Page 1

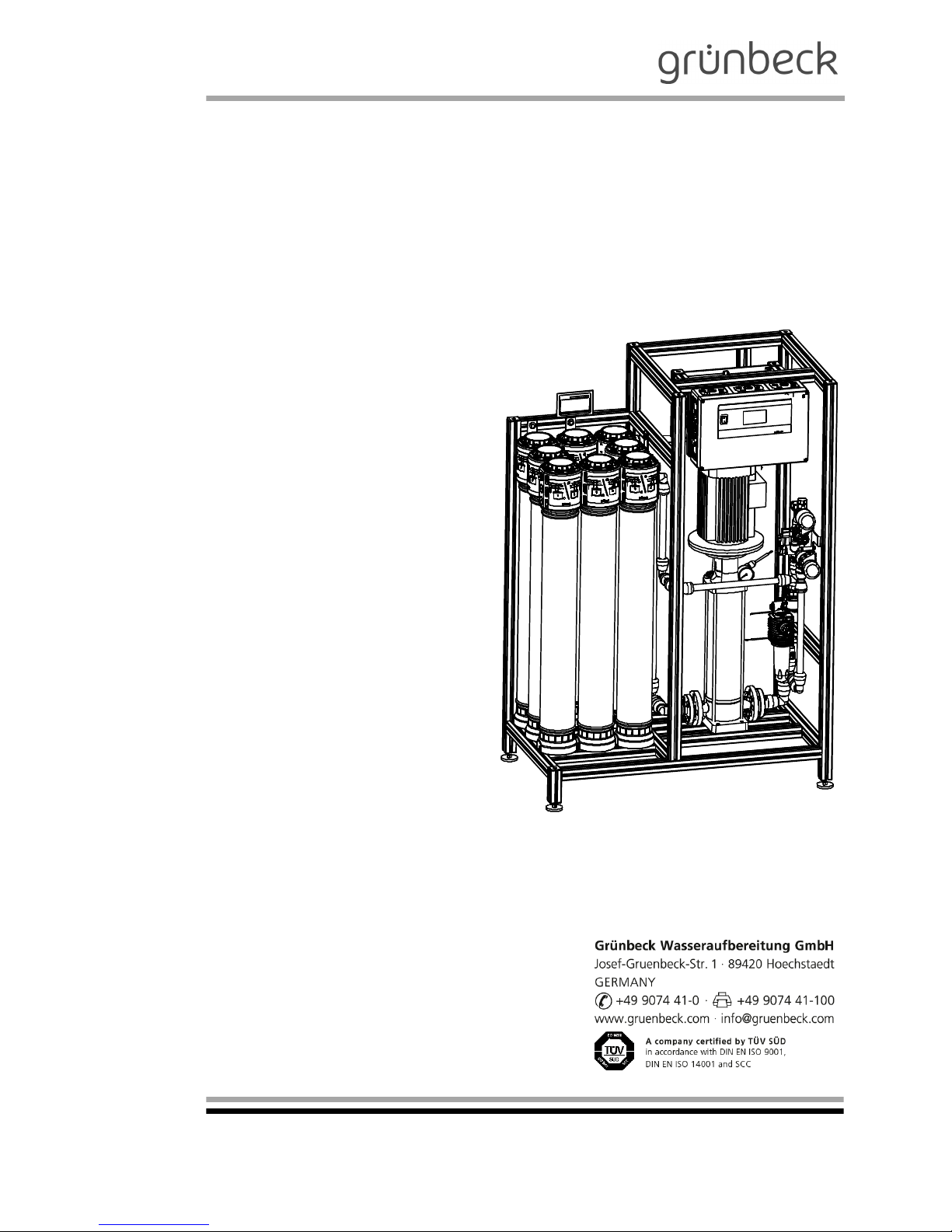

Operation manual

Reverse osmosis system GENO-OSMO-X

with GENO-tronic operating element

and GENO-OSMO-X controller

starting from software version V1.11

Edition: April 2018

Order no. 124 750 927-inter

Page 2

Page 3

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

1

Table of contents

AGENERAL ............................................................................................................................................................................................ 4

1 | P

REFACE

..................................................................................................................................................................................................... 4

2 | H

OW TO USE THIS OPERATION MANUAL

............................................................................................................................................................ 4

3 | G

ENERAL SAFETY INFORMATION

..................................................................................................................................................................... 5

3.1Symbols and notes .............................................................................................................................................................................. 5

3.2Operating personnel ............................................................................................................................................................................ 5

3.3Appropriate application ........................................................................................................................................................................ 5

3.4Protection from water damage ............................................................................................................................................................. 6

3.5Indication of specific dangers ............................................................................................................................................................... 6

4 | S

HIPPING AND STORAGE

................................................................................................................................................................................ 6

5 | D

ISPOSAL OF USED PARTS AND MATERIALS

...................................................................................................................................................... 6

BBASIC INFORMATION ........................................................................................................................................................................ 7

1 | L

AWS, REGULATIONS, STANDARDS

.................................................................................................................................................................. 7

2 | W

ATER

........................................................................................................................................................................................................ 7

3 | F

UNCTIONAL PRINCIPLE OF REVERSE OSMOSIS

................................................................................................................................................. 8

CPRODUCT DESCRIPTION .................................................................................................................................................................. 9

1 | T

YPE DESIGNATION PLATE

.............................................................................................................................................................................. 9

2 | F

UNCTIONAL DESCRIPTION

........................................................................................................................................................................... 10

3 | T

ECHNICAL SPECIFICATIONS

......................................................................................................................................................................... 15

4 | A

PPROPRIATE APPLICATION

......................................................................................................................................................................... 16

4.1System idle time ................................................................................................................................................................................. 16

5 | A

PPLICATION LIMITS

.................................................................................................................................................................................... 17

6 | S

COPE OF SUPPLY

...................................................................................................................................................................................... 18

6.1Standard equipment ........................................................................................................................................................................... 18

6.2Optional accessories .......................................................................................................................................................................... 19

6.3Consumables ..................................................................................................................................................................................... 22

6.4Wearing parts .................................................................................................................................................................................... 23

DINSTALLATION ................................................................................................................................................................................. 24

1 | G

ENERAL INSTALLATION INSTRUCTIONS

........................................................................................................................................................ 24

1.1Preliminary work ................................................................................................................................................................................ 24

2 | W

ATER INSTAL LATION

.................................................................................................................................................................................. 24

3 | H

OW TO CONNECT THE SYSTEM

.................................................................................................................................................................... 25

4 | E

LECTRICAL INSTALLATION

........................................................................................................................................................................... 26

4.1Circuit diagram of power distribution .................................................................................................................................................. 26

4.2Connections within the GENO-OSMO-X control unit and the GENO-tronic operating element: ........................................................ 28

4.3Connections within the GENO-OSMO-X reverse osmosis system .................................................................................................... 29

4.4Connections to other subsystems - system output ............................................................................................................................. 30

4.5Connections to other subsystems – Residual hardness monitoring system NX1CQ1 for pre-treatment by water softener ................. 30

4.6Connections to other subsystems – Dosing pump RO1 P2 for antiscalant pre-treatment ....................................................................... 31

4.7Connections within the OSMO-X reverse osmosis system – AVRO pre-treatment RO1B5 ................................................................ 31

4.9Subsystems water softener and/or pressure booster interconnected via RS485 data line – Connection of terminating resistors ...... 32

4.10 Connections to other subsystems – Pre-treatment by water softener ................................................................................................. 32

4.11Connections to other sub-systems – Pressure booster installed downstream .................................................................................... 32

4.12Connections to other subsystems – Optional signals or accessories ................................................................................................. 33

ESTART-UP ......................................................................................................................................................................................... 34

1 | H

OW TO FLUSH THE SYSTEM

........................................................................................................................................................................ 34

1.1How to flush off the preservation agent .............................................................................................................................................. 34

FOPERATION ...................................................................................................................................................................................... 36

1 | I

NTRODUCTION

........................................................................................................................................................................................... 36

2 | S

CREEN LAYOUT OF THE

GENO-

TRONIC OPERATING ELEMENT

........................................................................................................................ 36

2.1Home screen ..................................................................................................................................................................................... 36

2.2Info level of GENO-OSMO-X.............................................................................................................................................................. 37

2.3Change, save, reject parameters ....................................................................................................................................................... 38

2.4Acknowledgement of errors/signals ................................................................................................................................................... 39

2.5Screen saver ...................................................................................................................................................................................... 40

3 | S

YSTEM RANGE

.......................................................................................................................................................................................... 40

3.1System menu I ................................................................................................................................................................................... 40

3.2Data logging on an SD card ............................................................................................................................................................... 42

3.2System menu II .................................................................................................................................................................................. 45

3.3Software version ................................................................................................................................................................................ 45

4 | SUB-

SYSTEM

GENO-OSMO-X

REVERSE OSMOSIS SYSTEM

........................................................................................................................... 45

4.1 User programming level ..................................................................................................................................................................... 46

4.2Installer level (Code 113) ................................................................................................................................................................... 48

4.3Customer service level ....................................................................................................................................................................... 54

4.4Extended customer service level I ...................................................................................................................................................... 54

4.5Extended customer service level II ..................................................................................................................................................... 54

4.6Counter readings, error memory ........................................................................................................................................................ 55

4.7Key operation ..................................................................................................................................................................................... 56

4.8Reset of counter readings .................................................................................................................................................................. 56

4.9Memory of operating parameters ....................................................................................................................................................... 56

5 | P

ERMEATE TANK

......................................................................................................................................................................................... 57

6 | PRE-

TREATMENT BY MEANS OF ANTISCALANT DOSING

..................................................................................................................................... 58

6.1Operator menu ................................................................................................................................................................................... 59

6.2Customer Service level ...................................................................................................................................................................... 5 9

GTROUBLESHOOTING ....................................................................................................................................................................... 60

1 | B

ASIC INFORMATION

.................................................................................................................................................................................... 60

2 | H

OW TO REMEDY WARNINGS

........................................................................................................................................................................ 61

3 | T

ROUBLESHOOTING

.................................................................................................................................................................................... 64

HMAINTENANCE ................................................................................................................................................................................. 7 0

1 | B

ASIC INFORMATION

.................................................................................................................................................................................... 70

2 | I

NSPECTION (FUNCTIONAL CHECK

) ................................................................................................................................................................ 70

3 | M

AINTENANCE

............................................................................................................................................................................................ 7 1

4 | O

PERATION LOG

......................................................................................................................................................................................... 72

Page 4

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

2

Publisher's information

All rights reserved.

Copyright by Grünbeck Wasseraufbereitung GmbH

Printed in Germany

Effective with the date of edition indicated on the cover sheet.

-We reserve the right to modifications, especially with regard to

technical progress-

Reprints, translations into foreign languages, electronic storage

or copying of this operation manual only with explicit written approval of Grünbeck Wasseraufbereitung GmbH.

Any type of duplication not authorised by Grünbeck Wasseraufbereitung is a copyright violation and subject to legal action.

Responsible for contents:

Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Str. 1, 89420 Hoechstaedt/Germany

Phone +49 9074 41-0 Fax +49 9074 41-100

www.gruenbeck.de service@gruenbeck.de

Print: Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Str. 1, 89420 Hoechstaedt/Germany

Page 5

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

3

EU Declaration of Conformity

This is to certify that the system designated below meets the safety and health requirements of

the applicable European guidelines in terms of its design, construction and execution.

