Page 1

We understand water.

Softening | Water softener Delta-p

Operation manual

Page 2

Central Contact

Germany

Sales

Phone +49 9074 41-0

Technical Service

Phone +49 9074 41-333

Fax +49 9074 41-120

Availability

Monday to Thursday

7:00 am - 6:00 pm

Friday

7:00 am - 4:00 pm

Your local point of contact: see

accompanying list of

representatives

Copyright

The manufacturer reserves the copyright to this operation manual. Without the written consent of

Grünbeck Wasseraufbereitung GmbH, no part of this manual may be reproduced in any way, nor

may any part be processed, duplicated or distributed using electronic systems.

Contraventions of the aforementioned requirements shall be subject to compensation in damages.

We reserve the right to modifications.

© by Grünbeck Wasseraufbereitung GmbH

Translation of the original operation manual

Edition of the operation manual: December 2017

Order no.: TD3-BM001en_014

Page 3

Table of contents

3 | 74

Table of contents

1

About this manual ............................................... 4

1.1Other applicable documents ................................ 4

1.2Target group ........................................................ 4

1.3Storage of the documents .................................... 4

1.4Symbols used ...................................................... 4

1.5Typographical conventions .................................. 5

1.6Validity of the manual .......................................... 7

1.7Type designation plate ......................................... 7

2Safety ................................................................... 8

2.1Safety measures .................................................. 8

2.2Safety information ................................................ 8

2.3Regulations .......................................................... 9

2.4Obligations on the specialist installer and/or

specialist company .............................................. 9

2.5Responsibilities of the owner-user ..................... 10

2.6Safety information for the specific system ......... 10

2.7Packaging, transport, storage and installation ... 11

3Product description .......................................... 12

3.1Intended use ...................................................... 12

3.2Foreseeable misuse .......................................... 12

3.3Product components .......................................... 13

3.4Accessories ....................................................... 13

3.5Functional description ........................................ 15

4Control unit ........................................................ 16

4.1Overview ............................................................ 16

4.2Display screens ................................................. 16

4.3Navigating the control unit ................................. 18

4.4Menu structure ................................................... 20

4.5Programming levels ........................................... 21

5Installation ......................................................... 25

5.1Requirements with regard to the installation site 25

5.2Checking the scope of supply ............................ 26

5.3Installing the product .......................................... 27

5.4Preparation ........................................................ 28

6Start-up .............................................................. 30

6.1Preparations ...................................................... 30

6.2Adjusting the water softener Delta-p .................. 33

6.3Handing over the operation manual to the

operator ............................................................. 33

7Operation ............................................................34

7.1Information about the basic display ....................34

7.2Request information ...........................................34

7.3Trigger regeneration manually ............................35

7.4Set current time ..................................................35

7.5Setting the water hardness .................................36

7.6Setting the operating parameters .......................37

7.7Refilling salt tablets .............................................37

8Cleaning, inspection, maintenance ..................38

8.1Intervals ..............................................................38

8.2Cleaning .............................................................38

8.3Inspection ...........................................................39

8.4Maintenance .......................................................39

8.5Consumables ......................................................41

8.6Wearing parts .....................................................42

9Fault ....................................................................43

9.1Messages on the display ....................................43

9.2Other observations .............................................47

10Disposal ..............................................................48

11Technical specifications ...................................49

11.1Continuous flow curve ........................................52

11.2Pressure loss curves ..........................................53

12Other information ...............................................54

12.1Explanation of terminology .................................54

12.2Soft water with blending .....................................54

12.3Sodium content in the water ...............................55

12.4Hardness range ..................................................55

13Mounting instructions .......................................56

13.1Water installation ................................................56

13.2Electrical installation ...........................................61

13.3Overview of electrical cable connection .............63

14Operation log ......................................................65

EC-Declaration of Conformity ....................................70

Index .............................................................................71

Page 4

About this manual

4 | 74

BA_TD3-BM001en_014_Delta-p.docx

1 About this manual

1.1 Other applicable documents

For Delta-p, the following documents are regarded as applicable documents:

● For Grünbeck's technical customer service-/authorised service company:

Operation manual for Grünbeck's technical service

Order no.: 185 951

● The manuals of all accessories used shall apply.

1.2 Target group

This manual is intended for specialist installers and owners/users.

1.3 Storage of the documents

This manual and all other applicable documents must be kept so as to be available if

required. Make sure that your specialist installer enters the proper start-up and annual

maintenance in chapter 14 of the operation log.

1.4 Symbols used

This symbol identifies information and instructions that you must comply with for your

personal safety as well as to avoid damage to property.

This symbol identifies instructions that you must comply with in order to avoid damage to

property.

This symbol identifies important information about the product or its handling.

This symbol identifies work that is only allowed to be carried out by a specialist installer. In

Germany, the installation company must be registered in an installation directory of a water

supply company acc. to §12(2) AVB Wasser V (German Ordinance on General Conditions

for the Supply of Water).

This symbol designates tasks that may only be performed by Grünbeck's technical

customer service-/authorised service company or by specialist installers trained by

Grünbeck.

This symbol identifies work that may only be carried out by electronically trained personnel

according to the VDE guidelines or according to the guidelines of similar local institutions.

Page 5

About this manual

5 | 74

BA_TD3-BM001en_014_Delta-p.docx

1.5 Typographical conventions

The following typographical conventions are used in this manual:

1.5.1 Menu paths

Menu paths are shown in a different font. The sequence of the menus is indicated by the ">"

sign.

Status level>Menu level>Submenu

1.5.2 Menu items

Menu items, e.g. within a software menu, are highlighted in grey.

Menu item

1.5.3 Buttons

Buttons are depicted with a doted frame.

Button

1.5.4 Instructions

Single-step instructions or instructions where the sequence of the actions is unimportant are

indicated as follows:

► Action

Multi-step instructions where the sequence of the actions must be observed are indicated as

follows:

1. First step

a First action in the first step

b Second step of the first action

2. Second action

Results of an instruction are indicated as follows:

» Result

Page 6

About this manual

6 | 74

BA_TD3-BM001en_014_Delta-p.docx

1.5.5 Lists

Bullet symbols used:

● First list point (level 1)

• First bullet point (level 2)

• Second bullet point (level 2)

● Second list point (level 1)

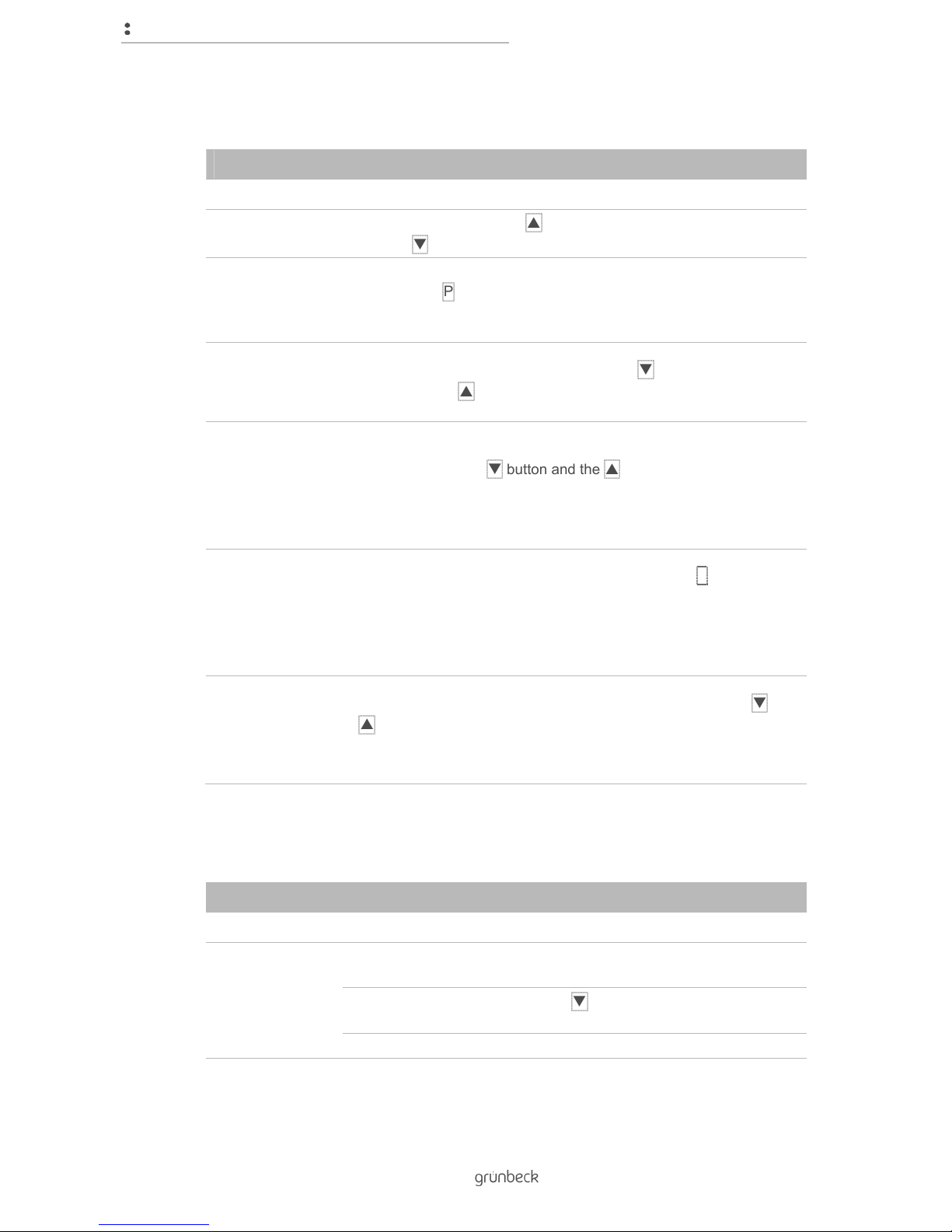

1.5.6 Operating states

Tanks described in the text, referred to below as exchangers, assume different operating

states. The following convention applies to the exchangers:

Depiction Explanation

Exchanger* Is in operation and usually has the lower remaining capacity. Is

due for regeneration next.

Exchanger** Is in operation and usually has the higher remaining capacity. Is

due for regeneration next but one.

Exchanger*** Is exhausted and is currently being regenerated or has already

been completely regenerated.

