Grunaire GMU018HXB-2, GMU024HXB-2, GMU028HXB-3, GMU028HXB-4 Service Manual

Service Manual

MODEL: GMU018HXB-2

GMU024HXB-2

GMU028HXB-3

GMU028HXB-4

(Refrigerant R410A)

Table of Contents

Summary and features..................................................................................1

Part 1 Safety Precautions

..........................................................................................2

Part 2 Specifications.....................................................................................................3

Part 3 Construction Views

........................................................................................7

Part 4 Refrigerant System Diagram

.....................................................................9

5.1 Electrical Data......................................................................................................10

5.2 Electrical Wiring....................................................................................................10

5.3 Printed Circuit Board.............................................................................................13

Part 5 Schematic Diagram......................................................................................10

6.1 Models GMU018HXB-2,GMU024HXB-2..............................................................20

6.2 Models GMU028HXB-3,GMU028HXB-4..............................................................24

Part 6 Description of Each Control Operation

............................................20

Part 7 Installation Manual

........................................................................................29

7.1 Installing the Outdoor Unit....................................................................................29

7.2 Bleeding...............................................................................................................29

7.3 Installation Dimension Diagram...........................................................................30

7.4 Check After Installation........................................................................................31

Part 8 Exploded Views and Parts List

..............................................................32

Part 9 Troubleshooting...............................................................................................40

9.1 ......................................................................................................40

9.2 ...............................................................................................40

9.3 .................................................................................................46

8.1 GMU018HXB-2.....................................................................................................32

8.2 GMU024HXB-2.....................................................................................................34

8.3 GMU028HXB-3 GMU028HXB-4...........................................................................37

Part10 Removal Procedure.......................................................................................54

10.1

Model:GMU018HXB-2

........................................................................................54

10.2

Model:GMU024HXB-2

.........................................................................................58

10.3

Model:GMU028HXB-3 GMU028HXB-4

...............................................................62

Common Parts

Malfunction Display

Troubleshooting

...

Summary and features

1

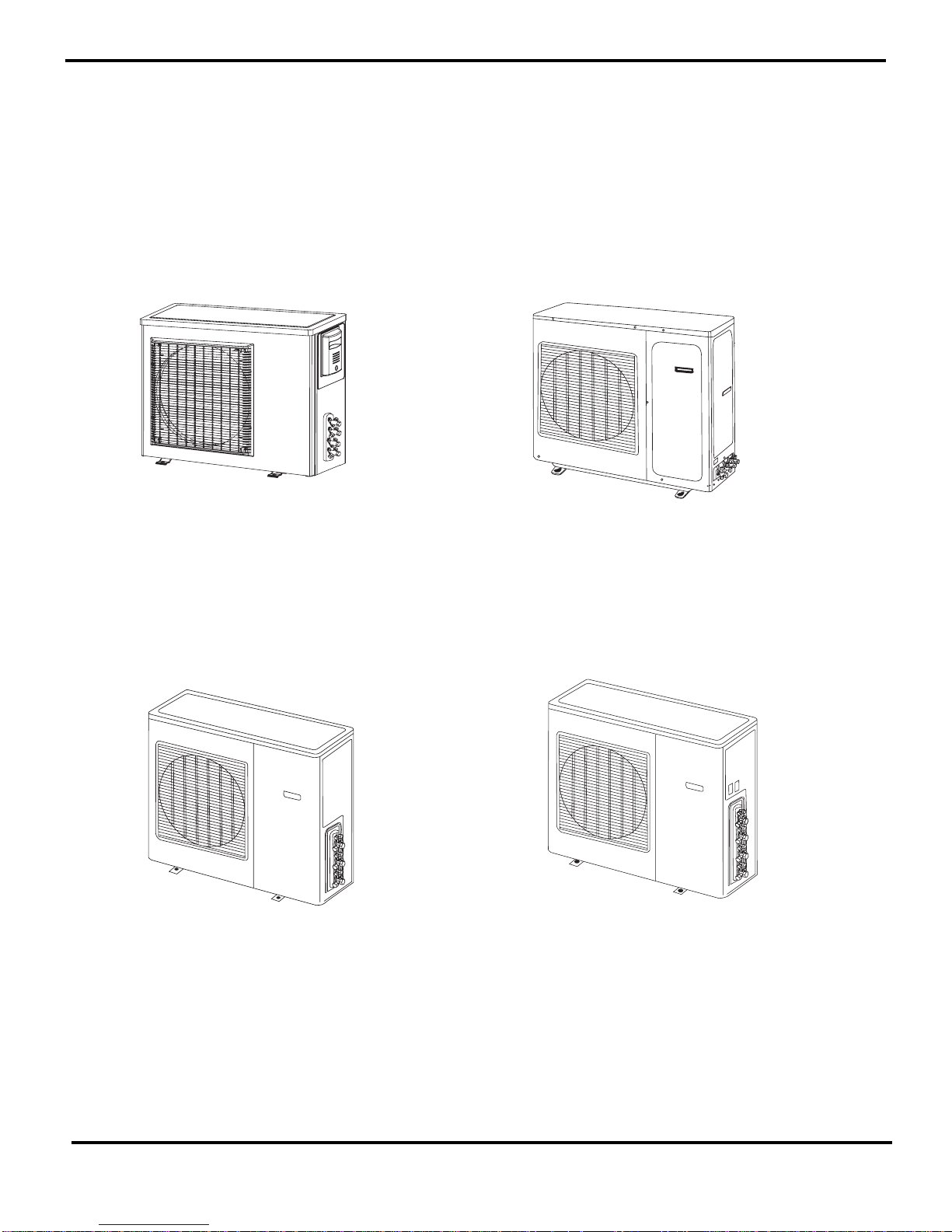

Model:

GMU018HXB-2

GMU028HXB-3

GMU024HXB-2

GMU028HXB-4

Summary and features

2

1.Safety Precautions

Safety Precautions

Caution

Warning

Warning

Caution

could result in

personal injury

or death.

Incorrect handling

result in

injury, or damage to product

or property.

Incorrect handling

may

minor

Recognize the following safety information:

Installing, starting up, and servicing air conditioner can be

hazardous due to system pressure, electrical components, and

equipment location, etc.

Only trained, qualified installers and service personnel are

allowed to install, start-up, and service this equipment.

Untrained personnel can perform basic maintenance functio ns

such as cleaning coils. All other operations should be

performed by trained service personnel.

When handling the equipment, observe precautions in the

manual and on tags, stickers, and labels attached to the

equipment. Follow all safety codes. Wear safety glasses and

work gloves. Keep quenching cloth and fire extinguisher nearby

when brazing.

Read the instructions thoroughly and follow all warnings or

cautions in literature and attached to the unit. Consult local

building codes and current editions of national as w ell as local

electrical codes.

All electric work must be performed by a licensed technician

according to local regulations and the instruct ions gi ven in this

manual.

Never supply power to the unit unless all wiring and tubi ng

are completed, reconnected and checked.

This system adopts highly dangerous electrical voltage.

Incorrect connection or inadequate grounding can cause

personal injury or death. Stick to the wiring diagram and all

the instructions when wiring.

Have the unit adequately grounded in accordance with

local electrical codes.

Have all wiring connected tightly. Loose connection may

lead to overheating and a possible fire hazard.

All installation or repair work shall be performed by your dealer

or a specialized subcontractor as there is the risk of fire, electric

shock, explosion or injury.

Make sure the ceiling/wall is strong enough to bear the

weight of the unit.

Make sure the noise of the outdoor unit does not disturb

neighbors.

Properly insulate any tubing running inside the room to

prevent the water from damaging the wall.

Make sure the outdoor unit is installed on a stable, level

surface with no accumulation of snow, leaves, or trash

beside.

Follow all the installation instructions to minimize the risk

of damage from earthquakes, typhoons or strong winds.

Avoid contact between refrigerant and fire as it generates

poisonous gas.

Apply specified refrigerant only. Never have it mixed with

any other refrigerant. Never have air remain in the

refrigerant line as it may lead to rupture and other hazards.

Make sure no refrigerant gas is leaking out when

installation is completed.

Should there be refrigerant leakage, the density of

refrigerant in the air shall in no way exceed its limited

value, or it may lead to explosion.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out and

tag switch with a suitable warning label.

Keep your fingers and clothing away from any moving

parts.

Clear the site after installation. Make sure no foreign

objects are left in the unit.

Always ensure effective grounding for the unit.

Never install the unit in a place where a combustible gas

might leak, or it may lead to fire or explosion.

Make a proper provision against noise when the unit is

installed at a telecommunication center or hospital.

Provide an electric leak breaker when it is installed in a

watery place.

Never wash the unit with water.

Handle unit transportation with care. The unit should not be

carried by only one person if it is more than 20kg.

Never touch the heat exchanger fins with bear hands.

Never touch the compressor or refrigerant piping withou t

wearing glove.

Do not have the unit operate without air filter.

Should any emergency occur, stop the unit and disconnect

the power immediately.

