GRS GRAVERMEISTER GG Operation Maintenance Manual & Parts List

MODEL GG

OPERATION

MAINTENANCE

PARTS LISTING

900 Overlander Road • Emporia, Kansas 66801

The GRAVERMEISTER fullls the need for a machine capable

of allowing rapid but precise cutting and carving of metal, stone,

and wood, as well as many other materials. The precise impact

control feature of the machine also makes it an ideal tool for stone

setting, stippling, matt nishing on jewelry, and stipple engraving

on crystal, etc.

The skills required to properly operate the GRAVERMEISTER,

while not within the ability of everyone, are easily mastered by one

who possesses certain obvious, natural skills.

The GRAVERMEISTER acts on the principle of an air-operated

hammer capable of delivering controlled impacts at speeds from

1600 to 2400 strokes per minute. The speed of the stroke is

varied by positioning an adjusting lever arm. The impact force is

controlled by depressing a foot pedal in much the same way the

gas pedal on a car is operated.

Because of both the large range of adjustments available, and the

precise control possible, delicate cuts can be combined with heavy

material-removal cuts for the desired effect.

To realize the full capability of the GRAVERMEISTER, it is

necessary for you to become totally familiar with both the operation

and proper maintenance of all the components of your machine.

It is also important to become familiar with various proven

techniques for use of the GRAVERMEISTER, and the wide variety

of tools used to produce the various effects desired. Tool geometry

and proper sharpening are as important as skillful use of the

GRAVERMEISTER. The rst section of this manual is intended to

help you avoid many of the difculties others have experienced

in achieving the desired results with the machine. This section is

worthy of frequent review until you master both the machine and

the proper preparation of the tool, or graver, that does the work.

This manual is broken down into the following four sections:

1. TIPS FOR EFFECTIVE USE OF THE GRAVERMEISTER

2. MACHINE OPERATION

3. MAINTENANCE

4. PARTS LISTING

TIPS FOR EFFECTIVE USE

OF THE GRAVERMEISTER

1.1 The GRAVERMEISTER provides an effective, unique method

for performing a variety of functions in many materials. You may

not achieve effective results with the machine at rst. In fact, your

initial attempts may be disappointing or downright discouraging!

Begin by expecting a learning period - whether you have had

experience engraving by another method, or are a novice. This

claim is also made: After the initial learning period, the results and

the satisfaction derived from use of the machine are fantastic!

It takes a little practice, some learning, and perhaps some relearning. It may seem awkward and ineffective at rst - like your

rst attempt to ride a bicycle - remember?

1.2 The easiest and most productive way to learn quickly is

to work with someone who is accomplished in the use of the

GRAVERMEISTER. If this is not possible, we hope the information

contained in these “TIPS” will be helpful. A most valuable and

useful information source is James B. Meek’s book, THE ART OF

ENGRAVING. We recommend it highly.

1.3 Most of the information in this section is directed toward

the task of metal engraving. Even if your purpose for using

the GRAVERMEISTER differs, this information is relevant and

helpful. The engraving of metal, especially steel, is most difcult

and demanding. When the principles of metal engraving are

understood, then other uses are easily acheived. We have never

known a person who could effectively carve a deep relief scene

in steel, who could not easily and effectively… set a stone…

orentine or engrave a ring… matt nish a piece of jewelry…carve

wood… or prepare a fossil.

1.4 Here are some reasons why you may not achieve effective

results with the GRAVERMEISTER at rst:

A. The concept of variable power applied to the tool holder, or

handpiece, seems strange at rst and must be experienced.

B. Coordination of power and tool cutting action with the foot

throttle might feel awkward, but a small amount of practice

makes it natural and automatic.

C. It seems strange and different at rst - but extremely effective

when mastered. Again, remember how easy it was to ride a

bicycle after you learned how. Successful cutting requires just

the right amount of forward pressure on the handpiece. Too

much pressure creates fatigue and impairs tool control. Too little

pressure quickly dulls the tool point.

1.5 Try these techniques - then review results and try them again:

A. Turn the machine ON, hold the handpiece in your hand, and

work the foot throttle to get the feel of the power variation from

light, short strokes to heavy, long strokes. You will begin to

anticipate the foot throttle position for the various power settings

desired.

