INSTRUCTION MANUAL S1230, Rev D

Air Operated Grease Ratio Pumps 50:1

GP1, GP2, GP3

Congratulations on purchase of this World Class Air Operated Grease Ratio Pump !

• World-class Industrial High Pressure Grease pump with guaranteed performance & hassle free operation

• Pump dispenses Grease at pressures upto 50 times the Air inlet pressure

• Designed to work in tough conditions- Ideal for use in Industry, workshop, farm, construction or as part of the Mobile Grease system

• All metal construction, fully CNC machined with hardened wear resistant moving parts

• Reciprocating piston operated 2.5” (63 mm) dia. Air Motor

• Fitted with strainer at suction tube inlet for clean grease to the bearing

• Supplied in two choices :-

- Pump Only

- Pump with Drum Cover, Rubber Lined Follower Plate, High Pressure Grease Hose, Z swivel & Professional Grease Control Valve

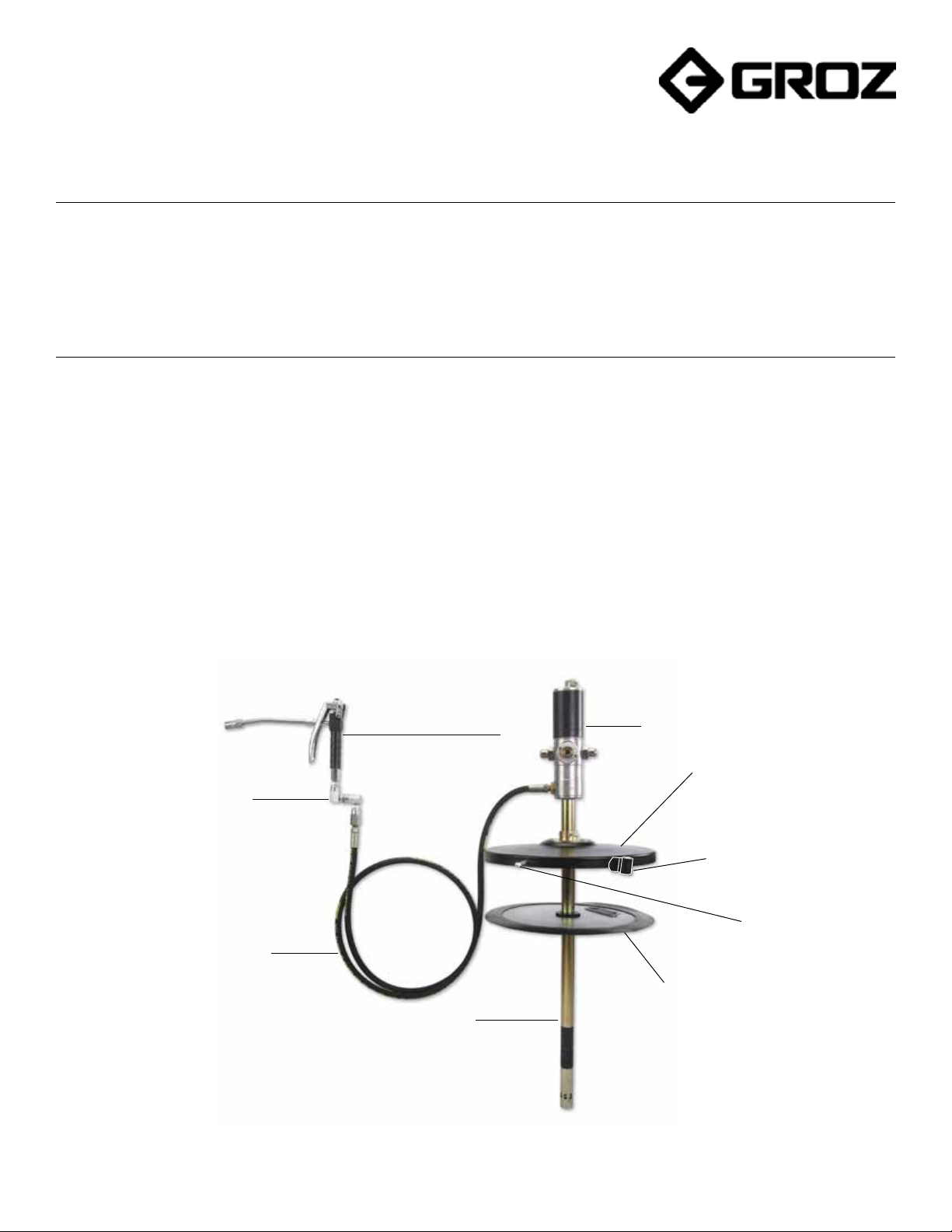

Z Swivel

High Pressure Rubber Hose

Grease Control Valve

Suction Tube

Fig.1

Air Motor Assembly

Drum Cover

Nozzle Holder

Cover Screws

Follower Plate

1

Contents Page No.

PUMP CONSTITUENTS ..................................................................................................

PUMP CONSTRUCTION .................................................................................................

WORKING OF PUMP .....................................................................................................

INSTALLATION ...............................................................................................................

PUMP OPERATION .........................................................................................................

MAINTENANCE & REPAIR .............................................................................................

• Pumping Section Kit Replacement ............................................................................

• Drive Section Kit Replacement. ................................................................................

EXPLODED VIEW ............................................................................................................

3

3

4

5

6

7-11

7-8

9-11

12

PARTS LIST .....................................................................................................................

TROUBLESHOOTING ........................................................................................................

REPLACEMENT & SERVICE PARTS PROGRAM FOR GREASE RATIO PUMP .................

• Replacement Parts Program .....................................................................................

• Service Parts Program (Pumping Section Kit - KIT/BTM/RP-G) ...............................

• Service Parts Program (Drive Section Kit - KIT/TP/RP-G) .........................................

SPECIFICATIONS ............................................................................................................

WARNINGS ....................................................................................................................

