Page 1

Operation manual

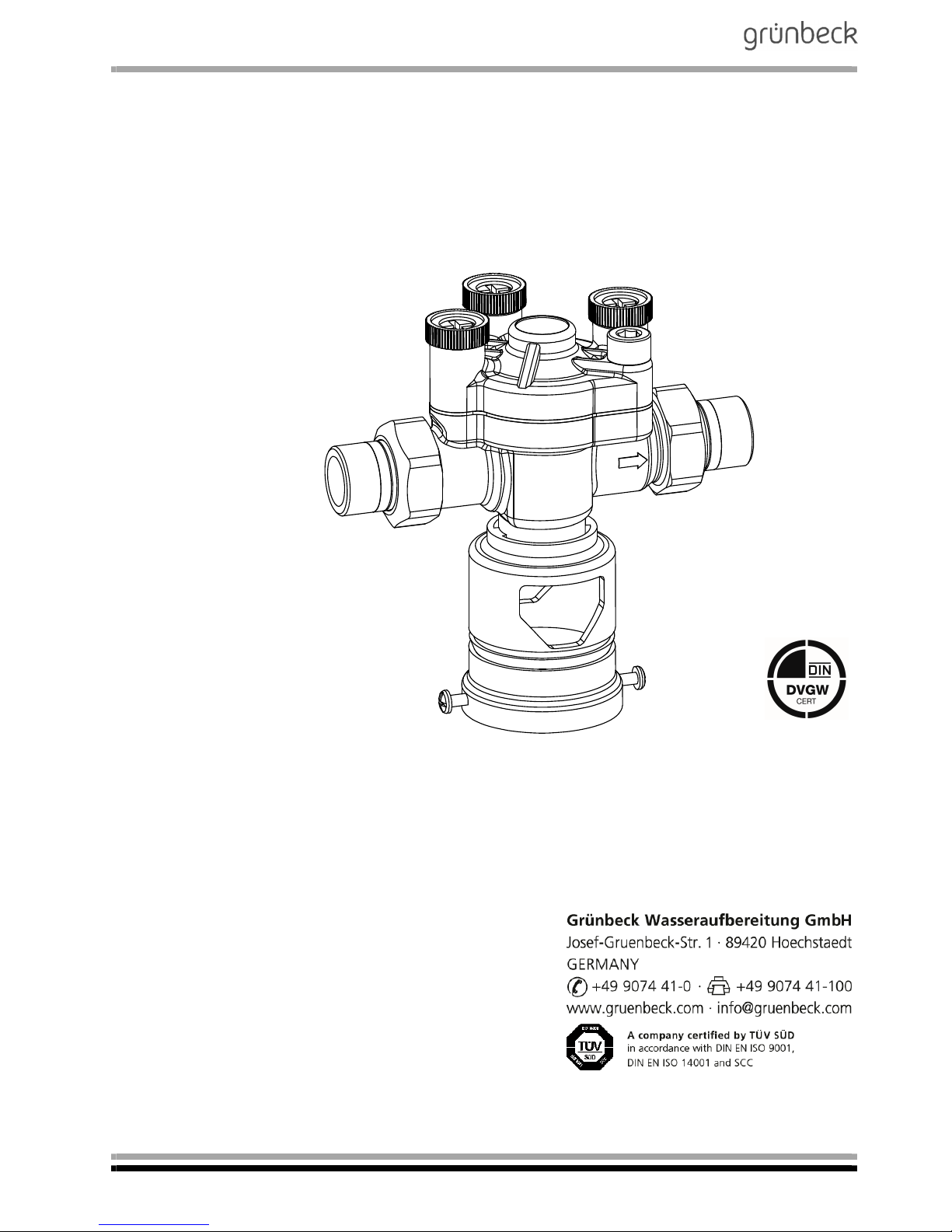

Euro-system separator GENO DK 2-Mini

Euro system separator GENO -DK 2 mini Nominal diameter DN 15

Edition: July 2017

Order no. 085 133 944-inter

Page 2

Page 3

Table of contents

A General

1 Preface

2 Warranty

3 General safety information

4 Shipping and storage

5 Disposal of used parts and materials

3

B Basic information

1 Laws, regulations, standards

2 Classification of liquid categories

5

C Product description

1 Type designation plate

2 Designated application

3 Functional description

4 Technical specifications

5 Scope of supply

6

D Installation and start-up

1 General installation instructions

2 Water installation

3 Start-up

4 Functional check

8

E Troubleshooting

10

F Maintenance, care and spare parts

1 Basic information

2 Inspection

3 Maintenance

4 Spare parts

11

Attachments: Warranty card

Publisher's information

All rights reserved.