If the system is modified in a way not approved by us, this certificate is void.

Manufacturer: Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Str. 1

89420 Hoechstaedt/Germany

Responsible for documentation:

Markus Pöpperl

System designation: Reverse osmosis system GENO-OSMO-X

System size: 200, 400, 800, 1200, 1600, 2200, 3000

Serial number: refer to type designation plate

Applicable guidelines: Machinery Directive (2006/42/EC)

EMC Directive (2014/30/EU)

Applied harmonised standards,

in particular:

DIN EN ISO 12100: 2011-03

DIN EN 61000-6-2: 2006-03

DIN EN 61000-6-3: 2011-09

Applied national standards

and technical

specifications,

in particular:

City, date and signature: Hoechstaedt, 30.04.2018 p.p.

M. Pöpperl

Dipl.-Ing. (FH)

Function of signatory: Head of Department for Technical Product Design

Page 6

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

4

A General

1 | Preface

Thank you for opting for a Grünbeck product. Backed by decades

of experience in the area of water treatment, we provide solutions

for all kind of processes.

All Grünbeck systems and devices are made of high-quality materials. This ensures reliable operation over many years, provided

you treat your water treatment systems with the required care.

This operation manual assists you with important information.

Therefore, please read the entire operation manual before installing, operating or maintaining the system.

Customer satisfaction is our prime objective and providing customers with qualified advice is crucial. If you have any questions

concerning this device, possible extensions or general water and

waste water treatment, our field staff, as well as the experts at

our headquarters in Hoechstaedt, are available to help you.

Advice and assistance

For advice and assistance please contact your local representative (see www.gruenbeck.de) or get in touch with our service

centre which can be reached during office hours:

Phone: +49 9074 41-333

Fax: +49 9074 41-120

Email: service@gruenbeck.de

We can connect you with the appropriate expert more quickly if

you provide the required system data.

2 | How to use this operation manual

This operation manual is intended for the operators of our sys-

tems. It is divided into several chapters and a letter is assigned to

each of them in alphabetical order. In order to find the specific information you are looking for, check for the corresponding chapter

on page 3.

Page 7

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

5

3 | General safety information

3.1 Symbols and notes

Important information in this operation manual is characterised

by symbols. Please pay particular attention to this information to

ensure the hazard-free, safe and efficient handling of the system.

Danger! Failure to adhere to this information will cause serious

or life-threatening injuries, extreme damage to property or inadmissible contamination of the drinking water.

Warning! Failure to adhere to this information may cause injuries, damage to property or contamination of the drinking water.

Attention! Failure to adhere to this information may result in

damage to the system or other objects.

Note: This symbol characterises information and tips to make

your work easier.

Tasks with this symbol may only be performed by Grünbeck's

technical service/authorised service company or by persons expressly authorised by Grünbeck.

Tasks with this symbol may only be performed by qualified electrical experts according to the VDE guidelines or according to

the guidelines of a similar local institution.

Tasks with this symbol may only be performed by water companies or approved installation companies. In Germany, the installation company must be registered in a water company installation directory as per §12(2) AVBWasserV (German Ordinance on

General Conditions for the Supply of Water).

3.2 Operating personnel

Only persons who have read and understood this operation

manual are permitted to work with the system. The safety guidelines are to be strictly adhered to.

3.3 Appropriate application

The system may only be used for the purpose outlined in the

product description (chapter C). The guidelines in this operation

manual as well as the applicable local guidelines concerning the

drinking water protection, accident prevention and occupational

safety must be adhered to.

In addition, appropriate application also implies that the system

may only be operated when it is in proper working order.

Any malfunctions must be repaired at once.

Page 8

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

6

3.4 Protection from water

damage

Warning! In order to properly protect the installation site against

water damage:

a sufficient floor drain system must be available or

a safety device (see chapter C Accessories) must be in-

stalled.

Warning! In case of a power failure, floor drains with a discharge to a lifting system will be out of operation.

3.5 Indication of

specific dangers

Danger due to electrical energy! Do not touch electrical parts

with wet hands! Disconnect the system from mains before starting work on electrical parts of the system. Have qualified experts

replace damaged cables immediately.

Danger due to mechanical energy! System parts may be subject

to overpressure. Danger of injury and damage to property due to

escaping water and unexpected movement of system parts.

Check pressure pipes regularly. Depressurise the system before

starting repair or maintenance work on the system.

Hazardous to health due to contaminated drinking water! The

system may only be installed by a specialist company. The operation manual must be strictly adhered to! Ensure that there is

sufficient flow. The pertinent guidelines must be followed for

starting-up after extended periods of standstill. Inspections and

maintenance must be performed at the intervals specified!

Note: By concluding a maintenance contract, you ensure that all

of the required tasks are performed on time. You may perform

the interim inspections yourself.

4 | Shipping and storage

Attention! The system may be damaged by frost or high tem-

peratures. In order to avoid damage of this kind:

Protect from frost during transportation and storage!

Do not install or store system next to objects which radiate a lot

of heat.

The system may only be transported and stored in its original

packing. Ensure that it is handled with care and placed the right

side up (as indicated on the packing).

5 | Disposal of used parts and materials

Used parts and materials are to be disposed of, or made availa-

ble for recycling purposes, according to the applicable local

guidelines.

If a material is subject to specific regulations, adhere to the instructions indicated on the packing.

If in doubt, contact your local waste disposal authority or the

manufacturer for more information.

Page 9

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

7

B Basic information

1 | Laws, regulations, standards

In the interest of good health, rules cannot be ignored when it

comes to the processing of drinking water. This operation manual takes into consideration the current regulations and stipulates information that you will need for the safe operation of your

water treatment system.

Among other things, the regulations stipulate that

only approved companies are permitted to make major modi-

fications to water supply facilities

and that tests, inspections and maintenance on installed de-

vices are to be performed at regular intervals.

2 | Water

Due to dynamic substance and water cycles, harmful elements,

which are only partly and only slowly biodegradable are increasingly released into nature. Over time, these elements therefore

accumulate in ground and surface water. Removing them again

from natural water bodies represents a particular challenge.

Grünbeck rises to this challenge and aims at generating unpolluted drinking and process water.

The water works provide us with pure drinking water that is suit-

able for consumption. However, if the water is to be used for

technical purposes, further treatment is frequently required.

Page 10

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

8

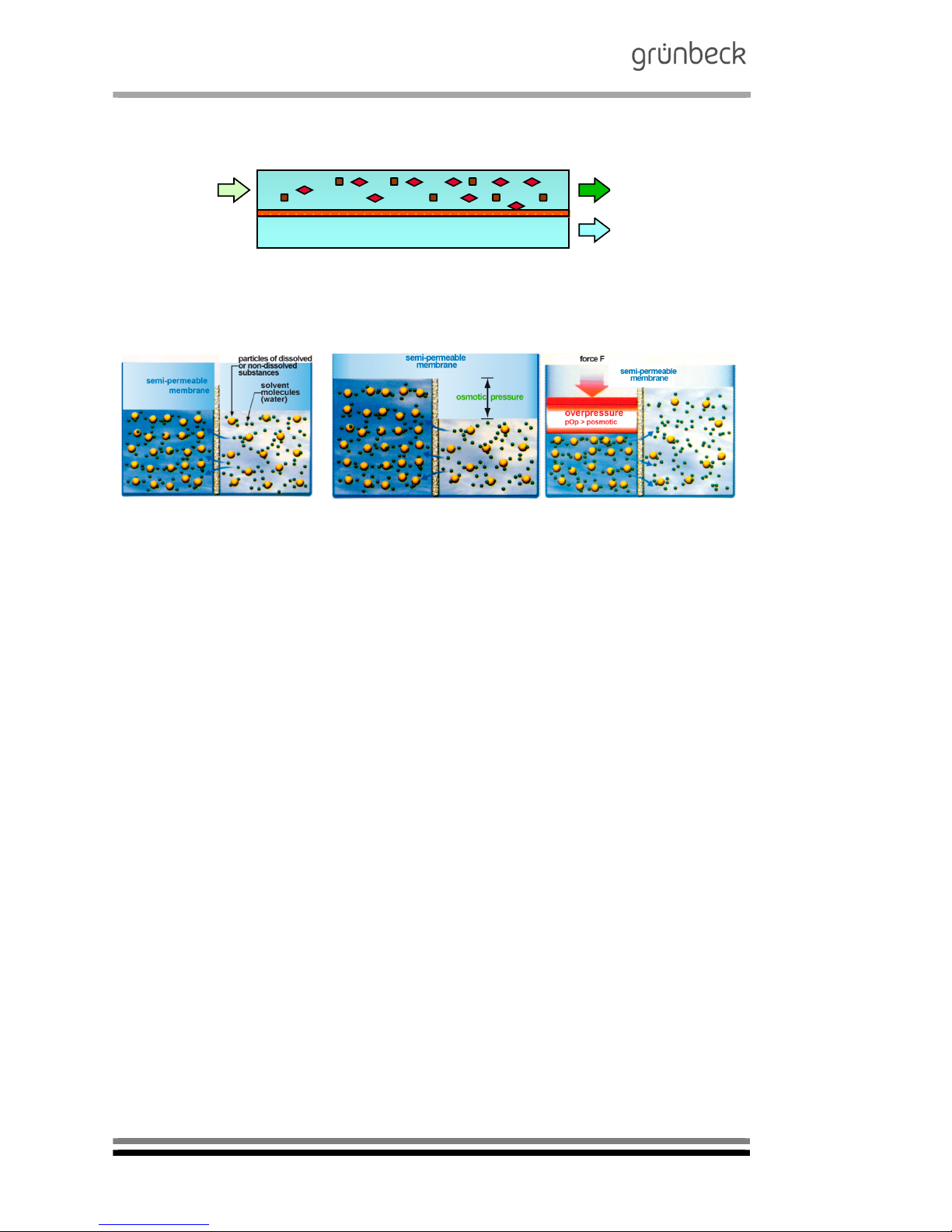

3 | Functional principle of reverse osmosis

Principle:

Pre-treated feed

water

Concentrate:

Permeate

Fig. B-1: Functional principle

Osmosis Osmotic pressure Reversed osmosis

Solution of high

concentration

Solution of low

concentration

Solution of high

concentration

Solution of low

concentration

Solution of high

concentration

(concentrate)

Solution of low

concentration

(permeate)

Fig. B-2: Reverse osmosis principle

In the osmosis process, watery solutions of different concentrations are separated by a semi-permeable membrane. In keeping

with the law of nature, the concentrations try to equalise. On the

side of the higher original concentration, the so-called "osmotic"

pressure is generated.

In case of reverse osmosis, this osmotic pressure is countered

by a higher pressure. The consequence: the process proceeds

in the reverse direction. A particular advantage of the reverse

osmosis technology compared to other water treatment processes is the fact that - apart from the removal of dissolved salts

- bacteria, germs and dissolved organic substances are also reduced.

