Gruetzner Lubricus LUB-C-1, Lubricus LUB-C-4, Lubricus LUB-C-3, Lubricus LUB-C-2, Lubricus LUB-C-1-1 User Manual

User Guide

Lubricus Controller

LUB-C-1, LUB-C-2,

LUB-C-3, LUB-C-4,

LUB-C-1-1

(24 VDC)

Lubricus Type C

page 2

Content

General Information, Scope of supply 3

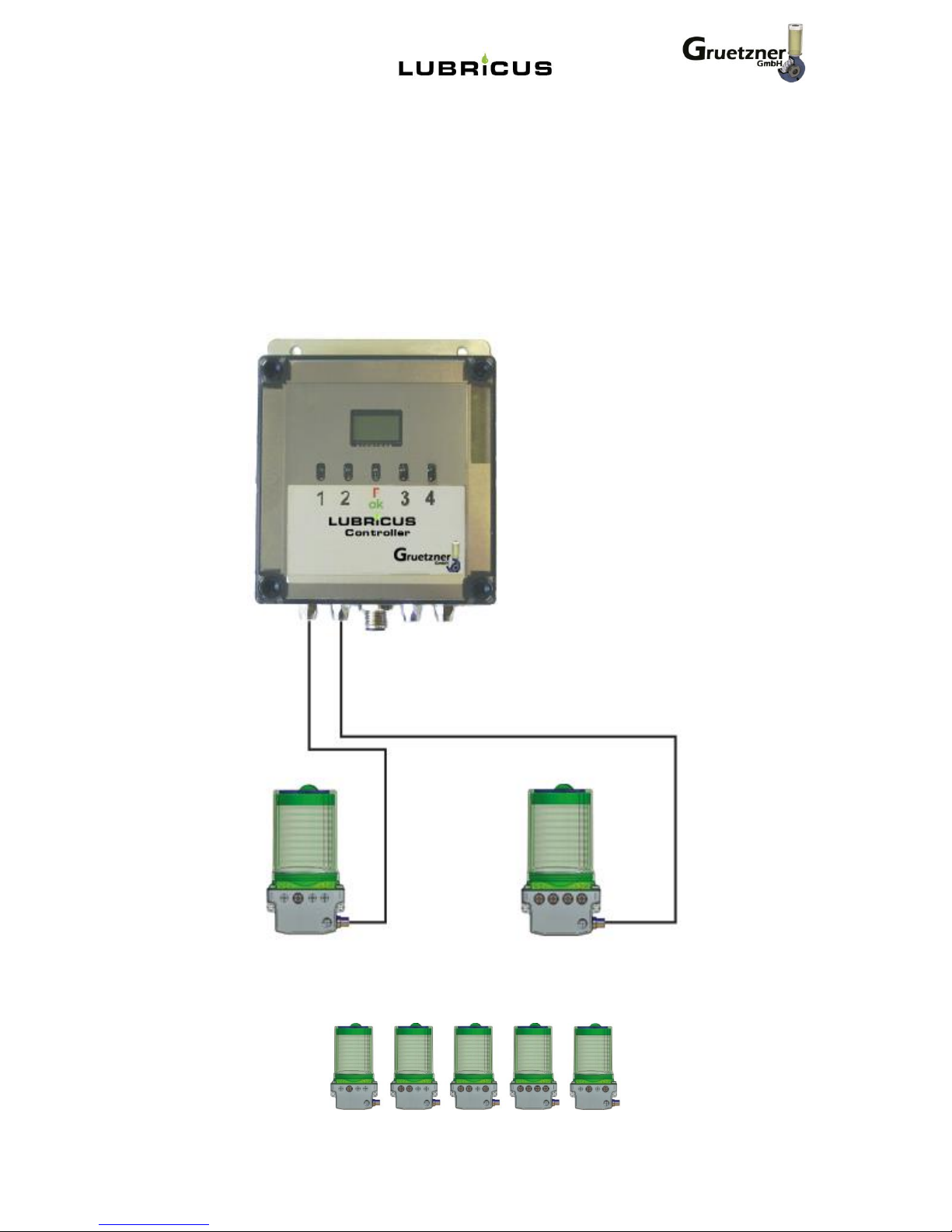

Overview: Lubricus Controller & Lubricus Lubrication System, Type C 4

General safety details 5

- Intended use 5

- Extent of warranty 5

- General safety information 5-7

- Transport and storage 7

- Installation instruction, Start up 7

Function 9

- Adjustment Flow Chart 10

- Flow chart details – Overview adjustment option 11-12

- Activation of exits, Pump specific adjustment 10-12

- Inputting the generation of the Lubricus C devices used 13

- Table pause time adjustments 14

- Table quantity adjustment 14

Details: Activation (Start/Stop/Adjustment) 15-18

- Functional problems: error, message and problems 17-18

Extras: Quick check function and system control 19

Communication Interface 20

Service: Lubricus, Type C with cartridge 21

Technical data: Lubricus Controller & Lubricus, Type C 23

Mounting: Lubricus Controller & Lubricus Lubrication System 24

Recommended tube/hose length & Disposal 25

page 3

General Information

Thank you very much to have decided to use our Lubricus Lubrication System and Lubricus Controller. Make sure that you

familiarize yourself with the safety instructions of this unit and the accessories supplied with this unit. This manual contains

important safety information.

