Page 1

Reverse Osmosis System

GENO

®

-OSMO RO 125K

,

Operation Manual

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Edition March 2014

Order no. 195 752 940 - inter

GrünbeckWasseraufbereitung GmbH

Josef-Grünbeck-Strasse 1

89420 Hoechstaedt/Danube · GERMANY

Phone +49 9074 41-0 · Fax +49 9074 41-100

www.gruenbeck.com · info@gruenbeck.com

A company certified by TÜV SÜD

in accordance with DIN EN ISO 9001, DIN

EN ISO 14001, DIN EN ISO 13485 and SCC

Page 2

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

2

Table of contents

This operation manual consists of several parts as shown in the table

below.

A General

5

1 Preface

2 Warranty

3 How to use this manual

4 General safety information

5 Shipping and storage

6 Disposal of used parts and materials

B Basic information 9

1 Laws, guidelines, standards

2 Water

3 Functional principle of reverse osmosis

C Product description 11

1 Type designation plate

2 Functional description

3 Designated application

4 Application limits

5 Scope of supply

D Installation 22

1 General installation instructions

2 Preliminary works

3 System connection on water side

E Start-up 28

1 System rinsing

F Operation 32

1 Preface

2 How to operate the control unit

3 Programming levels

4 How to operate the reverse osmosis

G Troubleshooting

41

H Maintenance and care

43

1 Basic information

2 Inspection (functional check)

3 Maintenance

4 Operation log (checklist for maintenance work)

Page 3

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

3

Publisher’s information

All rights reserved.

Copyright by Grünbeck Wasseraufbereitung GmbH

Printed in Germany

Effective with the date shown on the cover sheet.

– We reserve the right to modification, especially with regard to technical

progress -

Reprints, translations into foreign languages, electronic storage or copying

only with written approval of Grünbeck Wasseraufbereitung GmbH.

Any type of duplication not authorised by Grünbeck Wasseraufbereitung is a copyright violation and subject to legal action.

Responsible for contents:

Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Strasse 1 89420 Hoechstaedt/Germany

Phone +49 9074 41-0 Fax +49 9074 41-100

www.gruenbeck.de service@gruenbeck.de

Printed by: Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Strasse 1, 89420 Hoechstaedt/Germany

Page 4

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

4

EC Declaration of Conformity

This is to certify that the system designated below meets the safety and health requirements of the

applicable European guidelines in terms of its design, construction and execution.

If the system is modified in a way not approved by us, this certificate is void.

Manufacturer: Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Strasse 1

89420 Hoechstaedt/Germany

Responsible for documentation: Markus Pöpperl

System designation: Reverse osmosis system GENO®-OSMO RO 125K

System type: TL; TS

System number: Refer to type designation plate

Applicable EC guidelines: EC Machine Guideline (2006/42/EC)

EC Guideline EMV (89/336/ECC version 92/31/ECC)

Applied harmonized standards, in

particular:

DIN EN ISO 12100 - 1, DIN EN ISO 12100 - 2

DIN EN 61000-6-2, DIN EN 61000-6-3,

9

th

Guideline on Device and Product Safety

(Machine Guideline – 9. GPSGV)

1st Guideline on Device and Product Safety

(Ordinance on the Marketing of Electrical Operating Materials

to be used within specific voltage limits – 1. GPSGV)

Applied national standards and

technical specifications,

in particular:

DIN 1988

DIN 31000/VDE 1000 (03.79)

Date/Signature of

manufacturer:

12.08.11 i. V.

M. Pöpperl

Dipl. Ing. (FH)

Function of signatory: Head of Engineering Department for Serial Products

Page 5

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

5

A General

1 Preface

Thank you for opting for a Grünbeck product. Backed by decades of

experience in the area of water treatment, we provide solutions for all

kind of processes.

Drinking water is classified as food and requires particular care. Therefore,

always ensure the required hygiene in operating and maintaining systems

for drinking water treatment. This also applies to the treatment of water

for industrial or domestic use if repercussions for the drinking water cannot

completely be excluded.

All Grünbeck systems and devices are made of high-quality materials.

This ensures reliable operation over many years, provided you treat the

systems with the required care. This operation manual assists you with

important information. Therefore, read the complete manual before

installing, operating or maintaining your system.

Customer satisfaction is our prime objective and providing customers

with qualified advice is crucial. If you have any questions concerning this

system, possible extensions or general water and waste water treatment, our customer service staffs, as well as the experts at our headquarters in Hoechstaedt, are available to help you.

Advice and assistance

For advice and assistance please contact your local representative (refer

to www.gruenbeck.com ) or get in touch with our service centre which

can be reached during office hours:

Tel.: +49 9074 41-333

Fax: +49 9074 41-120

Email: service@gruenbeck.de

We can connect you with the appropriate expert more quickly if you

provide the required system data. In order to have this data handy at all

times, please copy it from the type designation plate to the overview on

page C-11.

Page 6

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

6

2 Warranty

All devices and systems supplied by Grünbeck Wasseraufbereitung

GmbH are manufactured according to the most recent technical standards and subjected to a comprehensive quality assurance system. All

warranty claims are subject to our General Terms and Conditions:

Terms and Conditions of Sale and Delivery (excerpt)

. . . . . . . .

11. Warranty

a) If goods and services are supplied which are obviously

defective, the Customer must report such defects

within 8 (eight) days after receipt of such goods and

services in order to maintain the liability claims.

b) If the defect is of such a nature that only a spare part

needs to be replaced, Grünbeck shall have the right to

request the Purchaser to replace the new part delivered by us if the costs for sending a technician to the

Purchaser's site are unreasonably high.

c) The warranty periods are:

- two years: for devices for private use (natural persons)

- one year: for devices for industrial or commercial

use (companies)

- two years: for all DVGW-certified devices, also for

industrial or commercial use within the framework

of the liability agreement with the ZVSHK.

after delivery/acceptance. This excludes electrical parts

and parts which are subject to wear and tear. The

warranty period shall only apply if the operating instructions are observed meticulously, if the device is

mounted, commissioned, operated and maintained

properly, and/or if a maintenance contract is made

within six months. If these requirements are not met,

the warranty shall be void. The warranty shall be void

if the purchaser uses dosing agents or chemicals supplied by other manufacturers and if the quality and

composition of such dosing agents or chemicals is beyond Grünbeck's control.

Grünbeck shall not be liable for defects or damage

resulting from inept handling or operation.

d) Grünbeck shall only be liable if the Customer performs

the maintenance work as stated in the operating instructions or has the maintenance work performed in

such a way and if the Customer uses spare parts supplied or recommended by Grünbeck.

e) Grünbeck shall not be liable for damage resulting from

frost, water or electrical over-voltage or from parts

which are subject to wear and tear. This applies in particular to electrical parts.

f) The claims of the Purchaser are limited to repair or

replacement, as the case may be, at the discretion of

Grünbeck. Grünbeck shall have the right to several attempts to repair. If Grünbeck fails to repair or re-place

the defective delivery within a reasonable time, the

customer shall have the right to either cancel the contract or demand an appropriate reduction of the purchase price.

g) In case of complaints with regard to systems that are

not installed in Germany, the warranty claim will be

settled by the local technical customer service authorised by Grünbeck. If no technical customer service is

designated in the specific country, the assignment of

Grünbeck’s technical customer service shall end at the

German border. All additional cost, apart from the material required, shall be borne by the customer.

. . . . . . . .

Page 7

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

7

3 How to use this operation manual

This operation manual is intended for the operators of our systems. It is

divided into several chapters (a letter is assigned to each of them) which

are listed in the Table of Contents on page 2 in alphabetical order. In

order to find the specific information you are looking for, check for the

corresponding chapter on page 2.

The headers and page numbers with chapter information make it easier

to find your way around in the manual.