Page 11

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

9

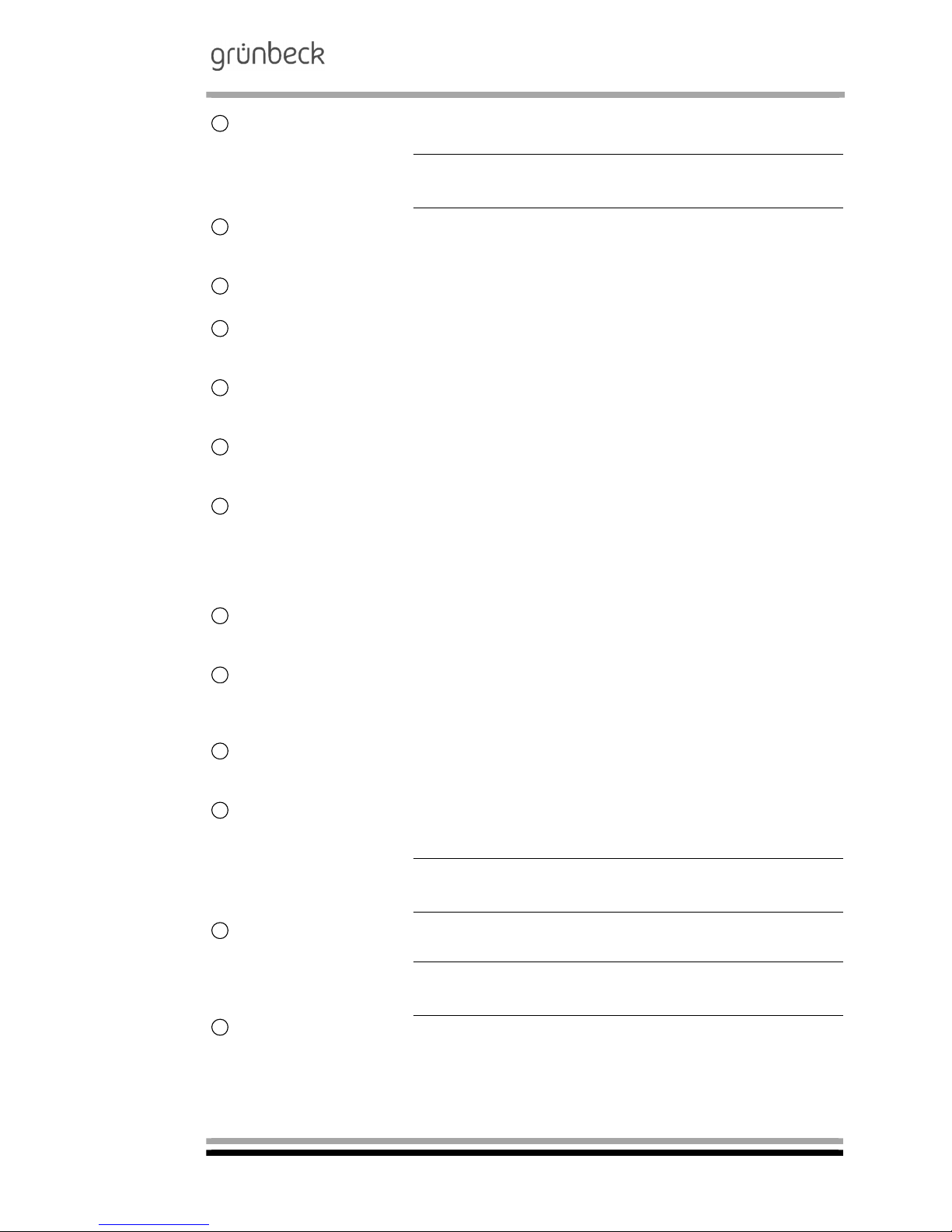

C Product description

1 | Type designation

plate

Please specify the data shown on the type designation plate of

your GENO-OSMO-X reverse osmosis system in order to speed

up the processing of enquiries or orders. Please copy the indicated information to the table below in order to have it handy

whenever necessary.

Reverse osmosis system

GENO-OSMO-X:

Serial number:

Order no.:

Fig. C-1: Type designation plate of the reverse osmosis system GENO-OSMO-X

Page 12

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

10

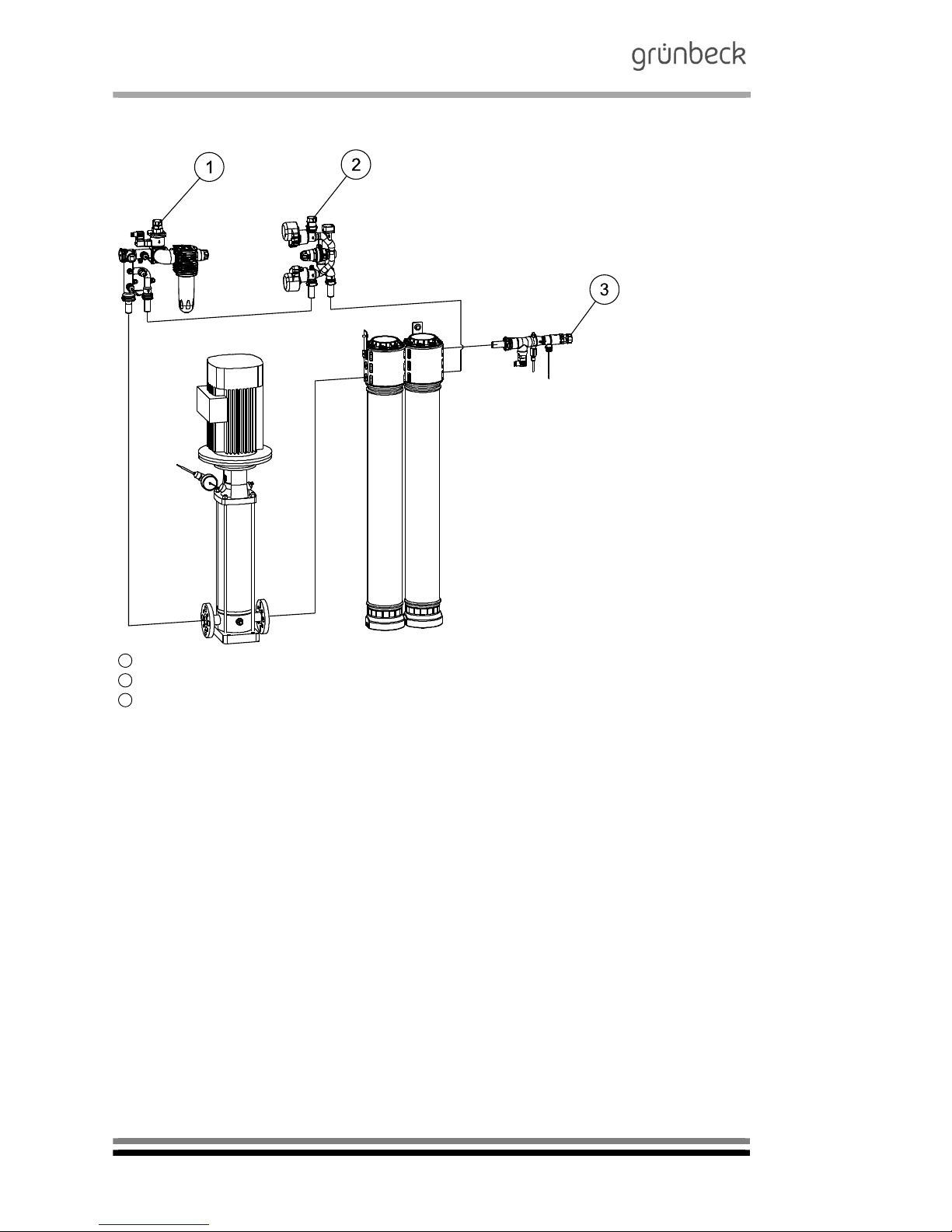

2 | Functional description

Feed water

Concentrate to drain

Permeate

Fig. C-2: System design of the reverse osmosis system GENO-OSMO-X

1

2

3

Page 13

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

11

Feed water inlet

BL1

Connection 1“ or 1¼ (male thread), flat sealing, for feed water

connection by others on site

Note: Provide connection by means of water meter screw connection.

Solenoid valve

for feed water

RO1V1

During the permeate production, this valve is always open. Following the system stop (tank full), the valve remains open for

the programmed flushing volume of the membrane(s).

Fine filter

RO1F1

Pre-filtration of the feed water incl. pressure reducer (pre-set)

4.0 bar and integrated pressure gauge for feed water pressure.

Flow sensor

feed

RO1CF2

Via pulse signal to the control unit.

Feed = Concentrate recirculation + Permeate + Concentrate to

drain.

Pressure switch for

minimum pressure

RO1CP1

To prevent the high-pressure pump from running dry. Switches

time-delayed after opening the solenoid valve for feed water.

Flow sensor

feed water

RO1CF1

Via pulse signal to the control unit.

Feed water = Permeate + Concentrate to drain.

Adjusting valve concentrate to drain with drive

RO1V3

To automatically adjust the volume flow concentrate to drain (recovery). During the permeate production, this portion of the water flow permanently flows to the drain. The volume flow is subject to the system size. In case of tank "full" as well as in case of

a system failure, the valve always opens the entire cross section

in combination with the solenoid valve for feed water.

Pressure reducer

concentrate

RO1H4

To improve the regulation accuracy of the adjusting valves (set

to 6 bar)

Adjusting valve

concentrate recirculation

with drive

RO1V2

For automatic adjustment of the volume flow concentrate recirculation. The volume flow is subject to the system size.

Sampling valve

concentrate

RO1H1

Allows manual quality determination via sampling valve.

Connection concentrate

to drain

BL2

1“ male thread, flat sealing

Note: Provide for connection via water meter screw connection.

Permeate connection

BL3

1“ male thread, flat sealing

Note: Provide for connection via water meter screw connection.

High-pressure pump

RO1P1

Centrifugal pump system (frequency-controlled) that generates

the operating pressure required for the membrane. Pump operates upon permeate demand from the level control located in the

permeate tank. By means of the frequency converter, the

pump's revolution speed is adapted in a way that the nominal

permeate capacity is achieved.

1

2

3

4

5

6

7

8

9

10

11

12

13

Page 14

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

12

Pressure switch

maximum pressure

RO1CP3

Prevents the system's operating pressure from exceeding

16 bar.

Membrane

RO1B1

Reverse osmosis membrane to generate the permeate.

Flow sensor permeate

RO1CF3

Via pulse signal at the control unit.

Sampling valve

permeate

RO1H5

Allows manual quality determination via sampling valve.

Conductivity

measurement

RO1CQ1

Conductivity sensor according to the 2-electrode principle (temperature-compensated (RO1CT1)) for the continuous measurement of the permeate conductivity. The measuring results are indicated in the control unit.

