Page 1

Operation Manual

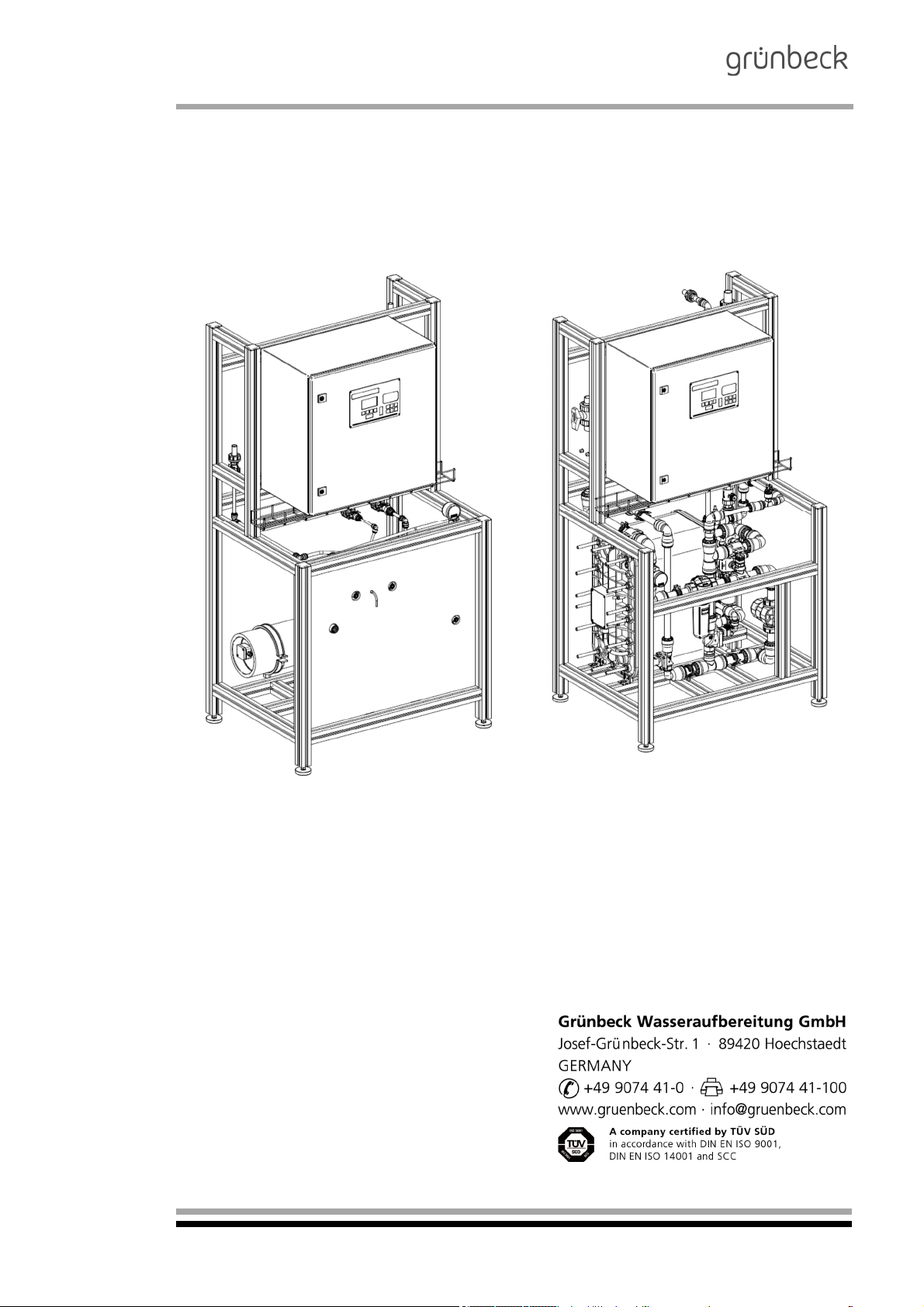

Electrodeionisation System GENO-EDI-X

with GENO-EDI-tronic

Version: December 2018

Order no. 024 770 901-inter

Page 2

Electrodeionisation System

GENO-EDI-X

Table of contents

AGENERAL INFORMATION .................................................................................................................................................................. 5

1 | P

REFACE

2 | H

3 | G

4 | S

5 | D

BBASIC INFORMATION ........................................................................................................................................................................ 9

1 | L

2 | W

3 | F

CPRODUCT DESCRIPTION (GENO-EDI-X) ........................................................................................................................................ 12

1 | T

2 | F

3 | B

4 | D

5 | T

6 | I

7 | A

8 | S

DINSTALLATION ................................................................................................................................................................................. 25

1 | G

2 | W

3 | H

4 | E

ECOMMISSIONING .............................................................................................................................................................................. 29

1 | G

2 | START EDI-X

FOPERATION ...................................................................................................................................................................................... 31

1 | I

2 | B

3 | S

4 | O

5 | O

GTROUBLESHOOTING ....................................................................................................................................................................... 56

1 | B

2| T

HMAINTENANCE ................................................................................................................................................................................. 5 8

1 | B

2 | I

3 | M

..................................................................................................................................................................................................... 5

OW TO USE THIS OPERATION MANUAL

ENERAL SAFETY INFORMATION

3.1

3.2

3.3

3.4

3.5

3.1 Functional principle of electrodeionisation ......................................................................................................................................... 10

3.2

NTENDED USE

6.1 | System shutdown ............................................................................................................................................................................ 19

8.1

8.2

8.3

1.1

1.1

NTRODUCTION

2.1

2.2

2.3

2.4

5.1

5.2

5.2.4System Configuration ............................................................................................................................................................ 37

5.2.5I/O Display ............................................................................................................................................................................... 38

5.2.6Error Memory .......................................................................................................................................................................... 38

5.2.7Basic Setting ........................................................................................................................................................................... 38

5.3

5.3.1Errors ...................................................................................................................................................................................... 3 9

5.3.2Warnings ................................................................................................................................................................................. 41

5.4

5.4.1User......................................................................................................................................................................................... 4 3

5.4.2Parameters .............................................................................................................................................................................. 43

5.4.3Times ...................................................................................................................................................................................... 46

5.4.4Errors ...................................................................................................................................................................................... 4 7

5.4.5Service Data ............................................................................................................................................................................ 50

5.4.6Reference Data ....................................................................................................................................................................... 51

5.4.7Basic Setting ........................................................................................................................................................................... 52

5.5

5.5.1User......................................................................................................................................................................................... 5 4

5.5.2Parameters .............................................................................................................................................................................. 54

5.5.3Errors ...................................................................................................................................................................................... 5 5

5.5.4Service Data ............................................................................................................................................................................ 55

5.5.5Basic Setting ........................................................................................................................................................................... 55

ROUBLESHOOTING

NSPECTION (FUNCTIONAL CHECK

3.1

Symbols and notes .................................................................................................................................................................... 6

Operating personnel .................................................................................................................................................................. 6

Designated application .............................................................................................................................................................. 6

Protection from water damage .................................................................................................................................................. 7

Description of specific dangers ................................................................................................................................................. 7

HIPPING AND STORAGE

ISPOSAL

..................................................................................................................................................................................................... 8

AWS, REGULATIONS, STANDARDS

ATER

........................................................................................................................................................................................................ 9

UNCTIONAL PRINCIPLE OF ELECTRODEIONISATION

Components of the electrodeionisation module (EDI module) ................................................................................................. 11

YPE DESIGNATION PLATE

LOW CHART DESIGN

ASIC FUNCTION OF THE ELECTRODEIONISATION SYSTEM

ESCRIPTION OF THE COMPONENTS

ECHNICAL SPECIFICATIONS

PPLICATION LIMITS

COPE OF SUPPLY

ENERAL INSTALLATION INFORMATION

ATER CONNECTION

OW TO CONNECT THE SYSTEM

LECTRICAL WIRING

ENERAL INFORMATION

RIEF DESCRIPTION OF

WITCH CABINET

PERATING THE CONTROL UNIT

PERATING THE CONTROL UNIT

ASIC INFORMATION

ASIC INFORMATION

AINTENANCE

............................................................................................................................................................................................ 1 9

