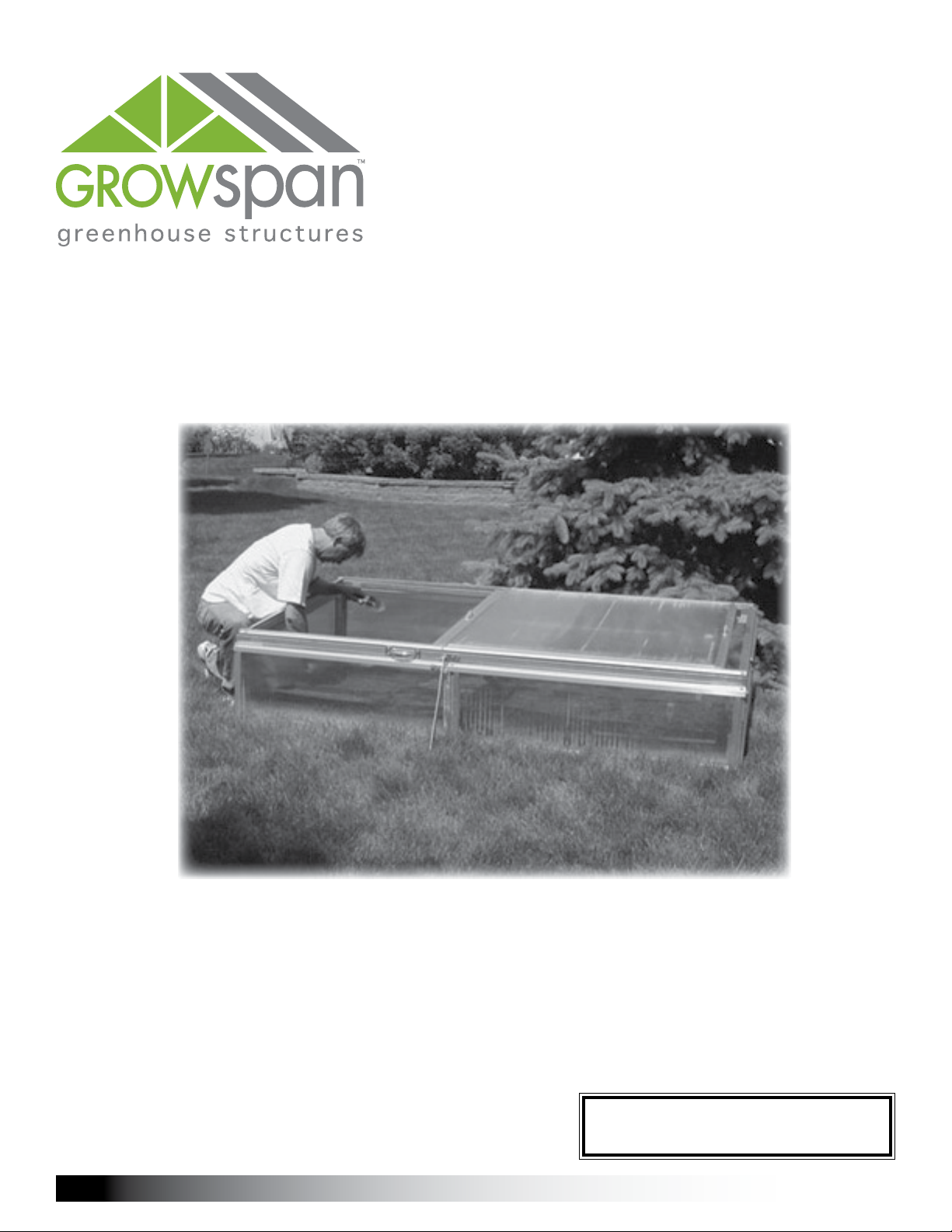

GROWSPAN™ COLD FRAMES & GREENHOUSES

GrowSpan™ Heavy-Duty

Commercial Cold Frame

©2018 GrowSpan

All Rights Reserved. Reproduction

is prohibited without permission.

Revision date: 05.08.18

Photo may show a different but similar model.

STK# DIMENSIONS

106363 4' W x 23" H x 7'-9" L

1

GROWSPAN™ COLD FRAMES & GREENHOUSES

YOU MUST READ THIS DOCUMENT BEFORE YOU

BEGIN TO ASSEMBLE THE SHELTER.

Thank you for purchasing this Commercial cold frame.

When properly assembled and maintained, this product will

provide years of reliable service. These instructions include

helpful hints and important information needed to safely

assemble and properly maintain the cold frame. Please

read these instructions before you begin.

If you have any questions during the assembly, contact

Customer Service at 1-800-245-9881 for assistance.

SAFETY PRECAUTIONS

LOCATION

Choosing the proper location is an important step before

you begin to assemble the cold frame.

The following suggestions and precautions will help you

determine whether your selected location is the best

location.

• This cold frame has a metal frame. Never erect the

cold frame under power lines or near fuse boxes or

sources of electricity.

• Identify whether underground cables and pipes are

present before preparing the site or anchoring the

cold frame.

• Location should be away from structures that could

cause snow to drift on or around the cold frame.

• Do not position the cold frame in a place where large

loads such as snow and ice, large tree branches, or

other overhead obstacles could fall.

• Wear eye protection.

• Wear gloves when handling panels and frame parts.

• Use a portable GFCI when working with power tools

and cords.

• Do not climb on the cold frame during or after

construction.

• Provide adequate ventilation if the structure is

enclosed.

• Do not store hazardous materials in the cold frame.

ANCHORING INSTRUCTIONS

Prior to assembling this cold frame, please read the MUST

READ document included with the shipment.

WARNING: Strong winds can cause the cold frame to

shift if it is not adequately secured to the site.

The site on which the cold frame is constructed will

determine the anchoring method that is required.

Consult a professional contractor to determine the best and

safest way to anchor the frame.

Contact your sales representative at 1-800-245-9881 for

anchoring suggestions.

SITE

After choosing a location, proper preparation of the site is

essential. The following site characteristics will help ensure

the integrity of the cold frame.

• For best results, the site must be level to properly and

safely erect and anchor the cold frame.

• Drainage: Water draining off the cold frame and from

areas surrounding the site should drain away from the

site to prevent damage to the site, the cold frame, and

contents of the cold frame.

WARNING: The individuals assembling this cold frame

are responsible for designing and furnishing all

temporary bracing, shoring and support needed

during the assembly process (if applicable). For safety

reasons, those who are not familiar with recognized

construction methods and techniques must seek the

help of a qualified contractor.

WARNING: To prevent property damage and serious

personal injury, the assembled cold frame must be

anchored to the site.

2

Revision date: 05.08.18

ASSEMBLY PROCEDURE

GROWSPAN™ COLD FRAMES & GREENHOUSES

UNPACK AND IDENTIFY PARTS

Following the instructions as presented will help ensure the

proper assembly of your cold frame. Failing to follow these

steps may result in an improperly assembled and anchored

cold frame and will void all warranty and protection the

owner is entitled.

The steps outlining the assembly process are as follows:

1. Verify that all parts are included in the shipment. Notify

Customer Service for questions or concerns.

2. Read these instructions and all additional

documentation included with the shipment before you

begin assembling the cold frame.

3. Gather the tools and assistants needed to assemble

the cold frame.

4. Re-evaluate the location and site based on the

information and precautions presented in the

documentation included with the shipment.

5. Assemble the frame components in the order they are

presented in these instructions.

6. Read the Safety and the Cold Frame Care and

Maintenance information at the end of these

instructions.

The following steps will ensure that you have all the

necessary parts before you begin to assemble the cold

frame.

1. Unpack the contents of the box or boxes and place

them where you can easily inventory the shipment.

Refer to the Bill of Materials/Spec Sheets.

2. Verify that all parts listed on the Bill of Materials/Spec

Sheets are present. If anything is missing or you

have questions, consult the Pictorial Parts Guide for

clarification, or contact Customer Service.

SAFETY INFORMATION

The cover of your cold frame is heavy. Use caution

when opening and closing the cold frame cover.

ATTENTION: When open, the cover must remain secured

at all times using the support arm and wing nuts.