4 General safety information

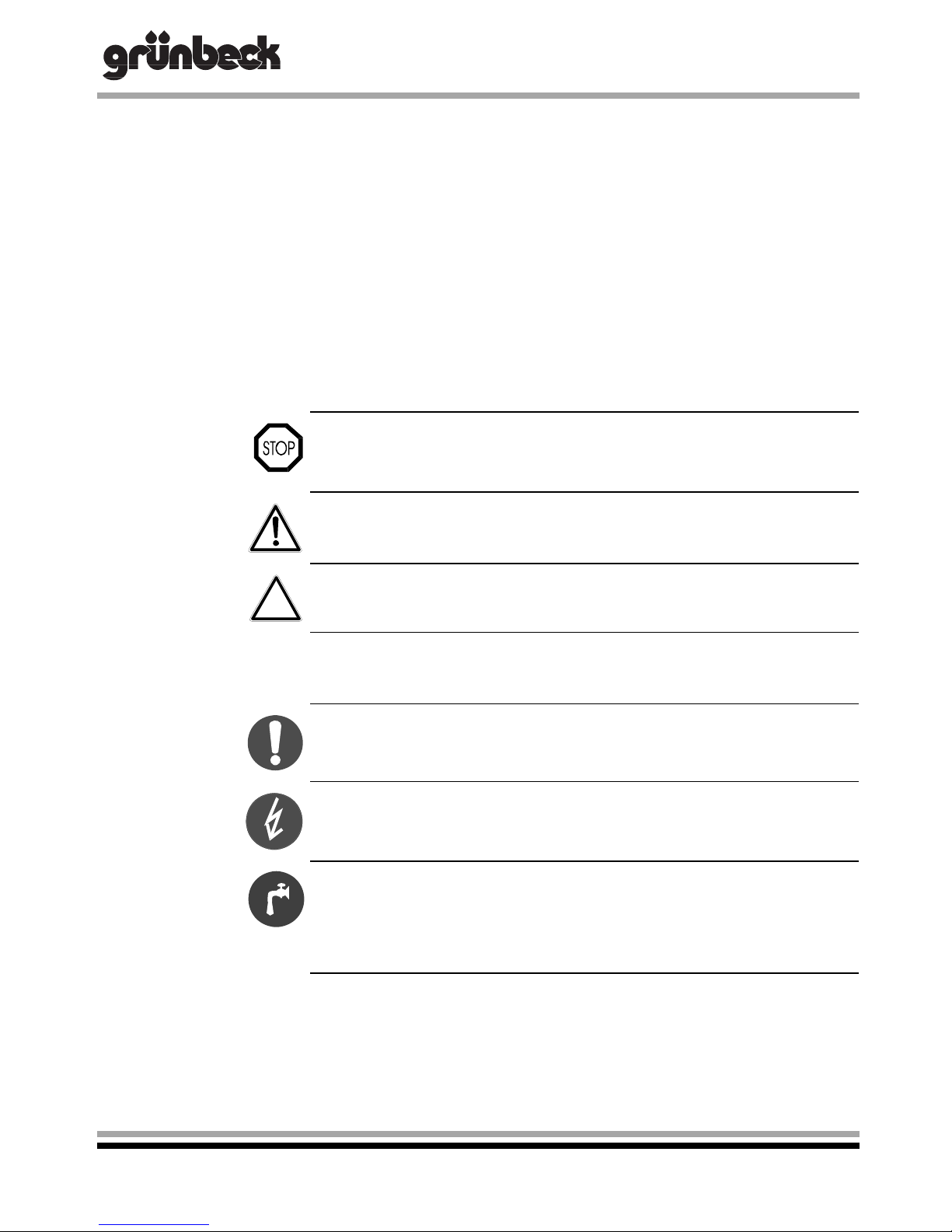

4.1 Symbols and

notes

Important notes in this operation manual are characterised by symbols.

Please pay particular attention to these notes in order to ensure a danger-free, safe and productive system operation.

Danger! Failure to adhere to these notes will cause serious or lifethreatening injury, extreme damage to property or inadmissible contamination of drinking water.

Warning! Failure to adhere to these notes may cause injury, damage to

property or contamination of the drinking water.

Attention! Failure to adhere to these notes may result in damage to

the system or other objects.

Note: This symbol characterises notes and tips to make your work easier.

Tasks with this symbol may only be performed by Grünbeck's technical

service or by persons expressly authorised by Grünbeck.

Tasks with this symbol may only be performed by qualified electrical

experts according to the VDE guidelines or according to the guidelines

of a similar local institution.

Tasks with this symbol may only be performed by water companies or

approved installation companies. In Germany, the installation company

must be registered in a water company installation directory as per

§12(2) AVBWasserV (German Ordinance on General Conditions for the

Supply of Water).

4.2 Operating

personnel

Only persons who have read and understood this operation manual are

permitted to work with the system. The safety guidelines are to be

strictly adhered to.

Page 8

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

8

4.3 Designated

application

The system may only be used for the purpose outlined in the product

description (chapter C). The guidelines in this operation manual as well

as the applicable local guidelines concerning the drinking water protection, accident prevention and occupational safety must be adhered to.

In addition, appropriate application also implies that the system may

only be operated when it is in proper working order. Any malfunctions

must be repaired at once.

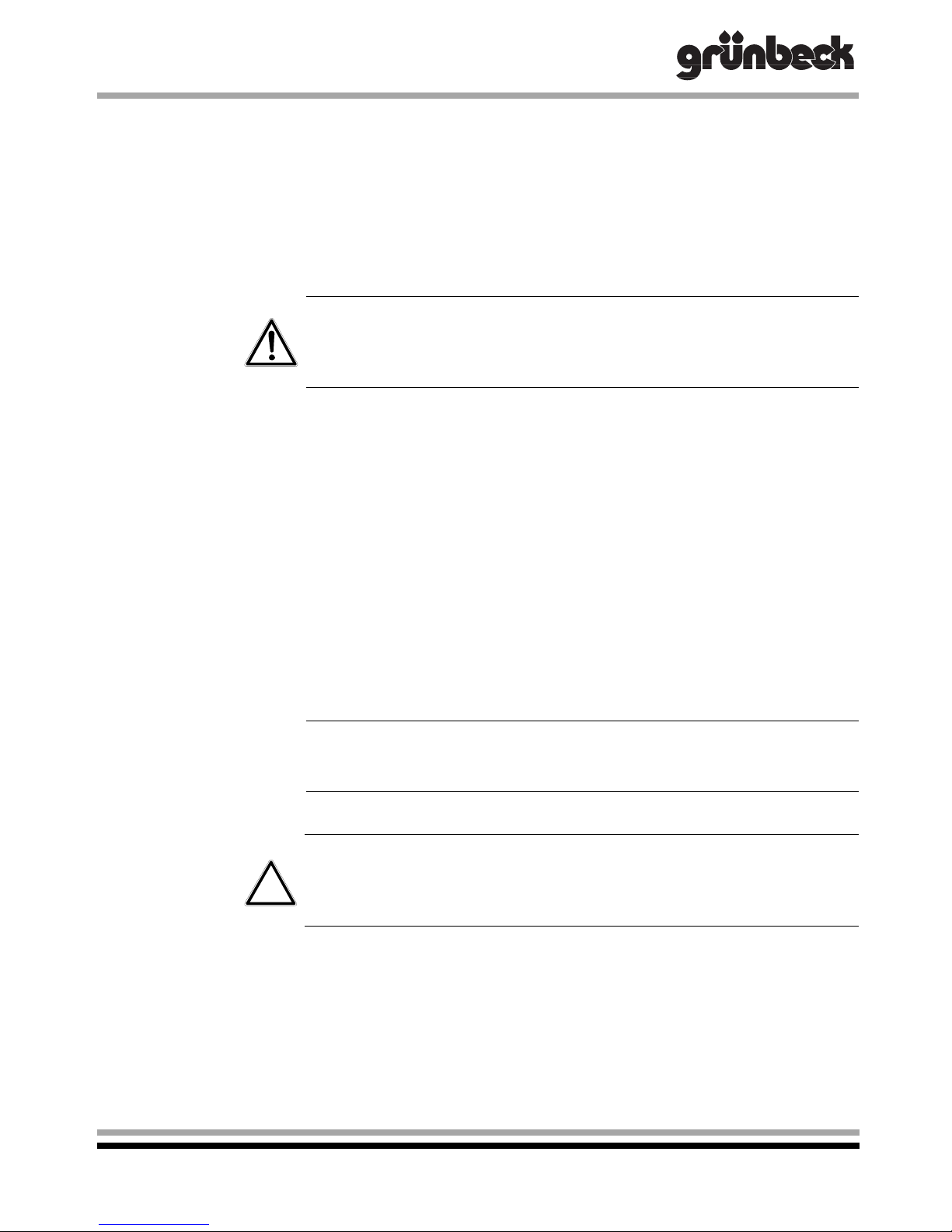

4.4 Protection from water damage

Warning!

In order to properly protect the installation site from water damage:

a) a sufficient floor drain system must be available or

b) a safety device (see chapter C Optional equipment) must be in-

stalled.

4.5 Indication of

specific dangers

Danger due to electricity! Do not touch electrical parts with wet

hands! Disconnect the system from mains before starting work on electrical parts of the system. Have qualified experts replace damaged cables

immediately.

Danger due to mechanical energy! System parts may be subject to

overpressure. Danger of injury and damage to property due to escaping

water and unexpected movement of system parts. Check pressure

pipes regularly. Depressurise the system before starting repair or

maintenance work on the system.

Hazardous to health due to contaminated drinking water! The system may only be installed by a qualified company. The operation manual must be strictly adhered to! Ensure that there is sufficient flow. The

pertinent guidelines must be followed for starting-up after long periods

of standstill. Inspections and maintenance must be performed at the

intervals specified!

Note: By concluding a maintenance contract, you ensure that all of the

required tasks are performed on time. You may perform the interim inspections yourself.

5 Shipping and storage

Attention! The system may be damaged by frost or high temperatures.

In order to avoid damage of this kind:

Protect from frost during transportation and storage! Do not install or

store system next to objects which radiate a lot of heat.

6 Disposal of used parts and materials

Used parts and materials are to be disposed of, or made available for

recycling purposes, according to the applicable local guidelines.

If a material is subject to specific regulations, adhere to the notes indicated on the packing.

If in doubt, contact your local waste disposal authority or the manufacturer for more information.

Page 9

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

9

B Basic information (reverse osmosis system)

1 Laws, guidelines, standards

In the interest of good health, rules cannot be ignored when it comes to

the processing of drinking water. This operation manual takes the applicable German guidelines into account and provides all the information

you need to safely operate your water treatment system.

Among other things, the regulations stipulate

that only approved companies are permitted to make major modifica-

tions to water supply systems.

and that tests, inspections and maintenance on installed devices are

to be performed at regular intervals.

2 Water

In nature, chemically pure water does not exist. Rain water already takes

up various substances from the air which change the properties of the

water to a larger or lesser extent. This process continues while the water

flows through the ground layers and takes up increasing amounts of

substances. In this context, carbon dioxide (CO2) is of major importance

as this substance further increases the dissolving power of the water.

Consequently, the concentrations of dissolved sodium, potassium, calcium, magnesium, iron, manganese, copper, zinc, chlorides, fluorides, sulphates but also nitrates, nitrites, phosphates and silicates contained in

the drinking water differ regionally.

For many decades, the ground water has been polluted with substances

originating from agricultural, industrial and other sources. As these pollutants can only be degraded over long periods of time, increasingly sophisticated technologies are required to remove high salt concentrations, hydrocarbons, nitrates, pesticides, heavy metals, etc.

The water works supply clean drinking water that is suitable for consumption. However, if the water is to be used for technical purposes,

further treatment is frequently required.

