OPERATION AND

MAINTENANCE OF THE

The GRS Diamond

Power Hone is designed for a

long, useful service life. The spindle is driven

by a smooth belt system at 240 RPM. The

diamond wheel supplied with your hone provides

true diamond performance. This means carbides,

hard metals, ceramics, and other exotic

materials are all within the capability of your

Power Hone. Replacement diamond wheels are

available from GRS Tools in several grits for a

wide range of applications.

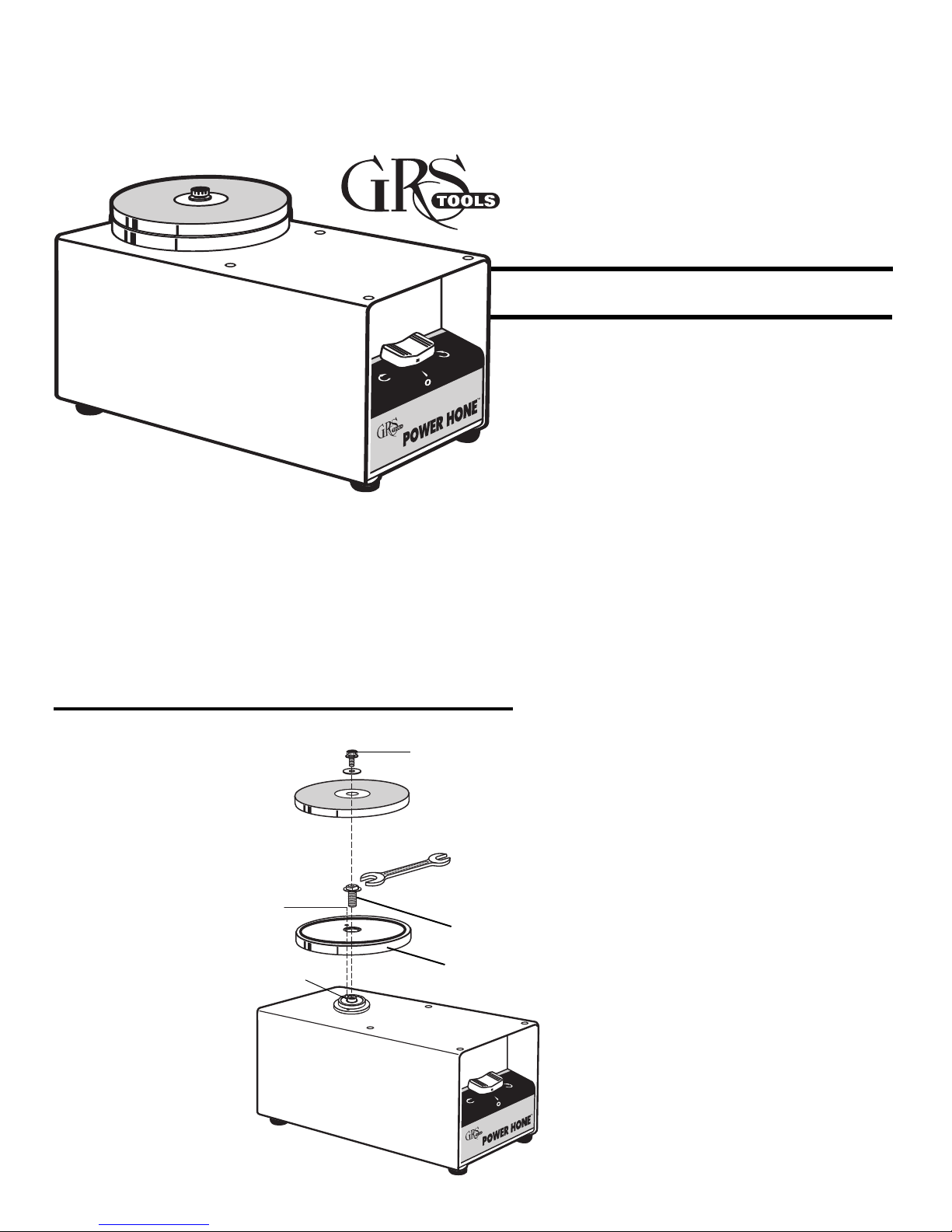

ATTACHING THE

QUICK CHANGE

DRIVE PLATE

FIRST - Align the pin located on

the spindle with hole in the QC

Drive Plate. Make sure plate

rests fully on spindle. Insert

Spindle Nut, tighten snug

with a 3/8" open end wrench.