13-14

15

16-18

16

17

18

19

19

2

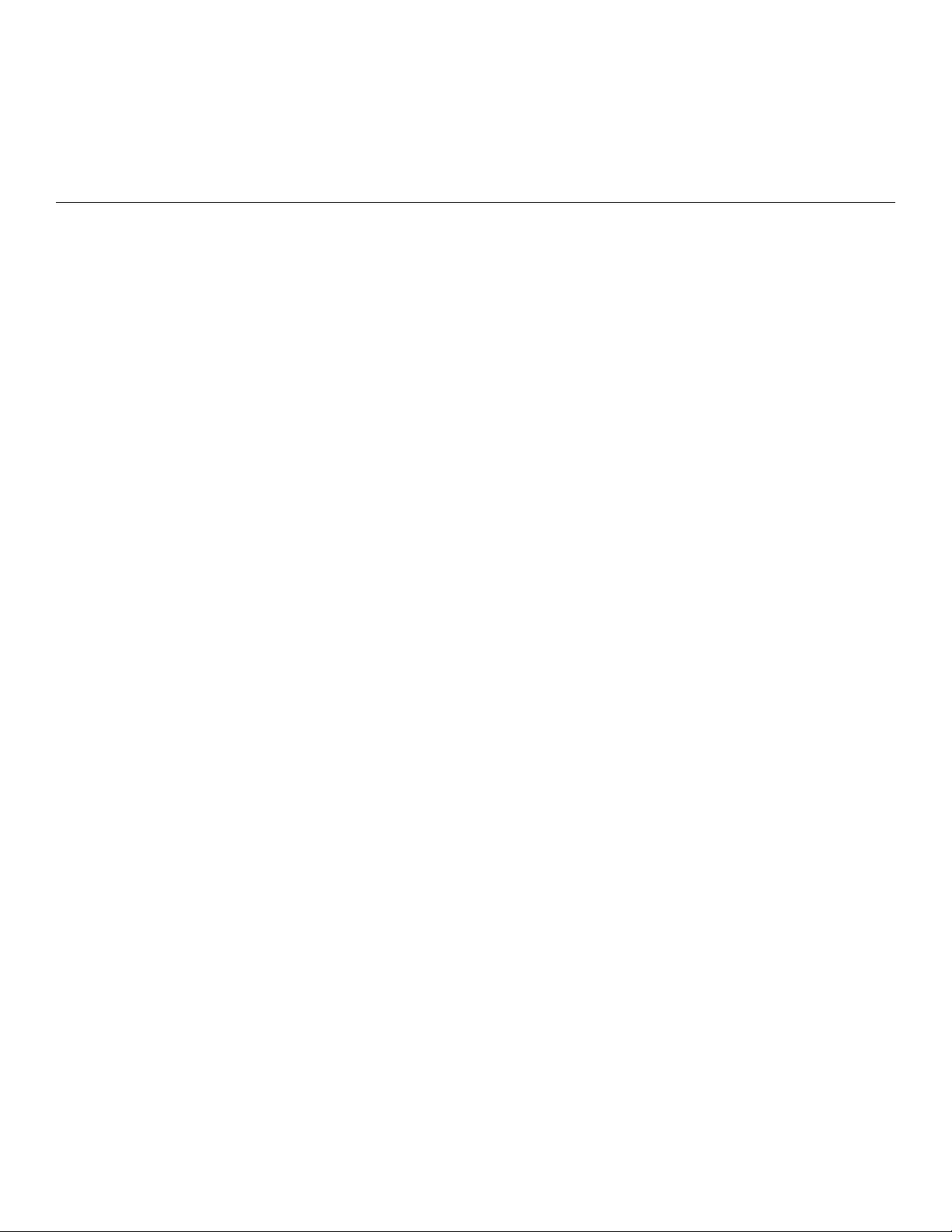

PUMP CONSTITUENTS

1. Grease Pump Assembly

2

3

1

2. Drum Cover with Thumb Screws

3. Rubber Lined Follower Plate

4. High pressure Rubber Hose

5. Professional Grease Control Valve with Z Swivel

Fig. 2

PUMP CONSTRUCTION

4

Fig. 3

Drive Section

The pump is made up of two sections as given below :-

• Drive section :- It consists of an Air Motor Assembly driven

• Pumping Section :- It consists of a pump in which a piston

5

by compressed air. The piston diameter of the air motor is

2.5” / 63 mm. The motor consists of an air cylinder with

piston and one reciprocal valve with a nylon slider. The valve

directs the compressed air alternately to the top or bottom

of the piston, thus producing a reciprocating motion of the

piston rod.

lifts the grease through Non Return Valves by reciprocating

inside the pump cylinder. The grease is discharged with

pressure (from the outlet located at bottom of Air Motor) into

the delivery hose.

Pumping Section

NOTE

AIR MOTOR of these pumps starts automatically when the

Grease Control Valve is opened. When the valve is closed, Air

Motor builds up a back-pressure and stops operating the pumping

section.

PRESSURE RATIO of the pump states the ratio of the output

grease pressure to the incoming air pressure. When the pressure

ratio is 50:1, we achieve an output grease pressure up to 7500 PSI

(500 BAR) when the incoming air pressure is 150 PSI (10 BAR ).

