Grunbeck MN-Z 25/13, MN-Z 40/18, MN-Z 30/14, MN-Z 40/17, MN-Z 50/19 Operating Manual

...

Operating manual

for demanganisation system

GENO-mat MN-Z

Edition July 2018

Order no. 095 153 048-inter

Iron / manganese removal

Demanganisation system GENO-mat MN-Z

Order no. 095 153 048-inter Edited by: nkes-mrie G:\BA-153048-INTER_095_GENO-MAT_MN-Z.DOCX

2

Table of contents

A General information .............................................................

5

1 Preface

2 How to use this operation manual

3 General safety information

4 Shipping and storage

5 Disposal of used parts and materials

B Basic information ................................................................. 9

1 Laws, regulations, standards

2 Designated application/area of application

3 Function

C Product description ............................................................. 11

1 Type plate ............................................................................

2 Technical specifications

3 Intended use

4 Scope of supply

5 Optional accessories

6 Consumables

D Installation and operation .................................................... 17

1 General installation instructions

2 Preliminary work

3 How to connect the system

E Commissioning .................................................................... 23

1 How to start up the system

F Operation .............................................................................. 26

1 How to operate the control unit

G Maintenance and care .......................................................... 29

1 Basic information

2 Inspection (functional check)

3 Maintenance

4 Spare parts

5 Operation log

Iron / manganese removal

Demanganisation system GENO-mat MN-Z

Order no. 095 153 048-inter Edited by: nkes-mrie G:\BA-153048-INTER_095_GENO-MAT_MN-Z.DOCX

3

All rights reserved.

© Copyright by Grünbeck Wasseraufbereitung GmbH

Printed in Germany

Effective with the date of edition indicated on the cover sheet.

-Subject to modifications in line with technical advances-

Reprints, translations into foreign languages, electronic storage or

copying of this operating manual - even in part - are only permitted

with the explicit written approval of Grünbeck Wasseraufbereitung

GmbH.

Any type of duplication not authorised by Grünbeck Wasseraufbereitung is a copyright violation and subject to legal action.

Responsible for contents:

Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Straße 1 89420 Höchstädt/Do., Germany

Phone 09074 41-0 Fax 09074 41-100

www.gruenbeck.de service@gruenbeck.de

Print: Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Str. 1, 89420 Höchstädt/Germany

Iron / manganese removal

Demanganisation system GENO-mat MN-Z

Order no. 095 153 048-inter Edited by: nkes-mrie G:\BA-153048-INTER_095_GENO-MAT_MN-Z.DOCX

4

EU Declaration of Conformity

This is to certify that the devices designated below meet the safety and health requirements of

the applicable European guidelines in terms of design, construction and execution.

If the systems are modified in a way not approved by us, this certificate is void.

Manufacturer: Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Str. 1

89420 Höchstädt

Germany

Responsible for documentation: Markus Pöpperl

Description of the system: Demanganisation system

Device type: GENO-mat MN-Z

Serial no.: Refer to type designation plate

Applicable Directives: Low Voltage (2014/35/EU)

EMC (2014/30/EU)

Applied harmonised standards,

in particular:

DIN EN 61000-6-2:2006-03

DIN EN 61000-6-3:2011-09

Applied national standards

and technical

specifications,

in particular:

DIN 19636-100:2008-02

Location, date and signature Höchstädt, 26/07/2018 p.p.

M. Pöpperl

Dipl.-Ing. (FH)

Function of signatory: Head of Technical Product Design

Iron / manganese removal

Demanganisation system GENO-mat MN-Z

Order no. 095 153 048-inter Edited by: nkes-mrie G:\BA-153048-INTER_095_GENO-MAT_MN-Z.DOCX

5

A General information

1 | Preface

Thank you for choosing a Grünbeck product. Backed by decades of

experience in the area of water treatment, we provide custom-made

solutions for all kinds of processes.

Drinking water is classified as food and requires particular care.

Therefore, always ensure the required hygiene in operating and

maintaining systems involved in the drinking water ordinance. This

also applies to the treatment of water for industrial use if repercussions for the drinking water cannot completely be excluded.

All Grünbeck systems and devices are made of high-quality materials. This ensures trouble-free operation over many years, provided

you treat your water treatment system with the required care. These

operating instructions assists you with crucial information. Please

read the entire operating instructions carefully before installing, operating or maintaining the system.

