EX600T/1000T

EX600/1000

Owners Manual

www.growonix.com

www.growonix.com toll free 888.406.8521, oce 818.510.0264, sales@growonix.com

1

EX600T

EX600

EX1000

EX1000T

EX 600/1000 SERIES

The strategy behind the EX Series is simply to

make the highest quality, most ecient water

lter, tuned specically to meet the rigors of

the industry.

Each lter system is designed, hand built, and

tested right here in the United States, using

American made, top-of-the-line ttings and

tubing. All components are housed in steel

powder-coated brackets fabricated in sunny

Los Angeles, California.

The crown jewel of the EX Line is the Dow

Membrane element, delivering a consistent

rejection of 98.5% at a 1:1 ratio.

No matter how big or small your water production

needs are, the EX Line has a solution for you.

FEATURES

600 TO 1000 GALLONS PER DAY

25 TO 42 GALLONS PER HOUR

1:1 WASTE RATIO

DOW CHEMICAL MEMBRANE

ECO GREEN CARBON BLOCK

HIGH FLOW WASHABLE SEDIMENT FILTER

STAINLESS STEEL LIQUID FILLED

PRESSURE GAUGES

CAN USE A BOOSTER PUMP

TO DOUBLE FLOW RATES

MEMBRANE VESSELS

RATED FOR 300/250 PSI

PATENTED METAL HOUSING

AUTO SHUTOFF VALVE

EZ HOOKUP KIT

NO ADDITIONAL PRE-FILTERS NEEDED

2

WALL MOUNTABLE

75% LESS WATER

THAN TRADITIONAL RO SYSTEMS

EX600/EX1000

SYSTEM SPECIFICATIONS:

The EX600 Designed to ow 25 GPH (Gallons

Per Hour) of pure RO water. Utilizing the best

membrane technology in the world, mounted

on locking casters, and wrapped in our EX

Series patented bracketing system; our EX600

will change the way you look at RO.

A pair of liquidlled stainless steel pressure

gauges tells you when it’s time to change the

pre-lters. A manual ush valve allows you to

clean the membrane, purging out pollutants

that could otherwise add buildup to the

system. Flushing adds considerable life to

the membrane. For those who demand even

more performance, the EX600 can be used

with a pressure-boosting pump to dramatically

increase GPD output.

Flow Rate EX1000 =1000 GPD

EX600 = 600 GPD

Max Flow Rate w/Booster Pump 2000

GPD(1800 GPD average)

Minimum Feed Pressure 40 psi

Recommended Feed Pressure 60 psi—80 psi

Recovery (system ratio 1:1) 50%

Operating Temperature 40°F—105°F

Operating pH 3-11

Dimensions LxWxH (in) 21x9x28

Weight 50 lbs.

Nominal % Rejection 98.5%

Maximum TS : 2000 ppm

Minimum NACL Rejection: 96%

Maximum Hardness : 15 gpg

Test Conditions:

Permeate ow and salt rejection based on

550 ppm, 80 psi, 77°F (25°C), pH 7, and 50% recovery.