Page 7

About this manual

7 | 74

BA_TD3-BM001en_014_Delta-p.docx

1.6 Validity of the manual

This manual applies to the following products:

● Water softener Delta-p

● Water softener Delta-p-I

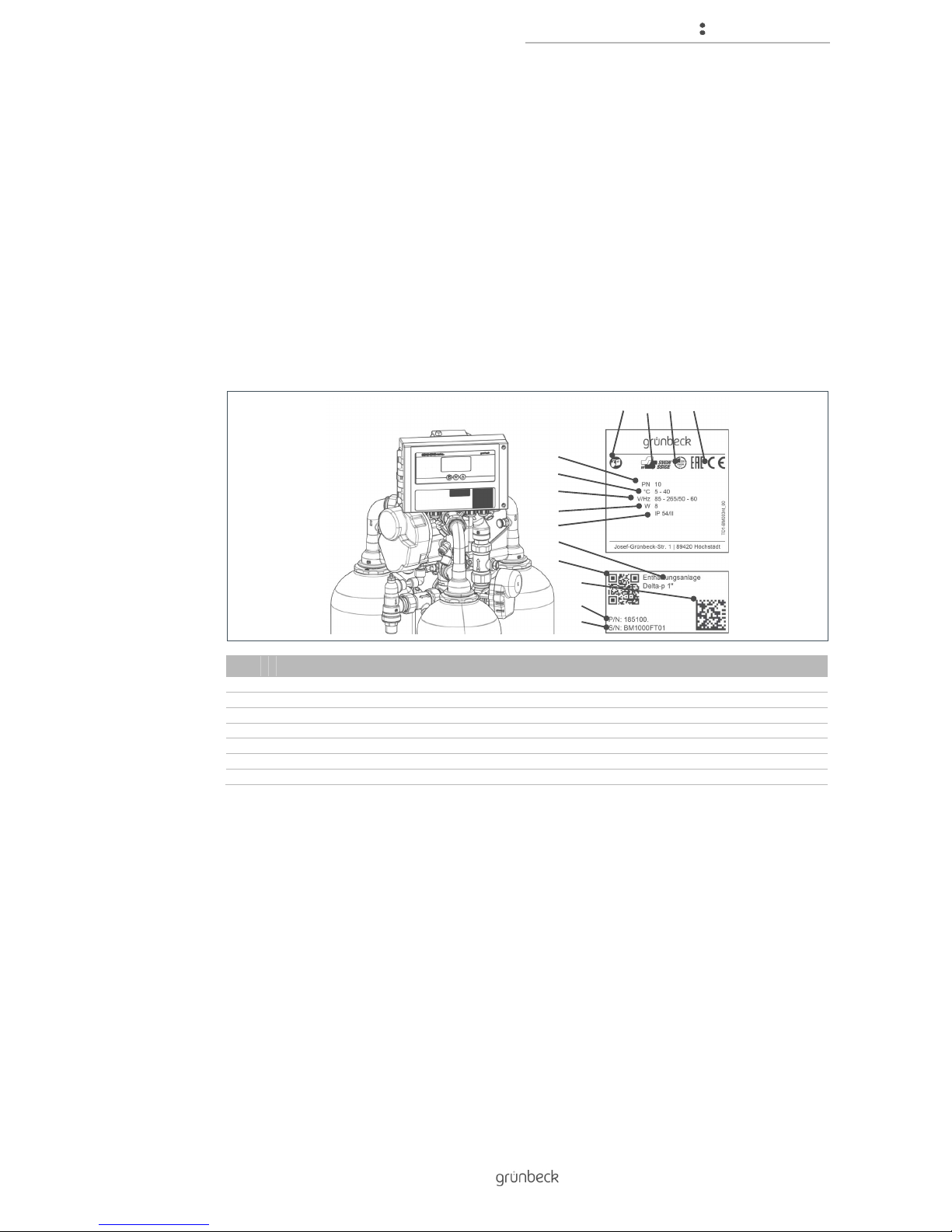

1.7 Type designation plate

The type designation plate can be found under the dome on the control unit of the water

softener below the display.

No. Designation No. Designation

1 Observe the operation manual 8 Power input

2 SVGW test mark 9 Index of protection

3 DVGW test mark 10 Product designation

4 CE mark 11 QR code

5 Nominal pressure 12 Data matrix code

6 Ambient temperature 13 Order no.

7 Power supply 14 Serial number

Please specify the data shown on the type designation plate in order to speed up the

processing of your enquiries or orders.

Therefore enter the necessary information in the table below to have it readily available

whenever necessary.

Product designation: ____________________

Order no.: ____________________

Serial no.: ____________________

2 1 3

4

5

9

6

8

7

12

10

11

14

13

Page 8

Safety

8 | 74

BA_TD3-BM001en_014_Delta-p.docx

2 Safety

WARNING: Contamination of drinking water due to improper handling.

● Risk of infectious diseases.

► Have the installation, start-up and annual maintenance carried out by specialist

installers only.

2.1 Safety measures

● Carefully read this manual before operating your product.

● Install the product in a frost-free room. Otherwise, the system may suffer

irreparable damage. The consequence can be a water damage.

● Only use genuine spare parts for maintenance or repair. If unsuitable spare parts

are used, the warranty for your product will be void.

● Do not use products which have a damaged power supply cable. This can lead to

injuries due to electric shock. Have damaged power supply cables replaced without

delay.

● Comply with the hygiene instructions in chapter 8. Failure to comply can result in

microbiological contamination of your drinking water installation.

● Only have persons working on your system that have read and understood the

present manual and that are qualified to do such work due to their vocational

training.

● Only operate the product if all components are installed properly.

● Safety device must never be removed, bridged or otherwise tampered with.

2.2 Safety information

This manual contains instructions that you must comply with for your personal safety as well

as to avoid damage to property. The information and instructions are highlighted by a

warning triangle and have the following structure:

CAUTION: Type and source of danger.

● Possible consequences

► Preventive measures

Page 9

Safety

9 | 74

BA_TD3-BM001en_014_Delta-p.docx

The following signal words were defined subject to the degree of danger and may be used in

the present document:

● DANGER means that serious or fatal injuries will occur if the corresponding

precautionary measures are not taken.

● WARNING means that serious or fatal injuries may occur if the corresponding

precautionary measures are not taken.

● CAUTION means that minor injuries may occur if the corresponding precautionary

measures are not taken.

● NOTE (without a warning triangle) means that damage to property can occur if the

corresponding safety measures are not taken.

2.3 Regulations

Comply with the following regulations and directives, amongst others, during installation and

start-up:

● Statutory regulations on environmental protection

● Provisions of the employers' liability insurance associations

● DIN EN 806 Specifications for installations inside buildings conveying water for

human consumption

● VDI/DVGW 6023 part 6

● Low Voltage Directive 2014/35/EU, Appendix IV

2.4 Obligations on the specialist installer and/or specialist

company

Comply with the following specifications to ensure correct and safe function of the product:

● Only perform activities described in this manual.

● Perform all activities in accordance with all applicable standards and regulations.

● Brief the owner/user on the function and operation of the product.

● Advise the owner/user of the maintenance of the product.

● Instruct the owner-user about possible dangers that can arise during operation of

the product.

Page 10

Safety

10 | 74

BA_TD3-BM001en_014_Delta-p.docx

2.5 Responsibilities of the owner-user

Comply with the following specifications to ensure correct and safe function of the product:

● Arrange for only a specialist installer to carry out installation, start-up and

maintenance.

● Have the product explained to you by the specialist installer.

● Only perform activities described in this manual.

● Do not carry out any activities that are explicitly indicated for a specialist installer.

● Only use this product in accordance with its designated application.

● Make sure that the required inspection- and maintenance work is carried out.

● Keep this manual.

2.6 Safety information for the specific system

WARNING: Risk of contamination of the drinking water in case of incorrect discharge of the

regeneration water

● Health risk due to contamination of the drinking water.

► When installing a discharge line for the regeneration water, do not connect any

devices directly to the drain outlet of the water softener. To install a drain, use

only the supplied black hose to allow the regeneration water to flow to the drain

connection.

WARNING: Danger of contamination of the drinking water due to prolonged periods of

inactivity of the system without automatic regeneration.

● Bacterial growth in the drinking water.

► Automatic regeneration with disinfection counteracts the bacterial growth. Do not

disconnect the water softener from the power and water supply when you are

absent for longer periods of time.

WARNING: Danger of drinking water contamination due to stagnation.

● Bacterial growth in the drinking water.

► According to VDI/DVGW 6023, filling the system with raw water prior to starting

the designated operation is prohibited.

Page 11

Safety

11 | 74

BA_TD3-BM001en_014_Delta-p.docx

CAUTION: Insoluble impurities in the salt may cause malfunctions at the brine valve and at

the injector of the control valve.

● Dosage of salt according to requirements is not guaranteed.

► A defined salt quality is required for the reliable function of the water softener.

Only use salt tablets as per DIN EN 973 type A.

CAUTION: Blocking of reverse osmosis systems by blended raw water.

● The functionality of reverse osmosis systems is threatened.

► If the water softener is installed before a reverse osmosis system, the feed line to

the reverse osmosis system is not allowed to be configured as soft water with

blending.

CAUTION: Risk of uncontrolled water leakage during regeneration if there is a power

failure.

● Uncontrolled water leakage into the drain or brine tank.

► If there is a power failure, check the water softener and block the raw water

supply if necessary.

2.7 Packaging, transport, storage and installation

Transport and store the product:

● in its original packaging

● correct way up

Transport, store and install the product free from:

● Strong heat

● Frost

● Direct sunlight

● Chemicals, dyes, solvents and their vapours

Page 12

Product description

12 | 74

BA_TD3-BM001en_014_Delta-p.docx

3 Product description

3.1 Intended use

The water softeners Delta-p are have been developed for the continuous production of

softened and partially softened water and can be used in these areas:

● Continuous soft water supply

● Softening and partial softening of:

• Well water

• Process water

• Boiler feed water

• Cooling water

• Air-conditioning water

• Cold drinking water

• industrial water

3.2 Foreseeable misuse

The water softeners Delta-p cannot be used in these areas:

● Slow removal of water

● Widely diverging performance

● Load above nominal flow

Also comply with the information in the technical specifications (refer to chapter 11)

