GRS Silentair 50-15 Instructions Manual

Silentair 50-15

7

4

5

7

6

8

9

PART #004-678

INSTRUCTIONS

PACKAGE CONTENTS

The Silentair compressor comes in two boxes.

Box #1 (Small Box) Contains:

• Compressor Fan – (#004-693)

• 1 Bottle of Silentair Synthetic Oil,

with Applicator Spout – (#022-163)

• Silentair Reservoir Bottle

Box #2 (Large Box) Contains:

• Silentair Compressor Assembly,

with Coalescing Filter

• Silentair Regulator / Primary Filter

• 2 Rolls of Nylon Tubing

• Packet of Threaded Fastener*, Short Clear

Hose*, and Black Air Intake Filter —

Attached to Red Cap on Compressor

*Not used for this application.

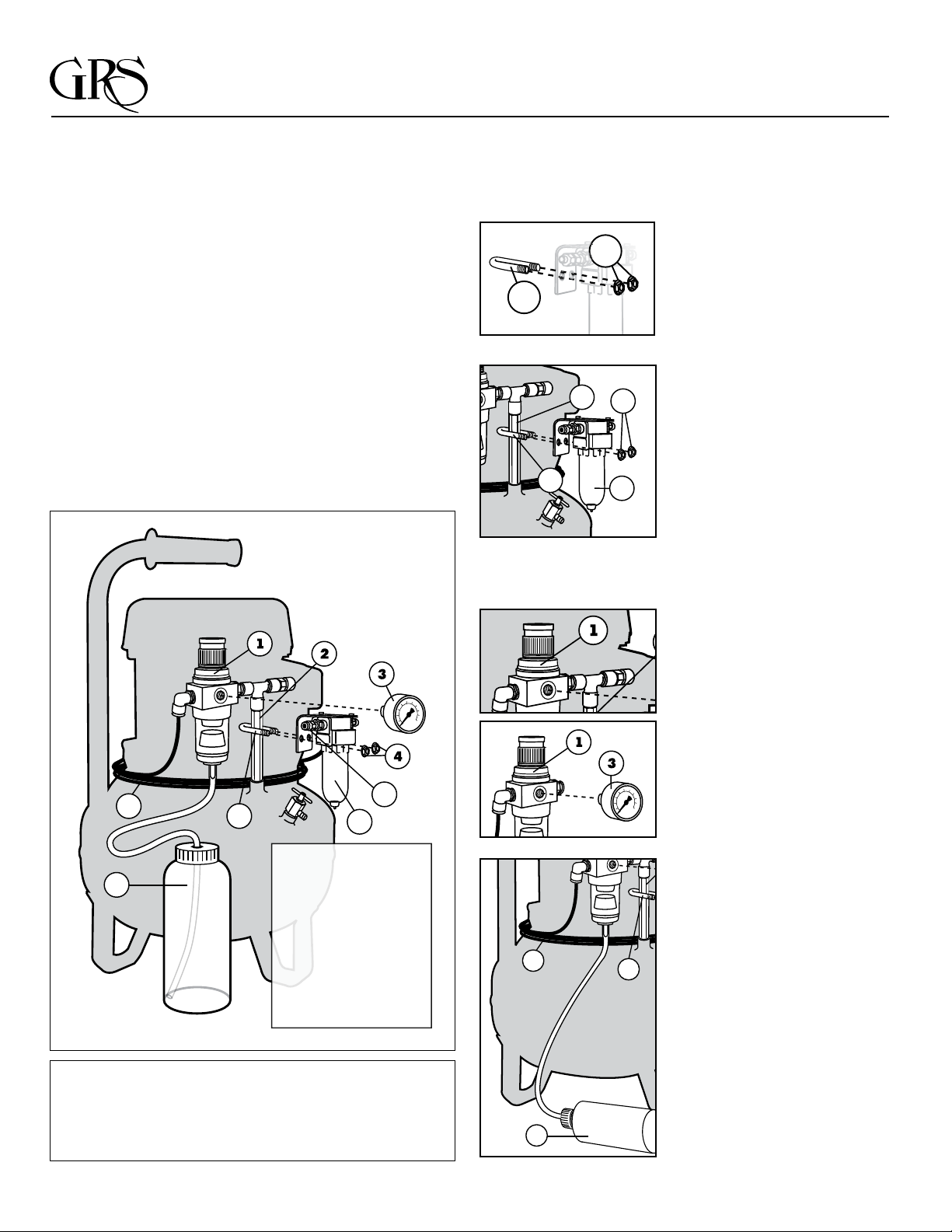

Fig. A

NOTE: Before using this compressor, read all

instructions to avoid DAMAGE.