Page 10

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

10

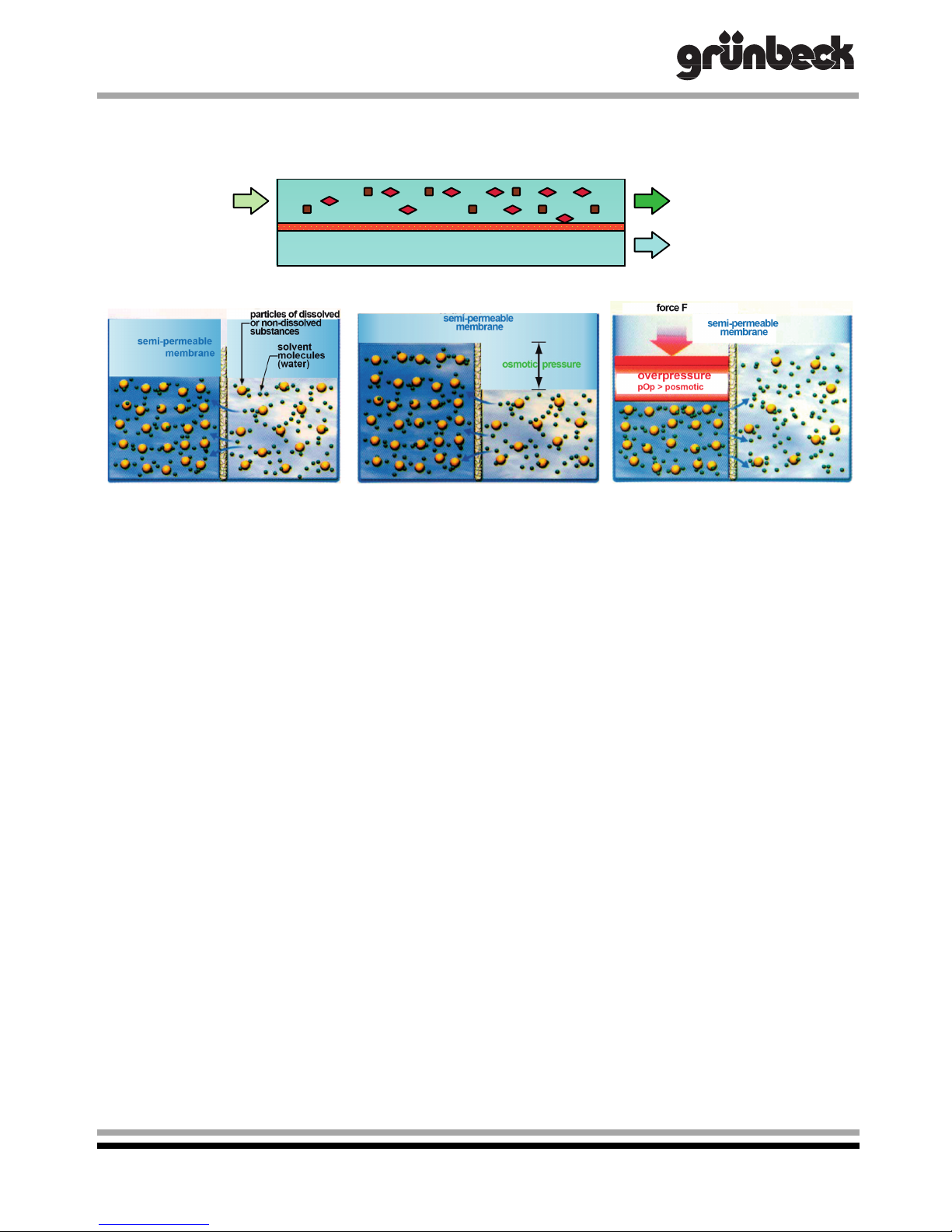

3 Functional principle of reverse osmosis

Principle:

Pre-treated feed

water

Fig. B-1: Functional principle

Concentrate:

Permeate

High concen-

tration solution

Low concentration

solution

High concen-

tration solution

Low concentration

solution

High concen-

tration solution

(concentrate)

Low concentration

solution

(permeate)

Fig. B-2: Principle of reverse osmosis

In the osmosis process, watery solutions of different concentrations are

separated by means of a semi-permeable membrane. In keeping with the

law of nature, the concentrations try to equalize. On the side of the higher

original concentration, the so-called “osmotic” pressure is generated. In

the case of reverse osmosis, this osmotic pressure is countered by a higher

pressure. The consequence: The process proceeds in the reverse direction.

A particular advantage of the reverse osmosis technology compared to

other water treatment procedures is the fact that in addition to the removal of dissolved salts, also bacteria, germs, particles and other dissolved organic matter are reduced.

Page 11

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

11

C Product description (GENO®-OSMO RO 125K)

1 Type designation plate

The type designation plate is located at the housing of the reverse os-

mosis system GENO®-OSMO RO 125K. Please specify the data shown on

the type designation plate in order to be able to faster proceed your

inquiries or orders. Simply copy the information from the type designation plate to the form below so that all the required information is available when needed.

Reverse osmosis system GENO®-OSMO RO 125K

125K- Serial no.: /

Order no.:

Fig. C-1: Type designation plate

2 Functional description

Downstream of the fine filter 5 μm, the pre-treated feed water is guided

to the valve control unit. A high-pressure pump then brings the feed

water to the pressure required for the osmotic membrane to begin functioning. The RO membrane separates the water into the partial streams

of permeate and concentrate. The permeate water is directed to a UVinsensitive reservoir made of PE. The concentrate partial stream is re-fed

to the membrane by means of a circulation line via the high-pressure

pump and thus increases the recovery and the economic efficiency of

the reverse osmosis system GENO

®

-OSMO RO 125K and ensures an

even flow off on the membrane. A small part of the concentrate, containing the water soilage retained by the membrane, is run into the

sewage system.