© Copyright by Grünbeck Wasseraufbereitung GmbH

Printed in Germany

Effective with the date of edition indicated on the cover sheet.

-We reserve the right to modifications, especially with regard to technical progress-

Reprints, translations into foreign languages, electronic storage or copying only with explicit written approval of Grünbeck Wasseraufbereitung GmbH.

Any type of duplication not authorised by Grünbeck Wasseraufbereitung is a copyright violation and subject to legal action.

Responsible for contents:

Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Str. 1, 89420 Hoechstaedt/Germany

Phone +49 9074 41-0 Fax +49 9074 41-100

www.gruenbeck.de service@gruenbeck.de

Print: Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Str. 1, 89420 Hoechstaedt/Germany

Page 4

Euro-System Separator

GENO

DK 2-Mini

Order no. 085 133 944-inter Edited by: fger/mrie G:\BA-133944-INTER_085_SYSTEMTR-DK_2-MINI.DOCX

2

A General

1 | Preface

Thank you for opting for a Grünbeck product. Backed by decades of experience

in the area of water treatment, we provide solutions for all kind of processes.

All Grünbeck systems and devices are made of high-quality materials. This ensures reliable operation over many years, provided you treat your water treatment system with the required care. This operation manual assists you with important information. Therefore, please read the entire operation manual before installing, operating or maintaining the system.

Customer satisfaction is our prime objective and providing customers with qualified advice is crucial. If you have any questions concerning this device, possible

extensions or general water and waste water treatment, our field staff, as well as

the experts at our headquarters in Hoechstaedt, are available to help you.

Advice and assistance

For advice and assistance please contact your local representative

(see www.gruenbeck.de) or get in touch with our service centre which can be

reached during office hours:

Phone: +49 9074 41-333

Fax: +49 9074 41-120

Email: service@gruenbeck.de

We can connect you with the appropriate expert more quickly if you provide the

required system data. In order to have the required data handy at all times,

please copy it from the type designation plate to the overview in chapter C-1.

2 | Warranty

All devices and systems supplied by Grünbeck Wasseraufbereitung GmbH are

manufactured according to the most recent technical standards and subjected to a

comprehensive quality assurance system. All warranty claims are subject to our

General Terms and Conditions of Sale and Delivery.

3 | General safety information

Operating personnel

Only persons who have read and understood this operation manual are permitted

to work with our systems and devices. The safety guidelines are to be strictly adhered to.

Symbols and notes

Important information in this operation manual is characterised by symbols.

Please pay particular attention to this information to ensure the hazard-free, safe

and efficient handling of the system.

Danger! Failure to adhere to this information will cause serious or life-threatening

injuries, extreme damage to property or inadmissible contamination of the drinking water.

Warning! Failure to adhere to this information may cause injuries, damage to

property or contamination of the drinking water.

Attention! Failure to adhere to this information may result in damage to the system or other objects.

Page 5

Euro-System Separator

GENO

DK 2-Mini

Order no. 085 133 944-inter Edited by: fger/mrie G:\BA-133944-INTER_085_SYSTEMTR-DK_2-MINI.DOCX

3

Note: This symbol characterises information and tips to make your work easier.

Tasks with this symbol may only be performed by Grünbeck's technical service/authorised service company or by persons expressly authorised by

Grünbeck.

Tasks with this symbol may only be performed by trained and qualified electrical

experts according to the VDE guidelines or according to the guidelines of a similar local institution.

Tasks with this symbol may only be performed by water supply companies or approved installation companies. In Germany, the installation company must be registered in an installation directory of a water company as per §12(2) AVBWasserV

(German Ordinance on General Conditions for the Supply of Water).

4 | Shipping and storage

Attention! The systems and devices may be damaged by frost or high tempera-

tures. Protect from frost during transportation and storage! Do not install or store

the systems or devices next to objects, which radiate a lot of heat.