Customer satisfaction is our primary aim, and providing customers

with skilled advice is crucial at Grünbeck. If you have any questions

concerning the present product, possible extensions or general water and waste water treatment, our field staff, as well as the experts

at our headquarters in Höchstädt, are available to help you.

Advice and assistance

For advice and assistance please contact your local representative

(refer to www.gruenbeck.com). You can also get in touch with our

service centre, which can be reached during business hours:

Phone: +49 9074 41-333

Fax: +49 9074 41-120

Email: service@gruenbeck.de

We can connect you with the appropriate expert more quickly if you

provide the required system data. In order to have the required data

handy at all times, please copy it from the type designation plate to

the overview in chapter C-1.

Iron / manganese removal

Demanganisation system GENO-mat MN-Z

Order no. 095 153 048-inter Edited by: nkes-mrie G:\BA-153048-INTER_095_GENO-MAT_MN-Z.DOCX

6

2 | Notes on using the operation manual

This operation manual is intended for operators of our systems. It is

divided into several chapters (a letter is assigned to each of them)

that are listed in the "Table of contents" on page 2 in alphabetical order. Check for the corresponding chapter on page 2 in order to find

the specific information you are looking for.

The headers and page numbers with chapter information make it

easier to find your way around these operating instructions.

3 | General safety information

3.1 Symbols and

notes

Important information in this operation manual is emphasised by

symbols. Please pay particular attention to this information to ensure

the hazard-free, safe and efficient handling of the system.

Danger! Failure to adhere to this information will cause serious or

life-threatening injuries, extreme damage to property or inadmissible

impurities in the drinking water.

Warning! Failure to adhere to this information can cause injuries,

damage to property or impurities in the drinking water.

Caution! Failure to adhere to this information can result in damage

to the system or other objects.

Note: This symbol emphasises information and tips that facilitate

your work.

Tasks with this symbol may only be performed by Grünbeck's technical service/authorised service company or by persons expressly

authorised by Grünbeck.

Tasks with this symbol may only be performed by trained and qualified electrical experts according to the VDE guidelines or according

to the guidelines of a similar local institution.

Tasks with this symbol may only be performed by water suppliers or

approved installation companies. In Germany, the installation company must be registered in a water company installation directory as

per §12(2) AVBWasserV (German Ordinance on General Conditions

for the Supply of Water).

3.2 Operating personnel

Only allow persons who have read and understood this operation

manual to work with the system. Strictly observe the safety information.

Iron / manganese removal

Demanganisation system GENO-mat MN-Z

Order no. 095 153 048-inter Edited by: nkes-mrie G:\BA-153048-INTER_095_GENO-MAT_MN-Z.DOCX

7

3.3 Intended use

The system may only be used for the purpose outlined in the product

description (chapter C). The guidelines in this operation manual as

well as the applicable local guidelines concerning drinking water protection, accident prevention and occupational safety must be observed.

In addition, intended use also implies that the system may only be

operated when it is in proper working order.

Any errors must be eliminated at once.

3.4 Protection from

water damage

Warning! To properly protect the installation site from water dam-

age:

a) a sufficient floor drain system must be available or

b) a water stop device (see chapter C Accessories) must be in-

stalled.

Warning! Floor drains that discharge to a lifting system will not work

in case of a power failure.

3.5 Indication of

specific dangers

Danger due to electrical energy! Do not touch electrical components with wet hands! Disconnect the system from the mains before

starting work on electrical system components! Have qualified experts replace damaged cables immediately.

Danger due to mechanical energy! System components can be subject to overpressure. Risk of injuries and damage to property due to

escaping water and unexpected movement of system parts.

Check pressure pipes regularly. Depressurise the system before

starting repair or maintenance work on the system.

Hazardous to health due to contaminated drinking water! The

system should be installed by a specialist company only. Strictly adhere to the operation manual! Ensure that there is sufficient flow,

and observe the relevant guidelines when starting up the system after extended periods of standstill. Perform inspections and maintenance at the intervals specified!

Note: By concluding a maintenance contract, you ensure that all of

the required tasks are performed on time. The intermediate inspections can be performed in-house.