3

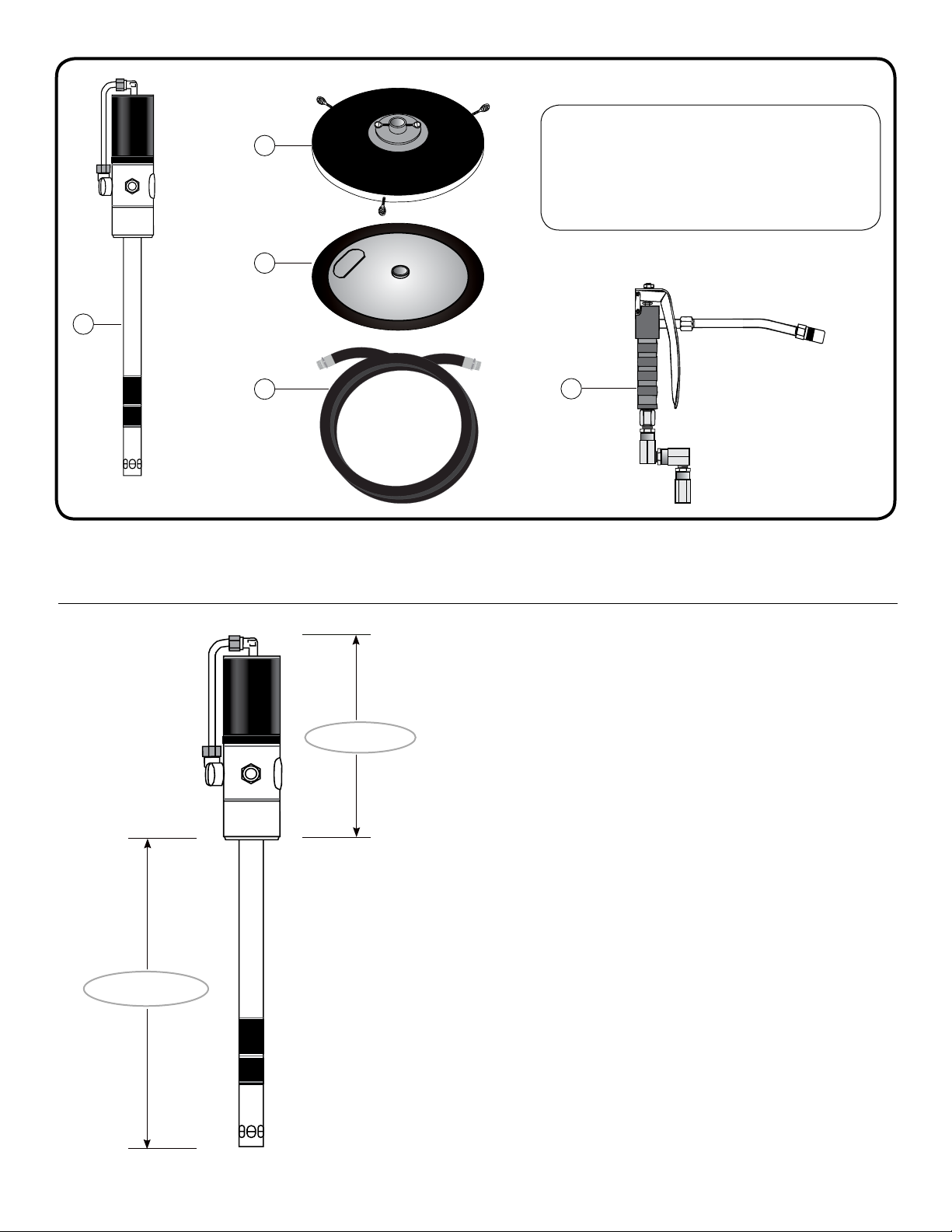

WORKING OF PUMP

UPSTROKE DOWNSTROKE

C

A

I

Fig. 4 Fig. 5

C

B

E

G

F

H

A

I

B

G

F

H

E

J

D

UPSTROKE -

When Grease Control Valve is opened, compressed air enters

at arrow A and passes through passage B to the underside of

the Piston C, driving the Piston C and Piston Rod D upwards.

The air above the Piston is evacuated through passage E,

past the Slider Valve F and out at arrow G.

The Piston approaches top dead centre and Piston Rod D

makes contact with the Slider Rod H. Now the Slider Rod H

starts moving up with the Piston Rod D.

The air motor repeats Upstroke & Downstroke in continuous cycle to produce a reciprocating motion, driven

by compressed air. This motion is transferred via a connecting rod to the piston in the Pumping Section.

During every upstroke, non return valves (with spring & ball check) get opened & the piston lifts the grease.

During every downstroke, non return valves get closed & the piston discharges grease from the outlet valve.

Closing the Grease Control Valve shuts off the air motor & pump stops dispensing grease.

D

J

DOWNSTROKE -

The incoming air is now led via passage E to the upper side

of Piston C, driving it and the Piston Rod D downwards.

The air under the Piston C is evacuated through passage B,

past the Slider Valve F and out at arrow G.

The Piston approaches bottom dead centre and Piston rod

D makes contact with the Slider Rod H. When Slider Rod H

passes its centre position, the Pusher Spring I and Pusher

Button J snap it over to its lower position.

4

INSTALLATION

NOTE

An FRL (Filter-Regulator-Lubricator) unit must be used in the Air supply, before it is connected to the pump. Set the regulator to 6 BAR

(90 PSI) or any required inlet pressure, but never more than 150 PSI (10 BAR) or less than 30 PSI (2 BAR).