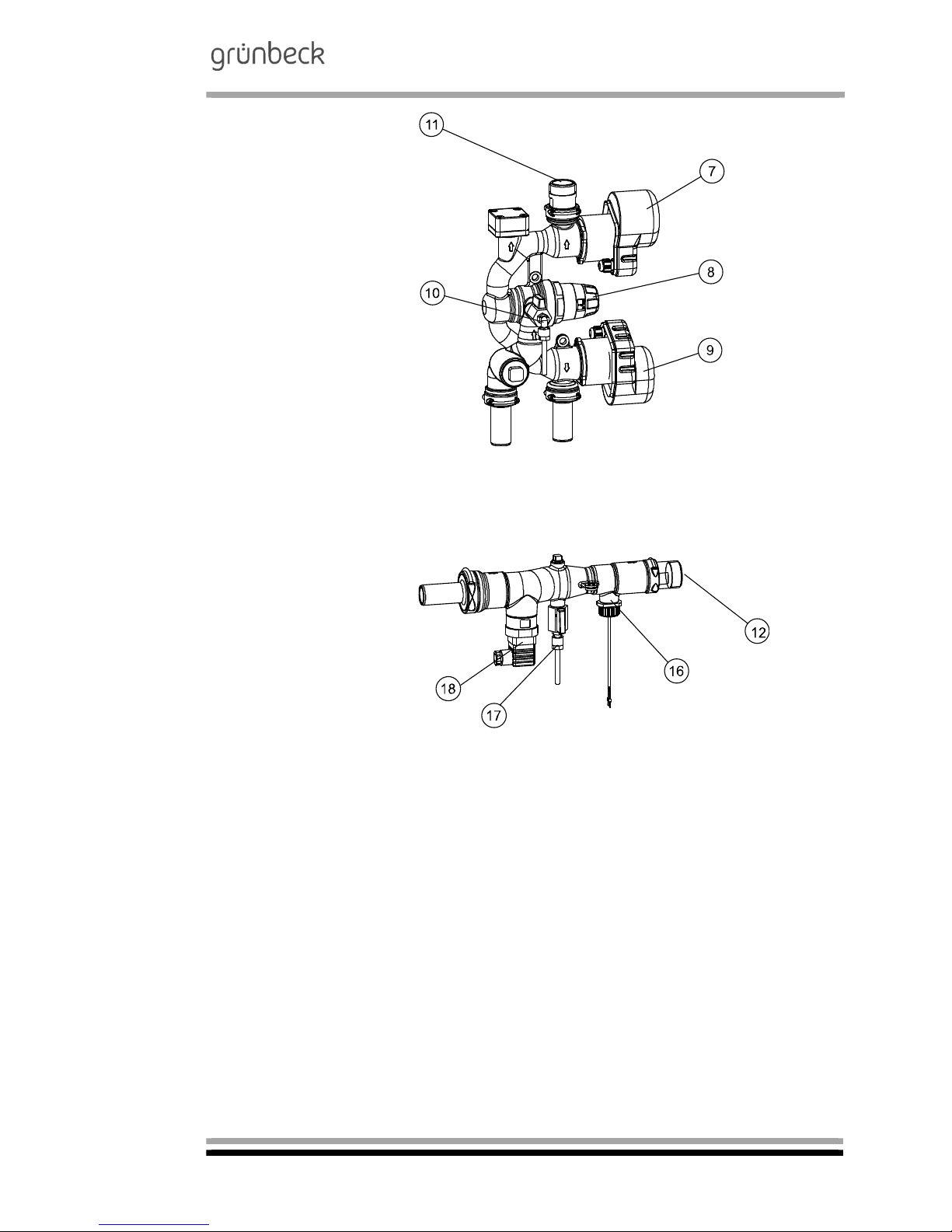

Fig. C-3: Reverse osmosis system GENO-OSMO-X hydro module

for feed water

14

15

16

17

18

Page 15

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

13

Fig. C-4: Reverse osmosis system GENO-OSMO-X hydro module

for concentrate

Fig. C-5: Reverse osmosis system GENO-OSMO-X hydro module for permeate

Page 16

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

14

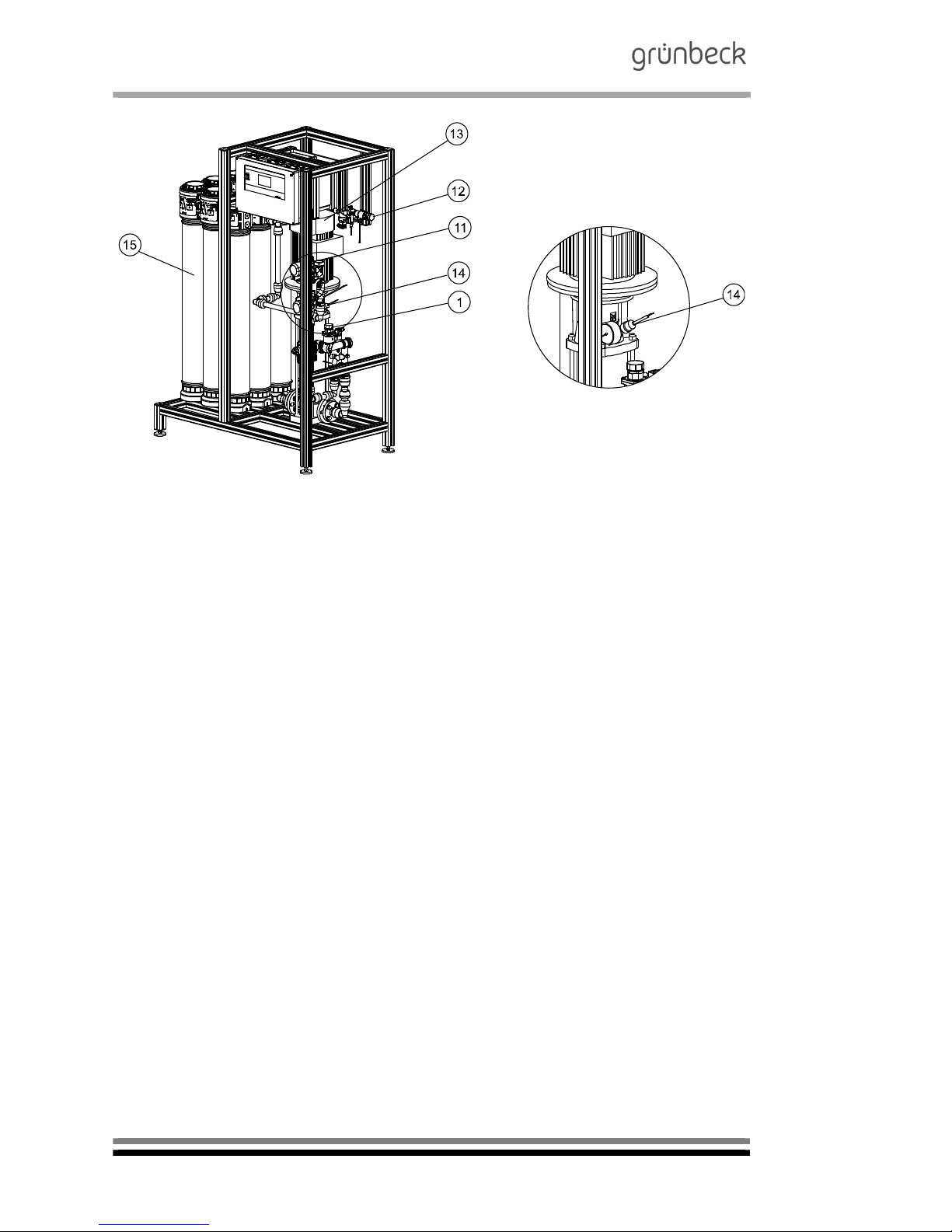

Fig. C-6: Reverse osmosis system GENO-OSMO-X 3000 with fine filter,

hydraulic connections, membrane and high-pressure pump

Page 17

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

15

3 | Technical specifications

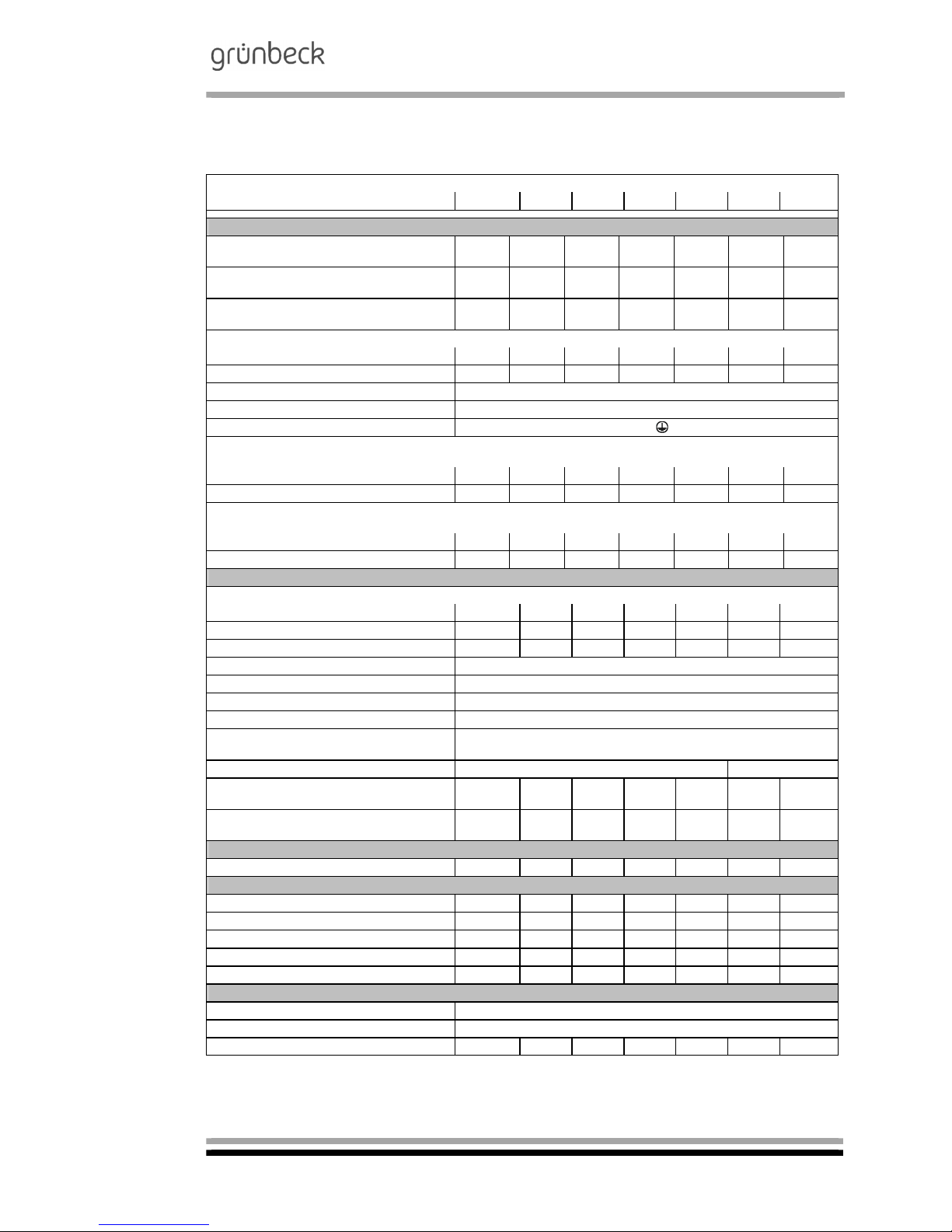

Table C-1: Technical specifications Reverse osmosis system GENO-OSMO-X

200 400 800 1200 1600 2200 3000

Connection data

Nominal connection diameter (male thread)

of feed water inlet

1“

1“ 1“ 1“ 1“

1 ¼“ 1 ¼“

Nominal connection diameter (male thread)

of permeate outlet

1“

1“ 1“ 1“ 1“ 1“ 1“

Nominal connection diameter (male thread)

of concentrate outlet

1“

1“ 1“ 1“ 1“ 1“ 1“

Min. drain connection

Without optional AVRO DN 50 DN 50 DN 50 DN 50 DN 50 DN 50 DN 50

With optional AVRO DN 50 DN 50 DN 50 DN 100 DN 100 - -

Power supply [V/Hz] 3/N/PE, 400 V/50...60 Hz

Min. power outlet provided on site 5.5 kW / C 20 A / 2.5 mm²

Protection/protection class

IP 54/

Power input in case of unpressurised delivery of the permeate into a tank at a switching frequency of the frequency

converter of 8 kHz and an inlet pressure of 4 bar in the feed water

Recovery of 80 % [kW] 0.53 0.87 0.94 1.40 1.74 2.10 2.30

Recovery of 50 % [kW] 0.53 0.88 0.94 1.30 1.60 - -

Power input if the permeate is delivered directly to the consumers with a supply pressure of 3.8 bar at a switching

frequency of the frequency converter of 8 kHz and an inlet pressure of 4 bar in the feed water.

