Grunbeck AVRO 125 TS, AVRO 125 TL Operation Manual

Operation manual

Reverse osmosis system

AVRO 125 TS/TL

Edition January 2018

Order no. 185 752 945-inter

Reverse osmosis system

AVRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie G:\BA-752945-INTER_185_AVRO_125.DOCX

2

Table of contents

The operation manual consists of several chapters, which are

listed below.

A General information

5

1 Preface

2 How to use this operation manual

3 General safety information

4 Shipping and storage

5 Disposal of used parts and materials

B Basic information 8

1 Laws, regulations, standards

2 Water

3 Functional principle of reverse osmosis

C Product description 10

1 Type designation plate

2 Functional description

3 Intended use

4 Application limits

5 Scope of supply

D Installation 23

1 General installation instructions

2 Preliminary works

3 Connecting the system on the water side

4 Electrical installation

E Commissioning 29

1 How to flush the system

F Operation 33

1 Preface

2 Operating the control unit

3 Programming levels

4 Operating reverse osmosis

G Troubleshooting 41

H Maintenance and care 43

1 Basic information

2 Inspection (functional check)

3 Maintenance

4 Operation log (maintenance checklist)

Reverse osmosis system

A

VRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie :\BA-752945-INTER_185_AVRO_125.DOCX

3

Publisher's information

All rights reserved.

© Copyright by Grünbeck Wasseraufbereitung GmbH

Printed in Germany

Effective with the date of edition indicated on the cover sheet.

-We reserve the right to modifications, especially with regard to

technical progress-

Reprints, translations into foreign languages, electronic storage

or copying only with explicit written approval of

Grünbeck Wasseraufbereitung GmbH.

Any type of duplication not authorised by Grünbeck Wasseraufbereitung

is a copyright violation and subject to legal action.

Responsible for contents:

Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Straße 1 89420 Hoechstaedt/Germany

Phone 09074 41-0 Fax 09074 41-100

www.gruenbeck.de service@gruenbeck.de

Printing: Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Str. 1, 89420 Hoechstaedt/Germany

Reverse osmosis system

AVRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie G:\BA-752945-INTER_185_AVRO_125.DOCX

4

EU Declaration of Conformity

This is to certify that the system designated below meets the safety and health requirements of

the applicable European guidelines in terms of its design, construction and execution.

This certificate will become invalid if the system is modified in a way not approved by us.

Manufacturer: Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Strasse

89420 Hoechstaedt/Germany

Responsible for documentation: Markus Pöpperl

System designation: Reverse osmosis system AVRO

125

System type: TL/TS

Serial no.: Refer to type designation

plate

Applicable directives: Machinery Directive (2006/42/EC)

EMC (2014/30/EU)

Applied harmonised standards,

in particular:

EN ISO 12100:2011-03,

EN 61000-6-2:2006-03

EN 61000-6-3:2011-09

Applied national standards

and technical specifications,

in particular:

DIN 31000/VDE 1000:2011-

05

Place, date and signature: Hoechstaedt, 05.04.2016 i. V.

M. Pöpperl

Dipl. Ing. (FH)

Function of signatory: Head of Product Implementation and Product Launch

Reverse osmosis system

A

VRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie :\BA-752945-INTER_185_AVRO_125.DOCX

5

A General information

1 | Preface

Thank you for opting for a Grünbeck product. Backed by decades of

experience in the area of water treatment, we provide customised

solutions for all kind of processes.

Drinking water is classified as food and requires particular care.

Therefore, always ensure the required hygiene in operating and

maintaining systems involved in the drinking water supply. This also

applies to the treatment of water for industrial use if repercussions for

the drinking water cannot completely be excluded.

All Grünbeck systems and devices are made of high-quality materials.

This ensures trouble-free operation over many years, provided you

treat your water treatment system with the required care. These

operating instructions assist you with important information.

Therefore, please read the entire operation manual before installing,

operating or maintaining the system.

Customer satisfaction is our prime objective. And providing customers

with qualified advice is crucial. If you have any questions concerning

this system, possible extensions or general water and waste water

treatment, our field service staff, as well as the experts at our

headquarters in Hoechstaedt, are available to help you.

Advice and assistance

For advice and assistance please contact your local representative

(refer to www.gruenbeck.de). You can also get in touch with our

service centre, which can be reached during business hours:

Phone: +49 9074 41-333

Fax: +49 9074/41-120

E-mail: service@gruenbeck.de

We can connect you with the appropriate expert more quickly if you

provide the required system data. In order to have the required data

handy at all times, please copy it from the type designation plate to

the overview in chapter C-12.

2 | Notes on using the operation manual

This operation manual is intended for operators of our systems. It is

divided into several chapters (a letter is assigned to each of them)

that are listed in the "Table of contents" on page 2 in alphabetical

order. Check for the corresponding chapter on page 2 in order to find

the specific information you are looking for.

The headers and page numbers with chapter information make it

easier to find your way around in the operation manual.