Wing nuts must be tight to lock the support arm is in place.

7. Complete and return all warranty information as

instructed.

REQUIRED TOOLS

The following list identifies the main tools needed to

assemble the cold frame. Additional tools and supports may

be needed depending on the location and application.

• Tape measure or measuring device

• Variable speed drill and sockets (cordless with

extra batteries works best)

• Hammers and gloves

• Blade or power tool to cut polycarbonate panels

• Metal cutting saw to cut aluminum profile

ASSEMBLY NOTE: Install Tek screws using a clutched

drill driver running approximately 750 RPM while applying

approximately 50 lbs of force.

Do not use an impact driver to install Tek screws!

WARNING! DO NOT prop the cover open! Serious

injury may occur if the prop slips out of position.

Damage to the polycarbonate panel may occur if a

prop is used.

TO PREVENT DAMAGE OR INJURY OR BOTH, DO

NOT CLIMB OR STORE ANYTHING ON THE COLD

FRAME.

ALWAYS USE THE HANDLE WHEN RAISING OR

LOWERING THE COVER.

WARNING: THIS COLD FRAME IS NOT A TOY!

NEVER ALLOW CHILDREN TO PLAY IN OR AROUND

THE COLD FRAME. TEMPERATURES INSIDE THE

COLD FRAME CAN BECOME EXTREMELY HIGH

WHEN THE COVER IS CLOSED AND THE FRAME IS

IN DIRECT SUNLIGHT.

NEVER USE THE COLD FRAME AS A SHELTER FOR

SMALL ANIMALS AND PETS.

Revision date: 05.08.18

3

GROWSPAN™ COLD FRAMES & GREENHOUSES

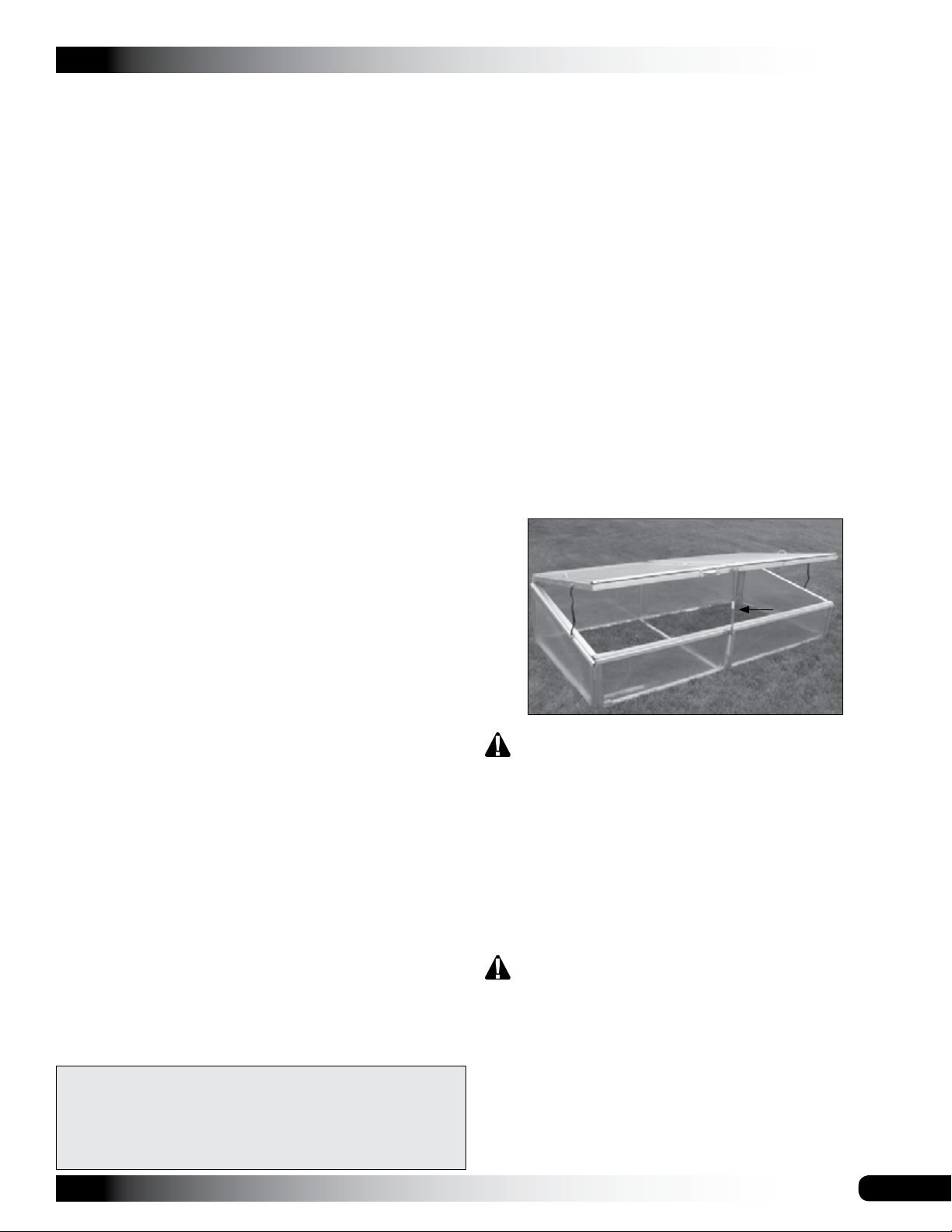

The following graphics and photos will help you identify the

different parts and show you how they are used.

(Some parts are not shown.)

ASSEMBLY NOTE: Install Tek screws using a clutched

drill driver running approximately 750 RPM while applying

approximately 50 lbs of force.

Do not use an impact driver to install Tek screws!

FA4472B

Tek Screw

104548

End Cap Profile

Doors/Fans/Vents

102921B & FA4474B

Tek Screws and

Neo-bonded washers

113236z096

Aluminum H-Channel

Profile

NOTE: Install center bolt

channel to the outside.