...................................................................................................................................................................................... 21

Standard equipment ................................................................................................................................................................ 21

Optional features ..................................................................................................................................................................... 22

Wearing parts .......................................................................................................................................................................... 24

Preliminary work ...................................................................................................................................................................... 25

Preliminary work ...................................................................................................................................................................... 29

SYSTEM OPERATION

............................................................................................................................................................................................ 31

Field of application .................................................................................................................................................................. 31

Function .................................................................................................................................................................................. 31

Basic technical parameters – control panel ............................................................................................................................. 31

Basic technical parameters – MK200 basic module ................................................................................................................. 31

......................................................................................................................................................................................... 32

Basic information regarding the operation of the control unit ................................................................................................... 34

System menu .......................................................................................................................................................................... 34

Messages and signals ............................................................................................................................................................. 39

Electrodeionisation (GENO-EDI-X system) .............................................................................................................................. 4 2

Pressure booster (PB system) if activated in system menu ..................................................................................................... 53

............................................................................................................................................................................................ 5 9

Operation log ........................................................................................................................................................................... 59

............................................................................................................................................................ 5

..................................................................................................................................................................... 6

................................................................................................................................................................................ 7

.................................................................................................................................................................. 9

......................................................................................................................................... 10

............................................................................................................................................................................ 12

................................................................................................................................................................................... 12

.............................................................................................................................................................. 15

......................................................................................................................................................................... 18

.................................................................................................................................................................................... 20

.......................................................................................................................................................... 25

................................................................................................................................................................................... 26

.................................................................................................................................................................................... 28

.................................................................................................................................................................................... 56

..................................................................................................................................................................................... 57

.................................................................................................................................................................................... 58

.................................................................................................................................................................... 27

............................................................................................................................................................................... 29

.............................................................................................................................................................. 30

GENO-EDI-

TRONIC

.................................................................................................................................................. 31

.................................................................................................................................................................... 33

.................................................................................................................................................................... 34

) ................................................................................................................................................................ 58

GENO-EDI-X (

WITHOUT OPTIONS

) ............................................................................ 13

2

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Page 3

Publisher's information

All rights reserved.

Copyright by Grünbeck Wasseraufbereitung GmbH

Printed in Germany

Effective with the date of edition indicated on the cover sheet.

-We reserve the right to modifications, especially with regard to

technical progress-

Reprints, translations into foreign languages, electronic storage

or digital copying of this operation manual – even in parts – may

take place only with explicit written approval of Grünbeck Wasseraufbereitung GmbH.

Any type of duplication not authorised by Grünbeck Wasseraufbereitung is a copyright violation and will be prosecuted.

Responsible for contents:

Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Straße 1 89420 Höchstädt/Do.

Phone 09074 41-0 Fax 09074 41-100

www.gruenbeck.de service@gruenbeck.de

Electrodeionisation System

GENO-EDI-X

Printing: Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Straße 1, 89420 Höchstädt/Do.

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

3

Page 4

Electrodeionisation System

GENO-EDI-X

EC Declaration of Conformity

We hereby declare that the system designated below meets the safety and health requirements

of the applicable European guidelines in terms of its design, construction and manufacture.

This certificate will become invalid if the system is modified in a way not approved by us.

Manufacturer: Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Str. 1

89420 Hoechstaedt/Germany

Responsible for documentation: Roland Rehberger

System designation:

System size: 100, 180, 360, 720, 1100, 1450, 2000, 2700

System number: Refer to type designation plate

Applicable directives: Machinery Directive (2006/42/EC)

Applied harmonised standards,

in particular:

Applied national standards

and technical

specifications,

in particular:

Place / Date / Manufacturer's signature:

Function of signatory: Head of Technical Systems and Equipment

Electrodeionisation system GENO-EDI-X

EMC (2014/30/EU)

EN ISO 12100:2011-03,

EN 61000-6-2:2006-03

EN 61000-6-3:2011-09

Höchstädt, 2018-10-11 p.p.a.

P. Höß

4

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Page 5

A General information

Electrodeionisation System

GENO-EDI-X

1 | Preface

Thank you for opting for a Grünbeck product. Backed by

Advice and assistance

decades of experience in the area of water treatment, we

provide solutions for all kind of processes.

All Grünbeck systems and devices are made of high-quality

materials. This ensures trouble-free operation over many years,

provided you treat your water treatment system with the required

care. This operation manual assists you with important

information. Therefore, please read the entire operation manual

before installing, operating or maintaining the system.

Customer satisfaction is our prime objective and providing

customers with qualified advice is crucial. If you have any

questions concerning this device, possible extensions or general

water and waste water treatment, our field service staff, as well

as the experts at our headquarters in Hoechstaedt, are available

to help you.

For advice and assistance please contact your local

representative (refer to www.gruenbeck.de).

In case of emergency, please get in touch with our service hotline at +49 9074 41-333. We can connect you with the appropriate expert more quickly if you provide the required system data.

To ensure that this information is to hand at all times, please

keep the precise equipment data to hand (refer to the type plate

in chapter C-1).

2 | How to use this operation manual

This operation manual is intended for the operators of our sys-

tems. It is divided into several chapters (a letter is assigned to

each of them) which are listed in the table of contents on page 2

in alphabetical order. Check for the corresponding chapter on

page 1 in order to find the specific information you need.

The headers and page numbers with chapter information make it

easier to find your way around in the operation manual.

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

5

Page 6

Electrodeionisation System

GENO-EDI-X

3 | General safety information

3.1 Symbols and notes

Important information in this operation manual is emphasised by

symbols. Please pay particular attention to this information to

ensure the hazard-free and safe handling of the system.

Danger! Failure to adhere to this information will cause serious or

life-threatening injuries, extreme damage to property or

inadmissible contamination of the drinking water.

Warning! Failure to adhere to this information may cause

injuries, damage to property or contamination of the drinking

water.

Caution! Failure to adhere to this information may result in

damage to the system or other objects.

Note: This symbol emphasises information and tips that make your

work easier.

Tasks with this symbol may only be performed by Grünbeck's

technical service/authorised service company or by persons

expressly authorised by Grünbeck.

Tasks with this symbol may only be performed by trained and qualified electrical experts according to the VDE guidelines or according

to the guidelines of a similar local institution.

Tasks with this symbol may only be performed by water

suppliers or approved installation companies. In Germany, the

installation company must be registered in an installation

directory of a water supplier as per §12(2) AVBWasserV

(German Ordinance on General Conditions for the Supply of Water).

3.2 Operating personnel

3.3 Designated application

Only persons who have read and understood this operation

manual are permitted to work with the system. Strictly observe

the safety information.

The system may only be used for the purpose outlined in the

product description (chapter C). The guidelines in this operation

manual as well as the applicable local guidelines concerning

drinking water protection, accident prevention and occupational

safety must be observed.

In addition, intended use also implies that the system may only

be operated when it is in proper working order.

Any errors must be eliminated at once.

The GENO-EDI-X is exclusively designed for use in the industrial and commercial field.

6

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Page 7

3.4 Protection from water

damage

3.5 Description of

specific dangers

Electrodeionisation System

GENO-EDI-X

Warning! In order to properly protect the installation site against

water damage:

A sufficiently dimensioned floor drain system must be

available or

a water stop device (refer to chapter C “Accessories”) must

be installed.

Warning! Floor drains that discharge to a lifting system will not

work in case of a power failure.

Danger due to electrical energy! Do not touch electrical parts

with wet hands! Disconnect the system from the mains before

starting work on electrical system components. Have qualified

experts replace damaged cables immediately.

Danger due to mechanical energy! System components may be

subject to overpressure. Danger of injury and damage to

property due to escaping water and unexpected movement of

system components. Check pressure pipes regularly.

Depressurise the system before starting repair or maintenance

work on the system.

Hazardous to health due to contaminated drinking water! The

system shall be installed only by a specialist company. Strictly

observe the operation manual! Ensure that there is sufficient

flow; the relevant guidelines must be followed for commissioning

after extended periods of standstill. Inspections and

maintenance must be performed at the intervals specified!