Iron / manganese removal

Demanganisation system GENO-mat MN-Z

Order no. 095 153 048-inter Edited by: nkes-mrie G:\BA-153048-INTER_095_GENO-MAT_MN-Z.DOCX

8

4 | Shipping and storage

Caution! The system can be damaged by frost or high tempera-

tures. In order to avoid damage of this kind:

Protect from frost during transportation and storage!

Do not install or store system next to objects which radiate a lot of

heat.

The system may only be transported and stored in its original pack-

ing. Ensure that it is treated with care and placed the right side up

(as indicated on the packaging).

5 | Disposal of used parts and consumables

Used parts and consumables should be disposed of or made available for recycling purposes according to the applicable local guidelines.

If consumables are subject to specific determination, observe the

corresponding instructions on the packaging.

If in doubt, contact your local waste disposal authority or the manufacturer for more information.

Iron / manganese removal

Demanganisation system GENO-mat MN-Z

Order no. 095 153 048-inter Edited by: nkes-mrie G:\BA-153048-INTER_095_GENO-MAT_MN-Z.DOCX

9

B Basic information

1 | Laws, regulations, standards

In the interest of good health, rules cannot be ignored when it comes

to the processing of drinking water. This operation manual takes into

consideration the current regulations and stipulates information that

you will need for the safe operation of your demanganisation system.

Among other things, the set of rules stipulates that:

only approved companies are permitted to make major modifica-

tions to water supply facilities

and that tests, inspections and maintenance on installed devices

are to be performed at regular intervals.

2 | Designated application/area of application

The GENO-mat MN-Z demanganisation systems are designed for

the reduction of iron and/or manganese. They are used in the residential sector for private water supply plants with maximum values

of up to 3.0 mg/l of iron and 1.0 mg/l of manganese. If the systems

are operated properly and handled according to the operation manual, pure water values as required by the German Drinking Water

Ordinance (TrinkwV) can be achieved.

For an optimum reduction of iron and manganese, a pH value > 7.2

is required. A dosing system for oxidants has to be provided upstream of the demanganisation system.

However, should ammonium (> 0.1 mg/l) be detected in the raw water, an additional treatment step is required.

3 | Function

The demanganisation system GENO-mat MN-Z is operated with the

natural, catalytic filter material Fermanit. A central control valve automatically controls the operating cycles filtration - backwash - and first

filtrate.

Iron / manganese removal

Demanganisation system GENO-mat MN-Z

Order no. 095 153 048-inter Edited by: nkes-mrie G:\BA-153048-INTER_095_GENO-MAT_MN-Z.DOCX

10

3.1 Filters

The raw water flows into the filter tank via the raw water inlet and

then, from top to bottom, through the catalytic filter material. By

means of an oxidation process, dissolved iron and manganese salts

are transformed into insoluble oxides and are deposited on the Fermanit material.

In this oxidation process, the Fermanit releases electrons to the iron

and manganese until the supply is exhausted. The electrons have to

be replaced continuously by dosing GENO-oxi plus (refer to product

data sheet).

By dosing oxidants, the oxidation and precipitation of iron and manganese already takes place prior to their contact with the Fermanit

material. Thanks to its catalytic properties a complete oxidation and

due to the excellent filtration characteristics, an optimum filtration are

achieved. The filtered pure water is then directed via the lower distributing nozzle and the riser pipe through the pure water outlet into

the piping system.

3.2 Backwashing

During the backwash process, the filter bed is forcibly flushed from

bottom to top and thus loosened up. Impurities retained during the

filtration process are washed out via the drain outlet at the control

valve. The demanganisation system must be backwashed every 6

days at the latest (for the setting refer to chapter F).

3.3 First filtrate

By an automatic switch-over of the central control valve, the filter

bed will forcibly be flushed from top to bottom. This first filtrate is discharged to the drain and afterwards, the demanganisation system

GNEO-mat MN-Z is ready for operation once again.

3.4 Regeneration/disinfection

For operating and hygienic reasons, the demanganisation system

must be regenerated every 6 months with GENO special granulate

or GENO-oxi plus.

3.5 Control unit

The demanganisation system GENO-mat MN-Z is time-controlled

via an electrical timer.