Page 13

Product description

13 | 74

BA_TD3-BM001en_014_Delta-p.docx

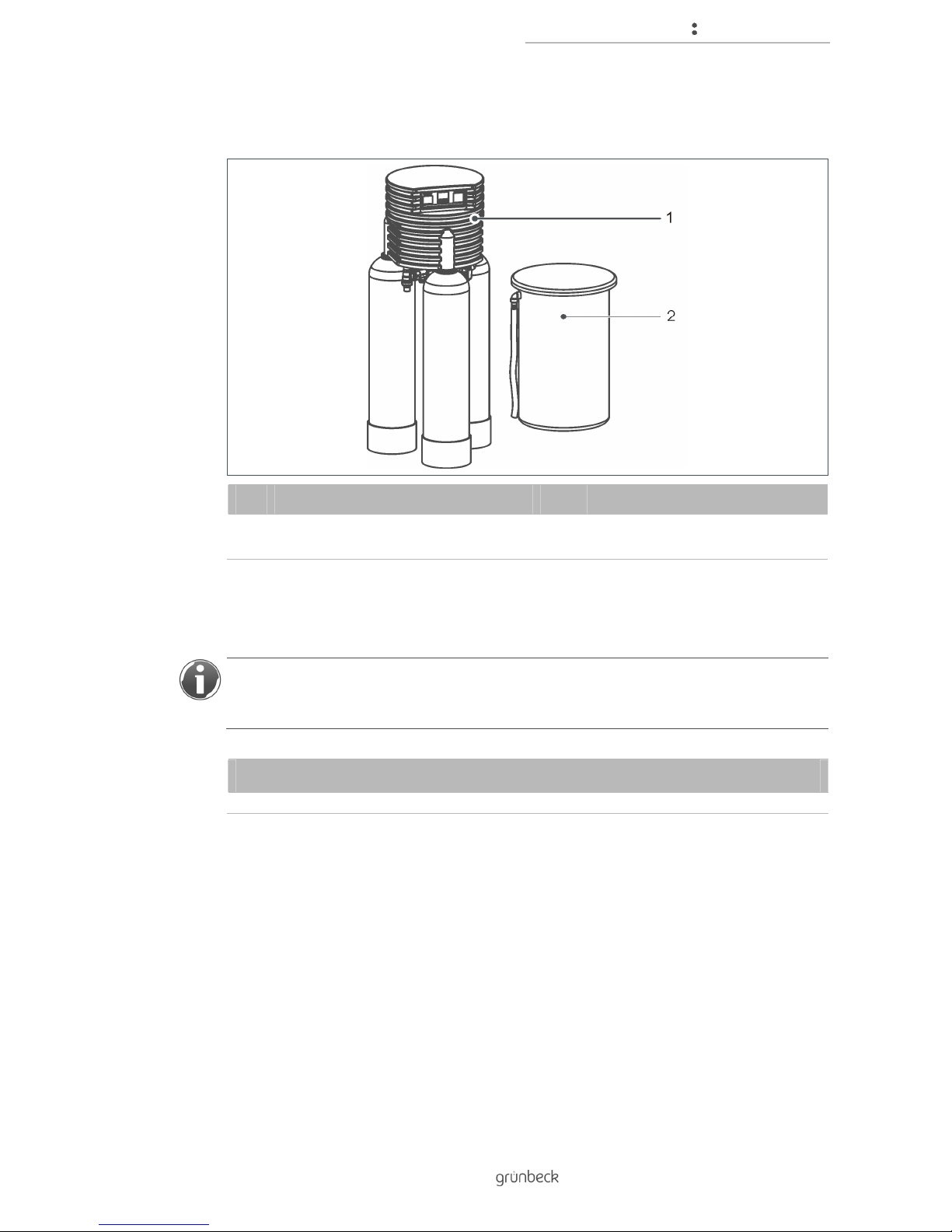

3.3 Product components

No. Designation No. Designation

1 Water softener with central control

valve and control unit

2 Brine tank with sieve bottom

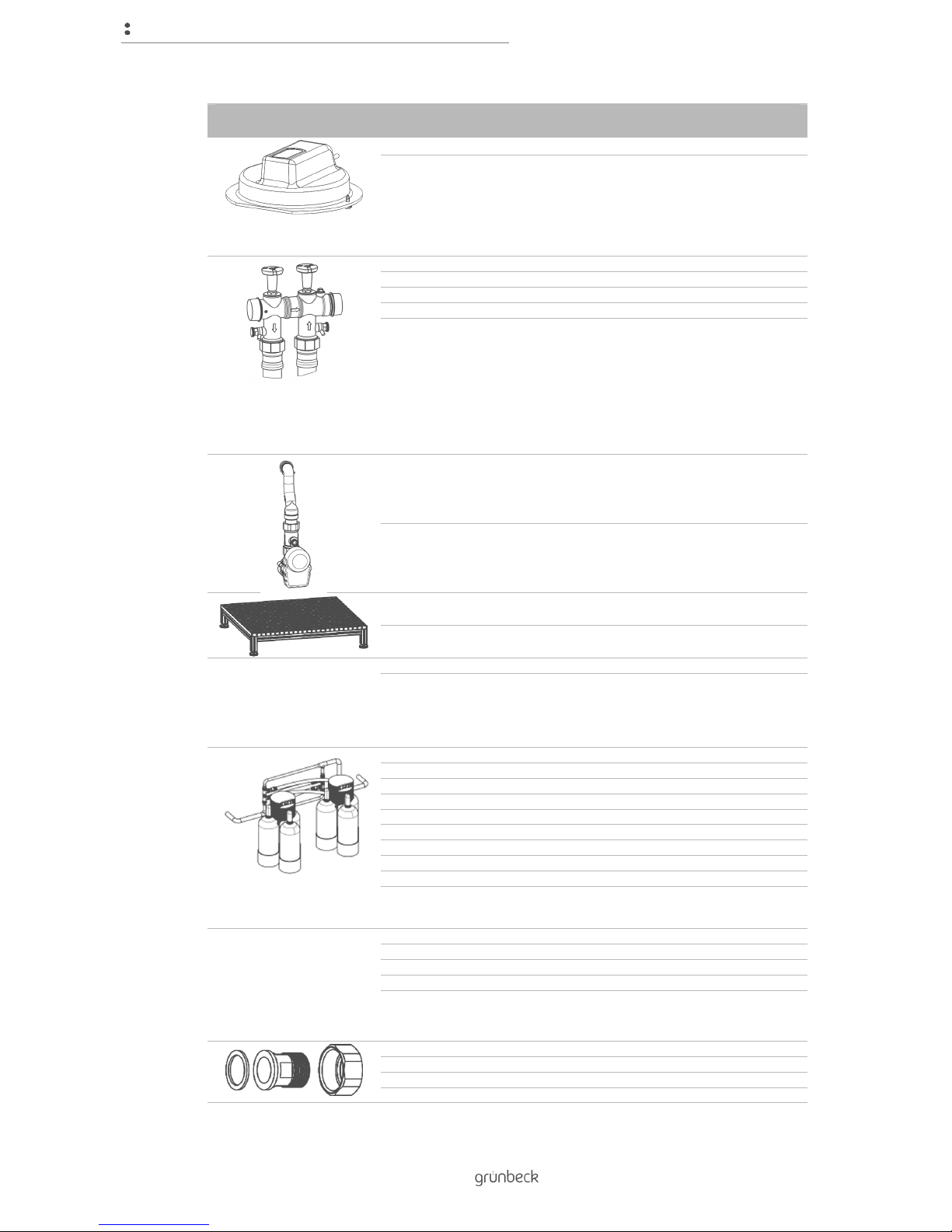

3.4 Accessories

You can retrofit your product with additional accessories. Please contact your local

Grünbeck representative or Grünbeck’s headquarters in Hoechstaedt for details (refer to

www.gruenbeck.de).

Water softener Delta-p

Accessories

Image Designation Order-no.

Page 14

Product description

14 | 74

BA_TD3-BM001en_014_Delta-p.docx

Water softener Delta-p

Accessories

Pre-alarm salt supply 185 335

Infrared light sensor to detect the minimum quantity of

salt in the brine tank. Signal via control unit.

Connection set 1"-1¼" 185 807

Connection set 1"-1¼"-I 185 808

Connection set 1½"-2" 185 823

Connection set 1½"-2"-I 185 824

Connection set (for convenient connection to the water

installation) compact valve block, built-in overflow valve

(not with Delta-p-I version), shut-off valves for hard and

soft water, sample valves for raw and soft water (only

with 1"-1¼"), 2 flexible, pressure-resistant connection

hoses. (For Switzerland, connection hoses are not

included in the scope of delivery. Install the fixed

pipework on site.)

Blending with Delta-p 1"-1¼" 185023

Blending with Delta-p 1½"-2" 185006

Pedestal Delta-p 1"-1¼" 770x770x200 mm 185 820

Pedestal Delta-p 1½"-2" 880x880x200 mm 185 825

M-Bus-measuring transducer D-DAM complete 115 850

Transmitting the flow and meter readings, as well as

statistical values of the turbine water meter via M-Bus

(IEC870). The pulse output is proportional to the flow

rate at the analogue output and relay contact of the

Grünbeck-control.

Dimensions: 160x240x160 mm.

Parallel piping Delta-p 2x1" PVC 185 450

Parallel piping Delta-p 2x1¼" PVC 185 455

Parallel piping Delta-p 2x1½" PVC 185 460

Parallel piping Delta-p 2x2" PVC 185 465

Parallel piping Delta-p 3x2" PVC 185 470

Parallel piping Delta-p 2x1" VA 185 400

Parallel piping Delta-p 2x1¼" VA 185 405

Parallel piping Delta-p 2x1½" VA 185 410

Parallel piping Delta-p 2x2" VA 185 415

Parallel piping (Tichelmann-piping) of two or several

triple water softeners, including all the necessary

connection pieces and connection sets.

Cascade connection Delta-p 1"-1¼" - 2-way 185 360

Cascade connection Delta-p 1½"-2" - 2-way 185 365

Cascade connection Delta-p 2" - 3-way 185 370

Cascade connection Delta-p 2" - 4-way 185 375

Cascade control for parallel-piped water softeners

Delta-p. The cascade connection is required in

conjunction with water softeners Delta-p in parallel

connection.

Screw connection for connection block 1" 185 846

Screw connections for connection block 1¼" 185 847

Screw connections for connection block 1½" 185 848

Screw connection for connection block 2" 185 849

Page 15

Product description

15 | 74

BA_TD3-BM001en_014_Delta-p.docx

Water softener Delta-p

Accessories

Screw connections for connection block. Water meter

screw connections with seals for pre-installation of the

connection block.

Disinfection set Delta-p 1"-1¼" 185 830

Disinfection set Delta-p 1 ½"-2" 185 835

Disinfection of the water softener, e.g. after extremely

long periods of stagnation or contamination. With

GENO-perox, canister and personal protective

equipment.

Communication module DE200 Profibus 185 890

Profibus-DP slave module, including GSD-file

Brine tank 210 litres 185 510

Brine tank 750 litres 185 525

3.5 Functional description

3.5.1 Physical

The water softeners Delta-p are equipped with a central control valve for the three

exchangers and are controlled depending on the quantity.

Regeneration is triggered when the next exchanger to be regenerated is exhausted or 50%

of the next but one exchanger to be regenerated is exhausted.

The water softener regenerates with raw water.

3.5.2 Chemical

The exchanger contains ion exchanger resin in the form of small resin beads. Sodium ions

adhere to each resin bead. Hard water with a large proportion of calcium and magnesium

ions flows through the exchanger.

The ion exchanger resin absorbs calcium and magnesium ions from the water in exchange

for sodium ions. This reaction is called ion exchange. The calcium and magnesium ions are

retained in the exchanger. Soft water without calcium and magnesium ions, but containing

sodium ions, leaves the exchanger.

This process continues until no more sodium ions are available. The ion exchanger resin is

exhausted.

The exchange can be reversed if a large amount of sodium ions is added.

The exchanger is rinsed with brine, water containing salt.

By their sheer number, sodium ions displace calcium and magnesium ions on the ion

exchanger resin. This water containing calcium and magnesium ions is discharged to the

drain. The initial condition is restored.