B. Be sure the tool is seated fully and tight in the handpiece chuck.

(see OPERATING TECHNIQUES on page 9)

C. When cutting or engraving, hold the handpiece as you would

a table knife - not as a pencil. Place your index nger on

the graver, or chisel, as you would on a knife blade to exert

slight downward pressure. You hold it like a pencil only when

stippling, background matting, chipping, etc. (see How to Hold

the Handpiece on page 8)

D. Place the tool cutting point on the work piece before applying

power with the throttle. Attempting to enter the cut with the

power ON and the handpiece stroking will quickly dull the tool

point.

E. Apply power with the throttle only after positioning the tool on

the work. Use slight pressure to keep the tool point moving

forward into the cut. Both tool angle and downward pressure

control depth of cut. Too much downward pressure will tire you,

though.

F. Vary the power input with the throttle to control the speed and

depth of cut. Do not let the cutting action get ahead of your

ability to guide the tool. Stop the throttle action to reposition the

work. Leave the tool point in position in the cut.

G. Overcome the tendency to let the handpiece continue to stroke

when not actually cutting (by failing to manipulate the Throttle).

With practice, control of the Throttle becomes an automatic

response.

H. Use a stable vise, or heavy engraver’s block to hold the work. If

the work is not held solidly, vibration will decrease effectiveness

of the machine power and will more quickly dull or chip the

tool point. The GRS MAGNABLOCK is the most effective

work-holding block, allows the needed rotation of the work,

and was designed for use with the GRAVERMEISTER. (see

OPERATING TECHNIQUES on page 10)

I. Don’t push hard! If your hand becomes tired or cramped, you

aren’t using the power of the machine to do the work - or you

may not have the tool properly sharpened or heeled. (see 1.12

“B” page 4)

2

J. Keep the tool sharp and properly heeled. Sharpen frequently -

before you lose the point entirely. With practice you will begin

to “feel” when the point is beginning to dull. At this time, only a

slight amount of sharpening is necessary to bring it back to the

desired sharpness. Hardness of the material you are cutting will

greatly affect tool life.

K. There should be no noticeable vibration of the tool point in the

cut. If the point is allowed to vibrate in the cut, the point will dull

quickly.

The Important Tool Sharpening Techniques

1.6 While the GRAVERMEISTER is a tremendous aid in solving

the most difcult task in engraving or carving, it does not help

in another important area - the task of tool sharpening. In fact, it

perhaps even emphasized that problem. You will be cutting faster

and deeper, and point geometry and condition will soon become

apparent. Be prepared to go through a learning period in the tool

sharpening task. Here too, a few minutes spent with someone who

knows how to sharpen tools properly can save hours of frustrating

experimentation. A word of caution though! BE SURE YOUR

ADVISOR REALLY KNOWS.

1.7 If a session with someone who knows how is not possible,

read the following information - and practice. In the end, you must

learn an effective technique so that when you put the tool into the

work, you know the result will be as you planned.