Reverse osmosis system

AVRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie G:\BA-752945-INTER_185_AVRO_125.DOCX

6

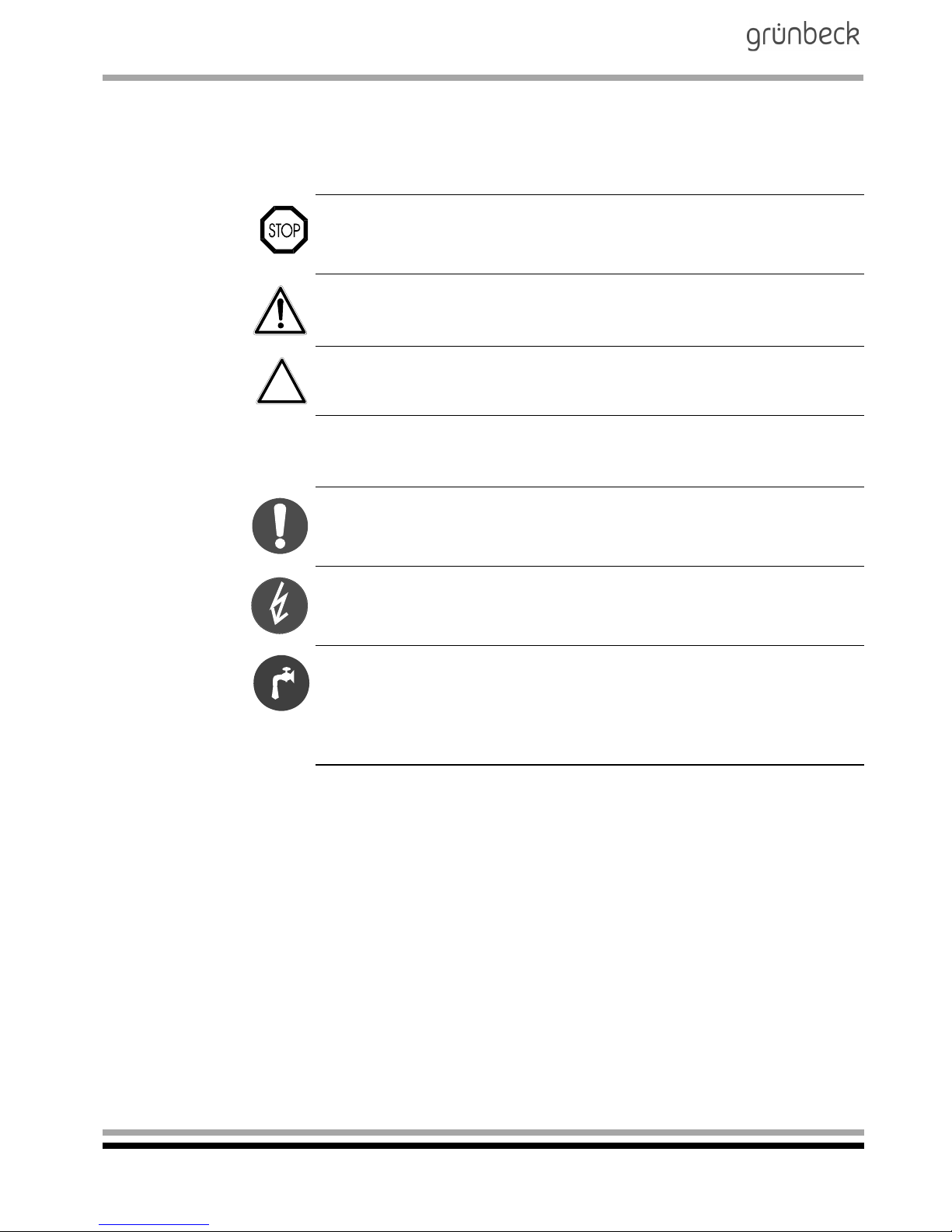

3 | General safety information

3.1 Symbols and notes

Important information in this operation manual is emphasised

by symbols. Please pay particular attention to this information to

ensure the hazard-free, safe and efficient handling of the system.

Danger! Failure to adhere to this information will cause serious or

life-threatening injuries, extreme damage to property or inadmissible

contamination of the drinking water.

Warning! Failure to adhere to this information can cause injuries,

damage to property or contamination of the drinking water.

Caution! Failure to adhere to this information can result in damage

to the system or other objects.

Note: This symbol emphasises information and tips that make your

work easier.

Tasks with this symbol are only allowed to be performed by

Grünbeck's technical service/authorised service company or by

persons expressly authorised by Grünbeck.

Tasks with this symbol are only allowed to be performed by trained

and qualified electrical experts according to the VDE guidelines or

according to the guidelines of a similar local institution.

Tasks with this symbol are only allowed to be performed by water

suppliers or approved installation companies. In Germany, the

installation company must be registered in an installation directory of

a water supplier as per §12(2) AVBWasserV (German Ordinance on

General Conditions for the Supply of Water).

3.2 Operating

personnel

Only allow persons who have read and understood this operation

manual to work with the system. The safety guidelines are to be

strictly adhered to.

3.3 Intended use

The system is only allowed to be used for the purpose outlined in the

product description (chapter C). The guidelines in this operation

manual as well as the applicable local guidelines concerning the

drinking water protection, accident prevention and occupational safety

must be adhered to.

In addition, appropriate application also implies that the system

is only allowed to be operated when it is in proper working order.

Any malfunctions must be repaired at once.

Reverse osmosis system

A

VRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie :\BA-752945-INTER_185_AVRO_125.DOCX

7

3.4 Protection from water damage

Warning! In order to properly protect the installation site from

water damage:

a)

a sufficient floor drain system must be available or

b)

a safety device (refer to chapter C Optional accessories) must be

installed.

Warning! Floor drains that discharge to a lifting system will not

work in case of a power failure.

3.5 Indication of

specific dangers

Danger due to electrical energy! Do not touch electrical parts with

wet hands! Disconnect the system from the mains before starting

work on electrical system components! Have qualified experts replace

damaged cables immediately.

Danger due to mechanical energy! System components can be

subject to overpressure. Danger of injury and damage to property due

to escaping water and unexpected movement of system parts.

Check pressure lines regularly. Depressurise the system before

starting repair or maintenance work on the system.

