Gruetzner Lubricus LUB-V1, Lubricus LUB-V2, Lubricus LUB-B1, Lubricus LUB-B2 Operating Instructions Manual

Operating Instructions: LUB-V

Operating Instructions

(24 VDC)

Operating instructions: LUB-V 2

Table of Contents

Contents 2

1) General Information 2

1.1 Warning 3

1.2 Scope of supply

1.3 Overview – the Lubricus Lubrication System

1.4 Symbols and notes 4

1.5 Intended use

1.6 Liability and extent of guarantee 5

2) Safety Information 6

2.1 General safety information

2.2 Transport and storage 7

2.3 Installation

2.4 Maintenance

3) Function/Principle 9

3.1 Starting

3.2 Setting options

Commissioning (switch on / switch off / resetting) 10

4.1 General information

4.2 Starting Lubricus for the first time

4.3 Switching off Lubricus

4.4 Ventilating the lubrication system 11

4.5 Programming Lubricus 12

4.6 Quick Check – dispensing an individual dose 13

4.7 Switching off Lubricus

5) Display, Messages, Errors (shown on LCD/LED) 14

5.1 Error messages on the display

6) LED cable / Communication interface (M12x1 connector) 14

7) Maintenance: cartridge and battery changing 15

8) Technical Data 16

9) Installation – Lubricus Lubrication System 17

10) Recommended tube lengths 18

11) Disposal 19

12) Appendix 20

12.1 List of tables and diagrams

12.2 Table of lubrication intervals LUB-V-1 21

12.2 Table of lubrication intervals LUB-V-2 22

Operating instructions: LUB-V 3

Please note!

1) General information

Thank you very much for choosing the Lubricus Lubrication System.

Please ensure you familiarise yourself with the safety instructions before using the pump and accessories supplied.

This manual contains important safety information.

The Lubricus Lubrication System is a very compact lubrication pump for oil and grease up to NLGI class 2.

The Lubricus types LUB-V1 (1 outlet) and LUB-V2 (2 outlets) are made for a 24 VDC power supply and require a mains

connection.

The lubricant reservoir (400 cm³) is in a rigid, disposable cartridge.

Supply pressure is <70 bar.

Depending on the model, the Lubricus Lubrication System has 1 outlet (LUB-V-1) or 2 outlets (LUB-V-2).

1.1 Warning

The Lubricus Lubrication System is designed for use in normal industrial environments, but not for use in or on motor vehicles.

Use only original Lubricus spare parts and accessories (cartridges, fittings, connectors and tubes).

1.2 Scope of supply

The scope of supply may vary from country to country.

Standard supply includes:

the Lubricus Lubrication System (1 or 2 outlets);

tube connector attached to the outlet(s) for medium-pressure PA tube 6 x 4 (Ø 6mm outer and Ø 4mm inner diameter)