The Lubricus Lubrication System is a very compact lubrication pump for oil and grease up to NLGI 2. The types LUB-C-1,

LUB-C-2, LUB-C-3, LUB-C-4 and LUB-C-1-1 are designed for external control (Lubricus Controller) and a power supply of 24

VDC. The lubricant reservoir (400 cm³) is located in a cartridge.

- Lubricus Lubrication System (Type LUB-C-1, LUB-C-2, LUB-C-3, LUB-C-4, and LUB-C-1-1) will be installed near the

lubrication point

- Lubricus Controller (System Control) will be installed in a central location

Depending on the configuration of Lubricus Lubrication System, Type C is available with up to four outlets and therefore

suitable to lubricate several lubrication points.

Warning

Lubricus Lubrication System is designed for use in normal industrial environment indoor as well as outdoor but is not suitable

for mounting on moving equipment for example trucks. Only use original Lubricus cartridges and original spare parts. None

original spare parts can destroy the Lubricus Lubrication System or the Lubricus Controller.

Scope of supply

Standard delivery Lubricus Controller includes:

- Lubricus Controller

- Operating Instructions

Standard scope of supply Lubricus Lubrication System, Type C:

- Lubricus Lubrication System, (Type LUB-C-1, LUB-C-2, LUB-C-3, LUB-C-4, LUB-C-1-1)

