80 / DN 100

100 µm filter element

107 061

107 062

107 063

8.6 Wearing parts

Although these parts are wearing parts, we grant a limited warranty period of 6 months.

Designation

Order no.

1" / 1¼"

1½" / 2" / DN 65

DN 80 / DN 100

Gasket kit (O-rings)

107 755

Lower nozzle

107 021e

Brush

(quantity required)

107 860e

1 piece

2 pieces

3 pieces

Page 54

Troubleshooting

54 | 72

BA_TD3-AM001en_014_MXA.docx

9 Troubleshooting

WARNING: Risk of contaminated drinking water due to unintentional, significant reduction

in pressure.

● Risk of infectious diseases.

► Remedy this malfunction immediately.

► If you cannot remedy malfunctions with the instructions given below, contact

Grünbeck's technical service/authorised service company.

► Have your system data (refer to chapter 1.7) handy.

Troubleshooting may only be carried out by a specialist installer.

Refer to technical service manual TD4-AM001 for GENO-backwash filter MXA.

9.1 Display messages

Status level

1. Acknowledge the malfunction Er Xby pressing one of the three buttons on the

display.

2. Watch the display.

3. If the cause of the error was not eliminated, the error will reoccur after a short

period of time.

Page 55

Troubleshooting

55 | 72

BA_TD3-AM001en_014_MXA.docx

Troubleshooting

Explanation/Cause of error

Troubleshooting

Er 1

Control unit does not receive enough

pulses from the microswitch

Contact the specialist

installer or Grünbeck's

technical service.

If water leaks from the drain

opening, close the filter

manually.

Motor blocked or defective

Mechanical connection between motor

and pipe nozzle sheared off

Worn thread

Microswitch defective or set incorrectly

Line interrupted between microswitch

or motor and control unit

Control unit defective

Er 2

Control unit receives too many pulses

from the microswitch

Contact the specialist

installer or Grünbeck's

technical service.

If water leaks from the drain

opening, close the filter

manually.

Rubber gasket for backwash water

outlet has fallen out

Mechanical connection in the filter

sheared off

Microswitch defective or set incorrectly

Er 3

Filter element can no longer be

cleaned due to severe contamination of

the raw water

Contact the specialist

installer or Grünbeck's

technical service.

In case of severe

contamination, we

recommend installing a

coarse dirt filter upstream.

Work on the water supply network

If a malfunction Er 1, Er 2 or Er 3 is acknowledged, the control unit closes the filter for a

period of approximately 60 s to ensure that it is closed and then performs a backwash for

checking purposes.

Page 56

Troubleshooting

56 | 72

BA_TD3-AM001en_014_MXA.docx

Troubleshooting

Explanation/Cause of error

Troubleshooting

Er 4

Maintenance interval has elapsed or

permissible number of backwash

processes per maintenance interval

has been exceeded

Contact the specialist installer

or Grünbeck's technical

service.

Er 5

Differential pressure sensor or its

connection line defective

Contact the specialist installer

or Grünbeck's technical

service.

Have the sensor and its

connection line replaced.

Er 6

Progressive wear and tear of thread

Contact the specialist installer

or Grünbeck's technical

service.

Have maintenance performed.

There is a threat of damage as

explained under Er 1 or Er 2.

Page 57

Troubleshooting

57 | 72

BA_TD3-AM001en_014_MXA.docx

9.2 Other malfunctions

Troubleshooting

Explanation/Cause of

error

Troubleshooting

No indication, motor does

not rotate any longer

System fuse blown

Replace the T2A fuse (microfuse, nominal value 2A,

characteristic “slow-blow”).

(For position of the fuse refer

to chapter 4.4.5 – „Wiring

diagram of control unit“)

Green lamp above

terminal 20 lights up dimly

or not at all

Wiring error

(terminals 10…21)

Contact the specialist installer

or Grünbeck's technical

service.

Connected component

defective (terminals 10...21)

Motor does not rotate or is

buzzing only

Wiring error (terminals

10…21 in the RS-tronic or

connecting terminals at the

motor’s mounting plate)

Check the wiring according to

the wiring diagram.

Motor or control unit

defective

Contact the specialist installer

or Grünbeck's technical

service.

Differential pressure too

high

The filter elements are dirty

Carry out a backwash.

The shut-off valves are not

completely open

Completely open the shut-off

valves.

Cannot be determined

Contact the specialist installer

or Grünbeck's technical

service.

Despite several backwash

processes, the differential

pressure does not

decrease

The filter elements are

severely contaminated,

clogged

Check the filter elements.

Manually clean the filter

elements with a brush.

Replace the filter elements.