The system may only be transported and stored in its original packing. Ensure

that it is handled with care and placed the right side up (as indicated on the packing).

5 | Disposal of used parts and materials

Used parts and materials are to be disposed of, or made available for recycling

purposes, according to the applicable local guidelines.

If a material is subject to specific regulations, adhere to the instructions indicated

on the packing.

If in doubt, contact your local waste disposal authority or the manufacturer for

more information.

Page 6

Euro-System Separator

GENO

DK 2-Mini

Order no. 085 133 944-inter Edited by: fger/mrie G:\BA-133944-INTER_085_SYSTEMTR-DK_2-MINI.DOCX

4

B Basic information (system separators)

1 | Laws, regulations, standards

In the interest of good health, rules cannot be ignored when it comes to the processing of drinking water. This operation manual takes into consideration the current regulations and stipulates information that you will need for the safe operation of your system separator.

Among other things, the regulations stipulate that

only approved companies are permitted to make major modifications to water

supply facilities

and that tests, inspections and maintenance on installed devices are to be per-

formed at regular intervals.

2 | Classification of liquid categories

Liquid category 1

Water for human consumption that is withdrawn directly from a drinking water installation.

Examples:

Temporary turbidity due to air bubbles.

Liquid category 2

Liquids that do not represent a health risk to human beings.

Liquids that are suitable for human consumption - including water originating from

a drinking water installation - that may exhibit modifications with regard to taste,

smell, colour or temperature (heating up or cooling down).

Examples:

Coffee, heated drinking water.

Liquid category 3

Liquids that represent a health risk to human beings due to the presence of one

or several poisonous or highly poisonous substances.

Examples:

Ethylene glycol, copper sulphate solution, heating water without additives or with

additives as per liquid category 3.

Liquid category 4

Liquids that represent a health risk to human beings due to the presence of one

or several poisonous or highly poisonous substances or one or several radioactive, mutagenic or carcinogenic substances.

Examples:

Lindane, phosalone, parathion (insecticides), hydrazine, heating water with additives as per liquid category 4.

Liquid category 5

Liquids that represent a health risk to human beings due to the presence of microbial or viral pathogens of communicable diseases.

Examples:

Hepatitis viruses, salmonellae

(excerpt of DIN EN 1717, part 5.2)

Attention! System separators are safety devices. They protect the drinking water

from modified drinking water. They can only work reliably provided inspections

and maintenance are carried out at regular intervals.

Page 7

Euro-System Separator

GENO

DK 2-Mini

Order no. 085 133 944-inter Edited by: fger/mrie G:\BA-133944-INTER_085_SYSTEMTR-DK_2-MINI.DOCX

5

C Product description (system separators)

1 | Type designation plate

The type designation plate is located on the housing of the system separator. In order to speed up the processing of your inquiries or orders, please specify the data

shown on the type designation plate of your device when contacting Grünbeck.

Please copy the indicated information to the table below in order to have it handy

whenever necessary.

Euro system separator GENO DK-2 Mini

Serial number: /

Order number:

2 | Appropriate application

The Euro system separator, construction design BA, is a safety device to be installed in water pipes if special withdrawal points or appliances are connected to the

drinking water supply. The Euro system separator prevents the back-flow, backpressure and back-suction of modified drinking water into the drinking water network. The construction design BA is approved as safety device for systems up to

and including liquid category 4 as per DIN EN 1717, part 5.2 (refer to chapter B;

classification of liquid categories).

Attention! System separators are safety devices. They protect the drinking water

from modified drinking water. They can only work reliably provided inspections and

maintenance are carried out at regular intervals.

3 | Functional description

Fig. C-1: Detailed drawing of

Euro system separator GENO-DK 2-Mini

The system separator consists of a housing (item 1), a housing lid with connection threads for test sockets (item 2), a

non-return valve on the inlet side (item 3), a non-return valve

on the outlet side (item 4) as well as a discharge valve

(item 5).

The two non-return valves separate three different zones of

three different pressures:

Primary pressure zone (item A): Area upstream of the non-return valve on the inlet side

Middle pressure zone (item B): Area between the non-return

valves

After-pressure zone (item C): Area downstream of the nonreturn valve on the outlet side

Note: Prior to start- up, the air above the membrane must be released in order to

ensure safe operation (item 7).

