GRS 003-570 Instructions Manual

Dual Angle Sharpening Fixture

INSTRUCTIONS • 003-570

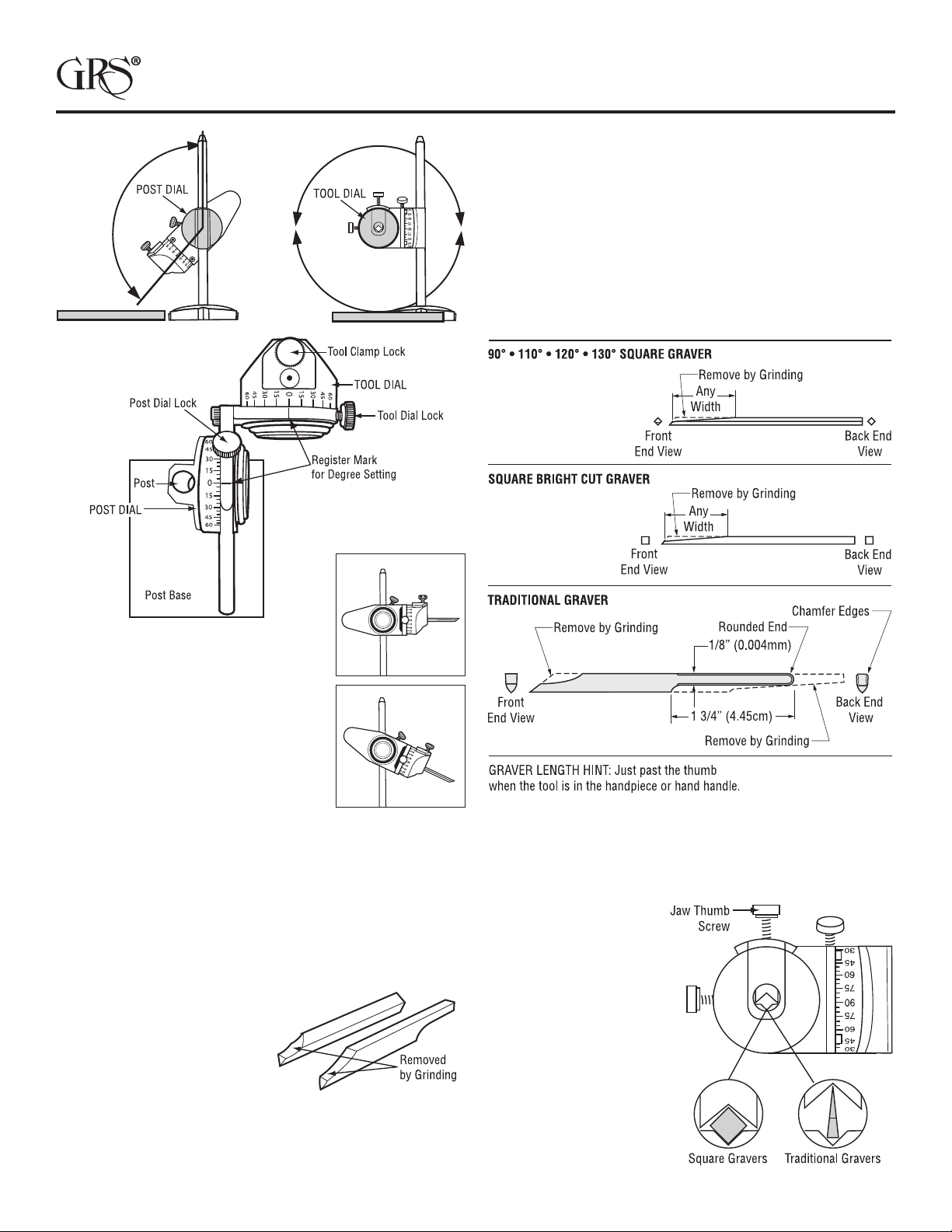

FIG. 1

WORN. A face mask should also be worn to prevent breathing

wheel dust.

Tools can easily be damaged while grinding. Do not let the tool

tip get hot and burn. Burning means the tool metal will turn blue,

which takes the temper or hardness out of the tool and it will not

hold a cutting edge. To avoid burning the tool, take your time and

do not press too hard against the wheel. Have a container of

water by your grinder and frequently dip the tool BEFORE it gets

warm in your hand.

SUGGESTIONS ON HOW TO PRE-SHAPE THE GRAVER

FIG. 5

FIG. 2

Set both dials at 0° to the register marks

(FIG. 1). Slide the xture onto the base post

and hold it out in front of you. Position the

xture so that it is square to your body and

the tool being sharpened is pointing “straight”

away from you (FIG. 2). As you change this

angle, the position of the xture will rotate

down (FIG. 3).