In order to properly use the automatic timer control, the time interval

between two filter sequences (backwash interval in days) must be

set.

Iron / manganese removal

Demanganisation system GENO-mat MN-Z

Order no. 095 153 048-inter Edited by: nkes-mrie G:\BA-153048-INTER_095_GENO-MAT_MN-Z.DOCX

11

C Product description

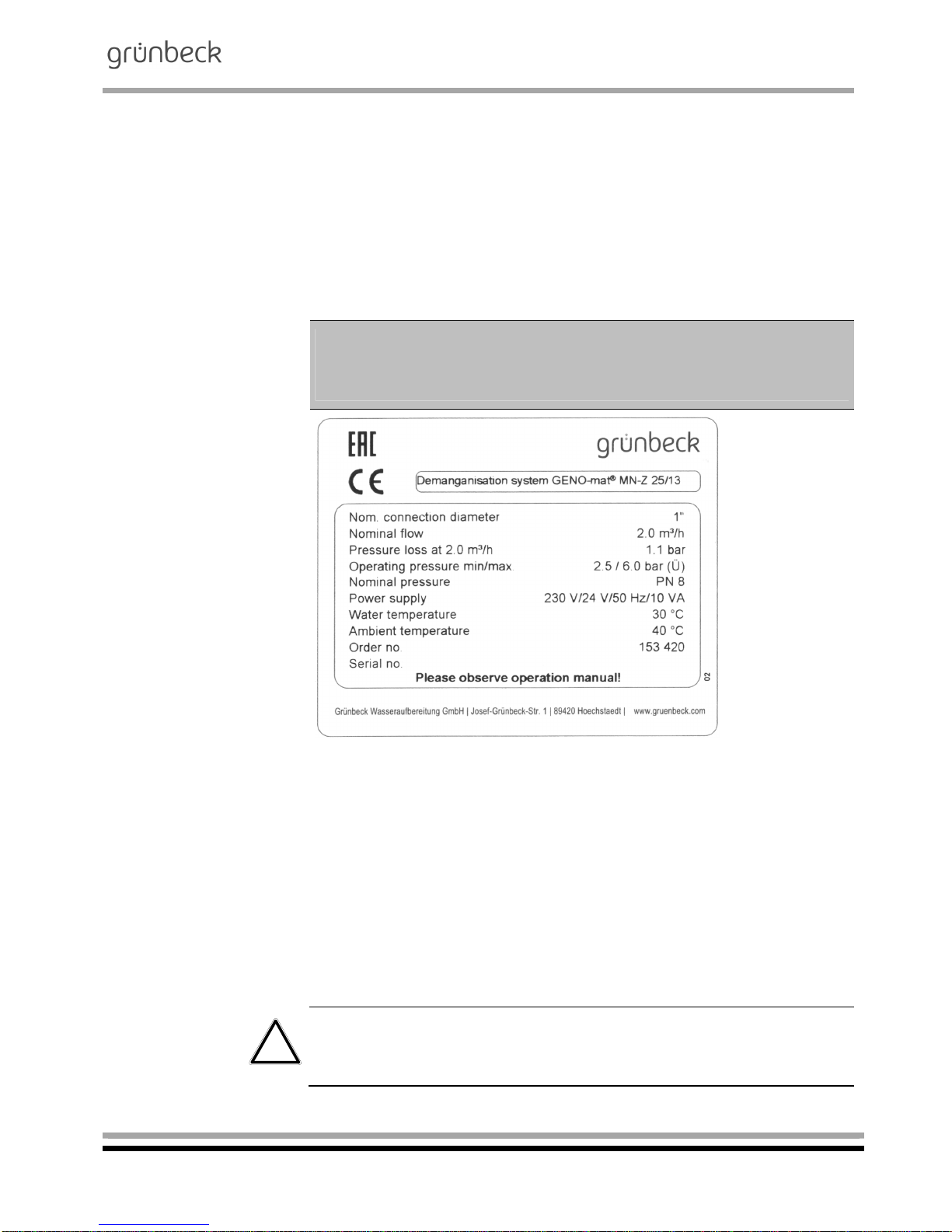

1 | Type designation plate

The type designation plate is located on the control head of the de-

manganisation system. In order to speed up the processing of your

inquiries or orders, please specify the data shown on the type designation plate of your system when contacting Grünbeck. Please add

the necessary information to the table below to have it readily available whenever necessary.