Hazardous to health due to contaminated drinking water! The

system shall be installed only by a specialist company. Strictly adhere

to the operating instructions! Ensure that there is sufficient flow. The

pertinent guidelines must be followed for starting-up after extended

periods of standstill. Inspections and maintenance must be performed

at the intervals specified!

Note: By concluding a maintenance contract, you ensure that all of

the required tasks are performed on time. You can perform the interim

inspections yourself.

4 | Shipping and storage

Caution! The system can be damaged by frost or high temperatures.

In order to avoid damage of this kind:

Protect from frost during shipping and storage!

Do not install or store system next to objects which radiate a lot of heat.

5 | Disposal of used parts and consumables

Used parts and consumables are to be disposed of or made available

for recycling purposes according to the applicable local guidelines.

If consumables are subject to specific regulations, adhere to the

corresponding information on the packing.

If in doubt, contact your local waste disposal authority or the

manufacturer for more information.

Reverse osmosis system

AVRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie G:\BA-752945-INTER_185_AVRO_125.DOCX

8

B Basic information (reverse osmosis system)

1 | Laws, regulations, standards

In the interest of good health, rules cannot be ignored when it comes

to the processing of drinking water. This operation manual takes into

consideration the current guidelines and stipulates information that

you will need for the safe operation of your water treatment system.

Among other things, the regulations stipulate that

only approved specialist companies are permitted to make major

modifications to water supply systems

and that checks, inspections and maintenance on installed devices

are to be performed at regular intervals.

2 | Water

There is no chemically pure water in nature. Even in the

atmosphere, rain water absorbs various substances that change the

properties of the water to a greater or lesser degree. This process

continues as the water passes through the ground layers, with the

result that the water is enriched with increasingly large quantities of

materials. Carbon dioxide (CO2) is particularly important here, since

this substance increases the dissolving capability of the water even

more. Consequently, drinking water contains quantities of dissolved

sodium, potassium, calcium, magnesium, iron, manganese, copper,

zinc, chlorides, fluorides, sulphates and also nitrates, nitrites,

phosphates and silicates that vary greatly from location to location.

Due to dynamic substance and water cycles, harmful elements,

are increasingly being released into the natural environment.

These are only partially and slowly broken down by natural effects.

Consequently, these elements build up in the groundwater and

surface water over the course of time. Removing them from

natural water deposits again represents a particular challenge.

Grünbeck faces this challenge with the aim of producing unpolluted

drinking and industrial water.

The water works provide us with pure drinking water that is suitable

for consumption. However, if the water is to be used for technical

purposes, further treatment is frequently required.

Reverse osmosis system

A

VRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie :\BA-752945-INTER_185_AVRO_125.DOCX