The TOOL DIAL can turn left or right 360°, but always use one

of the 0° as a reference point. After grinding the face angle, turn

the tool over (180°) by rotating from reference point 0° to new

reference point 0°. Now you can set the angles desired, left and

right, from the new 0° reference point.

GETTING THE GRAVER READY TO SHARPEN

Most tools need some type of preparation before sharpening.

Shank modication to t a hand handle or power handpiece,

or just shortened to t your personal needs. GRS Tools offers

gravers that are already modied

and ready to be sharpened.

Removal of excess metal from the

top/front of the tool tip makes it

quicker and easier to re-sharpen

(FIG. 4). It also allows a better

view of the tip when in use. You will need to use a bench grinder

or a Power Hone with a 260 grit wheel. Rough grind with a bench

grinder rst, then true the surface with the Power Hone if you

desire. When using a bench grinder, eye protection MUST BE

FIG. 4

FIG. 3

MOUNTING A TOOL IN THE TOOL DIAL

Open and close the jaws by turning the Jaw Thumb Screw. The

illustration below shows the correct placement for holding square

and traditional gravers. Properly position the graver squarely in

the jaws and tighten snugly

with your ngers, but do not

overtighten. A secure hold

prevents tool movement.

HINT: Use the 0° by the

Jaw Thumb Screw when

sharpening the FACE

ANGLE. Lock the dial into

position before inserting a

tool. When inserting the tool,

make sure its face angle is

facing down, away from the

Jaw Thumb Screw.

FIG. 6

Page 1 of 4 LIT-181

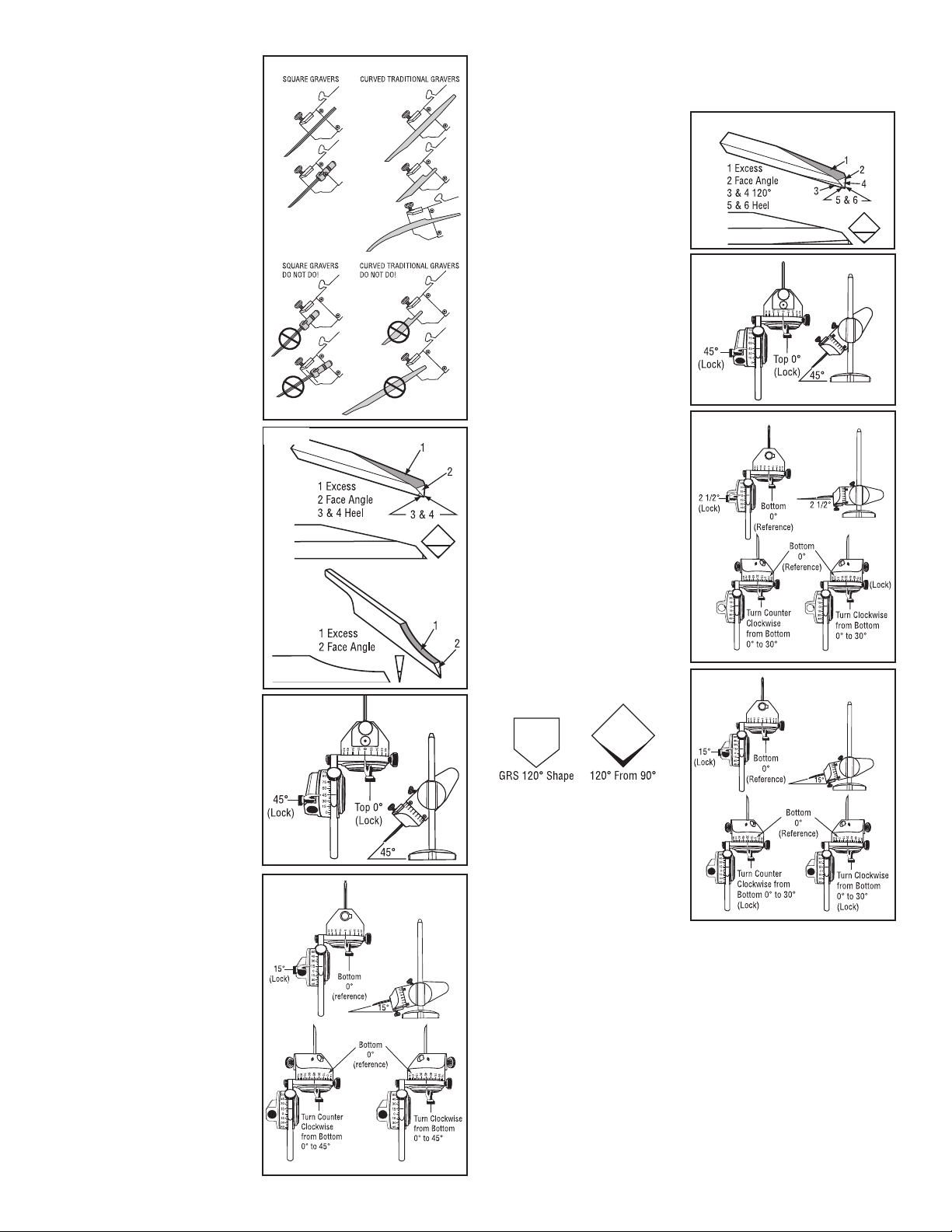

Square Gravers in Quick

Change holders (FIG. 7), must

be inserted into the jaws from

the back. DO NOT hold tool

by the Quick Change holder in

the jaw.