Attention! If the bulge of the cap sieve (item 6) protrudes into the system separator,

the non-return valve (item 3) on the inlet side might be actuated, releasing permanent draining. Therefore, it is compulsory that the cap sieve is installed with the

bulge directing opposite the flow direction.

Page 8

Euro-System Separator

GENO

DK 2-Mini

Order no. 085 133 944-inter Edited by: fger/mrie G:\BA-133944-INTER_085_SYSTEMTR-DK_2-MINI.DOCX

6

4 | Technical specifications

Table C-1: Technical specifications

Euro system separator GENO-DK 2-Mini

Connection data

Nominal connection diameter [DN] 15

Threaded connection (male thread) [R] ½“ (red. ¾“)

Performance data

Nominal pressure [bar] PN 10

Min. flow pressure [bar] 1

Max. flow [m³/h] 3.5

KV value (p = 1 bar)

[m³/h] 2

Dimensions and weights

A Installation length with screw connections [mm] 130

B Installation length without screw connections [mm] 83

C Drain connection HT pipe [mm] 40

D Height above centre of pipe connection [mm] 47

E Height below centre of pipe connection [mm] 80

F Total height [mm] 127

G Total width [mm] 54

H Distance to wall [mm] 35

H Space required above centre of pipe connection (e. g. for maintenance) [mm] 200

L Clearance for the drain connection has to be provided in accordance

with the planned running of the pipes

[mm]

Observe installation requirements!

Empty weight [kg] 0.9

Operating weight [kg] 1.2

Consumption data

Dripping water volume per opening and closing process, approx. [ml] 10

Max. waste water volume at drain connection [m³/h] 1.5

Test certificate/Certification mark

DVGW registration number NW-6305BR0345

Ambient data

Max. water temperature [°C] 60

Max. ambient temperature [°C] 60

Order no. 133 100

Fig. C-2: Dimensional drawing

of Euro system separator GENO-DK 2-Mini

Fig. C-3: Pressure loss curve of

Euro system separator GENO-DK 2-Mini

5 | Scope of supply

Euro system separator GENO DK 2-Mini

Strainer for coarse dirt on inlet side

2 screw connections R ½“

2 reduction pieces R ¾“ male thread – R ½“ female thread

Flat seals

Operation manual

Page 9

Euro-System Separator

GENO

DK 2-Mini

Order no. 085 133 944-inter Edited by: fger/mrie G:\BA-133944-INTER_085_SYSTEMTR-DK_2-MINI.DOCX

7

D Installation and start-up

1 | General installation instructions

Please observe the local installation guidelines and the general regulations.

The installation site must be accessible for maintenance work, flood- and frost-

proof and ensure the system's protection from chemicals, dyes, solvents and

vapours.

Installation according to its nominal width in pipes of similar dimensions.

According to DIN EN 806-2, quick-closing shut-off fittings that might cause pos-

itive or negative water hammer may only be used for continuous actuation in

water installations if the max. admissible water hammer pressure and operating pressure are taken into account. Exceptions apply for fittings that are used

for test purposes only and are operated by experts.

Attention! Dirt and corrosion particles might cause malfunctions or damage the

system separator. Prior to start-up, flush the feed pipe at maximum performance.

2 | Water installation

Binding rules

The installation of a system separator represents a major interference with the

drinking water system. Therefore, only authorised experts may install such systems.

Preliminary work

1. Unpack all system components.

2. Check for completeness and soundness.

Install as per the installation drawing (fig. D-1).

Make sure that built-in parts (e. g. EBRO flaps) installed upstream or downstream

of the device to not protude into the system separator and damage internal components.

Make sure that the system separator's cap sieve is installed with its bulge direct-

ing opposite the flow direction (refer to fig. F-1).

Gate valve

Drinking water filter BOXER-KD

with pressure reducer

Gate valve with draining

○

4

Euro system separator GENO-DK 2-Mini

Waste water connection

Gate valve

Fig. D-1: Installation example: filter combination of fine filter BOXER-KD with Euro system separator GENO DK 2

Page 10

Euro-System Separator

GENO

DK 2-Mini

Order no. 085 133 944-inter Edited by: fger/mrie G:\BA-133944-INTER_085_SYSTEMTR-DK_2-MINI.DOCX

8

Note: Install strainer/fine filter directly upstream of the system separator, otherwise malfunctions in the system separator may occur.