3

Specifications

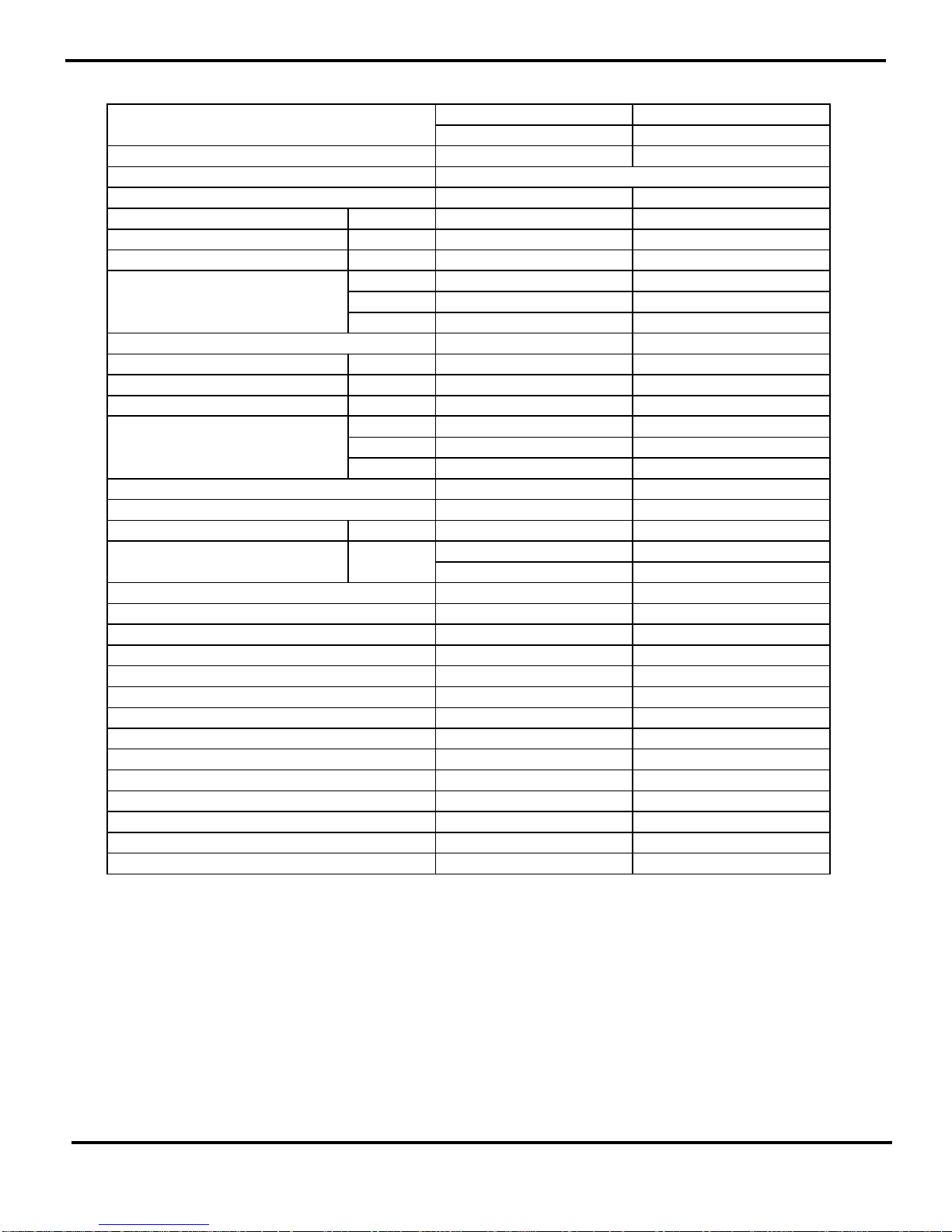

2.Specifications

GMU018HXB-2 GMU024HXB-2

(

1 to 2

)(

1 to 2

)

CB228W0030_ K27204 CB228W0040_ K27204

R410A R410A

Cooling capa c ity Max 21 28

(KBTU) Nom 18 24

Min 7.2 10

Max 2300 3300

Nom 1550 2250

Min 620 1100

16 16

Heatin g c apa c ity Max 22 33

(KBTU) Nom 19 29.5

Min 6.5 9

Max 2400 3500

Nom 1750 2600

Min 650 1250

56 59

52/57 68/73

Liquid connections Diameter mm Φ6 Φ6

Gas connec tions Diameter mm Φ9.52 Φ12

Shenyang SANYO Shenyang SANYO

C-6RVN93HOV C-7RZ233H1A

Rotary Rotary

41 34

8.96 8.2

1470 1760

1NT11L-3979 1NT11L-3979

Elec tronic E xpansion Valve Electronic Ex pa nsion Valve

Tr ansducer starting Transducer starting

-7≤T≤43 -7≤T≤43

Aluminum fin-copper tube Aluminum fin-coppe r tube

Φ7 Φ9.52

2-1.4 2-1.4

806X660X22 683X813X44

Outdoor unit Model

Product Code

Power supply 1PH 208- 230V~ 60Hz

Refrigerant

Total power input in cooling mode (W)

SEER

Total power input in heat ing mode

Sound pr essure level In door un it

outd oor Ne t Weight /Gross Weight ( k g )

Compressor Manuf ac t ur er /tr ademark

Compressor Model

Compressor T ype

L.R.A. (A)

Compressor RLA(A)

Compressor Pow er Input( W )

Over load P r ot ec t o r

Thr ottlin g Method

St arting Method

Wor k i ng Temp Range (℃)

Condenser

Pipe Diameter (mm)

Rows-Fin Gap(mm)

Coil lengt h (l) X height (H) X coil width (L)

Specifications

4

The above data is subject to change without notice. Please refer to the nameplate of the unit.

780/-/600 780/-/600

60 60

0.65 0.65

33

//

Ax ial fan Axial f an

460 460

Auto defrost Auto defrost

T1 T1

II

IP24 IP24

3.8 3.8

1.2 1.2

56/54 59/58

66/64 69/68

913X680X378 950X840X412

994X428X750 1100X450X905

52/57 68/73

1.6 2.5

Fan Motor Spee d ( r p m) (H/M/L)

Output of Fan Mot o r (W)

Fan Mot or RLA( A)

Fan Motor Capac itor (μF)

Air F low Volume of Outdoo r U nit

Fan Type

Fan Di ameter (mm)

Defrosting Method

Climate T ype

Isolation

Moist ur e Protection

Permissib le E xc essiv e Operating Pressure for the

Discharge Side ( MP a)

Dimension of Pack a ge (L/W /H)( mm)

Net Weight /Gro ss Weight ( k g)

Refrigerant Charge (kg)

Permissib le E xc essiv e Operating Pressure for the

Suction Side(M Pa)

Sound Pressure Level dB (A) (H/L)

Sound P ower Level dB ( A) ( H/L)

Dimension ( W/H/D) ( mm)

5

Specifications

GMU028HXB-3 GMU028HXB-4

(

2 to 3

)(

2to 4

)

CB228W 00 50_ K27 204 CB228W 00 60_ K272 04

R410A R410A

Cooling capa c ity Max 34 34

(KBTU) Nom 28 28

Min 10 10

Max 4700 4700

Nom 2600 2600

Min 900 900

16 16

Heatin g c apa c i ty Max 37 37

(KBTU) Nom 31 31

Min 9 9

Max 3000 3000

Nom 2500 2500

Min 800 800

60 60

75/80 75/80

Liquid connec tions Diameter mm Φ6 Φ6

Φ9.52 Φ9.52

Φ12 Φ12

Shenyang SANYO Shenyang S ANYO

C-7RZ233H1A C-7RZ233H1A

Rotary Rotary

34 34

8.2 8.2

1760 1760

1NT11L-3979 1NT11L-3979

Electronic Ex pa nsion Valve Electronic Ex pan sion Valve

Tr ansducer st ar ting Transducer st ar t ing

-7≤T≤43 -7≤T≤43

Aluminum fin-coppe r tube Al uminum fin-c o pper tube

Φ9.52 Φ9.52

2-1.4 2-1.4

806X813X44 806X813X44

Outdoor unit Model

Product Code

Power supply 1PH 208-230V~ 60Hz

Refrigerant

Total power input in cooling mode (W)

SEER

Total power input in heat in g mode

Sound pr essure level I ndoor u nit

outd oor N et Weight /Gross Weight ( kg)

Gas connec tions Diameter mm

Compressor Manuf ac turer/tr ademark

Compressor Model

Compressor T ype

L.R.A. (A)

Compressor RLA(A)

Compressor Pow er Input( W)

Over load P r ot ec tor

Thr ottlin g Method

Rows-Fin Gap(mm)

Coil lengt h (l) X height (H) X coil width (L)

St arting Method

Wor k ing T emp Range (℃)

Condenser

Pipe Diameter ( mm)

Specifications

6

The above data is subject to change without notice. Please refer to the nameplate of the unit.

840/740/640 840/740/640

68 68

0.68 0.68

33

//

Ax ial fan Axial f an

460 460

Auto defrost Auto defrost

T1 T1

II

IP24 IP24

3.8 3.8

1.2 1.2

60/54 60/54

70/64 70/64

950X840X412 950X840X412

1100X450X905 1100X450X905

75/80 75/80

3.3 3.3

Dimension of Pack a ge (L/W /H)( mm)

Net Weight /Gro ss Weight ( k g)

Refrigerant Charge (kg)

Permissib le E xc essiv e Operating Pressure for the

Suction Side(M Pa)

Sound Pressure Level dB (A) (H/L)

Sound P ower Level dB ( A) ( H/L)

Dimension ( W/H/D) ( mm)

Climate T ype

Isolation

Moist ur e Protection

Permissib le E xc essiv e Operating Pressure for the

Discharge Side ( MP a)

Air F low Volume of Outdoo r U nit

Fan Type

Fan Di ameter (mm)

Defrosting Method

Fan Motor Spee d ( r p m) (H/M/L)

Output of Fan Mot o r (W)

Fan Mot or RLA( A)

Fan Motor Capac itor (μF)

