Groz FM-20 Instruction Manual

INSTRUCTION MANUAL S1730, Rev C

Digital Fuel Meter

FM-20

Congratulations on purchase of this World Class Digital Fuel Meter!

• Digital turbine meter designed to measure the flow of low

viscosity fluids

Meter

1

• Easy installation, both for in-line as well as end of line

applications; with advantage of Bi-directional operation

• Polyamide Turbine measuring mechanism

• Electronic Display powered by two AAA 1.5 V batteries

1” (M) Port

• Display can be rotated in four different positions

• Aluminum body and sealed electronic card makes it suitable

for use in severe weather conditions

• Features a non-volatile memory for storing the dispensing

data, in the event of a complete power break for long periods

• Measures in Litres, Quarts, Pints & Gallons

• Easy user recalibration

PART DESCRIPTION

Rubber Shroud

2

1” (F) Port

REFERENCE NUMBER DESCRIPTION QUANTITY

1

2

Meter

Rubber Shroud

1

1

1

SPECIFICATIONS

Meter Type Digital

Meter Mechanism Turbine

Inlet / Outlet Position In-Line

Male / Female Port Size 1”

Threads BSP or NPT

Flow Rate 7 to 120 LPM ( 2 to 32 GPM )

Accuracy +/- 1%

Repeatability +/- 0.30 %

Max. Working Pressure 300 PSI ( 20 BAR)

Burst Pressure (Min.) 1500 PSI (100 BAR)

Pressure Loss at 100 LPM (27 GPM) with Diesel 4.5 PSI (0.30 BAR)

Working Temperature Range -10° C to +50° C (14° F to 122° F)

Max Resettable Batch Total 99999 Units

Max Non Resettable Totalizer 9,99,999 Units

Least Count/ Resolution 0.001 Unit

Filter/ Screen Included No

Viscosity of Media (Range) 2 – 5.35 cSt

Option to Recalibrate by User Yes

No. of positions in which the display can be rotated 4

Protective Shroud on Meter YES

Weights & Measures Approved NO

Calibration Certificate Included NO

Water resistance IP65

CE Listed YES

For use with Electric Fuel Pumps YES

For use with Gravity Flow YES (Minimum 4 feet head is required)

Power supply 2 x 1.5 Alkaline batteries ( Size AAA )

RECOMMENDED USE

Diesel, Gasoline, Bio-Diesel, Windshield Fluid, Water

DO NOT USE WITH

Oils

WETTED COMPONENTS

Aluminum, Polyamide

In order to improve the life of the turbine, it is recommended to fit

a filter before the meter itself.

2

INSTALLATION

This is a bi-directional meter with 1” threaded male & female

ports. The meter can be installed in any position - fixed in line or

mobile on a control nozzle.