Attention! Observe the flow direction.

Only install the system separator horizontally and without any loads and

stresses.

Provide a drain connection as per the technical specifications.

Make sure there is a free outlet and the water is discharged without back-pres-

sure.

3 | Start-up

1. Slowly open the shut-off valves (items 1 and 4) upstream and downstream of

the system separator. Afterwards, the system separator moves to its operating position. Make sure that the discharge valve (item 5) is closed.

2. Completely deaerate the system separator by opening the bleeding screws

(item 3).

3.

Perform a visual check. Make sure that no water leaks from the device anywhere.

Gate valve on inlet side

Euro system separator GENO-DK 2-Mini

Bleeding screw

Gate valve on outlet side

Draining of gate valve on inlet side

Fig. D-2: Detailed drawing of Euro system separator GENO-DK 2-Mini

4 | Functional check

After the successful start-up of the system separator, close the shut-off valve

(item 1). Pressure relief in the primary pressure zone is initiated by opening the

discharge valve (item 5).

Note: Afterwards, the system separator must go into separating position and

thereby drain the middle pressure zone.

Afterwards, close the discharge valve (item 5) and slowly open the shut-off valve

(item 1). Then the system separator must move into the operating position again,

and must be completely tight.

Page 11

Euro-System Separator

GENO

DK 2-Mini

Order no. 085 133 944-inter Edited by: fger/mrie G:\BA-133944-INTER_085_SYSTEMTR-DK_2-MINI.DOCX

9

E Troubleshooting

Even carefully designed and manufactured technical systems that are operated

properly, may experience malfunctions. The table below provides an overview of

possible problems that may occur during the operation of system separators and

indicates the causes and their elimination.

Attention! Short-term, undefined water leakage at the discharge valve of the system separator does not represent a malfunction but is a normal control behaviour

of the system separator caused by pressure fluctuations on the inlet side in the

water supply system.

Note: In case of disturbances, e.g. permanent water leakage at the discharge

valve, proceed as per the checklist below:

Irrespective of the disturbance, you may identify the fault by systematically performing the individual steps.

Test step 1

Close shut- off

valve on outlet

side.

Permanent

discharge.

Non-return valve

on inlet side or discharge valve leaky.

Remove and

check.

Put system separator

into operation again.

No draining.

Put system separator

into operation again.

Test step 2

Close the shut-off

valve on the inlet

side and then open

the sampling

valve (pressure

measuring point).

Discharge valve

does not open; discharge is minimal

and lasts for

more than 1 minute.

Discharge valve

blocked

Aeration and

deaeration clogged

Remove and

check.

Put system separator

into operation again.

Discharge valve

opens abruptly.

Devices empties

in less than 1

minute.

Put system separator

into operation again.

Test step 3

Open

shut-off valve

on outlet side.

Permanent

draining.

Non-return valve

on outlet side

leaky.

Remove and

check.

Put system separator

into operation again.

Remove and

check.

Put system separator

into operation again.

No

draining.

Put system separator

into operation again.

Note: In case of disturbances that you cannot remedy yourself, please contact

your local Grünbeck service/Grünbeck's authorised service company (see

www.gruenbeck.de).

Page 12

Euro-System Separator

GENO

DK 2-Mini

Order no. 085 133 944-inter Edited by: fger/mrie G:\BA-133944-INTER_085_SYSTEMTR-DK_2-MINI.DOCX

10

F Maintenance, care and spare parts

1 | Basic information

In order to guarantee the reliable function of the system separator over a long period of time, some maintenance work has to be performed at regular intervals. This

applies in particular to safety fittings for the supply of drinking water where the required measures are defined in the pertinent regulations and guidelines. All regulations and guidelines which apply at the installation site must be strictly adhered to.

Inspection and maintenance based on DIN EN 806-5 and W/TPW 135, appendix I.

The semi-annual inspection may be performed by the operator or the installa-

tion company.