www.growonix.com toll free 888.406.8521, oce 818.510.0264, sales@growonix.com

3

600

550

500

450

400

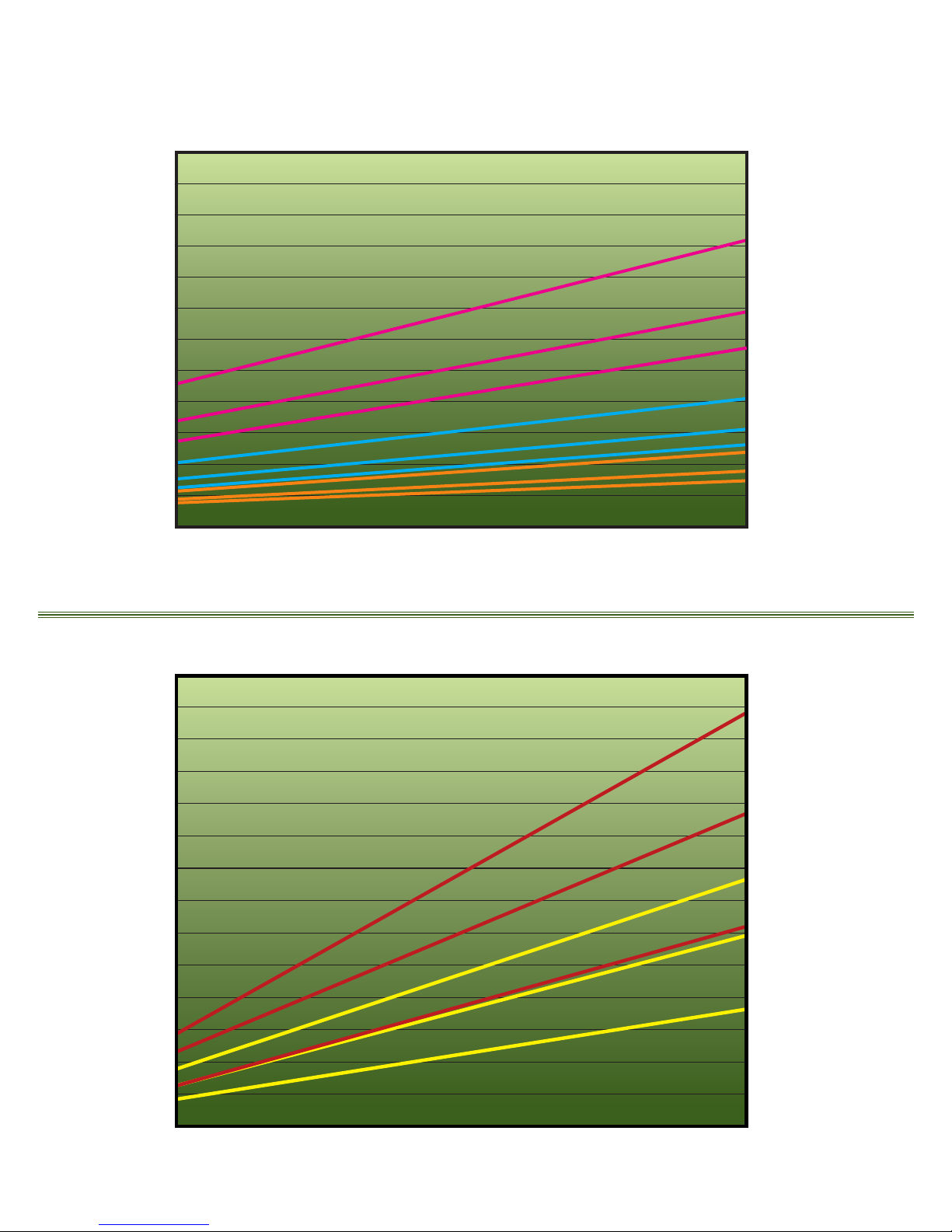

FLOW RATES

100GPD—400GPD FILTER FLOW RATES

EX/GX400-HF, 77ºF

GALLONS PER DAY

350

300

250

200

150

100

50

0

40 45 50 55 65 7560 70 80

WATER PRESSURE (PSI) WITH OR WITHOUT PUMP

600GPD—1000GPD FILTER FLOW RATES

2800

2600

2400

EX/GX400-HF, 60ºF

EX/GX400-HF, 50ºF

EX/GX200-HF, 77ºF

EX/GX200-HF, 60ºF

EX/GX200-HF, 50ºF

EX100-HF, 77ºF

EX100-HF, 60ºF

EX100-HF, 50ºF

EX/GX1000-HF, 77ºF

2200

2000

1800

1600

1400

1200

1000

GALLONS PER DAY

800

600

400

200

0

40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

WATER PRESSURE (PSI) WITH OR WITHOUT PUMP

4

EX/GX1000-HF, 60ºF

EX/GX600-HF, 77ºF

EX/GX1000-HF, 50ºF

EX/GX600-HF, 60ºF

EX/GX600-HF, 50ºF

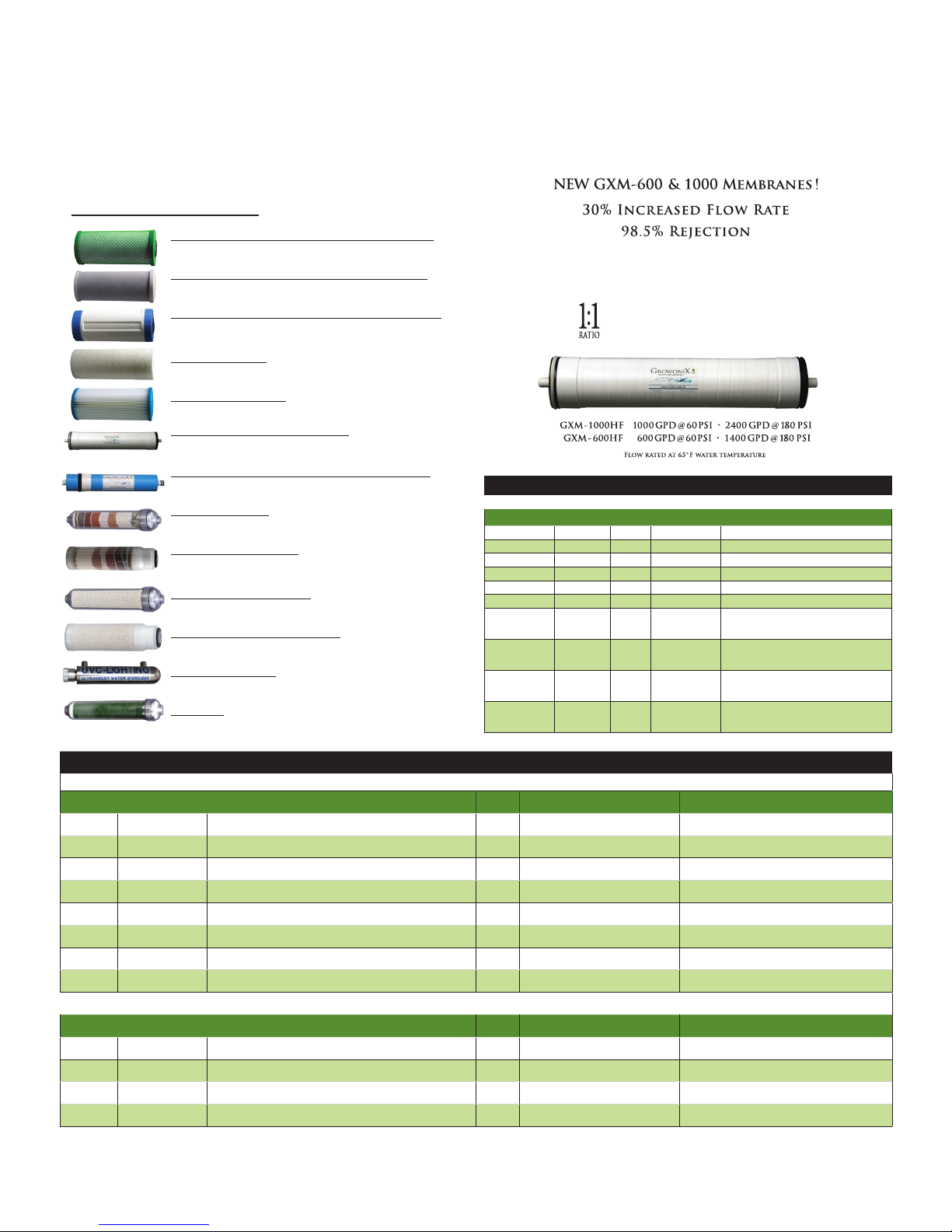

MEMBRANE INDEX

COCONUT CARBON FILTER— “GREEN BLOCK”

PREMIUM COCO CARBON, PRODUCED USING ECO-FRIENDLY LOW

EMISSIONS PROCESSES