104625

2-Way Fitting

102947

D-ring Strap

4

105240

Cover Bracket

QH1330

Angle Bracket

Revision date: 05.08.18

GROWSPAN™ COLD FRAMES & GREENHOUSES

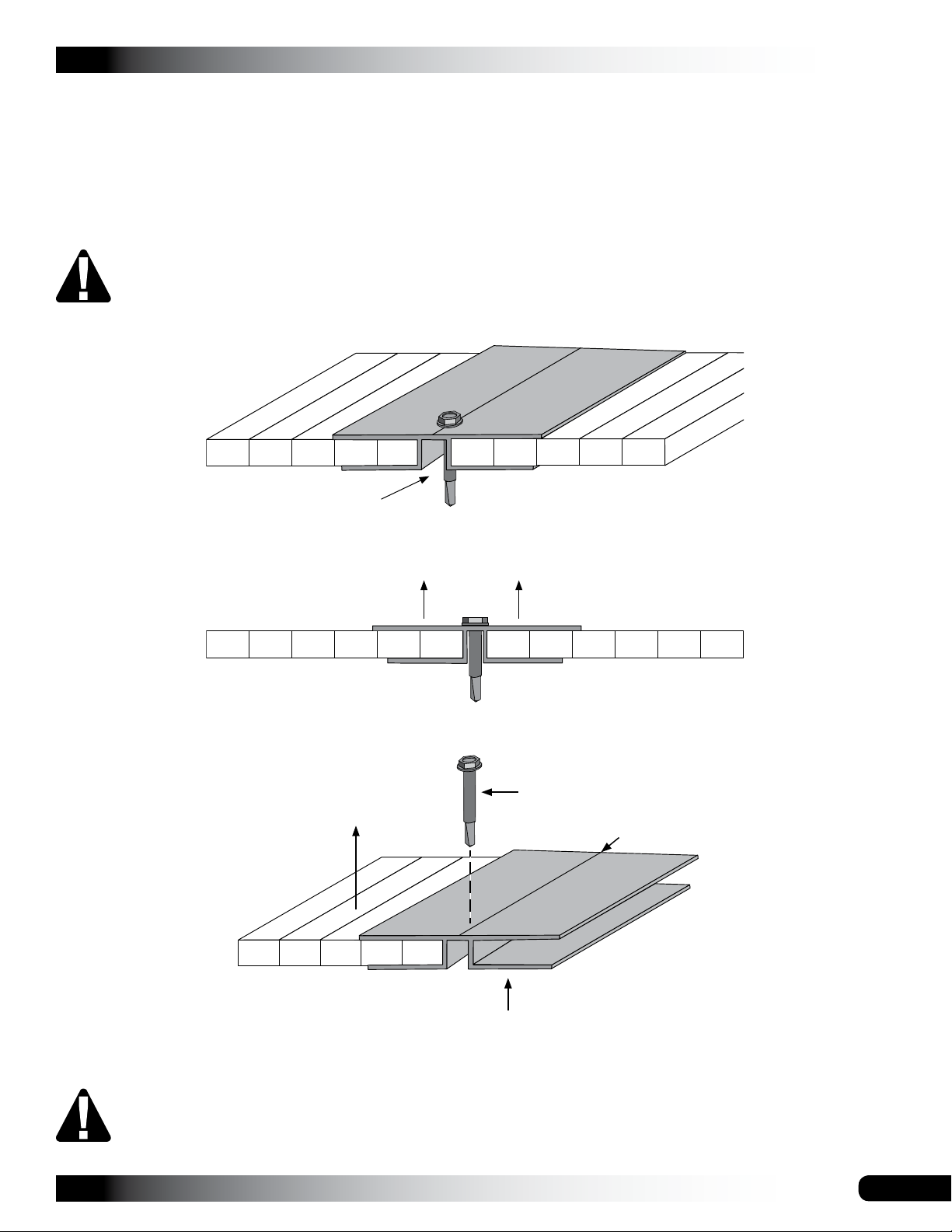

H-CHANNEL INSTALLATION INSTRUCTIONS

The new H-channel design requires installation of the at side facing out with channel side toward

the building. Some diagrams and photos in this document show installation of original H-channel with

channel side facing out. Design of new H-channel does not allow channel-side out installation.

Use the diagrams on this page to install H-channel with at side facing out.

ATTENTION: Use only 1-1/2" Tek screws to attach H-channel to building frame. Do not use

shorter screws. They will not hold. Do not use washers on Tek screws when installing

H-channel.

Flat

Side

Channel

UV-protected side

toward sun.

Flat side toward the sun.

Install 1-1/2" Tek screws through

H-channel into building frame.

Center Groove

ATTENTION: Install all twin-wall poly carbonate panels with UV-protected side toward the sun.

Revision date: 05.08.18

H-Channel

5

GROWSPAN™ COLD FRAMES & GREENHOUSES

ASSEMBLY NOTE: Install Tek screws using a clutched

drill driver running approximately 750 RPM while applying

approximately 50 lbs of force.

Do not use an impact driver to install Tek screws!