Note: By concluding a maintenance contract, you ensure that all

of the required tasks are performed on time. You may perform

the interim inspections yourself.

4 | Shipping and storage

Caution! The system may be damaged by frost or high

temperatures. In order to avoid damage of this kind:

Protect from frost during transportation and storage!

Do not install or store the system next to objects which radiate a

lot of heat.

The system may only be transported and stored in its original

packing. Ensure that it is handled with care and placed the right

side up (as indicated on the packaging).

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

7

Page 8

Electrodeionisation System

GENO-EDI-X

5 | Disposal

Comply with the applicable national regulations.

5.1 Packaging

5.2 Product

Dispose of the packaging in an environmentally friendly manner.

If this symbol (crossed out waste bin) is on the product, this

product is subject to the European Directive 2012/19/EU. This

means that this product or the electrical and electronic components must not be disposed with household waste.

Learn about the local regulations on the separate collection of

electrical and electronic products.

For information on collection points for your product, contact

your municipality, the public waste management authority, an

authorised body for the disposal of electrical and electronic products or your waste disposal service.

8

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Page 9

Electrodeionisation System

GENO-EDI-X

B Basic information

1 | Laws, regulations, standards

In the interest of good health, rules cannot be ignored when it

comes to the processing of drinking water. This operation

manual takes into consideration the current guidelines and

stipulates information that you will need for the safe operation of

your water treatment system.

Among other things, the set of rules stipulate that

only approved specialist companies are permitted to make

major modifications to water supply systems

and that tests, inspections and maintenance on installed

devices are to be performed at regular intervals.

2 | Water

As a result of dynamic substance and water cycles, increasingly

polluting elements are being released into the natural

environment. These are only partially and slowly broken down by

natural effects. Consequently, these elements build up in the

groundwater and surface water over the course of time.

Removing them from natural water deposits again represents a

particular challenge. Grünbeck faces this challenge with the

aim of producing unpolluted drinking and industrial water.

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

9

Page 10

Electrodeionisation System

GENO-EDI-X

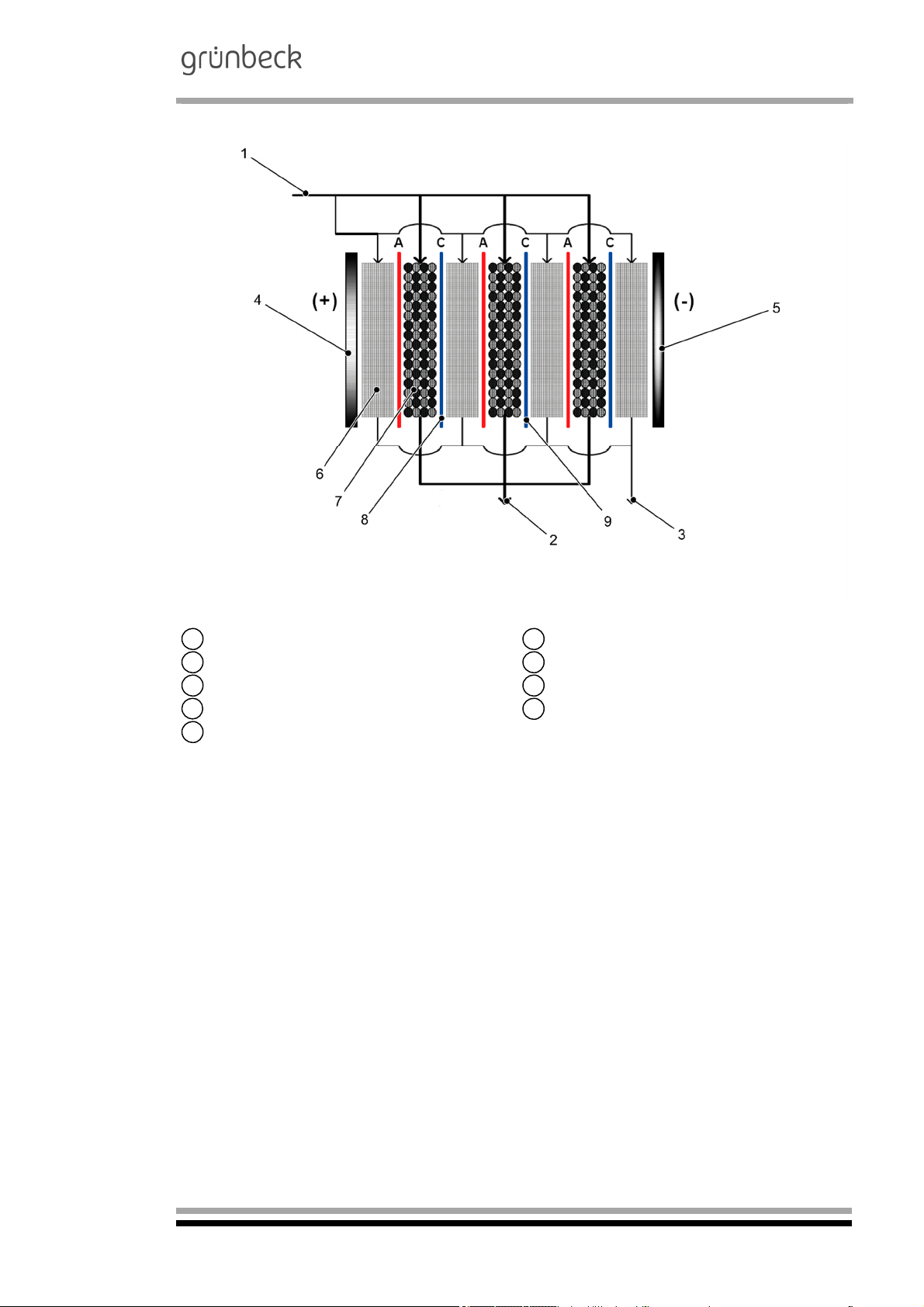

3 | Functional principle of electrodeionisation

3.1 Functional principle of electrodeionisation

Function

The electrodeionisation represents a continuous, electrochemical

membrane process that combines membrane technology and ion

exchanger technology.

In this process, ion exchanger resin, ion-selective membranes

and direct current are used to remove ions from the permeate of

a reverse osmosis system.

The resulting diluate (ultra-pure water) has a residual

conductivity of < 0.2 µS/cm. The residual conductivity depends

on the quality of the feed water (permeate).

The advantage of this technology is the fact that the

regeneration (by means of direct current) continuously takes

place during operation and no chemicals (acids/bases) are

required.

Contrary to common ion exchanger systems, the

electrodeionisation system GENO-EDI-X considerably

reduces the TOC values.

The core – the EDI module – consists of several chambers filled

with layers of anion and cation exchanger resins. The chambers

are separated from each other by anion and cation membranes.

The feed water (permeate) flows into the EDI module and is

divided into a diluate, concentrate and electrolyte water flow.

Due to the direct voltage applied, the ions move from the

diluate chambers filled with ion exchanger resin to the

concentrate chambers that are also filled with ion exchanger

resin.

While the water is in the diluate chambers is being fully

demineralised, the direct current splits the water into hydrogen

ions (H+) and hydroxide ions (OH

exchanger resins are regenerated again.

A part (10 %) of the feed water volume (permeate) rinses the

concentrate and the electrode chambers. The volume

designated as concentrate (unpressurised) is then either

directed to the drain or returned to the inlet of the reverse

osmosis system to be fed again.

The electrodeionisation system GENO-EDI-X has a recovery of

90 - 95 %.

-

) by which in turn the ion

10

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Page 11

Electrodeionisation System

3.2 Components of the electrodeionisation module (EDI module)

GENO-EDI-X

Permeate inlet Diluate outlet

1 2

Concentrate outlet

3 4

Cathode (-)

5 6

Diluate chamber with ion exchanger resin

7

Cation membrane (C)

9

Anode (+)

Concentrate chamber with ion exchanger resin

Anion membrane (A)

8

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

11

Page 12

Electrodeionisation System

GENO-EDI-X

C Product description (GENO-EDI-X)

1 | Type designation

plate

Please specify the data shown on the type designation plate of

your GENO-EDI-X electrodeionisation system in order to speed

up the processing of enquiries or orders. Please add the

necessary information to the overview below to have it readily

available whenever necessary.