Hold Curved Traditional

Graver (FIG. 7) as shown.

NOTE: Because of the tool’s

curve, you will need to estimate

the angle needed to set the face

angle.

90 DEGREE SQUARE GRAVER

With the graver’s excess metal

removed — see getting the

graver ready to sharpen (FIG. 8)

— you are ready to make the

face angle (FIG. 9). With the tool

mounted, face angle down, and

the TOOL DIAL locked at 0°,

set the POST DIAL at 45°. This

is just an example, you may

change face angles to t your

needs. If you are using a square

blank graver, start your face

angle by using a 260 grit wheel

on the Power Hone. Finish the

face surface by stepping up to a

600 grit, then a 1200 grit. Once

you have nished the face, you

will only need to take these

steps again if the tip becomes

severely damaged. If you’re not

using a Power Hone, shape the

face as close as possible on a

bench grinder and nish with

this xture and a stone.

A 15° heel will be used for this

example (FIG. 10). Set the

POST DIAL at 15° and lock it.

Rotate the TOOL DIAL halfway

around or 180°, go from the top

0° setting until the bottom 0°

setting is on top. From the new

0°, tool pointing away from

you, turn dial clockwise, until it

reads 45° and lock. Sharpen

on a ceramic wheel, making

the heel about 1/32" long. If

you heel on a 1200 grit wheel,

use the xture and stroke the

graver a couple times without

turning the Power Hone on.

After forming this heel, turn the

dial counterclockwise, going

past the 0° until it reads 45° and

lock in position. Finish the heel

on this side using the same

method. It is important that both

heels are the same size and

symmetrical.

LIT-181 Page 2 of 4

FIG. 7

FIG. 8

FIG. 9

FIG. 10

Face Angle

MAKING A 120 DEGREE GRAVER FROM A SQUARE GRAVER

Refer to “SHARPENING A 90° GRAVER”, for details. With the

graver’s excess metal removed (FIG. 11) mount the tool face angle

down in the TOOL DIAL and

lock at 0°. Set the POST DIAL at

FIG. 11

45° (or desired face angle) and

grind the face (FIG. 12). Turning

the TOOL DIAL around 180° to

reference 0° and change the

POST DIAL to 2-1/2° (halfway

between 0° and 5°) and lock

in position. From reference 0°,

rotate dial clockwise to 30° and

FIG. 12

grind angle (FIG. 13). Make

this angle grind about 1/2" long.

Rotate TOOL DIAL counter

clockwise past reference 0°

to 30°, lock and grind angle

(FIG. 13). Make this side the

same length as the other side

(FIG. 13). TIP: To measure how

much you are grinding off, time

it or count while it’s grinding. It

FIG. 13

may be necessary to regrind

the other side to make both

sides equal. But it is important

that the sides are equal and

symmetrical.

Make the heel (FIG. 14) by

changing the POST DIAL to

15° (or desired heel angle).

The TOOL DIAL is already at

30° left, so make this heel and

rotate TOOL DIAL right, past

reference 0° to 30° and make

the other heel. The 120° graver

is complete.

FIG. 14

HOW TO MAKE A 110 DEGREE

& 130 DEGREE OUT OF A

SQUARE GRAVER

Basically, making a 110° or 130°

graver is the same as making

a 120° graver, just change the

TOOL DIAL angle for different

side angles.

110° graver (FIG. 13): The side angle POST DIAL is set at 2-1/2°,

but set the TOOL DIAL from reference 0° left 35° and make one

side, then right 35° from reference 0° to make the other side.

130° graver (FIG. 13): The side angle POST DIAL is set at 2-1/2°,

but set the TOOL DIAL from reference 0° left 25° and make one

side, then right 25° from reference 0° to make the other side.

How do you gure this angle setting? The sides of a 90° tool

mounted in a xture, dial set at 0°, are 45° from the wheel. Adding

all angles: 45° + 45° + 90° = 180° (a at plane). Using 180° minus

(desired tool angle) let’s say, 110° = 70°. There are two sides to

the tool, so you divide 70° by 2 which equals 35°, the setting to

make a 110° graver.

Loading...

Loading...