INSTALLATION

1. Begin by installing the

Coalescing Filter (Fig. A–6).

Remove the 2 Lock Nuts

(Fig. A–4) that hold the

U-bolt (Fig. A–7) on the

bracket.

2. Wrap the U-bolt (Fig.

2

A–7) around the Standing

4

T-Fitting (Fig. A–2) that rises

out of the air tank. Slide the

Coalescing Filter bracket

7

onto the threads. Use your

6

fingers to tighten the nuts

evenly first, then use a 7/16”

wrench to tighten.

NOTE: For most secure fit, place back of bracket

against a flat side of the Standing T-Fitting.

8

9

7

1 Regulator Air Filter

2 Standing T-Fitting

3 Air Pressure Gauge

4 2 Lock Nuts

5 Tubing B Connector

(to Engraving System)

6 Coalescing Filter

7 U-Bolt

8 Buffer Air Tubing A

9 Air Filter Clean-out

Reservoir Bottle

5

6

NOTE: The air filter will empty contents of

bowl into the Reservoir Bottle. The bottle

will need to be checked and emptied often to

avoid overfilling.

3. Install the Silentair

Regulator Air Filter (Fig.

A–1) by threading it onto

the pipe nut located on

the T-Fitting. Do not over

tighten!

4. Install the Air Pressure

Gauge (Fig. A–3) by simply

threading the gauge into the

fitting below the Air Filter

(Fig. A–1) as shown.

5. Install the Silentair

Reservoir Bottle (Fig. A–9)

by pushing the bowl drain

hose into the hole in the cap

of the bottle.

NOTE: Located on the

side of the compressor top

cover is a red protector

cap covering the air intake

opening, red warning label

and zip-lock bag. Unthread

the red protector cap and

remove the tag and bag.