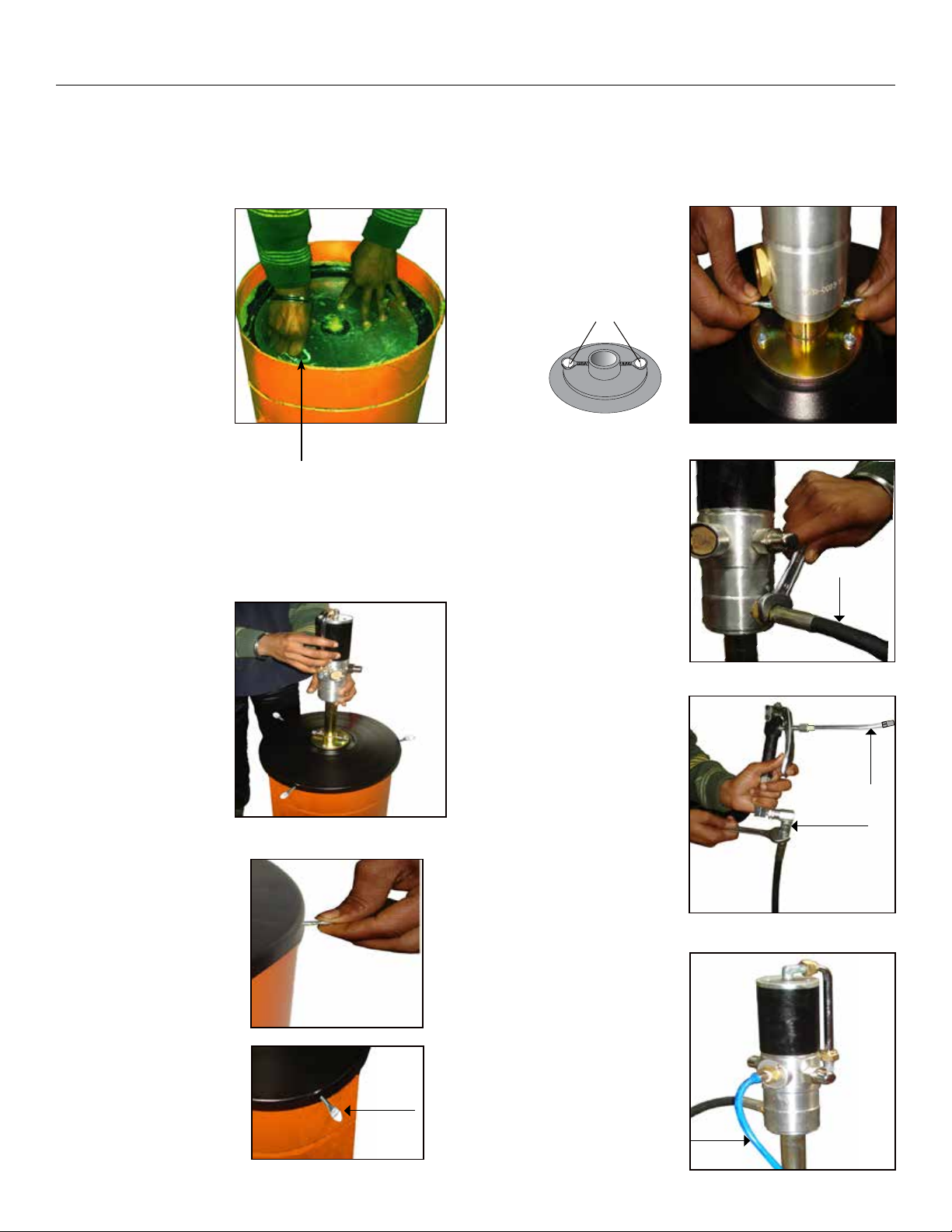

1. Fill the drum with

Grease leaving empty

space of about 2” from

the top rim. Shake the

drum after it is filled

to remove air pockets.

Place the follower

plate in the grease

drum with the

lift handle facing

upwards. Push the

follower plate down,

until some grease is

forced through the

centre hole on the

plate.

2. Place the drum cover

on the drum. Lift the

pump assembly &

slide the suction tube

through the drum

cover & centre hole in

the follower plate.

3. Push the pump

assembly down till

the bottom of the

pump touches the

base of the drum.

Adjust the drum cover

and tighten it with

the thumb screws

provided along with

the drum cover.

Lift Handle

4. Tighten the drum cover

with the pump suction

tube with the help of

thumb screws.

Thumb Screws

5. Use a wrench to tighten

high pressure hose to the

pump outlet.

6. Use a wrench to tighten

the other end of the hose

to Z Swivel of grease

control valve. Tighten the

outlet extension & coupler

to the control valve outlet.

Use thread sealant on all

connections to ensure

leak-proof working.

7. With the air supply turned

off, connect the Air line

into the air inlet on the

pump.

Hose

Extension

& Coupler

Z Swivel

Thumb

Screw

Air Line

5

PUMP OPERATION

1. Partially open the on/off air valve (It helps in creating initial vacuum when filling a totally dry pump). Pump will start operating

automatically until it gets primed. Pump is said to be Primed when grease is available at the pump outlet, making the pump ready to use.

Once primed, the air motor will stop. Open the on/off air valve fully.

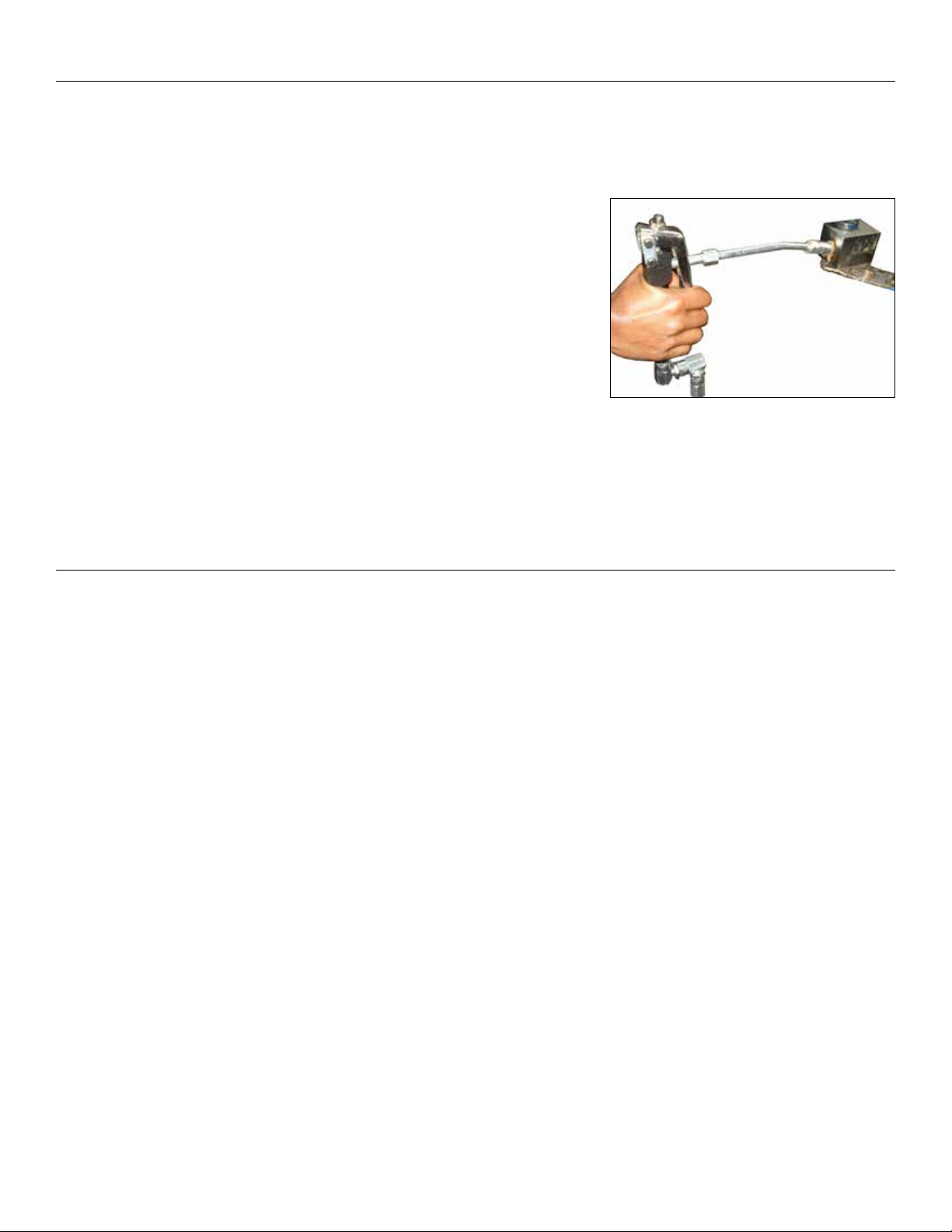

2. Hold the grease control valve near a container & press the trigger. Pump will start

operating with continuous grease discharge as long as the trigger is pressed. Release

the trigger & this will stop the pump. Check for any leaks from any of the connections &

Tighten again if required.

