Page 1

8 Spare parts

Spare filter

elements applicable for filter

type

FS-B

1”-1¼“

FS-B

1½“- 2“

Ord. no. Ord. no.

Filter elements

80 µm (2 pcs.)

103 075 103 077

Filter elements

50 µm (2 pcs.)

103 068 103 070

Filter elements

20 µm (2 pcs.)

103 071 -

Filter elements

5 µm (2 pcs.)

103 081 103 083

Consumables and spare parts may be

ordered from authorised sanitary companies or Grünbeck’s customer service/authorised service company.

When inquiring, please indicate filter type,

filter size and serial number (indicated on

the type designation plate).

Note: Seals are wearing parts.

Although these parts are wearing parts, we

grant a limited warranty period of 6 months

for them.

9 Accessories

Designation Order no.

Differential pressure monitoring of filter

upon

request

Inse r t with n o n - retur n v a l v e 1 " 101 644e

Inserts to convert an older Grünbeck

filter to an FS-B

Inser t for Order no.

FS 1“/Ultra 99 R 101 647e

FS 1¼“ 101 852

FS 1½“ 101 651e

FS 2“ 101 652e

Connection flange

A + D (V.2, V.3)

¾“ 101 862

1“ 101 646e

1¼“ 101 864

Connection flange

D (V1) delivered

until year of construction 06/99

1“ 101 865

1¼“ 101 866

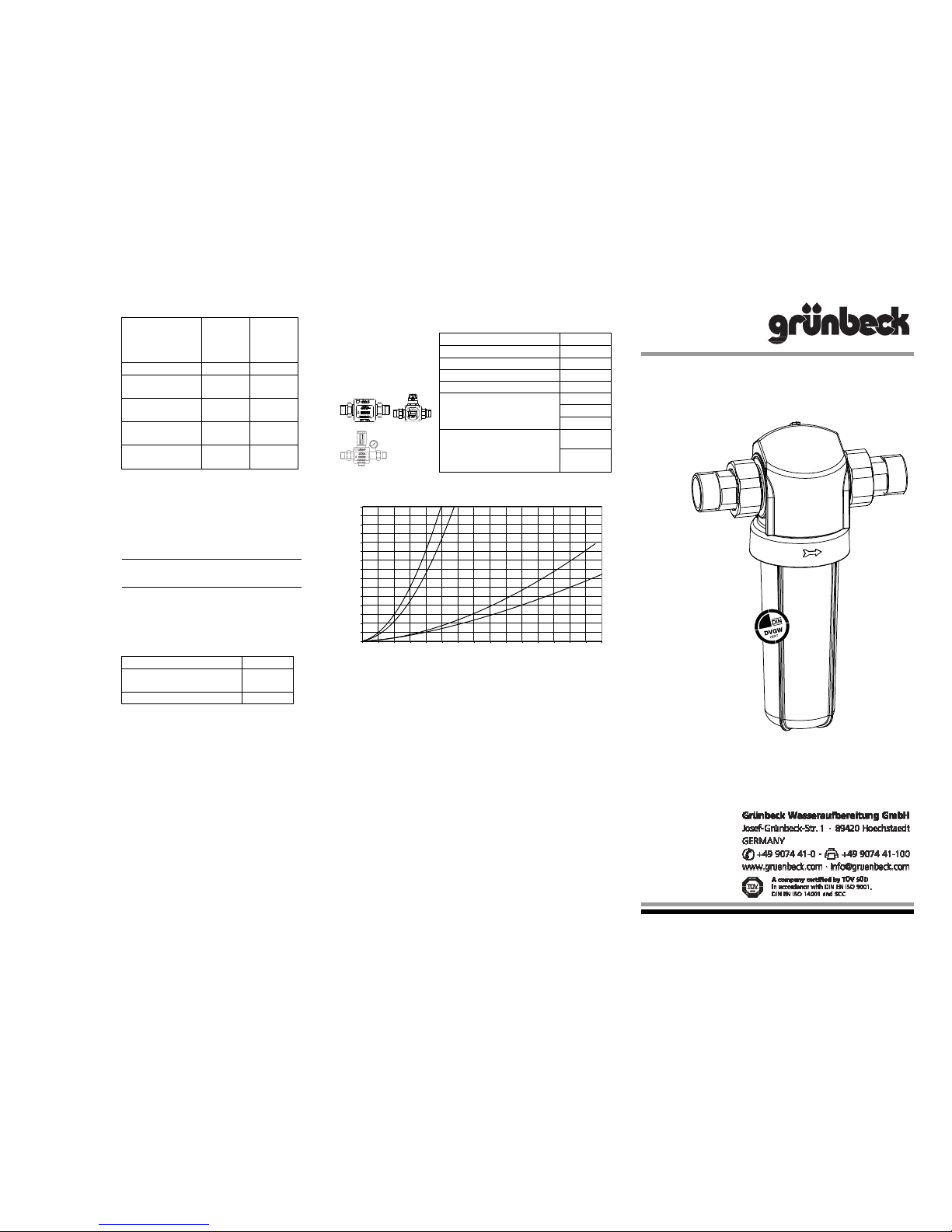

Pressure loss curve

0,0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,9

1,0

1,1

1,2

1,3

1,4

1,5

0,0 2,0 4,0 6,0 8,0 10,0 12,0 14,0 16,0 18,0 20,0 22,0 24,0 26,0 28,0 30,0

Durchfluss [m³/h]

Differenzdruck [bar]

FS-B DN 32FS-B DN 25

FS-B DN 40

FS-B DN 50

Operation Manual

Fine filter FS-B

Edition 05/2013

Order no. 076 101 196-inter

Differential pressure [bar]

Flow [m³/h]

Page 2

General notes

Our systems have to be installed by an

approved sanitary or heating company.

Prior to installation, check the components for shipping damage.

The devices must be protected against

frost and must not be installed near heat