Page 16

Control unit

16 | 74

BA_TD3-BM001en_014_Delta-p.docx

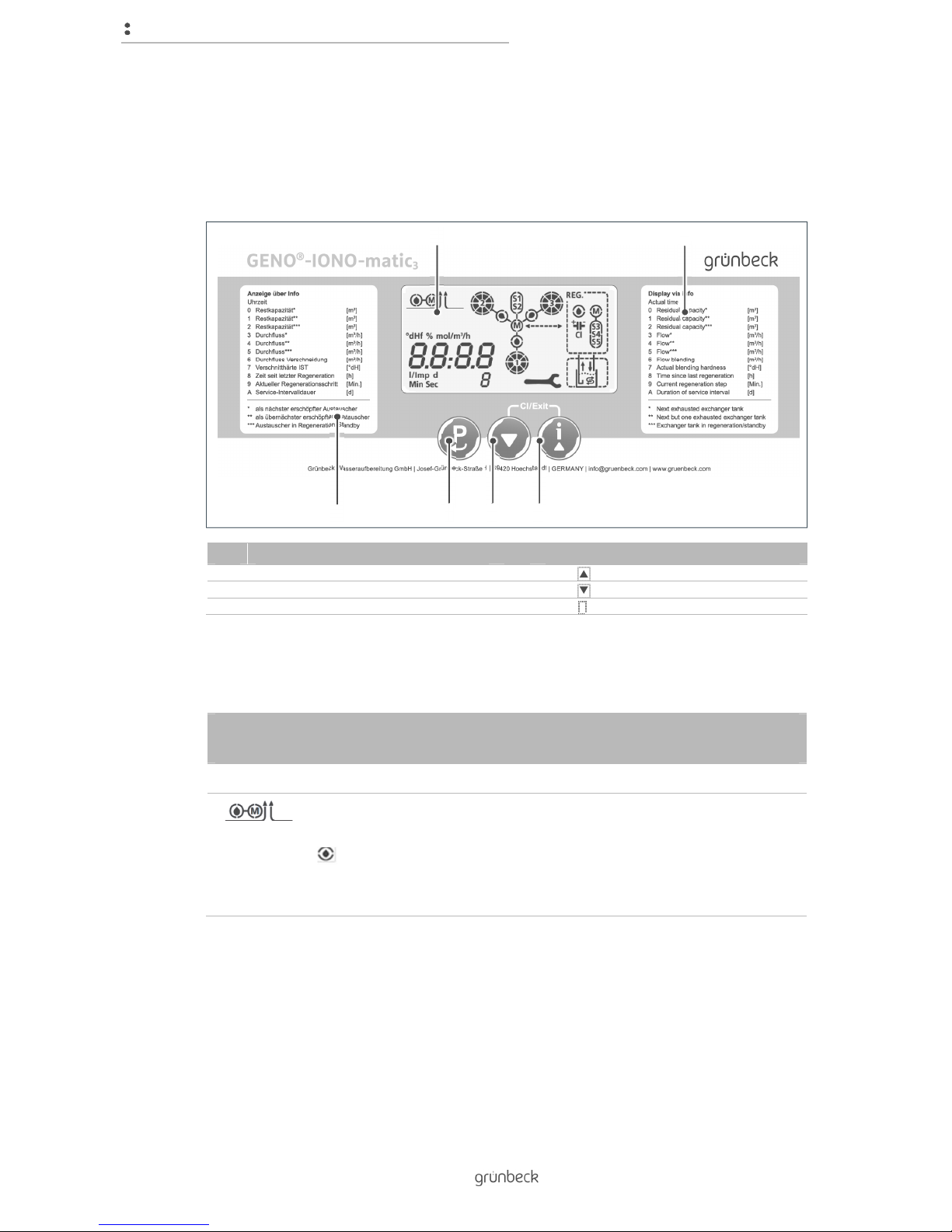

4 Control unit

4.1 Overview

No. Designation No. Designation

1 Display 3

Button

2 Explanations 4

Button

5

Button P

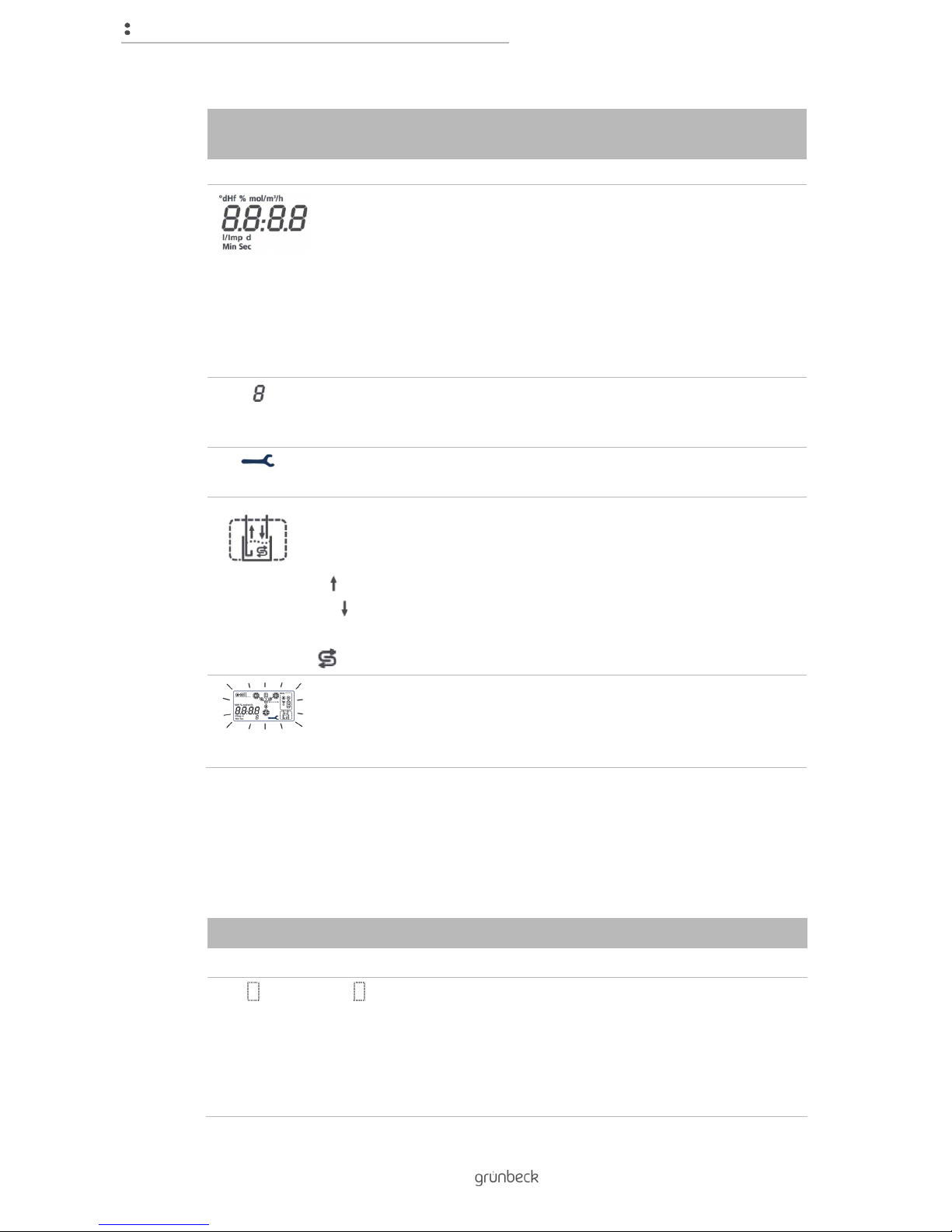

4.2 Display screens

Display GENO-IONO-matic

3

First line

Figure Explanation

Blending valve

not with Delta-p-I

flashes while water is withdrawn (ratio of raw water).

Blending motor runs (M) in order to maintain a constant blending hardness

in case of a variable withdrawal volume.

1

2

2

5 4 3

Page 17

Control unit

17 | 74

BA_TD3-BM001en_014_Delta-p.docx

Display GENO-IONO-matic

3

First line

Exchanger tank

At the status level:

The two exchangers in operation are displayed with their number and

remaining capacity.

The eight circle segments each represent 12.5 % remaining capacity.

Residual capacity between 87.5 % and 75 %.

Residual capacity between 50 % and 37.5 %.

Exchanger exhausted.

In the Information menu level:

Remaining capacity and flow rate displayed in the numeric display refer to

the exchanger which has its number displayed.

Transfer valve

Motor transfer valve is running (M) for switching to the next pair of

exchanger tanks; microswitches (S1, S2) are actuated to detect when this

position has been reached.

Drop symbol

Flashes when there is flow at the corresponding turbine water meter 1, 2

or 3.

Flow arrow

Indicates the direction of flow when there is flow between the regeneration

and transfer valves.

First filtrate: Transfer valve -> Regeneration valve; waste water to the

drain.

Salting/slow rinsing: Regeneration valve -> Transfer valve, brine or

water to the exchanger.

Backwashing: Regeneration valve -> Transfer valve, waste water to the

drain.

Filling the brine tank: No water is flowing through this connection,

direction arrow not active.

Regeneration valve

Display during the entire regeneration.

Regeneration step fill brine tank:

Drop symbol flashes when there is flow at the turbine water meter.

Regeneration step - salting:

Symbol appears if the electrolysis-current for chlorine production

(disinfection of the exchanger) is OK.

Motor regeneration valve is running (M) for switching to the next

regeneration step; microswitches (S3, S4, S5) are actuated to detect

when the next regeneration step has been reached

Symbols show the current status

Page 18

Control unit

18 | 74

BA_TD3-BM001en_014_Delta-p.docx

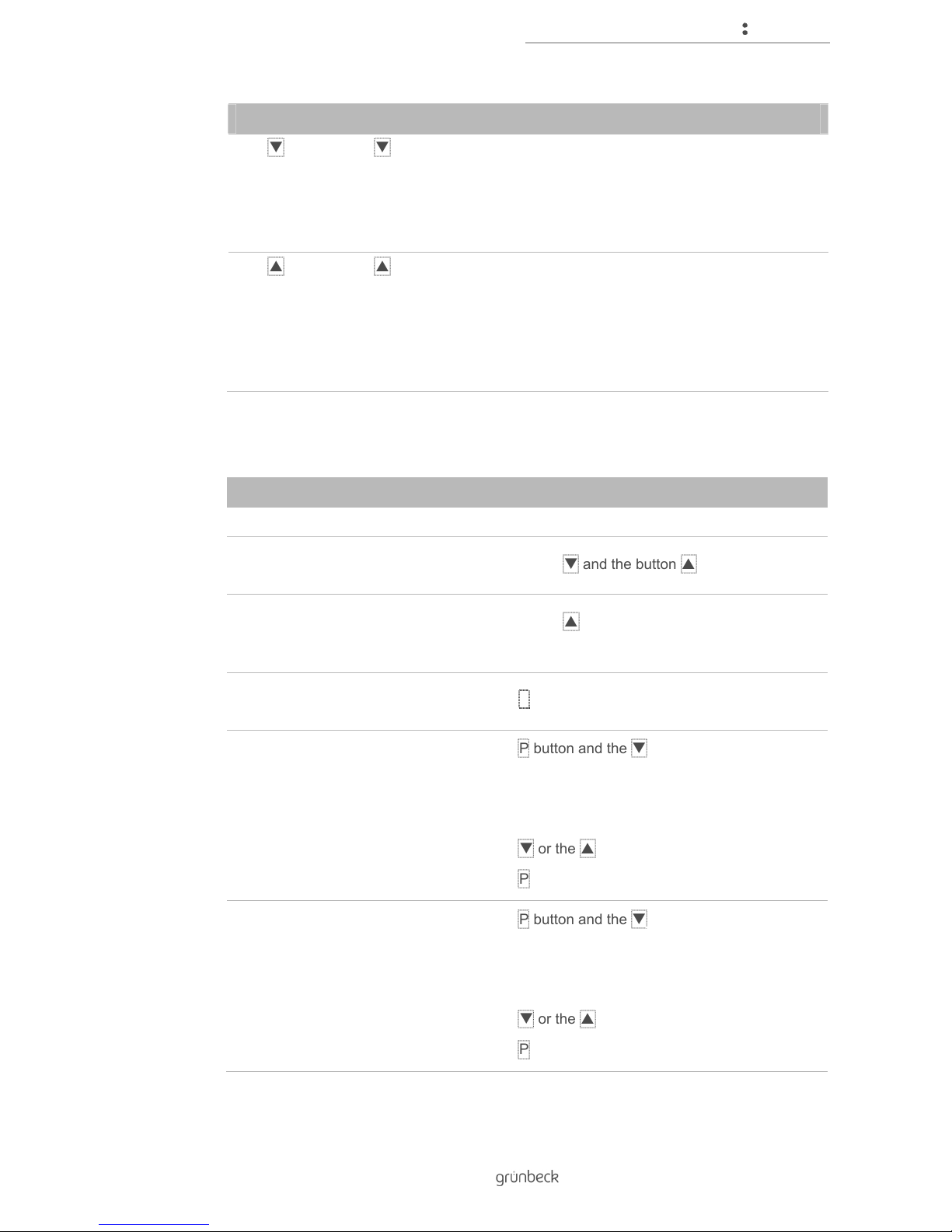

Display GENO-IONO-matic

3

Second line

Figure Explanation

Numbers and unit display

At the status level:

Indicates the time.

