GRS Airtact Operation And Maintenance Manual

& Accessories

OPERATION AND MAINTENANCE MANUAL

WELCOME TO THE WORLD OF AIRTACT!

This is the most versatile control system ever developed with an

expandable range of actuation. The heart of the Airtact system is

the air control unit where the throttle command is processed. This

simple and robust system requires dry, clean, oil-free air, and

a GraverMate, GraverMax, GraverMax SC, or GraverMach as

engraving system. Hook up is easy; just follow these step-by-step

instructions and the instructions provided with the connection kit if

required for your machine.

TERMS USED IN THESE INSTRUCTIONS

Control box or air control unit: Airtact and Touch Elements

GETTING STARTED

Decide on a location for the control box. This needs to be a

place where you can easily access the front of the unit for hose

connections and air adjustments. If you are connecting your

Airtact to a GraverMax or GraverMate, an additional kit will be

required.

#004-971 GraverMax A/T Filter Hook Up Kit

#004-972 GraverMate A/T Filter Hook Up Kit

NOTE: The black hose (#044-136) is for connecting the HIGH

pressure air coming from your compressor. The clear hose

(#044-135) is for connecting LOWER pressure air from the

“THROTTLE CONNECTION” port to the Airtact.

Turn off the air supply to your engraving system and bleed off

any remaining air in the line. Depending on the engraving system

that will be used, install the hoses as shown in Fig. 1 or Fig. 2.