Page 12

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

12

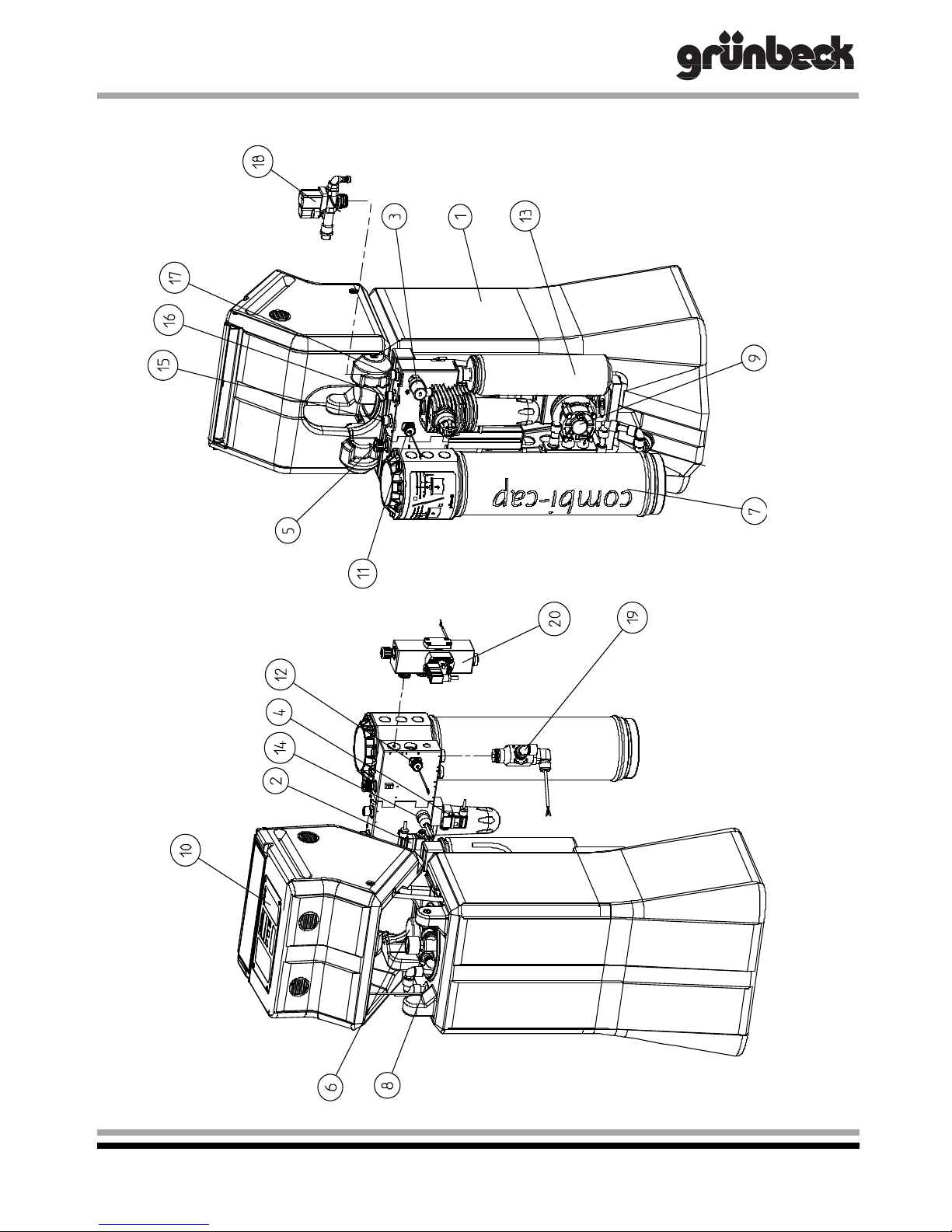

2.1 System components

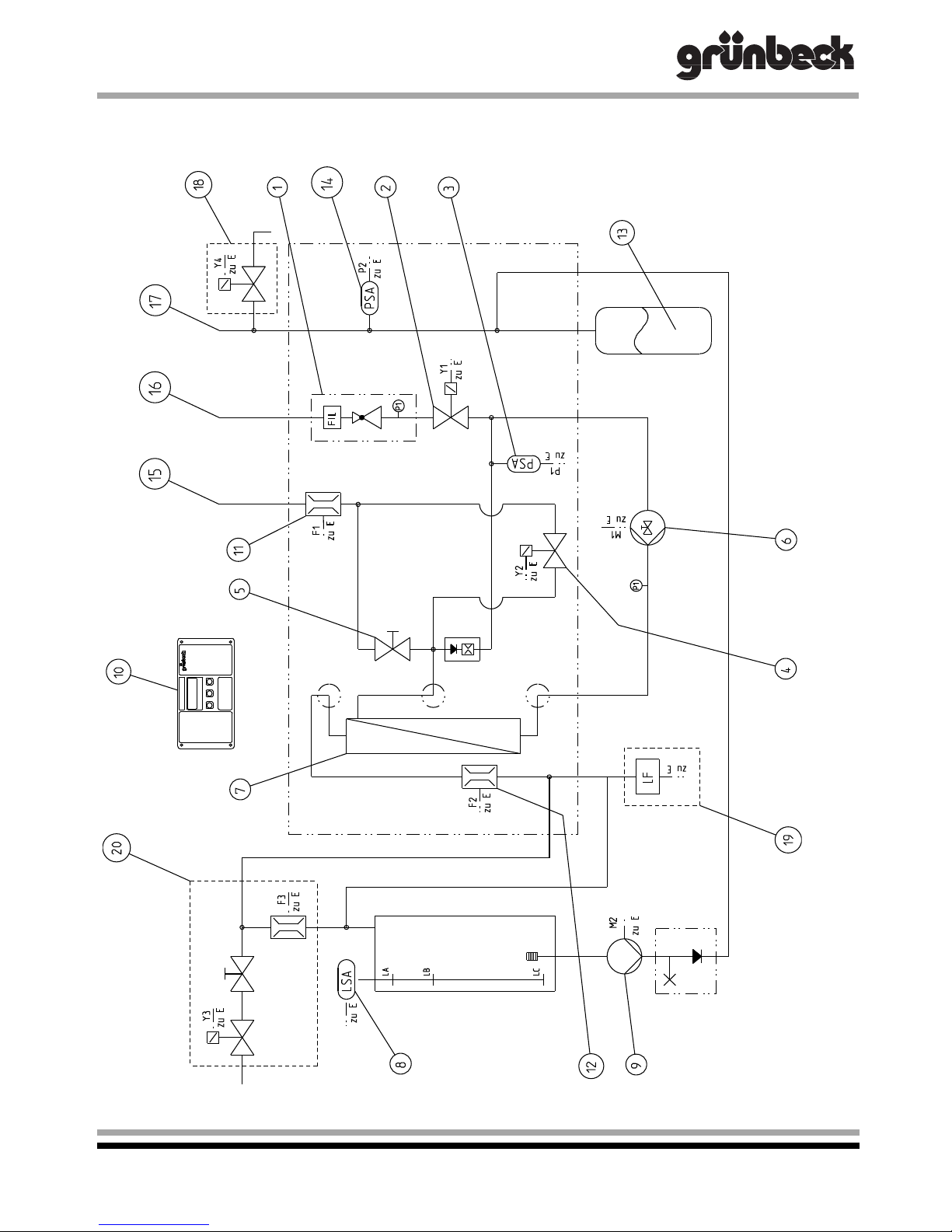

Fig. C-2: Components of reverse osmosis system GENO

®

-OSMO 125K-TS

Page 13

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

13

1

5 μm fine filter

incl. pressure reducer

Pressure reducer is preset to 2.5 bar, incl. pressure gauge.

2

Inlet solenoid valve

During the production of permeate, this valve is always open. When the

system stops (tank full), the valve remains open for the set membrane

rinsing time. Visual indication in control electronics

10

.

3

Pressure switch

High pressure pump

To prevent the high pressure pump from running dry. It switches time-delayed after

the solenoid valve

2

has opened. Visual indication in control electronics10.

4

Rinsing solenoid valve

This valve opens for a set period of time after the level control

8

in the

tank signals "FULL" to the control electronics. The valve also opens in

case of malfunctions and always in connection with the inlet solenoid

valve

2

.

5

Needle valve

Concentrate

To set the feed water dependent volume flow of “concentrate” to the

drain. During permeate production, this amount of water is always discharged to the drain.

6

High pressure pump Pump aggregate that generates the operating pressure required for the mem-

brane. Pump starts operation upon permeate demand by the level control

8

(LB

switches) in the permeate tank. A control valve to set the operating pressure is

integrated in the pump head. Visual indication in control electronics

10

.

7

Membrane Reverse osmosis membrane for the production of permeate.

8

Level control Float level control for regulating the water level in the permeate supply tank

(only TS version).

9

Pressure booster pump Pressure booster pump with integrated pressure switch. Delivers permeate

to the consumer network (only TS version).

10

Control electronics The microprocessor controller and the corresponding aggregates regulate

the permeate production and the supply of the downstream consumers.

11

Flow sensor

Concentrate

Measures the concentrate volume and supplies the control electronics with

pulses. Visual indication of the concentrate volume in the control electron-

ics

10

.

12

Flow sensor

Permeate

Measures the permeate volume and supplies the control electronics with

pulses. Visual indication of the permeate volume in the control electron-

ics

10

.

13

Membrane expansion

vessel

Permeate buffer to reduce the switching cycles of the pressure booster

pump

14

Pressure switch

Pressure booster pump

Switches the pressure booster on when water is withdrawn and off after

water withdrawal has been completed.

15

Connection ½“ (DN 15) MT Concentrate to drain

16

Connection ½“ (DN 15) MT Feed water

17

Connection ½“ (DN 15) MT Permeate/consumer

18

Option: Solenoid valve for forced withdrawal

19

Option: Conductivity measurement

20

Option: Blending device

Page 14

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

14

2.2 Flow chart of reverse osmosis system GENO®-OSMO-RO 125k

Fig. C-2.1: Flow chart of reverse osmosis GENO

®

-OSMO RO 125K-TS (for corresponding legend, please refer to previous page)

Page 15

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

15

Table C-1: Technical specifications Reverse osmosis system GENO®-OSMO RO

125K-TS 125K-TL

Connection data

Nominal connection diameter for feed water inlet

½“ (DN 15) male thread

Nominal connection diameter for permeate outlet

½“ (DN 15) male thread

Nominal connection diameter for concentrate outlet

½“ (DN 15) male thread

Required drain connection min.

[DN] 50

Connected electrical load approx.

[kW] 0.85 0.50

Power supply, approx.

[V/Hz] 230 V / 50 Hz

Protection

IP 54

Performance data

Permeate volume at feed water temperature of

10° C / 15 °C

[l/h] 105/125

Electrical pump capacity at operating pressure

[kW] 0.37

Daily permeate volume (max. 24 h) approx. min./max.

[m³/d] 2.5/3.0

Inlet flow pressure of feed water, min.

[bar] 2.5

Permeate supply, approx.

[l] 38 -

Hydraulic capacity pressure booster max.

[l/h/bar] 900/3.8 -

Pump capacity curve – pressure booster [l/h/bar] 170/4.0 – 250/3.7 Nominal pressure

PN 16

Salt retention

95-99%

Total salt concentration in feed water, as NaCl max.

[ppm] 500

Concentrate volume flow, min./max. (at 15 °C)

[l/h] 40/125

Feed water volume flow (fresh water at 15 °C)

at a recovery of 75 %, max.

[l/h] 160

Recovery min./max.

[%] 50-75 (adjustable)

Dimensions and weights

Dimensions w x d x h [mm] 450 x 430 x 1120

Empty weight, approx. [kg] 37 30

Operating weight, approx. [kg] 75 30

Ambient data

Feed water temperature min./max. [°C] 10/30

Ambient temperature, min./max. [°C] 5/35

Order no. 752 100 752 110

Page 16

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

16

3 Designated application

The reverse osmosis system GENO®-OSMO RO 125 K is designed to de-

mineralise feed water. The water is primarily used for industrial applications.

The system may only be used after a prior water analysis and an appropriate pre-treatment of the water have been performed.

The continuous permeate capacity of the system depends on the temperature. It was defined at a temperature of 15°C. In case of an increasing resp. decreasing feed water temperature, the permeate output may

decrease (decreasing temperature) or increase (increasing temperature)

by up to 3 % per °C.

The system is adapted to the permeate requirements to be expected at

the installation site. It is not suitable for strongly deviating output.

The system may only be operated if all components are installed properly. You MUST NOT remove bridge or in any other way tamper with safety devices.

The designated application of the system also implies that the information contained in this manual and all safety guidelines applying at the

installation site be observed. Finally, the system must be maintained and

inspected at the specified intervals.

4 Application limits

The upper limit values concerning substances in the water as stipulated

by the German Drinking Water Ordinance constitute the application limits for the reverse osmosis system GENO®-OSMO RO 125 K.

< 22°dH (39,2° f; 3,96 mmol/l) without water analysis

Free chlorine, unverifiable)

Iron < 0.2 mg/l

Manganese < 0.05 mg/l

Silicic acid < 15 mg/l

Chlorine dioxide, unverifiable

Turbidity < 1 TE/F

Silt density index < 3

pH range 3 - 9

Note: The permeate produced by the reverse osmosis system is no

drinking water. If it is to be used as drinking water, additional treatment

is required (blending, hardening).

Page 17

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

17

5 Scope of delivery

5.1 Standard

equipment

Free-standing casing made of photo-resistant PE for the integration of

all aggregates and control elements. The casing also serves as supply

tank (only in case of GENO®-OSMO RO 125 K-TS).

Microprocessor controller with LC display, volt.-free collective fault

signal and volt.-free signal contact (maintenance intervals, various

pre-alarms), integrated in the free-standing casing.

Sliding vane rotary pump made of corrosion-resistant brass with mo-

tor as high pressure pump to supply the membrane, incl. control valve

for operating pressure and pressure gauge.

1)

External pressure booster pump with integrated pressure switch and

membrane connection tank for permeate supply of consumers downstream

Hydro distribution block for the water supply within the membrane

system. Integrated valves and measuring instruments for an easier system adjustment.

The hydro module features a 5 μm fine filter with integrated pressure

reducer that is preset to 2.5 bar

Ultra-low pressure reverse osmosis membrane, installed in a pressure

pipe made of high-duty PE

Flow sensor for measuring the volumes of the permeate and concen-

trate flows

Operation manual

1)

only in case of GENO®-OSMO RO 125 K-TS

5.2 Optional equipment

Note: It is possible to retrofit existing systems with optional components. Please contact your local Grünbeck representative or Grünbeck’s

headquarters for details.