In the Information menu level and the Operator menu level:

Indicates the numerical value of the parameter in the menu; if available

with physical unit.

In the case of malfunctions / warnings:

The currently fault or warning Er x is displayed.

Index/parameters

Displays the consecutive number of the current value in the numerical

display 9 for guidance.

Screw wrench

Displayed when maintenance interval has expired.

Brine tank

Displayed during regeneration.

Appropriate arrow for the corresponding regeneration step appears:

Brine is drawn out of the tank

Raw water is fed into brine tank

Pre-alarm salt supply, if installed:

Symbol appears when salt needs to be refilled.

Backlight

Is switched on up to 10 minutes after the last button press.

Each press of a button initially activates the back lighting.

Flashes during malfunctions/warnings.

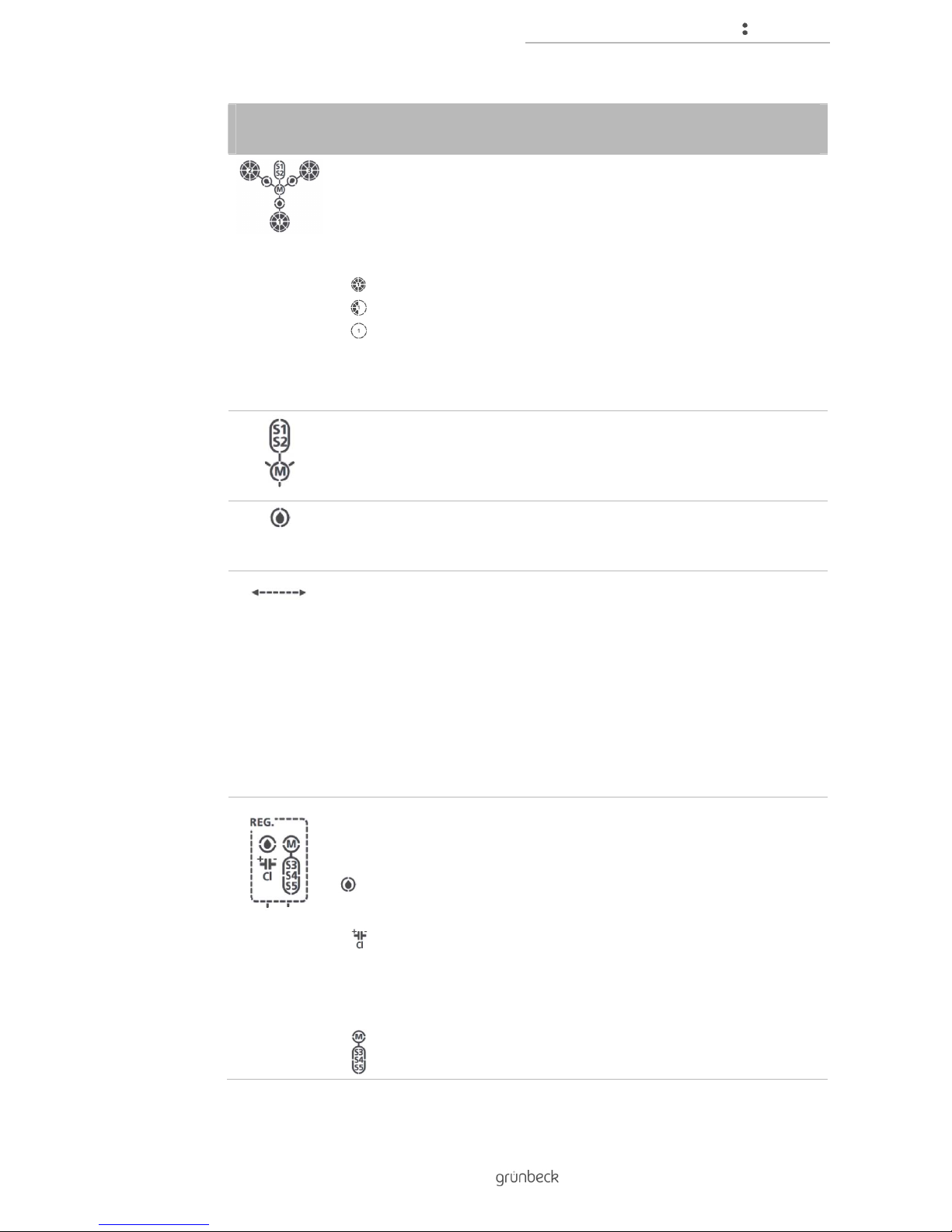

4.3 Navigating the control unit

4.3.1 Buttons of the control unit

Control unit GENO-IONO-matic3

Figure Designation Function

P Button P

In the status level:

Switches to User menu level. (> 5 s press)

Acknowledges malfunctions.

In the Menu level User:

Opens parameters.

Stores the settings and closes parameters.

Page 19

Control unit

19 | 74

BA_TD3-BM001en_014_Delta-p.docx

Control unit GENO-IONO-matic3

Button

In the status level:

Triggers regeneration by hand. (> 5 s press)

In the Menu level User:

Returns to the previous parameter.

Decreases numerical values.

Button

In the status level:

Calls up the Information menu level.

Advances the display.

In the Menu level User:

Switches to the next parameter.

Increases the numerical values.

4.3.2 Select menu level

Control unit GENO-IONO-matic3

Objective Step

Status level

► Press the button and the button at the same time.

Information menu

level

► Press the button in the status level. 1x - 11x, rotating

through the display back to the basic display.

Menu level User

► Press the P button in the status level for more than 5°s

Menu level

Programming

1. Press the P button and the button in the status level

at the same time for more than 1 s.

» The display switches from time to the three flashing

digits "000", preceded by a "C".

2. Press the or the button to select code 290.

3. Press the P button to confirm your selection.

Advanced

programming menu

level

1. Press the P button and the button in the status level

at the same time for more than 1 s.

» The display switches from time to the three flashing

digits "000", preceded by a "C".

2. Press the or the button to select code 113.

3. Press the P button to confirm your selection.

Page 20

Control unit

20 | 74

BA_TD3-BM001en_014_Delta-p.docx

4.3.3 Setting the parameters

Control unit GENO-IONO-matic3

Objective Step

Select parameters

On every menu level, the button switches to the next parameter

and the button switches to the previous parameter.

Open parameters When the intended parameter is displayed on the screen, open it by

pressing the P button.

» The value of the parameter flashes.

Change parameter

If the opened parameter flashes, press the button for lower

values and the button for higher values.

Close parameter

without saving

If you want to exist the settings for the opened parameter without

changes, press the button and the button at the same time.

» The parameter will be closed and the display shows the

unchanged value continuously.

Save parameters

If the correct value flashes on the display, press the P button to

save it.

» The parameter will be closed and the display shows the

set value continuously.

Exit menu level

When you have made and saved the desired settings, press and

buttons simultaneously.

» The display shows the basic display on the status level.

4.4 Menu structure

Control unit GENO-IONO-matic3

Menu level Menu items Values/settings

Status level Acknowledge

malfunctions

Press one of the buttons

Regeneration by

hand

Press the button for more than 5°s

Select menu level (refer to chapter 4.3)

Page 21

Control unit

21 | 74

BA_TD3-BM001en_014_Delta-p.docx

Control unit GENO-IONO-matic3

Information 0 Remaining capacity exchanger *

1 Remaining capacity exchanger **

2 Remaining capacity exchanger ***

3 Flow rate exchanger *

4 Flow rate exchanger **

5 Flow rate exchanger ***

6 Flow rate blending

7 Soft water hardness actual value

8 Time since last regeneration

9 Current regeneration step

A Current regeneration step

Step 1-3:

Regeneration step: Remaining time of the

current regeneration step

Step 4:

Regeneration step: Flow rate

Operator Set the time Hours and minutes separately, [hh:mm]

Set the actual raw

water hardness

Adjust soft water

hardness with

blending

Must not be changed with Delta-p-I

Programming

levels

To the settings and displays

(refer to chapter 4.5).

4.5 Programming levels

NOTE: Non-compliance will result in serious damage to product and user.

● The function of the product can be significantly impaired and result in a health

hazard for users.

► The settings described here may only be performed by specialist installers and

trained personnel.

Page 22

Control unit

22 | 74

BA_TD3-BM001en_014_Delta-p.docx

The GENO-IONO-matic3 controls the operating and regeneration processes of water

softeners in the Delta-p series automatically depending on the selected operating mode,

water consumption, daily interval and time selected. The different parameters of the water

softener are stored in the programming levels and can be set with code protection via the

menu navigation.

A programmable input, a programmable output and an input for the pre-alarm salt supply

accessory are available

4.5.1 Menu level Programming

Status level>Programming menu level

Parameters of the Programming menu level

Control unit GENO-IONO-matic3

Index/parameters Meaning Factory

settings

Setting range

0 Hardness unit Configuration of the display for

hardness values with corresponding

unit. Applies to raw water and soft

water hardness as well as the

capacity value

0 0 = °dH

1 = °f

2 = mol/m³

1 Water softener-

Data record

CA31: Delta-p 1"

CA32: Delta-p 1¼"

CA35: Delta-p 1½"

CA36: Delta-p 2"

Warning: Changes only permitted by

Grünbeck's technical

service'-/authorised service

company!

Depending

on water

softener

(nominal

width)

2 Capacity rate CA31: 48

CA32: 79

CA35: 165

CA36: 229

Depending

on water

softener

(nominal

width)

Indication only

3 Turbine water meter-

Constant exchangers

0.0314 Indication only

4 Turbine water meter

constant regeneration

valve

CA31: 0.0313

CA32: 0.0313

CA35: 0.0325

CA36: 0.0325

Depending

on water

softener

(nominal

width)

Indication only

5 Turbine water meter

constant blending valve

0.0309 Indication only

6 Activation time Applies to regeneration over a daily

interval

00: 00: ... 23:

7 Activation time Applies to regeneration over a daily

interval

:00 :00 ... :59

8 Disinfection program Is started by reprogramming to

value 1. Attention: Observe the

instructions of the

disinfection-chemical!

0 0 ... 1

9 Triple manual

regeneration

Is started by reprogramming to

value 1/2/3. All 3 exchangers are

regenerated 1x in succession up to

3x. In between there is a waiting time

of 15 minutes in each case.

0 0 ... 3

Page 23

Control unit

23 | 74

BA_TD3-BM001en_014_Delta-p.docx

4.5.2 Advanced programming menu level

Status level>Advanced programming menu level

Parameters of the Advanced programming menu level

Control unit GENO-IONO-matic3

Index/parameters Meaning Factory

setting

Setting range

0 Programmable input

function

0 = No function

1 = External release of regeneration

2 = External lock of regeneration

3 = External 3-way regeneration

triggering

4 = Reserved function

0 0 ... 2

1 Programmable output

function

0 = No function

1 = Closed during regeneration step

1 Salting

2 = Closed during the entire

regeneration

3 = Closed if flow rate with flow at

exchanger * and

exchanger ** = 0 m³/h or with

bottle changeover or in case of

malfunction

80/210 = reserved function

0 0 ... 3/80/210

2 Delay time for

programmable output

with setting = 3

After the bottle changeover has been

completed, the contact opens again

with a delay.