7

Constrction views

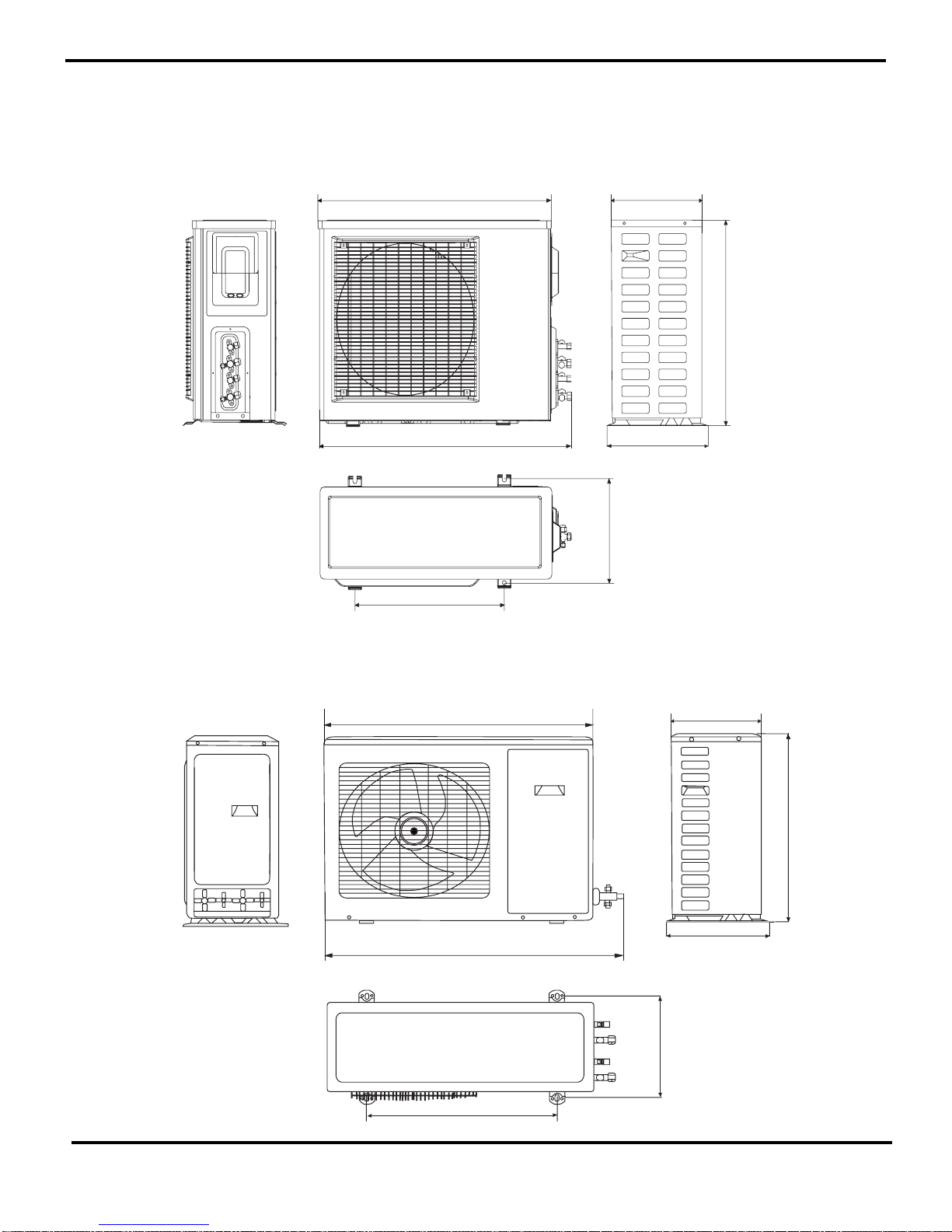

3. Construction Views

Model GMU018HXB-2

550

680

342

846

300

913

572

340

840

378

950

1018

Unit:mm

GMU024HXB-2

412

378

Constrction views

8

572

340

840

378

950

1018

572

412

840

378

950

1018

GMU028HXB-4

GMU028HXB-3

340

412

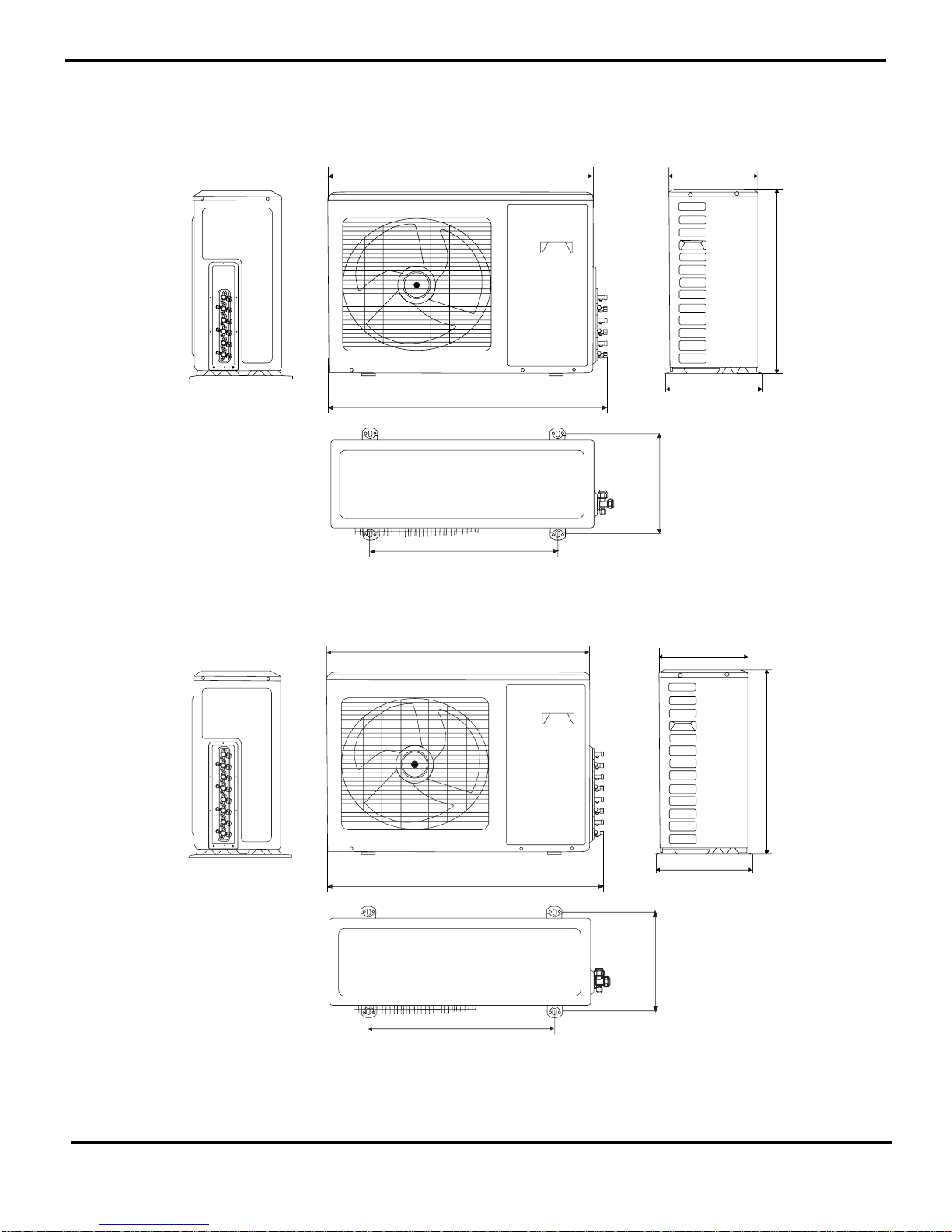

9

Refrigerant System Diagram

4. Refrigerant System Diagram

'

&

%

$

$

%

&

'

GMU018HXB-2

Refrigerant pipe diameter

Liquid : 1/4" (6 mm)

Gas :3/8" (9.52mm)

GMU024HXB-2

Refrigerant pipe diameter

Liquid : 1/4" (6 mm)

Gas :1/2" (12mm)

GMU028HXB-3,GMU024HXB-2

Refrigerant pipe diameter

Liquid : 1/4" (6 mm)

Gas :3/8" (9.52mm)

1/2" (12mm)

Indoor Unit

Outdoor Unit

Heat exchanger

Electric expansion valve

Filter

Electric expansion valve

Filter

Electric expansion valve

Filter

Electric expansion valve

Filter

Heat exchanger

Heat exchanger

Heat exchanger

Fan

Filter

High pressure liquid receiver

Note: it is not available for 1-to-2 model.

4-way valve

Outdoor heat exchanger

SP high pressure cut-out

Note: it is not available for 1-to-2 model.