3. Connect coupler fitted onto the control valve extension with the grease nipple & press trigger. Be careful not to over-lubricate as the pump

will keep dispensing grease as long as the trigger is pressed. Once the trigger is released, pump will stop dispensing grease & the air

motor will stop.

4. When not in use & at the end of each day, air supply to the pump must be switched off.

6

MAINTENANCE & REPAIR (Refer to Exploded View - Page 12)

Service Precautions

• Before performing any service operation, always shut off the air supply and release the pressure of the medium, i.e. let the grease out so

that the pressure decreases. When storing the pump assembly without the bucket, cover the Filter Tube (57) with Filter Cap (62).

• Be careful not to damage any parts when dismantling. While removing shafts which do not have key flats, use a Pipe wrench, Polygrip

wrench or the like. The easiest way to remove such a shaft is to grip it in a vice with aluminium or copper jaws, clamp the shaft in a

hand-drill chuck and then turn the chuck by hand.

• Be careful when fitting O-rings and seals. Always lubricate them with grease before fitting. They must never be threaded over sharp

edges when being fitted. Lubricate all moving parts with synthetic grease. Apply minor locking fluid on all threaded joints.

• When troubleshooting, be on a lookout for dirt in valves / ball seats, scratches in sealing surfaces & damaged O-rings / seals / gaskets.

Recommended Tools

Phillips Screwdriver

T- Handle

Size 10 mm

Adjustable Caliper Wrench

Combination Wrench

Size 10, 14, 21, 25, 28 & 32 mm

Pin Punch

2 mm

Tweezer

Pumping Section Kit Replacement (Refer to Table 5 - Page 17)

1. Hold Barrel (63) in a soft-

jaw vice. Pull out Filter

Cap (62) by hand.

3. Unscrew Top Coupler (52)

using wrench (size 28

mm) on the given flats.

Remove lower coupler

assembly.

1/2” Male Threaded Pipe

Ball Pein Hammer

Plastic Mallet

A Soft - Jaw vice

(Aluminum or Copper Jaws)

2. Unscrew Nyloc Nut (61)

using T-handle (size 10

mm) & also remove

Piston Washer (60) from

the end of Filter Tube

(57).

Nyloc Nut Piston Washer

Lower Coupler Assembly

4. Remove the outlet adapter

(35) using wrench (size 25

mm).

7

5. Tighten a 1/2” male

threaded pipe into the

outlet port & unscrew

Air Motor Assembly

anticlockwise. Carefully

remove Air Motor from

Barrel (63).

8. Hold Filter Tube (57) in

vice. Using two wrenches

(size 28 mm), hold Bottom

Coupler (54) & unscrew

Top Coupler (52). Remove

Slide Bush (53).

Slide Bush

6. Support Pump Cylinder

(51) on a V block &

insert a pin punch

vertically into the hole

of Pump Cylinder (51).

Tap lightly with a hammer

to drive out lower Slotted

Spring Pin (44) taking

care not to bend the

Extension Rod (46).

7. Unscrew Pump Cylinder

(51) & remove upper

Steel Ball (47) & Non

Return Spring (48).

9. Unscrew Bottom Coupler

(54) with wrench (size 28

mm) & remove Guide Bush

(56).

Guide Bush

10. Replace the Repair Kit (KIT/BTM/RPG) as mentioned in Table

5 - Page 17, by following the steps 1-9 in reverse order taking

care of the points below:

• Pump Cylinder (51) has a pin-hole

end that must face upwards;

towards Extension Rod (46).

Non return

Spring

Steel Ball

• Slide Bush (53) has a slotted end

that must always face upwards;

towards Top Coupler (52).

• Replace Part No. 51, 52, 53 & 55 TOGETHER as a set

even if there is a need to replace only one of these

parts. Apply minor grease on all the moving parts

before assembly. Also, ensure movement of part 51,

52 & part 53, 55 is smooth.

8

Drive Section Kit Replacement (Refer to Table 6 - Page 18)

1. Hold Barrel (63) in a soft-

jaw vice. Pull out Filter

Cap (62) by hand.

2. Unscrew Nyloc Nut (61)

using T-handle (size 10

mm) & also remove

Piston Washer (60) from

the end of Filter Tube (57).

5. Support Extension

Rod (46) on a V block

& insert a pin punch

vertically into the hole

of Connector (45).

Tap lightly with a

hammer to drive out

upper Slotted Spring Pin

(44) taking care not to

bend Extension Rod (46).

3. Remove the outlet

adapter (35) using

wrench (size 25 mm).

4. Tighten a 1/2” male

threaded pipe into the

outlet port & unscrew

Air Motor Assembly

anticlockwise. Carefully

remove Air Motor from

Barrel (63).

6. Unscrew Connector

(45) with wrench (size

14 mm) & separate Air

Motor Assembly from

Extension Rod (46).

7. Hold Air Motor

Assembly in a soft-

jaw vice. Loosen both

Coupling Nuts (2) using

wrench (size 21 mm).

9

8. Remove Bend Pipe (1)

along with both Coupling

Nuts (2) & Sealing Rings

(3). Unscrew Exhaust Valve

(23) with an adjustable

wrench.

13. Unscrew both Pushers

(15) using wrench (size

25 mm).

9. Unscrew both Bends (4)

using wrench (size 13

mm).

10. Lightly tap Cylinder (10)

with a plastic hammer &

unscrew it .

14. Remove both Pushers

(15), Springs (17), Pusher

Nuts (18) & Pusher

Buttons (19).

15. Using two wrenches

(size 10 mm), hold

Plunger Rod (9) &

turn Connecting Rod

(43) anticlockwise.

This will unscrew

Connecting Rod (43).

11. Unscrew Inlet Cover

Adapter (34) using wrench

(size 25 mm).

12. Connect a caliper wrench

into the holes on inlet

Cover (32) & unscrew it.

16. Remove Connecting

Rod (43) along with

Washer (42), Spring (41),

Seal Support (40), Seals

(39) & Slider Guide (38).

If Connecting Rod (43) is

still attached to the inner

rod of Slider (30), hold

the inner rod in a vice &

unscrew Connecting Rod

(43) with wrench (size 10

mm).

10

17. Remove Slider (30) with a

tweezer.

