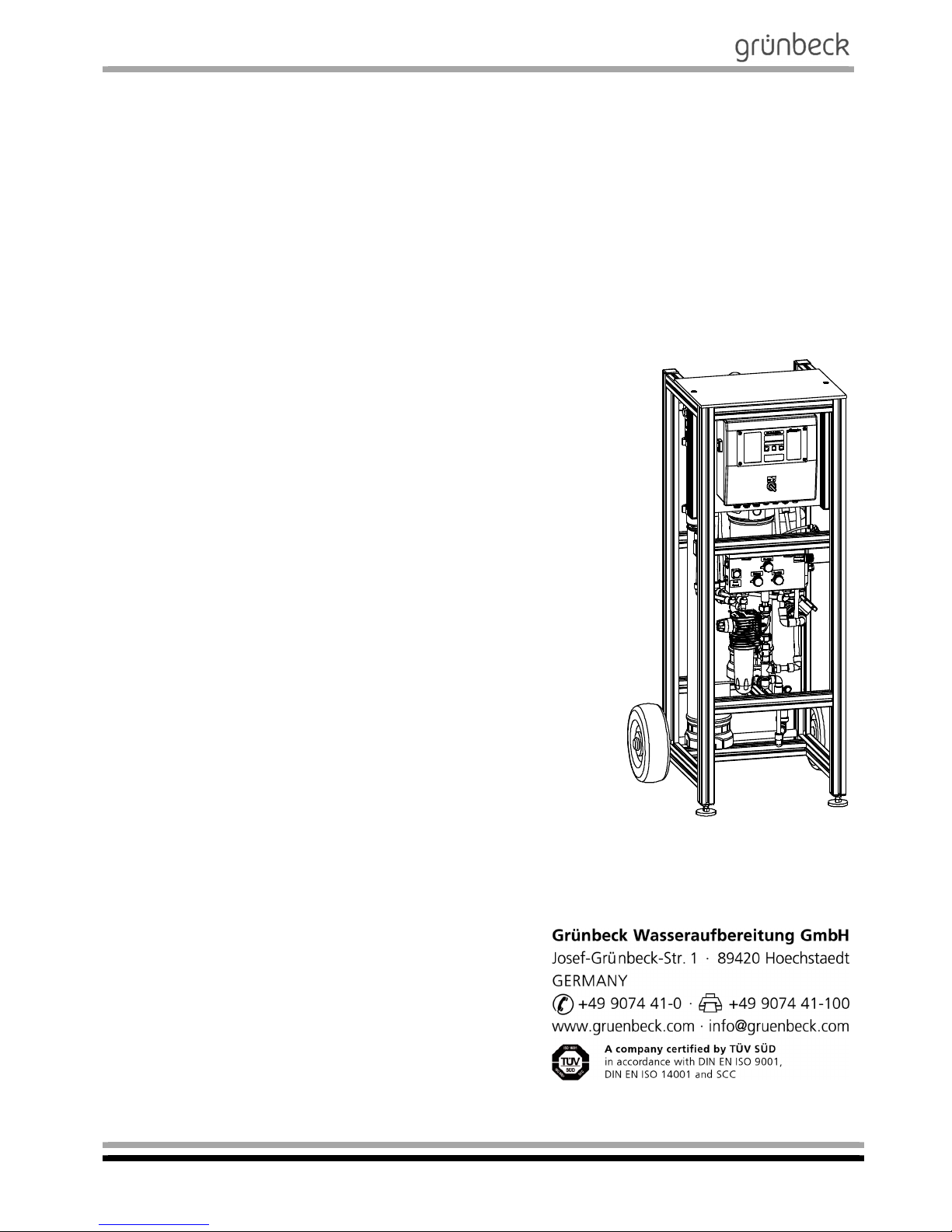

Grunbeck AVRO-flex 400 Operation Manual

Operation Manual

Mobile reverse osmosis system

AVRO-flex 400

Starting from software version V1.33

Edition November 2018

Order no. 095 752 946-inter

Mobile reverse osmosis system

AVRO-flex 400

Order no. 095 752 946-inter Edited by: phar-mrie G:\BA-752946-INTER_095_AVRO-FLEX_400.DOCX

2

Table of contents

AGeneral .................................................................................................................................................................. 5

1 | Preface ..........................................................................................................................................................................................................5

2 | How to use this operation manual .................................................................................................................................................................6

3 | General safety information ............................................................................................................................................................................6

3.1Symbols and notes ..................................................................................................................................................................................6

3.2Operating personnel ...............................................................................................................................................................................7

3.3Intended use ............................................................................................................................................................................................7

3.4Protection from water damage ................................................................................................................................................................7

3.5Indication of specific hazards ..................................................................................................................................................................7

4 | Shipping and storage .....................................................................................................................................................................................8

5 | Disposal .........................................................................................................................................................................................................8

5.1Packaging ................................................................................................................................................................................................8

5.2Product ....................................................................................................................................................................................................8

BBasic information ................................................................................................................................................. 9

1 | Laws, regulations, standards .........................................................................................................................................................................9

2 | Water .............................................................................................................................................................................................................9