Exhaust muffler

Discharge temp sensor

Gas-liquid separator

Variable speed compressor

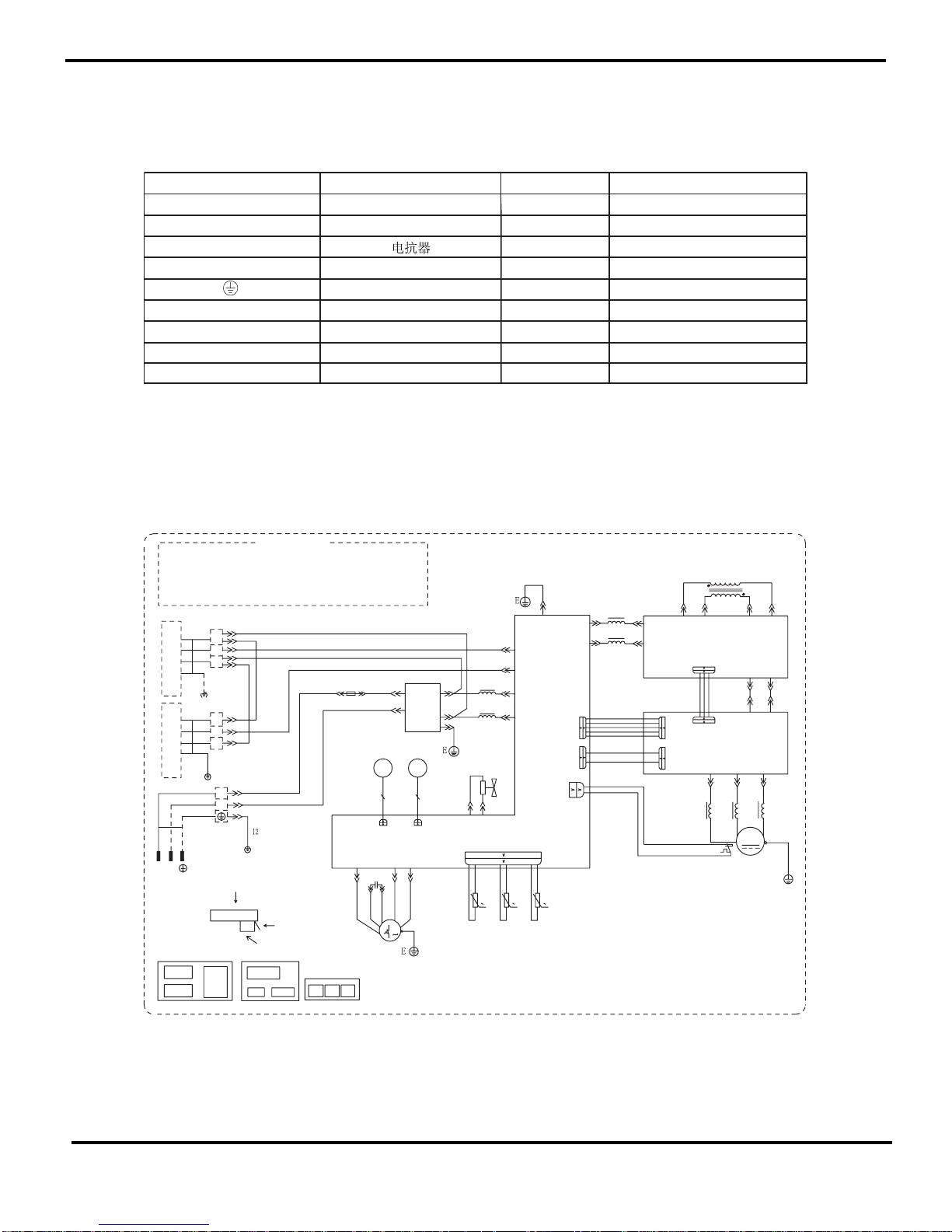

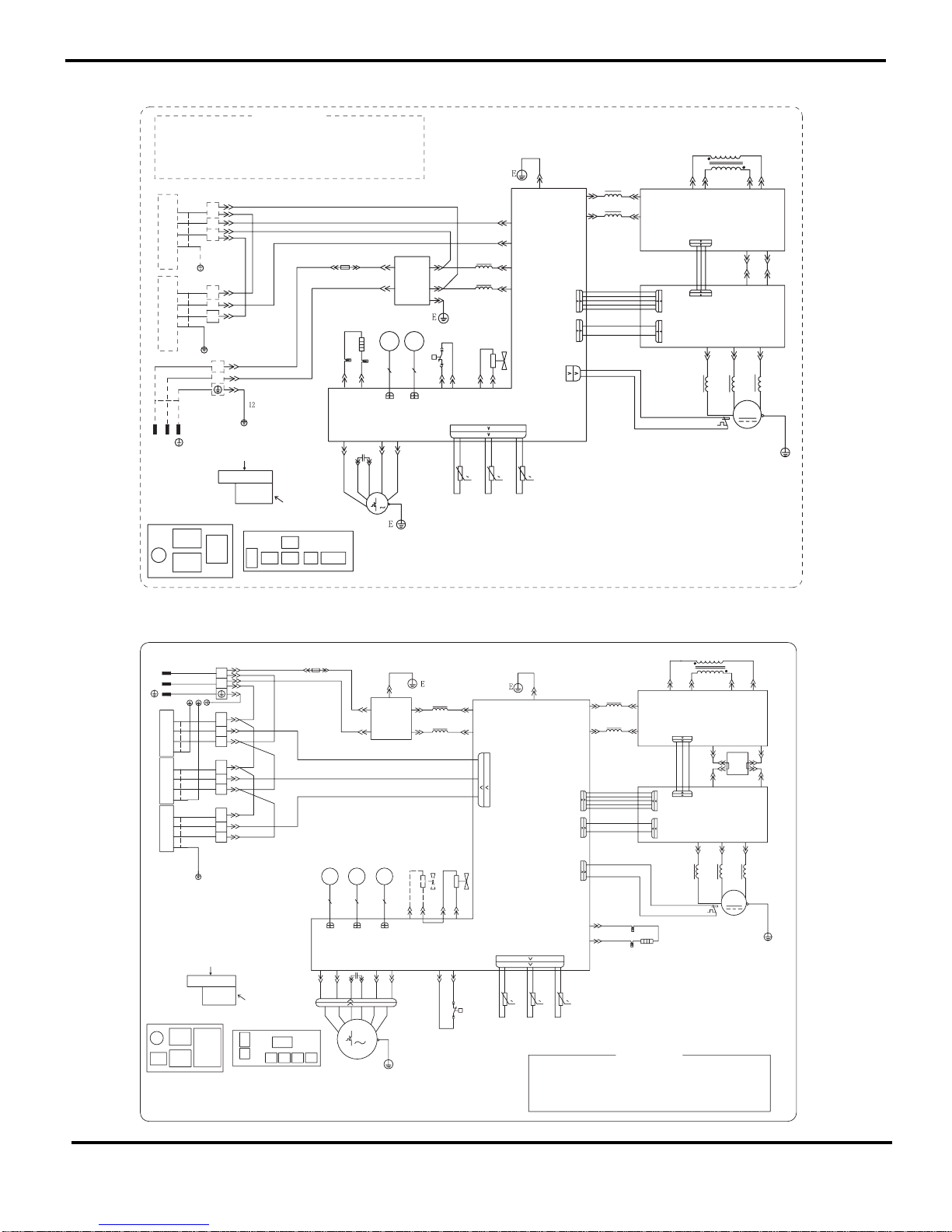

Schematic Diagram

10

5. Schematic Diagram

5.1 Electrical Date

5.2 Electrical wiring

Symbol Parts name Symbol Color symbol

L1 L2

REACROR

WH

WHITE

YK

Four-way-Valve

YE

Y ELLOW

RD

RED

L

BN

SA T O VERLOA D BN BROWN

COMP

COMPRESSOR

BU

BLUE

PROTECTIVE EA RTH

BK

BLACK

YEGN

YELLOW G REEN

GY GRAY

AP4 Power Module

Drive BoardAP3

AP2 PFC Module

AP1 Main Board

XTA

XT1

XTB

3

2

N(1)

E

E

E

L2

3

2

L

L

N(1)

L2

C

C

0

0

0

FU1

2BN

FU1

ELECTRICAL BOX

A

A

B

B

C1

AP1

AP2

AP3

7BU

L1

YE

WH

BU

BN

AC-L1

LAC

15BN

AC-L3AC-N3AC-L1

AC-N1

14YEGN

X14

FAN MOTOR

BKWH

X25

S

C(T)

R

EXHAUST

TUBE

ROOM

OVERLOAD

X5

X101

X3

X12

XH-3

W34

W33

AC-N1

NAC

16BU

S1

20WH

19WH

4V

24YEGN

COMP.

23WH

22BU

21YE

18RD

17BK

V

U

W

N

N

P

PR

10GY

E

4BN

2

4

FILTER

6BU

1

3

1BN

3BU

AC-N

AC-L

X28

X13(COM-B)

X18(COM-A)

11BK

C1

BN

BN

BK

BU

WH

YEGN

8BU

9BN

POWER

INDOOR UNIT A

INDOOR UNIT B

WHEN THE UNIT IS RUNNING OR STOPED IN 2

MINUTES OR THE VOLTAGE LESS THAN 30V

BETWEEN P AND N OF IPM,PLEASE DON©T TOUCH

ANY TERMINAL,AVOIDING ELECTRICAL SHOCK HAZARD.

WARNING

5BN

XT1XTAXTB

Val.

MOTOR

FILTER

FBFA

FAN-L

FAN-H

X25

TEM.SENSOR

EXHAUST

TEM.SENSOR

OUTROOM

TEM.SENSOR

OUTTUBE

RT5

RT4

RT3

X4

W35

AP1

AP2

M2

AP3

4V

13YEGN

MOTOR

Val.

M1

YEGN

CN101 CN102

FA FB

OUTDOOR UNIT

Model GMU018HXB-2

11

Schematic Diagram

Model GMU024HXB-2

XTA

XT1

XTB

3

2

N(1)

E

E

E

L2

3

2

L

L

N(1)

L2

0

0

0

WH

BU

BK

BN

BN

C1

FAN MOTOR

2BN

FU1

A

C1

B

ELECTRICAL BOX

A

B

7BU

L1

YE

WH

BL

BN

AC-L1

LAC

15BN

AC-L3AC-N3AC-L1

AC-N1

14YEGN

X14

S2

21BU

22YE

BKWH

S

C(T)

R

OVERLOAD

X5

X101

X3

X12

W34

W33

AC-N1

NAC

16BU

S1

24WH

23WH

28YEGN

COMP.

27WH

26BU

25YE

18RD

17BK

V

U

W

N

N

P

PR

10GY

4BN

2

4

FILTER

6BU

1

3

1BN

3BU

AC-N

AC-L

X13(COM-B)

X18(COM-A)

11BK

YEGN

8BU

9BN

POWER

INDOOR UNIT A

INDOOR UNIT B

WHEN THE UNIT IS RUNNING OR STOPED IN 2

MINUTES OR THE VOLTAGE LESS THAN 30V

BETWEEN P AND N OF IPM,PLEASE DON©T TOUCH

ANY TERMINAL,AVOIDING ELECTRICAL SHOCK HAZARD.