Electrodeionisation system GENO-EDI-X:

Serial number:

Order number:

2 | Flow chart design

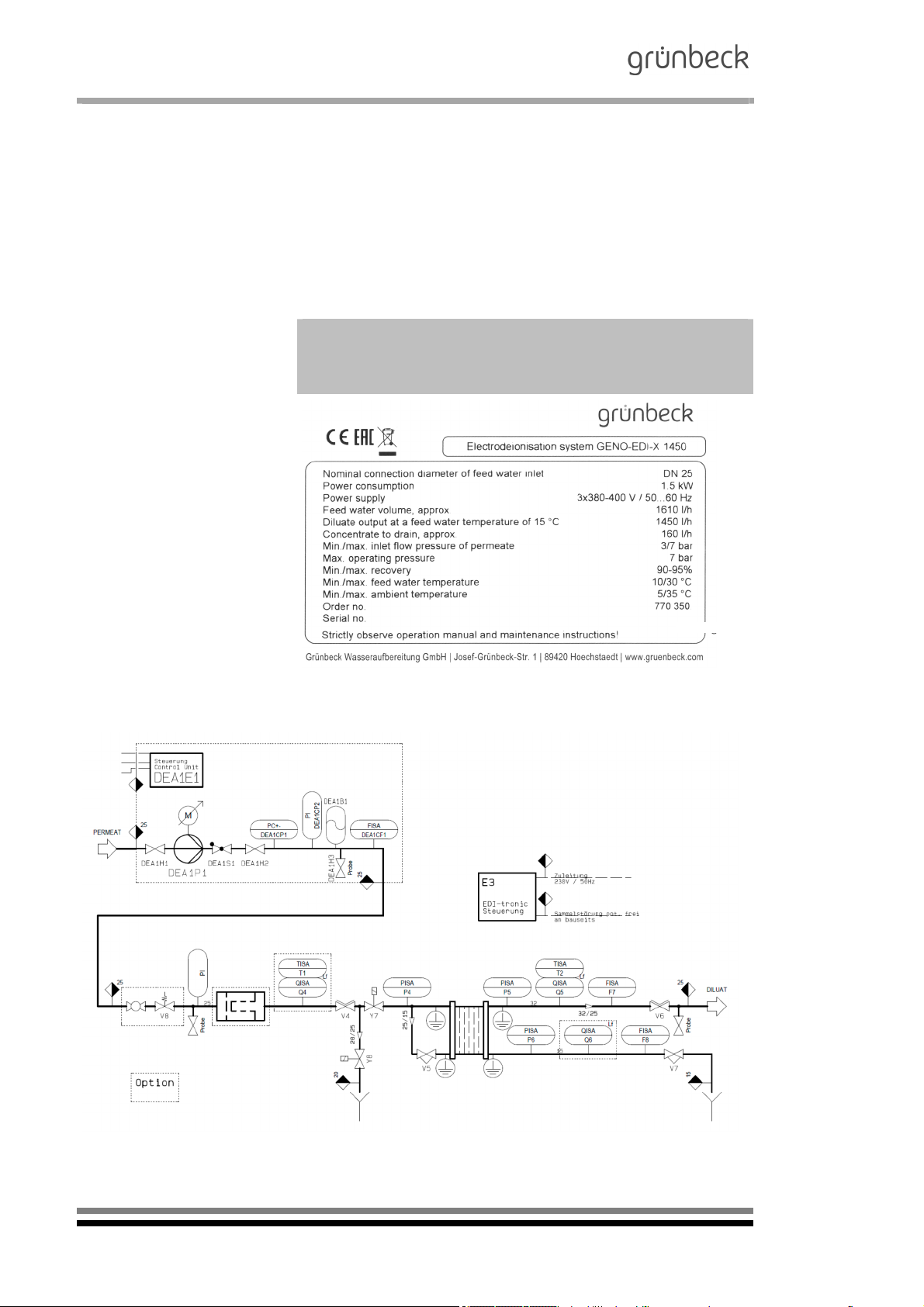

Fig. C-1: Type designation plate of the electrodeionisation system GENO-EDI-X

Fig. C-2: Flow chart of GENO-EDI-X

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

12

Page 13

Electrodeionisation System

GENO-EDI-X

3 | Basic function of the electrodeionisation system GENO-EDI-X

(without options)

If the system is in standby mode and ready for operation, the

inlet rejection valve and the inlet valve are closed. There is no

voltage present at the EDI module. If available, the outlet

rejection valve is open and the outlet valve closed. The

electrodeionisation system receives its start signal from the level

control system of the diluate tank. Then, the EDI controller

transmits the start signal to the RO controller. The RO system

starts operation and produces permeate. By means of the inlet

rejection valve, the time-controlled discharge of the permeate to

the drain takes place. In case the conductivity measuring cell for

permeate is installed, the rejection can be terminated prematurely if the max. permeate conductivity set is undershot.

Upon termination of the inlet rejection, the inlet valve opens and

the inlet rejection valve closes. When the inlet valve opens, the

EDI cell is supplied with voltage. From the moment the inlet

valve opens, the flows diluate and concentrate, the diluate

conductivity, the pressure of permeate, diluate and concentrate

as well as the temperature and the diluate are monitored and

trigger a time-delayed (adjustable) warning or an alarm. The

diluate is rejected via time by means of the outlet rejection - if

available (option) -, with premature termination in case the max.

diluate conductivity set is undershot. Following the opening of

the outlet valve, the outlet rejection valve is closed. The diluate

produced is now directed to the diluate tank.

As soon as the tank is full, a stop signal is transmitted to the EDI

controller. Within the electrodeionisation system, the voltage

supplied to the EDI cell is interrupted and the monitoring function

of the EDI system is deactivated. After a set rinsing sequence,

the RO system receives its stop signal and the valves move to

the following positions: Inlet rejection valve and inlet valve close

and – if available – the outlet rejection valve is open and the outlet vale is closed. Now, the electrodeionisation system remains

in standby mode until the next demand is made.

If the system is in standby mode, the inlet rejection valve Y8 and

the inlet valve Y7 are closed. There is no voltage present at the

EDI module.

The GENO-EDI-X system receives a start signal from the level

control system of the diluate tank. Then, the EDI controller transmits the start signal to the RO controller.

The RO system starts operation and produces permeate. By

means of the inlet rejection valve Y8, the discharge of the permeate to the drain takes place over a pre-set time period. Upon

termination of the inlet rejection, the inlet valve Y7 opens and the

inlet rejection valve Y8 closes.

When the inlet valve Y7 opens, the EDI module is supplied with

the divided partial permeate flows of diluate and concentrate.

In addition, the voltage and current are switched to the EDI module.

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

13

Page 14

Electrodeionisation System

GENO-EDI-X

From the moment the inlet valve Y7 opens, the diluate F7 and

concentrate F8 flows, the diluate conductivity Q5, the pressure

of permeate P4, diluate P5 and concentrate P6, as well as the

temperature of the diluate T2 are monitored and trigger a timedelayed (adjustable) warning and/or an error.

The diluate produced is now directed to the diluate tank. As soon

as the tank is full, a stop signal is transmitted to the EDI controler. Within the GENO-EDI-X electrodeionisation system, the

voltage supplied to the EDI cell is interrupted and the monitoring

function of the GENO-EDI-X system is deactivated.

After a set rinsing sequence, the RO system receives its stop

signal and the valves move to the following positions: inlet rejection valve Y8 and inlet valve Y7 closed.

Now, the GENO-EDI-X system remains in standby mode until

the next request is made.

*Diluate = deionate, ultra-pure water

14

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Page 15

4 | Description of the components

Electrodeionisation System

GENO-EDI-X

Adjusting valve

Operating

V4

1

2

3

4

5

6

7

pressure

(OPTION)

Adjusting valve

V5

Concentrate

volume

Adjusting valve

V6

Diluate pressure

Adjusting valve

V7

Concentrate

pressure

Permeate

V8

overflow valve

(OPTION)

Sample valve of

Pr-P

feed water

(Permeate)

Sample valve of

Pr-D

diluate

To throttle the permeate supply flow in case of excess capacity

from on-site feed pumps.