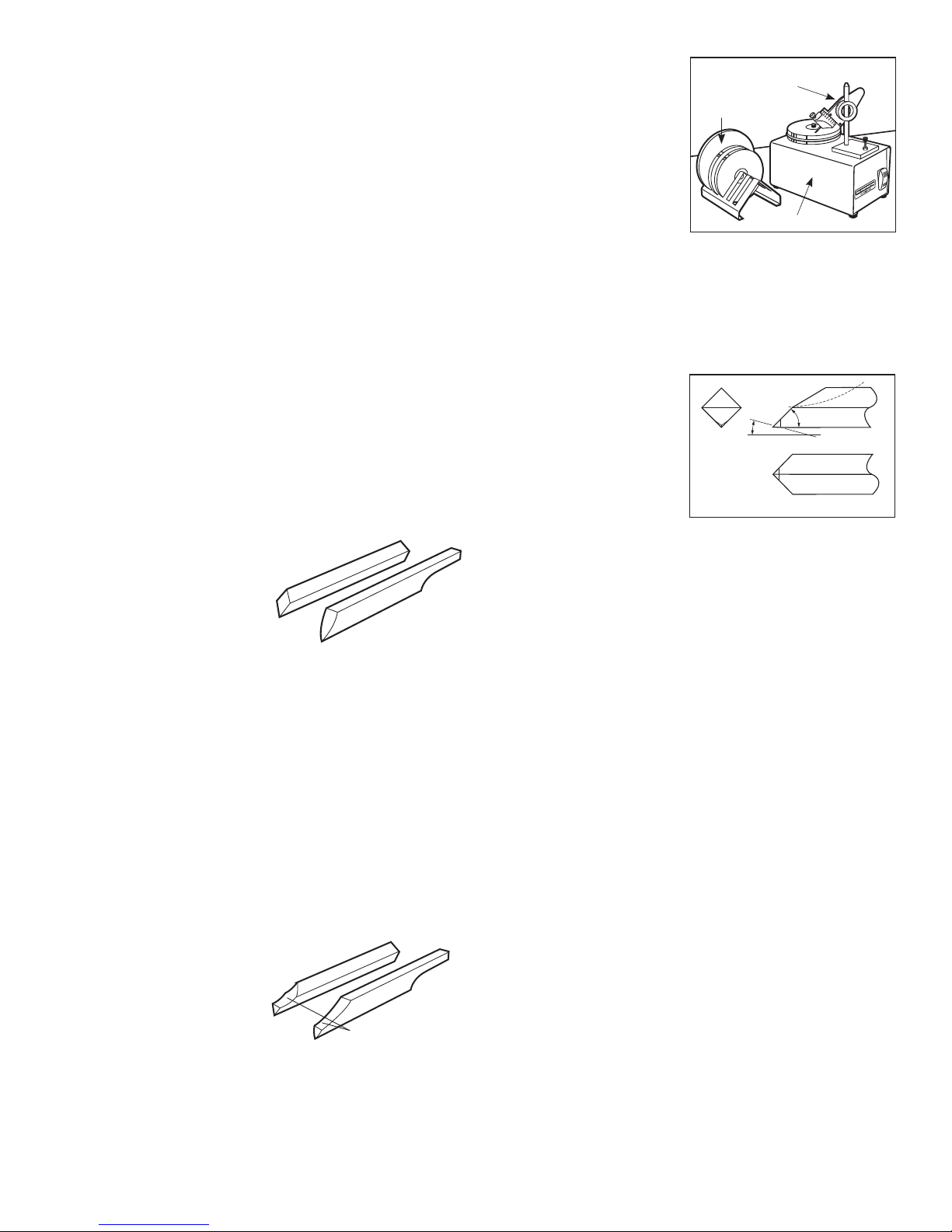

1.8 Various types of gravers

are used for different types and

styles of cutting, but the square

and point (Onglette) are the most

important in metal cutting, and

once you master the sharpening

techniques for them, you should

have little difculty with others.

SQUARE

POINT or ONGLETTE

consistent results.

A. The GRS Power Hone is a

valuable aid. Since the stone

or lap rotates, it is necessary

DUAL ANGLE

SHARPENING FIXTURE

CERAMIC LAP &

DIAMOND WHEELS

only to hold the graver at the

correct angle. You may leave

the graver in the Handpiece

as the added length provides

a convenient handle.

B. The combination of the

GRS Power Hone and

GRS POWER HONE

the Sharpening Fixture

provides the ideal sharpening system. The Sharpening Fixture

is designed specically for use with the Power Hone. With

this combination, you can sharpen repeatedly with consistent

results time after time. It is easy to learn - you merely follow

the instructions. A square graver can also be ‘heeled” with the

xture.

1.13 For good results, the

graver must be heeled, or

set-up. This task takes some

experimentation and practice

to produce satisfactory results.

FRONT

VIEW

SIDE

VIEW

45

15

HEEL ANGLE

The nish of the engraved cut is

greatly affected by the nish of

the graver heel. For a bright cut,

BOTTOM

VIEW

nish the heel using polishing

paper or a ceramic lap. Here is what the heel accomplishes:

A. It raises the working angle of the graver to a convenient height

from the work serface.

B. It provides depth control.

C. It gives clearance when working on irregular surfaces, and

prevents the bottom surface of the graver from dragging on the

edges of the cut when making curved cuts.

D. It improves the quality and appearance of the cut.

1.9 In the book, THE ART OF ENGRAVING, Mr. Meek’s excellent

illustration and discussion of the importance of proper tool

sharpening technique and geometry is especially helpful. He

relates to this subject in chapters 2, 4 and 7. This subject is of

utmost importance, and this reference material is most helpful.

1.10 Gravers should be ground on the face rst. The approximate

45-degree angle should be maintained. Keep the graver in the

handpiece for free hand sharpening. First, this will save time.