Make sure to press them into the quick connect fittings all the

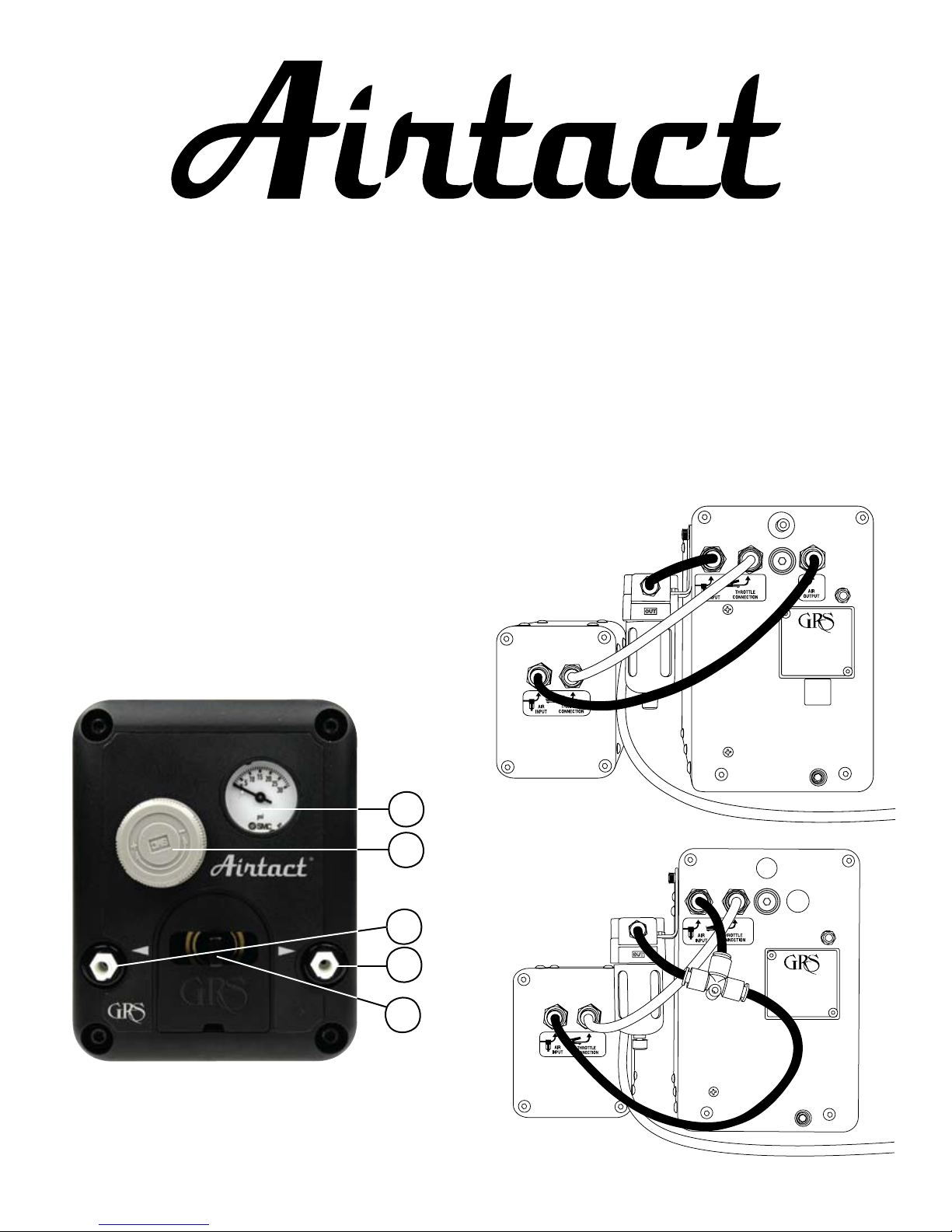

1 Airtact pressure gauge

2 Airtact pressure regulator

3 Twist-lock control port #1

4 Twist-lock control port #2

5 Control port switch

1

Fig. 1: GraverMach to Airtact Hook-up

2

3

4

5

Fig. 2: GraverMax SC & older GraverMach to Airtact Hook-up

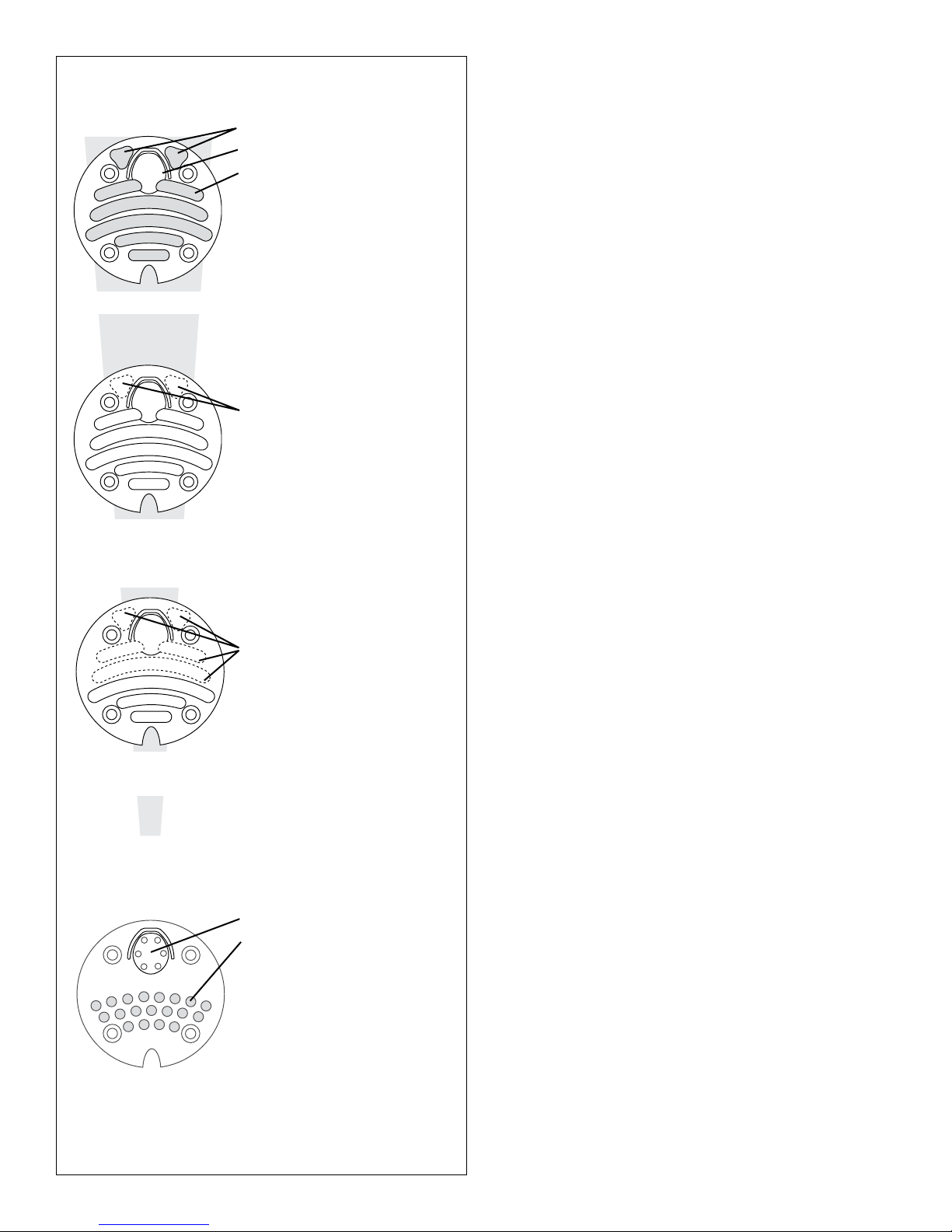

Fig. 3: Palm Pad Modifications

PALM PAD C2

Raised Bumps

Control Flap

Raised Ridges

Palm Pad C2 Style

If you find that you would like

a more sensitive touch the

raised ridges can be reduced

or removed by using an razor

knife or grinding with a flexshaft,

dremel, NSK E-Max, etc.

way. NOTE: When installing hoses, trim excess length. NOTE: It is

not possible to use the existing foot throttle with the Airtact system.

