Growonix GX400, GX300 Owner's Manual

GX300/GX400

Owners Manual

www.growonix.com

www.growonix.com toll free 888.406.8521, oce 818.510.0264, sales@growonix.com

1

INTRODUCTION

OUR MISSION

Durability, Reliability, Eciency, Purity, and Conservation form the foundation on which we design

and build all of our products. Consistent and superior quality sets us apart from other manufacturers

and increases our value to you - our customer. Whether you are a hydroponics hobbyist, serious

enthusiast, or large-scale gardener, GrowoniX is committed to bringing you the best solution for

water purication systems.

WHAT IS REVERSE OSMOSIS?

Reverse osmosis (RO) is a ltration method that removes many types of large molecules and ions

from solutions by applying pressure to the solution when it is on one side of a selective membrane.

This ltering process ensures that the solute (waste water) is contained within the pressurized

chamber while the pure solvent (RO water) is allowed to pass freely through the membrane.

TUNED FOR GROWING - IN TUNE WITH OUR CUSTOMERS

Traditional RO systems have waste ratios of approximately 4:1, which means there are 4 gallons

of waste water produced for every 1 gallon of puried water. GrowoniX line of water lters achieve

waste ratios of 2:1 with the EX100 through GX400 and an astounding 1:1 ratio with the GX600 and

GX1000.

GrowoniX has created a complete product line that will address the needs of hydroponic operations

of all sizes. Our lters will signicantly reduce your water use while dramatically increasing your yields.