3 | Functional principle of reverse osmosis ......................................................................................................................................................10

3.1Functional principle of the AVRO system ..............................................................................................................................................11

CProduct description ........................................................................................................................................... 12

1 | Type designation plate ................................................................................................................................................................................12

2 | Functional description ..................................................................................................................................................................................13

3 | Technical specifications ...............................................................................................................................................................................17

4 | Intended use ................................................................................................................................................................................................18

5 | Application limits ..........................................................................................................................................................................................19

6 | Scope of supply ...........................................................................................................................................................................................20

6.1Standard equipment ..............................................................................................................................................................................20

6.2Optional accessories .............................................................................................................................................................................21

6.3Consumables .........................................................................................................................................................................................22

6.4Wearing parts ........................................................................................................................................................................................22

DInstallation .......................................................................................................................................................... 23

1 | General installation instructions ...................................................................................................................................................................23

1.1Water connection ...................................................................................................................................................................................23

EStart-up................................................................................................................................................................ 24

1 | How to connect the system to the water supply ..........................................................................................................................................24

2 | How to flush the system ..............................................................................................................................................................................26

2.1How to flush off the preserving agent ....................................................................................................................................................26

2.2Filling mode ...........................................................................................................................................................................................26

2.3Workshop mode ....................................................................................................................................................................................28

FOperation (control unit) ..................................................................................................................................... 29

1 | Preface ........................................................................................................................................................................................................29

2 | How to operate the control unit....................................................................................................................................................................30

2.1Reading the operating status ................................................................................................................................................................31

2.2How to set the time ................................................................................................................................................................................31

2.3Access to the programming levels - change parameters ......................................................................................................................32

2.4Software version Code 999 ...................................................................................................................................................................32

3 | Programming levels .....................................................................................................................................................................................33

3.1 Input logic Code 113 .............................................................................................................................................................................33

3.2 System parameters Code 290 ..............................................................................................................................................................33

3.3Reference values / times Code 302 ......................................................................................................................................................34

3.4Error memory / water volumes Code 245 ..............................................................................................................................................35

3.5Diagnosis Code 653 ..............................................................................................................................................................................35