(Do NOT

machine in, turn it on, check

to see if plate runs true and

does not wobble. If it wobbles,

turn of

the pin aligns with the hole

in QC plate and is seated

properly on spindle.

Place diamond wheel on

top of QC plate and insert

thumb screw/ washer into

spindle nut and finger tighten.

over tighten) Plug

SPINDLE

f, double check that

ALIGN

PIN IN

HOLE

PIN

Lit #193

FINGER

TIGHTEN ONLY

WRECH

3/8"

OPEN

END

SPINDLE

NUT

QC DRIVE

PLATE

POWER

TM

HONE

MODEL B

TOOL SHARPENING

When using the Power Hone, hold the

tool relatively stationary while the rotary

motion of the wheel sharpens the tool.

Sweep the tool slowly across the working

surface of the wheel. This extends wheel

life by using the entire cutting face and

prevents grooving. The Power Hone is

designed mainly for fine tool sharpening

and finishing. Use a bench grinder to rough

shape tool points, then give them a fine

finish on the Power Hone. This will save

time and extend diamond wheel life.

Engraving & Jewelry Tools

The Power Hone was originally

designed to sharpen engraving and jewelry

tools. Sharpening fixtures to hold the

gravers to the precision angles required

for fine engraving tools are available

from GRS Tools. See the “accessories”

section or the GRS Tools catalog for the

sharpening fixtures that are available.

NOTE:

For very delicate work such as heeling

small gravers, try using the diamond wheel

with the machine turned off. This will

prevent removing too much material.

Household & Shop Items

The Power Hone is useful around the

house and shop to sharpen items like;

scissors, knives, craft tools, hobby

tools, chisels, wood and metal lathe

tools, etc. With the ceramic lap wheel

you can even put an edge on a

razor blade.