9

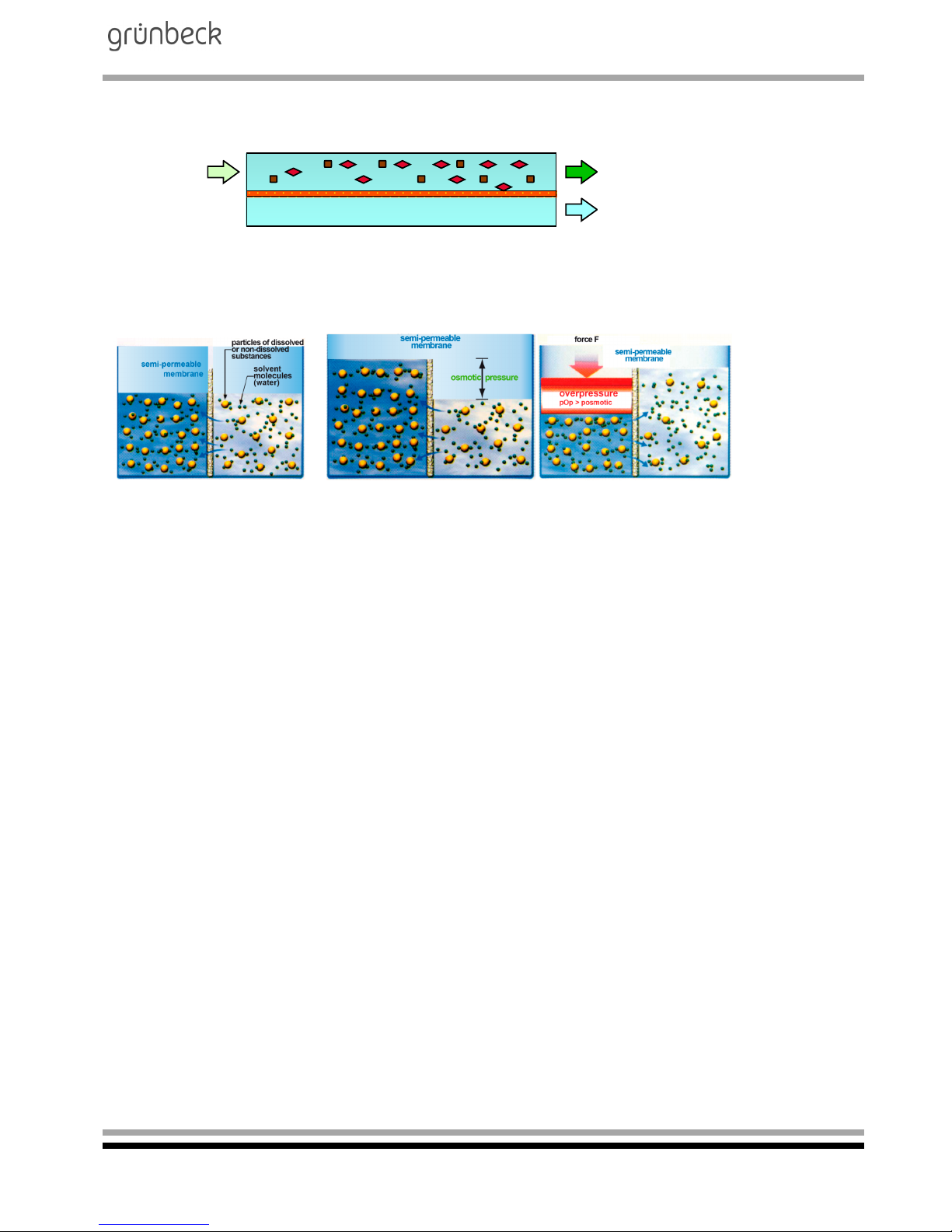

3 | Functional principle of reverse osmosis

Principle:

Pretreated

feed water

Concentrate:

Permeate

Fig. B-1: Functional principle

Osmosis Osmotic pressure Reversed osmosis

Solution of

high

concentration

Solution of low

concentration

Solution of

high

concentration

Solution of low

concentration

Solution of

high

concentration

(concentrate)

Solution of low

concentration

(permeate)

Fig. B-2: Reverse osmosis principle

In the osmosis process, aqueous solutions of different

concentrations are separated by a semi-permeable

membrane. In keeping with the law of nature, the

concentrations will tend to equalise. What is referred

to as "osmotic pressure" is generated on the side of

the higher original concentration.

In case of reverse osmosis, this osmotic pressure is

countered by a higher pressure. The consequence:

The process runs in the opposite direction.

A particular advantage of the reverse osmosis

technology compared to other water treatment

processes is the fact that apart from the removal of

dissolved salts, bacteria, germs, particles, and

dissolved organic substances are also reduced.

Reverse osmosis system

AVRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie G:\BA-752945-INTER_185_AVRO_125.DOCX

10

C Product description

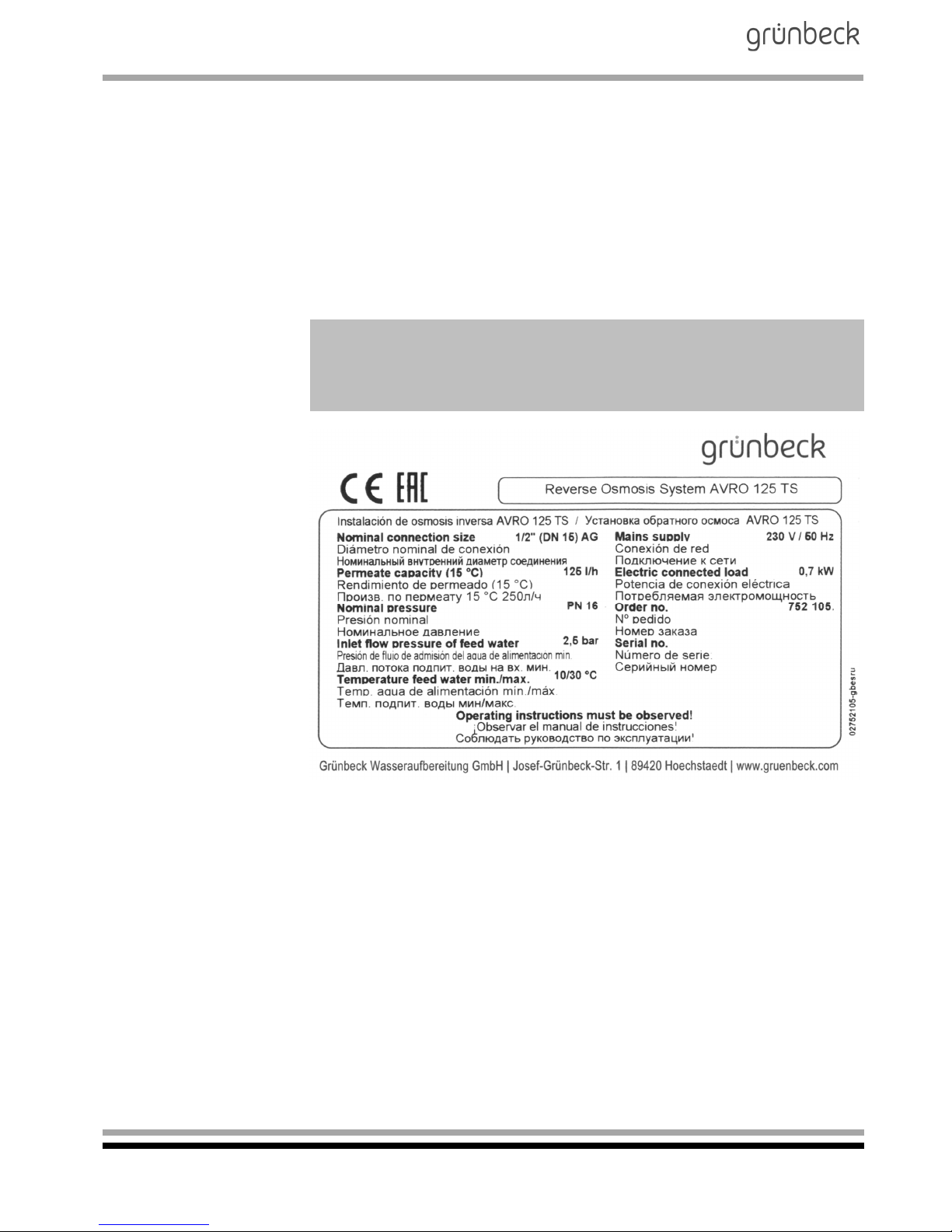

1 | Type designation plate

The type designation plate can be found on the housing of the reverse

osmosis system AVRO 125 TS/TL. In order to speed up the processing

of your inquiries or orders, please specify the data shown on the type

designation plate of your system when contacting Grünbeck. Please

copy the indicated information to the table below in order to have it

handy whenever necessary.