18. Open the two Screws (29)

with a Philips screwdriver

& remove Clip (28).

22. Replace the Repair Kit (KIT/TP/RPG) as mentioned in Table 6

- Page 18, by following the steps 1-21 in reverse order taking

care of the points below:

• Ensure all mating

surfaces are clean

before reassembly.

Apply minor grease

on all mating

surfaces, O Rings &

moving parts before

reassembly.

Clean & apply grease

5.3 - 5.7 mm

• Ensure that height of

Nylon Slider (27) is

approx. 5.3 - 5.7 mm.

Also, hollow portion

of Nylon Slider

should rest evenly on

top of Seat (25).

19. Remove Nylon Slider (27).

20. Remove Slider Guide (26).

21. Remove Seat (25) &

Paper Seal (24). Clean the

bottom surface thoroughly.

• When fitting Pushers

(15), see through

Inlet Cover (32)

& ensure Pusher

Buttons (19) are

installed in centre

position. Also ensure

that Clip (28) is tight

& Nylon Slider (27)

moves smoothly.

• When fitting Plunger

Rod (9) & Connecting

Rod (43), apply

locking fluid on the

inner rod of Slider

(30).

• Conical side of

Seals (39) must face

upwards. Assemble

them with Slider

guide (38), Seal

Support (40) & mount

them as a set on

Connecting Rod (43).

38

39

40

Conical side of

Seals (39) must

face upwards

11

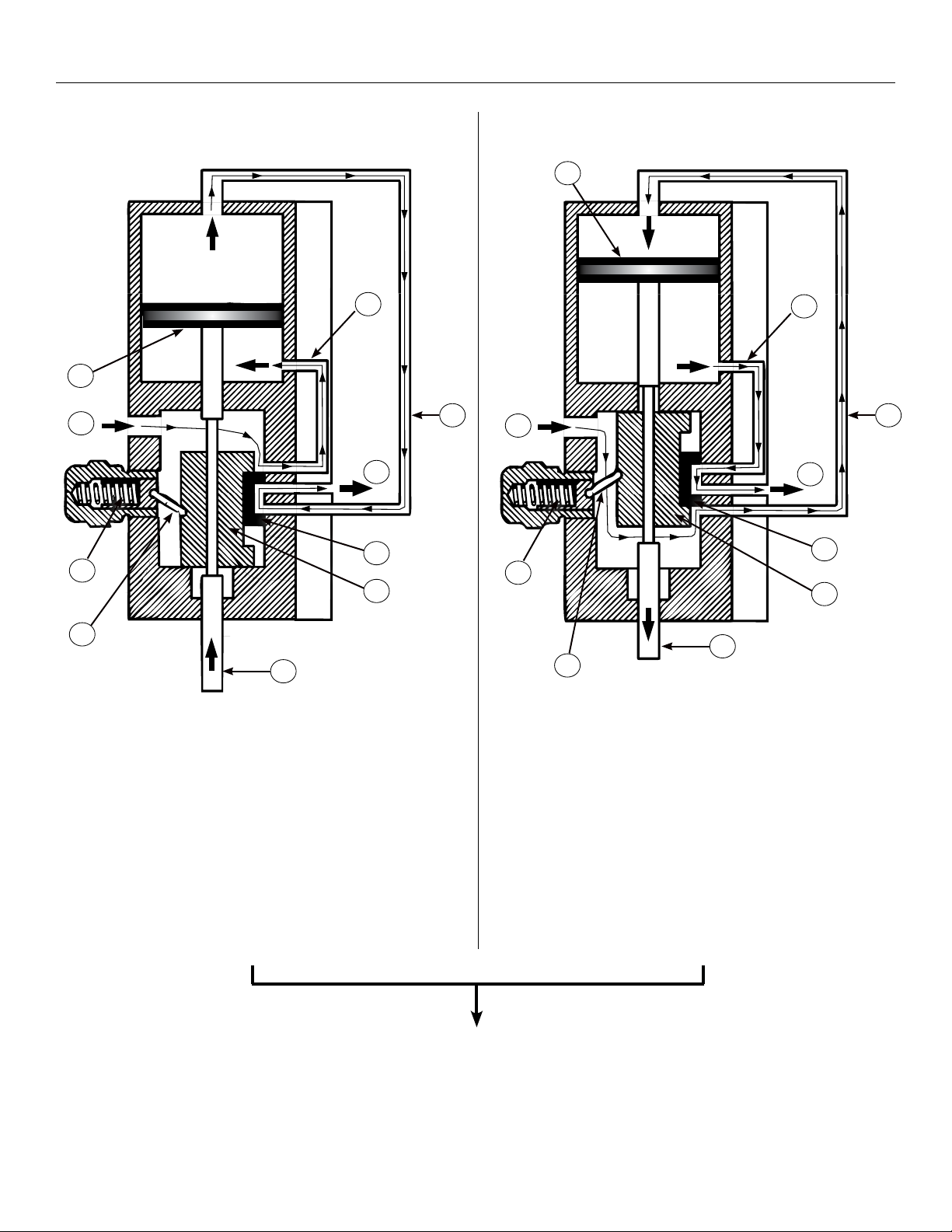

EXPLODED VIEW

PUMP ASSEMBLY

3

2

1

7

10

12

2

3

21

14

13

19

23

37

38

39

11

42

43

16

20

15

17

18

4

21

22

63

16

19

40

DRUM COVER, FOLLOWER PLATE, HOSE,

Z SWIVEL & GREASE CONTROL VALVE

4

5

6

8

9

11

25

24

6

26

18

17

16

35

36

41

KIT/TP/RP-G

KIT/BTM/RP-G

27

28

31

32

33

29

30

15

Correct Fitment of

16

34

68

67

Fig. 7Fig. 6

Seals (39)

38

52

53

56

50

50

54

57

58

59

45

46

47

49

47

62

51

48

55

60

61

44

44

48

39

Conical side of

Seals (39) must

face upwards

40

Replace Component No.