WARNING

5BN

HEATER

19RD

20RD

COMP

Val.

MOTOR

YEGN

M1

X25

FAN-H

FAN-L

FU1

FBFA

XTB

FILTER

XTA XT1

L1

AP3

AP2

AP1

X2

X8

AC-N

P

OVC

X25

TEM.SENSOR

EXHAUST

TEM.SENSOR

OUTROOM

TEM.SENSOR

OUTTUBE

RT5

RT4

RT3

EXHAUST

TUBE

ROOM

XH-3

X4

W35

4V

AP1

AP2

M2

AP3

4V

E

13YEGN

X28

MOTOR

Val.

CN101 CN102

FA FB

OUTDOOR UNIT

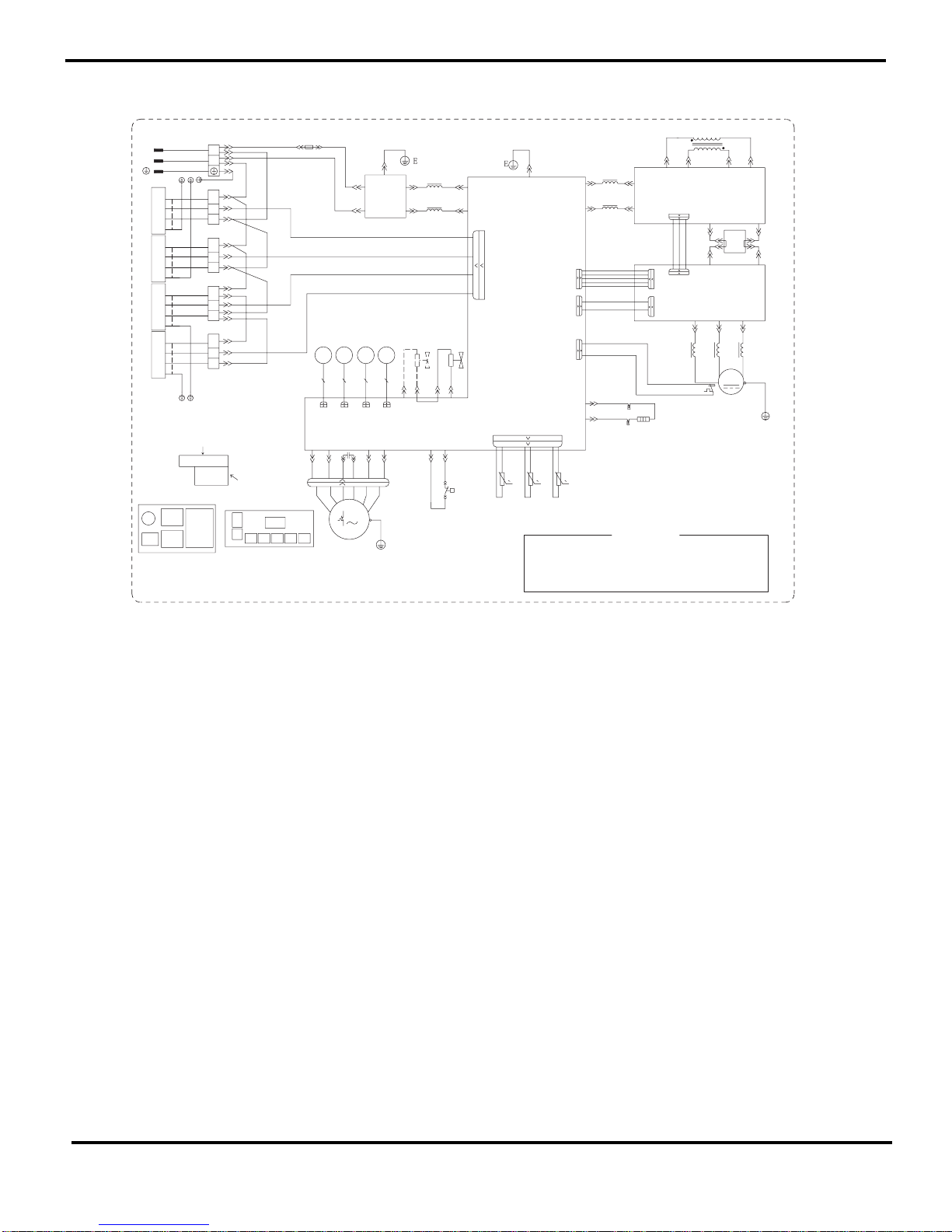

Model GMU028HXB-3

XTC

XTB

XT1

XTA

26BK

27RD

35BK

36RD

C(WH)

B(GY)

A(BK)

28BN

18YEGN

16BN

17BU

15BU

14BN

12WH

11GY

10BK

9YEGN

7BU

6BU

5BU

3BN

2BN

1BN

E

L

L2

3

2

N(1)

N(1)

2

3

YE

WH

BL

BN

20BN

19YEGN

21BU

29WH

30WH

34YEGN

33WH

32BU

31YE

E

L2

3

2

L

N(1)

PR

P

N

N

PR

N

0

0

FU

FU

XT1

XTC

BTXATX

INDOOR UNIT CINDOOR UNIT B

A

C1

B

ELECTRICAL BOX

A

B

L

AC-L1

AC-L3AC-N3AC-L1

AC-N1

S2

S(W)

C(T)

R

0

X5

X3

XH-3

X4

W38

W37

AC-N1

S1

COMP.

V

U

W

POWER

INDOOR UNIT A

WHEN THE UNIT IS RUNNING OR STOPED IN 2

MINUTES OR THE VOLTAGE LESS THAN 30V

BETWEEN P AND N OF IPM,PLEASE DON©T TOUCH

ANY TERMINAL,AVOIDING ELECTRICAL SHOCK HAZARD.

WARNING

E

N(2)

N©(4)

FILTER

P(1)

P©(3)

C1

M1

FAN MOTOR

COMP

HEATER

AP4

AP4

Val.

MOTORMOTOR

Val.

4V2V

BU BU VT VT

HEAT-C

X5

2V

AC-N

X29

X20

FBFA

Val.

MOTOR

FA FB

CN2

FC

FILTER

L

AP3

AP2

AP1

X2

X4

X6

X14

P

OVC

25BU

24YE

BKWH

X25

TEM.SENSOR

EXHAUST

TEM.SENSOR

OUTROOM

TEM.SENSOR

OUTTUBE

RT5

RT4

RT3

EXHAUST

TUBE

ROOM

OVERLOAD

X101

X12

W39

X1

X3

AP1

AP2

M2

AP3

4V

X9(AC-N)

X10(AC-L)

X28

22RD

23WH

FC

OUTDOOR UNIT

X1

213564

42BN

X11X7X8

FAN-M

40YE

FAN-L

FAN-H

X2

43BN

44BK

45BU

41WH

YEGN

E

Schematic Diagram

12

XTD

XTC

XTB

XT1

XTA

26BK

27RD

35BK

36RD

D(RD)

C(WH)

B(GY)

A(BK)

28BN

18YEGN

16BN

17BU

15BU

14BN

13RD

12WH

11GY

10BK

9YEGN

8BU

7BU

6BU

5BU

4BN

3BN

2BN

1BN

E

L

L2

N(1)

2

3

3

2

N(1)

N(1)

2

3

YE

WH

BL

BN

20BN

19YEGN

21BU

29WH

30WH

34YEGN

33WH

32BU

31YE

E

L2

3

2

L

N(1)

PR

P

N

N

PR

N

0

0

E

FU

FU

XT1

XTD

XTC

XTAXTB

M1

INDOOR UNIT DINDOOR UNIT CINDOOR UNIT B

A

C1

B

ELECTRICAL BOX

A

B

L

AC-L1

AC-L3AC-N3AC-L1

AC-N1

S2

FAN MOTOR

S(W)

C(T)

R

0

X5

X3

XH-3

X4

W38

W37

AC-N1

S1

COMP.

V

U

W

N(2)

N©(4)

FILTER

P(1)

P©(3)

C1

POWER

INDOOR UNIT A

WHEN THE UNIT IS RUNNING OR STOPED IN 2

MINUTES OR THE VOLTAGE LESS THAN 30V

BETWEEN P AND N OF IPM,PLEASE DON©T TOUCH

ANY TERMINAL,AVOIDING ELECTRICAL SHOCK HAZARD.

WARNING

COMP

HEATER

X1

213564

42BN

AP4

AP4

Val.

MOTOR

Val.

MOTORMOTOR

Val.

4V2V

BU BU VT VT

HEAT-C

X11X7X8

FAN-M

40YE

YEGN

E

X5

2V

AC-N

X29

X20

FBFA

Val.

MOTOR

FA FB

CN2

CFDF

FILTER

L

AP3

AP2

AP1

X2

X4

X6

X14

P

OVC

25BU

24YE

FAN-L

FAN-H

X2

BKWH

X25

TEM.SENSOR

EXHAUST

TEM.SENSOR

OUTROOM

TEM.SENSOR

OUTTUBE

RT5

RT4

RT3

EXHAUST

TUBE

ROOM

OVERLOAD

X101

X12

W39

X1

X3

AP1

AP2

M2

AP3

4V

X9(AC-N)

X10(AC-L)

X28

22RD

23WH

43BN

44BK

45BU

41WH

FC FD

OUTDOOR UNIT

Model GMU028HXB-4

These circuit diagrams are subject to change without notice. Please refer to the one supplied with the unit.