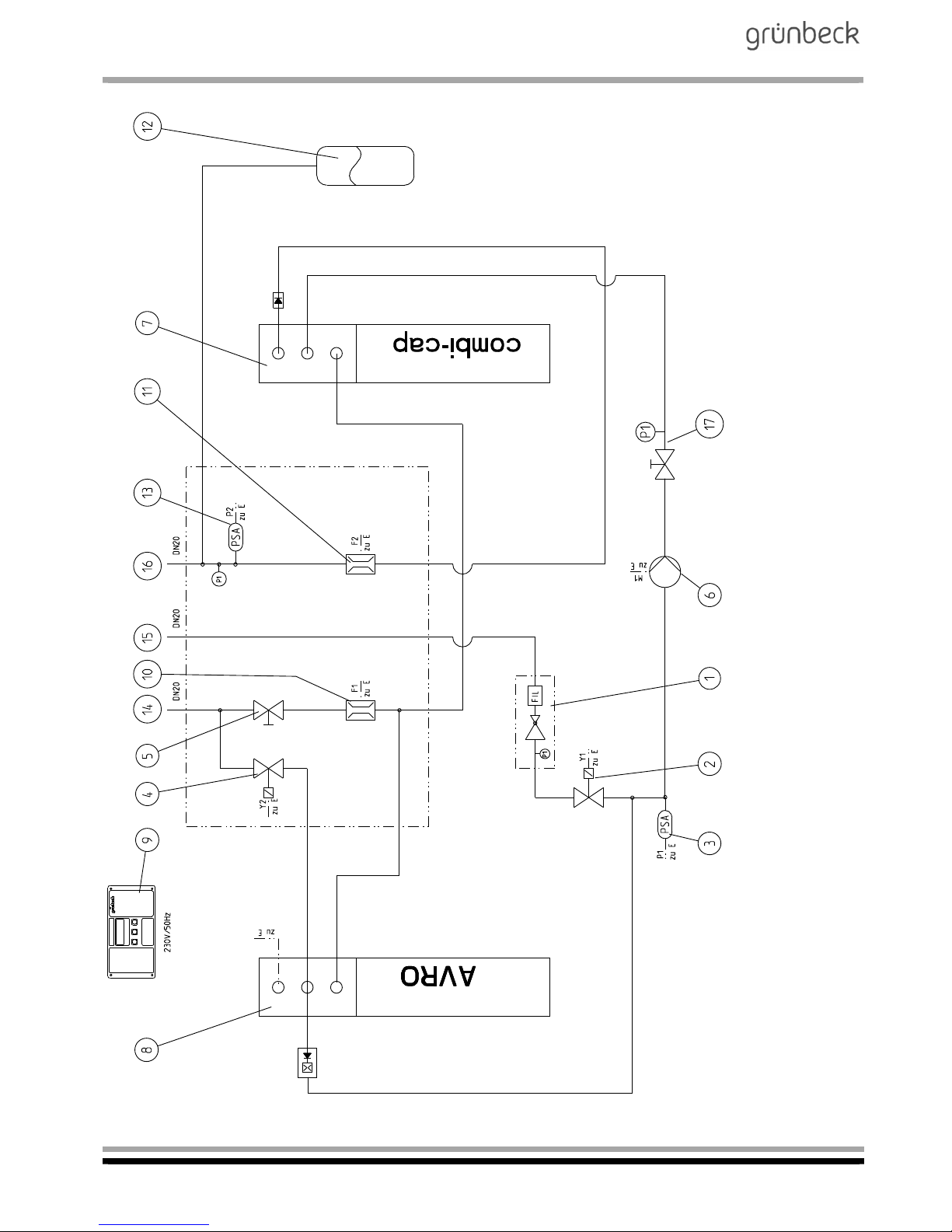

4 | Wiring diagram of mobile reverse osmosis system AVRO-flex 400 ............................................................................................................36

5 | Operation of reverse osmosis system AVRO-flex 400 ................................................................................................................................38

5.1How to set the system recovery ............................................................................................................................................................38

GTroubleshooting ................................................................................................................................................. 40

HMaintenance and care ........................................................................................................................................ 42

1 | Basic information .........................................................................................................................................................................................42

2 | Inspection (functional check) .......................................................................................................................................................................42

3 | Maintenance ................................................................................................................................................................................................43

3.1Operation log .........................................................................................................................................................................................44

4 | Operation log ...............................................................................................................................................................................................45

Maintenance work on mobile reverse osmosis system AVRO-flex 400 .................................................................... 46

Maintenance work on mobile reverse osmosis system AVRO-flex 400 .................................................................... 48

Maintenance work on mobile reverse osmosis system AVRO-flex 400 .................................................................... 50

Mobile reverse osmosis system

AVRO-flex 400

Order no. 095 752 946-inter Edited by: phar-mrie G:\BA-752946-INTER_095_AVRO-FLEX_400.DOCX

3

Publisher's information

All rights reserved.

©

Copyright by Grünbeck Wasseraufbereitung GmbH

Printed in Germany

Effective with the date of edition indicated on the cover sheet.

-We reserve the right to modifications, especially with regard to technical progress-

Reprints, translations into foreign languages, electronic storage or

copying only with explicit written approval of Grünbeck Wasseraufbereitung GmbH.

Any type of duplication not authorised by Grünbeck Wasseraufbereitung is a copyright violation and subject to legal action.

Responsible for contents:

Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Str. 1 89420 Hoechstaedt/Germany

Tel. +49 9074 41-0 Fax +49 9074 41-100

www.gruenbeck.com service@gruenbeck.con

Print: Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Str. 1, 89420 Hoechstaedt/Germany

Mobile reverse osmosis system

AVRO-flex 400

Order no. 095 752 946-inter Edited by: phar-mrie G:\BA-752946-INTER_095_AVRO-FLEX_400.DOCX

4

EU Declaration of Conformity

This is to certify that the system designated below meets the safety and health requirements of

the applicable European guidelines in terms of its design, construction and execution.

If the system is modified in a way not approved by us, this certificate is void.

Manufacturer: Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Str. 1

89420 Hoechstaedt/Germany

Responsible for documentation: Markus Pöpperl

System designation: Mobile reverse osmosis system

System type: AVRO-flex 400

Serial no.: Refer to type designation plate

Applicable directives: Machinery Directive (2006/42/EU)

EMC (2014/30/EU)

Applied harmonised standards,

in particular:

DIN EN ISO 12100:2011-03,

DIN EN 61000-6-2:2006-03

DIN EN 61000-6-3:2011-09

Applied national standards

and technical specifications,

in particular:

Place, date and signature: Hoechstaedt, 30.04.2018 i. V._____________

M. Pöpperl

Dipl. Ing. (FH)

Function of signatory: Head of Technical Product Design

Mobile reverse osmosis system

AVRO-flex 400

Order no. 095 752 946-inter Edited by: phar-mrie G:\BA-752946-INTER_095_AVRO-FLEX_400.DOCX

5

A General

1 | Preface

Thank you for opting for a Grünbeck product. Backed by decades of

experience in the area of water treatment, we provide customised solutions for all kind of processes.

Drinking water is classified as food and requires particular care.

Therefore, always ensure the required hygiene when operating and

maintaining systems involved in the drinking water supply. This also

applies to the treatment of water for industrial use if repercussions for

the drinking water cannot completely be excluded.

All Grünbeck systems and devices are made of high-quality materials.

This ensures reliable operation over many years, provided you treat

your water treatment systems with the required care. This operation

manual assists you with important information. Therefore, please read

the entire operation manual before installing, operating or maintaining

the system.

Customer satisfaction is our prime objective and providing customers

with qualified advice is crucial. If you have any questions concerning

this system, possible extensions or general water and waste water

treatment, our field staff, as well as the experts at our headquarters in

Hoechstaedt, are available to help you.