0.5 0.1 … 9.9

3 Activation pre-alarm

salt supply (optional)

0 = is not evaluated

L = Infrared-light sensor detects the

filling level in the brine tank. If no

object is detected within the

adjustable switching gap for

longer than 5 min, warning Er A +

symbol appears

0 0 ... 999/L

reserved function 0 1 … 999

4 Serial interface RS 485 0 = deactivated

1 = Optional module

DE2000 Profibus available

2 = Protocol mode RTU for

networking with reverse osmosis

GENO-OSMO-X

0 0 … 2

5 Pulse divider for

EXAcount pulse

output 1: …

The input pulses of the water meters

exchanger */exchanger **/blending

are used for the pulse output.

1 (0)/1/12/18/31/42

Note: Divider "0" must not be used in

combination with the dosing

computer EXADOS!

Setting "0" is reserved for the

Delta-p- cascade circuit.

Observe the following tables.

Page 24

Control unit

24 | 74

BA_TD3-BM001en_014_Delta-p.docx

Divider for index/parameter 5, Advanced programming menu level

Dosing system GENODOS DME

DME 6 DME 10 DME 20 DME 30

Water softener

Delta-p 1" 1

1

Delta-p 1¼"

1

31

Delta-p 1½" 31 42

Delta-p 2" 31 42

The dividers in bold type indicate the sensible combinations of the water softener Delta-p

and dosing system GENODOS DME. With other dividers, the full flow rate of the water

softener or dosing system cannot be achieved.

Resulting pulse sequence [l/pulse]

Pulse division

1 12 18 31 42

0.031 0.372 0.558 0.961 1.319

Page 25

Installation

25 | 74

BA_TD3-BM001en_014_Delta-p.docx

5 Installation

The installation is only allowed to be carried out by a specialist installer.

NOTE: Significant temperature differences occurring when the product is moved from one

location to another can lead to moisture forming on electronic components within the

control unit at the beginning.

● Possible malfunction of the control unit during initial start-up.

► We recommend unpacking the product prior to installation and allowing it to rest

at the installation site for 1 hour without being used. Possible moisture formation

on electronic components inside the control unit will be able to dry off.

WARNING: Danger of contaminated drinking water if the work is not carried out properly

● Risk of infectious diseases.

► Pay attention to hygiene when working on the installation.

5.1 Requirements with regard to the installation site

5.1.1 Requirements with regard to the water connection

Comply with the instructions on installation (refer to chapter 2.7).

For critical applications such as boiler feed water, we recommend the installation of an

automatic water analyser (refer to chapter 3.4).

● Drinking water filter upstream of the system

● Drain connection for drainage of the flushing water (refer to chapter 11)

● Floor drain or a corresponding safety device

● Existing lifting system salt water-resistant

● Clean water side of the system made of corrosion-resistant material or use

anticorrosive agent

Page 26

Installation

26 | 74

BA_TD3-BM001en_014_Delta-p.docx

5.1.2 Requirements on the electrical wiring

● Push socket with earthing contact within approx. 1.2 m of the control unit.

● Push socket with earthing contact must carry continuous voltage.

CAUTION: The electrically operated valves do not close automatically If

there is a power failure.

● Until intervention by the operator, flow of water through the drain

outlet or the brine tank.

► Socket must carry continuous voltage. Do not connect the socket

with lighting and heating switches.

► In case of power failure, check the water softener and shut-off the

water supply, if necessary.

5.2 Checking the scope of supply

No. Designation No. Designation

1 Cover 4 Exchanger bottles

2 Water test kit "Total hardness“ 5 Central control valve in parts and control unit

3 Operation manual 6 Brine tank

Check the scope of supply for completeness and possible damage.

Page 27

Installation

27 | 74

BA_TD3-BM001en_014_Delta-p.docx

5.3 Installing the product

In order for the water pipe to be properly connected to the protective-equipotential bonding

on both sides of the product, we recommend establishing a corresponding electrical bypass

according to DIN VDE 0100-540.

No. Designation No. Designation

1 Drinking water filter 2 Connection set

The water softener Delta-p is installed in the water pipe in accordance with DIN EN 806-2

and DIN 1988-200.

Please observe:

● The nominal connection diameter and connection size.

● Installation in horizontal orientation.

● The designation of the flow direction on the housing must correspond to the flow

direction on site.

● Stress-free installation.

● Free outlet and discharge of the backwash water without back-pressure.

Page 28

Installation

28 | 74

BA_TD3-BM001en_014_Delta-p.docx

The sequence of devices in the direction of flow is:

● Water meter

● Drinking water filter

● Shut-off valve 1

● Water softener Delta-p

● Sampling valve

● Shut-off valve 2

● Distribution pipes or devices to be protected

5.4 Preparation

Threads and connection holes are closed with protective caps against contamination.

Remove the protective caps before starting installation.

WARNING: Danger of drinking water contamination due to stagnation.

● Bacterial growth in the drinking water.

► According to VDI/DVGW 6023, filling the system with raw water prior to starting

the designated operation is prohibited.

5.4.1 Filling the exchangers

No. Designation No. Designation

1 Centring the riser pipe 2 Unscrewing the bottle adapter

Note: The water softeners Delta-p 1" and 1¼" are filled with resin at the factory.

Page 29

Installation

29 | 74

BA_TD3-BM001en_014_Delta-p.docx

Fill the resin and glass dry into the exchangers. Wet filling is only allowed immediately before

start-up. If this is not possible, the water softener must be disinfected before starting up

(refer to chapter Fehler! Verweisquelle konnte nicht gefunden werden.).

Delta-p

1½" 2"

Quantity of

glass

[l] 10 15

Quantity of resin [l] 75 100

You may order spare parts and consumables from your local Grünbeck representative, refer

to the Internet at www.gruenbeck.de.

Proceed as follows to fill the exchangers:

1. Unscrew the bottle adapter by turning it to the left.

2. Centre the riser pipe in the exchanger.

3. Put on the filling adapter.

4. Place the pipe section on the filling adapter.

5. Fill the glass through the funnel into the exchanger.

6. Make sure that the glass filling is evenly distributed.

7. Fill the resin through the funnel into the exchanger.

8. Remove the funnel, pipe section and filling adapter.

9. Clean the threads and sealing surfaces on the exchanger for the connection of the

bottle adapter to remove any glass and resin adhering to them.

10. Place the bottle adapter from above with the head nozzle in front over the riser

pipe.

11. Tighten the bottle adapter by turning it to the right.

» The exchanger is filled.

5.4.2 Installation

For the plug-and-play-installation instructions for the water softener Delta-p, refer to

chapter 13.

Page 30

Start-up

30 | 74

BA_TD3-BM001en_014_Delta-p.docx

6 Start-up

Start-up may only be carried out by a specialist.

WARNING: Danger of drinking water contamination due to stagnation.

● Bacterial growth in the drinking water.

► According to VDI/DVGW 6023, filling the system with raw water prior to starting

the designated operation is prohibited.

6.1 Preparations

6.1.1 Filling the brine tank

WARNING: Danger of contaminated drinking water if the work is not carried out properly

● Risk of infectious diseases.

► Pay attention to hygiene when working on the installation.

► Store the packs of salt only in dry and clean rooms.

► Do not use opened packs.

► Clean the packs before opening them.

► Fill the salt directly from the pack into the brine tank.

► Close the brine tank immediately after filling.

Proceed as follows to fill the brine tank:

1. Remove the cover from the brine tank.

2. Carefully fill the brine tank with raw water until the water level is about 30 mm

above the sieve bottom.

CAUTION: Insoluble impurities in the salt may cause malfunctions at the

brine valve and at the injector of the control valve.

● Dosage of salt according to requirements is not guaranteed then.

► A defined salt quality is required for the reliable function of the

water softener. Only use salt tablets as per DIN EN 973 type A.

3. Fill the brine tank completely with salt tablets.

4. Fill the brine tank with raw water. See the following table.

Page 31

Start-up

31 | 74

BA_TD3-BM001en_014_Delta-p.docx

Water softener Delta-p

Filling brine tank 1" 1¼" 1½" 2"

Salt supply

standard-Brine tank

max.

[kg] 75 75 200 200

Operating water volume [l] 4.2 6.9 14.4 20.0

5. Close the tank immediately after filling.

» You have completed filling the brine tank.

6.1.2 Start-up

Measures after times without operation

Period of

inactivity

What to do

≥ 4 [d] Regeneration of each exchanger is sufficient for the start-up.

> 4 [d] A disinfection of the water softener by Grünbeck's customer service

is required before start-up (refer to www.gruenbeck.de)

Venting the system

1. Connect the mains plug to the socket.

2. Open the client's valve at the raw water inlet.

3. Trigger a regeneration by hand (refer to chapter 7.3). The three exchangers are

now regenerated one after the other.

4. When regeneration is complete, open the customer's valve at the soft water outlet.

5. Check the system for leaks.

» The system is vented.

Page 32

Start-up

32 | 74

BA_TD3-BM001en_014_Delta-p.docx

No. Designation No. Designation

1 Bottle adapter 2 Withdrawal valve

Hardness determination

1. Perform the 0 °dH (0 °f, 0 mmol/l) test. To do this, take water samples from the

water softener in operation:

a Open one of the customer's withdrawal points downstream of the water

softener. Without this measure, you will receive a mixture of waters from the

exchanger* and exchanger** at the sample valves.

b Take samples from each of the three bottle adapters on its sampling valve.

c In the case of systems with a blending valve, take an additional water sample at

the client's withdrawal point downstream of the system.

d Close the client's withdrawal point downstream of the water softener

2. Measure the hardness of the samples with the water test kit "total hardness".

3. Record your work in the start-up log and countersign it (refer to chapter 14).

Carrying out 1st maintenance

► Carry out maintenance according to the checklist for 1st maintenance and record

the determined data.

» You have completed the start-up.

Page 33

Start-up

33 | 74

BA_TD3-BM001en_014_Delta-p.docx

6.2 Adjusting the water softener Delta-p

This subchapter describes the adjustment of the electronically controlled blending valve of

the water softener Delta-p.

The blending valve is not part of the water softener Delta-p-I. It can be retrofitted to the

water softener Delta-p-I if required. Contact Grünbeck's technical service-/authorised

service company beforehand.

The water softeners Delta-p are controlled by quantity. The operating parameters are

already stored in the GENO-IONO-matic

3

control unit. During start-up, all parameters must

be entered which are required for the automatic calculation of the regeneration interval.

Check the factory-set data record.

The GENO-IONO-matic

3

control unit is operated via buttons (refer to chapter 4.3).

Perform the settings according to chapters 7.3 to 7.5.

6.3 Handing over the operation manual to the operator

Inform the owner/user about the need for inspections and maintenance.

Page 34

Operation

34 | 74

BA_TD3-BM001en_014_Delta-p.docx

7 Operation

Observe the intervals for inspection and maintenance (refer to chapter 8)

7.1 Information about the basic display

Status level

The display continuously gives information about the operating status of the system. The

following parameters are shown on the basic display:

● Functions that are activated to trigger a regeneration.

● The function by which the current regeneration was triggered.

● Whether a regeneration is active.

● The time that is stored in the system.

7.2 Request information

Status level>Information level

Press the button to call up information about other parameters:

Button

pressed Display Explanation

1x XXX.X Remaining capacity exchanger * In operation

2x XXX.X Remaining capacity exchanger

**

3x XXX.X Remaining capacity exchanger

***

In regeneration/standby

4x XX.XX Flow rate exchanger * In operation

5x XX.XX Flow rate exchanger **

6x XX.XX Flow rate exchanger *** In regeneration/standby

7x XX.XX Flow rate blending

Page 35

Operation

35 | 74

BA_TD3-BM001en_014_Delta-p.docx

Button

pressed Display Explanation

8x XXX Soft water hardness actual

value

Only with blending valve and

programmed soft water

hardness

9x XXXX Time since last regeneration

10x X_:YY Current regeneration step X: Regeneration step

YY: Step time remaining

[min], at step 4 flow [m³/h] fill

brine tank

11x XXX Time until service is due

7.3 Trigger regeneration manually

Status level

Follow the steps below to trigger a regeneration manually:

► Press the button for more than 5°s

» Water softener carries out regeneration.