LIT-073

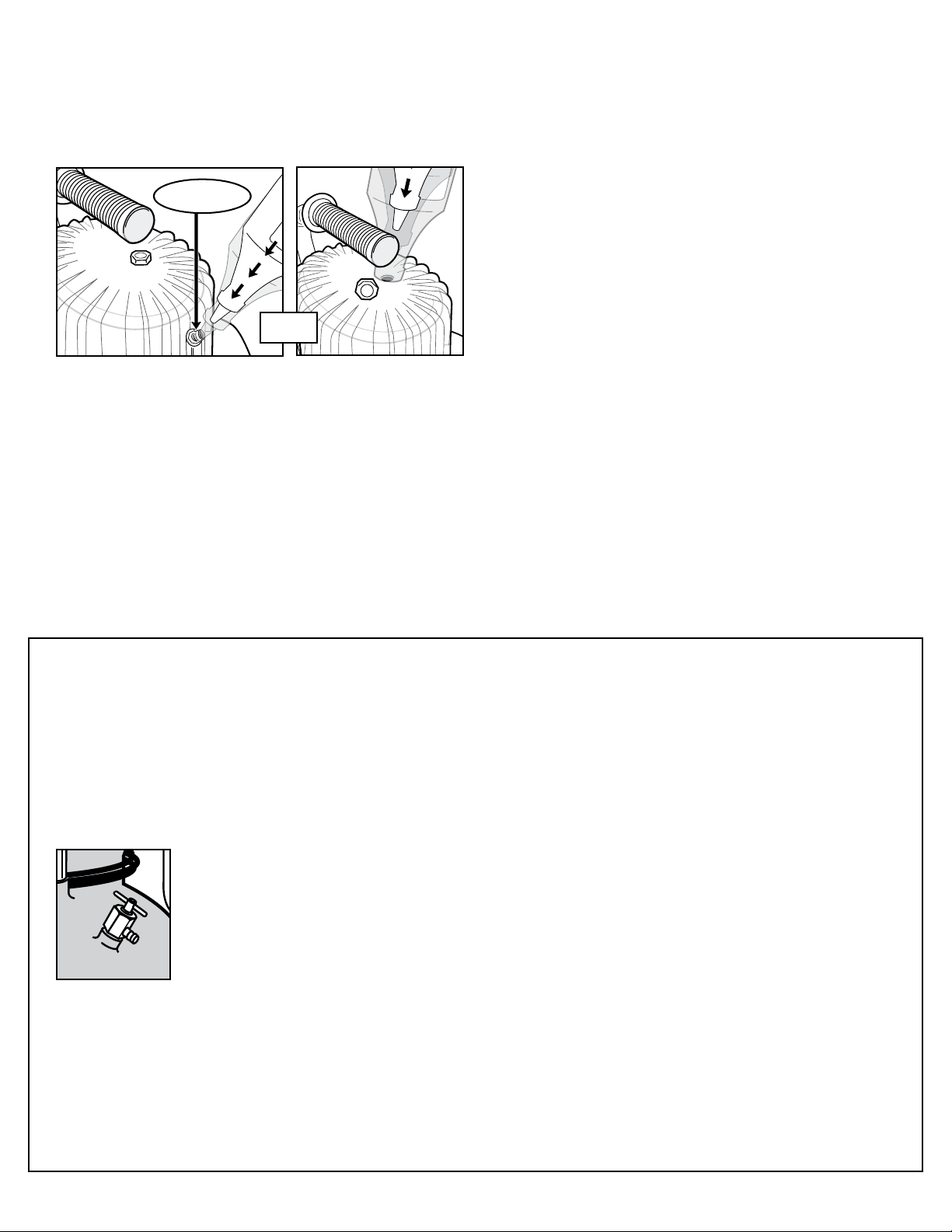

6. Open the bottle of Silentair Synthetic Oil. Using

OIL

AIR INTAKE

OPENING

5

6

the Applicator Spout, carefully add the oil through

the Air Intake opening. As an alternative, you can

add the oil through the plug at the top of the head

marked OIL by unthreading the knob.

AIR INTAKE

OPENING

9. Two sets of tubing are included:

1. Buffer Air Tubing A (Fig. A–8)

• Extra length replacement tubing for around

the compressor pump head.

• Allows air from the compressor to cool,

depositing oil droplets in the tubing before

going to the Coalescing Filter.

• Replace when Coalescing Filter is replaced,

or if tubing becomes contaminated with oil.

OIL

OIL

or...

7. Check the oil level on the sight glass located by

the T-Fitting. The oil should be at the halfway mark.

NOTE: For best operation, change and refill the oil

with fresh Silentair Synthetic Oil after the first 150

hours of compressor use. USING ANY OTHER OIL VOIDS

THE 1-YEAR MANUFACTURER’S WARRANTY and will cause

increased wear and excessive oil blow-by.

8. Install the Air Intake Filter by threading it into the

Air Intake opening.

ADDITIONAL INSTRUCTIONS, NOTES & MAINTENANCE HINTS

• OPTIMAL OPERATING PSI • This compressor has

been adjusted to provide a maximum of 80 psi (plus

or minus 10 psi). By operating at this conservative

80 psi pressure, the compressor stays cooler. The

air pressure is ample for operating air tools such

as a GraverMach, GraverMax SC, System 3, rotary

handpieces, and other similar air tools.

• DRAINING WATER • Water

is generated as a by-product of

compressing air. The small T-Fitting

with the spout is for draining the air

tank. The valve has an extension

that goes to the tank bottom to

allow complete system draining.

It is not necessary to remove the

bottom tank plug or tip the compressor on its side to

drain water. Drain regularly as needed.

• SHIPPING • If shipping is required, remove

ALL OIL to prevent oil leakage and damaging oil

contamination of the air components. Do not assume

the shipper will keep the box upright during transit.

2. Tubing B (Connects to Fig. A–5)

• 50 ft. (30.5m) long.

Use entire length. Coil excess.

• Connects compressor to engraving system.

10. To connect Tubing B:

• Connect the end without a compression

fitting to Tube B Connector (Fig. A–5).

• Gently snug the nut using a wrench.

• Connect the other end to engraving system.

NOTE: To connect a GraverMax SC or GraverMach,

remove the tube fitting. Install the tube directly into

the Quick Disconnect.

11. Follow the Installation Instructions on the

following page to install the Auxiliary Cooling Fan.

• USING THE RIGHT OIL • This air compressor is

designed to be remarkably quiet and long-lasting.

To accomplish this, it requires special oil inside the

compressor housing. The right oil to use – Silentair

Synthetic Oil (#022-163) – is included with the

compressor. Call GRS to order additional bottles.

• CHANGING OIL • When changing the compressor

oil, warm a cold machine up by running it for several

minutes and then unplug the electric cord. Drain the

tank of water. Remove the Air Intake Filter located in

the compressor head. Tip the compressor over on its

side to drain the used oil from the pump housing into

a suitable container. Properly dispose of used oil.

Stand machine back up on a level surface and refill

to the correct level with fresh Silentair Oil.

For help with this product or to order additional

supplies, please call GRS at 1-800-835-3519 or

620-343-1084 (Monday – Friday, 8 am – 5 pm).

Always add oil before use.

LIT-073

Loading...

Loading...