Demanganisation system

GENO-mat MN-Z

Serial number:

/

Order number:

Fig. C-1: Type plate for demanganisation system GENO-mat MN-Z

2 | Technical specifications

The GeNO-mat MN-Z demanganisation system is a single system

with integrated bypass for the supply of raw water during the backwash process. It is equipped with a timer control. The backwash is

initiated after a set time interval.

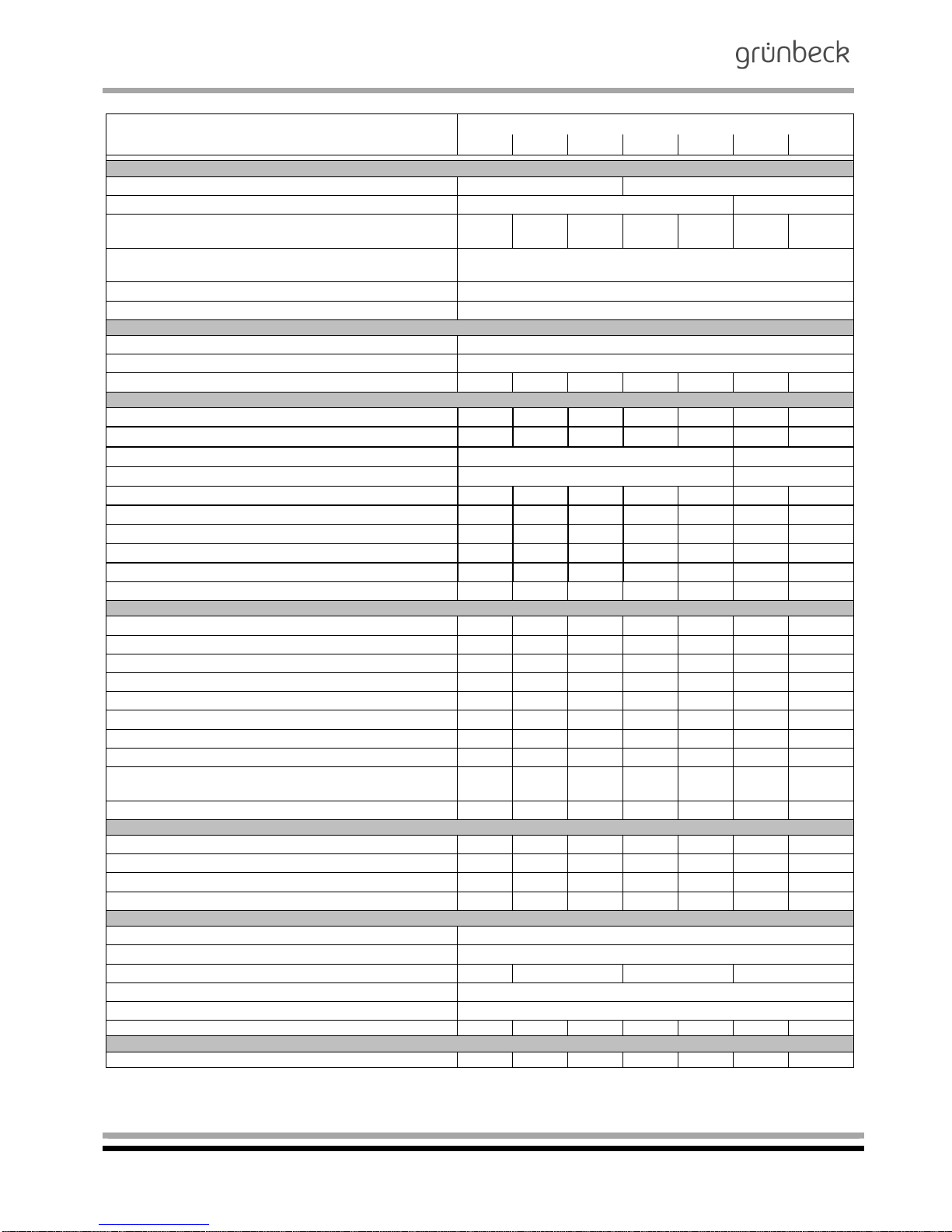

All system data is summarised in table C-1. The data refers to the

standard versions of the GeNO-mat MN-Z demanganisation system.