Connection block for GENO

®

-OSMO-RO 125K

Connection block (installation length 190 mm).

Permeate-resistant, incl. two shut-off valves -

suitable for connection set

752 840

Connection set for GENO

®

-OSMO 125K

2 flexible connection hoses DN 15

(l = 600 mm) for feed water and permeate

1 drain hose for concentrate

752 830

Page 18

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

18

Conductivity meter for

GENO®-OSMO RO 125K

As plug-on circuit board for the control elec-

tronics. Indication at the display with limit value

and delay incl. connection line and conductivity

measuring cell, installed in combi-cap pressure

pipe.

752 820

Solenoid valve forced withdrawal for

RO 125K

Solenoid valve adaptable to permeate outlet of

hydro module for forced withdrawal from the

tank of the GENO

®

-OSMO RO 125K in case of

longer periods of standstill. Electrically triggered

by the control electronics of the GENO

®

-OSMO

RO 125K.

752 810

Blending unit for GENO

®

-MSR system 200

Control unit adaptable to hydraulic unit GENO®OSMO RO 125K consisting of:

Connection G ¾ for feed water, solenoid valve;

needle valve, flow sensor to display the total

blended water in the control electronics GENO®OSMO RO 125K, connection available for

blended water in GENO®-OSMO RO 125K

and/or tank (provided by others)

752 800

Fine filter BOXER

®

K 1”

80 μm cartridge fine filter for pre-filtration

101 210

Euro system separator GENO

®

-DK 2 Mini

To protect the water supply system from installations and systems endangering the drinking

water, as per DIN 1988 part 4 (DIN EN 1717)

GENO®-DK 2 Mini.

133 100

Water softener Weichwassermeister

GSX 10 I in industrial design

Twin softening unit for alternating operation,

with connection block and flexible connection

hoses.

187 350

GENO

®

-softwatch Komfort

for automatic monitoring of the residual/total

hardness (water hardness).

172 500

Page 19

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

19

GENO®-activated carbon filter AKF 250

To reduce the chlorine concentration in the water.

109 010

GENO-STOP

®

for optimum protection from

water damage.

The new safety device GENO-STOP® provides reliable and comprehensive protection from water

damage. The GENO-STOP® can be equipped

with up to 2 wired water sensors and 5 wireless

water sensors.

GENO-STOP

®

1“

For additional models, please inquire.

126 875

Pure water tank for the intermediate stor-

age of the unpressurised permeate from

the GENO® reverse osmosis systems

Tank version:

All tanks are pre-assembled and feature a PVC

overflow pipe as well as connections for permeate inlet and suction line of pressure booster

system. Grey PE. Hand hole with removable

screw lid and external level control system

GENO®-Multi Niveau (switching level).

Basic pure water tank RT “sterile”, com-

plete Usable volume approx. 850 l

l 780 / w 990 / total height 2000 mm*

712 400

Additional tank RT for basic pure water

tank Usable volume approx. 850 l

l 780 / w 780 / total height 2100 mm*

712 405

Basic pure water tank RT “standard”

Usable volume approx. 850 l

l 780 / w 1000 / total height 2050 mm**

712 410

* Tank height incl. connection pieces; for larger tanks, please inquire

** No sterile overflow as siphon – overflow de signed as down-pipe

Additional tank, level control and overflow loop

not included, 2 connection pipes included, inside

diameter =36 mm.

Note: A maximum supply battery of 4 tanks may be realised.

Page 20

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

20

Pressure booster system

GENO® FU 2/40-1 N 10

Compact, pressure-controlled pump aggregate,

consisting of a centrifugal pump, completely

made of stainless steel as well as integrated pressure and flow sensor for pump control and an integrated dry run protection. Special version to

deliver permeate.

Delivery rate: max. 1.2 - 4.2 m³/h

Delivery height: max. 18.2 – 45.6 m

Power supply: 230 V / 50 Hz

Connected load: 1 kW

Connections: DN 25 / DN 32

Protection: IP 55

730 505

Pressure booster system

GENO® FU 2/40-2 N 10

As for single pressure booster system, however,

featuring the possibility for a time/load switchover

730 515

Switch cabinet

for time/load switch-over in case of

GENO®-FU 2/40-2 N 10

730 375

Rotary power switching point (1.25-5A)

1)

Power unit for single pressure booster

972 20 550

AC power switching point (2.2 kW)

1)

Power unit for single pressure booster

212 254

1)

Level control - to be provided by others on site – for

dry-run protection in permeate tank is required.

5.3 Consumables

To ensure reliable system operation, only genuine consumables should

be used.

GENO

®

-replacement filter element 5 μm

with protective cylinder

Packing unit: 2 pcs

103 061

Reverse osmosis membrane with seal

Packing unit: 1 pc

720 290

Water test kit „Total hardness“

1 pc

10 pcs

170 145

170 100

Page 21

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

21

5.4 Wearing parts

Seals and valves are subject to a certain wear and

tear. Wearing parts are listed below.

Note: Although these are wearing parts, we grant a limited warranty of

6 months. The same applies for electrical components.

a) Solenoid valves, regulating valves, concentrate, seals

b) High pressure pump

Fig. C-3: Valves Fig. C-4: High pressure pump

Page 22

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

22

D Installation (GENO®-OSMO RO 125K)

1 General installation information

The installation site must provide adequate space. A foundation of suffi-

cient size and load carrying capacity must be provided. The required

connections must be provided prior to the installation of the system.

Please refer to table C-1 for dimensions and connection data.

Note: When installing systems with optional equipment (refer to chapter C, 5.2), you must also observe the operation manuals supplied with

such equipment.

1.1 Sanitary

installation

When installing the reverse osmosis system GENO

®

-OSMO RO 125K,

certain rules MUST always be observed. Additional recommendations

facilitate your work with the system. The installation instructions described herein are illustrated in fig. D-4.

Binding rules

The installation of a reverse osmosis system GENO®-OSMO RO 125K is a

major interference with the drinking water system. Only authorised

companies may install such systems.

Observe the local installation guidelines and the general guidelines.

The system must be preceded by a fine filter (e.g. BOXER

®

KD) (op-

tion)

The system must be preceded by a system separator (option).

The system must be preceded by a water softener (option).

If necessary, install an activated carbon filter (option)

Provide a drain connection (at least DN 50) to discharge the concen-

trate.

Note: If the concentrate is directed to a lifting system, the delivery rate of

the lifting system should at least amount to 500 l/h.

Warning! A floor outlet must be available in the installation room. If

this is not the case, an appropriate safety device must be installed (refer

to option C-6).

Recommendations

Provide a sampling valve directly upstream and downstream of the reverse osmosis system GENO®-OSMO RO 125 K. This will facilitate the

sampling for the regular quality control (functional check).

Page 23

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

23

1.2 Electrical

installation

Internal wiring of the GENO-OSMO-RO125K control unit

The system is completely wired (if necessary, incl. optional equipment) at

the factory and will be delivered ready-to-plug-in. During start-up, the parameter ECL: 1 must be changed to ECL: 0 in Code level 113 (normally

closed contact >>normally open contact). This is a safety measure, so that

the system cannot be switch-on accidentally after plugging in the mains

cable without the system being properly deaerated first.

Jumpers must be plugged this way

Conductivity module

Mains cable

PS-pump

(pressure booster)

HP-pump

Thermal circuit breake

r

of HP-pump

Release of analysis

Hardness monitoring device

Pumps

Solenoid

valve

Mains

Fig. D-1: PCB configuration of GENO®- OSMO RO 125K

Terminal no. Terminal Function (colour of wire) Remarks

All protective conductors are connected with the 7 pole protective conductor terminal on the left mounting rail

X1 3 L 230 V / 50 Hz phase

Mains cable, protection provided by others on

site at least 6 A

2 N Neutral conductor

1 PE Protective earth conductor

X2 6 MVW 230 V / 50 Hz phase Solenoid valve rinsing Joint neutral termi-

nal

5 N Neutral conductor

7 MVE 230 V / 50 Hz phase Inlet solenoid valve

10 MVR 230 V / 50 Hz phase Option:

Solenoid valve forced withdrawal

9 N Neutral conductor

Page 24

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

24

Terminal no. Terminal Function (colour of wire) Remarks

X3 12 PS 230 V / 50 Hz phase

GENO

®

-OSMO RO 125K-TS

Triggering of high pressure pump via relay

K2, protection via fuse F3 (T3, 15A)

GENO

®

-OSMO RO 125K-TL

Triggering of high pressure pump volt.-free

contact, relay K2, terminals 21-24

Control voltage for external power unit

230 V~: relay K2, terminals 14-A2

13 N Neutral conductor

14 HP 230 V / 50 Hz phase Option:

Solenoid valve „blending unit“

13 N Neutral conductor

14 HP 230 V / 50 Hz phase Triggering of high pressure pump via relay

K1, protection via fuse F2 (T 4,0 A)

2 N Neutral conductor

X4 33 + AVRO electrode line

Only used for AVRO 125 TS/TL!

34 GND

X5 15 COM Joint root

Volt.-free contacts N. C. 250 V~ / 3 A with

joint root COM

16 SAMS Fault signal contact

17 MELD Signal contact

X6 28 GND Joint mass (brown)

Hall pulse cable of turbine water meter

29 WZ0 Pulse input permeate

green

30 WZ1 Pulse input concentrate

31 WZ2 Option:

Pulse input „blending unit“

32 +12V Joint source voltage

12 VDC (white)

X7 24 Level „a“ Switch-off level high pressure

pump

brown

Level control permeate tank

25 Level „b“ Switch-on level high pressure

pump

green

26 Level „c“ Dry-run protection pressure

booster pump

yellow

27 +24V Joint source voltage 24 VDC white

X8 18 DS_HP Pressure switch high pressure pump

Low pressure of feed water, dry-run protection high pressure pump

19 +24V Source voltage 24 VDC

20 DS_PS Pressure switch pressure booster pump Pressure switch to control pressure booster

pump (GENO

®

-OSMO RO 125K-TS resp.