Operating Instructions

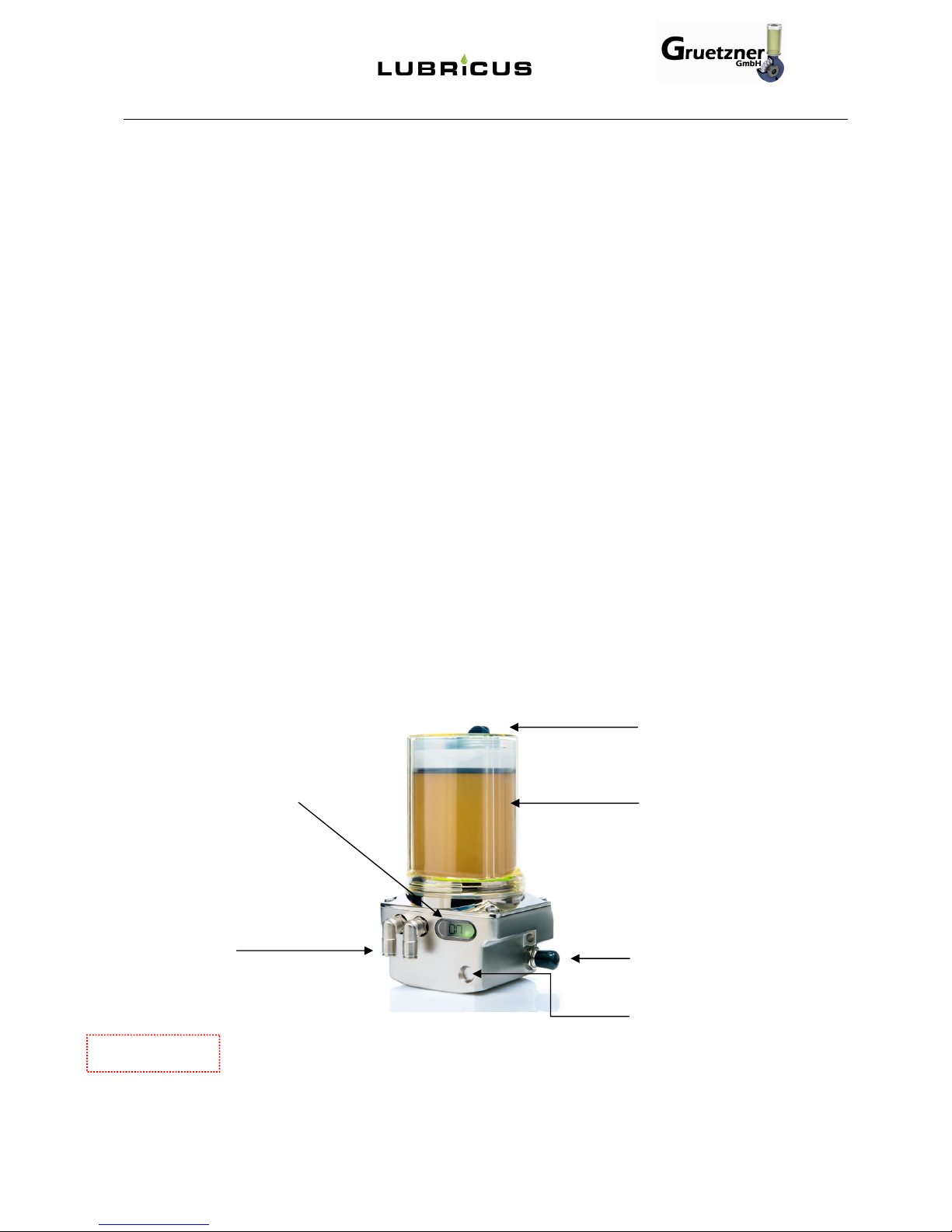

1.3 Overview – the Lubricus Lubrication System

Installing the Lubricus Lubrication System is simple. These instructions should help you to install your pump swiftly and easily, and to

quickly learn the basics.

Ventilation for changing the

cartridge (here you will find the

actuation magnet)

Housing/covering

Communication interface

(output M12x1)

Actuation pad

Outlets (1 or 2)

LCD/LED

display

– shows settings

and messages

Unused outlets should not be closed!

Diagram 1

Operating instructions: LUB-V 4

Please note!

Attention

Attention

Attention

1.4 Symbols & Notes

Please pay attention, not only to these safety instructions, but also to the special safety instructions on other pages.

This symbol warns of electrical voltage.

This general danger symbol denotes safety instructions, the disregarding of which could lead to bodily harm.

This heading is used if incorrect compliance or non-compliance with the Operating Instructions or specified work

procedures etc. may result in damage of the system.

This term will be used to draw your attention to special information.

Instructions attached directly to the machine must be strictly followed and kept in clearly legible condition!

1.5 Intended Use

The Lubricus Lubrication System is only approved for industrial use. The Lubricus Lubrication System may only be used

in accordance with the Technical Data (see chapter “Technical Data”).

Unauthorised structural changes to the Lubricus Lubrication System are not permitted.

We do not assume liability for damages to persons or machines resulting from such.

Additional instructions for use in conformity with the intended use:

pay attention to all information in the Operating Instructions;

carry out all maintenance work;

use only Grützner GmbH lubrication tubes and connectors;

follow all appropriate regulations for work safety and accident prevention during the entire lifespan of the Lubricus Lubrication

System;

only qualified and authorized personnel should carry out work of any kind on the Lubricus Lubrication System.

Other uses or uses beyond those described above shall be deemed as not in conformity with the intended use.