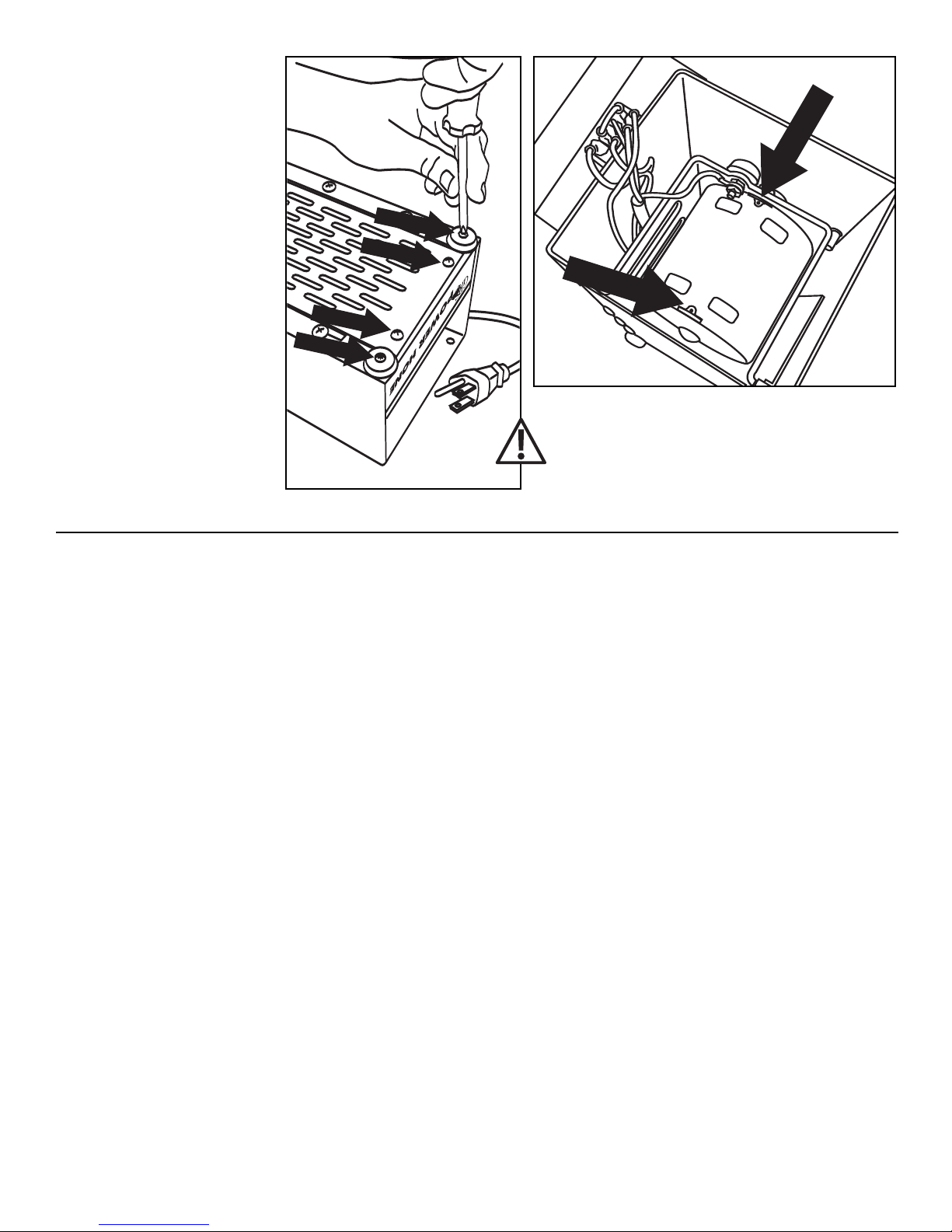

POWER HONE

MAINTENANCE

The GRS Power Hone

is virtually maintenance

free. For normal service,

yearly lubrication is

required. For extremely

heavy service, the motor

should be oiled every 6

months with several drops

of SAE 20 non-detergent

oil. Oil holes for the two

motor bearings are

accessible by removing

the front switch plate. Turn

machine upside down and

remove four screws: two

holding the front rubber

feet and the two between

them (See ILL A).

ILL A

OIL

OIL

Recommended Oil: SAE 20 weight non-detergent

Always unplug machine before

any service is done.

1 011-209 Rubber Foot Assy.

2 011-400 Yellow Common Jumper Assy.

3 011-401 Red Capacitor Lead Assy.

4 011-402 Blue Capacitor Lead Assy.

5 001-976 Bearing Bridge Assy.

6 001-975 Spindle Bearing Assy.

7 001-977 Hone Body

8 002-113 Quick Disconnect Terminal

9 022-568 2 Position Switch

10 022-530 115 Volt AC Motor

11 022-567 Capacitor for Motor

12 DIAMOND WHEEL (SEE BACK PAGE)

13 002-140 Drive Belt

14 001-641 Double Pulley Assy.

15 001-533 115 V Power Cord Assy.

16 022-576 Plastic 1/4-20 Set Screw

17 002-186 Pop Rivet

18 002-064 #8-32 X 1/2 SHCS

19 002-084 O-RIng 3/8 X 1/2 X 1/16

20 022-001 #8-32 X 1/2 SHCS

21 002-247 Washer

22 002-104 #8-32 Nut

23 002-289 #8-32 X 3/4 RHMS

24 002-063 #8 Lock Washer

25 002-568 #8-32 X 1/4 RHMS

26 022-572 10-32 X 1/2 Truss Head

27 002-108 #8-32 X 3/16 SSS

28 002-204 #10-32 Hex Nut

29 002-062 #8-32 X 1/2 RHMS

30 002-110 #8 Pltd. Washer

31 002-065 #10-32 X 3/8 RHMS

32 002-069 #10 Pltd. Washer

33 011-393 Motor Mount Bridge

34 011-396 Vented Bottom Panel

35 011-395 Cord End Panel

36 011-394 Switch End Panel

37 011-398 Spindle Nut

38 011-397 Quick Change Drive Plate

39 001-115 Motor Pulley 1/8"