7.4 Set current time

Status level>Operator menu level

Follow the steps below to set the hours on the display of the control unit:

1. Press the P button to open the parameter for hours.

» The display for hours flashes.

2. Press the button or the button to set the intended value of the parameter.

3. Press the P button to save the parameter for hours.

» You have set the hours.

Page 36

Operation

36 | 74

BA_TD3-BM001en_014_Delta-p.docx

4. Press the button to switch to the display for minutes.

5. Press the P button to open the parameter for minutes.

» The display for minutes flashes.

6. Press the button or the button to set the intended value of the parameter.

7. Press the P button to save the parameter for minutes.

» You have set the time.

7.5 Setting the water hardness

7.5.1 Actual raw water hardness

Status level>Operator menu level

1. Press button to switch to the display for actual raw water hardness.

2. Press button P to open the parameter for the actual raw water hardness.

» The display for the actual raw water hardness flashes.

3. Press the button or the button to set the intended value of the parameter.

4. Press button P to save the parameter for the actual raw water hardness.

» You have set the actual raw water hardness.

Page 37

Operation

37 | 74

BA_TD3-BM001en_014_Delta-p.docx

7.5.2 Setting soft water hardness with blending

Status level>Operator menu level

1. Press button to switch to the display for soft water hardness.

2. Press the P button to open the parameter for the soft water hardness.

» The soft water hardness display flashes.

3. Press the button or the button to set the intended value of the parameter.

4. Press button P to save the parameter for soft water hardness with blending.

» You have set the soft water hardness with blending.

7.6 Setting the operating parameters

NOTE: Non-compliance will result in serious damage to product and user.

● The function of the product can be significantly impaired and result in a health

hazard for users.

► The settings described here may only be performed by specialist installers and

trained personnel.

For settings other than the normal operating parameters, refer to chapter 4.5.

7.7 Refilling salt tablets

For filling the brine tank, refer to chapter 6.1.1.

Page 38

Cleaning, inspection, maintenance

38 | 74

BA_TD3-BM001en_014_Delta-p.docx

8 Cleaning, inspection, maintenance

WARNING: Danger of contaminated drinking water if the work is not carried out properly

● Risk of infectious diseases.

► Pay attention to hygiene when working on the installation.

8.1 Intervals

Operation Interval Execution

Inspection 2 months Owner/user

Maintenance semi-annually Owner/user or installation

company

annually Installation company

Complying with the inspection and maintenance intervals is important for trouble-free and

hygienic operation.

8.2 Cleaning

WARNING: Danger of contaminated drinking water if the work is not carried out properly.

● Risk of infectious diseases.

► Pay attention to hygiene when working on the installation.

NOTE: Do not clean the product with alcohol or cleaning agents containing solvents!

● Such substances damage components made of plastic.

► Only clean the external surfaces of the product. To do so, use a cloth moistened

with water.

● Only clean the outside of the product.

● Do not use any strong or abrasive cleaning agents.

● Wipe the housing with a cloth that is moistened water.

Page 39

Cleaning, inspection, maintenance

39 | 74

BA_TD3-BM001en_014_Delta-p.docx

8.3 Inspection

WARNING: Danger of contaminated drinking water if the work is not carried out properly.

● Risk of infectious diseases.

► Pay attention to hygiene when working on the installation.

● Determine the raw water hardness. To do this, use the water test kit "total

hardness".

● Determine the soft water hardness. To do this, use the water test kit "total

hardness".

● Check the amount of salt in the brine tank. When doing this, pay attention to the

minimum amount of salt in the brine tank and, if necessary, top up with salt tablets

according to DIN EN 973 A (refer to chapter 6.1.1)

● Check the system for leaks.

● Check the tightness of the control valve to the drain in the operating state, without

regeneration procedure.

8.4 Maintenance

8.4.1 Semi-annual maintenance

WARNING: Danger of contaminated drinking water if the work is not carried out properly.

● Risk of infectious diseases.

► Pay attention to hygiene when working on the installation.

The following work must be carried out as part of the semi-annual maintenance:

● Read the water meter.

● Determine the raw water hardness. To do this, use the water test kit "total

hardness".

● Determine the soft water hardness. To do this, use the water test kit "total

hardness".

● Check the setting of the control unit:

• Time

• Actual raw water hardness

• Soft water hardness with blending. Not allowed to be changed on Delta-p-I.

Page 40

Cleaning, inspection, maintenance

40 | 74

BA_TD3-BM001en_014_Delta-p.docx

● Check the filling level of the salt in the brine tank. When doing this, pay attention to

the minimum amount of salt in the brine tank and, if necessary, top up with salt

tablets according to DIN EN 973 A (refer to chapter 6.1.1)

● Check the condition of the salt. Break up clumps with a suitable tool.

● Evaluate the salt consumption subject to the water volume consumed.

Minor deviations in salt consumption are normal and cannot be avoided

technically. If the deviations are considerable, contact Grünbeck's technical

service/authorised service company.

● Check the system for leaks.

● Check the tightness of the control valve to the drain in the operating state, without

regeneration procedure.

● Enter all data and work in the operation log.

8.4.2 Annual maintenance

Annual maintenance must be performed by the Grünbeck’s technical service/authorised

service company or by an approved company.

WARNING: Danger of contaminated drinking water if the work is not carried out properly

● Risk of infectious diseases.

► Pay attention to hygiene when working on the installation.

Document all data, work and repairs in the operation log (refer to chapter 14)

The following work must be carried out as part of annual maintenance:

● Read the following data:

• Water pressure

• Flow pressure

• Water meter reading

● Determine the raw water hardness. To do this, use the water test kit "total

hardness".

● Determine the raw water hardness. To do this, use the water test kit "total

hardness".

Page 41

Cleaning, inspection, maintenance

41 | 74

BA_TD3-BM001en_014_Delta-p.docx

● Perform the 0 °dH, 0 °f, 0 mmol/l test if necessary:

• Readjust the electronically controlled blending valve (refer to chapter 7.5).

• Check the soft water hardness again.

• Program the desired soft water hardness into the control unit.

● Check the programming of the control unit.

● Check the brine control:

• Salting

• Filling the brine tank

● Check the function of the safety fitting, e.g. system separator, against backflow.

● Check the function of the disinfection device in the control unit.

We recommend replacing the chlorine cell(s) after 2 years at the latest.

● Query regeneration counters, total soft water volume, error memory; a system data

printout is possible via the serial interface of the control unit.

We recommend replacing the push-in turbines after a total water volume of

20,000 m³ has been reached; however, at the latest after 3 years.

Reset the maintenance interval.

8.5 Consumables

CAUTION: Insoluble impurities in the salt may cause malfunctions at the brine valve and at

the injector of the control valve.

● Dosage of salt according to requirements is not guaranteed.

► A defined salt quality is required for the reliable function of the water softener.

Only use salt tablets as per DIN EN 973 type A.

Consumables Delta-p Quantity Order no.

Regeneration salt [kg] 25 127 001

Water test kit "Total hardness“ pc. 1 170 145

10 170 100

Page 42

Cleaning, inspection, maintenance

42 | 74

BA_TD3-BM001en_014_Delta-p.docx

8.6 Wearing parts

NOTE: Danger of damaging the installation unsuitable parts are used.

● Risk of functional impairment, malfunctions and loss of warranty.

► Only use genuine parts.

Seals are wearing parts.

Although these parts are wearing parts, we grant a limited warranty period of 6 months.

Wearing parts Delta-p

Place Figure Wearing parts

Control valve

Seals, injector, servomotors,

turbine water meters, transfer

valves

Brine valve

Brine, float and closing valves

Disinfection unit

Chlorine cells and seals

Page 43

Fault

43 | 74

BA_TD3-BM001en_014_Delta-p.docx

9 Fault

WARNING: Danger of contaminated drinking water due to stagnation.

● Risk of infectious diseases.

► Remedy this malfunction immediately.

WARNING: Danger of contaminated drinking water if the work is not carried out properly.

● Risk of infectious diseases.

► Pay attention to hygiene when working on the installation.

The potential-free signal contact (terminals 37-39) opens when the maintenance interval

has expired and Er A. For all other faults Er X opens the fault signal contact (terminals

39-41). Both signals, signal contact and fault signal contact, are active.

If malfunctions occur that cannot be rectified by following the instructions below, contact

Grünbeck's technical service-/authorised service company.

Have the installation data handy (refer to chapter 14).

9.1 Messages on the display

Status level

1. Acknowledge the fault by pressing button P on the display.

2. Watch the display.

3. If the cause of the error was not eliminated, the error will reoccur after a short

period of time.

Page 44

Fault

44 | 74

BA_TD3-BM001en_014_Delta-p.docx

Control unit GENO-IONO-matic3

Fault Explanation Remedy

Er 0 Power failure > 5 minutes has

occurred.

The signal of a power failure is

not activated in the

GENO-IONO-matic

3

ex-works.

If the exchangers in operation

have been subjected to further

stress during the power failure, the

affected exchangers should be

regenerated by initiating a

regeneration manually (refer to

chapter 7.3).

Contact Grünbeck's technical

service-/authorised service

company. A different parameter

setting could be required.

Er 1

Run-time monitoring motor

regeneration valve has responded.

Connection cable from the

regeneration valve to the control

unit is incorrectly connected or

defective.

Microswitch S3 ... S5 defective.

Motor of the regeneration valve

defective.

Control unit defective.

Notify Grünbeck's technical

service-/authorised service

company.

Fuse F2 has tripped. Replace fuse with the same type

(refer to chapter 13.3).

Pressure reducer on regeneration

valve set incorrectly (completely

open).

Notify Grünbeck’s technical

service-/authorised service

company.

Er 2

Run-time monitoring

motor-Transfer valve has been

activated.

Transfer valve-control unit

connection cable incorrectly

connected or defective.

Microswitch S1 ... S2 defective.

Motor transfer valve defective.

Control unit defective.

Call Grünbeck's technical service/

authorised service company.

Fuse F2 has tripped. Replace fuse with the same type

(refer to chapter 13.3).

Page 45

Fault

45 | 74

BA_TD3-BM001en_014_Delta-p.docx

Control unit GENO-IONO-matic3

Er 3 The regeneration of exchangers **

is due, but the regeneration of

exchanger * is not yet completed.

This means only mixed or raw

water is available.

The hard water-signal Er 3 is not

activated in the

GENO-IONO-matic

3

ex-works.

Reduce water withdrawal. The

fault is acknowledged

automatically when 2 exchangers

with a corresponding capacity are

in operation again.

Contact Grünbeck's technical

service-/authorised service

company. A different parameter

setting could be required.

Er_4 Chlorine generation for disinfection

of the exchanger during

regeneration has not been carried

out properly.

Check connection cable control

unit – disinfection device.

The electrolysis-current is too low

due to insufficient brine

concentration.

Check the minimum quantity of

salt in the brine tank and top up

with salt tablets according to

DIN EN 973 A. Wait for 5

minutes and then acknowledge

fault.

Call Grünbeck's technical

service/ authorised service

company.