THE TRADITIONAL WAY

takes 4 gallons of waste water to produce 1 gallon of pure water

THE

GrowoniX WAY

www.growonix.com toll free 888.406.8521, oce 818.510.0264, sales@growonix.com

5

600

550

500

450

400

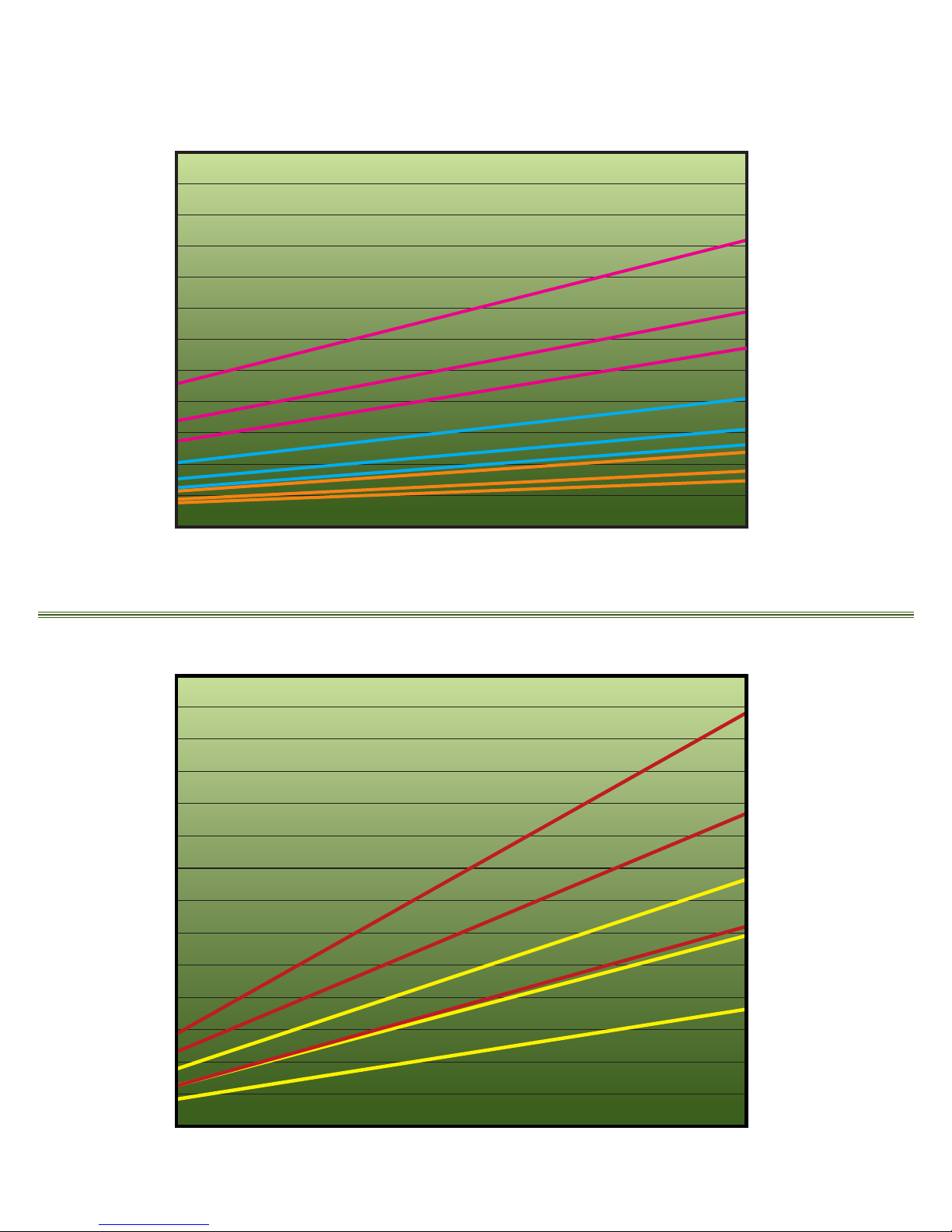

FLOW RATES

100GPD—400GPD FILTER FLOW RATES

EX/GX400-HF, 77ºF

GALLONS PER DAY

350

300

250

200

150

100

50

0

40 45 50 55 65 7560 70 80

WATER PRESSURE (PSI) WITH OR WITHOUT PUMP

600GPD—1000GPD FILTER FLOW RATES

2800

2600

2400

EX/GX400-HF, 60ºF

EX/GX400-HF, 50ºF

EX/GX200-HF, 77ºF

EX/GX200-HF, 60ºF

EX/GX200-HF, 50ºF

EX100-HF, 77ºF

EX100-HF, 60ºF

EX100-HF, 50ºF

EX/GX1000-HF, 77ºF

2200

2000

1800

1600

1400

1200

1000

GALLONS PER DAY

800

600

400

200

0

40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

WATER PRESSURE (PSI) WITH OR WITHOUT PUMP

8

EX/GX1000-HF, 60ºF

EX/GX600-HF, 77ºF

EX/GX1000-HF, 50ºF

EX/GX600-HF, 60ºF

EX/GX600-HF, 50ºF

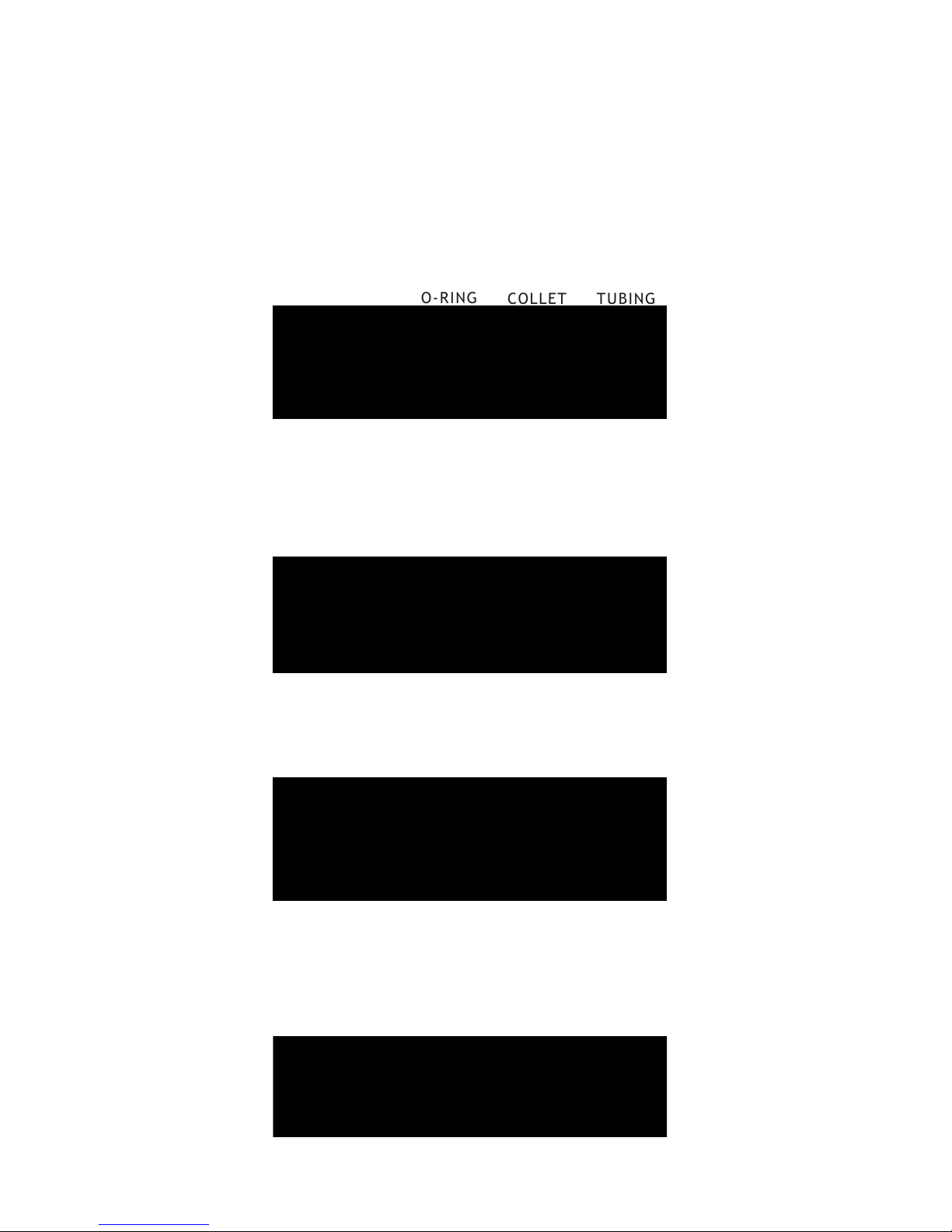

INFORMATION ON QUICK CONNECT FITTINGS

O-RING

COLLET

TUBING

GROWONIX WATER FILTERS USE QUICK CONNECT FITTINGS

THAT ALLOW FOR EASY MAINTENANCE.

MAKE A CLEAN TUBE CUT

Cut the tube squarely and if using plastic tubing, ensure that the cut has not made the tube out of round.

Also ensure that the tube has a smooth outside diameter without any burrs or score marks

prior to inserting it into the tting

INSERT TUBE INTO FITTING

Push the tubing through the collet and dual o-rings until it bottoms out against the tube stop.

The collet holds the tube in place and the dual o-rings provide a leak resistant seal.

.

TEST AND INSPECT

Push and pull the tubing toward and away from the tting to ensure that it has been installed properly.