40 011-399 Power Hone Spindle

41

42

43

44

45

46

47

48

49

50

51

1-289

01

1-403

01

002-137

022-056

002-300

002-279

002-780

002-036

002-770

022-571

1-270 Electrical Warning Label

01

Power Hone Label 115 Volt

Power Hone I.D. Decal

ire Tie

W

Thumbscrew Knob

Cord Retainer

Nylon W

O-Ring

Rubber Mounting Foot

Driv-Lok Pin

4.5" Cooling Fan

asher

230 VOLT UNIT #001-543B

10 022-547 230 Volt 50HZ PH Motor

11 022-578 Capacitor for 230V Motor

15 004-650 230 V Power Cord Assy.

41 011-290 Power Hone Label 230 Volt

45 002-955 Cord Retainer

UNPLUG THE MACHINE

BEFORE OPENING UNIT:

REPLACING THE DRIVE BELTS

These drive belts are made of a special elastic material

designed for this service. Regular belt inspections are

unnecessary. If you were to notice a drag or loss of power

while honing, it may be a broken belt. A spare set of belts is a

good item to have on hand (part #002-140 - two required).

Below are instructions for belt replacement.

Tools Required:

1/8" & 3/32" Hex Wrench, 3/8" Open End Wrench, #2

Phillips Screwdriver and Needle Nose Pliers.

UNPLUG THE MACHINE BEFORE OPENING UNIT:

Turning the switch off is NOT sufficient.

1. Turn the machine upside down and remove the bottom

cover (3 screws) -

2. Remove rear cover by removing the two rubber feet - ILL B.

Note: Power cord will limit cover movement.

ILL A.

ILL B.

ILL A.

3. Lay hone on its side and loosen the set screw for the fan

and pulley -

Pull the spindle out of the bearing. Use one hand to counter

4.

the sideward pull of the rubber belts. IMPORTANT: Make sure

to locate and save the nylon washer that is above the pulley

assembly - ILL D.

Remove the front panel by removing

5.

the front rubber feet. Disconnect the two

center wires on the switch using a pair

of needle nose pliers - ILL E.

Remove the ground (green/yellow stripe)

wire from the motor mount - ILL F.

Loosen the front two motor mount

6.

screws and slide them out of the

assembly using the slots cut in the

hone body Loosen - BUT DO NOT REMOVE the

rear motor mount screws. Slide the

motor mount out the front of the hone

body, guiding the pulley past the

threaded standoffs -

(CONTINUED ON BACK)

ILL C.

ILL G.

ILL H.

ILL

ILL C.

ILL E.

G.

ILL

WASHER

F.

IMPORTANT: DO NOT

LOOSEN THESE BOLTS

THEY HOLD THE LOWER SPINDLE

BUSHING PLATE THAT IS

PRECISION ALIGNED

AT THE FACTORY

www.GrsTools.com

CONTINUED -

7. Replace belts and slide motor pulley assembly

back into the housing, guiding the pulley past the

threaded standoffs - ILL I.

8. Stand the hone on its end and let the motor

mount seat all the way onto the rear mounting

screws. Snug but do not tighten these screws.

Replace the front motor mount screws by sliding

them into place through the slots cut in the hone

body. Tighten all 4 screws -

9. Insert the spindle into the bearing far enough that

you can place the nylon washer on it from inside the

hone body and slip the spindle into it far enough to allow the

fan to be slipped onto the shaft also -

ILL K. Pull the pulley assembly back

ILL J.

ILL L.

ILL I.