Not required for agreed-upon RO/EDI system combinations.

For the adjustment of the concentrate volume conducted to the

drain. This value corresponds with 10% of the permeate feed

value.

For the adjustment of the diluate counter-pressure.

For the adjustment of the concentrate pressure to the diluate

pressure.

Conducts the permeate from upstream RO systems to the drain;

these systems work in forced operation mode.

Protects the permeate side of the RO system in case the

solenoid valves of the GENO-EDI-X system do not open.

Adjustment: OPEN at 4 bar (g).

Possibilities of manual quality determination

via sample valve.

Possibilities of manual quality determination

via sample valve.

10

11

Registers the permeate quantity and sends pulses to the control

electronics.

8

9

diluate

Flow sensor

F8

Concentrate

Permeate

P4

pressure sensor

Pressure sensor

P5

Diluate

Flow sensor of

F7

Visual indication of the diluate quantity in the control electronics.

If the minimum flow of the diluate is undershot, an error is emitted.

GENO-EDI-X system STOP

Registers the concentrate volume and sends pulses to

the control electronics.

Visual indication of the concentrate volume in the control

electronics. If the minimum flow of the concentrate is undershot,

an error is emitted.

GENO-EDI-X system STOP

The maximum limit value is 4 bar(g)

When the set maximum permeate pressure value is exceeded,

the GENO-EDI-X system STOP takes place with a time delay.

Visual indication in the control electronics.

Indicates the diluate pressure value in the control electronics.

P5 must be at least 0.2 bar higher than P6!

The alarm signal takes place with a time delay when the

concentrate pressure value P6 is higher than/equal to the diluate

pressure value P5.

GENO-EDI-X system STOP

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

15

Page 16

Electrodeionisation System

GENO-EDI-X

Indicates the concentrate pressure in the control electronics.

P5 must be at least 0.2 bar higher than P6!

The alarm signal takes place with a time delay when the

concentrate pressure value P6 is higher than/equal to the diluate

pressure value P5.

GENO-EDI-X system STOP

Always open during diluate production.

Opens after a settable time interval (permeate rejection). Opens

after inlet rejection at conductivity < 20 µS/cm measured via Q4

(option).

Locked in case of errors in the GENO-EDI-X system.

Visual indication in the control electronics.

Opens for an adjustable time after EDI start.

Opens after start of EDI until a conductivity of 20 µS/cm measured via Q4 is undershot (option).

Closes after inlet rejection. Visual indication in the control

electronics.

12

13

14

Concentrate

P6

pressure sensor

Inlet solenoid

Y7

valve of permeate

Permeate inlet re-

Y8

jection valve

15

16

17

18

Outlet solenoid

valve of diluate

Y9

(OPTION)

Outlet rejection

valve of diluate

Y10

(OPTION)

Conductivity

measuring cell of

Q4

permeate

(OPTION)

Conductivity

Q5

measuring cell of

diluate

Opens after diluate rejection from Y10 if the conductivity limit

value for diluate is undershot.

Closes after GENO-EDI-X system STOP, locked in case of

errors in the GENO-EDI-X system.

Visual indication in the control electronics.

Opens after GENO-EDI-X system START and completed inlet

rejection, closes when the conductivity limit value for diluate is

undershot.

Visual indication in control electronics.

Indicates the quality of the permeate in the control electronics.

Enables quality-controlled permeate rejection.

Y8 CLOSED and Y7 OPEN if the set conductivity limit value

is undershot.

Visual alarm signal in the control electronics when the set conductivity limit value is exceeded.

GENO-EDI-X system STOP.

Indicates the quality of the diluate in the control electronics.

Enables quality-controlled diluate rejection.

Y10 CLOSED and Y9 OPEN if the set conductivity limit value is

undershot.

Visual alarm signal in the control electronics when the set conductivity limit value is exceeded.

GENO-EDI-X system STOP.

19

20

16

Conductivity

measuring cell

Q6

Concentrate

(OPTION)

Permeate temperature sensor

T1

(OPTION)

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Indicates the quality of the concentrate in the control electronics.

Indicates the temperature of the permeate in the control electronics.

Y8 CLOSED and Y7 OPEN if the set temperature value is exceeded.

Visual alarm signal in the control electronics when the set limit

value is exceeded.

GENO-EDI-X system STOP.

Page 17

Electrodeionisation System

GENO-EDI-X

Indicates the temperature of the diluate in the control electronics.

21

22

23

Diluate

temperature

T2

sensor

(OPTION)

Permeate feed

M8/

pump

P8/

Frequencycontrolled

P9

(OPTION)

Level control

L4

system of diluate

tank

Y9 CLOSED and Y10 OPEN if the set temperature value

is exceeded.

Visual alarm signal in the control electronics when the set limit

value is exceeded.

GENO-EDI-X system STOP.

Increases the permeate feed pressure.

Permeate pump M8 START through min. pressure contact P8.

Permeate pump M8 STOP through max. pressure contact P8.

Alternatively, M8 is operated using pressure sensor P8 in a

frequency-controlled manner.

M8 release always provided in case of inlet valve Y7 OPEN.

M8 is locked in case of min. pressure switch P9 (min. pressure).

Visual alarm signal on the frequency converter and in the

control electronics.

GENO-EDI-X system STOP.

Visual indication in the control electronics.

L4a+ full signal, GENO-EDI-X system STOP

L4b- request, GENO-EDI-X system START

L4c- additional and emergency feed (option)

L4d+ empty signal, dry-run protection for

PBS pump M6/M7, time-delayed

release for PBS pump M6/M7 in case level is exceeded

Visual indication in the control electronics.

Actuated by the pre-selector (H-O-A) in the control electronics.

Pressure booster

M6/

system

M7/

Diluate pressure

switch

P7

(OPTION)

Pressure switch with min. and max. pressure contact.

In case of automatic operation:

- M6/M7 ON via min. pressure contact of P7

- M6/M7 OFF via max. pressure contact of P7

- Time-controlled changeover operation of pumps M6/M7.

M6/M7 re locked in case of dry-run protection L4d.

Visual alarm signal in control electronics.

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

17

Page 18

Electrodeionisation System

GENO-EDI-X

5 | Technical specifications

Table C-1: Technical

Electrodeionisation system GENO-EDI-X

specifications

100 180 360 720 1100 1450 2000 2700

Connection data

Nominal connection diameter of

permeate feed line (screw connection)

Nominal connection diameter of

diluate outlet line (screw connection)

Nominal connection diameter of

concentrate outlet line

(screw connection)

Min. drain connection required [DN] 50

Connected load, approx.

Power supply [V/Hz] 1x 230 / 50

Protection type IP 54

Performance data

Feed water volume flow

(nominal)

Diluate capacity at a feed water

temperature 15°C and

a recovery of approx. 90 % (nominal)

Concentrate volume flow at

a recovery of approx. 90% (nominal)

Diluate capacity max.**** [l/h] 150 300 600 1000 1350 2100 2600 3750

Min. diluate flow*** required [l/h] 62,5 125 250 550 550 1100 1100 1400

Min. required flow of

concentrate***

Operating voltage [V-DC] < 106 < 213 < 426 < 130 < 130 < 240 < 240 < 300

Operating current [A] < 2.5 < 2.5 < 2.5 < 5 < 5 < 5 < 5 < 5

Inlet flow pressure of permeate,

min./max.

Outlet pressure of diluate, approx. [bar] 0.5/1.5

Max. operating pressure

Feed conductivity equivalent (FCE)**,

max.