Test and inspect the installation for any leaks.

TUBE REMOVAL

Relieve pressure from the tubing and tting. Push uniformly around the collet ange against the

tting body while pulling the tubing away from the tting to release it.

PUSH COLLET IN

PULL TUBE OUT

www.growonix.com toll free 888.406.8521, oce 818.510.0264, sales@growonix.com

7

tuned for growing

FEATURES:

tm

150 GALLONS PER DAY / 200 GALLONS PER DAY

GX300/GX400

2:1 WASTE RATIO

6.25 GALLONS PER HOUR

2:1 WASTE RATIO

GX150HR - DOW CHEMICAL MEMBRANE

GX200HF -HIGH FLOW COLD WATER

MEMBRANE

HIGH FLOW WASHABLE SEDIMENT FILTER

CLEAR FILTER HOUSINGS

STAINLESS STEEL LIQUID FILLED

PRESSURE GAUGES

PATENTED METAL HOUSING

AUTO SHUTOFF VALVE

EZ HOOKUP KIT

WALL MOUNTABLE

USES 50% LESS WATER THAN TRADITIONAL

RO SYSTEMS

w/HIGH FLOW

MEMBRANE

THE GX300

When we developed the GX300, we decided to pack all the high end features into a tight ecient RO

unit. We engineered a 50% increase in water production over traditional ROs, lowered the waste ratio to

2:1, and still oered it to you for the same price point of an entry level RO lter. But we didn’t stop there.

We topped it all o with a 2” stainless steel liquid-lled pressure gauge, never before seen in a lter this

size, and integrated it into our patented GX Series bracketing system. A manual ush valve allows you

to clean the membrane, purging out pollutants that could otherwise add buildup to the system. Flushing

adds considerable life to the membrane. With ow rates at 6.25 GPH (Gallons Per Hour), the GX200HF

delivers the same excellent ltration as our larger models.

2

NO ADDITIONAL PRE-FILTERS NEEDED

MEMBRANE FLUSH KIT INCLUDED

Built in the U.S.A.

No Assembly Required

Loading...

Loading...