10. Slide the spindle all the way into the hone body.

Slide the pulley up and trap the nylon washer

between it and the bushing. With gentle pressure

remove any end play and tighten the set screw of

the pulley onto the flat, milled on the spindle. Slide

the fan up to the pulley and tighten it onto the

spindle also -

WASHER

11. Attach the ground wire to the motor mount and

the two wires to the switch center posts It will not matter if you turn these wires around.

12. Attach the end panels - ILLOand the bottom

panel -

ILL M.

ILL K.

ILLN.

ILL P.

ILL L.

ILL J.

POSITION FLAT

FOR SET SCREWS

N.

ILL

ILL M.

ILL O.

ILL

POWER

TM

HONE

P.

WIRING DIAGRAM

115V 60HZ (230V 50HZ)

DIAMOND WHEEL CARE

Diamond wheels provide long term economy and

performance in abrasive service if used correctly.

Although the diamond is the hardest material known,

the bonding which holds the diamond particles in

place can be damaged. Grooving the wheel by

gouging the bonding material is the biggest error.

The finer the grit, the easier it is to damage the wheel.

The user should not be afraid to apply moderate

pressure while honing, as the wheels are designed

for this. The following tips will provide valuable

information on using diamond wheels.

1. Approach the diamond surface carefully with the

tool. Apply cutting pressure smoothly. Be especially

attentive when first cutting sharp points.

2. Wet the diamond surface with a water soluble

wetting agent sprayed on with a spray bottle.

Occasional spraying to keep surface wet is all

that is required. A wet wheel will cut better, yield

superior tool finishes, and resist loading.

WHEELS AND ACCESSORIES

002-138 5" Dia. - 260 Grit Diamond Wheel

002-055 5" Dia. - 600 Grit Diamond Wheel

002-139 5" Dia. - 1200 Grit Diamond Wheel

002-415 6" Ceramic Lap Wheel

Make your own abrasive /strop wheel.

Simply adhere the desired grit of sandpaper

or leather to these blank wheels. Wheels are

machined to a perfectly flat surface.

002-537 Blank Wheel for Power Hone - 6"

002-129 Blank Wheel for Power Hone - 5"

002-752 Diamond Spray, 1/4 Micron

002-753 Diamond Spray, 1/2 Micron

002-754 Diamond Spray, 1 Micron

002-755 Diamond Spray, 3 Micron

Wheel Wetting Agent Concentrate

001-659 Pkg of 3 - makes 1 gal. per pkg

001-660 Pkg of 12

3. Remove and clean wheel when dirty. Usually

scrubbing with water, mild scouring powder, and

a clean cloth is sufficient. Our diamond wheel

cleaning sticks, #001-783, are designed for a

thorough cleaning. These soft abrasive sticks are

consumed while cleaning the wheel. Proper use

will extend wheel life. We do NOT normally

advise using solvents on wheels. If solvents are

used, NEVER dip or soak wheel in a solvent.

Only wipe top cutting surface and then immediately

wash with soap and water. Keep wheel out of

direct sunlight and away from excessive heat.

Use the entire face of the wheel for cutting.

4.

The 600 grit wheel is recommended for general

5.

use. It provides a good finish with an adequate

material removal rate. Finer grits are normally for

finishing operation after using a coarser wheel or

other abrasive.

001-783 Wheel Cleaning Sticks

001-694 Wheel Storage Rack

001-838 Quick Wheel Change Adapter

001-958 Power Hone Parts Kit

GRAVER SHARPENING FIXTURES

003-100 Standard Graver Sharpening Fixture

003-570 Dual Angle Sharpening Fixture

003-580 QC Sharpening Fixture

Other wheels available, contact your

dealer OR our sales department for

complete information.

1-800-835-3519

Fax: 620-343-9640

Tel: 620-343-1084

e-mail: GRS@GrsT

Or write: GRS Tools

900 Overlander Road

P.O. Box 1153

Emporia, KS 66801 USA

ools.com

www.GrsTools.com

Loading...

Loading...