Page 58

Troubleshooting

58 | 72

BA_TD3-AM001en_014_MXA.docx

Troubleshooting

Explanation/Cause of

error

Troubleshooting

Water leaks from the lower

drain outlet, backwash

filter cannot be closed by

means of the control unit

A particle got stuck

between the lower suction

nozzle and the filter funnel

Mechanical blockage in the

backwash filter

Carry out several backwash

processes.

If water continues to escape,

check the filter for foreign

particles and for damage at

the built-in parts.

Gasket at the lower suction

nozzle defective or worn

Check the gasket of the drain

nozzle and replace the

suction nozzle unit, if

required.

Motor does not rotate or

runs sluggish

Mechanical blockage in the

backwash filter

Check the filter for foreign

particles and for damage at

the built-in parts.

Thread of the suction

nozzle worn

Check the thread of the

suction nozzle for wear and

tear and replace it, if required.

Leaks between upper

suction nozzle below the

motor and the housing

O-ring gasket of upper

suction nozzle worn

Dismount the upper suction

nozzle and replace the O-ring.

Little water discharge

during backwash

Sieve bottom dirty, clogged

Clean the sieve bottom.

Page 59

Troubleshooting

59 | 72

BA_TD3-AM001en_014_MXA.docx

9.3 Manually closing the filter’s suction nozzle

Due to malfunctions, it may be necessary to close the filter’s suction nozzle manually to

avoid unnecessary water leakage.

To do so, you will need the following:

● Open-ended wrench (SW11) or

● Flat-head screwdriver

Proceed as follows:

1. Disconnect the mains plug from the socket.

2. Close the shut-off valves.

Page 60

Troubleshooting

60 | 72

BA_TD3-AM001en_014_MXA.docx

3. Loosen the nuts of the cover.

4. Lift the cover of the filter housing.

5. Disconnect the cables of the microswitch.

» You can now dismount the motor.

6. Lift the motor unit off the filter housing.

Page 61

Troubleshooting

61 | 72

BA_TD3-AM001en_014_MXA.docx

7. Loosen the nut.

8. Remove nut and cam disc.

9. Using an open-ended wrench or a screwdriver, turn the wrench flat of the pipe

nozzle to the left until the mechanical stop is reached.

» The suction nozzle is closed manually.

10. Slowly open the shut-off valves.

» The water no longer escapes.

► Mount the drive unit in reverse order.

NOTE: The filter’s suction nozzle has been tightened too much.

● The lower suction nozzle got stuck.

● The drive unit does not provide the torque required to open the suction nozzle.

There is a risk of damage when the unit is put back into operation.

► After manual closing, start a manual backwash.

► Check whether the drive unit properly opens the suction nozzle.

» The water flows from the bottom of the backwash water connection.

Page 62

Disposal

62 | 72

BA_TD3-AM001en_014_MXA.docx

10 Disposal

Comply with the applicable national regulations.

10.1 Packaging

Dispose of the packaging in an environmentally sound manner.

Dispose of the filling material (foam) as non-recyclable waste.

10.2 Product

If this symbol (crossed out waste bin) is on the product, this product is subject to the

European Directive 2012/19/EU. This means that this product or the electrical and

electronic components must not be disposed with household waste.

Dispose of electrical and electronic products and components in an

environmentally sound manner.

Learn about the local regulations on the separate collection of electrical and

electronic products.

Make use of the collection points available to you for the disposal of your product.

For information on collection points for your product, contact your municipality, the public

waste management authority, an authorised body for the disposal of electrical and

electronic products or your waste disposal service.

Page 63

Technical specifications

63 | 72

BA_TD3-AM001en_014_MXA.docx

11 Technical specifications

Dimensions and weights

GENO-backwash filter MXA with screw connections

Nominal connection diameter

DN 25

DN 32

DN 40

DN 50

Connection diameter

1"

1¼“

1½"

2"

A

Installation length without screw

connection

[mm]

190

190

206

206

B

Installation length with screw connection

[mm]

276

281

342

323

C

Min. distance to wall

[mm]

115

115

115

115

D

Overall height above centre of connection

[mm]

153

153

233

233

E

Overall height up to centre of connection

[mm]

194

194

212

212

F

Total height

[mm]

347

347

445

445

G

Clearance above upper edge of filter

[mm]

130

H

Clearance required for the replacement of

the filter element

[mm]

100

100

min. 100 / optimum from 215

Length of cable for differential pressure sensor

[mm]

1500

Length of cable for drive unit

[mm]

1500

Length of mains cable

[mm]

1500

Empty weight with control unit GENO-RS-tronic,

approx.