The yearly maintenance must be carried out by an installation company or by

Grünbeck's technical service/authorised service company.

Note: A maintenance contract ensures that all the required maintenance work will

be performed in due time.

2 | Inspection

Check for tightness, visual check:

If no water is withdrawn, no water may leak.

If a withdrawal point is opened downstream, no leakages must occur.

3 | Maintenance

Check for tightness, visual check:

If no water is withdrawn, no water may leak.

If a withdrawal point is opened downstream, no leakages must occur.

Functional check:

Close the shut-off valves upstream of the system separator. Relieve the pres-

sure from the primary pressure zone between the shut-off valve and the system separator by opening the discharge valve.

Empty/drain off the inlet pressure zone between the closed shut-off valves and

the system separator.

Afterwards, the system separator must go into separating position, and must

completely drain the middle pressure zone.

Note: Should you detect any malfunctions during inspection or maintenance,

please refer to chapter E - Troubleshooting - for remedies.

Note: The cap sieve must be cleaned during every maintenance.

Page 13

Euro-System Separator

GENO

DK 2-Mini

Order no. 085 133 944-inter Edited by: fger/mrie G:\BA-133944-INTER_085_SYSTEMTR-DK_2-MINI.DOCX

11

4 | Spare parts

For spare parts and consumables please contact your local representative. The

parts listed below are considered to be wearing parts.

Note: Although these are wearing parts, we grant a limited warranty period of 6

months.

Fig. F-1: Spare parts for Euro system separator GENO-DK 2-Mini

Item Order no. Designation PU Remarks

1 133 622e Discharge valve, complete 1 Content: 1 pc

2 133 623e Non-return valve, outlet, complete 1 Including circlip

3 133 624e Non-return valve, inlet, complete 1 Including circlip

4 707601e Cap sieve, complete 1 Please observe

installation position

(refer to chapter D)

Page 14

Euro-System Separator

GENO

DK 2-Mini

Order no. 085 133 944-inter Edited by: fger/mrie G:\BA-133944-INTER_085_SYSTEMTR-DK_2-MINI.DOCX

12

Operation log

Customer

Name: ............................................................................................

Address: ........................................................................................

......................................................................................................

......................................................................................................

Euro-system separator GENO-DK

(please check appropriate box)

Serial number

Installed by

½“

¾“

1“

1 ¼“

1 ½“

2“

DN 50

DN 65

DN 80

DN 100

DN 150

DN 200

DN 250

Connection data: Drain connection

DIN EN 1717

yes no

(please check appropriate

box)

Page 15

Euro-System Separator

GENO

DK 2-Mini

Order no. 085 133 944-inter Edited by: fger/mrie G:\BA-133944-INTER_085_SYSTEMTR-DK_2-MINI.DOCX

13

Operation log

for inspection, maintenance and repair work

on Euro system separators GENO-DK

Work performed Execution confirmed

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...........................................

Name: .................................................

Date/

Signature: ............................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...........................................

Name: .................................................

Date/

Signature: ............................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...........................................

Name: .................................................

Date/

Signature: ............................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...........................................

Name: .................................................

Date/

Signature: ............................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...........................................

Name: .................................................

Date/

Signature: ............................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...........................................

Name: .................................................

Date/

Signature: ............................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...........................................

Name: .................................................

Date/

Signature: ............................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...........................................

Name: .................................................

Date/

Signature: ............................................

Page 16

Euro-System Separator

GENO

DK 2-Mini

Order no. 085 133 944-inter Edited by: fger/mrie G:\BA-133944-INTER_085_SYSTEMTR-DK_2-MINI.DOCX

14

Operation log

for inspection, maintenance and repair work

on Euro system separators GENO-DK

Work performed Execution confirmed

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Page 17

Euro-System Separator

GENO

DK 2-Mini

Order no. 085 133 944-inter Edited by: fger/mrie G:\BA-133944-INTER_085_SYSTEMTR-DK_2-MINI.DOCX

15

Operation log

for inspection, maintenance and repair work

on Euro system separators GENO-DK

Work performed Execution confirmed

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Inspection

Maintenance

Repair

Description: ________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

Company: ...............................................

Name: .....................................................

Date/

Signature: ................................................

Loading...

Loading...