51, 52, 53 & 55

as a SET

Correct Fitment of

Slide Bush (53) &

Pump Cylinder (51)

Slottted side

must face

upwards

53

Pin Hole end

must face

upwards

51

66

65

64

12

PARTS LIST

PARTS LIST FOR PUMP ASSEMBLY Table 1

REF. NO. FROM EXPLODED VIEW DESCRIPTION QUANTITY

1 Bend Pipe 1

2 Coupling Nut 1

3 Sealing Ring 2

4 Bend 2

5 Cylinder Cover 1

6 O Ring BS141 2

7 Plunger Nut 1

8 Rubber Plunger 1

9 Plunger Rod 1

10 Cylinder 1

11 O Ring BS614 2

12 Rod Guide 1

13 O Ring 1

14 Housing 1

15 Pusher 2

16 O Ring BS617 4

17 Pusher Spring 2

18 Pusher Nut 2

19 Pusher Button 2

20 Circlip 1

21 Filter (B) 2

22 O Ring BS121 1

23 Exhaust Valve 1

24 Paper Seal 1

25 Seat 1

26 Slider Guide 1

27 Nylon slider 1

28 Clip 1

29 Self Tapping Screw 2

30 Slider 1

31 O Ring BS129 1

32 Inlet Cover 1

33 Filter (S) 1

34 Air Inlet Adapter 1

35 Outlet Adapter 1

36 Adapter Cap 1

37 O Ring BS115 1

38 Seal Guide 1

39 Seal 4

40 Seal Support 1

41 Spring 1

13

REF. NO. FROM EXPLODED VIEW DESCRIPTION QUANTITY

42 Washer 1

43 Connecting Rod 1

44 Slotted Spring Pin 3

45 Connector 1

46 Extension Rod 1

47 Steel Ball (7/32”) 2

48 Non Return Spring 2

49 Valve 1

50 O ring (BS812) 2

51 Pump Cylinder 1

52 Top Coupler 1

53 Slide Bush 1

54 Bottom Coupler 1

55 Piston Rod 1

56 Guide Bush 1

57 Filter Tube 1

58 Filter Washer 1

59 Filter Circlip 1

60 Piston Washer 1

61 Nyloc Nut 1

62 Filter Cap 1

63 Barrel 1

PARTS LIST FOR DRUM COVER, FOLLOWER PLATE,

HOSE, Z SWIVEL & GREASE CONTROL VALVE

REF. NO. FROM EXPLODED VIEW DESCRIPTION QUANTITY

64 Follower Plate 1

65 Drum Cover 1

66 Hose 1

67 Z Swivel 1

68 Grease Control Valve 1

Table 2

14

TROUBLESHOOTING

(Refer to Maintenance & Repair - Page 7)

PROBLEM POSSIBLE CAUSE SOLUTION

Grease is too thick / too cold Store grease in a warm place

Table 3

Pump operates, but does not

dispense any grease

Pump not working / less

discharge

Pump continues to operate

even after the trigger of Grease

Control Valve (68) has been

released

Grease comes through the air

Exhaust Valve (23)

Air passes directly from inlet

to the outlet & pump does not

work

Air pockets in grease

Dent in the Grease Bucket restricting

movement of Follower Plate (64) leading to

formation of air pockets in the bucket and

inefficient working

Inlet pressure is too less Increase inlet pressure. It must be at least 30 PSI (2 BAR)

Nylon Slider (27) is jammed / overtight

Piston / Piston Rod / Plunger jammed.

NOTE

Especially check Extension Rod (46),

Cylinder (51), Top Coupler (52), Slide

Bush (53) & Piston Rod (55) as shown in

EXPLODED VIEW

Leakage in the assembly

Grease leaks into the Air Motor

Nylon Slider (27) is jammed / overtight

Shake the Grease bucket & manually force down the

Follower Plate (64) to remove air pockets

Get the dent removed to ensure proper movement of

Follower Plate (64)

Refer to Drive Section Kit Replacement - Page 8

1. Check for any build-up edge on Clip (28) & tighten it

again. Make sure the movement of Nylon Slider (27) is

neither very loose nor very tight

2. If needed, replace Nylon Slider (27). Also replace the

Paper Seal (24), Seat (25) & Slider Guide (26) to ensure

the best fitting

Refer to Pumping Section Kit Replacement - Page 6

1. Remove suction tube. Disconnect Air Motor Assembly

from Pumping Section by removing the upper Slotted

Spring Pin (44) from Connector (45)

2. Supply input air to Air Motor. If it works properly

without the barrel assembly, then the problem lies with

the pumping section. Otherwise check the Air Motor

for smooth movement

3. After locating the faulty section, check the respective

Piston / Plunger & the associated washers & seals for

any overlap or wear & tear. Replace the defective parts

from Repair Kit

4. Ensure to replace the moving parts having close

tolerances (such as Piston & Cylinder alongwith Non

Return Springs & balls) as a SET to ensure the best

fitting

Check all the connections to ensure they are air tight. Use

thread sealant.

Check O rings & seals for damage. Replace the defective

parts from Repair Kit

Check Slider Guide (38), O Ring (37), lower O Ring (11),

Seals (39) & Seal Support (40) for wear & tear. Replace the

damaged parts from Repair Kit

Refer to Drive Section Kit Replacement - Page 8

1. Check for any build-up edge on Clip (28) & tighten it

again. Make sure the movement of Nylon Slider (27) is

neither very loose nor very tight

2. If needed, replace Nylon Slider (27). Also replace the

Paper Seal (24), Seat (25) & Slider Guide (26) to ensure

the best fitting

Discharge suddenly stopped

while the pump was running

Seals / O Rings Damage

Chip / Other foreign particles get clogged at

discharge coupler

Clogging of Filter Tube (57) Open Filter Tube (57), clean it & reassemble it properly

15

Check all seals / O Rings & replace the damaged parts from

Repair Kit

Open the coupler, remove all foreign particles / chips &

reassemble properly

REPLACEMENT & SERVICE PARTS PROGRAM FOR GREASE RATIO PUMP

(Refer to Exploded View - Page 12)

REPLACEMENT PARTS PROGRAM

Table 4

REF. NO. FROM

EXPLODED VIEW

64 FLP/241-288/6

FLP/322-380/6

FLP/550-602/6/GP3

65 DC/GP1/BL

DC/GP2/BL

DC/GP3/BL

66 HOSE/GRP/84/B

HOSE/GRP/84/N

67 HFC/1-4F/1-4M/B

HFC/1-4F/1-4M/N

68 APG/04/1-4F/B

APG/04/1-4F/N

PART NO. DESCRIPTION QUANTITY

GP1 Follower Plate

GP2 Follower Plate

GP3 Follower Plate

GP1 Drum Cover

GP2 Drum Cover

GP3 Drum Cover

Hose, BSP Threads

Hose, NPT Threads

Z Swivel, BSPT Threads

Z Swivel, NPT Threads

Grease Control Valve, BSPT Threads

Grease Control Valve, NPT Threads

1

1

1

1

1

1

1

1

1

1

1

1

16

SERVICE PARTS PROGRAM (Pumping Section Kit - KIT/BTM/RP-G)