AVRO 125 TS integrated in system)

In case of the RO/AVRO 125-TL version, a

jumper must be set at terminals X8 20/21.

21 +24V Source voltage 24 VDC

22 CLOSE Release input Close

System switches off if thermal circuit

breaker of HP pump is triggered

Lock system externally, eg. pretreatment,

residual hardness ... For this purpose, a

normally closed contact (NCC) provided by

others must be switched in series with the

thermal circuit breaker.

23 +24V

Source voltage 24 VDC

L1

a N.C.

b N.O.

c N.O.

Page 25

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

25

Terminal no. Terminal Function (colour of wire) Remarks

X9 35 Screen Conductive measuring cell

with 2 electrodes, not temperature compensated, cell

constant 0,1 or 1.0

Option:

Conductivity meter

36 LF E white

37 LF V

brown

Relais

K1

31

34

Release signal/analysis start

hardness monitoring device

Contact is closed

if system produces permeate.

Connect GENO

®

-Softwatch Komfort:

to terminals 16/17.

Configuration of the components on the mounting rails, accessible after

the control unit has been dismantled:

Protective conductor termi-

nal, mounted below the two

fuses F2 and F3

Fig. D-2: Position of protective conductor terminal

2 Preliminary works

1. Unpack all system components.

2. Check for completeness and perfect condition.

3. Set up the reverse osmosis system GENO

®

-OSMO RO 125 K at the

designated installation site.

Page 26

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

26

3 System connection on water side

Connect the feed water to the system (refer to fig. D-4)

Connect the permeate pipe to the system. In case of GENO

®

-OSMO

RO 125K-TL connect to tank provided by others on site.

Attention! If withdrawal/feed points (e. g. tank provided by others on

site) of permeate originating from the RO-125K are located below the

connection level of the system, a pressure maintaining valve must be

installed into the permeate pipe in order to protect the permeate tank

from being siphoned.

Fig. D-3: Withdrawal point below system level

Page 27

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

27

A

BOXER®-KD

Concentrate connection

B

Euro system separator DK 2-Mini

Permeate connection

C

Water softener Weichwassermeister 2 GSX I

Feed water connection

D

Activated carbon filter AKF

E

GENO®-OSMO-RO 125K-TS

Fig. D-4 Installation drawing of reverse osmosis system

GENO

®

-OSMO RO 125K

Fig. D-4(a) Installation drawing of

reverse osmosis system

GENO

®

-OSMO RO 125K

Page 28

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

28

E Start-up (reverse osmosis system GENO®-OSMO RO 125K)

The work described below may only be performed by trained experts.

For safety reasons, we recommend to have the start-up performed by

Grünbeck’s customer service/authorised service.

1 System rinsing

1.1 Mounting of rinsing line

Disassemble permeate line from supply tank (refer to fig. E-1, E-2, item 1)

and route to drain by means of a separate hose.

Fig. E-1: Permeate line RO 125 K-TS

Fig. E-2: Permeate line RO-125 K-TL

Page 29

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

29

1.2 Rinsing of preservative

A special preservative is used to protect the membrane during storage

and shipping. The first step is to rinse this preservative from the system.

To prevent the system from being accidentally started before this agent

has been removed, the system is locked electronically.

Note: Please refer to chapter F for detailed information on the

controller.

Release system via Code 113, (refer to table E-1: excerpt from…), parameter ECL: To do so, open parameter by means of key, set ECL: 1

by means of key and confirm by means of key

Via Code 113, (rever to table E-1: excerpt from…), parameter EnL: 1

open both solenoid valves („DEAERATION“) and rinse preservative

from system for 30 min. To do so, access the parameter by means of

key and set EnL: 1 with key . Confirm with key

To terminate program step „DEAERATION“: access parameter with

key , set EnL:0 by means of key and confirm with

Quit programm „EnL“ by simultaneously pressing keys and

Page 30

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

30

Table E-1: Excerpt from pagaragraph F-3.1 Input logicCode 113

Display

Factory

setting

Parameter Setting

range

Remarks

E-A: 1 Contact type level „a“ 0 ... 1 0 = NOC

1 = NCC

E-b: 0 Contact type level „b“ 0 ... 1 0 = NOC

1 = NCC

E-c: 0 Contact type level „c“ 0 ... 1 0 = NOC

1 = NCC

EHP: 2 Contact type pressure

switch low pressure HP

(High pressure pump).

0 ... 3 0 = NOC

1 = NCC

2 = NOC with autom.

restart 1)

3 = NCC with autom.

restart 1)

EPS: 0 Contact type pressure

switch PS (Pressure

booster pump).

0 ... 1 0 = NOC

1 = NCC

ECL: 0 Contact type input

Close.

0 ... 1 0 = NOC

1 = NCC

EnL: 0 Rinse system (Solenoid

valves inlet and rinsing).

0 ... 1 1 = opens solenoid valves

(only possible if system

is switched off via key

).

0 = closes solenoid valves

again

A.PF:0 Function signal contact

terminals 15/17.

0 ... 1 0 = Contact opens in case

of deactivation of HP

pressure, pre-alarm

conductivity, level “c”

undershot, maintenance interval expired.

1 = Contact is closed when

HP pump is running..

Page 31

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

31

1.3 Permeate production / deaeration of pressure pump

Remount permeate line to supply tank (refer to fig. E-1).

Switch on the reverse osmosis system RO 125 K by means of key.

The system produces permeate in the tank.

Note: The following only applies to reverse osmosis system

RO-125 K-TS

The pressure booster pump is deaerated if permeate flows from the

deaeration/sampling valve (refer to fig. E-3, item 1) (it will takes approx. 15 minutes for the permeate to start flowing). Close deaeration

valve.

Plug the plug of the pressure switch (refer to fig. E-4, item 1) onto

the presure switch – pressure booster pump starts delivering.

Note: In order for the pressure pump to reach ist bearing pressure, the

pipe downstream must also be deaerated, therefore it is essential to establish permeate consumption.

Switch-on pressure approx. 1.8 bar; switch-off pressure approx. 3.0

bar.

Fig. E-3: Deaeration of pressure booster Fig. E-4: Pressure switch of pressure

booster

Page 32

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

32

F Operation

1 Preface

Note: Instructions printed in bold letters are absolutely necessary for the

continuation of the operation. All other instructions may be omitted, if

the value shown in the display remains unchanged.

Settings in the customer service programming level may only be performed by Grünbeck’s technical customer service/authorised service or

by trained experts explicitly authorised by Grünbeck.

Warning! Incorrect settings may result in dangerous operating states

which may cause damage to persons, health or property.

Strictly observe the operation manual! Only make settings that are described in this manual!

Fig. F-1: Control unit

Page 33

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

33

2 How to operate the control unit

Display symbols:

Fig. 2: Operating panel of GENO

®

- OSMO RO 125K control

unit

Operating mode display

appears when the system is switched on via

key (> 5 sec. in basic display “time”)

High pressure pump

appears when high pressure pump produces

permeate (blinking in case of malfuntion Er1)

Pressure booster pump

appears when the pressure booster pump delivers permeate resp. the power unit K2 is active.

Solenoid valve inlet

appears when permeate is being produced resp.

when the system is being rinsed

Solenoid valve rinsing

appears when the system is being rinsed

Solenoid valve forced withdrawal

appears when the content of the permeate tank

is discharged to the drain

Filling level indication permeate tank

Upper wave: Switch-off level for high pressure

pump

Wave in the middle: Switch-on level for high

pressure pump

Lower wave: Dry-run protection for pressure

booster pump

Display „Numerical values“

indicates time and operating parameters

in the Info level

indicates the parameters of the Code

levels

indicates symbols in addition to the

error signal

Bars for water meter pulses

blink with every 5th pulse of the water meter

Permeate resp. Konzentrat (concentrate)

Point appears as long as pressure booster pump

is locked (after ON via key , when the lower

wave permeate tank was exceeded, acknowledge

after malfunction)

Bar for operation standby of high pressure pump

(HP) and pressure booster pump (PS)

indicates the state of the pressure switch feed

water inlet (bar appears when pressure is pending) and operation release of PS pump (bar appears when operation is released)

P

Is blinking, if – during the permeate production –

the pressure switch of the high pressure pump is

de-energised (lack of pressure in the feed water)

Bar for signal and fault signal contact

appears when the maintenance interval has

expired, pressure switch high pressure pump has

dropped out, conductivity pre-alarm, permeate

tank empty. Er appears in case of malfunctions

Er0 … Er6

Bar for input Close

appears when the release signal Close is pending

at the input, i. e. the system is locked

appears when high pressure pump is overheated

±

Symbol not relevant for GENO®-OSMO

RO 125K TL/TS

Page 34

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

31

1.3 Permeate production / deaeration of pressure pump

Remount permeate line to supply tank (refer to fig. E-1).

Switch on the reverse osmosis system RO 125 K by means of key.

The system produces permeate in the tank.

Note: The following only applies to reverse osmosis system

RO-125 K-TS

The pressure booster pump is deaerated if permeate flows from the

deaeration/sampling valve (refer to fig. E-3, item 1) (it will takes approx. 15 minutes for the permeate to start flowing). Close deaeration

valve.

Plug the plug of the pressure switch (refer to fig. E-4, item 1) onto

the presure switch – pressure booster pump starts delivering.

Note: In order for the pressure pump to reach ist bearing pressure, the

pipe downstream must also be deaerated, therefore it is essential to establish permeate consumption.

Switch-on pressure approx. 1.8 bar; switch-off pressure approx. 3.0

bar.