Reverse osmosis system AVRO 125 TS/TL

125

Serial number:

/

Order number:

Fig. C-1: Type designation plate

Reverse osmosis system

A

VRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie :\BA-752945-INTER_185_AVRO_125.DOCX

11

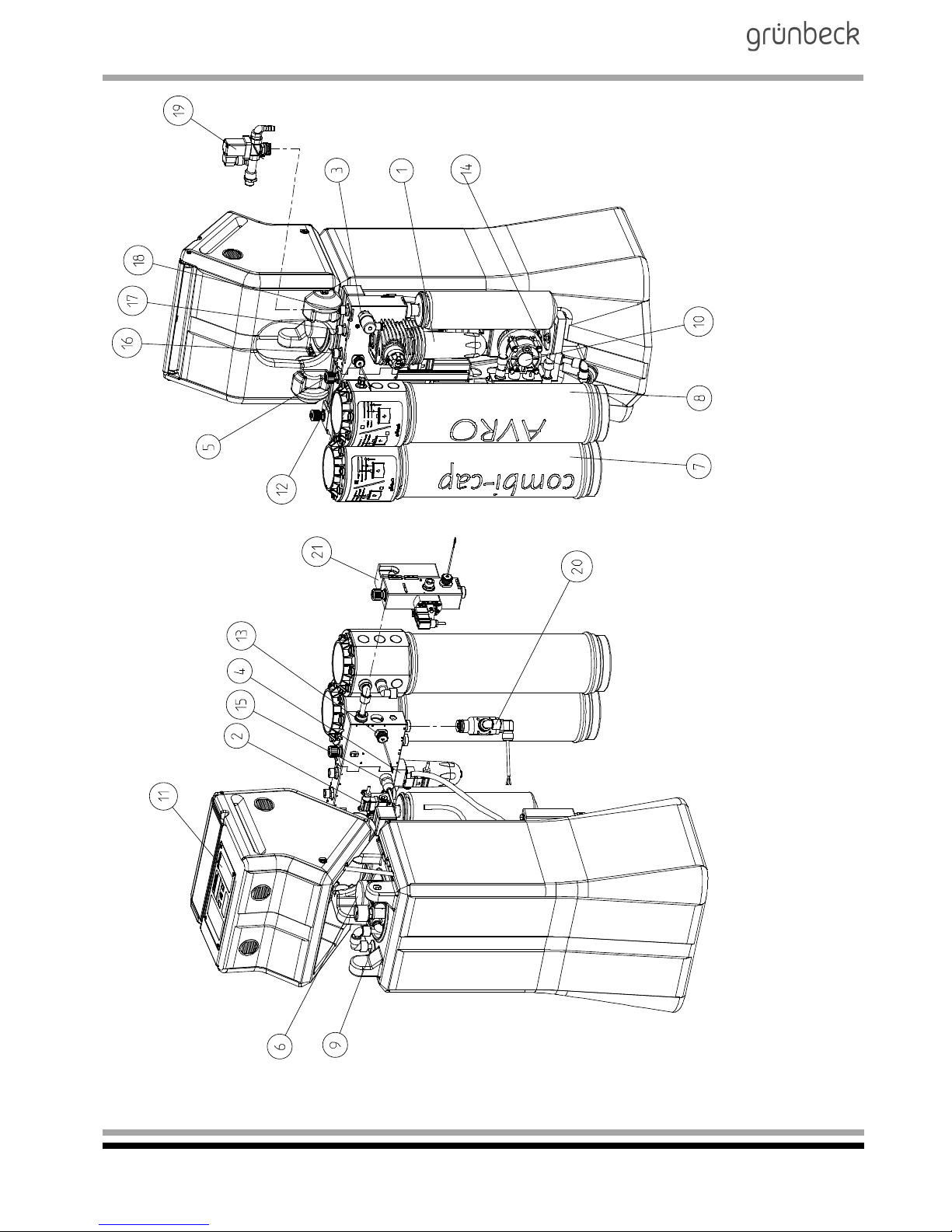

2 | Functional description

Via the 5 µm drinking water filter (filter element), the water is directed

to the inlet of the feed water section. The water flows to the highpressure pump via the inlet solenoid valve with a downstream

pressure switch for minimum pressure. By means of an adjusting

valve, the pressure generated by the pump is reduced to the required

operating pressure and the water is directed to the membrane.

The membrane separates the water into the partial flows permeate

and concentrate. A partial flow of the concentrate is returned to the

feed water via an orifice regulating independently of pressure and

thus ensures a steady flow over the reverse osmosis membrane and

increases the economic efficiency of the reverse osmosis system.

At the same time, the concentrate volume flow is run via an AVRO

treatment module. where seed crystals are formed at a cathode due

to the application of direct current. These seed crystals are then

washed out with the residual concentrate and thus the reverse

osmosis membrane is protected from clogging. Whenever the system

is switched off (tank full) or in case of disturbances, the substances

retained on the membrane are flushed off by means of the inlet

solenoid valve and a solenoid valve switched in parallel to the control

valve for concentrate.

The hydraulic set-up of the system is designed in a way that the

concentrate volume and the permeate volume are registered by

means of flow sensors and are displayed in the control unit.

The system recovery can also be called up in the control unit.