Second, the additional length provided is an aid in maintaining the

proper angle on the stone. It requires a considerable amount of

care and practice to maintain the proper angle while sweeping the

tool point across the stone.

1.11 A common error in

sharpening is the tendency

to increase the angle of the

face gradually each time the

graver is resharpened. To help

prevent this and to reduce the

sharpening time, it is helpful

to remove some of the excess

REMOVED

BY GRINDING

material near the point with a

bench grinder.

1.12 GRS sharpening equipment is a most valuable aid in tool

sharpening. It is especially helpful for beginners in the art of

engraving, and has been readily accepted by accomplished

engravers who have found that it is faster and produces more

Usually a heel angle of 15 degrees is used. Only a small amount of

material need be removed. A few light strokes on a ne, hard stone

is sufcient. Don’t be confused by the tremendous number and

variety of gravers available in the supply catalogs; virtually all work

can be accomplished with a small variety of points.

Tips for Practice Sessions

1.14 Start with simple cuts. Using a square or point (Onglette)

graver, begin by cutting straight lines - then simple curves. Practice

depth control, cutting both ne shallow lines, and deep cuts. It is

good practice to master the technique of varying the depth of cut

to produce a pleasing shaded effect. These practice sessions will

help you acquire the necessary skills in both tool control and tool

sharpening technique.

1.15 After you have mastered the basic skill, you can concentrate

on learning the more difcult and intricate designs. With condence

in your ability to control the tool, you will be able to execute

progressively more difcult patterns with varying depth of cut and

subtle shading - and nally on curved or irregular surfaces.