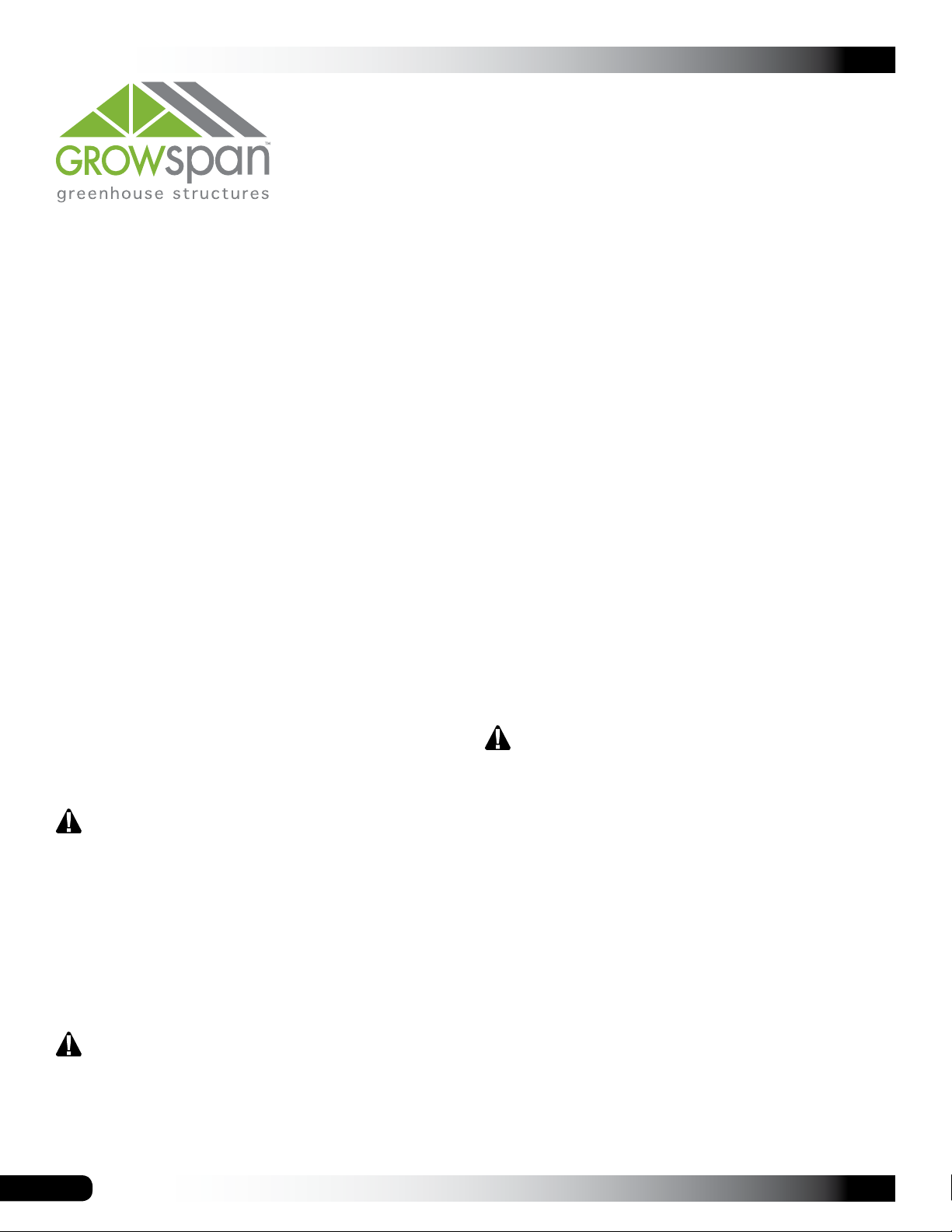

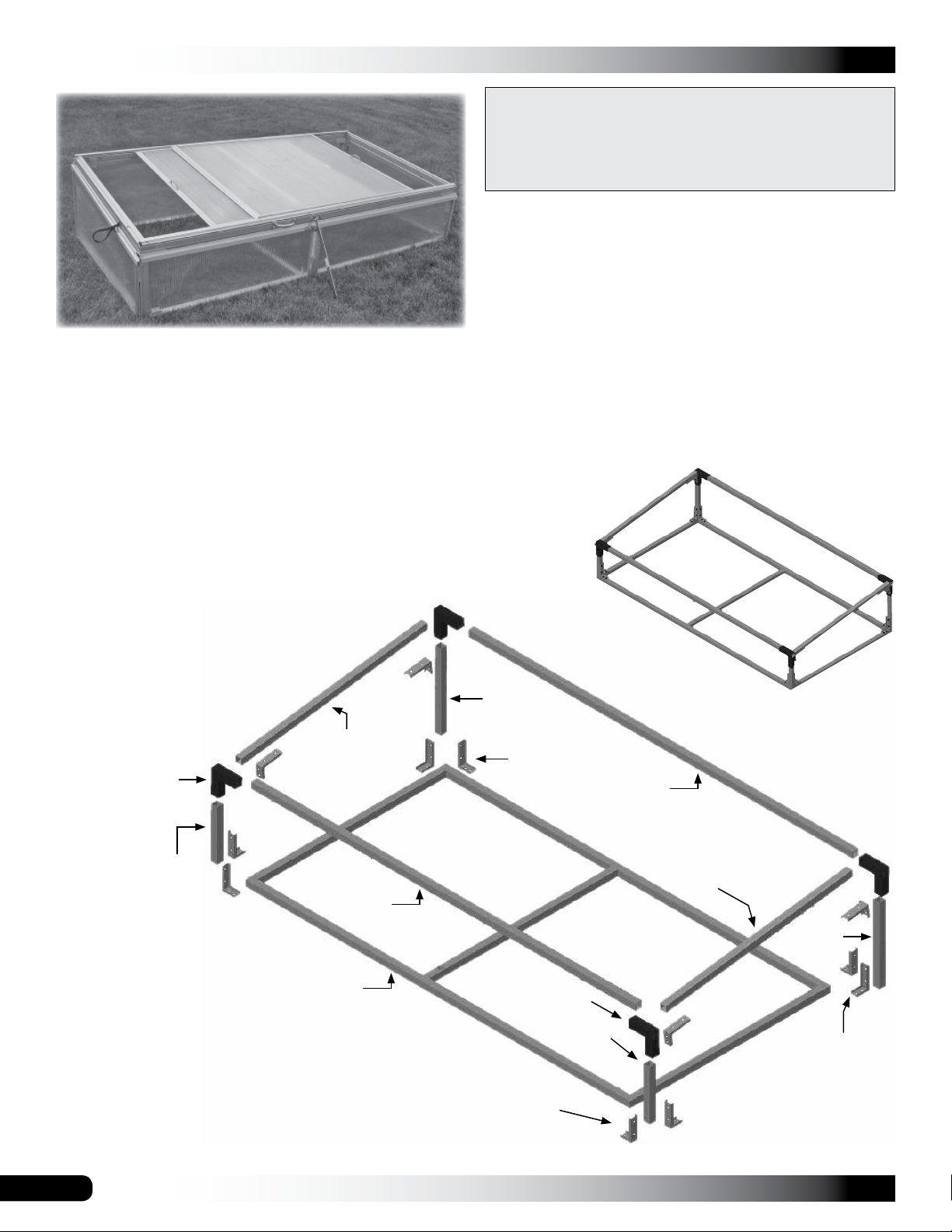

OVERVIEW

This section describes the process for assembling your

commercial cold frame. See the illustration below to identify

main parts of cold frame.

1. Locate the required parts for each assembly procedure.

2. Assemble and anchor the frame.

3. Cut and assemble the polycarbonate panels.

4. Assemble and install sliding cover panels.

5. Install safety straps and cover hardware.

S15P045

104625

GrowSpan™ Heavy-Duty

Commercial Cold Frame

S15P018

QH1330

S15P092

Assembled View

S15P012

S15P092

102923*

* A second 102923

is used for the cold

frame cover.

NOTE: Use FA4472B Tek screws to secure

the parts above during the assembly.

6

QH1330

104625

S15P012

S15P045

S15P018

QH1330

Revision date: 05.08.18

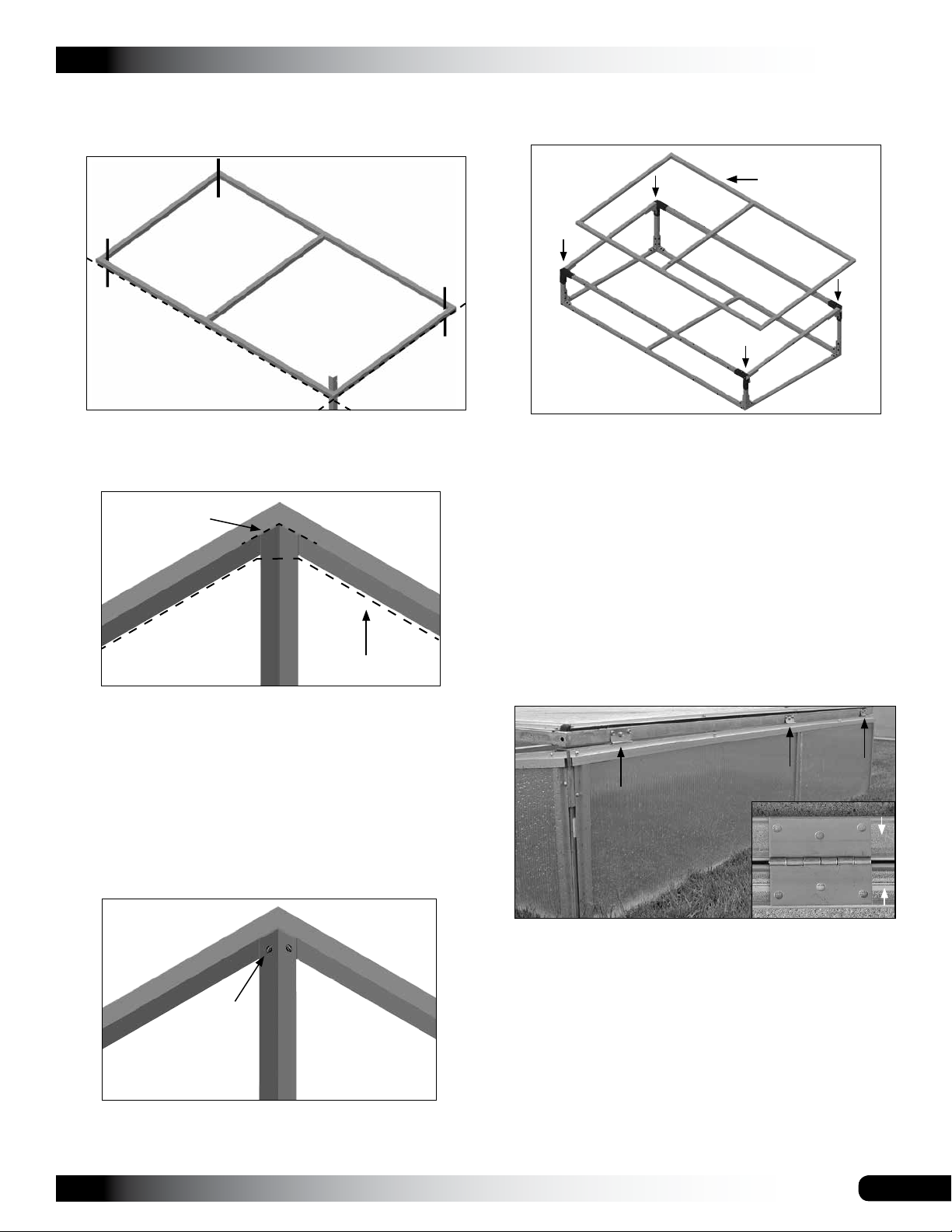

FRAME ASSEMBLY INSTRUCTIONS

After all parts are identified, assemble the frame.

NOTE: Consult the exploded frame diagram on the

previous page for part identification and clarification.

Gather the parts:

• Main frame (#102923)

• Square tubes (#S15P092 and #S15P045)

• Square tubes (#S15P018 and #S15P012)

• 2-way fittings (#104625)

• Angle brackets (#QH1330)

• Corner stakes (#105232) and hinges (#FA5030)

• Tek screws (#FA4472) and screws (#105116)