- Tube connector attaches to the outlet, suitable for flexible tube 6 x 4

- Operating Instructions

Lubricus Lubrication System, Type C

LUB-C-1

LUB-C-2

LUB-C-3

LUB-C-4

LUB-C-1-1

page 4

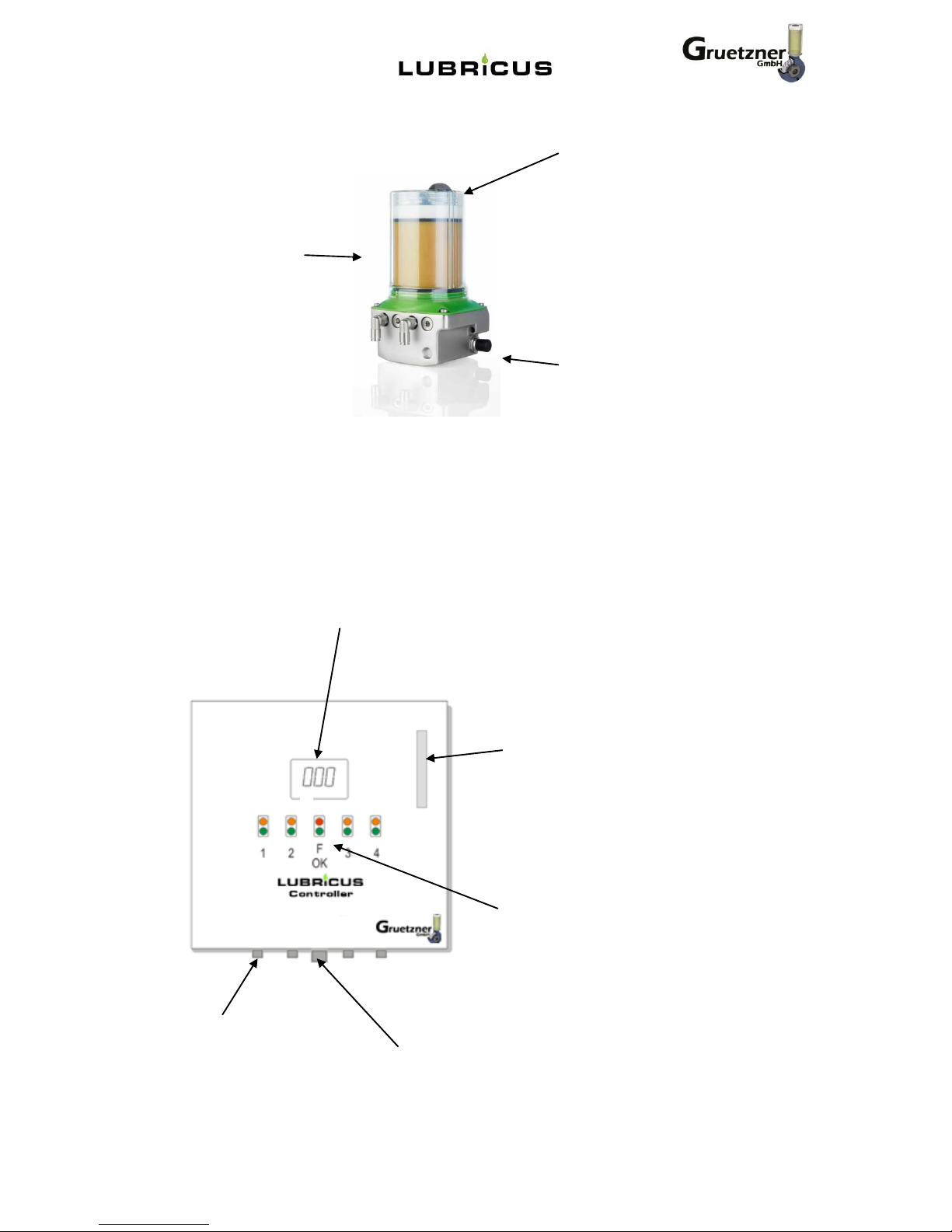

Lubricus Lubrication System

Important remark: unused exits cannot be closed and must remain open to avoid damage to the Lubricus

Lubrication System!

Lubricus Controller

Connection Lubricus Controller

Ventilation Lock & programming key

(The programming key is conveniently stored on top of

the clear housing, to remove the key for Setup or

Adjustments of your Lubricus (Simply turn clockwise to

release key)

The point of the key is used for programming.

Please note: Always replace the key for safe keeping

as this also forms part of the cover.

Cover for cartridge

Display showing adjustment

values and error messages

Sensor for Activation and programming key

Connector pin M12 x 1 = connection to plc +

power supply 24 VDC

LED: Status indicator

4 Outlets for Lubricus,

Connector pin M8 x 1

page 5

Attention

General safety details

Everybody who is involved with the installation, start-up, maintenance and operation of the Lubricus Lubrication System

must read these instructions carefully!

Use in accordance with guide

Lubricus Lubrication System is only allowed for industrial use.

Lubricus Lubrication System may only be put into service, if it is integrated or attached to another

machine and will be operated together with that machine.

Lubricus Lubrication System may only be used according to the technical data (see chapter

“technical data”).

Unauthorized structural changes at the Lubricus Lubrication System are not permitted. We do

not assume liability for damages of persons or machines which result from that.

Other uses or uses beyond those described above cannot be considered to be in

accordance with the regulations.

Extent of warranty

Warranties concerning operating safety, reliability and capacity, are only granted under the following conditions:

Assembly, installation, maintenance and repair are only carried out through trained specialist. Hazardous hot or cold

machine parts must be shielded to prevent touching.

Lubricus Lubrication System must be used according to the instructions in the technical operating manual

- the rated technical data must not be exceeded in any case.

- Retrofitting and repair work on the Lubricus Lubrication System may only be done by manufacturer.

Liability and extent of guarantee

Proper functioning of the Lubricus Lubrication System can only be achieved through use of recommended lubricants from the

original Lubricus range of accessories, and by observation of all installation, operation and maintenance instructions.

Grützner GmbH excludes all liability if these instructions are not observed.

Grützner GmbH grants guarantees concerning operating safety, reliability and performance only under the following

conditions:

assembly, installation, maintenance and repairs are carried out by qualified staff only;

hazardous hot or cold machine parts must be shielded to prevent skin contact;

the Lubricus Lubrication System must be used according to the Technical Data and instructions;

the limit values stated in the Technical Data are under no circumstances to be exceeded;

retrofitting and repair work on the Lubricus Lubrication System may only be carried out by the manufacturer;

the lubrication system must be protected against damp and wet.

If a lubricant that has not yet been tested for compatibility with the Lubricus Lubrication System be supplied or requested for

use in the Lubricus Lubrication System by the purchaser/customer, the purchaser/customer undertakes the risk and

responsibility.

This product is subject to strict production controls and fulfils our company’s factory specifications. However, guarantee of

testing of each individual case cannot be given due to the numerous factors involved.

We therefore strongly recommend that test runs be carried out.

All liability is excluded.

The Lubricus Lubrication System lubricant cartridge has been constructed and produced for one-time use only. Multiple use

of the lubricant cartridge is not envisaged. After being used once, the lubricant cartridge is to be completely replaced; refilling

is not permitted. Noncompliance will lead to nullification of the guarantee.