The original foot throttle must be completely disconnected for the

Airtact to work properly. If foot control is desired, use the FootPod

Touch Element.

#004-956 FootPod Touch Element Kit F1

You are now ready to hook up the touch element of your choice.

#004-952 Palm Touch Element Kit Monarch MI

#004-952-SS Palm Touch Element Kit Monarch MI Stainless Steel

#004-953 Palm Touch Element Kit 901 N1

#004-953-SS Palm Touch Element Kit 901 N1 Stainless Steel

#004-954 Thumb/Finger Touch Element Kit Monarch TM1

#004-955 Thumb/Finger Touch Element Kit 901 TN1

Connect the larger handpiece hose to the normal handpiece

air supply port on the GraverMach/MaxSC/Max/Mate. Take the

smaller hose and gently twist the hose end connector knob 1/2

turn clockwise until it stops to the left or right port on the front

of the Airtact. Turn the air supply pressure back on and check

carefully for leaks.

MODERATE

SENSITIVITY

PALM PAD C2

HIGHER SENSITIVITY

PALM PAD C2

Reduce or Remove

Moderate Sensitivity

(more sensitive)

Palm Pad C2 Style

Reduce or remove the raised

ridges that are illustrated with

a dotted line. This will give you

a more sensitive handpiece that

will allow for less hand force.

Reduce or Remove

Higher Sensitivity

(even more sensitive)

Palm Pad Style

Reduce or remove the raised

ridges that are illustrated with

a dotted line. This will give you

a very sensitive handpiece with

even less hand force.

AIR PRESSURE ADJUSTMENTS

Begin by turning the power switch on to the engraving system

and adjust the strokes per minute (SPM) knob to 2300 or 2400

SPM. On the GraverMax/SC/Mach, switch the handpiece selector

knob to the handpiece you wish to use.

The Airtact control unit has a regulator and gauge on the face

located above the paddle switch. This controls how much power

you want for the handpiece to have. The lower the pressure the

lighter the handpiece will stroke, and the more air pressure, up to

12psi (0.8 bar), the harder it strokes.

1. On the Airtact unit, move the paddle switch in the direction of

the handpiece connection you wish to use and increase the

Airtact air pressure to 12 psi (0.8 bar).

2. On the GraverMach/MaxSC/Max/Mate back the air pressure

off at the regulator knob by turning it counter-clockwise

until the gauge shows 5 psi (0.4 bar). Hold the handpiece

vertically next to your ear and slowly begin to increase the

air pressure by turning the regulator knob clockwise. You will

feel the handpiece begin to buzz, then vibrate, and knock

lightly. When the knocking stops on a GraverMach or SC, your

handpiece is considered “tuned.”

NOTE: If you are using a Generation 1 GraverMax or GraverMate,

add 2 psi (0.1bar) to the gauge reading where the handpiece

stops knocking.

Control Flap

Raised Bumps

Palm Pad D1 Style

D1 is overall more sensitive than

C2. To reduce its sensitivity,

reduce the thickness of the

control flap by using a razor

knife or grinding with a flexshaft,

PALM PAD D1

dremel, NSK E-Max, etc.

on the outside (top) surface.

Check for proper handpiece operation by placing the paddle

switch in the center position. This should immediately give full

handpiece power if your connections are correct, if not, find the

problem and correct. NOTE: The center paddle switch position

will also give you an automatic stroking feature that is designed

for stippling or other operations where multiple hits are desired

without the need for control inputs.

SUGGESTIONS

Airtact Touch Element:

• Atapproximately12psi,theAirtactwillgivefullpowerrange

for any handpiece. Less than 12 psi, you will have reduced

power. This can be very useful for shading because you can

lessen the pressure (try 4 or 5 psi) to limit the power for really

fine control. ALWAYS BE AWARE THAT AT LESS THAN 12

PSI you will NOT have full power.

• SwitchingtheGraverMach/MaxSC/Max/Matehandpiece

selector does NOT switch the handpieces connected to the

Loading...

Loading...