Recovery of 80 % [kW] 0.86 1.44 1.60 2.00 2.31 2.30 2.80

Recovery of 50 % [kW] 0.81 1.20 1.41 1.90 2.11 - -

Performance data

Permeate capacity at a

Feed water temperature of 10 °C [l/h] 170 340 680 1020 1360 1870 2550

Feed water temperature of 15 °C [l/h] 200 400 800 1200 1600 2200 3000

Feed water temperature of 15 °C [m³/d] 4.8 9.6 19.2 28.8 38.4 52.8 72.0

Min. inlet flow pressure of feed water [bar] 2.5

Min. outlet pressure of permeate [bar] 0.5

Nominal pressure PN 16

Salt rejection 95 – 99 %

Total salt concentration in the feed water as NaCl, max.

[ppm] 1000

Recovery min./max. [%] 50-80 (adjustable) 65-80 (adjustable)

Volume flow concentrate to drain at a

recovery of 80%. (at 15°C)

[l/h] 50 100 200 300 400 550 750

Feed water volume flow (15 °C)

drain at a recovery of 80%.

[l/h] 250 500 1000 1500 2000 2750 3750

Filling volumes and consumption data

Number of modules (size 4") [pcs.] ½ 1 2 3 4 6 8

Dimensions and weights

System width [mm] 900 900 1035 1035 1170 1170 1170

System height [mm] 1700 1700 1700 1700 1700 1700 1700

System depth [mm] 675 675 675 675 675 675 675

Room height/installation height, min. [mm] 1800 1800 1800 1800 1800 1800 1800

Operating weight, approx. [kg] 100 115 145 170 195 240 290

General

Feed water temperature, min./max. [°C] 10/301)

Ambient temperature, min./max. [°C] 5/35

Order no. 750 200 750 210 750 220 750 230 750 240 750 250 750 260

1)

For temperatures of feed water > 20 °C a separate configuration of the system is required.

Page 18

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

16

4 | Appropriate application

The reserve osmosis system is designed for the demineralisa-

tion of drinking water according to the German Drinking Water

Ordinance (TrinkwV). The generated water is primarily used for

industrial applications.

A corresponding pre-treatment is required and the application

limits (paragraph 5) must be adhered to.

Note: In case of water that does not comply with the stipulations

of the German Drinking Water Ordinance (TrinkwV), a water

analysis is required beforehand.

The continuous permeate capacity is subject to the temperature

and was defined at 15°C. The permeate capacity decreases by

up to 3 % per degree centigrade of the feed water temperature .

Note: This reverse osmosis system adjusts the permeate capacity automatically subject to the temperature. The recovery (concentrate to drain) as well as the concentrate recirculation are

adapted to the modified permeate capacity.

The system is adjusted to the permeate requirements to be ex-

pected at the installation site, it is not suitable for major deviations.

The system may only be operated if all components are installed

properly. Safety devices and equipment must NEVER be removed, bridged or tampered with.

Appropriate application of the device also implies that the information contained in this operation manual and all safety guidelines applying at the installation site be observed. Furthermore,

the maintenance and inspection intervals have to be observed.

4.1 System idle time

If the system is out of operation for more than 14 days, it must

be preserved by Grünbeck's technical customer service/authorised service company. The maximum time, the system can remain in the preserved condition is 6 months.

In case the down time is longer, the system must be preserved

again in regular intervals by Grünbeck's technical customer service/authorised service company. Prior to resuming operation,

the preserving agent must be flushed from the system.

Page 19

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

17

5 | Application limits

For the application of the reverse osmosis system, the limit val-

ues stipulated in the German Drinking Water Ordinance represent the upper limits for the admissible substances contained in

the water.

Total hardness < 0.1 °dH

1)

(0.18 °f; 0.018 mmol/l)

Free chlorine not detectable

Iron < 0.10 mg/l

Manganese < 0.05 mg/l

Silicate < 15 mg/l

Chlorine dioxide not detectable

Turbidity < 1 FTU

Colloid index (SDI) < 3

pH range 3-9

1)

Different application limits for the total hardness do apply for

the optional pre-treatment AVRO resp. antiscalant.

Note: The permeate originating from the reverse osmosis system is not potable but requires additional treatment (blending,

hardening) if it is to be used as drinking water.

Page 20

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

18

6 | Scope of supply

6.1 Standard equipment

Control unit with 4.3" graphics touch panel to indicate the op-

erating state and system values. Voltage-free contacts to relay advance warnings and safety shut-downs. Digital input for

priority permeate production in times when electricity tariffs

are low (smart metering). Fully automatic monitoring and control of the system parameters permeate flow, monitoring of

the permeate conductivity by means of limit value default settings in the control unit, recovery, concentrate recirculation

and pump frequency (subject to the water temperature). Recording of measured data on integrated SD card. Possibility

to interconnect systems installed upstream or downstream

(water softener, dosing system, permeate tank, pressure

booster) and to operate them by remote control.

Power distribution with mains switch and automatic circuit

breakers as feeding point for power supply provided by others on site.

High-pressure centrifugal pump made of stainless steel

1.4401 to supply the reverse osmosis membrane(s).

Ultra-low pressure reverse osmosis membrane(s), installed in

pressure pipe made of high-strength PE.

Three-part hydro module made of red bronze, chemically

nickel-plated, featuring pressure gauges, adjusting resp. solenoid valves and sampling valves. Flow sensors integrated

in the hydro module, volume measurement of the system

flows permeate, concentrate and concentrate recirculation.

The permeate hydro module features a conductivity measuring cell (temperature-compensated).

Pipework between pump and reverse osmosis membrane

made of high-pressure resistant PE pipes and PP compression fittings.

High-quality system rack made of anodised aluminium to

house all system components.

A ventilation device to be mounted onto the concentrate pipe

provided by others on site.

Fine filter incl. pressure reducer, completely preassembled in

system inlet.

Installation and operation manual.

Page 21

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

19

6.2 Optional accessories

Note: It is possible to retrofit existing systems with optional components. Please contact your local Grünbeck representative or

Grünbeck’s headquarters in Hoechstaedt for details.

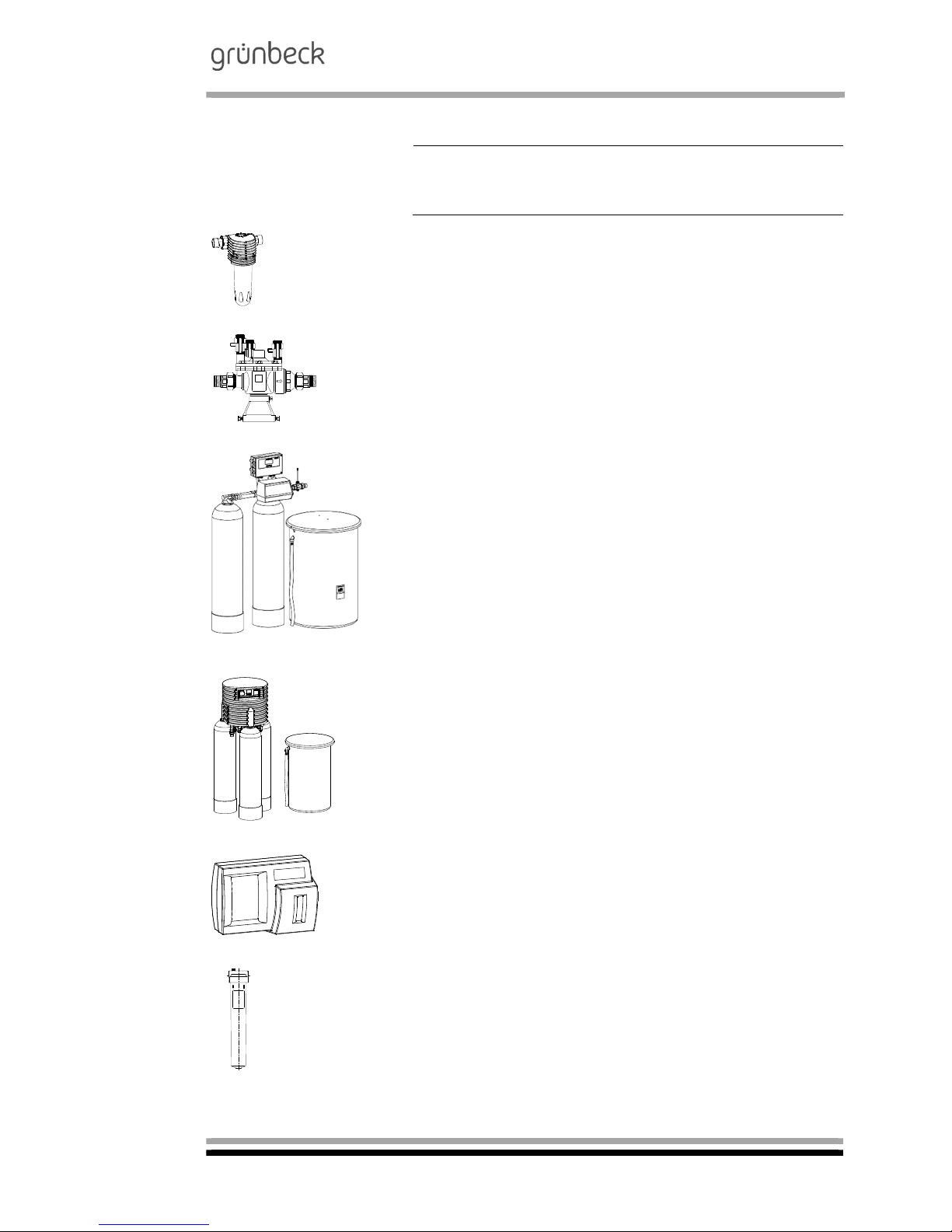

BOXER K 1" drinking water filter

Filter cartridge for pre-filtration

101 210

Euro system separator GENO-DK 2

To secure devices and systems endangering the

drinking water according to DIN 1988, part 4

GENO-DK 2 DN 15

GENO-DK 2 DN 20

132 510

132 520

GENO-mat duo WE-X water softener

Fully automatic double water softener based on

the ion exchange principle for the generation of

fully softened water with volume-controlled regeneration.

-For larger systems, please inquire-

186 100

Delta-p water softener

Fully automatic triple water softener based on the

ion exchange principle for the generation of fully/

partially softened water with volume-controlled regeneration.

- For larger systems, please inquire -

185 100

GENO-softwatch Komfort

For automatic monitoring of the limit value for

residual/total hardness (water hardness).