Fig. E-3: Deaeration of pressure booster Fig. E-4: Pressure switch of pressure

booster

Page 35

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

34

Key functions:

Basic functions:

Extended functions in programming levels:

Acknowledgement of malfunctions

Access to time programming mode

(press key for > 2.5 sec. )

Access parameter for editing (value is blinking)

Store parameter and close

To switch off the system (> 5 sec. in basic

display “time”)

Reduce the value

Return to the previous menu item

To switch on the system (> 5 sec. in basic

display “time”), to indicate operating values

of the Info level

Increase the value

Go to the next menu item

+

Access to the Code protected programming

levels (Code request C 000)

+

Close open parameter without saving

(present value is kept)

Return to the basic display time

2.1 How to read the

operating state

Within the Info level, various operating parameters can be displayed. The

Info level may be accessed by pressing the key (> 5 sec.) You may

access other parameters by tapping the key. As long as the system has

not yet been released via the input signal Close, the info level is also still

locked.

Key Display Parameter

00:00

Basic display time

When pressing this key (> 5 sec.) for the first time, the system is

being switched on!

365 Remaining time of maintenance interval [days]

0000 Displayed value not relevant for RO 125 K TL/TS

LF022 Permeate conductivity [μS/cm] (optional – displayed

value blinks if pre-alarm value is exceed)

P0200 Permeate flow [l/h]

c0200 Concentrate flow [l/h]

u0320 Blending flow [l/h] (option 752 800)

A 050 System recovery [%]

Page 36

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

35

2.2 How to program

the time

Precondition:

The basic display time must be indicated.

1. Press key for > 2.5 seconds, only the hours are still displayed 00:

2. Press key to modify the hours (when the value is blinking, set the

desired value by means of keys and , and save with the key )

or

press to switch to the minutes :00

3. Press key to modify the minutes (when the value is blinking, set

the desired value by means of keys and , and save with key )

4. By simultaneously pressing the keys and , return to the basic

display.

2.3 Access to the

programming

levels – modification of parameters

1. By simultaneously pressing (> 1 sec.) keys and , the Code re-

quest C 000 appears.

2. Set the required Code with keys or and confirm with key .

3. Select the desired parameter in the programming level by keys or

and open it for editing with key (the value starts blinking).

4. Change the parameter setting to the desired value by keys or

5. Save the new parameter settings with the key (value stops blink-

ing) or reject the modification by simultaneously pressing keys

and and close the parameter again (value stops blinking and

the previous setting remains stored).

6. Return to the basic display time by simultaneously pressing keys

and .

7. When no keys are operated within the parameter level for more than

5 minutes, the display automatically returns to the basic indication of

the time. Parameters that might be open (blinking value) are closed

and the previously stored value is kept.

2.4 Software version

Display Parameter

P1.00 Software version RO-matic control unit

Page 37

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

36

3 Programming levels

3.1 Input logic Code 113

Display

Factory-

setting

Parameter Setting

range

Remarks

E-A: 1 Contact type level „a“ 0 ... 1 0 = NOC

1 = NCC

E-b: 0 Contact type level „b“ 0 ... 1 0 = NOC

1 = NCC

E-c: 0 Contact type level „c“ 0 ... 1 0 = NOC

1 = NCC

EHP: 2 Contact type pressure

switch low pressure HP

(high pressure pump)

0 ... 3 0 = NOC

1 = NCC

2 = NOC with autom. restart

(1)

3 = NCC with autom. restart

(1)

EPS: 0 Contact type pressure

switch PS (pressure

booster pump)

0 ... 1 0 = NOC

(RO/AVRO 125-TS)

1 = NCC

(RO/AVRO 125-TL)

ECL: 0 Contact type input

Close

0 ... 1 0 = NOC

1 = NCC

EnL: 0 Rinse system (solenoid

valves inlet and rinsing)

0 ... 1 1 = opens solenoid valves

(only possible, if system is switched off via

key )

0 = closes solenoid valves

again

A.PF:0 Function signal contact

terminals 15/17.

0 ... 1 0 = Contact opens in case

of deactivation of HP

pressure, pre-alarm

conductivity, level „c“

undershot, maintenance interval expired.

1 = Contact is closed

when HP pump is

running.

Page 38

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

37

(1)

If the error Er1 occurs while the permeate production is running (pressure switch low pressure high pressure pump), the system tries to restart

in the following time intervals:

5 ... 10 ... 20 ... 40 ... 80 ... 160 minutes

If sufficient pressure is available, permeate is being produced until level

„a“ is reached and the error quits itself.

During the wait time between the start attempts, the symbol is

blinking in the display.

2)

Pressure switch: Switch-on pressure 1.8 bar

Switch-off pressure 3.0 bar

The hysteresis of the pressure switch may be adjusted in parallel by

means of the screw.

3.2 System parameters Code 290

Display

Factory-

setting

Parameter Setting

range

Remarks

1. 0 Cell constant conductivity measurement

(optional)

0.0 / 0.1 /

1.0

0.0 = Conductivity mea surement deactivated,

i. e. parameter

2 ... 4 not effective

0.1 = Measuring range

0 ... 99 μS/cm

1.0 = Measuring range

0 ... 999 μS/cm

2. 080 Limit value conductivity

for malfunction Er 3

[μS/cm]

1 ... 999

Note: Setting value

must be chosen according to the cell

constant (i. e. measuring range)!

3. 070 Conductivity pre-alarm

[μS/cm] (display in the

info level starts blinking

and signal contact

switches)

1 ... 999

4. 05 Switch-off delay in case

of Er 3 [minutes]

0 ... 99 Also delay time for the

release of the status signal

in case the conductivity

pre-alarm is exceeded

P

Page 39

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

38

Display

Factory-

setting

Parameter Setting

range

Remarks

5. 0 Return of power

reaction for malfunction Er 0 (power failure

> 5 minutes)

0 ... 2 0 = No matter whether

the system was off or

on prior to the power

failure, after return of

power, it remains

switched off and malfunction Er 0 is indicated

1 = Malfunction Er 0 is

deactivated

2 = After return of power,

the system is on or off

such as it was before

the power failure and

the malfunction Er 0 is

indicated

6. 1 Interval in days for

forced operation /

forced withdrawal

[days]

1 ... 3 If the interval in days since

the last permeate production is reached at the programmed time, forced

operation or forced withdrawal takes place, depending on which of the

two has been activated

In case of RO125K,

forced withdrawal is

only admissible in combination with the option solenoid valve

forced withdrawal!

7.18:00 Time for forced operation / forced withdrawal

00:00 ...

23:59

8. 0 Duration of forced operation [hours]

0 ... 9

9. 3.0 Opening period of solenoid valve forced

withdrawal [minutes]

0.1 ...

99.9

A. 0 Monitoring or recovery

(Er 5)

0 … 1 For AVRO 125 TS/TL, the

recovery monitoring must

be activated!

b. 80 Upper limit value for

recovery [%]

1 … 99

Attention! In case of

AVRO 125 TS/TL , the

recovery must be set

to 50 %!

c. 060 Delay time for recovery

switch off [min.]

0 … 240

Page 40

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

39

4 Operation of reverse osmosis

4.1 How to set the system recovery

In order to prevent the membrane from clogging (scaling), a certain

amount of feed water has to be rejected. The ratio between the permeate volume produced and the concentrate volume flowing to the drain

is called recovery.

4.1.1 How to set the permeate volume

Switch on the system via key (refer to chapter F-2) at the control

electronics.

Throttle the pump by means of the setting valve (refer to fig. F-3,

item 1) for operating pressure (refer to fig. E-2) in a way that the system specific permeate flow of 125 l/h is obtained.

Note: The current permeate flow may be indicated at the control unit (refer to chapter F, paragraph 2.1, „How to read the

operating state“).

Fig. F-3: pump

Page 41

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

40

4.1.2 How to set the concentrate volume

Set the concentrate flow at the concentrate needle valve (refer to fig.

F-4, item 1).

In case of standard systems, the concentrate flow has to be set in a

way that a recovery of 50 % is reached (125 l/h permeate flow,

125 l/h concentrate flow)

Note: The current concentrate flow resp. the recovery may be indicated

at the control unit (refer to chapter F, paragraph 2.1 „How to read the

operating state“).

Attention! If the setting of the recovery is not observed, scaling (precipitation of dissolved minerals) on the reverse osmosis will occur.

After 10 minutes, measure the water values of feed water, permeate

and concentrate and record the values in the operation log.

Switch off the system (refer to chapter F-2).

Fig. F-4: Hydro distribution block

Example for calculation of recovery

[l/h]flow eConcentrat[l/h]flow Permeate

100%x[l/h]flow Permeate

[%]Recovery

][l/hflow Permeate

[%]recovery eConenctrat

100x[l/h]flow Permeate

[l/h]flow eConcentrat

Page 42

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

41

G Troubleshooting

Even carefully designed and manufactured technical systems that are

operated properly may experience malfunctions. Table G-1 provides an

overview of possible problems that might occur during operation of the

systems. It also indicates the causes and remedies.

The systems are equipped with error detection and reporting system.

If an error message is displayed:

1. Press key (= acknowledge malfunction).

2. Watch the display.

If the signal reappears, compare to table G-1.

3. If necessary, notify technical customer service.

Note: The customer service must definitely be notified in case of malfunctions that cannot be remedied with the information provided in table G-1! When you contact the customer service, please provide the

following information: system designation, serial number and, if applicable, the error message displayed.

Table G-1: Troubleshooting

What you see Why it happened What to do

Water quality decreased

by 50 %

Membrane clogged

Replace or rinse membrane 1)

Feed water values

deteriorated

Check feed water values

Solenoid valve

does not open

Coil defective or fuse on circuit

board blown

Replace coil resp. replace fuse

Solenoid valve

does not close

Valve dirty Clean valve

In the display, a bar appears above the Close

symbol

HP pump: thermal circuit

breaker was activated, overheating of pump.

Hardness monitoring or water

treatment locks system.

Wait until the pump has cooled

down, the system resumes operation automatically.

Check system installed up-

stream.

In the display, a bar appears above the screw

driver symbol (without

additional indication of a

malfunction)

Maintenance interval has expired Have maintenance performed

Measured conductivity

value in the info level is

blinking and a bar appears

above the screw driver in

the display.