For guarantee conditions see the sales and delivery conditions of Grützner GmbH

Attention

page 6

Remark

Attention

General safety information

Basic information, which must be followed during service, operation and maintenance, are listed as follows.

It is absolutely essential to read the operator’s manual / user guide by respective technical staff / technical operator before

installation and start up.

In addition to this, it must be permanently available at the site.

IMPORTANT

Please pay attention, not only to the safety instructions under this main point, but also to those special security cautions that

are mentioned on the other pages.

This symbol warns of electrical voltage.

Safety instructions which, if not complied with, may endanger persons, are marked specifically with

the general hazard symbol.

This heading is used if inaccurate compliance or non-compliance with the operating Instructions or

specified work procedures etc. may result in damage.

Points out special information.

Notes attached directly on the machine, must be strictly followed and maintained in completely readable

condition!

Qualification and training of the personnel

The operation, maintenance, service and installation personnel must have appropriate qualifications for this

work. Responsibility and supervision of the personnel must be clearly defined by the end user / operator. If

the personnel do not have the necessary knowledge, they must be trained and instructed. The operator must

ensure that the personnel have completely understood the contents of the user information.

Non-observance of the safety information can be dangerous

Not observing the safety information can lead to danger for people, environment and machines.

Not observing the safety information can mean the loss of any or all damage claims. In special cases, nonobservance can, for example, lead to the following dangers:

Failure of important plant functions.

Failure of prescribed methods of maintenance and preventive maintenance.

Endangering people due to electrical, mechanical and chemical effects.

Endangering the environment due to leaks of dangerous materials.

page 7

Safety information for operators/operating staff

Hot or cold machine parts are hazardous and must be protected from touching. The protection on

"moving or rotating parts" must not be removed.

In case of leakages of dangerous media proper disposal not endangering environment and people must

be ensured.

Legal Regulation must be observed and complied.

Eliminate any danger due to electrical power.

Safety information for maintenance, inspection and assembly work

All maintenance, inspection and installation work may only be carried out by trained specialists who

have been informed appropriately by studying the user information closely.

All work must only be carried out when machine is shut down and while wearing appropriate protective

clothing. Always comply with the procedures for shutting the machine down that are described in the

operating manual. All the safety and protective equipment must be replaced immediately after completing

work. Environmentally hazardous substances that endanger the environment must be disposed in

accordance with local regulations. Secure the system during maintenance and repair work, against

intentional or unintentional operation. Dispose of used lubricants in accordance with the safety data sheets of

the lubricant manufacturer.

Alterations and manufacture of spare parts without authority

Rebuilding or altering the Lubricus Lubrication System is only allowed after consultation with the

manufacturer. Original spare parts and accessories authorized by the manufacturer are for safety

purposes. Using other parts results in loss of liability for claims resulting out of this. For components,

retrofitted by the operator, the manufacturer does not assume guarantee nor claims for damages.

Prohibited methods of operation

Operational security of the Lubricus Lubrication System is only guaranteed if it is operated in accordance with the

operating instructions. The limit values stated in the technical data must not be exceeded under any circumstances.

General risk reference

All components of the system are designed in accordance with the prevailing regulations of the construction

of technical machines, in regards to operational safety and accident prevention. Operation outside of these

constraints can lead to dangers for the user respectively third persons or other technical facilities. The

Lubricus Lubrication System therefore may fulfil only in technically fault-free condition its intended use.

This may only be carried out under compliance of the safety regulations and the attention of the operator's

manual.

Therefore please regularly inspect the pump and its attachments for possible damage or leaks.

Transport and storage

Use suitable lifting gear for transport.

Do not throw or expose the Lubricus Lubrication System to strong shock loads.

Store the Lubricus Lubrication System in a cool and dry place to avoid corrosion of the system’s individual parts.

Pay attention to the current safety- and accident prevention instructions during the transport. Wear suitable

protection equipment if necessary!

page 8

Installation instruction

The following conditions have to be satisfied during the installation of this Lubricus Lubrication System, thus it

can be assembled, with other parts, to a complete machine without affecting the safety and health of

humans.

The housing of the Lubricus and/or Lubricus Controller should not be exposed to direct sunlight

and/or radiant heat preventing the formation of condensation.

Electrical connection

Have the electric power supply connected only by a trained electrician!

Connection and wiring of the electric components should be done by an expert trained in this field.

Check the voltage details with the existing power supply voltage!

Maintenance /repair

Disconnect the voltage feed, before starting with maintenance or repair.

Maintenance and repair work may only be done with the system shut down.

Check the surface temperature of Lubricus Lubrication System, due to danger of burning by radiant heat.

Always wear heat-resistance gloves! Protect the system from activation during maintenance and repair work!

Loading...

Loading...