172 500

GENO-activated carbon filter AKF 600

To reduce the chlorine concentration contained in

the water.

- For larger filters, please inquire -

109 160

Page 22

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

20

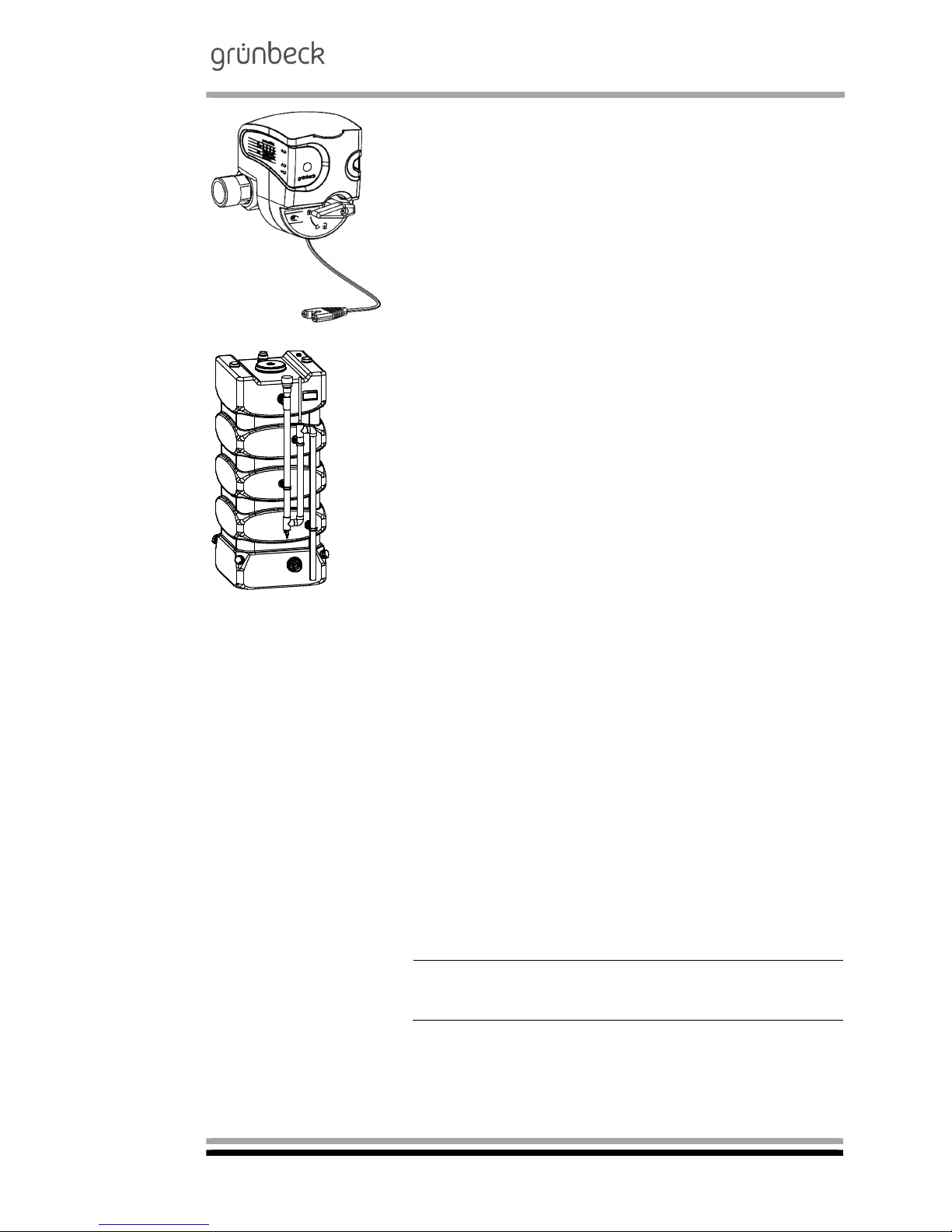

Communication module Profibus DP

For connection to a Profibus DP „Master“

750 160

Communication module BACnet IP

For connection to a BACnet IP „Master“

750 170

Communication module Modbus RTU

For connection to a Modbus RTU „Master“

750 175

Voltage-free signals

For connection to a BMS/CMS

750 180

Analogue signals 4-20 mA

For connection to a BMS/CMS

750 185

Page 23

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

21

Safety device protectliQ:A20

Product for protection against water damage in one

and two-family homes.

- For additional versions, please inquire -

126 400

Pure water tank for intermediate storage of permeate flowing unpressurised from GENO-reverse osmosis systems

Tank design:

All tanks are pre-assembled, with PVC overflow

pipe as well as connections for the permeate inlet

and the suction line of the pressure booster system.

Grey PE. Hand hole with removable screw cap.

Basic pure water tank

RT-X 1000 with sterile air filter and level sensor

Useful capacity approx. 850 litres

l 780 / w 990 / total height 2000 mm

1)

712 480

Additional tank RT for

basic pure water tank

Useful capacity approx. 850 litres

l 780 / w 780 / total height 2100 mm

1)

712 405

Basic pure water tank

RT-X 1000

2)

with level sensor

Useful capacity approx. 850 litres

l 780 / w 1000 / total height 2050 mm

1)

712 490

1)

Tank height incl. connecting pieces.

For larger tanks, please inquire

2)

No sterile overflow as siphon

- overflow as down pipe

Additional tank without overflow loop,

incl. 2 connecting lines, id=36 mm.

Note: A maximum of four supply tanks can be combined.

Page 24

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

22

Pressure booster system

GENO FU-X 2/40-1 N

Compact, pressure-controlled pump aggregate

consisting of a centrifugal pump completely made

of stainless steel as well as an integrated pressure and contact water meter. Control electronics

with increase in capacity, backlit graphical display.

Operating switch, operating log via SD card, voltage-free signal / fault contact, non-return valve,

shut-off valve for every pump (suction and pressure side) and membrane pressure expansion

vessel with forced flow.

Delivery rate: max. 1.2-4.2 m³/h

Delivery height max. 18.2 - 45.6 m

Power supply: 230 V / 50 Hz

Power input 1 kW

Connections: DN 25 / DN 32

Protection: IP 55

730 640

Pressure booster system

GENO FU-X 2/40-2 N

Description as for single pressure booster system,

however, with the possibility for time-/load switchover.

- For additional pressure booster systems,

please inquire -

730 641

6.3 Consumables

Only use genuine consumables in order to ensure the reliable

operation of the system.

GENO-replacement filter element, with protective

cylinder

Packing unit: 2 pcs

103 061

RO-membrane with seal 4“ x 40“

Reverse osmosis system GENO-OSMO-X 400 -

GENO-OSMO-X 3000

Packing unit: 1 pc

750 261

RO-membrane with seal 4“ x 21“

Reverse osmosis system GENO

-

OSMO-X 200

Packing unit: 1 pc

750 293

Activated carbon filter element MKCA

Reverse osmosis system GENO

-

OSMO-X 200

Packing unit: 1 pc

109 615

Page 25

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

23

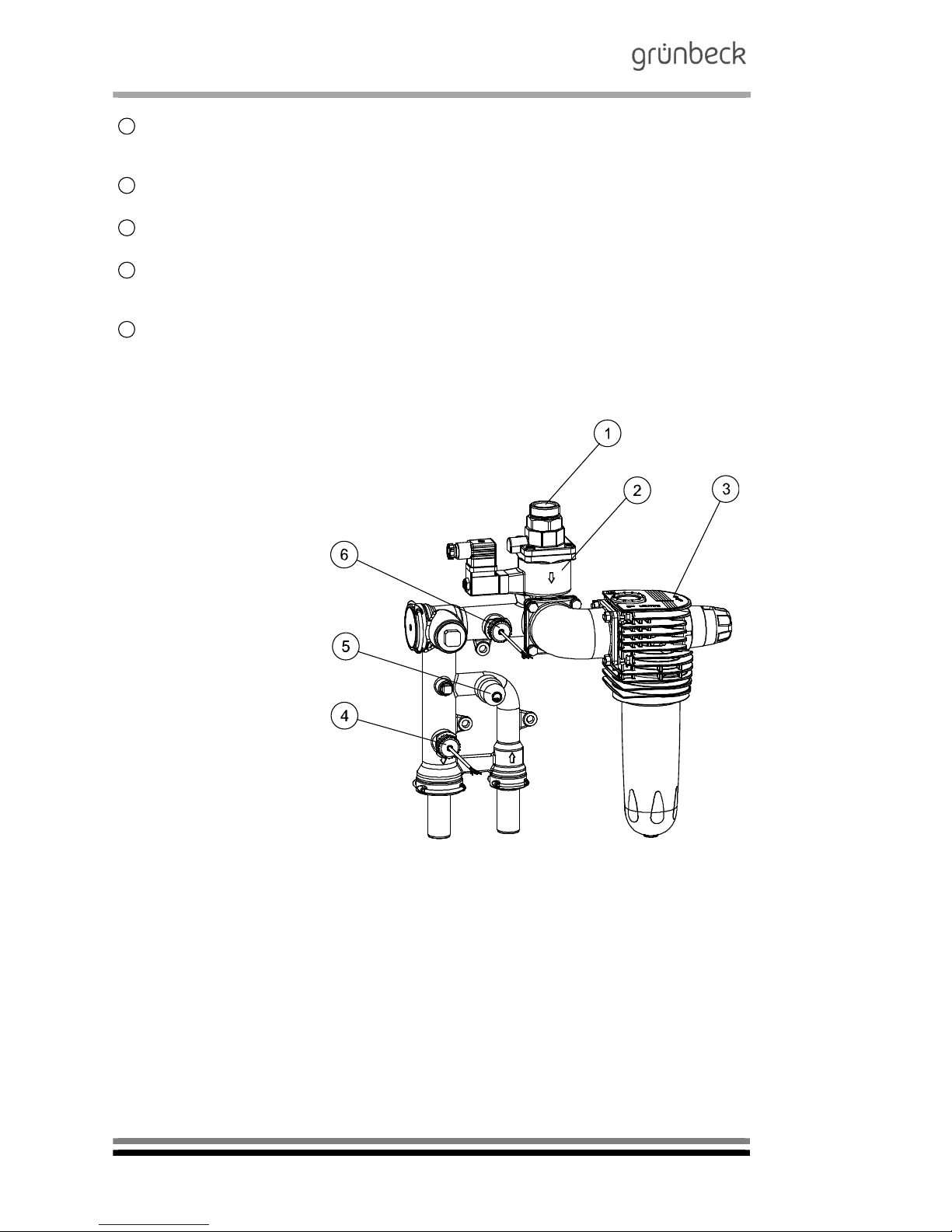

6.4 Wearing parts

Seals and valves are subject to a certain wear and tear. Wearing

parts are listed below.

Note: Although these are wearing parts, we grant a limited warranty period of 6 months.

Solenoid valves, adjusting valves, water meters, seals

Fig. C-7: Hydro module

Face seal of high-pressure pump

Fig. C-8: High-pressure pump

Page 26

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

24

D Installation

1 | General Installation Instructions

The installation site must provide adequate space. Only the left

side (pressure pipes) of the system may be placed flush to the

wall. In front, behind and on the right side of the system, adequate

clearance for installation and service work must be provided

(> 50 cm). A foundation of a sufficient size and adequate load carrying capacity must be provided. The required connections must

be provided prior to the installation. For dimensions and connection data, please refer to table C-1.