Advice and assistance

For advice and assistance please contact your local representative

(see www.gruenbeck.com) or get in touch with our service centre

which can be reached during office hours:

Phone: +49 9074 41-333

Fax: +49 9074 41-120

Email: service@gruenbeck.de

We can connect you with the appropriate expert more quickly if you

provide the required system data. In order to have the required data

handy at all times, please copy it from the type designation plate to

the overview in Chapter C-1.

Mobile reverse osmosis system

AVRO-flex 400

Order no. 095 752 946-inter Edited by: phar-mrie G:\BA-752946-INTER_095_AVRO-FLEX_400.DOCX

6

2 | How to use this operation manual

This operation manual is intended for the operators of our systems. It

is divided into several chapters which are listed in the “Table of contents” on page 2 in alphabetical order. In order to find the specific information you are looking for, check for the corresponding chapter on

page 2.

The headers and page numbers with chapter information make it easier to find your way around in the manual.

3 | General safety information

3.1 Symbols and notes

Important information in this operation manual is characterised by

symbols. Please pay particular attention to this information to ensure

the hazard-free, safe and efficient handling of the system.

Danger! Failure to adhere to this information will cause serious or

life-threatening injuries, extensive damage to property or inadmissible contamination of the drinking water.

Warning! Failure to adhere to this information may cause injuries,

damage to property or contamination of the drinking water.

Attention! Failure to adhere to this information may result in damage

to the system or other objects.

Note: This symbol characterises information and tips to make your

work easier.

Tasks with this symbol may only be performed by Grünbeck's technical service/authorised service company or by persons expressly

authorised by Grünbeck.

Tasks with this symbol may only be performed by trained and qualified electrical experts according to the VDE guidelines or according

to the guidelines of a similar local institution.

Tasks with this symbol may only be performed by the local water supply companies or approved installation companies. In Germany, the

installation company must be registered in an installation directory of

a water company as per §12(2) AVBWasserV (German Ordinance on

General Conditions for the Supply of Water).

Mobile reverse osmosis system

AVRO-flex 400

Order no. 095 752 946-inter Edited by: phar-mrie G:\BA-752946-INTER_095_AVRO-FLEX_400.DOCX

7

3.2 Operating

personnel

Only persons who have read and understood this operation manual

are permitted to work with the system. The safety information in particular is to be strictly adhered to.

3.3 Intended use

The system may only be used for the purpose outlined in the product

description (Chapter C). The instructions in this operation manual as

well as the applicable local guidelines concerning drinking water protection, accident prevention and occupational safety must be adhered

to.

In addition, intended use also implies that the system may only be operated when it is in proper working order. Any malfunctions must be

repaired at once.

3.4 Protection from water damage

Warning! In order to properly protect the installation site from water

damage:

a. a sufficient floor drain system must be available or

b. a safety device (refer to Chapter C “Optional accessories”) must be

installed.

Warning! Floor drains with discharge to a lifting system do not work

in case of a power failure.

3.5 Indication of

specific hazards

Danger due to electrical energy! Do not touch electrical parts with

wet hands! Unplug the mains plug before starting work on electrical

parts of the system. Have qualified experts replace damaged cables

immediately.

Danger due to mechanical energy! System parts may be subject to

overpressure. Danger of injury and damage to property due to escaping water and unexpected movement of system parts. Check pressure pipes regularly. Depressurise the system before starting repair

or maintenance work on the system.

Hazardous to health due to contaminated drinking water! The system may only be installed by a specialist company. The operation

manual must be strictly adhered to! Ensure that there is sufficient

flow. The pertinent guidelines must be followed for start-up after extended periods of standstill. Inspections and maintenance must be

performed at the intervals specified!

Note: By concluding a maintenance contract, you ensure that all of

the required tasks are performed on time. You may perform the interim inspections yourself.

Mobile reverse osmosis system

AVRO-flex 400

Order no. 095 752 946-inter Edited by: phar-mrie G:\BA-752946-INTER_095_AVRO-FLEX_400.DOCX

8

4 | Shipping and storage

Attention! The system may be damaged by frost or high tempera-

tures. In order to avoid damage of this kind:

Protect from frost during transportation and storage!

Do not install or store system next to objects which radiate a lot of

heat.

5 | Disposal

Comply with the applicable national regulations.

5.1 Packaging

Dispose of the packaging in an environmentally sound manner.

5.2 Product

If this symbol (crossed out waste bin) is on the product, European

Directive 2012/19/EU applies to this product. This means that this

product and the electrical and electronic components must not be

disposed of as household waste.

Dispose of electrical and electronic products or components in an

environmentally sound manner.

For information on collection points for your product, contact your

municipality, the public waste management authority, an authorised

body for the disposal of electrical and electronic products or your

waste collection service.

Mobile reverse osmosis system

AVRO-flex 400

Order no. 095 752 946-inter Edited by: phar-mrie G:\BA-752946-INTER_095_AVRO-FLEX_400.DOCX

9

B Basic information

1 | Laws, regulations, standards

In the interest of good health, rules cannot be ignored when it comes

to the processing of drinking water. This operation manual takes into

consideration the current regulations and stipulates information that

you will need for the safe operation of your water treatment system.