Nyloc Nut

61

NN/M6/RP-G

Fig. 8

47

Steel Ball (7/32”)

SB/7-32

48

Non Return Spring

SPR/NR/RP-G

Rod & Cylinder Assembly

ROD/CYL/RP-G

Component

must be replaced TOGETHER

even if only one of these

component need replacement

51 52 53 55

Pump Cylinder

51 53

CYL/RP-G

Top Coupler

52 55

CPL/TOP/RP-G

Slide Bush

BSH/SLD/RP-G

Piston Rod

ROD/PST/RP-G

60

Piston Washer

WSR/PST/RP-G

50

O Ring

ORG/BS812

Fig. 9

62

Filter Cap

IC/FLT/RP-G

KIT PART NO. KIT

DESCRIPTION

KIT/BTM/RP-G PUMPING

SECTION KIT

Fig. 10

56

Guide Bush

BSH/RP-G

Table 5

CONSTITUENT

PART NO.

SB/7-32 Steel Ball (7/32”) 47 1

SPR/NR/RP-G Non Return Spring 48 1

ORG/BS812 O Ring 50 2

Pump Cylinder (CYL/RP-G) 51 1

ROD/CYL/RP-G

BSH/RP-G Guide Bush 56 1

WSR/PST/RP-G Piston Washer 60 1

NN/M6/RP-G Nyloc Nut 61 1

IC/FLT/RP-G Filter Cap 62 1

Top Coupler (CPL/TOP/RP-G) 52 1

Slide Bush (BSH/SLD/RP-G) 53 1

Piston Rod (ROD/PST/RP-G) 55 1

PART

DESCRIPTION

REFERENCE NO. FROM

EXPLODED VIEW

QTY.

PER KIT

17

SERVICE PARTS PROGRAM (Drive Section Kit - KIT/TP/RP-G)

Fig. 11

43

Connecting Rod

ROD/CNR/S/RP

Bend

4

BEND/90/RP

39

Seal

SEAL/RP

Fig. 12

3

Sealing Ring

SR/B/RP

44

Slotted Spring Pin

SSP/3/0.6/15.3

Slider Guide

GUD/SEL/RP

Fig. 13 Fig. 14

38

O Ring

ORG/BS115

Seal Support

40

SU/SEL/RP

37

O Ring

11

ORG/BS614

22

O Ring

ORG/BS121

Seat

SET/RP

ORG/BS129

Paper Seal

24

SEL/R/RP

Nylon Slider

25

SLD/NY/RP

Replace Component No.

24, 25 & 27 as a SET

O Ring

31

O Ring

ORG/BS141

27

4

O Ring (37) is assembled

over Slider Guide (38)

KIT PART NO. KIT

DESCRIPTION

KIT/TP/RP-G DRIVE SECTION KIT

16

O Ring (11) is assembled

into Seal Support (40)

O Ring

ORG/BS617

Table 6

CONSTITUENT

PART NO.

SR/B/RP Sealing Ring 3 2

BEND/90/RP Bend 4 2

ORG/BS141 O Ring 6 2

ORG/BS614 O Ring 11 1

ORG/BS617 O Ring 16 4

ORG/BS121 O Ring 22 1

SEL/P/RP Paper Seal 24 1

SET/RP Seat 25 1

SLD/NY/RP Nylon Slider 27 1

ORG/BS129 O Ring 31 1

ORG/BS115 O Ring 37 1

GUD/SEL/RP Seal Guide 38 1

SEAL/RP Seal 39 4

SU/SEL/RP Seal Support 40 1

ROD/CNR/S/RP Connecting Rod 43 1

SSP/3/0.6/15.3 Slotted Spring Pin 44 3

PART

DESCRIPTION

REFERENCE NO. FROM

EXPLODED VIEW

QTY.

PER

KIT

18

SPECIFICATIONS

MODEL GP1 GP2 GP3

Bucket Capacity 20-30 Kg / 5 Gal / 25-50 lbs. 50-60 Kg / 16 Gal / 120 lbs. 180 Kg / 55 Gal / 400 lbs.

Suction Tube Length 17.32” (440 mm) 28.74” (730 mm) 37.38” (950 mm)

Suction Tube Dia. 1.18” (30mm)

Flow Rate 1.10 Kg / min. (2.42 lbs / min)

Working Pressure 10 BAR (150 PSI)

Maximum Outlet Pressure 500 BAR (7500 PSI)

Air Inlet Connection 1/4” (F)

Pump Outlet Connection 1/4” (F)

Air Consumption 230 LPM (61 GPM)

Hose Length* 7’ (84”)

Noise Level 81 db

* IT MAY VARY FROM ONE MODEL TO ANOTHER

• Always wear protection gear like safety goggles, gloves, apron, and ear plugs while operating the pump

• Never let any body part come in front of, or in contact with the control outlet

• Always cut off air supply after use, so that media cannot leak in case any of the pump component fails

• Before switching the air supply on, check hoses for sign of wear, leak or loose fittings. Replace as necessary

• Do not smoke near the pump. Do not use the pump near a source of spark / open flames

• When changing the working fluid, at least 1 litre of new fluid should be discarded to avoid mixing of fluids

• Pump should NOT be operated for more than 4 hrs continuously

• Pump must be supplied with CLEAN & DRY compressed air via an FRL unit

• Before attempting any repair of this product, disconnect air supply and then squeeze control valve trigger to release fluid pressure

• Use only genuine factory parts for repair

Table 7

WETTED COMPONENTS

Steel, Brass, Aluminium, & Polyurethane

RECOMMENDED USE

With light and self collapsing grease up to NLGI No. 2

19

Groz Engineering Tools (P) Ltd.

Groz Net Industries

Village Kherki Daula, National Highway-8

Gurgaon-122001, Haryana, INDIA

TEL +91.124.282.7700 / 221.4050

FAX +91.124.2827986 / 221.4224

FAX (USA) +1.509.271.7848

FAX (UK) +44.870.121.1854

E-MAIL info@groz-tools.com

URL www.groz-tools.com

The Groz name, Groz logo and the mark are

trademarks of Groz Engineering Tools (P) Ltd. India

20

Loading...

Loading...