1)

The permeate produced is fed into a light-tight reservoir. A level

control with three switching contacts is integrated in the tank. In order

to supply the consumers with permeate, a centrifugal pump made of

high-performance plastics including pressure switch and diaphragm

expansion tank is integrated in the system as pressure booster

system.

1)

Only AVRO 125 TS

Reverse osmosis system

AVRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie G:\BA-752945-INTER_185_AVRO_125.DOCX

12

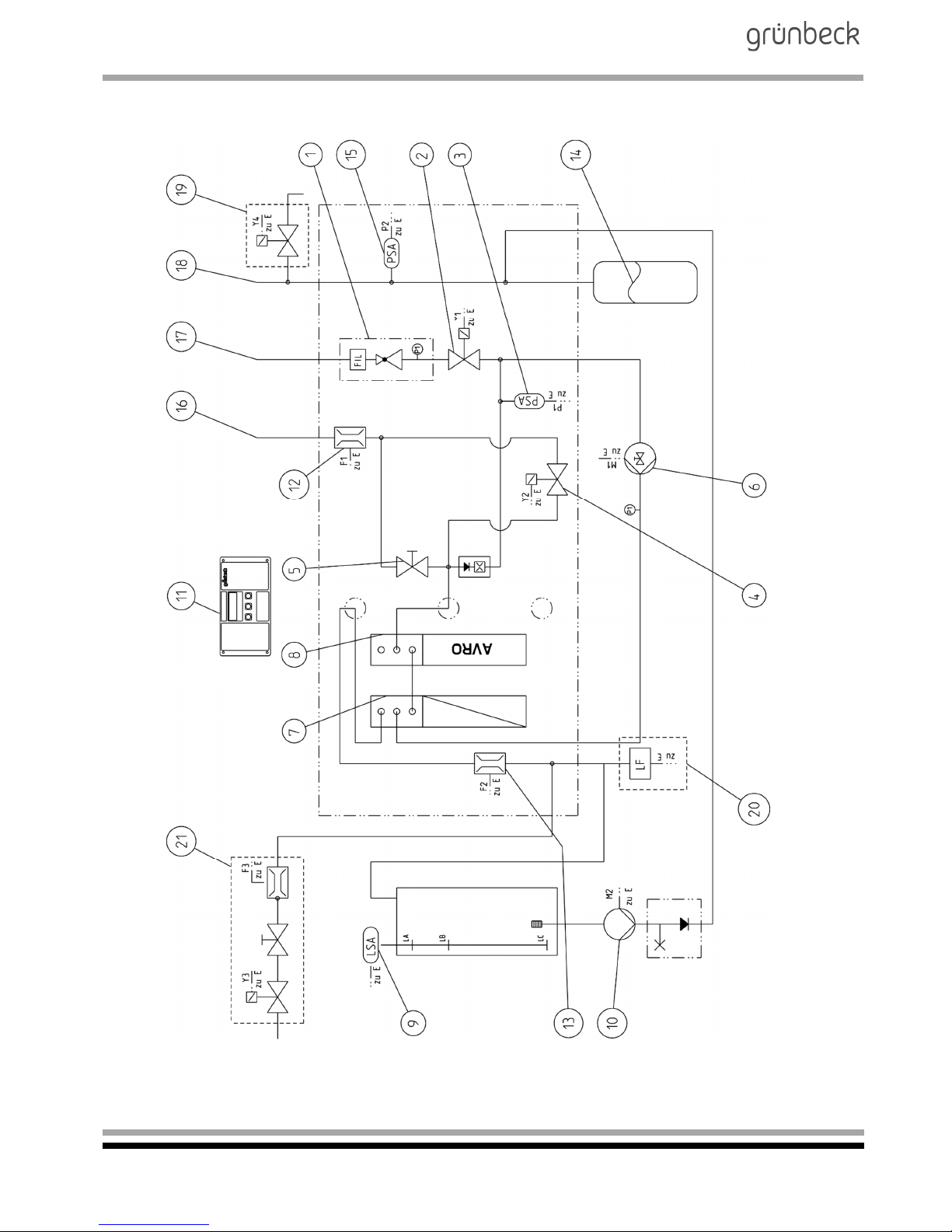

Fig. C-2: Exploded drawing reverse osmosis system AVRO 125 TS/TL-TS

Reverse osmosis system

A

VRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie :\BA-752945-INTER_185_AVRO_125.DOCX

13

5 µm fine filter incl.

pressure reducer

Pressure reducer preset to 2.5 bar, incl. pressure gauge.

Inlet solenoid valve During permeate output, this valve is always open. Following the system

stop (tank full), the valve remains open for the programmed flushing time

of the membranes. Visual indication in the control unit .

Pressure switch

Pressure booster pump

Switches the pressure booster on when water is required, and off again

after water withdrawal ends.

Flushing solenoid valve

Opens after the level control in the tank reports "FULL" to the control

unit for a set time. The solenoid valve also opens in the event of

system malfunctions and always in conjunction with the inlet solenoid

valve .

Needle valve, concentrate To set the feed water-dependent "concentrate" volume flow to the drain.

During permeate output, this portion of the water flow permanently flows

to the drain.

High-pressure pump Pump unit that generates the operating pressure required for the

membrane. Pump operates on permeate request from the level

control (LB switches) located in the permeate tank. A control valve

for adjusting the operating pressure is integrated in the pump head.

Visual indication in the control unit .

Membrane Reverse osmosis membrane to generate the permeate.

AVRO treatment unit AVRO treatment unit to generate seed crystals.

Level control Float level control for controlling the water level in the permeate tank

(TS version only).