GROWSPAN™ COLD FRAMES & GREENHOUSES

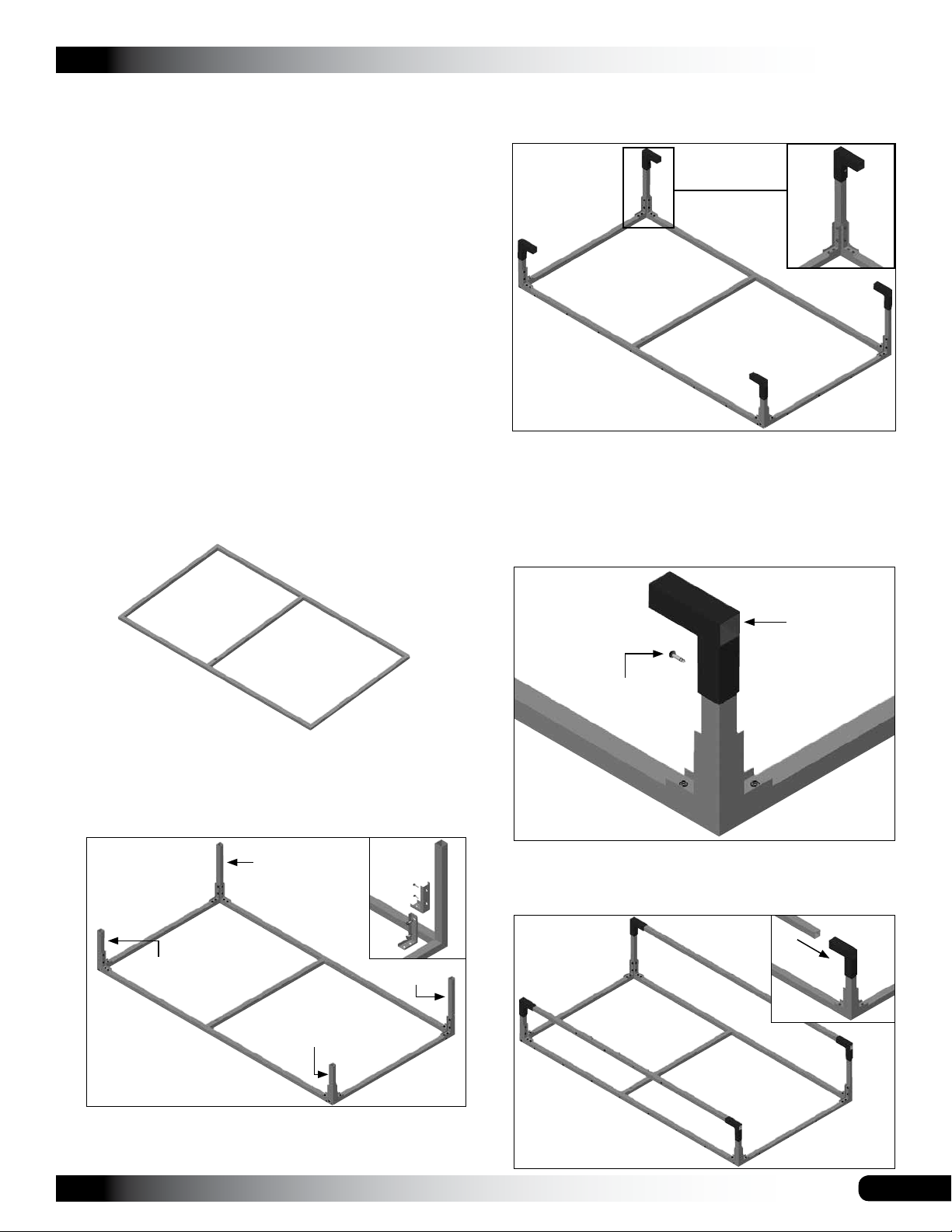

3. After all four corner tubes are in place, slide the four (4)

2-Way fittings (#104625) onto the corner frame tubes

as shown and secure with Tek screws.

Complete these steps:

1. Locate one (1) main frame component (102923),

assemble (if needed), and place it where you want to

assemble the cold frame.

2. Using the Tek screws (#FA4472) and the angle

brackets (#QH1330), attach the sidewall corner tubes.

NOTE: The 18" lengths are positioned to the back and

the 12" lengths are positioned to the front.

#S15P018

NOTE: The open end of the 2-Way fitting faces to the

outside/inside of the frame.

Install all Tek screws so that their heads do not interfere

with the installation of the polycarbonate panels. See

the following diagram.

Opening

Tek Screw

4. Locate the two (2) tubes (#S15P092) for the front and

back wall upper supports and slide these through the

openings in the 2-way fittings shown below.

#S15P012

#S15P012

#S15P018

HINT: Attach the two (2) brackets first to the square

tube and then attach the brackets and tube to the

frame.

Revision date: 05.08.18

7

GROWSPAN™ COLD FRAMES & GREENHOUSES

FRAME ASSEMBLY INSTRUCTIONS (CONTINUED)

5. With the ends of the tubes flush to the outside of each

of the 2-Way fittings, secure the tubes in the fittings

using the Tek screws (#FA4472B).

6. Locate one (1) square tube (#S15P045) for the upper

end sidewall frame and attach it as shown below.

Set Flush

NOTE: The upper sidewall tube is flush with the top of

the longer front and back frame tubes. See dashed line

in previous diagram.

Diagram shows the assembled frame without the cover.

8. Locate the four (4) angle iron corner ground stakes

(#105232) and the remaining frame assembly

(#102923) to use as a guide for driving the stakes.

NOTE: If you are positioning the cold frame on a

surface such as concrete that will not allow you to drive

ground stakes, skip this step and read the suggestions

for anchoring the cold frame.

If you plan to use the ground stakes, continue with the

next step to drive and attach the ground stakes to the

assembled frame.

# S15P045

HINT: Adjust the QH1330 brackets to fit the angle of the

sidewall. It is easiest to attach the brackets first to the

45" square tube and then to the corner tubes already

attached to the frame.

7. Repeat the steps to attach the remaining sidewall

upper support tube.

9. Position the remaining frame, which will be ultimately

used for the cold frame cover, in the location you want

the assembled cold frame.

NOTE: This frame (#102923) is used as a pattern to

position the ground stakes. It is removed after setting

the stakes.

10. Take one (1) corner stake (#105232) and drive it into

the ground as shown below. Allow a few inches of the

stake to remain above the frame.

Ground Level

ATTENTION: Position the stake to the inside of the

frame as shown above. The dashed line in the insert

diagram shows the inside edge of the frame.

8

Revision date: 05.08.18

FRAME ASSEMBLY INSTRUCTIONS (CONTINUED)

11. Repeat the steps to drive the remaining corner stakes

into the ground.

Stakes are positioned to the

inside of the frame.

Small Side

GROWSPAN™ COLD FRAMES & GREENHOUSES

16. Once the lower frame is secured to the stakes (if used),

set and center the remaining frame (#102923) on top of

the assembled cold frame.

Small square of

the cover frame

Dashed line shows

the ground level.

12. After all stakes are partially driven into the ground,

return to each stake and drive it flush to the top of the

frame.

Flush at top

Ground Level

Diagram shows the inside view and how to attach the

ground stake. Dashed line shows the ground level.

13. Once all stakes are flush as shown above, lift the frame

up and off the driven stakes.

14. With help, lift and move the assembled frame and

position the frame over the ground posts.

Front or low side

of the frame

NOTE: The cross brace of the cover frame is slightly

off center. While standing in front of the cold frame,

position the small square of the cover frame on the

left. This helps when the sliding cover panels are

assembled and installed.

17. Attach the hinges to the cover frame and the

assembled cold frame.

ATTENTION: Space hinges evenly along the cover

frame and secure using wafer-head screws (#105116).

Consult the photo below to properly position the hinges.

Photos below show the frame from the back.

Cover

Hinge (#FA5030)

Cover Frame

15. Secure each stake to the frame using two (2) Tek

screws in each corner. See the diagram below.

Tek Screws

NOTE: Tek screws can be driven through the ground

stake and into the frame if there are no pre-drilled holes

in the stakes or the holes do not line up with the frame.

Revision date: 05.08.18

Main Frame

Frame shown may differ slightly from actual frame.

NOTE: The above photo shows the assembled cold

frame from the back with an attached cover. As shown,

the aluminum profile regarding the back panel of the

cold frame is installed over the secured lower portion of

the hinge.

Panels are installed after the cover frame is attached

and the cold frame is anchored to the site.

18. Continue with anchoring information and the panel

installation instructions.

9

GROWSPAN™ COLD FRAMES & GREENHOUSES

ANCHOR THE FRAME

The following anchoring methods are recommended to

properly anchor the assembled frame.

The diagrams below illustrate two possible ways to properly

anchor the frame. The frame shown may be different. It is

used for illustration purposes only.

The parts shown in the diagrams regarding anchor systems

are not included with the cold frame. Contact Customer

Service at 1-800-245-9881 to purchase additional parts to

anchor the shelter.