Among other things, the regulations stipulate that

only approved companies are permitted to make major modifications

to water supply facilities

and that tests, inspections and maintenance on installed devices are

to be performed at regular intervals.

2 | Water

There is no chemically pure water in nature. Even in the atmosphere,

rain water absorbs various substances that change the properties of

the water to a greater or lesser degree. This process continues as the

water passes through the ground layers, with the result that the water

is enriched with increasingly large quantities of materials. Carbon dioxide (CO2) is particularly important here, since this substance increases the dissolving capability of the water even more. Consequently, drinking water contains quantities of dissolved sodium, potassium, calcium, magnesium, iron, manganese, copper, zinc, chlorides,

fluorides, sulphates and also nitrates, nitrites, phosphates and silicates that vary greatly from location to location.

Due to dynamic substance and water cycles, harmful elements,

which are only partly and only slowly biodegradable are increasingly

released into nature. Over time, these elements therefore accumulate

in ground and surface water. Removing them from natural water bodies again represents a particular challenge. Grünbeck rises to this

challenge and aims at generating unpolluted drinking and industrial

water.

The water works provide us with pure drinking water that is suitable

for consumption. However, if the water is to be used for technical purposes, further treatment is frequently required.

Mobile reverse osmosis system

AVRO-flex 400

Order no. 095 752 946-inter Edited by: phar-mrie G:\BA-752946-INTER_095_AVRO-FLEX_400.DOCX

10

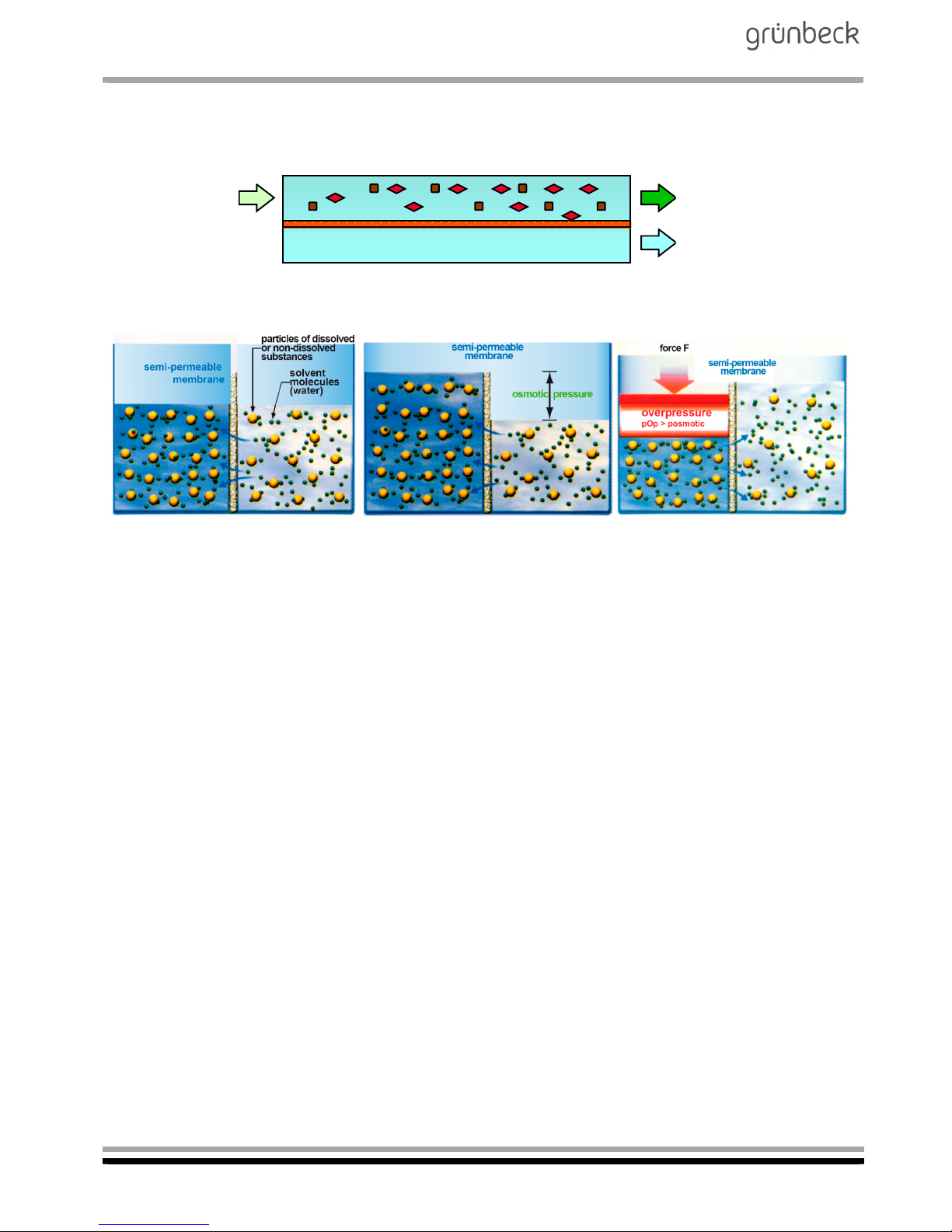

3 | Functional principle of reverse osmosis

Principle:

Pretreated

feed water

Concentrate:

Permeate

Fig. B-1: Functional principle

Solution of high

concentration

Solution of low

concentration

Solution of high

concentration

Solution of low

concentration

Solution of high

concentration

(concentrate)

Solution of low

concentration

(permeate)

Fig. B-2: Reverse osmosis principle

In the osmosis process, watery solutions of different concentrations

are separated by a semi-permeable membrane. In keeping with the

law of nature, the concentrations try to equalise. On the side of the

higher original concentration, the so-called "osmotic" pressure is generated. In case of reverse osmosis, this osmotic pressure is countered by a higher pressure. The consequence: the process proceeds

in the reverse direction. A particular advantage of the reverse osmosis technology compared to other water treatment processes is the

fact that - apart from the removal of dissolved salts - bacteria, germs,

particles and dissolved organic substances are also reduced.

Mobile reverse osmosis system

AVRO-flex 400

Order no. 095 752 946-inter Edited by: phar-mrie G:\BA-752946-INTER_095_AVRO-FLEX_400.DOCX

11

3.1 Functional principle of the AVRO

system

AVRO is an alternative anti-scaling process to the common traditional

processes of "softening" or “antiscalant dosing”. Contrary to these

processes, AVRO does not require any addition of auxiliary additives.

The chemical composition of the generated concentrate is not modified. There is only a doubling of the concentration (standard recovery

50 %).

Hydraulically, the AVRO is installed in the concentrate pipe downstream of the membrane.

The treatment unit consists of two inert special electrodes to which a

low current is applied. Seed crystals (calcium carbonate) are generated at the cathode and are permanently directed via the concentrate

recirculation. The salts of the supersaturated concentrate continue to

grow on these seed crystals, and they are finally washed out to the

drain with the residual concentrate flow. This reliably prevents scaling

(deposits of insoluble salts on the membrane). Some of the calcium

carbonate remains on the cathode of the AVRO and due to increasing

electrical resistance, limits the service life of the AVRO treatment unit

to 3000 operating hours (permeate production) or 5 years.

Mobile reverse osmosis system

AVRO-flex 400

Order no. 095 752 946-inter Edited by: phar-mrie G:\BA-752946-INTER_095_AVRO-FLEX_400.DOCX