Diluate conductivity*

TOC reduction

SiO2 reduction

Recovery***

Dimensions and weights

Dimensions (w x h x d) [mm] 900 x 1700 x 675

Min. room/installation height required [mm] 2000

Operating weight, approx. [kg] 95 105 115 170 170 190 190 215

Ambient data

Temperature of feed water, min./max. [°C] 10/25

Ambient temperature, min./max. [°C] 5/35

Order no. 770 300 770 310 770 320 770 330 770 340 770 350 770 360 770 370

*

Subject to the feed water quality

** For calculation, refer to the formula under “Application limits”

*** These volume flows must be considered as the absolute minimum for the flow rates of the EDI module!

**** In case of maximum recoveries of 93 and/or 95 %, the following shall further apply with regard to the feed water

specification:

< 0.02 ppm and SiO2 < 0.5 ppm

CaCO

3

[DN] 15 25

[DN] 15 25

[DN] 15 15

0.5 1.0 1.5 1.0 1.0 1.5 1.5 1.5

[kW]

[l/h]

110 200 400 800 1200 1600 2200 3000

[l/h] 100 180 360 720 1100 1450 2000 2700

[l/h] 10 20 40 80 100 150 200 300

[l/h] 10 20 40 40 40 65 65 85

[bar] 2/5 3/7

bar OP] 5 7

[µS/cm] 40

[µS/cm]

< 0.2

60 - 80

90 - 99

90 - 93 90 - 95

18

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Page 19

Electrodeionisation System

GENO-EDI-X

6 | Intended use

The electrodeionisation system GENO-EDI-X is designed for the

further quality enhancement of permeate generated by a

reverse osmosis system.

The most common areas of application for the diluate produced

(ultra-pure water) are:

- Steam sterilisation

- Semi-conductor industry

- Generation of pure steam

- Laboratories

The system can be used only after a prior water analysis and

corresponding pretreatment.

The continuous diluate output of the system is subject to the

temperature and is defined at 15°C. The diluate outputs can fall

(falling temperature) or rise (rising temperature) by up to 3 % for

each °C the raw water temperature increases or decreases.

Only operate the system if all components are properly installed.

Safety devices must NEVER be removed, bridged or otherwise

tampered with.

Appropriate application of the device also implies that the

information contained in this operation manual and all safety

regulations applying at the installation site be observed.

Furthermore, the maintenance and inspection intervals have to

be observed.

6.1 | System shutdown

During decommissioning of the GENO-EDI-X system, the

necessary measures must be decided upon together with

Grünbeck’s technical service.

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

19

Page 20

Electrodeionisation System

GENO-EDI-X

7 | Application limits

Conductivity equivalent

FCE*: < 40 µS/cm

(CO

included)

2

Range of pH value: 4 – 11

Cl

concentration: < 0.02 ppm

2

Fe concentration: < 0.01 ppm

Mn concentration: < 0.01 ppm

Sulphide concentration: < 0.01 ppm

Concentration of residual

hardness (CaCO

(^ 0.056 °dH)

TOC concentration < 0.5 ppm

Silicate concentration (SiO

Water temperature: 10 – 25°C

*FCE = permeate conductivity + (ppm CO

+ (ppm SiO

): < 1.0 ppm

3

x 1.94)

2

): < 1.0 ppm

2

x 2.79)

2

Note: The diluate from GENO-EDI-X system is not drinking

water!

*

For the determination of this value, the formulae in section E,

chapter 1 must be used!

20

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Page 21

8 | Scope of supply

Electrodeionisation System

GENO-EDI-X

8.1 Standard equipment

Device that is ready for connection for the continuous,

electrochemical, residual demineralisation of permeate

originating from a reverse osmosis system, completely

pre-assembled to an anodised aluminium system rack.

Microprocessor controller with LCD graphic display

(70 x 38 mm backlit) Flow chart of the electrodeionisation

system with collection tank including level control, pressure

booster system for diluate as well as indication of the flow,

pressure and conductivity values of the electrodeionisation

system.

Version: Membrane keyboard with 12 buttons and serial

interface RS 232, system piping within the

electrodeionisation system equipped with pressure sensors,

adjusting and/or solenoid valves, as well as sampling fittings.

Integrated flow sensors to monitor the volume flows diluate

and concentrate. The switch cabinet features all power units

as well as the control electronics. Quality assurance of

diluate by means of temperature-compensated conductivity

measurement with digital indication at the display of the

control electronics Piping within the system completely made

of high-pressure resistant PE plastic pipes.

EDI module as the main core of process engineering.

Installation and operation manual.

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

21

Page 22

Electrodeionisation System

GENO-EDI-X

8.2 Optional features

Note: It is possible to retrofit existing systems with optional

components. Please contact your local Grünbeck field service

staff or Grünbeck’s headquarters in Hoechstaedt for more

information.

GENO-EDI-Profibus DP

Module to provide system data

770 860

For GENO-EDI-X 100 through 360 770 815

For GENO-EDI-X 720 through 2700 770 875

For GENO-EDI-X 720 through 2700

GENO-EDI voltage-free single fault signals

for DDC/central building and control system

Module for single fault signals (voltage-free) to

control centre

Quality-controlled permeate rejection

Rejection of feed permeate in the inlet to the

electrodeionisation system

(conductivity-controlled)

Analogue outputs (4-20 mA) for conductivity

and diluate temperature

Module for outputting measuring values to control

centre

Quality-controlled diluate rejection

Rejection of diluate prior to filling

the pure water tank (conductivity-controlled)

Measuring of conductivity and temperature of

EDI concentrate

Module to measure the conductivity / temperature

in the EDI concentrate (waste water)

in the feed water

For GENO-EDI-X 100 through 360

GENO membrane degassing system

MEC 500-1 (single-stage)

For removing CO

of the electrodeionisation system

Flow volume of feed water:

0.1 – 0.7 m³/h

Amount of stripping gas* required:

0.2 – 1.8 Nm³/h

GENO membrane degassing system

MEC 500-2 (2-stage)

For removing CO

of the electrodeionisation system

Flow volume of feed water:

0.1 – 0.7 m³/h

Amount of stripping gas* required:

0.4 – 3.6 Nm³/h

from the feed water (permeate)

2

from the feed water (permeate)

2

770 855

770 800

770 810

770 805

770 870

770 200

770 205

22

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Page 23

Electrodeionisation System

GENO-EDI-X

GENO membrane degassing system

MEC 2200-1 (single-stage)

For removing CO

from the feed water (permeate)

2

of the electrodeionisation system

Flow volume of feed water:

0.5 – 3.41 m³/h

Amount of stripping gas* required:

0.8 – 5.1 Nm³/h

GENO membrane degassing system

MEC 2200-2 (two-stage)

For removing CO

from the feed water (permeate)

2

of the electrodeionisation system

Flow volume of feed water:

0.5 – 3.41 m³/h

Amount of stripping gas* required:

1.6 – 10.2 Nm³/h

*Stripping gas = oil-free, compressed air

Pure water tank for intermediate storage of the

diluate flowing unpressurised from the

GENO-EDI-X electrodeionisation systems

Tank version:

All tanks are pre-assembled, with PVC overflow pipe as

well as connections for the inlet, diluate and the suction

line of the pressure booster system. Grey PE. Hand-hole

with removable screw cap. Level probe for installation

into the tank, electrically connected to GENO-EDI-tronic

controller.

Basic clean water tank X

RT 1000 with sterile filter and level measuring probe

Net volume approx. 850 litres

L 780 / W 990 / total H 2000 mm

1)

.

770 210

770 215

712

480

Additional tank RT for basic pure water tank

Net volume approx. 850 litres

L 780 / W 780 / total H 2100 mm

1)

Tank height including connecting pieces.

1)

.

For larger tanks, please inquire

Additional tank without level control and overflow loop,

including 2 connecting lines, id=36 mm.

Note: A maximum of four supply tanks can be combined.

For larger CO

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

trap for pure water tank

CO

2

For the removal of free carbon dioxide from the tank's

ventilating air.

traps, please inquire

2

712

405

712 800

23

Page 24

Electrodeionisation System

GENO-EDI-X

Pressure booster system

GENO-FU-X 2/40-1 NE

Compact, pressure-controlled pump aggregate

consisting of a centrifugal pump completely made of

stainless steel as well as an integrated pressure and

flow meter for pump control and dry-run protection.

Special version for the delivery of diluate.

Delivery rate: Max. 1.2 - 4.4 m³/h

Delivery head: max. 26.7 - 59.4 m

730 790

Power supply: 230 V / 50 Hz

Power consumption: 1.07 kW

Connections: DN 25 / 1”

Protection type: IP 55

For larger systems, please inquire

8.3 Wearing parts

Seals and valves are subject to a certain wear and tear. Wearing

Pressure booster system

GENO-FU-X 2/40-2 NE

Description as for single pressure booster system,

however, with the possibility for time-load switch-over.

parts are listed below.