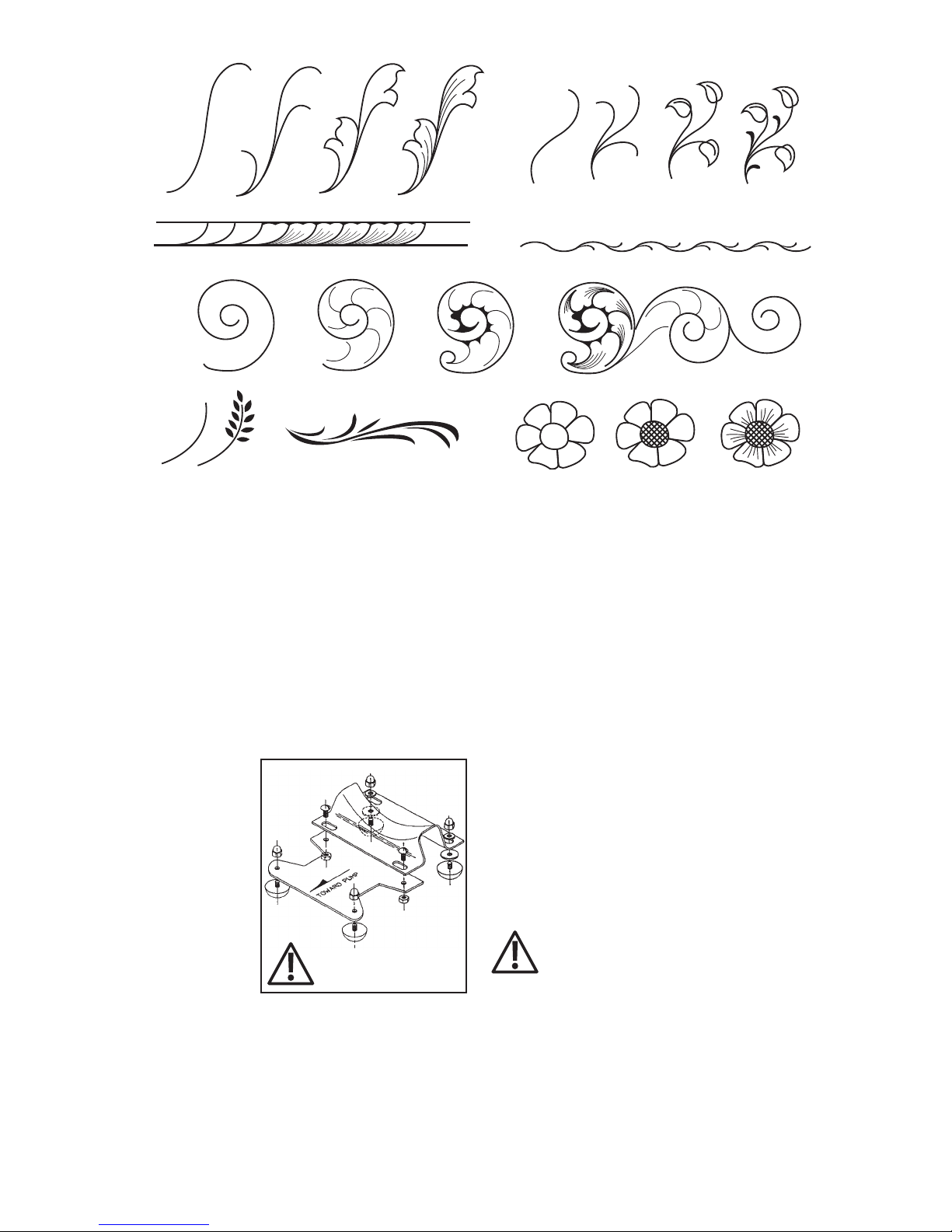

1.16 Simple exercises like those sketched on the top of the next

page are good beginning practice designs as they are relatively

simple. It is easy to determine the progression of the cuts to

generate the design, and they do not require a large amount of

rotation or manipulation of the work piece. This type of design is

also good practice for the beginning woodcarver.

3

MACHINE OPERATION

1

2

3

4

5

6

7

8

1

2

3

4

5

The operation section is divided into the following ve parts:

2.1 MACHINE STARTUP

2.2 HANDPIECE

2.3 THROTTLE

2.4 STROKE SPEED CONTROL

2.5 PUMP

2.1 Machine Startup

The GRAVERMEISTER has been completely checked out and set

for proper operation at the factory. It is shipped with the throttle,

handpiece, and accessories disassembled and packed separately

in the carton. The throttle hose is connected to the proper location

on the machine. To unpack:

A. Remove the machine from

the shipping carton.

B. Install the Foot Support

Assembly on the Pump

Mount. (Refer to instructions

on the foot support package

or the illustration below for

proper installation).

C. Connect the hose already

attached to the machine to

the foot throttle. Connect

the handpiece hose, the

shorter one, to the machine

valve assembly. Do not

interchange these hoses.

The handpiece hose must be shorter than the throttle hose for

proper operation.

D. The machine is now ready for operation, but please familiarize

yourself with all sections of the manual, and keep it handy for

future reference. It is valuable aid for successful use of the

GRAVERMEISTER.

2.2 Handpiece

The GRAVERMEISTER Handpiece is that portion of the machine

FOOT SUPPORT

ASSY. #002-024

WARNING: NEVER OIL

the non-lubricated pump.

It will cause unit to fail.

which acts as an air-driven hammer, and is used to hold and

provide power to the tool. It consists of the Chuck and Body

Assembly, Piston, Spring, and Air Connector. Currently ve

handpieces are available for use with the GRAVERMEISTER, and

they are easily interchanged.

A. The Handpieces are designed to work with a wide variety of

gravers, liners, wood chisels, chippers, etc. GRS gravers t

all GRS handpieces. Most other brand gravers will need to be

altered to t the handpiece chuck. Normal tool shank diameter

for each handpiece is 1/8 inch.

B. The Piston is the stroking element. Its reciprocating action

delivers the impact to the tool.

C. The Spring holds the Piston in its proper position in the

Handpiece body and is an important element in the stoke

control characteristics of the machine.

D. Only one handpiece can be connected to the Gravermeister

at a time. GRS offers a Quick Disconnect Kit (#004-615)

that allows you to switch from one handpiece to another in

seconds.

HOW TO HOLD THE HANDPIECE

Normally, you should hold the handpiece like a table knife, not like

a pencil. A few exceptions are hammering and stippling. Resist the

urge to grip the handpiece tightly. Train yourself to hold it as softly

as you can.

IMPORTANT

Gravermeister handpieces have an internal piston that

creates some vibration during operation. A few people are more

sensitive to this hand vibration than others. Should the user

experience hand or nger numbing, excessive tingling, pain,

etc. the use of this tool should be discontinued. There are many

variables and several steps can be taken to reduce the effect of

this vibration.

Operator Tips that lessen hand fatigue and vibration:

1. Hold the handpiece as loosely as possible. Studies done

on a variety of power tools indicate that strong tool gripping

signicantly aggravates hand vibration problems.

4

Loading...

Loading...