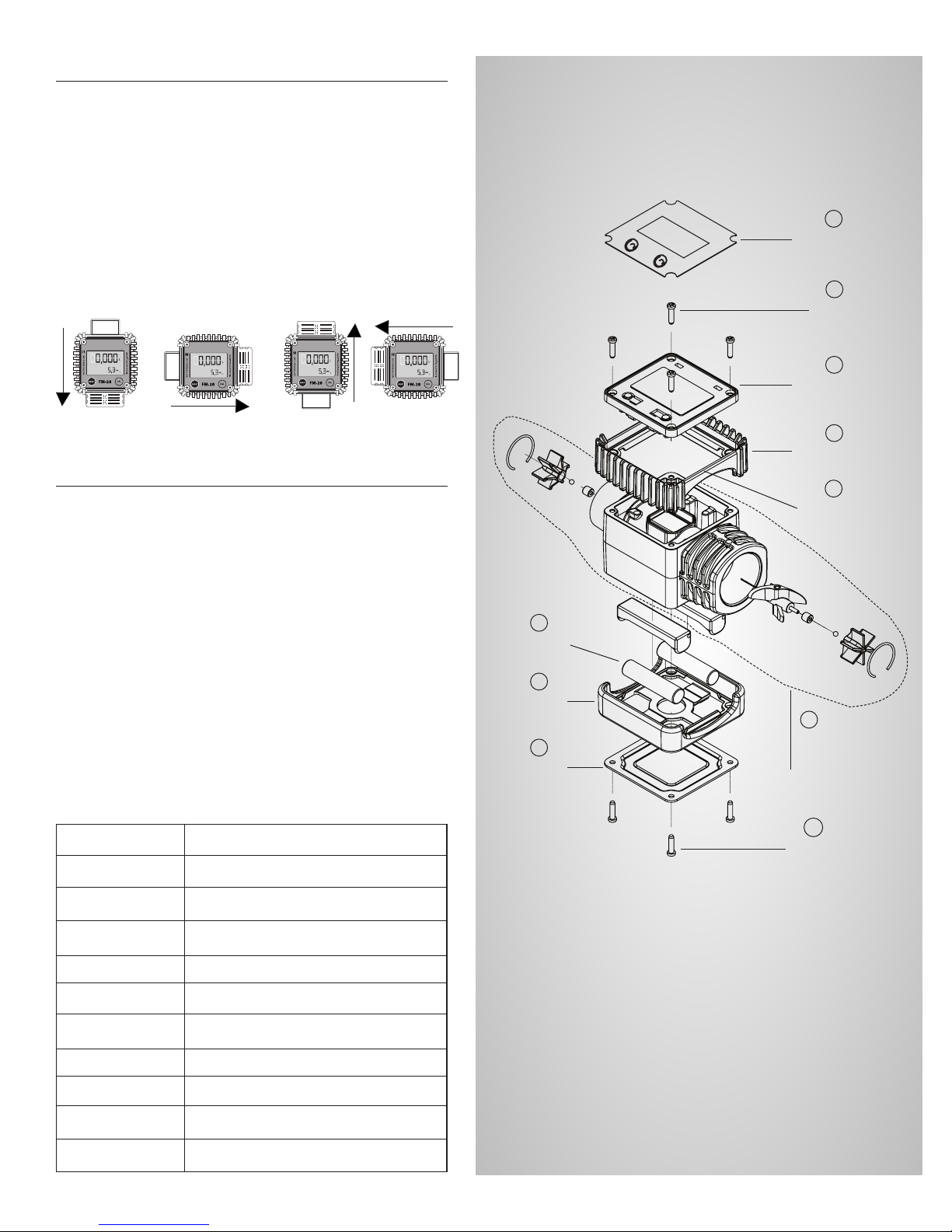

How to rotate the display

1. Remove the four screws (2) and separate the card housing

(5) from the turbine assembly (6).

2. Rotate the card housing in any of the four positions as shown

in the picture and tighten the card housing with four screws

(2)

KNOW ABOUT YOUR FLOW METER

Table of Contents

A. Component List & Exploded View

B. Major Components

C. Measurement Units Configuration

D. Normal Dispensing Mode

E. Resetting The Batch Total

F. Resetting The Reset Total

G. Dispensing with Flow Rate Mode display

H. Calibration

I. Calibration Procedures –

• In-Field Calibration Sequence,

• Direct Calibration Sequence

A. COMPONENT LIST & EXPLODED VIEW

7

Batteries

8

Battery

Case

9

Battery

Cap

1

Meter Label

2

Screws

4 Nos.

3

Display with

Microprocesser

4

Rubber Shroud

5

Card Housing

6

Turbine Assembly

(as a Single Unit)

Sl. No. Component List

1 Meter Label

2 Screw (Nos. 4)

3 Display with Microprocessor

4 Rubber Shroud

5 Card Housing

6 Turbine Assembly (as a Single Unit)

7 Batteries

8 Battery Case

9 Battery Cap

10 Screw (Nos. 4)

10

Screws

4 Nos.

3

Loading...

Loading...