Note: Although these parts are wearing parts, we grant a limited

warranty period of 6 months. The same applies to electrical components.

Solenoid valves, adjusting valves (operating pressure, concentrate volume, concentrate pressure, diluate pressure), sample

valves and water meters

730 791

24

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Page 25

Electrodeionisation System

GENO-EDI-X

D Installation

1 | General installation information

The installation site must offer adequate space. For installation

and service work, sufficient clearance (> 50 cm, > 20 cm from

the wall) must be provided around the system. A foundation of a

sufficient size and adequate load carrying capacity must be provided.

The required connections must be provided prior to the installation of the system. For dimensions and connection data, please

refer to the table "Technical specifications".

The installation of an electrodeionisation system represents a

major interference with the drinking water system. Therefore,

only approved installation companies may install such systems.

Observe local installation guidelines and general regulations.

Install a drinking water filter upstream (e.g., pureliQ).

Install a system separator upstream.

Install a water softener upstream.

1.1 Preliminary work

Install an activated carbon filter upstream.

Install a reverse osmosis system upstream If the CO

tion is too high, a membrane degassing system must be provided in addition.

Provide a drain connection (at least DN 50) to discharge the

concentrate.

For the electrical connection, a feed line to the system must be

provided on site according to the electric circuit diagram. This

line must be dimensioned according to the system type.

The installation site must have a floor drain. If no floor drain is

available, an adequate safety device needs to be installed. Floor

drains that discharge to a lifting system will not work in case of a

power failure.

Safe unloading/placing of the system.

Unpacking of the system/system components.

Check of the system for any damage.

Erection of the electrodeionisation system.

Check of the mechanical and electrical connections; these

connections might have to be retightened after transport.

concentra-

2

Note: When installing systems with optional features, also

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

observe any additional operation manuals.

25

Page 26

Electrodeionisation System

GENO-EDI-X

2 | Water connection

Certain binding rules must always be observed when installing

the electrodeionisation system. Additional recommendations are

given in order to facilitate the handling of the system.

Mandatory regulations

The installation of the electrodeionisation system may be

performed by an approved installation company only.

Observe local installation guidelines and general

regulations.

Establish the feed water connection (permeate).

Establish the concentrate connection.

Guarantee free access to the drain!

Establish the diluate connection.

Testing of the tightening torques on the bolts of the

EDI module

Tighten any bolts according to specification.

Applies to: GENO-EDI-X 720 / 1100 / 1450 / 2000 / 2700.

Provide a drain connection (minimum DN 50) to

discharge the concentrate.

Note: If the concentrate is directed to a lifting system, the

delivery rate of the lifting system must be > 500 l/h.

Warning! At the installation site, you must ensure that the

depressurised waste water can flow off to the drain without

obstruction.

Warning! The installation site must have an adequate exchange

of air!

26

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Page 27

3 | How to connect the system

Remove the protective caps from system’s feed water (= per-

meate), diluate and concentrate-to-drain connections

Connect the feed water (= permeate).

Connect the concentrate to drain according to DIN 1988.

Establish the connection between diluate outlet and diluate

tank.

Electrodeionisation System

GENO-EDI-X

Mount CO

Limit of supply

Grünbeck

by others

Raw water

Diluate

Concentrate

Fig. D-1: Installation drawing

1

Drinking water filter BOXER K 1"

System separator DK 2

2

Delta-p water softener

3

4

GENO-softwatch Komfort

Activated carbon filter AKF

5

trap to vent the diluate tank

2

Reverse osmosis system GENO-OSMO-X

6

Electrodeionisation system GENO-EDI-X

7

(Optionally with integrated GENO membrane

degassing system MEC)

8

Diluate tank with CO2 trap

9

Pressure booster system GENO-FU-X

Note: In the feed water (= permeate), concentrate and diluate

pipes provided by others on site, separable connections must be

present (e.g. screw connections) to be able to separate the

pipes.

Note: The feed water (= permeate), diluate and concentrate

pipes have to be made of corrosion-proof material.

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

27

Page 28

Electrodeionisation System

GENO-EDI-X

4 | Electrical wiring

Note: The pertinent electric circuit diagrams are located

separately in the switch cabinet of the GENO-EDI-X system. The

power feed line dimensions can be found there.

1. For the electrical connection, a supply line to the system

must be provided on site according to the electric circuit

diagram. This line must be dimensioned according to the

system type.

2. Wire the level control of the collection tank according to the

electric circuit diagram.

3. Testing of the earth connections of the EDI module

Each of the 4 connection pieces on the EDI module must

4. Any connection of a collective fault signal must take place

on site.

be earthed!

28

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Page 29

K

Electrodeionisation System

GENO-EDI-X

E Commissioning

The work described below may only be performed by trained

experts. For safety reasons, the commissioning must be

performed by Grünbeck's trained and authorised technical

customer service/authorised service company.

1 | General information

The GENO-EDI-X systems are factory-tested and pre-adjusted and

have undergone a test run.

1.1 Preliminary work

Commission the upstream RO system, guarantee the

permeate inlet to the GENO-EDI-X system and disconnect

the connection to the diluate tank.

Ensure the electrical power supply and activate the ON mains

switch.

Determining the required current value for the regeneration of

the GENO-EDI-X system.

For this purpose, the following is required:

a) CO

b) SiO

content in permeate

2

content in permeate

2

c) Total conductivity (conductivity of permeate)

d) Feed conductivity equivalent (FCE)

Calculation according to the following formula:

FCE = conductivity + (ppm CO

x 2.79) + (ppm SiO2 x 1.94)

2

e) The required current value for GENO-EDI-X 100 / 180 / 360

is then calculated as follows:

Q

xFCE

I

Diluate flow Q

in l/h

h

Feed Conductivity Equivalent FCE in µS/cm

EDI module index K = 3660 for EDI-X 100

EDI module index K = 7320 for EDI-X 180

EDI module index K = 14640 for EDI-X 360

The required current value for GENO-EDI-X 720 / 1100 /

1450 / 2000 / 2700 is then calculated as follows:

,

I

Diluate flow Q

in l/min

h

Feed Conductivity Equivalent FCE in µS/cm

EDI module index N = 10 for EDI-X 720 / 1100

EDI module index N = 18 for EDI-X 1450 / 2000

EDI module index N = 24 for EDI-X 2700

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

29

Page 30

Electrodeionisation System

GENO-EDI-X

2 | START EDI-X system operation

Switch on the GENO-EDI-X system on the control

electronics using the “ON” button.

Calibration of the flow sensors F7/F8 (gauging during

production).

Check of the flow values for diluate and concentrate.

Readjustment on the adjusting valves V5, V6, V7.

Check of the differential pressure between the diluate and

concentrate (set point dp > 0.2 bar and < 0.5 bar);

reregulation at V6 and V7 as required.

Setting of the determined current value in the control

electronics (refer to section “F” in chapter 4.4.2 “Main

menu/parameters”).

During the stable operation of the GENO-EDI-X system at

constant values, the parameters must be entered in the log

sheet. This should stop after about 2 operating hours.

A stable operation for at least 12 h for the initial start-up

must be targeted to run in the EDI module.

Note:

The GENO-EDI-X system is switched off in the control

The most important parameters for EDI adjustment are as

follows:

1. Inlet pressure

2. Differential pressure of diluate/concentrate

3. Operating current/voltage

Switching off the GENO-EDI-X system

electronics using the “0-ON” button.

After a brief run-down time, the GENO-EDI-X comes to a stop.

30

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Page 31

F Operation

1 | Introduction

Note: Instructions in bold are absolutely essential to ensure that

2 | Brief description of GENO-EDI-tronic

work can continue. All other instructions can be ignored if the

value shown on the display remains unchanged.

Settings in the technical service programming level may only be

performed by Grünbeck's technical customer service/authorised

service company or by persons expressly authorised by

Grünbeck.