13

Schematic Diagram

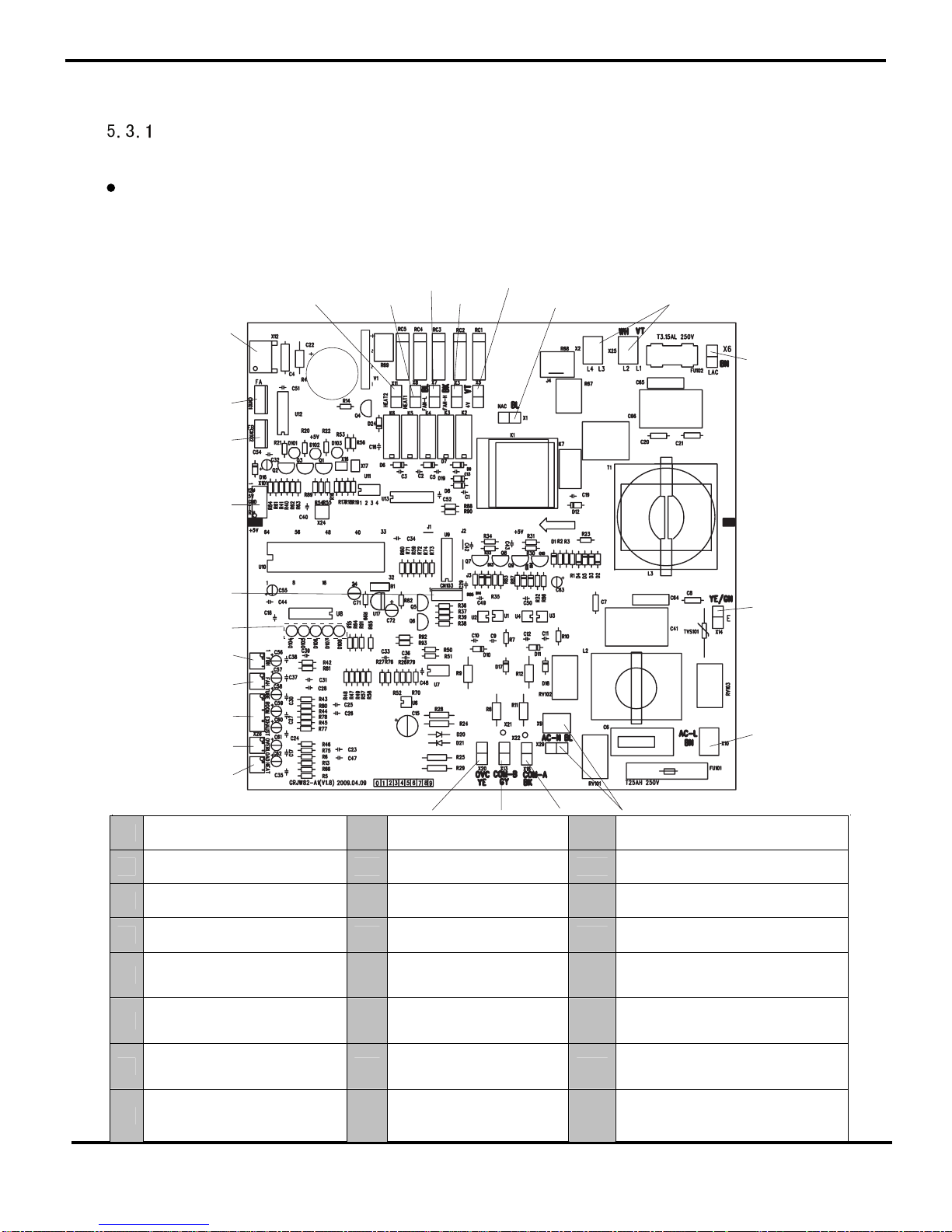

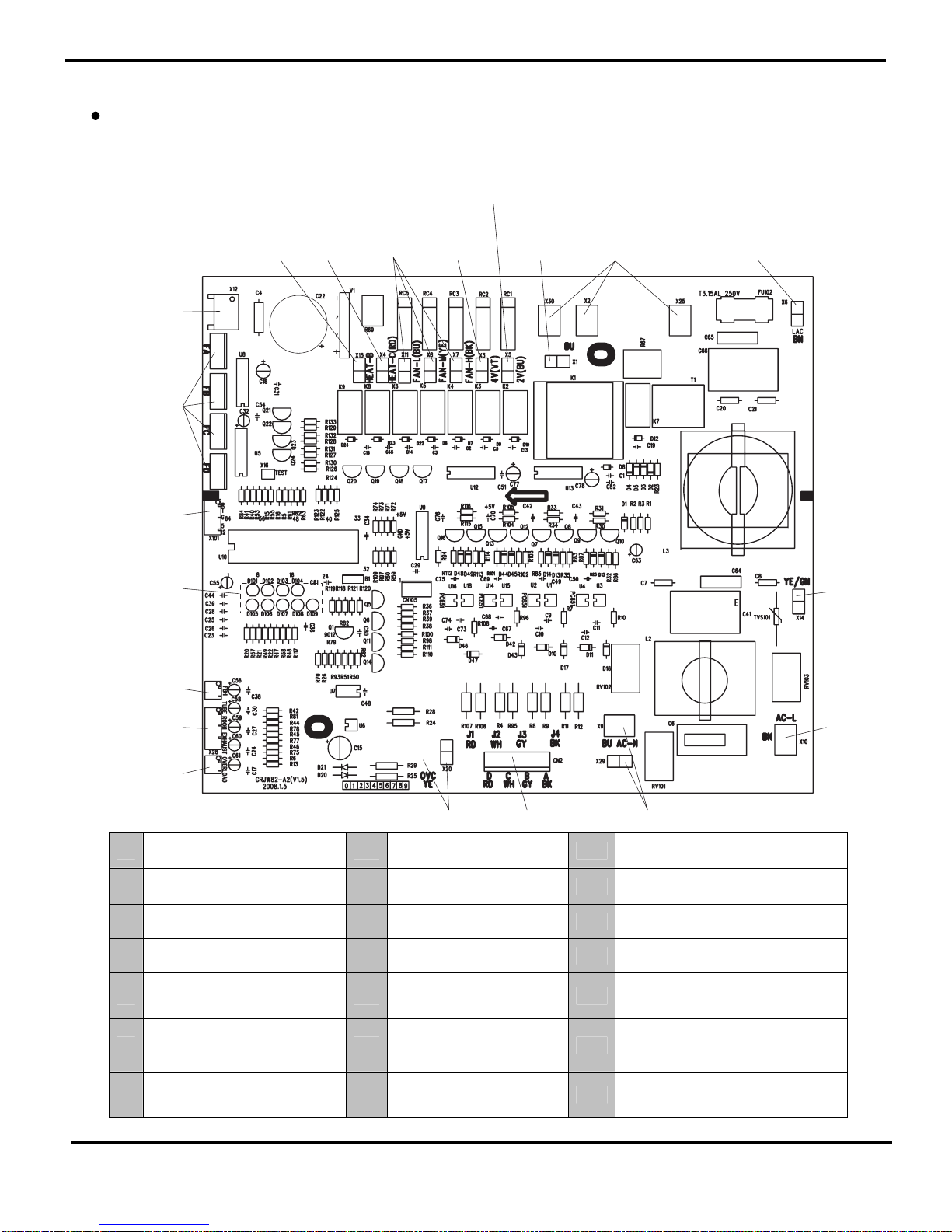

5.3 Printed Circuit Board

Model GMU018HXB-2,GMU024HXB-2

TOP VIEW

Mainboard

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

18

21

22

23

24

1 Electric heater on chassis(reserved) 9 Ground wire 17 Terminal of temp sensor

2 Heating tape of compressor (reserved) 10 Live wire 18 Reserved terminal

3 Low speed of fan 11 Null wire 19 Reserved terminal for adjusting frequency

4 High speed of fan 12 Communication terminal 20 Error LED

5 Wire of 4-way valve 13

Communication terminal for 1-to-2

model B unit(reserved)

21 5-core wire connecting to drive board

6 Null wire connecting to PFC board 14

High pressure protection

terminal(reserved)

22

Terminal for electric expansion valve

(reserved for 1-to-two units)