[kg]

8.6

8.7

12.7

12.7

Performance data

Flow rate at Δp 0.2 (0.5) bar

[m3/h]

8.5 (13)

12 (18.5)

22 (30)

27 (38.5)

KV value

[m3/h]

18

25

46

56

Pore size

[µm]

100

Largest/smallest pore size

[µm]

110/90

Nominal pressure

PN 16

Minimum flow pressure

[bar]

2

Operating pressure at max. water temperature

[bar/°C]

10/90

Differential pressure release

[bar]

0.4 - 0.5

General

DVGW registration number NW-9301BO0194

Max. water temperature

[°C]

90

Max. ambient temperature

[°C]

5 - 40

Order no. 107 450

107 455

107 460

107 465

Connection data

Rated voltage range

[V]

230

Rated frequency

[Hz]

50 - 60

Power input (standby)

[W]

19

Power input (operation = max))

[W]

26

Protection / protection class IP54/

Page 64

Technical specifications

64 | 72

BA_TD3-AM001en_014_MXA.docx

Dimensions and weights

GENO-backwash filter MXA with flange connection

Nominal connection diameter

DN 65

DN 80

DN 100

B

Installation length without counter-flanges;

flanges PN 16 acc. to DIN EN 1092-1

[mm]

220

250

250

C

Min. distance to wall

[mm]

115

125

125

D

Overall height above centre of connection

[mm]

233

243

243

E

Overall height up to centre of connection

[mm]

212

302

302

F

Total height

[mm]

445

545

545

G

Clearance above upper edge of filter

[mm]

130

H

Clearance required for the replacement of

the filter element

[mm]

min. 100

optimum from 215

min. 100

optimum from 315

I

Bolt circle diameter of flange

[mm]

145

160

180

J

Max. sealing surface

[mm]

122

140

158

K

Number of M 16 screws

[pcs] 4 8

8

Length of cable for differential pressure sensor

[mm]

1500

Length of cable for drive unit

[mm]

1500

Length of mains cable

[mm]

1500

Empty weight with control unit GENO-RS-tronic,

approx.

[kg]

14.8

19

20

Performance data

Flow rate at Δp 0.2 (0.5) bar

[m3/h]

30 (47)

60 (96.5)

60 (98)

KV value

[m3/h]

69

124

138

Pore size

[µm]

100

Largest/smallest pore size

[µm]

110/90

Nominal pressure

PN 16

Minimum flow pressure

[bar]

2

Operating pressure at max. water temperature

[bar/°C]

10/90

Differential pressure release

[bar]

0.4 - 0.5

General

DVGW registration number NW-9301BO0194

Max. water temperature

[°C]

90

Max. ambient temperature

[°C]

5 - 40

Order no. 107 470

107 475

107 480

Connection data

Rated voltage range

[V]

230

Rated frequency

[Hz]

50 - 60

Power input (standby)

[W]

19

Power input (operation = max))

[W]

26

Protection/protection class IP 54/

Page 65

Technical specifications

65 | 72

BA_TD3-AM001en_014_MXA.docx

11.1 Pressure loss curves

Pressure loss curves of GENO-backwash filters MXA 1" and 1¼"

Item

Designation

Item

Designation

1

Pressure difference [bar]

2

Flow rate [m3/h]

Pressure loss curves of GENO backwash filters MXA 1½" and 2"

Item

Designation

Item

Designation

1

Pressure difference [bar]

2

Flow rate [m3/h]

Page 66

Technical specifications

66 | 72

BA_TD3-AM001en_014_MXA.docx

Pressure loss curves of GENO backwash filters MXA DN 65, DN 80 and DN 100

Item

Designation

Item

Designation

1

Pressure difference [bar]

2

Flow rate [m3/h]

Consumption data

Backwash water volume at a water pressure of 3 bar and a backwash time of 1.5 min,

approx.

[l]

40

Max. backwash volume flow at 9 bar, approx.

[m3/h]

4

Max. admissible differential pressure

[bar]

0.4

Page 67

Operation log

67 | 72

BA_TD3-AM001en_014_MXA.docx

12 Operation log

Filter | GENO-backwash filter MXA ____________

Serial no.: ________________________________

12.1 Start-up log

Customer

Name:

Address:

Installation/Accessories

Drain connection acc. to DIN EN 1717:

yes

no

Floor drain available:

yes

no

Safety device:

yes

no

Operating values

Water pressure at raw water inlet

[bar]

Water pressure downstream of

pressure reducer

[bar]

Residential water meter reading

[m3]

Parameters

Backwash interval:

yes

no

Start interval-controlled backwash:

[hh:mm]

Backwash lock:

yes

no

Off-periods:

[hh:mm]

Remarks

Start-up

Company:

Service technician:

Work time certificate (no.):

Date/signature:

Page 68

Operation log

68 | 72

BA_TD3-AM001en_014_MXA.docx

12.2 Maintenance

Date

Work performed

Signature

Page 69

EU Declaration of Conformity

69 | 72

EU Declaration of Conformity

In accordance with the EU Low-Voltage Directive 2014/35/EU, Appendix IV

This is to certify that the system designated below meets the safety and health requirements of the

applicable European guidelines in terms of its design, construction and execution.