Carbon electrodes consumed. Call Grünbeck's technical service/

authorised service company.

Er--4

Short circuit on carbon electrodes. Call Grünbeck's technical service/

authorised service company.

Check connection cable control

unit – disinfection device.

Er 6 Water quantity for refilling the brine

tank was not reached within the

required time. For the next

regeneration, it may not be

possible to produce enough brine.

Check/establish raw water

supply.

Remove kinks.

Turbine water meter 4 - pulse

cable defective.

Turbine water meter 4 faulty.

Control unit defective.

Call Grünbeck's technical service/

authorised service company.

Er 8 One of the exchangers' water

meters does not work.

Check that all cables are

connected to the turbine water

meter of the correct exchanger

or regeneration/transfer valve.

Call Grünbeck's technical

service-/authorised service

company.

Page 46

Fault

46 | 74

BA_TD3-BM001en_014_Delta-p.docx

Control unit GENO-IONO-matic3

Er 9 The control unit detects an invalid

microswitch-position on the

regeneration or transfer valve.

Connection cable regeneration

valve-control unit or transfer

valve-control unit incorrectly

connected or defective.

Microswitch S1 ... S5 defective.

Control unit defective.

Check the connection cable.

Check cabling.

Call Grünbeck's technical

service-/authorised service

company.

Er A with

symbol

Display only if pre-alarm salt

supply accessory is installed and

code 113, parameter 3 = L are

programmed.

Check the minimum quantity of

salt in the brine tank and top up

with salt tablets according to

DIN EN 973 A.

Request Grünbeck's technical

service-/authorised service

company if the display appears

despite the quantity of salt being

at or above the minimum.

Er C Nominal flow of water softener

exceeded. Risk of damage to

system components.

Reduce the flow rate via the water

softener until the nominal flow rate

is no longer exceeded.

Er D Run-time monitoring motor

blending valve has responded.

Soft water hardness is

programmed although no blending

valve is installed.

Set parameters for soft water

hardness with blending to 0 °dH

(0 °f, 0 mol/m³).

Parameters for soft water

hardness selected too high in

relation to raw water hardness.

Program parameters for soft water

hardness lower. 50% of the raw

water hardness can be achieved at

most.

Cabling of turbine water

meter/motor blending valve faulty.

Check cabling.

Turbine water meter 5 – pulse

cable defective.

Turbine water meter 5 faulty.

Control unit defective. Blending

valve defective.

Call Grünbeck's technical service/

authorised service company.

Er F Connection to accessories

communication moduleDE200-Profibus is faulty.

Restore connection.

Restore power supply to the

option module.

Maintenance interval has expired. Call Grünbeck's technical service/

authorised service company.

Page 47

Fault

47 | 74

BA_TD3-BM001en_014_Delta-p.docx

9.2 Other observations

Water softener Delta-p

Fault Explanation Remedy

Hardness increase in the

soft water

- Water softener overrun -

Water softener does not have

permanent power supply; it is

coupled with light switch.

Check/change type of power

supply.

No impulses from the turbine

water meter at the control

unit.

Check turbine water meter

and impulse cable; replace

defective parts.

Incorrect setting of the control

unit.

Check and correct settings

and parameters.

Water softener does not

draw in enough brine.

Not enough water in brine

tank.

Clean injector.

Check regeneration step

Fill brine tank.

- Other explanation -

Setting on the external

blending valve, if available.

Check raw resp. soft water

hardness. Check and correct

the setting of the blending

valve.

Supply of raw water

interrupted.

Open the shut-off valves.

Flow rate above specified

nominal flow on type

designation plate.

Reduce flow rate.

Not enough salt in brine tank. Check the salt level and refill.

Resin in discharge pipe. Defective jet system. Call Grünbeck's technical

service-/authorised service

company.

Pressure loss too great. Resin is polluted by

undissolved particles.

Call Grünbeck's technical

service-/authorised service

company.

Water softener does not

draw in brine/brine tank is

full.

Water pressure too low. Increase flow pressure to at

least 2.0 bar.

Injector clogged. Clean injector

Injector sieve clogged. Clean injector sieve

Brine valve clogged. Remove brine valve and

clean thoroughly

Incorrectly mounted transfer

valve.

Check "point-to-point"

mounting.

Display shows nothing. Fuse F3 or transformer fuse

has tripped.

Replace fuse with the same

type.

Page 48

Disposal

48 | 74

BA_TD3-BM001en_014_Delta-p.docx

10 Disposal

● Do not dispose of the packaging, the product and/or the accessories with the

domestic waste.

● Comply with the applicable national regulations for disposal.

● Make sure that the packaging, the product and the accessories are disposed of

properly.

Page 49

Technical specifications

49 | 74

BA_TD3-BM001en_014_Delta-p.docx

11 Technical specifications

Water softener Delta-p 1" 1¼" 1½" 2"

Connection data

Nominal diameter DN 25

(1" male

thread)

DN 32

(1¼" male

thread)

DN 40

(1½" male

thread)

DN 50

(2" male

thread)

Min. drain connection DN 50 DN 70

Power supply [V]/[Hz] 230/50-60

(operation of water softener with safety extra-low voltage 24/50-60)

Connected load in operation =

max./Standby

[VA] 26/19 32/19

Protection/Protection class IP 54/

Performance data

Nominal pressure PN 10

Min./max. operating pressure [bar] 2/10

Nominal flow

(restricted by hard raw water from

20 °dH / 39.2 °f / 3.92 mmol/l)

[m3/h] 3 5 8 12

Nominal flow rate soft water with

blending

(raw water hardness 20 °dH (35.6 °f,

3.56 mmol/l)

Soft water hardness 8 °dH (14.2 °f,

1.42 mmol/l)),

not Delta-p-

[m3/h] 5 8.3 13.3 20

Pressure loss [bar] 0.5 0.8 0.5 0.8

Nominal flow rate according to DIN EN

14743 or k

V

-value at pressure loss

1.0 bar (theoretical reference value)

[m

3

/h] 4.2 5.6 11.3 13.4

Continuous flow

(Maximum value reduced by hard raw

water from 20 °dH / 35.6 °f /

3.56 mmol/l)

Depending on the raw water hardness (refer to continuous flow curve)

Minimum quantity of water removed for

perfect system control,

raw water hardness 0 °dH (0 °f,

0 mmol/l)

(The use of a blending valve increases

the minimum quantity by the amount of

water added by the blending)

[l/h] 70 180

Nominal capacity [mol] 8.2 13.2 27.8 38.6

[m³ x °dH] 48 79 165 229

[m³ x °f] 58.4 140.6 293.7 407.6

Capacity per kg of regeneration salt [mol/kg] 5.7

Page 50

Technical specifications

50 | 74

BA_TD3-BM001en_014_Delta-p.docx

Water softener Delta-p 1" 1¼" 1½" 2"

Dimensions and weights

A Total height

without pedestal / with pedestal

[mm] 1300/1500 1640/1840 1760/1960

B Connection height of control

valve; soft water

[mm] 1155/1255 1485/1684 1605/1805

C Connection height of control

valve; raw water

[mm] 860/1060 1125/1325 1245/1545

D Height Standard-brine

tank

[mm] 670/870 860/1060

Accessories for

brine tank

860/1060 (210 l) 1250/1450 (750 l)

E Height

safety

over flow

Standard-brine

tank

[mm] 575/775 785/985

Accessories for

brine tank

785/985 (210 l) 1100/1300 (750 l)

F Ø Standard-brine tank [mm] 410 570

Accessories for brine tank 570 (210 l) 900 (750 l)

G Ø Exchanger tank [mm] 210 257 369 406

H Width of water softener [mm] 580 630 900 960

I Recommended foundation depth min.

with standard-brine tank

[mm] 920 1020 1400 1450

J Recommended foundation width

min. with standard-brine tank

[mm] 1240 1400 1770 1850

Operating weight, approx. [kg] 255 /

403 (210 l)

322 /

471 (210 l)

745

1400 (750 l)

862 /

1520 (750 l)

Page 51

Technical specifications

51 | 74

BA_TD3-BM001en_014_Delta-p.docx

Water softener Delta-p 1" 1¼" 1½" 2"

Filling volumes and consumption data

Resin volume (tank) [l] 21 33 75 100

Freeboard (resin in form of sodium),

approx.

[mm] 135 160 195 265

Salt consumption per regeneration,

approx.

[kg] 1.5 2.5 5.2 7.2

Regenerating salt supply max.

standard brine tank/accessory brine

tank

[kg] 65/180 (210 l) 180/630 (750 l)

Salt consumption per m³ and °dH [kg/m³ x °dH] 0.03

Salt consumption per m³ and °f [kg/m³ x °f] 0.018

Salt consumption per m³ and mol [kg/mol] 0.18

Max. rinsing water volume [m³/h] 0.6 0.9 1.9 2.0

Total waste water volume per

regeneration, approx.

[l] 68 110 235 315

Waste water volume per m³ and °dH [l/m³ x °dH] 1.42

Waste water volume per m³ and °f [l/m³ x °f] 0.79

Waste water volume per m³ and mol [l/mol] 7.8

Operating water volume [l] 4.2 6.9 14.4 20

General

Max. water temperature [°C] 30

Max. ambient temperature in case of

purely technical applications

[°C] 40

Max. ambient temperature in line

with the German Drinking Water

Ordinance

[°C] 25

Iron content in raw water max. [mg/l] 0.2

Manganese content in raw water

max.

[mg/l] 0.05

DVGW-registration number

(not Delta-p-I)

NW-9151BU0049

SVGW-certificate-number

(not Delta-p-I)

1305-6162

Data record in the control unit CA31 CA32 CA35 CA36

Order-no. Delta-p 185 100 185 110 185 120 185 130

Order-no. Delta-p ready for

connection on pedestal

185 105 185 115 185 125 185 135

Order-no. Delta-p-l 185 200 185 210 185 220 185 230

Order-no. Delta-p-l ready for

connection on pedestal

185 205 185 215 185 225 185 235

Page 52

Technical specifications

52 | 74

BA_TD3-BM001en_014_Delta-p.docx

11.1 Continuous flow curve

Continuous flow curve Delta-p

No. Designation No. Designation

1 max. continuous flow rate in % of nominal flow

rate at 0 °dH, 0 °f, 0 mmol/l

2 Raw water hardness in °dH

Conversion table

°dH 14 16 18 20 22 24 26 28 30 32 34

°f 24.9 28.5 32.0 35.6 39.2 42.7 46.3 49.8 53.4 57.0 60.5

mmol/l 2.49 2.85 3.20 3.56 3.92 4.27 4.63 4.98 5.34 5.70 6.05

Page 53

Technical specifications

53 | 74

BA_TD3-BM001en_014_Delta-p.docx

11.2 Pressure loss curves

Pressure loss curves Delta-p

No. Designation No. Designation

1 Pressure loss in bar at 0 °dH, 0 °f, 0 mmol/l 2 Flow in m³/h

Page 54

Other information

54 | 74

BA_TD3-BM001en_014_Delta-p.docx

12 Other information

12.1 Explanation of terminology

Capacity

Describes the amount of fully softened water that the water

softener can produce in its entirety or in any part of it.

Regeneration water

After the regeneration, this water is saturated with calcium

ions and is flushed out of the system into the drain.

Raw water

Raw water is the untreated water before it passes through

the filter.

Stagnation

Inadequate water flow without pressure to force the water. In

dead-end pipes and in cross-connections, also in pipes that

are not being used such as during holidays.

Period of inactivity

Time in which a system filled with raw water is available

without power supply and without removal of water.