sources which radiate a lot of heat.

Attention: Do not clean the filter with

cleaning agents that contain alcohol or

solvents!

In case of drinking water that contains a

lot of coarse dirt, a coarse filter must be

installed upstream.

1 Application

The FS-B filters are designed for the

filtration of drinking water. The filters are

not suited for circulation water that has

been treated with chemicals. Furthermore, it is neither suited for oils, greases, solvents, soaps and other lubricating

media nor for the separation of watersoluble materials. The filters may be

used in the pressure and negative pressure range.

2 Technical specifications

Fine filter FS-B

Connection diameter 1“ 1¼“ 1½“ 2“

Nominal connection diameter [DN] 25 32 40 50

Nominal flow at

p 0.2(0.5) bar

[m³/h] 3.7(6,0) 4.0(6,2) 11.1(19,9) 13.9(23,3)

Filter fineness [µm] 80

Diameter of upper/ lower

outlet

[µm] 140/80

Nominal pressure PN 16

Total height [mm] 265 508

Replacement height for

filter element

[mm] 150 390

Length with/without screw

connections

[mm] 182/100 191/100 283/160 277/160

Empty weight [kg] 1.2 1.4 3.7 4.4

DVGW registration mark

NW-9301BT0200

Max. water / ambient

temperature

[°C] 30/40

Order no.

101 170 101 175 101 180 101 185

3 Installation

requirements

Please observe local installation guidelines

and general regulations as well as technical specifications.

The installation site must be frost-proof

and must ensure the protection of the

filter against chemicals, dyes, solvents,

vapours and direct sunlight.

Observe flow direction ( indicated on

the housing)! Install voltage-free. The

installation site must be frost-proof.

The filter should be installed in equally

dimensioned pipes according to its

nominal diameter.

4 Scope of

delivery

Filter with protective cover and built-

in maintenance indicator.

Screw connections with seals made

of LD-PE.