CUT AND ASSEMBLE THE POLYCARBONATE PANELS

FOR THE COLD FRAME: OVERVIEW

Each polycarbonate panel is cut from the large sheets of

polycarbonate shipped with the cold frame. The following

steps describe cutting all panels. (The sliding cover panels

are assembled in the next procedure.) The general steps to

cut and install the panels are as follows:

1. Use the cut sheets near the back of these instructions

to measure and cut each panel.

2. Use the individual panels to measure and cut the

aluminum profile for each panel.

ATTENTION: Consult the diagrams (at the back of

these instructions) and the photos in this section to

properly account for the installation requirements of the

profile.

3. Install the profile on each panel.

NOTE: A small piece of tape (not included) can be

used to hold the profile in place on the panel if needed

as you attach the panels to the frame.

Anchor System for use on concrete

4. Attach the panels to the frame using screws (#105116).

CUT AND ASSEMBLE THE POLYCARBONATE PANELS

The following procedure describes cutting all panels for the

cold frame and cover. (The cover panels are set aside and

assembled and installed in the next procedure.) After the

panels are cut to the proper size, the aluminum profile is

attached to the panels for the main cold frame only.

This is the suggested method since panels adjacent to

each other are trimmed with a single piece of profile and

must be assembled together.

ATTENTION: Always install the UV-protected surface of the

polycarbonate panel to the outside of the cold frame.

The protective film that covers each panel can be peeled

away from the edges to install the profile and then

completely removed when the panels are attached to the

frame.

IMPORTANT! The cells within the polycarbonate panel

must run up and down so that moisture drains from the

panel. DO NOT install the panels with the cells running

horizontally.

Ground Anchor System *

*This system can be used in addition to the ground stakes

identified above.

ATTENTION: Ground stakes alone are not sufficient to

properly anchor the cold frame to the site.

10

USE 105116 WAFER-HEAD SCREWS TO ATTACH

ALL ALUMINUM PROFILE TO THE FRAME.

Do not allow the panels to remain in direct sunlight when

the protective film is intact. Consult the notes on the Cut

Sheet pages for additional information.

Revision date: 05.08.18

CUT AND ASSEMBLE THE POLYCARBONATE PANELS

(CONTINUED)

1. Locate the Cut Sheet for the A and B Panels and

the Panel Location Diagrams at the back of these

instructions.

ATTENTION: For the best results, read through the

panel installation procedures and consult all diagrams

and photos before cutting the panels.

Read the additional notes on the diagrams at the back

of these instructions before you continue.

2. Using the diagrams, measure, mark and cut the panels.

Mark each panel with its ID number/letter so it is

installed in the correct position on the frame and with

the UV-protected surface toward the sun.

ATTENTION: Cut Panel A and Panel B from one 4' x 8'

polycarbonate panel and set these aside to be used for

the sliding cover panels.

Cut Panels 1-Front, 2-Front, 1-Back, 2-Back and C

from the next 4' x 8' polycarbonate panel.

3. After cutting the first set of panels and marking them

with the ID, select the next polycarbonate sheet and cut

Panel D from that panel using the Cut Sheet diagrams.

NOTE: Mark the panel with its ID after. Extra panel

material has been sent in case a panel needs re-cut.

4. Using the diagrams as a guide, select a section of

aluminum profile (#104548) and a panel and cut the

profile to the correct length.

Consult the photos for Step 6 before cutting the profile

to view how to position the profile on the panels.

All profile installed in the horizontal positions on the

cold frame extends beyond the edges of the cut panels.

Refer to the photos before cutting the panels and

profile.

GROWSPAN™ COLD FRAMES & GREENHOUSES

NOTE: The profile (#104548) that runs at the tops and

bottoms of Panels 1-Front and 2-Front and 1-Back and

2-Back spans the vertical joint between the two panels.

Consult the profile installation notes on the Panel

Location Diagrams for the proper location of the

H-Channel profile (#113236Z096), which is the profile

used for the vertical seam between adjacent panels

(front and back). Attach using FA4474B Tek screws.

113236Z096

5. After cutting the profile, install the profile on the panel

edges in the proper locations.

NOTE: Use a small piece of tape (not supplied) to hold

the profile in place on the panel (if needed). After each

panel is attached to the frame as shown below, the

tape can be removed when the protective film of the

polycarbonate is removed.

Peel the protective cover from the panel. DO NOT

allow the protective film to remain on the panel in direct

sunlight. This will make the film difficult if not impossible

to remove.

6. Attach the assembled panel sections to the frame in

the locations identified on the diagrams.

The upper and lower sections of profile for the ends, back

and front panels run to the edge of the frame.

Wafer-Head Screw (#105116)

ATTENTION: This profile (#104548) is installed on all

edges of a panel unless otherwise noted. This profile

is not used for the vertical seam where two adjacent

panels are joined (front and back).

Revision date: 05.08.18

Upper Profile (Horizontal)

Vertical profile sections for the same panels run between

the horizontal lengths of profile.

11

GROWSPAN™ COLD FRAMES & GREENHOUSES

CUT AND ASSEMBLE THE POLYCARBONATE PANELS

(CONTINUED)

ASSEMBLE THE TWO (2) SLIDING PANELS FOR THE

COVER

NOTE: The vertical profile where it meets the horizontal

profile of the ends can be cut at a slight angle to match

the angle of the upper profile if desired. See black

dashed line in the previous photo.

Edge of

Frame

Horizontal profile

sections for the

front and back run

to the edge of the

frame. See solid

lines and arrows

to the right.

Vertical profile

sections run

between the

horizontal lengths.

Wafer-Head

Screw (#105116)

Horizontal Profile

Panel A and Panel B are assembled differently. Consult

the panel diagrams for each panel at the back of these

instructions for dimensions and additional information.

Assemble Panel A

1. Use the panel from Step 1 (previous procedure), the

panel diagram, and the diagram below to cut the first

profile section to the proper length.

2. Take the tube of silicone and apply a thin layer along

the edge as shown.

Profile runs parallel with the cells in the panel.

Dashed line shows the

edge of the panel.

Edge of Frame

7. After attaching all main cold frame panels, continue

by assembling and installing the sliding panels for the

cover.

Cut and attach

this section of

profile first.

Panel will slide in this direction when installed. Handle

is attached to this section of profile.

3. Install profile flush to the ends of the panel. Consult the

diagrams for the proper position.

12

Revision date: 05.08.18

ASSEMBLE THE TWO (2) SLIDING PANELS FOR THE

COVER (CONTINUED)

4. After the silicone has set, measure from the inside

edge of the first profile to the end of the panel and cut

two additional sections of profile to that length. Consult

the Panel A diagrams and the dashed lines below to

measure and position the profile.

Measure from the inside edge to the end of the panel.

5. Apply a thin film of silicone on each side of the panel

and slide a section of profile onto the panel as shown

below.

ATTENTION: Do not plug the panel cell holes with

silicone! Cells must remain open for proper venting.

GROWSPAN™ COLD FRAMES & GREENHOUSES

7. Carefully rotate the panel and repeat the steps to apply

silicone and to install the next section of profile for the

panel.

When installed correctly, the profile will appear as

shown below for Panel A.

Flat Side of Profile

NOTE: Consult the panel diagrams when installing

the profile to ensure that the UV-protected side of the

polycarbonate panel is installed toward the sun.

For Panel A, the above photo shows the top of

the panel and the UV-protected surface of the

polycarbonate.

For Panel B, the photo shows the underside of the

panel. Consult the Panel B diagrams for additional

information.

6. With the profile pressed onto the panel, use your finger

to spread the silicone along the edge of the profile

to seal the area if needed. See the dashed line in

the photo on the next page. Remove excess silicone

before it dries.

8. Allow the silicone to set and continue by assembling

Panel B.

Assemble Panel B

The steps to install the profile on Panel B are slightly

different from those of the Panel A. Consult the Panel B

diagrams for additional information.

1. Take the polycarbonate for Panel B and first install the

profile along the edges of the panel that run parallel

with the cells in the polycarbonate panel.

NOTE: Verify that the UV-protected side is in the

correct position when installing the profile. Apply

silicone and attach the profile as described in Step 1 of

the previous procedure.