1.1 Preliminary work

Unpack all system components.

Check for completeness and soundness.

Place the reverse osmosis system at the designated location.

Note: Also observe the operation manuals that have been supplied with the optional accessories (see chapter C-6.2) for your

system (if applicable).

2 | Water installation

Certain binding rules must always be observed when installing a

reverse osmosis system. Additional recommendations are given

in order to facilitate the handling of the system. The installation

instructions described below are also illustrated in fig. D-1.

Binding rules

The installation of a reverse osmosis system represents a major

interference with the drinking water system. Therefore, only authorised experts may install such systems.

Please observe the local installation guidelines and the gen-

eral regulations.

Install a drinking water filter upstream of the system (e.g.

BOXER K).

A system separator must be installed upstream as well.

Install a water softener upstream.

Mount an activated carbon filter, if necessary (take water

analysis into consideration).

Provide a drain connection (minimum DN 50) to discharge

the concentrate.

Note: If the concentrate is directed to a lifting system, the delivery

rate of the lifting system should at least have the concentrate volume flow indicated in table C-1.

Warning! The installation site must have a floor drain. If no floor

drain is available, an adequate safety device needs to be installed (refer to option C-9).

Warning! In case of a power failure, floor drains with a discharge to a lifting system will be out of operation.

Page 27

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

25

3 | How to connect the system

Remove the protective caps at the feed water, permeate and

concentrate to drain connections of the system.

Connect the feed water.

Connect the concentrate to drain according to DIN 1988 and

install the pipe aeration above system level.

Make the connection between permeate outlet and supply

tanks.

BOXER K 1" drinking water filter

Reverse osmosis system GENO-OSMO-X

System separator GENO-DK 2

Permeate tank with sterile air filter and level sensor

Delta-p water softener

Pressure booster system GENO FU-X 2/40-1 N

GENO-softwatch Komfort

Activated carbon filter AKF

Fig. D-1: Installation drawing

Note: The feed, concentrate resp. permeate pipe provided by

others on site must feature a provision to separate the pipes

(e. g. a screw connection).

Note: The permeate and concentrate pipes have to be made of

corrosion-proof material.

1 6

2 7

3

8

4

5

Page 28

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

26

4 | Electrical installation

As the reverse osmosis system GENO-OSMO-X features a frequency converter for the high-pressure pump, problems with the

residual current circuit breaker installed in the feeder may occur.

We therefore recommend:

Use of an AC/DC sensitive RCCB with a response threshold

of 300 mA.

For the power supply of the system, a power outlet 3 x 400 V /

50 Hz/L/N/PE with a fuse protection of 20 A has to be provided

by others on site.

The aluminium system rack must be connected to the equipotential bonding on-site. The earth wire must have a minimum cross

section of 6 mm² Cu or 10 mm² Al.

The necessary connecting materials (screw, hammer nuts,

washers, etc.) are located in a bag in the system power distributor (see Chapter F-4.1).

The connection to the equipotential bonding is required because

the speed-controlled high-pressure pump has a ground leakage

current of > 10 mA during its designated operation.

4.1 Circuit diagram of power distribution

The power distribution features the mains switch of the

GENO OSMO-X system and is accessible if the

GENO-OSMO-X control unit is flipped downwards. If required,

the entire "production line" (softening + residual hardness monitoring or antiscalant dosing, reverse osmosis, pressure booster

system) can be supplied by the power distribution.

The power line of an antiscalant dosing pump is plugged into the

mains socket of the power distribution in order to be able to

quickly replace it during servicing.

Page 29

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

27

Page 30

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

28

4.2 Connections within the GENO-OSMO-X control unit and the

GENO-tronic operating element:

The following connections are pre-set at the factory and must

not be modified:

Linux operating element

Power supply of programming board

From terminal of circuit board to terminal of programming board

91 +24 V= 8

92 mass 7

Serial connection RS 485

88 RS 485 A 11

89 RS 485 B 10

90 RS 485 GND 9

Fuses of circuit board

F1 T2A Main fuse of power input

F2 T0.63 A 24 V = solenoid valves, step motors

F3 T0.5A Programming board 24 V=

Page 31

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

29

4.3 Connections within the GENO-OSMO-X reverse osmosis system

The following connections are preset internally at the factory and

must not be modified:

From

GENO-OSMO-X

control unit

to component Line Signal

1 Mains switch housing lid H05VV-F 5G1.5 mm² L From mains

switch

2 N

3 L To mains

switch

4 N

PE PE

5 230 V~ feed from

power distribution

RO1E2

38 H05VV-F 3G0.75 mm² L

6 39 N

PE 40 PE

12 Frequency converter

of high-pressure pump

RO1P1A1

1 LiYcY 7x0.25 mm² + 24 V= WH Release FU

13 2 IN BN

56 10 + 24 V= GY Fault signal

FU (

57 11 DI 6 PK

40 6 4-20 mA YE Desired value

FU

41 7 GND GN

PE Shield

20 Feed water solenoid valve

RO1V1

H05VV-F 2x0.5 mm² + 24 V= (clocked for power reduction

21 GND

28 Regulating valve concentrate

to drain

RO1V3

(step motor)

LiYY 7x0.25 mm² (blue

strand is not used)

Ph1 GN

29 Ph1 WH

30 Com1 BN

31 Ph2 PK

32 Ph2 YE

33 Com2 GY

34 Regulating valve concentrate

recirculation KR RO1V2

(step motor)

LiYY 7x0.25 mm² (white

strand is not used)

Ph1 GN

35 Ph1 BU

36 Com1 BN

37 Ph2 PK

38 Ph2 YE

39 Com2 GY

42 Temperature measurement

RO1CT1

LiYcY 4x0.25 mm² Pt 100 BN

43 GN

PE Conductivity measuring cell

RO1CQ1 cell constant 0,1

K= 0.1 1/cm Shield

44 WH

45 YE

46 Conductivity measuring cell

RO1CQ1 cell constant 0,1

LiYcY 4x0,25 mm² K= 0,1 1/cm

47 WH

YE

54 Pressure switch for minimum

pressure RO1CP1

LiYY 2x0.5 mm² + 24 V= WH

55 DI 5 BN

58 Pressure switch for maximum

pressure RO1CP3

LiYY 2x0.5 mm² + 24 V= WH

59 DI 10 BN

73 Feed water flow sensor

RO1CF1

LiYY 3x0.25 mm² +12 V= WH

74 [pulse] GN

75 GND BN

76 Flow sensor Feed

RO1CF2

LiYY 3x0.25 mm² +12 V= WH

77 [pulse] GN

78 GND BN

79 Flow sensor ermeate

RO1CF3

LiYY 3x0.25 mm² +12 V= WH

80 [pulse] GN

81 GND BN

Page 32

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

30

4.4 Connections to other subsystems - system output

From

GENO-OSMO-X

control unit

to component Line Signal Colour

System output Tank

68 Digital signals BB1 for regis-

tration of filling level of pure

water tank BB1CL1

LiYY 5x0.25 mm² +24 V=

69 System OFF BB1CL1

70 System ON / bypass closed BB1CL2

71 Bypass closed / dry run pro-

tection of pressure booster

OFF

BB1CL3

72 Dry-run protection of pressure

booster ON

BB1CL4

Or alternatively

86 Analogue signals BB1 for

registration of filling level of

pure water tank BB1CL1

LiYY 3x0.34 mm² + 24 V= WH

87 IN BN

PE Shield YE-GN

24 RO1 V4 (first permeate)

or

RO1 V7 (blending valve)

H05VV-F 2x0.5 mm² 24 V= BN

25 GND BU

System output Online

84 Pressure measuring transducer

RO1 CP2 0…6 bar

LiYcY 2x0.25 mm² + 24 V= WH

85 In BN

PE Shield

4.5 Connections to other subsystems – Residual hardness monitoring system NX1CQ1

for pre-treatment by water softener

From

GENO-OSMO-X

control unit

to component Line Signal

14 GENO-softwatch Komfort ter-

minals 16/17

LiYY 4x0.25 mm² Com

15 N.O.

66 GENO-softwatch Komfort ter-

minals 8/10 and wire jumper between 7/12

+24 V=

67 DI9

4.5.1 Connections to other subsystems – Residual hardness monitoring system

NX1CQ1 for pre-treatment by water softener (GENO-Softwatch Komfort, from serial no.

40342)

From

GENO-OSMO-X

control unit

to component Line Signal

14 GENO-softwatch Komfort ter-

minals 18/19

LiYY 4x0.25 mm² Com

15 N.O.

66 GENO-softwatch Komfort ter-

minals 10/12 and wire jumper

between 9/14

+24 V=

67 DI9

Page 33

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

31

4.6 Connections to other subsystems – Dosing pump RO1 P2 for antiscalant pre-treatment

From

GENO-OSMO-X

control unit

to component Line Signal Colour Connector

pin

16 Pulse input LiYY 2x0.25 mm² + WH 4

17 - BN 1

63 Signal/fault signal output LiYY 4x0.25 mm² +24 V= WH, BN 1.2

64 Empty/fault signal RO1CL2 YE 3

65 Pre-warning RO1CL1 GN 4

4.7 Connections within the OSMO-X reverse osmosis system – AVRO pre-treatment

RO1B5

From

GENO-OSMO-X

control unit

to component Line Signal

82 AVRO treatment module(s) H05VV-F 2x0.5 mm² + 1

83 - 2

4.8 Connection to other subsystems – Dosing pump RO1P3 in case of pre-treatment by

means of antiscalant

From

GENO-OSMO-X

control unit

to component Line Signal Colour Connector

pin

18 Pulse input LiYY 2x0.25 mm² + WH 4

19 - BN 1

50 Signal/fault signal output LiYY 4x0.25 mm² +24 V= WH, BN 1,2

51 Pre-warning RO1CL3 GN 4

62 Empty/fault signal RO1CL4 YE 3

Page 34

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

32

4.9 Subsystems water softener and/or pressure booster interconnected

via RS485 data line – Connection of terminating resistors

If more than two subsystems are interconnected or if the length

of the line between the two is > approx. 20 m, the so-called terminating resistors have to be connected to the "endpoints". This

is done by means of dip switches. If required as per the following

table, both dip switches have to be set to "ON".

RS485 interconnection between Connection of terminating resistors for

GENO-mat duo WE + GENO-OSMO-X GENO-mat duo WE and GENO-OSMO-X (*)

GENO-OSMO-X + pressure booster GENO-OSMO-X + pressure booster (*)

GENO-mat duo WE-X + GENO-OSMO-X +

pressure booster GENO-FU (HR)-x

GENO-mat duo WE

pressure booster

(*) for line length RS485 > approx. 20 m

OSMO-X:

The terminating resistors are aligned below the sheet covering of

the circuit board

Close to terminal 43 (connection to

GENO-mat duo WE water softener)

Close to terminal 47 (connection to the pressure booster)

IONO-matic WE controller resp. PBS controller:

Close to terminal 36

4.10 Connections to other subsystems – Pre-treatment by water softener

From

GENO-OSMO-X

control unit

to component Line Signal

93 IONO-matic WE

control unit

36 LiYcY 3x0.25 mm² (*)

RS485 A

94 37 RS485 B

95 GND2 GND

4.11 Connections to other sub-systems – Pressure booster installed downstream

From

GENO-OSMO-X

control unit

to component Line Signal

96 Control unit Pres-

sure booster system

GENO-FU (HR)-X

38 LiYcY 3x0.25 mm² (*) RS485 A

97 39 RS485 B

98 GND2 GND

(*) A shielded line is required in case of line lengths of > 20 m. The shield has to be connected on one side

to a free PE terminal.