Filter element 80 µm

Operation manual

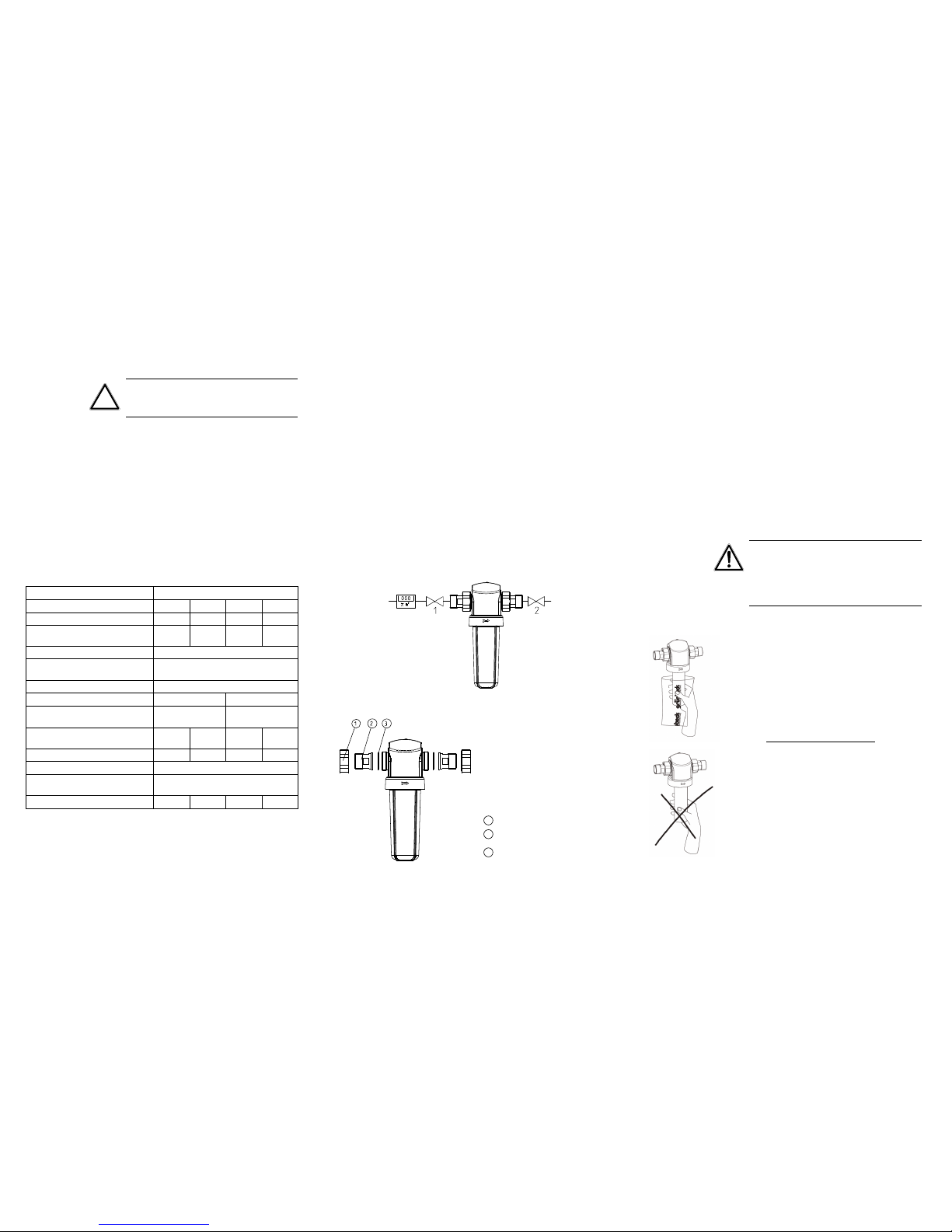

5 Installation

As per DIN EN 806-2 and DIN 1988-200

the FS-B filter has to be installed in the

cold water pipe downstream of the water

meter and upstream of the distribution

pipes respectively upstream of the devices to be protected. Install shut-off

valves upstream and downstream of the

filter (refer to fig. 1). The filter is suited

for horizontal installation only.

Fig. 1: Installation drawing FS-B front view

1

Union nut

2

Insert

3

Flat seal

Fig. 2: View FS-B

6 Start-up

After completion of the installation, put

the filter into operation by opening the

shut-off valves. Then de-aerate the

piping via the nearest screw connection.

Leakage test

A leakage test must be performed on the

filter directly after installation and after

each time maintenance work was performed. In order to check the filter for

tightness, the highest pressure admissible must be applied.

7 Inspection /

Maintenance

According to the DIN Standard EN 8065, the operator must inspect the filters

every two months (functional inspection).

During the inspection, the filter element

must be checked for contamination and

be replaced, if necessary (contamination

and/or increased differential pressure).

Check for tightness.

Furthermore, maintenance has to be

performed by the operator or the installation company every six months.

Warning! According to DIN EN 806-5

the filter element must be replaced for

hygienic reasons every 6 months. Furthermore, we recommend replacing the

seal of the protective cylinder every 2

years using a set of seals.

Replacement of

filter element

Fig.3: Replacement of

filter element

How to proceed

Place a bucket beneath the filter.

Close the shut-off valves.

Depressurize the pipe.

Manually unscrew the filter cylinder.

Remove the dirty filter element from

the supporting fabric and replace by

new filter element. For hygienic reasons, do not touch the new filter element with bare hands.

Hygienic filter replacement:

Open the foil and push the filter element including the foil over the supporting fabric, pull off the foil without touching the filter element. (see fig. 3)

Check that the sealing surfaces as

well as the O-ring are clean and

manually screw on the filter cylinder

to the stop.

Start up as described in point 6.

Edited by: KONS-fger-mrie G:\BA-101196-INTER_FS-B.DOC

Loading...

Loading...