Possible deviations in case of special versions are communicated

separately, if applicable.

Caution! Electrically operated valves. In case of a power failure during the backwash, water may enter the drain. In the event of power

failure, check the system and shut-off the water supply, if necessary.

Iron / manganese removal

Demanganisation system GENO-mat MN-Z

Order no. 095 153 048-inter Edited by: nkes-mrie G:\BA-153048-INTER_095_GENO-MAT_MN-Z.DOCX

12

Table C-1: Technical specifications Demanganisation system GENO-mat MN-Z

20/10 25/13 30/14 40/17 40/18 50/19 60/20

Connection data

Nominal connection diameter DN 25 (1") DN 40 (1½“)

Min. drain connection DN 50 DN 70

Nominal flow rate (depending on the iron concen-

tration)

[m³/h] 1.5 2.0 3.0 4.0 5.0 6.0 8.0

Power supply [V/Hz]

230 V, 50 Hz

operation with protective low voltage 24 V/50 Hz

Connected load [VA] 10

Protection type IP 54

Performance data

Nominal pressure (PN) 8.0

Min./max. operating pressure [bar] 2.5/6.0

Pressure loss at nominal flow [bar] 0.5 1.1 1.0 1.1 1.0 0.8 1.1

Dimensions and weights1)

Total height [mm] 1360 1620 1620 1900 1900 1870 2100

Exchanger tank

[mm]

210 260 340 370 420 550 620

Regeneration tank

[mm]

465 680

Height of regeneration tank [mm] 840 1010

Connection height/raw water piping [mm] 1160 1420 1420 1710 1710 1680 1910

Connection height/pure water piping [mm] 1210 1470 1470 1735 1735 1705 1935

Distance to wall [mm] 200 230 280 280 300 365 405

Depth of foundation [mm] 400 450 500 500 550 600 650

Length of foundation [mm] 1850 1950 2050 2050 2100 2250 2350

Operating weight (incl. water) [kg] 76 135 213 311 361 642 947

Filling volume and consumption data1)

Filter layer I, bottom, gravel 3.0 - 5.6 [kg] 10 10 25 25 25 50 50

Filter layer I, bottom, gravel 3.0 - 5.6 [l] 7 7 18 18 18 35 35

Filter layer I, bottom, gravel 3.0 - 5.6 (dimension a) [mm] 860 1170 1100 1400 1430 1320 1570

Filter layer II, middle, GENO Fermanit [kg] 25 50 50 100 125 200 325

Filter layer II, middle, GENO Fermanit [l] 12.5 25 25 50 63 100 163

Filter layer II, middle, GENO Fermanit (dimension b) [mm] 500 690 810 930 950 900 1020

Filter layer III, top, with quartz sand 0.4 – 0.8 [kg] 10 25 50 75 75 150 250

Filter layer III, top, with quartz sand 0.4 – 0.8 [l] 7 17 33 50 50 100 167

Filter layer III, top, with quartz sand 0.4 – 0.8 (dimen-

sion c)

[mm] 300 370 430 460 560 490 450

Free board [l] 7 12 30 22 40 74 71

Amount of regeneration agent required

Preparation amount [l] 302) 502) 602) 1002) 1002) 2002) 3002)

GENO special granulate [g] 105 175 210 350 350 700 1050

GENO-oxi plus [l] 5 9 11 17 17 35 53

Total waste water volume per regeneration (3 bar) [m³] 1 1.3 1.7 2 2.7 3.4 5.4

Ambient data

Duration of washing out (regeneration) [min.] 30

Duration of backwash [min.] 10

Backwash capacity [m³/h] 1.6 2.3 3.4 5.7

Max. water temperature [°C] 30

Max. ambient temperature [°C] 40

Order no. 153 … 410 420 430 440 450 460 470

Spare filter filling3)

Order no. 153 … 020 022 024 026 028 030 032

1)

All indications are approximate.

2)

If the liquid product GENO-oxi plus is used, the GENO-oxi plus amount must be subtracted from the batch size.

3)

all three filter layers

Loading...

Loading...