Option conductivity meter:

Pre-alarm for conductivity,

chapter F / item 3.2 / parameter 4

exceeded

Check feed water values and rinse

membrane, if necessary

Page 43

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

42

Table G-1 continued: Troubleshooting

What you see Why it happened What to do

Er 0 Power failure for > 5 minutes

refer to chapter F / item 3.2 / parameter A:

Depending on the setting, the

system continues running or remains switched-off

Check power supply for failures

Er 1 Pressure loss at pressure switch

HP:

Refer to chapter F / item 3.1 / parameter EHP:

Depending on the setting, the

system has unsuccessfully tried to

restart 6 times.

Re-establish feed water inlet pressure

Er 2 Inadmissible level position in per-

meate tank

Check wiring resp. settings in Code

113, check parameters E-A, E-b and

E-c and correct, if necessary (allocation NCC/NOC)

Er 3 Option conductivity meter:

Limit value for conductivity chapter F / item 3.2 / parameter 3 exceeded

Check feed water values, rinse

membrane or replace it, if necessary

Symbol

P

is blinking

(starting with software

version V1.22) resp.

Symbol is blinking (up

to software version V1.19)

Refer to Er 1: Wait time between

2 start-up trials is running

Re-establish initial feed water pressure

Er 5 System recovery too high. Volumetrically measure system and

readjust.

1)

Special rinsing instructions for the membranes are available for authorised service personnel (order no. 700 950)

Page 44

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

43

H Maintenance and care for reverse osmosis system RO 125K

1 Basic information

In order to guarantee the reliable function of the systems over a long

period of time, maintenance has to be performed at regular intervals.

Furthermore, all regulations and guidelines which apply at the installation site must be observed.

The quality and the system volume flows must be checked daily.

Maintenance must be performed by the manufacturer's customer service or

by an authorised company. The maintenance intervals depend on the load.

However, maintenance must be performed at least once a year.

An operation log as well as the corresponding test report must be

kept in order to record the maintenance work performed.

Note: A maintenance contract ensures that all the required maintenance work will be performed in due time.

The maintenance work performed must be documented in the checklist,

refer to attachment „operation log“

2 Inspection (functional check)

You may perform the daily inspections yourself.

Please refer to the summary below for a list of tasks to be performed

within the framework of an inspection.

Overview: Inspection work

Determine the feed water hardness (inlet).

(water analysis kit „Total Hardness“)

Determine the permeate quality. In case of built-in conductivity moni-

toring, the permeate quality is indicated in the display. Otherwise it

must be determined by means of a manual conductivity meter

Read recovery

Observe remaining time of maintenance interval

Chapter F, item 2.2, read operating state.

If the remaining time of the maintenance interval is < 30 days, contact

the technical customer service regarding maintenance.

Note: Minor deviations are normal and cannot be prevented technically.

However, if you detect major deviations from the standards, please contact the customer service.

Check water tightness of system to drain (if system is switched off – all

3 waves are visible in the display – refer to fig. F-2, item 5). Solenoid

valves are not activated, visible in display (refer to fig. F-2, items 9 and

10). In this mode, no leakage water may flow to the drain.

Note: Leaky solenoid valves cause an increased water consumption of

the system. The recovery will decrease.

Page 45

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

44

3 Maintenance

According to DIN 1988 part 8 / A 12, system maintenance may only be

performed by the manufacturer's customer service or an authorised

company.

An operation log/checklist must be kept for these systems. In this log,

the service technician records all maintenance and repair work performed. In case of a system failure, this log helps to identify possible

sources of the error. In addition, the log documents the proper system

maintenance.

Note: Make sure that all maintenance work is recorded in the operation

log as well as in the test report.

Overview: Maintenance work

Replacement of filter elements 80/50 μm or 5 μm.

If necessary, replace filter element for activated carbon filter.

Check the permeate quality, rinse or replace membrane, if necessary.

A special rinsing manual is available for authorised service personnel

(order no. 700 950).

Clean solenoid valves and check function.

Check the flow volumes and recalibrate the water meters.

Check the state of the entire system and test for tightness.

Check all components (pumps, valves, etc.) in terms of mechanical

and electrical function and performance.

Prepare a written maintenance report where you record all data and

activities, including repair work, analysis and evaluation of the operating parameters and water analyses.

Note: Make sure that all maintenance work is documented in the

checklist, refer to the attached “operation log”.

3.1 Operation log

The operation log as well as the corresponding test report can be found

in the chapter H, item 4 of the operation manual. When starting up the

system, make sure to record all data on the cover sheet of the operation

log and fill in the first column of the checklist.

The service technician will fill in a column of the operation log whenever

maintenance is performed. The log provides evidence of proper maintenance.

Page 46

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

45

4 Operation log

Customer

Name: ........................................................................

Address: .....................................................................

..................................................................................

..................................................................................

Reverse osmosis system GENO®-OSMO RO 125K

(please mark appropriate box)

Serial number ..............................................................................

Installed by ..................................................................................

Filter 80 μm: make/type .................. / ..........................................

System separator: make/type........... / ..........................................

Water softener: make/type .............. / ..........................................

Activated carbon filter: make/type ... / ..........................................

Filter 5 μm: make/type

.......................... / ....................................................

TL

TS

Connection data:

Drain connection DIN 1988

yes no

(please mark appropriate box)

Floor drain available yes no

Pipe upstream of

GENO®-OSMO RO 125K

galvanised

copper

plastics

Drain height . . . . . cm from bottom edge of system

Grünbeck Wasseraufbereitung Gmb

H

Josef-Grünbeck-Strasse 1

89420 Hoechstaedt/Danube · GERMANY

Phone +49 9074 41-0 · Fax +49 9074 41-100

www.gruenbeck.com · info@gruenbeck.com

A company certified by TÜV SÜD

in accordance with DIN EN ISO 9001, DIN

EN ISO 14001, DIN EN ISO 13485 and SCC

Page 47

Reverse Osmosis System

GENO

®

-OSMO RO 125K

Order no. 195 752 940-inter Edited by: KONS-phar-mrie G:\BA-752940-INTER_RO_125K.DOC

46

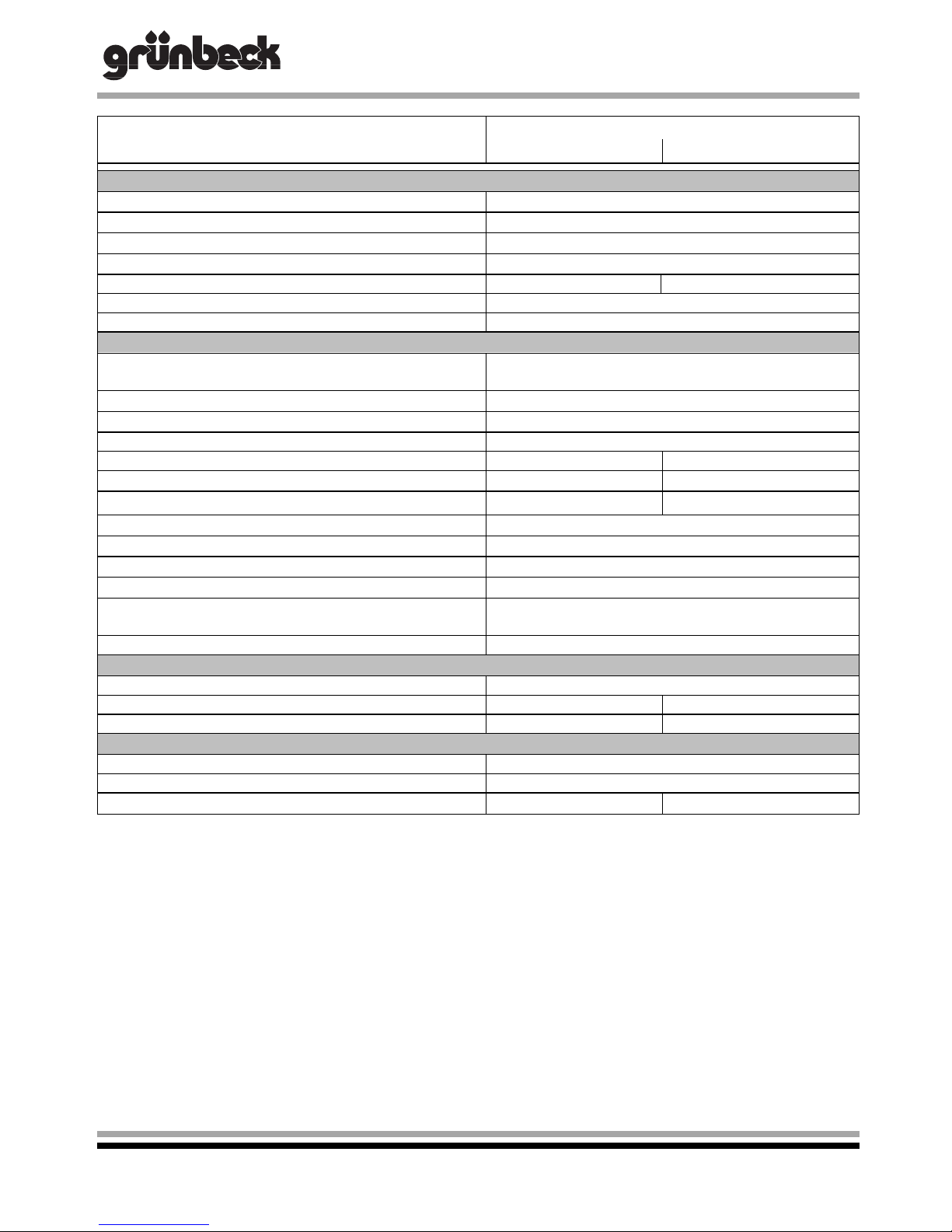

Maintenance work reverse osmosis system GENO®-OSMO RO 125K

Checklist

Please enter measured values. Confirm checks with OK or document repair work performed.

Maintenance performed with-

out module replacement

Maintenance performed

with module replacement

Start-up Date

Module no. .......................... Module no. .............................

Measured values