12

C Product description

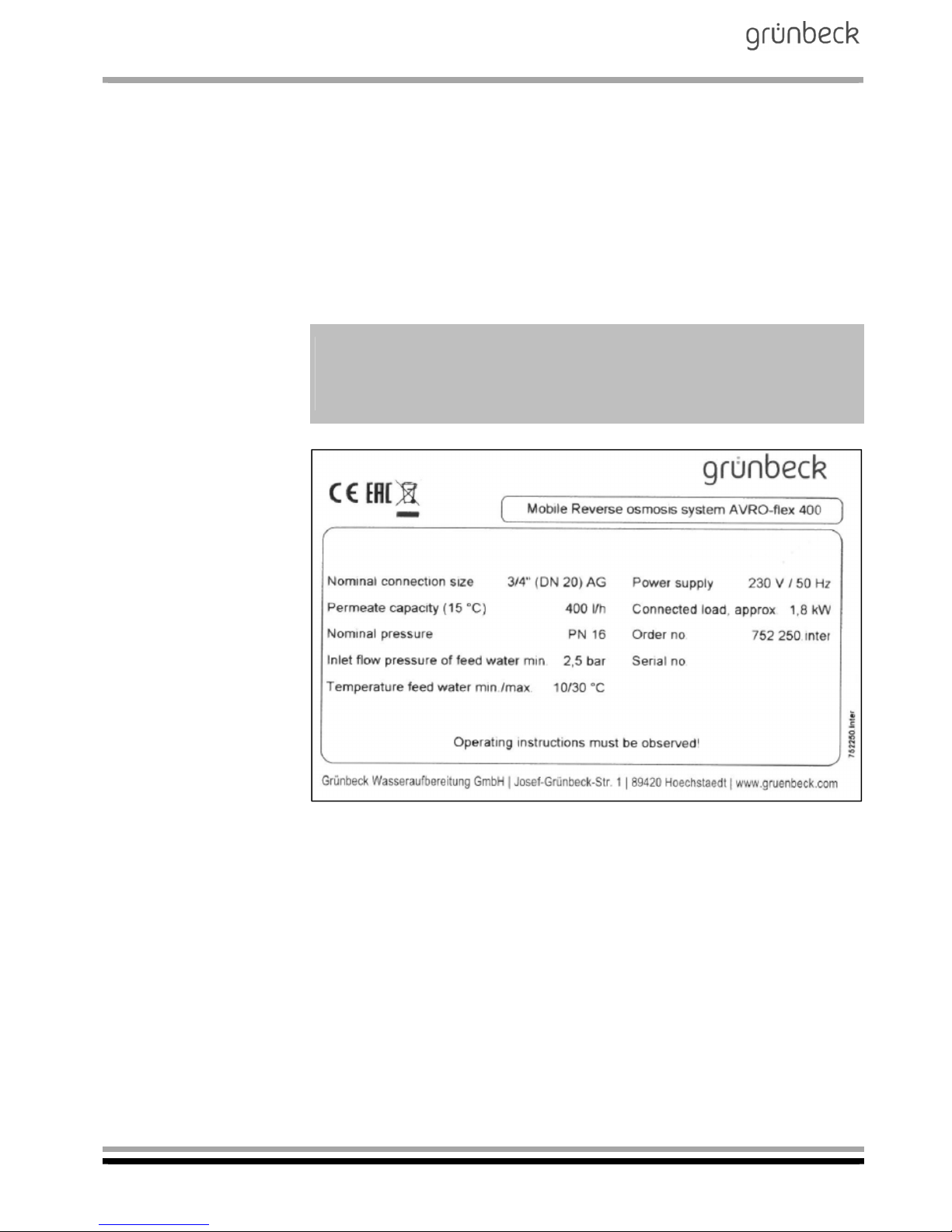

1 | Type designation plate

You may find the type designation plate at the housing of the mobile

reverse osmosis system AVRO-flex 400. In order to speed up the processing of your inquiries or orders, please specify the data shown on

the type designation plate of your system when contacting Grünbeck.

Please copy the indicated information to the table below in order to

have it handy whenever necessary.

Mobile reverse osmosis system AVRO-flex 400

Serial number:

Order number:

Fig. C-1: Type designation plate

Mobile reverse osmosis system

AVRO-flex 400

Order no. 095 752 946-inter Edited by: phar-mrie G:\BA-752946-INTER_095_AVRO-FLEX_400.DOCX

13

2 | Functional description

Via a fine filter (filter element), the water is directed to the inlet of the

feed water section. The water flows to the high-pressure pump via the

inlet solenoid valve with a downstream “pressure switch for minimum

pressure”. By means of a control valve, the pressure generated by the

high-pressure pump is reduced to the required operating pressure

and the water is directed to the membrane. The membrane separates

the water into the partial flows permeate and concentrate. A partial

flow of the concentrate is returned to the feed water via an orifice regulating independently of pressure and thus ensures a steady flow

over the membrane and increases the economic efficiency of the reverse osmosis.

At the same time, the concentrate volume flow is run via an AVRO

treatment module where seed crystals are formed at a cathode due to

the application of direct current. These seed crystals are then washed

out with the residual concentrate and thus the reverse osmosis membrane is protected from clogging. Whenever the system is switched

off or in case of disturbances, the substances retained on the membrane are flushed off by means of the inlet solenoid valve and a solenoid valve switched in parallel to the control valve for concentrate.

The hydraulic set-up of the system is designed in a way that the concentrate volume and the permeate volume are registered by means of

flow sensors and are displayed in the control unit. The system recovery can also be called up in the control unit.

Downstream of the membrane, the permeate produced can be delivered into the heating system with a counter-pressure of up to 3.5 bar.

Note: If the counter-pressure on the permeate side increases, the

permeate output decreases.

Filling mode:

If "filling mode" is selected via the selector switch on the controller,

three waves are visible in the controller. The pressure switch is interrogated as the start criterion.

Workshop mode:

If "workshop mode" is selected via the selector switch on the control-

ler, one wave is visible in the controller. Selection of the operating

switch is used as the start criterion. After 24 hours, permeate is produced over time. The workshop mode prevents germs from infecting

the system, thereby ensuring a constant permeate quality.

Mobile reverse osmosis system

AVRO-flex 400

Order no. 095 752 946-inter Edited by: phar-mrie G:\BA-752946-INTER_095_AVRO-FLEX_400.DOCX