Booster pump Pressure booster pump feeds permeate into the consumer network

(only TS version).

Control unit Microprocessor controller that in conjunction with the respective units,

regulates the permeate production and the supply of consumers

downstream.

Flow sensor, concentrate Registers the concentrate volume and sends pulses to the control unit.

Visual indication of the permeate volume in the control unit .

Flow sensor

Permeate

Records the permeate volume and sends pulses to the control unit.

Visual indication of the permeate volume in the control unit .

Diaphragm expansion tank Permeate buffer to reduce the switching operations of the DE pump.

Pressure switch

High-pressure pump

To prevent the high-pressure pump from running dry. Switches time-

delayed after the solenoid valve has opened . Visual indication in the

control unit .

Connection ½" (DN 15)

male thread

Concentrate to drain.

Connection ½" (DN 15)

male thread

Feed water.

Connection ½" (DN 15)

male thread

Permeate/consumer.

Option: Solenoid valve forced withdrawal.

Option: Conductivity measurement.

Option: Blending unit.

1

2

11

3

4

9

2

5

6

9

11

7

8

9

10

11

12

11

13

11

14

15

2

11

16

17

18

19

20

21

Reverse osmosis system

AVRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie G:\BA-752945-INTER_185_AVRO_125.DOCX

14

2.1 Flow chart of reverse osmosis system AVRO 125 TS/TL

Fig. C-2.1: Flowchart of reverse osmosis system AVRO 125 TS/TL-TS

Reverse osmosis system

A

VRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie :\BA-752945-INTER_185_AVRO_125.DOCX

15

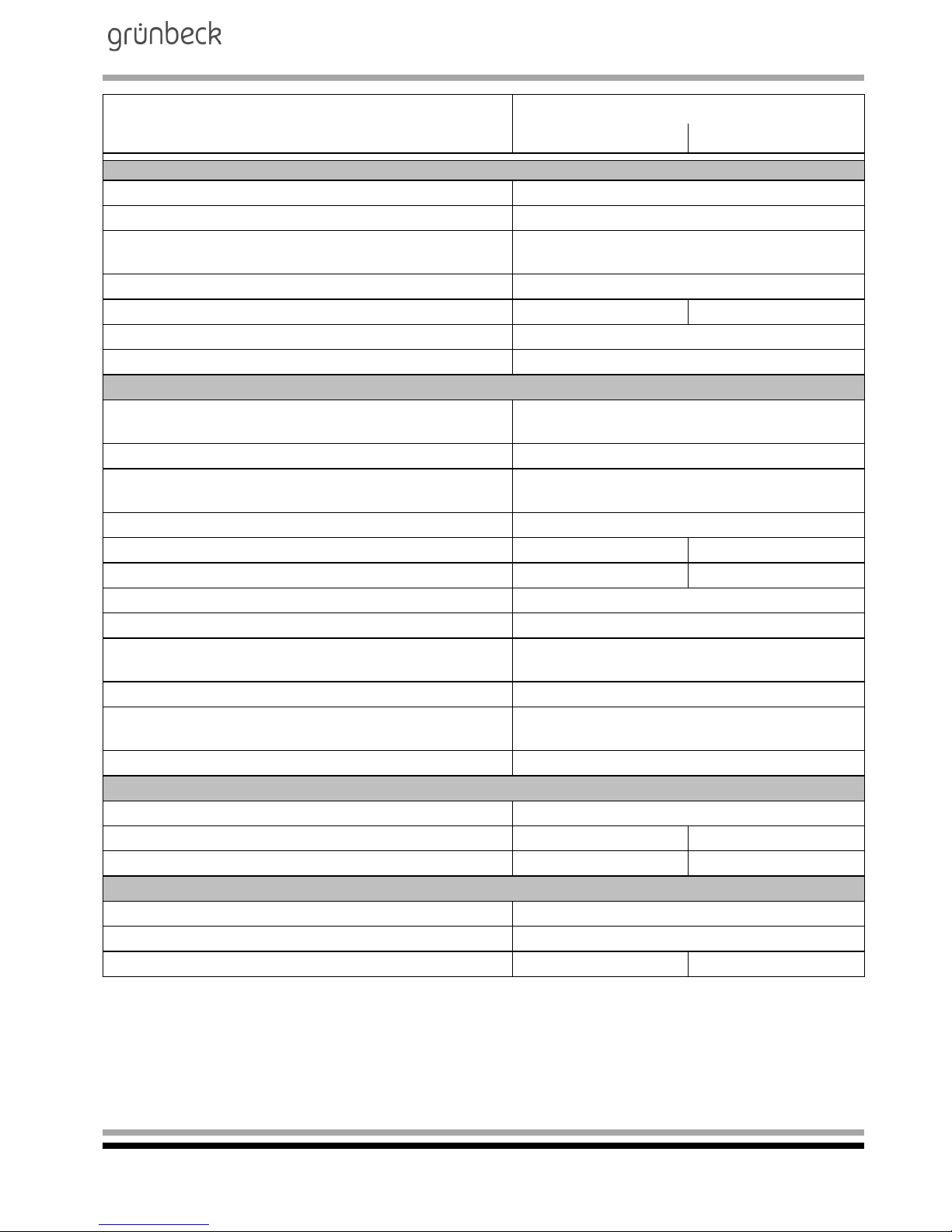

Technical specifications Reverse osmosis system

AVRO 125 TS AVRO 125 TL

Connection data

Nominal connection diameter of feed water pipe ½" (DN 15) male thread

Nominal connection diameter of permeat e outlet ½" (DN 15) male thread

Nominal connection diameter of concentrate

outlet

½" (DN 15) male thread

Min. drain connection required [DN] 50

Connected load, approx. [kW] 0.7 0.6

Power supply [V/Hz] 230 V / 50 Hz

Protection/protection class IP 54 / I

Performance data

Permeate output at a feed water temperature

of 10 °C / 15 °C

[l/h]

105 / 125

Electrical capacity of pump at operating pressure [kW] 0.55

Permeate output per day

(max. 24 h) approx. min./max.