Page 35

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

33

4.12 Connections to other subsystems – Optional signals or accessories

From

GENO-OSMO-X

control unit

to component Line Signal

7 The signals "collective fault sig-

nal" and "signal with joint control

common" open in case of power

failure or in case of error/signal

Voltage-free each,

max. 230 V~/1 A

Error

8 Signal

9 Joint control

common

10 Programmable output

(volt.-free, max. 230 V~/1 A)

max. 1.5 mm²

11

22 RO1V5 (blending valve)

or

RO1V6 (bypass valve)

RO1V8 (membrane degassing)

Oilflex-O 2x0.5 mm² 24 V= BN

23 GND BU

26 RO1V4 (first permeate)

RO1V7 (blending valve)

27

PE Reserve ----- -------- --------

48

49

52 Release - input max. 1.5 mm² + 24 V

53 DI4

60 Programmable fault signal input max. 1.5 mm² + 24 V

61 DI1

Page 36

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

34

E Start-up

The work described below may only be performed by trained experts. For safety reasons, the start-up must be performed by

Grünbeck's trained and authorised technical customer service/

authorised service company.

Note: Incorrect parameter settings or still missing signal connections may cause malfunctions due to which the flushing of the

preserving agent cannot be started.

1 | How to flush the system

1.1 How to flush off the

preservation agent

For the duration of storage and transport, the membrane(s) is

(are) protected by means of a preserving agent. First of all, this

preserving agent must be flushed off.

After switching on the power supply for the first time, select

the subsystem menu GENO-OSMO-X.

The following pop-up window will appear in the touch display

of the GENO-tronic control unit:

Tap on it.

Page 37

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

35

By tapping on "START", the feed water solenoid valve, the con-

trol valve concentrate to drain and sporadically the control valve

concentrate recirculation open. The preservation agent is

washed out to the drain.

Attention! While the preserving agent is being flushed off, the

system is deaerated at the same time. When skipping or prematurely aborting the step "flushing" and putting the system in operation, there are the following two risks

High-pressure pump is running dry.

The preserving agent gets into the permeate tank or into the

permeate line provided by others on site - these can only be

cleaned/flushed with difficulty.

Note: The flushing of the system can be restarted manually. Refer to chapter F-4.1: To do so, select the operating mode "flushing".

Page 38

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

36

F Operation

1 | Introduction

Note: Instructions in bold are absolutely essential to ensure that

work can continue. All other instructions can be ignored if the

value shown on the display remains unchanged.

Settings in the technical service programming level may only be

performed by Grünbeck's technical customer service/authorised

service company or by persons expressly authorised by Grünbeck.

Warning! Incorrect settings may lead to hazardous operating

conditions which cause injury, illness or damage to property.

The operation manual must be strictly adhered to! Only make

the settings described in there!

2 | Screen layout of the GENO-tronic operating element

2.1 Home screen

The home screen is the superordinate screen for all subsystems

connected to/interconnected with the control unit of the GENOOSMO-X: Here, it is set out from left to right how the water flows

through the individual treatment steps. On the far left, the system

range (cogwheels) for fundamental settings is located.

Lightly tapping on a subsystem provokes a switch-over to the

Info level of the respective subsystem.

Statusline,coloursignalsthe

systemstatus

Systemrange

Subsystemrange

Page 39

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

37

2.2 Info level of GENO-OSMO-X

If the subsystem features an ON/OFF function such as the re-

verse osmosis system OSMO-X, the Info level has an ON/OFF

button, too: Green = subsystem ON, Red = subsystem OFF. With

the Home button, you may return to the Home screen. By pressing on the illustration, you may access the submenu.

The following information is stored in the Info level of the OSMO-X

(can be accessed via arrow keys ^/v):

Operating mode

(locked / flushing / manual operation / automatic)

Permeate flow [l/h]

Current set value for permeate capacity [l/h]

Permeate conductivity [µS/cm]

Permeate recovery [%]

Water temperature [°C]

Service in [d]

AVRO RO1 B5 (only in case of AVRO pre-treatment) [h]

Concentrate to drain [l/h]

Concentrate recirculation [l/h]

Permeate pressure (only for Online version) [bar]

AVRO RO1B5 treatment current

(only in case of AVRO pre-treatment) [mA]

Output of regulating valve RO1V3 [%]

Output of regulating valve RO1V2 [%]

Conductivity of inlet and concentrate (only if optional conduc-

tivity measurement is available) [µS/cm]

Feed water flow [l/h]

Feed flow [l/h]

Analogue signal output to frequency converter [%]

Home button

Operating mode, current measuring values

Access to the

GENO-OSMO X

menu

ON/OFF button

Page 40

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

38

2.3 Change, save, reject parameters

In a menu with permanently stored selections, any

choice (line) can be selected by tapping on it. The

middle line is in slightly larger print, however.

Save your selection with this button.

Quit the menu with this button without changing

the prior selection.

The numerical and the alpha-numerical menu each

feature the same operating logic:

Save your selection with this button.

Quit the menu with this button without changing

the prior selection.

Save your selection with this button.

Quit the menu with this button without changing

the prior selection.

Page 41

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

39

2.4 Acknowledgement of errors/signals

In case of a pending signal or malfunction, the sta-

tus line changes its colour and on the home

screen, the subsystem concerned has a coloured

frame.

Yellow = signal

Red = error

Tap on the status line >>

Switch to error list

The error list may show one or several entries.

Tap on the entry you are interested in >> switch to

the acknowledgement window

Button to return to the Home screen

The acknowledgement window will show an illustration of the subsystem concerned.

Acknowledgement button of the signal/error

Button to call up a help text including the telephone

number of the technical customer service.

Button to return to the error list

The error can either be acknowledged or left pending. In any case, you will get back to the error list.

Acknowledge signal/error

Leave signal/error pending

Page 42

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

40

2.5 Screen saver

The screen saver is displayed automatically if the

screen is not touched for 5 minutes (or after an adjustable period of time).

As soon as the touch screen is tapped on or a signal or an error occurs, the display returns to the

basic display.

3 | System range

3.1 System menu I

System menu I can be accessed without entering a Code. The

parameters stored apply to all systems in case more subsystems

than just the GENO-OSMO-X are present and are operated via

the GENO-tronic operating element.

Page 43

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

41

Note: Prior to removing the SD card, make sure that the data

logging was terminated with "Nein/No"!

Note: The SD card used must be formatted FAT32. We recommend proper formatting instead of quick formatting.

Note: The SD card socket is integrated in the operating element

of the GENO-tronic - to insert the card, the control unit of the

GENO-OSMO-X must be opened.

Parameters Factory

setting

Setting

range

Comment

Operating language German German

English

French

Dutch

Italian

Russian

Spanish

System designation 18 digits, alphanumerical,

text will appear in the upper

left corner of the Home

screen

Date, time Incl. automatic switch-over

from daylight saving time to

standard time

Data logging Start Start/

Stop

All measured values of all

subsystems (Info level) are

logged on the SD card.

Interval [min] 1 ... 999 Indicates the frequency of

how often the measured values are stored on the SD

card

Load parameters Before doing so, load the pa-

rameter record stored on the

SD card

Attention: Do not execute

during permeate production!

Save parameters Save current parameter

record on the SD card

Screensaver [min] 1 0…99

Lock screensaver [sec] 30 10…99

Note: The protective foil over the touch screen may only be

wiped with a damp cloth and a mild soapsuds solution at the

most! Never use cleaning agents for plastics or stronger cleaning agents! Otherwise there is a risk that the foil will assume a

milky colour and therefore be difficult to read!

Page 44

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

42

3.2 Data logging on an SD card

The measured values on the SD card theoretically comprise an

entire "production line", from the softening or anti-scaling dosing)

to the reverse osmosis (electrodeionisation is still not possible at

present) and via the pure water tanks up to the pressure

booster.

The log files are not yet very clear when viewed with a text editor:

It is recommended to open the file with a spreadsheet program

(e.g. MS Excel) so that the structuring is easier to identify.

The system serial number is included in cell B1. The assignment

of all other information can be found in the following table. Unavailable sub-systems should be ignored.

Page 45

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

43

Table F-1: GENO-tronic data logging

Softening NX1 Residual hardness mon-

itoring system NX1CQ1

Dosing 1 P2/P3 Reverse osmosis 1

duo WE (refer to specifications) or Delta-p

Softwatch Komfort or

Softwatch Premium

Grundfos OSMO-X

Remaining capacity

exchanger*

C XX,XX [m³]

Remaining capacity

exchanger**

C XX,XX [m³]

(Delta-p only)

Flow rate

Q XX,XX [m³/h]

Time since last regen-

eration T XXX [h]

Current regeneration step

R (0/1…5)

Time until service is due

S XXX [d]

Regeneration counter

R XXXXXX

Soft water meter

V XXXXXX m³

without data logging

on SD card:

Software version

Softwatch Premium only

Current residual hardness

H XXX,XXXX

hardness unit [°dH, °e, °f,

mmol/l, ppm, mval/l]

Set limit value 1

HL XXX,XXXX

Remaining range of indi-

cator C XXX

(Premium only)

Status (analysis running),

see document „transmission range Softwatch Premium“

Number of analyses until

service is due

S XXX

Softwatch Komfort only

Status (ok/malfunction

)

RO1P2

Estimated range

of dosing chemical V XXXX [m³]

RO1P3

Estimated range

of dosing chemical V XXXX [m³]

Permeate flow

Q XXXX [l/h]

Permeate conductivity

C XX,X [µS/cm]

Recovery

A XX [%]

Water temperature

T XX [°C]

Permeate pressure

p X,XX [bar]

(only for Online system outlet)

Operating mode

(off/operation/flushing/

forced operation/

forced stop/rejection of

first permeate)

Z (0…6)

Flow concentrate to

drain

QKK XXXX [l/h]

Flow concentrate re-

circulation

QKR XXXX [l/h]

AVRO treatment

current

AVR XXX [mA]

(only for AVRO pretreatment,

AVRO+DOS)

Inlet conductivity

CR XXXX [µS/cm]

and concentrate conductivity

CK XXXX [µS/cm]

(only if conductivity

meter in inlet + concentrate active)

Time until service is

due

S XXX [d]

Time until AVRO ser-

vice is due

SAVR XXXX [h]

(only for AVRO pretreatment,

AVRO+DOS)

Page 46

Reverse osmosis system

GENO-OSMO-X

Order no. 134 750 927-inter Edited by: phar/mrie G:\BA-750927-inter_134_GENO-OSMO_X.docx

44

Continuation of table F-1: GENO-tronic data logging

Electrodeionisation

EDI1

Pure water tank

BB1

Pressure booster

DEA1P1/P2

Reverse osmosis

1 Permeate stage

EDI – deferred until EDI

receives the hardware

of the OSMO-X

Single or twin pres-

sure booster (see

specifications)

OSMO-X

Diluate flow

Q XXXX [l/h]

Diluate conductivity

C X,XX [µS/cm] or