7

Null wire behind 3.15A, connecting to

4-way valve and fan

15 Reserved terminal 23 Terminal of electric expansion valve

8

Live wire behind wave filter,

connecting to PFC board

16

Terminal for compressor overload

protector

24

Terminal for 2-core wire connecting to drive

board. Input voltage of the complete unit is

AC220V. Voltage of the terminal is DC310V

Refrigerant System Diagram

14

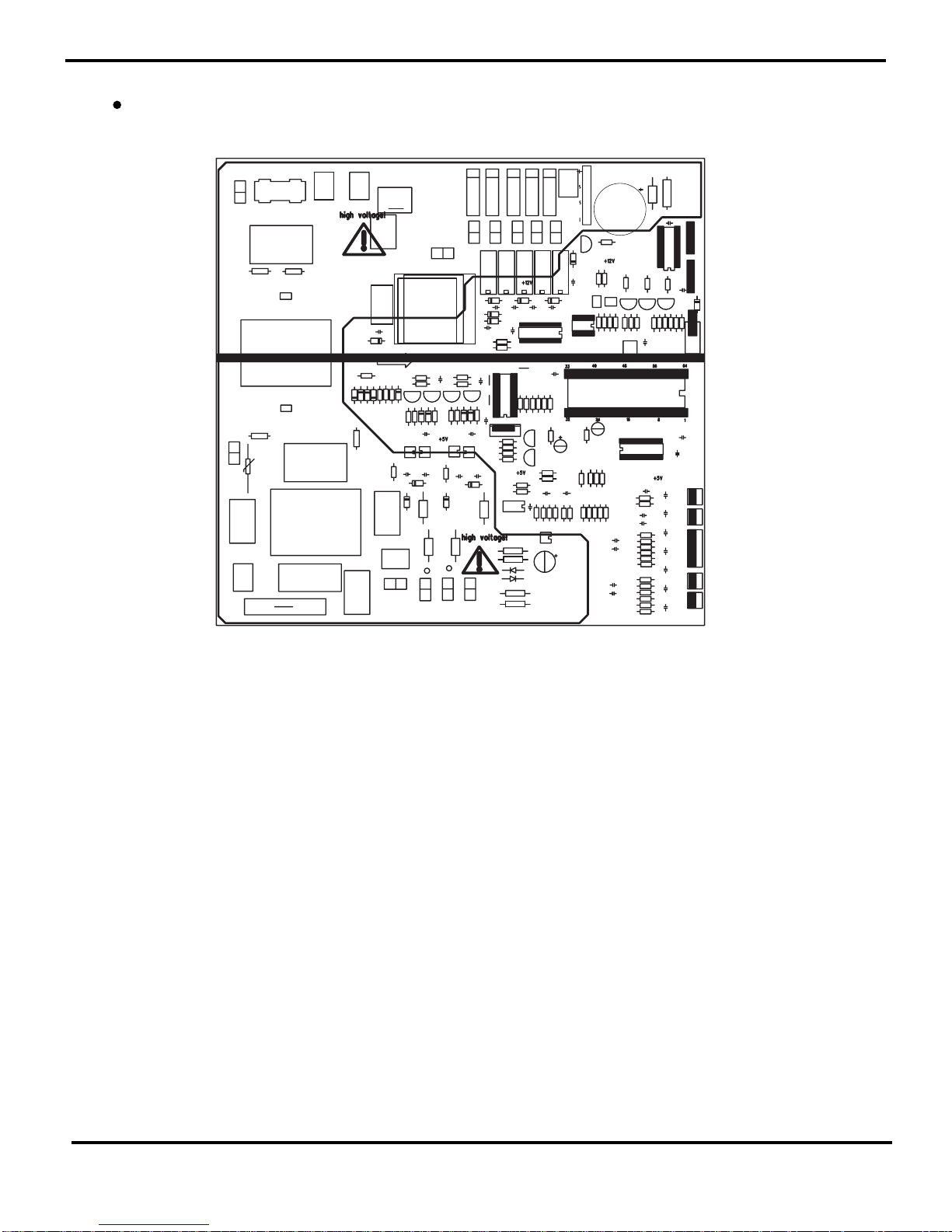

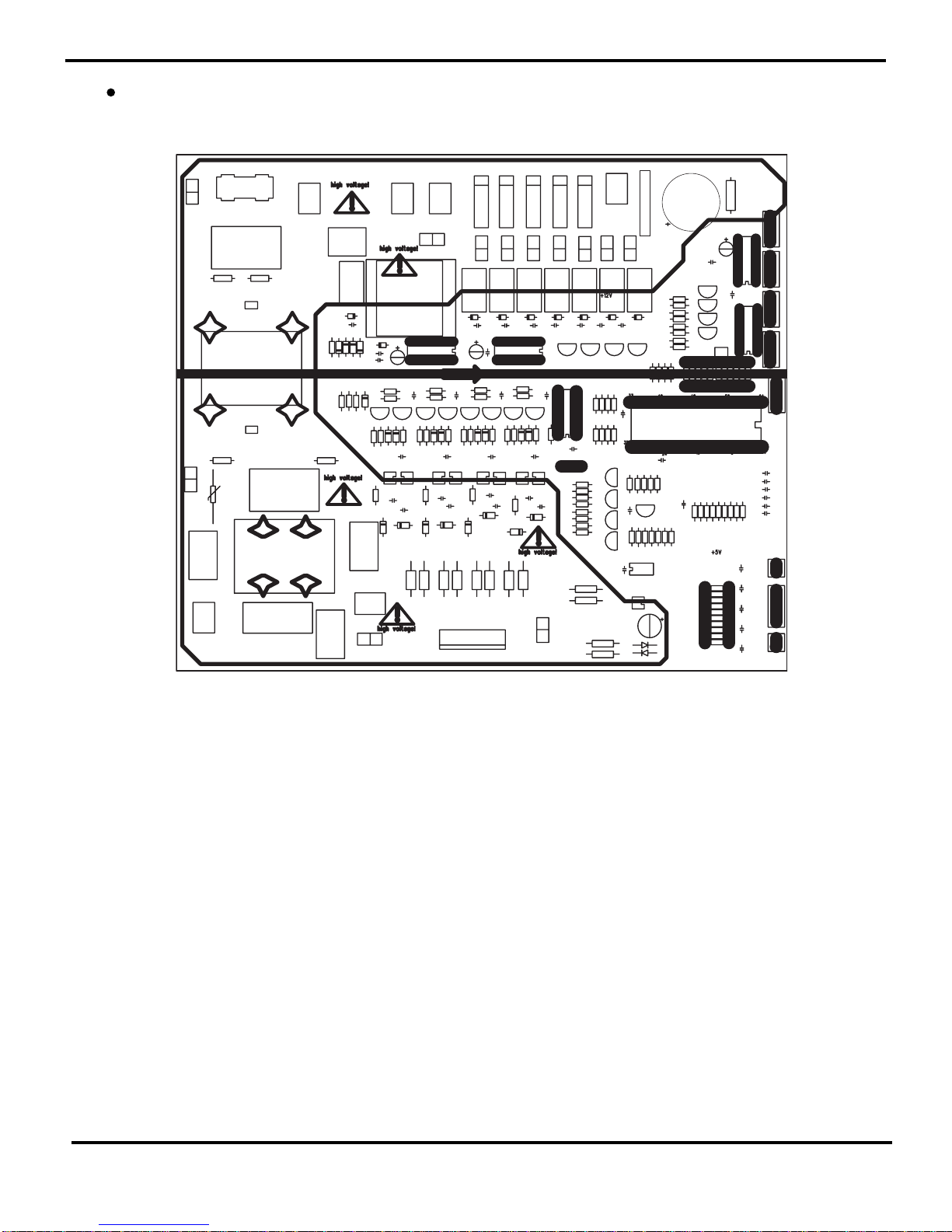

BOTTOM VIEW

15

Refrigerant System Diagram

Model GMU028HXB-3,GMU028HXB-4

TOP VIEW

1

2

3

4

5

6

7

8

9

10

11

1213

14

15

16

17

18

19

20

1 Terminal for electric heater on chassis 8

Live wire behind wave filter,

connecting to PFC board

15 Temp sensor terminal

2

Terminal for pre-heating tape of

compressor

9 Ground wire 16 Reserved terminal for adjusting frequency

3 Connecting wire for fan 10 Live wire 17 Error LED

4 Terminal for 4-way valve 11 Null wire 18 5-core wire connecting to drive board

5 Terminal for by-pass valve(reserved) 12 Communication connecting wire 19 Terminal for electric expansion valve

6 Null wire connecting to PFC board 13

Connecting wire for high pressure

protector

20

Terminal for 2-core wire connecting to drive