[m³/d]

2.5 / 3.0

Inlet flow pressure of feed water, min. [bar] 2.5

Permeate supply approx. [l] 38

-

Pump characteristic curve pressure booster [l/h/bar] 300 / 3.5 - 1200 / 1.0

-

Nominal pressure PN 16

Salt rejection 95 – 99 %

Total salt concentration of the feed water as

NaCl, max.

[ppm] 1000

Concentrate volume flow (at 15 °C) [l/h] 1251)

Feed water volume flow

(fresh water 15 °C) at a recovery of 50 %, max.

[l/h] 250

Recovery [%] 501)

Dimensions and weights

Dimensions (w x d x h) approx. [mm] 600 x 550 x 1120

Empty weight, approx. [kg] 45 38

Operating weight, approx. [kg] 85 40

Ambient data

Temperature of feed water, min./max. [°C] 10 / 30

Ambient temperature, min./max. [°C] 5 / 35

Order no. 752 105 752 115

1)

After a water analysis, the technical customer service can set a higher recovery.

Reverse osmosis system

AVRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie G:\BA-752945-INTER_185_AVRO_125.DOCX

16

3 | Intended use

The reverse osmosis system AVRO 125 TS/TL is used for

demineralising drinking water. The water is primarily used for

industrial applications.

The permeate capacity of the system depends on the temperature

and is defined at 15 °C. The permeate outputs can fall (falling

temperature) or rise (rising temperature) by up to 3 % for each °C rise

or fall in the feed water temperature.

The system is adjusted to the permeate requirements to be expected

at the installation site, it is not suitable for major deviations.

Only operate the system if all components are properly installed.

Safety devices and equipment must NEVER be removed, bridged or

tampered with.

Appropriate application of the device also implies that the information

contained in this operation manual and all safety guidelines applying

at the installation site be observed. Furthermore, the maintenance

and inspection intervals have to be observed.

3.1 System shutdown

If the system is shut down for more than 14 days, the reverse

osmosis system must be preserved by Grünbeck's technical customer

service/authorised service company. The maximum time, the system

can remain in the preserved condition is 6 months.

In case the down time is longer, the system must be preserved

again in regular intervals by Grünbeck's technical customer

service/authorised service company. Prior to resuming operation,

the preserving agent must be flushed from the system.

Reverse osmosis system

A

VRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie :\BA-752945-INTER_185_AVRO_125.DOCX

17

4 | Application limits

For the application of the reverse osmosis system AVRO 125 TS/TL,

the limit values stipulated in the German Drinking Water Ordinance

represent the upper limits for the admissible substances contained in

the water.

< 22°dH (39.2° f; 3.92 mmol/l) without water analysis

Free chlorine not detectable

Iron < 0.10 mg/l

Manganese < 0.05 mg/l

Silicate < 15 mg/l

Chlorine dioxide not detectable

Turbidity < 1 FTU

Colloid index < 3

pH range 3 - 9

For total hardness > 22 °dH or sulphate > 250 mg/l a water analysis is

required.

Note: The permeate originating from the reverse osmosis system is

not potable but requires additional treatment (blending, hardening) if it

is to be used as drinking water.

Caution! In case of an admissible excess of the sulphate

concentration due to geogenic conditions, the recovery with regard to

the standard settings according to layout might need to be reduced.

Reverse osmosis system

AVRO 125 TS/TL

Order no. 185 752 945-inter Edited by: nkes-mrie G:\BA-752945-INTER_185_AVRO_125.DOCX

18

5 | Scope of supply

5.1 Standard equipment

Stand-alone housing made of opaque PE to accommodate all

aggregates and control elements. Stand-alone housing also serves

as supply tank (AVRO 125 TS/TL-TS only).

Microprocessor controller with LC display, voltage-free collective

fault signal and voltage-free signal contact (maintenance interval,

various pre-warnings), installed in a stand-alone housing.

Sliding-vane rotary pump made of corrosion-resistant brass with

motor as high-pressure pump to supply the membrane, incl. control

valve for operating pressure and pressure gauge.

1) External pressure booster with pressure switch and membrane

connection vessel for supplying permeate to downstream

consumers.

Hydro module for the water supply within the membrane system.

Integrated valves and measuring instruments for easier system

calibration.

5 µm drinking water filter with integrated pressure reducer, preset

to 2.5 bar.

Ultra-low pressure reverse osmosis membrane, installed in

pressure pipe made of high-strength PE.

AVRO treatment unit, installed in a pressure pipe made of high-

strength PE.

Flow sensor to measure the volume of the system flows permeate

and concentrate.

Operation manual.

1)

only AVRO 125 TS.

5.2 Optional features

Note: It is possible to retrofit existing systems with optional

components. Please contact your local Grünbeck representative or

Grünbeck’s headquarters in Hoechstaedt for more information.

Connection block for RO 125 K/AV RO 125

Connection block (installation length 180 mm).

Permeate-resistant incl. two shut-off valves –

suitable for connection set

752 840

Connection set for RO 125 K/AVRO 125

2 flexible connection hoses DN 15

(L = 600 mm) for feed water and permeate

1 drain hose for concentrate

752 830

Loading...

Loading...