Warning! Incorrect settings may lead to hazardous operating

conditions which cause injury, illness or damage to property.

The operation manual must be strictly adhered to! Only make

the settings described there!

Electrodeionisation System

GENO-EDI-X

2.1 Field of application

GENO-EDI-tronic constitutes the control electronics for all

Grünbeck electrodeionisation systems GENO-EDI-X.

2.2 Function

GENO-EDI-tronic controls the operation of the

electrodeionisation system in connection with optional pressure

booster systems. In the system menu, the individual components

can be activated and are available as a flow chart on the display

( visualisation system).

2.3 Basic technical parameters – control panel

Table F-1:

Basic technical

parameters

Membrane keyboard with 12 buttons

Graphic display with 128 x 64 pixels

Dimensions: approx. 70 x 35 mm and backlight

Serial interface RS-232

Used for the connection of a PC (software update)

and actuation of the EDI power supply unit

Interface For the MK200 system bus for the actuation of the

MK200 / MSR module and extensions

Supply voltage 10 VAC and 18 VAC, galvanically isolated

Control panel

2.4 Basic technical parameters – MK200 basic module

Table F-2:

Basic technical

parameters

Dimensions (w x h x d) 130 x 108 x 75 mm

Ambient conditions Working temperature 0...50°C

Storage temperature –20...85°C

Relative humidity: maximum 95%

10 VAC and 18 VAC, galvanically isolated

Noise immunity according to EN 50082-2

Emissions according to EN 50081-1

MK200 basic module

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

31

Page 32

Electrodeionisation System

GENO-EDI-X

3 | Switch cabinet

The switch cabinet contains the terminals for all connecting line,

the power supply unit for the EDI module, the control

transformers for the voltage supply, the fuses and the protective

motor switch and the MK200 module, which controls the system

in conjunction with the control panel.

Note: The electric circuit diagram of the system can be found

here.

Fig. F-1 Switch cabinet

32

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Page 33

4 | Operating the control unit

Electrodeionisation System

GENO-EDI-X

Fig. F-2: Control panel

“Display” function in the respective menu

“Entry” function in the respective menu

Access to the “EDI System” menu

Access to the “PB System” menu or Exit

Access to the system menu

Switch the EDI system on/off

(green pilot LED lights up when ON)

Acknowledge the malfunction/leave an open entry field without

saving

Enter

Move the cursor to the left / right

Edit the values entered or move the cursor up and down

The red pilot LED lights up when the control unit detects an

error.

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

33

Page 34

Electrodeionisation System

GENO-EDI-X

5 | Operating the control unit

5.1 Basic information regarding the operation of the control unit

Fig. F-3: Menu access

Fig. F-3a EDI code entry

5.2 System menu

F1

The menu contains a few items that are not explained here.

These include adjusting values for expansion modules. The

documentation of these points is provided only together with

these modules. In the basic version, the items have no function.

Two screens are available in the system menu and in the

submenus of the respective system components.

On the "Display" screen, the parameters can be viewed,

but not changed.

In the "Entry" screen, all the parameters of the respective

menu level can be edited if the relevant code is entered.

Enter code: Move the cursor to the de sired point using the

buttons ◄ and ► and set the desired value using the

buttons ▲ and ▼. Confirm the entry with the button.

This menu includes the adjusting value related to the entire system. The system menu is called by pressing the button on

any system display screen. On the next screen, the only choices

still available are the display function (F1 button) and the entry

function (F2 button). The F4 button takes you back to the previous display screen. If the entry mode was selected with the F2

button, the code for the desired level must be entered and this

entry must be confirmed by pressing the button.

The system menu is structured as below:

System menu

> Input Logic

Output Logic

I/O Configuration

System Config.

I/O Display

Error Memory

Basic Setting

The selection is made using the arrow buttons ▲ and ▼. The

button takes you to the selected submenu. The F4 button (Exit)

takes you to the previous screen.

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

34

Page 35

5.2.1 Overview of the inputs and outputs

Input Function Output Function

1 P9 Low pressure switch for

pre-feed pump

2 L4a switch-off level

GENO-EDI-X

3 L4b switch-on level

GENO-EDI-X

4 L4c emergency and

additional feed

5 L4d dry-run protection

PB pump (diluate)

6 P8 pressure switch for

permeate pump M8

7 Error in permeate

pre-feed pump M8

8 “Standby” signal of RO

system (option)

9 P7 pressure switch of PB

pump (diluate) for rotary

current of PB pumps

10 Error in PB pump M6

P7 pressure switch for

alternating current

of PB pumps

11 Error in PB pump M7

Electrodeionisation System

GENO-EDI-X

1

RO system release

(option)

system

system

2

Supply of power supply

unit

3

Solenoid valve Y11

Emergency feed

4

Collective fault

5

PB pump M6

(diluate)

6

PB pump M7

(diluate)

7

Solenoid valve Y7, inlet

permeate

8

Solenoid valve Y8,

rejection permeate

9

Solenoid valve Y10,

rejection

diluate

10

Permeate

pre-feed pump M8

11

Solenoid valve Y9,

discharge

diluate

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

35

Page 36

Electrodeionisation System

GENO-EDI-X

Continuation Overview of inputs and outputs

Table F-4: Overview of inputs and outputs

5.2.2 Input Logic

Input Function Output Function

12 Error in power supply unit 1

(option)

13 Error in power supply unit 2

(option)

14 Error in power supply unit 3

(option)

15 Reserve

16 Programmable input

In this submenu, the logic of the digital inputs of the basic

module can be inverted. This submenu has the following

parameters:

Menu

Input Logic

Input XX:

(XX = 1...16)

Setting range

Logic setting for digital inputs

1...16

Basic setting Level

0

0: Input is an NO contact

1: Input is an NC contact

Table F-5: Input Logic

5.2.3 I/O Configuration

In this submenu, the universal inputs/outputs can be configured.

This submenu has the following parameters:

Menu

I/O Config.

E04: Level L4c present

E16: Message text for input 16

E16 function: Function of input 16

E16 delay: Delay time for input 16

Table F-6: Configuration

Setting range

NO: No function

YES: Input for level

switch L4c

Entry of up to 16 characters

FREE: No function

WARNING: Input leads to

a warning

ERROR: Input leads to

shut-down

Setting range: 0...999

seconds

Basic setting Level

NO

FREE

0 sec.

36

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

Page 37

5.2.4 System

Configuration

Electrodeionisation System

GENO-EDI-X

In this submenu, the existing system components can be

defined. This submenu has the following parameters:

Menu

System Config.

Language: GERMAN

PB system

present

Signals

module

Profibus module Definition of the Profibus

Setting range

ENGLISH

Definition of pressure

booster function

NO: No

pressure

booster

present

YES: Pressure

booster

present

Definition of the Signals

module.

NO: No Signals

module

present

YES: Signals

module

present

module

Basic setting Level

GERMAN Code

NO

NO

NO

0095

NO: No Profibus

module

present

YES: Profibus

module

Flow

module

System data

printout

Table F-7: System Configuration

present

Definition of the Flow

module

NO: No Flow

module

present

YES: Flow

module

present

Start of the system data

printout through the serial

interface by entering “1”.

After the start, the value is

automatically reset to “0”.

NO

0

Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx

37

Page 38

Electrodeionisation System

GENO-EDI-X

5.2.5 I/O Display

In this submenu, the current states of the inputs/outputs are

displayed. This submenu has the following parameters:

Menu

I/O Display

Inputs

E16 – E01:

Outputs

A11 – A01:

Table F-8: I/O Display

Setting range

Input states of the individual

inputs

Input 16 left /

Input 1 right

0: Input open

1: Input closed

Output states of the individual inputs

Output 11 left /

Output 1 right

0: Output not active

1: Output active

Basic setting Level

------ Code

0095

------ Code

0095

5.2.6 Error Memory

The error memory stores the last 16 messages whereby the last

message always appears at the top (position 01). In addition to

the position number and the message text, each line also includes the value of the operating hour meter at the point in time

at which the message was created. In the top line next to the

menu header, the current value of the operating hour meter can

be read. The contents of the error memory can be deleted by

pressing the F1 button when the service password is entered.