Revision date: 05.08.18

13

GROWSPAN™ COLD FRAMES & GREENHOUSES

ASSEMBLE THE TWO (2) SLIDING PANELS FOR THE

COVER (CONTINUED)

2. Take the two remaining lengths of profile for Panel B

and attach these as described in Step 5 of the previous

procedure.

Measure

between the

installed profile

and cut the

remaining

profile to that

length for

Panel B.

INSTALL THE SLIDING PANELS FOR THE COVER

For clarity, the diagrams and photos in the following

procedures show the cover frame before it is attached to

the assembled cold frame. If the procedures up to this point

were followed, the cover frame has been attached to the

main cold frame and the sliding panels are prepared.

IMPORTANT NOTE: For this procedure, the small square

(or opening) of the main cover frame is positioned on the

left as seen from the front of the cold frame. The sliding

panels are assembled differently. The panels are identified

as Panel A and Panel B and must be installed as described

in the following steps.

1. With the cover frame attached and the small side

on the left as seen from the front of the frame, cut a

length of aluminum profile (#104548) to cover the long

sections of the frame. See the dashed lines in the

diagram below.

ATTENTION: Refer to the Panel B diagrams to

properly position the profile. Verify that the

UV-protected surface is facing toward the sun.

3. Allow the silicone to set before continuing.

ATTACH HANDLES TO PANEL A AND PANEL B

1. Locate a handle (#104777) and four (4) Tek screws

(#FA4472B).

2. Center the handle in the proper position on the panel

profile and install a Tek screw in each hole.

NOTE: The bottom of each Tek screw will extend

through the bottom of the profile. DO NOT

OVERTIGHTEN THE SCREWS.

3. Repeat the steps to attach the handle to the remaining

sliding cover panel.

Panel A Panel B

Profile (and tape: Step 3)

runs from end to end.

Small Side

Front of Cold Frame

2. Along the lip of the profile, mark the mounting screw

locations in 18" increments and drill a 1/4" hole in those

locations and through the profile lip.

Drill first hole 1"

in from the end.

18"

End View of Profile

Consult the diagrams above for proper handle

positions.

14

Drill 1/4" holes through

the lip at 18" spacing.

3. Cut two (2) lengths of foam tape and attach the tape

to the cover frame in the locations identified by the

dashed lines in Step 1 diagram.

NOTE: Peel the paper from the foam tape at one

end, stick the tape to the frame, and work toward the

remaining end of the frame while peeling the paper and

pressing the tape in place. For best results, position the

tape slightly inside the edges of the frame.

Revision date: 05.08.18

INSTALL THE SLIDING PANELS FOR THE COVER

(CONTINUED)

4. With the tape in place on the frame, take one piece of

profile and position it on the tape and frame as shown

below.

NOTE: The ends of the profile will be flush with the

ends of the cover frame. The edge of the profile will be

flush with the edge of the cover frame.

The profile must run evenly along the edge of the cover

frame for the sliding panels to open and close properly.

Profile must run evenly

along the edge of the

Cover Frame

frame.

GROWSPAN™ COLD FRAMES & GREENHOUSES

7. With the two (2) long sections of profile attached to the

cover frame, cut a section of felt tape and attach it to

the center cross brace of the cover frame.

Felt Tape

View as seen looking down on the cover frame.

Apply a single piece of tape on three sides of the center

cross brace.

Top

5. With the profile in position, secure it to the frame using

Tek screws (#FA4472B) inserted through the pre-drilled

holes and into the cover frame.

ATTENTION: DO NOT OVERTIGHTEN THE

SCREWS! Screws should be snug. Profile must be

allowed to adjust to the sliding panels once these are

installed.

6. Repeat the step to secure the remaining profile to the

last long edge of the cover frame. The end view below

shows the profile in the proper position.

Back of Frame

Felt Tape

Cross Brace

End View of the cross brace showing tape location.

8. Take the assembled Panel A and insert its profile into

the guide tracks of the cover frame.

NOTE: Refer to the Panel A diagrams for proper

position. Panel A is slid into the guide track from the left

side of the cover frame.

Lift the handle of the panel to allow the mounting Tek

screws to clear the outside edge of the cover frame.

The inside edge of Panel A (this is the edge without

profile) will ride on top of the felt tape attached to the

cross brace of the cover frame.

The profile installed above acts as guide tracks for the

sliding cover panels. Diagram may differ slightly from

the actual frame. White dashed line shows the tape

location.

Revision date: 05.08.18

15

GROWSPAN™ COLD FRAMES & GREENHOUSES

INSTALL THE SLIDING PANELS FOR THE COVER

(CONTINUED)

Complete the following steps to install the cover support

arm.

9. Once Panel A is in place, cut two (2) 2" sections of felt

tape and stick one on Panel A and one on Panel B in

the locations shown on the panel diagrams.

NOTE: Felt tape is used to prevent the panels from

rubbing on each other.

10. With the tape applied, take Panel B and slide it into the

guide tracks from the right side of the cover frame.

ATTENTION: When installed correctly, Panel B

overlaps the inside edge of Panel A and rides on top of

Panel A.

11. With both sliding panels installed, cut and install the

remaining two (2) lengths of profile. Install the flat side

down and against the frame. This profile runs between

the long sections of profile of the cover frame.

ATTENTION: Do not install foam tape under these last

sections of profile.

12. Check the operation of the sliding panels. If the panels

bind, loosen the mounting Tek screws of the long

sections of cover frame profile to allow the tape to

expand and retry the doors.

NOTE: When properly installed, there will be a

noticeable drag between the panels when they are slid

open and closed.

1. Locate the center of the cover frame and main cover

and mark the location.

2. Take the two (2) brackets (#105240) and attach these

as shown using Tek screws.

Center mark on

main frame.

Front Panel

NOTE: The bracket is installed on the aluminum profile

of the front panel as shown above.

Center Mark

Cover Frame

13. Continue with the installation of the support arm,

brackets, and the safety straps.

INSTALL COVER SUPPORT ARM, BRACKETS AND

SAFETY STRAPS

The cover support arm is attached to the outside of the

cover frame and to the outside of the main frame.

Support Arm (#105239)

Front Panel

3. Insert the 5/16" bolt (#FAC182R) into the bracket

attached to the cover frame and attach the support arm

to the bracket using the 5/16" wing nut.

Wing Nut (#FA1105)

Machine Screw 5/16"

(#FAC182R)

Support Arm

(#105239)

NOTE: Wing nut should remain loose enough to swing

the arm into position.

16

Revision date: 05.08.18

INSTALL COVER SUPPORT ARM, BRACKETS AND

SAFETY STRAPS (CONTINUED)

4. Flip the support arm up and install and tighten the 1/4"

nut and bolt as shown.

Bolt 1/4"

(#FAG104B)

Tighten 1/4" Nut

5. Swing the support arm into position and install the 1/4"

wing nut as shown to lock the cover in place.

GROWSPAN™ COLD FRAMES & GREENHOUSES

SAFETY STRAP INSTALLATION

The safety straps are designed to prevent the cover from

opening too far and causing injury and damage. Safety

straps are attached using Tek screws (#FA4472) and

neo-bonded washers.

WARNING: The safety straps must be installed. This

cover is designed to open for venting and watering

only. The sliding panels can be slid open to either side

to access the interior of the cold frame.

Read the Safety Information for additional precautions.

Complete the following steps to install the safety straps.

NOTE: The safety straps are attached to the outside of the

frame and cover frame along the sides to prevent damage

to plants on the inside of the frame.

1. Raise the cover and lock it in the open position using

the locking hole in the support arm as shown.

6. With all brackets tight and the support arm installed,

attach the handle to the cover frame in the desired

position using the Tek screws.

7. Check the operation of the support arm and main

cover.

8. Install the safety straps.

Revision date: 05.08.18

2. Take one safety strap with D-rings and attach it to the

outside of the cover and main frame using Tek screws

(#FA4472B) and neo-bonded washers.

17

GROWSPAN™ COLD FRAMES & GREENHOUSES

SAFETY STRAP INSTALLATION (CONTINUED)

SAFETY INFORMATION

Allow a little slack to remain in the strap so you can

easily adjust the support arm when needed.