14

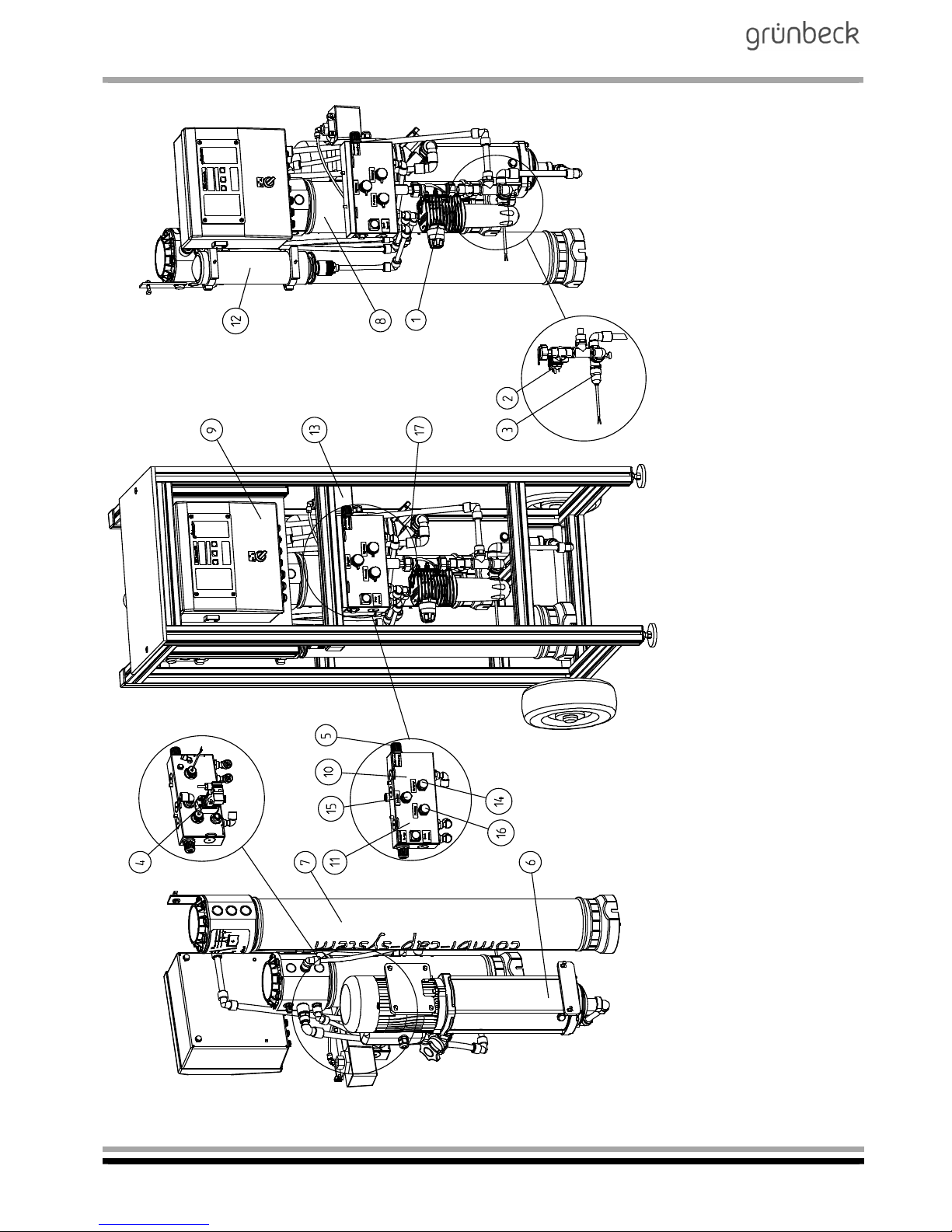

Fig. C-2: Exploded drawing of mobile reverse osmosis system AVRO-flex 400

Mobile reverse osmosis system

AVRO-flex 400

Order no. 095 752 946-inter Edited by: phar-mrie G:\BA-752946-INTER_095_AVRO-FLEX_400.DOCX

15

Fine filter incl.

pressure reducer

Pressure reducer preset to 2.5 bar, incl. pressure gauge.

Inlet solenoid valve During the permeate production, this valve is always open. Fol-

lowing the system stop (tank full), the valve remains open for

the programmed flushing time of the membrane. Visual indication in the control unit .

Pressure switch for minimum pressure of highpressure pump.

To prevent the high-pressure pump from running dry. Switches

time-delayed after the solenoid valve has opened . Visual indication in the control unit .

Flushing solenoid valve Opens after the pressure switch “switch-off pressure” has

reached the set pressure. The solenoid valve also opens in the

event of system malfunctions and always in conjunction with the

feed water inlet solenoid valve . Visual indication in the control unit .

Needle valve, concentrate To set the feed water-dependent "concentrate" volume flow to

the drain. During permeate production, this water constantly

flows to the drain.

High-pressure pump Pump unit that generates the required operating pressure for

the membrane and for the filling of heating water systems.

Membrane Reverse osmosis membrane to generate the permeate.

AVRO treatment unit AVRO treatment unit to generate seed crystals.

Control unit Microprocessor controller that in conjunction with the respective

units, regulates the permeate production and the supply of consumers downstream.

Flow sensor, concentrate Records the concentrate volume and sends pulses to the con-

troller. Visual indication of the concentrate volume in the controller .

Flow sensor, permeate Records the permeate volume and sends pulses to the control-

ler. Visual indication of the permeate volume in the controller .

Diaphragm expansion tank Permeate buffer to reduce the switching operations.

Pressure switch switch-off

pressure

Switches the reverse osmosis on when water is required, and

off again after water withdrawal ends.

Connection ¾“ (DN 20)

male thread or GEKA

Concentrate to drain.

Connection ¾“ (DN 20)

male thread or GEKA

Feed water.

Connection ¾“ (DN 20)

male thread or GEKA

Permeate/consumer.

Control valve for operating

pressure with pressure

gauge

To set the operating pressure, with pressure gauge as visual indicator.

1

2

9

3

2

9

4

2

9

5

6

7

8

9

10

9

11

9

12

13

14

15

16

17

Mobile reverse osmosis system

AVRO-flex 400

Order no. 095 752 946-inter Edited by: phar-mrie G:\BA-752946-INTER_095_AVRO-FLEX_400.DOCX

16

Fig. C-3: Flow chart of mobile reverse osmosis system AVRO-flex 400

Loading...

Loading...