Operating instructions: LUB-V 5

1.6 Liability and extent of guarantee

Proper functioning of the Lubricus Lubrication System can only be achieved through use of recommended lubricants from the original

Lubricus range of accessories, and by observation of all installation, operation and maintenance instructions.

Grützner GmbH excludes all liability if these instructions are not observed.

Grützner GmbH grants guarantees concerning operating safety, reliability and performance only under the following conditions:

assembly, installation, maintenance and repairs are carried out by qualified staff only;

hazardous hot or cold machine parts must be shielded to prevent skin contact;

the Lubricus Lubrication System must be used according to the Technical Data and instructions;

the limit values stated in the Technical Data are under no circumstances to be exceeded;

retrofitting and repair work on the Lubricus Lubrication System may only be carried out by the manufacturer;

the lubrication system must be protected against damp and wet.

If a lubricant that has not yet been tested for compatibility with the Lubricus Lubrication System be supplied or requested for use in the

Lubricus Lubrication System by the purchaser/customer, the purchaser/customer undertakes the risk and responsibility.

This product is subject to strict production controls and fulfils our company’s factory specifications. However, guarantee of testing of each

individual case cannot be given due to the numerous factors involved.

We therefore strongly recommend that test runs be carried out.

All liability is excluded.

The Lubricus Lubrication System lubricant cartridge has been constructed and produced for one-time use only. Multiple use of the

lubricant cartridge is not envisaged. After being used once, the lubricant cartridge is to be completely replaced; refilling is not permitted.

Noncompliance will lead to nullification of the guarantee.

For guarantee conditions see the sales and delivery conditions of Grützner GmbH

Operating instructions: LUB-V 6

2) Safety Information

Basic information, which must be followed during assembly, operation and maintenance, is listed as follows. These Operating

Instructions must be read by all installation and operation staff before assembly and operation, and must be permanently available on

site.

All personnel involved in installation, maintenance and operation of the system are to read these instructions carefully before beginning

assembly and operation.

2.1 General safety information

2.1.1 Qualification and training of personnel

All operation, maintenance, service and installation personnel must be appropriately qualified for this work. Responsibility

and supervision of the personnel must be clearly defined by the end user. If staff do not have the necessary knowledge,

they must be trained and instructed. The end user must ensure that staff have completely understood the contents of the

Operating Instructions.

2.1.2 Danger of non-compliance with the safety instructions

Non-compliance with the safety information can be dangerous for people, environment and machines. Non-

compliance with the safety information can mean the loss of any or all damage claims. In certain cases, non-compliance

can, for example, lead to the following hazards:

malfunction of important system functions.

malfunction of prescribed methods of maintenance and servicing.

danger to people due to electrical, mechanical and chemical effects.

danger to the environment due to leakage of dangerous substances.

2.1.3 Safety information for end user / operating staff

Moving, rotating, hot or cold machine parts are to be securely shielded on site to prevent accidental contact. The

shielding on moving or rotating parts is not to be removed.

Leakages of dangerous materials are to be removed in such a way as not to endanger people or the environment.

Legal regulations are to be complied with.

Electrical hazards are to be eliminated.

2.1.4. Safety information for maintenance, inspection and assembly work

All maintenance, inspection and installation work may only be carried out by trained specialists who have been

informed appropriately by carefully studying the Operating Instructions.

All work must only be carried out when the machine is witched off and while wearing appropriate protective clothing.

Always comply with the procedures for switching off as described in the Operating Instructions.

All safety and protective equipment must be replaced immediately after completing work.

Environmentally hazardous substances must be disposed of in accordance with local regulations.

Secure the system during maintenance and repair work against intentional or unintentional operation.

Dispose of lubricants in accordance with the safety data sheets of the lubricant manufacturer.

2.1.5 Unauthorised modification and manufacture of spare parts

Modification and alteration of the system is not permitted. Original spare parts and accessories authorised by the

manufacturer are for safety purposes. Using other parts can result in loss of liability for claims resulting out of this.

Grützner GmbH does not guarantee and is not liable for components retrofitted by the end user.

2.1.6 Prohibited methods of operation

Operational security of the Lubricus Lubrication System is only guaranteed if it is operated in accordance with the Operating

Instructions. The limit values listed in the Technical Data are under no circumstances to be exceeded.

Loading...

Loading...