Safety Strap

Tek Screw and

Neo-Bonded

Washer

3. Repeat the steps to install the remaining safety strap.

The cover of your cold frame is heavy. Use caution when

opening and closing the cold frame cover.

ATTENTION: When open, the cover must remain secured

at all times using the support arm and wing nuts.

Wing nuts must be tight to lock the support arm in place.

WARNING! DO NOT prop the cover open! Serious

injury may occur if the prop slips out of position.

Damage to the polycarbonate panel may occur if a

prop is used.

Photo shows properly installed safety straps.

4. Test the operation of the cover.

5. Continue by reading the safety information that follows.

• TO PREVENT DAMAGE OR INJURY OR BOTH, DO

NOT CLIMB OR STORE ANYTHING ON THE COLD

FRAME.

• SAFETY STRAPS MUST REMAIN PROPERLY

ATTACHED AT ALL TIMES. DO NOT REMOVE THE

SAFETY STRAPS!

• ALWAYS USE THE HANDLE WHEN RAISING OR

LOWERING THE COVER.

• ALWAYS LOCK THE COVER IN PLACE WHEN OPEN

USING THE SUPPORT ARM AND LOCKING WING

NUTS.

• NEVER ALLOW CHILDREN TO PLAY AROUND, ON,

OR IN THE COLD FRAME.

• COLD FRAME IS NOT DESIGNED FOR PETS OR

OTHER ANIMALS.

Continue by reading the care and maintenance information

that follows.

18

Revision date: 05.08.18

SHELTER CARE AND MAINTENANCE

Proper care and maintenance of your cold frame will help to

ensure years of service. The following items identify areas

that must be periodically checked to ensure that your cold

frame is maintained properly:

• Check the anchoring system (if applicable) to see that

all components are tight and in good repair.

• Check connections and all fasteners to verify that they

remain tight.

• Check the polycarbonate panels (if equipped) to verify

that these are in good repair.

• Do not climb or stand on the cold frame at anytime.

• DO NOT ALLOW CHILDREN OR PETS TO OCCUPY

THE INSIDE OF THE COLD FRAME!

• Remove debris and objects that can accumulate on

the cold frame. Use tools that will not damage the

polycarbonate panels when removing debris and when

trimming around the outside of the cold frame.

• Remove snow to prevent excess accumulation. Use

tools that will not damage the polycarbonate panels

when removing snow.

GROWSPAN™ COLD FRAMES & GREENHOUSES

Space below is reserved for customer notes.

• Check the contents of the shelter to verify that nothing

is touching the panels that could cause damage.

• Inspect the safety straps, support arm, and brackets to

verify that all screws and straps are tight and in good

repair.

• If the cold frame is moved, inspect all parts and

connections after moving and before use.

• For replacement or missing parts, call 1-800-245-9881

for assistance.

NOTE: With the exception of Truss Arch buildings,

GrowSpan™ shelters and greenhouses do not have any

tested loading criteria.

Revision date: 05.08.18

19

GROWSPAN™ COLD FRAMES & GREENHOUSES

QUICK START GUIDE

Commercial Cold Frame with Sliding Cover Panels

ASSEMBLY NOTE: Install Tek screws using a clutched

drill driver running approximately 750 RPM while applying

approximately 50 lbs of force.

Do not use an impact driver to install Tek screws!

20

Revision date: 05.08.18

PANEL A DIAGRAMS

Edge of Panel

Center handle and

secure with Tek

Screw (#FA4472B)

UV-Protected surface

is always installed

toward the sun.

Edge of Panel

GROWSPAN™ COLD FRAMES & GREENHOUSES

Felt Tape

44-3/4"

Handle

Top View of the Panel A

Flat Side Up

ATTENTION: Cut all profile for this

panel so that it is installed as shown

in these diagrams.

ATTENTION: Install all profile for

Panel A with the flat side up as

shown. UV-protected side of the

polycarbonate panel is always

installed toward the sun.

UV-Protected

Surface Up

Revision date: 05.08.18

DO NOT install profile along the

panel edge opposite where the

handle is attached. Panel A Only.

21

GROWSPAN™ COLD FRAMES & GREENHOUSES

PANEL B DIAGRAMS

Install felt tape

on the underside

of this length of

profile.

44-3/4"

Edge of Panel

Center handle and

secure with Tek

Screw (#FA4472B)

UV-Protected surface

is always installed

toward the sun.

Edge of Panel

Handle

Top View of the Panel B

Right-Angled Surface Up:

Flat Side Down

ATTENTION: Cut all profile for this

panel so that it is installed as shown

in these diagrams.

ATTENTION: Install all profile for

Panel B with the angled surface

up. UV-protected side of the

polycarbonate panel is always

installed toward the sun.

UV-Protected

Surface Up

22

Revision date: 05.08.18

PANEL LOCATION DIAGRAM:

TOP, FRONT AND RIGHT SIDE

GROWSPAN™ COLD FRAMES & GREENHOUSES

Dashed line shows the edge of

Panel A under Panel B.

A

1-Front

#113236Z096

NOTE: Position the H-Channel

between each long horizontal profile

section.

Install with flat side out. Use two (2)

FA4474B Tek screws.

2-Front

View shows the cold

frame from the front.

B

C

Revision date: 05.08.18

23

GROWSPAN™ COLD FRAMES & GREENHOUSES

PANEL LOCATION DIAGRAM:

BACK AND REMAINING SIDE

C

2-Back

#113236Z096

NOTE: Position the H-Channel

between each long horizontal profile

section.

Install with flat side out. Use two (2)

FA4474B Tek screws.

1-Back

View shows the cold

frame from the back.

D

24

Revision date: 05.08.18

CUT SHEETS: FRONT PANELS, "A" AND "B" PANELS

40" 48"

GROWSPAN™ COLD FRAMES & GREENHOUSES

1-Front

Read the instructions and use the diagrams

before cutting and installing the panels.

REMOVE THE PROTECTIVE FILM.

DO NOT ALLOW THE PANELS TO REMAIN IN

DIRECT SUNLIGHT WITH THE PROTECTIVE

FILM STILL IN PLACE. DOING SO WILL MAKE

THE FILM DIFFICULT IF NOT IMPOSSIBLE TO

REMOVE.

DAMAGE TO PANELS MAY OCCUR IF

STACKED IN DIRECT SUNLIGHT. PROTECT

STACKED PANELS FROM DIRECT SUNLIGHT.

2-Front

Sliding Door

Panels A & B

13-1/2"

44-3/4"

48"

ATTENTION: Install all UV-protected surfaces to the outside (toward the sun) of the cold frame.

Cut the panels as follows:

• Panel A and Panel B: one (1) 4' x 8' polycarbonate sheet

• Panels 1-Front, 2-Front, 1-Back, 2-Back, and Panel C: one (1) 4' x 8' polycarbonate sheet

• Panel D: one (1) 4' x 8' polycarbonate sheet (Part of this panel will remain in case a panel needs re-cut.)

Revision date: 05.08.18

25

GROWSPAN™ COLD FRAMES & GREENHOUSES

CUT SHEETS: BACK PANELS, "C" AND "D" PANELS

ATTENTION: Install all UV-Protected surfaces to the outside of the cold frame. See previous page to

determine which panels to cut from each 4' x 8' polycarbonate panel.

NOTE: Always read the instructions and use the diagrams before installing the panels.

40" 48"

1-Back 2-Back

C D

Dimensions for Panel C are the same as Panel D.

19-1/2"

19"

13-1/2"

45-1/2"

26

Revision date: 05.08.18

GROWSPAN™ COLD FRAMES & GREENHOUSES

Solar-Powered Opener*

(*Not included. Must be purchased separately.)

If the solar-powered opener was purchased for your commercial cold frame, use the installation instructions included

with the opener and the photos below to install the opener. Contact customer service at 1.800.245.9881 for additional

information, or to purchase the opener.

Views show the installed opener from the outside of the cold frame.

Views show the installed opener as seen from the inside of the cold frame.

ATTENTION: The support arm must remain "free" when using the solar-powered opener. To prevent damage to the cold

frame or the opener or both, DO NOT lock the cold frame lid closed after installing an opener.

Revision date: 05.08.18

27

Loading...

Loading...