board. Input voltage of the complete unit is

AC220V. Voltage of the terminal is DC310V

7

Null wire behind 3.15A, connecting to

4-way valve and fan

14

Terminal for compressor overload

protector

Schematic Diagram

16

BOTTOM VIEW

17

Schematic Diagram

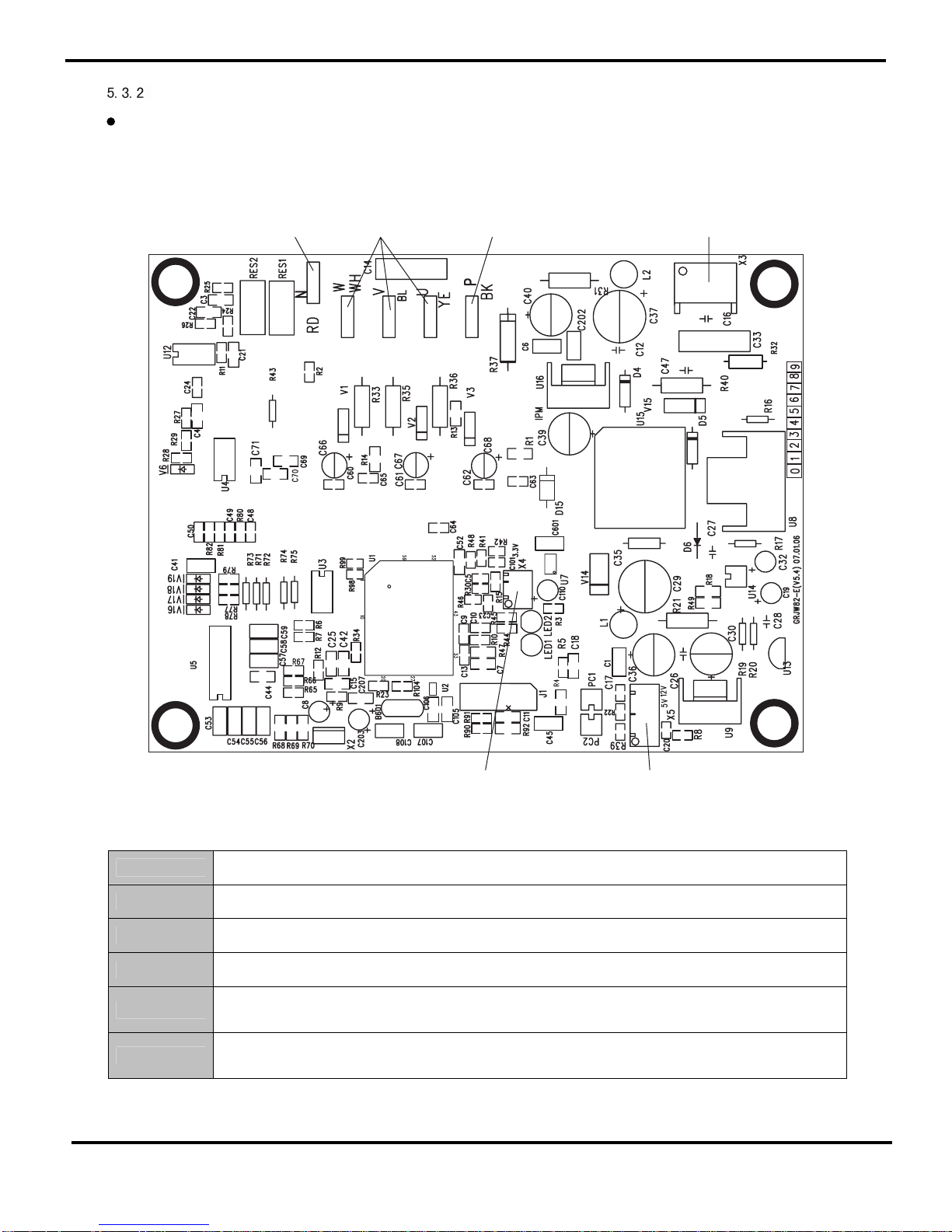

TOP VIEW

1

2

3

4

5

6

1 Negative terminal for input DC of PFC board

2 Terminals for three phases of compressor

3 Positive terminal for input DC of PFC board

4 Terminal for 2-core connecting wire of outdoor mainboard

5 Terminal for 5-core connecting wire of outdoor mainboard

6 Terminal for 3-core connecting wire of PFC board

Drive Board

Schematic Diagram

18

BOTTOM VIEW

19

Schematic Diagram

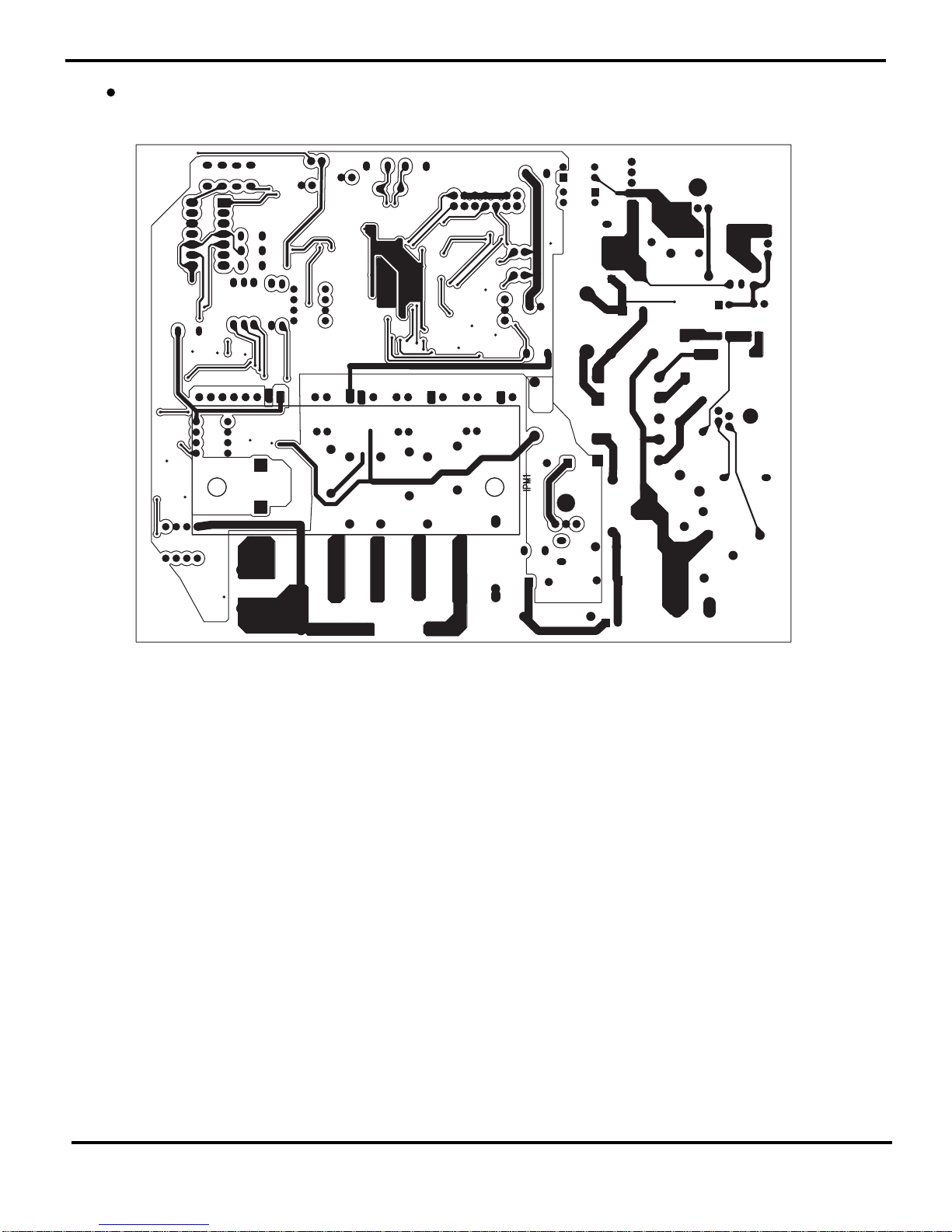

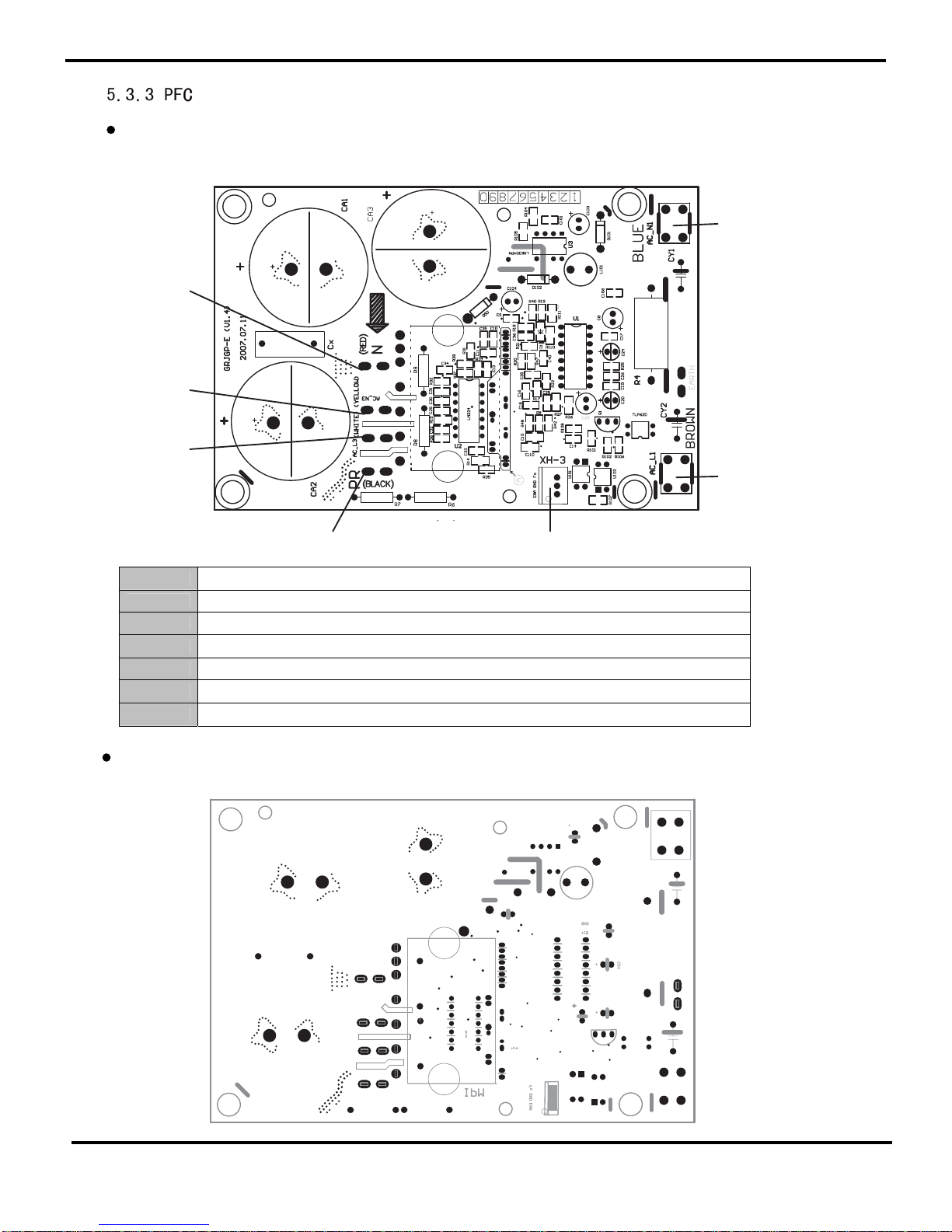

TOP VIEW

BOTTOM VIEW

Board

1

2

3

4

5

6

7

1 Zero terminal of DC, connecting to blue wire of inductor and null wire of outdoor mainboard.

2 Live terminal of AC, connecting to brown wire of inductor and live wire of outdoor mainboard.

3 Terminal for control signal input b drive board

4 Positive terminal of DC of drive board

5 Terminal for white wire of inductor

6 Terminal for yellow wire of inductor

7 Negative terminal of DC of drive board

Loading...

Loading...