COCONUT CARBON FILTER—”WHITE BLOCK”

ECONOMY COCO CARBON, SAME PERFORMANCE AS GREEN

BLOCK, FOR A LITTLE LESS MONEY.

KDF85/CATALYTYIC ACTIVATED CARBON FILTER

PREMIUM CARBON FILTER USING THE BEST ACTIVATED CARBON WITH

A BED OF KDF85 MEDIA. THERE’S NO BETTER CARBON AVAILABLE.

SEDIMENT SPUN

SPUN POLY SEDIMENT FILTERS WITH HUGE DIRT HOLDING CAPACITY.

SEDIMENT PLEATED

HIGH FLOW SEDIMENT FILTERS WITH ULTRA LOW PRESSURE DROP.

GXM INDUSTRIAL MEMBRANES

HIGHEST FLOWING DOW SHEET MEMBRANES ON THE PLANET, WITH

THE LOWEST WASTE RATIO.

GXM HIGH FLOW COLD WATER MEMBRANES

HIGHEST FLOWING RESIDENTIAL SIZED MEMBRANES.

ALWAYS 2:1 RATIO.

ALKALINE INLINE

INLINE FILTER ADDS CALCIUM & MAGNESIUM TO FILTERED WATER,

RAISES THE PH.

ALKALINE CARTRIDGE

CARTRIDGE ADDS CALCIUM & MAGNESIUM TO FILTERED WATER,

RAISES THE PH.

REMINERALIZING INLINE

INLINE FILTER ADDS CALCIUM & MAGNESIUM TO FILTERED WATER,

REMINERALIZING CARTRIDGE

CARTRIDGE ADDS CALCIUM & MAGNESIUM TO FILTERED WATER,

UV STERILIZATION

KILLS 99.9% BACTERIA AND VIRUSES.

DI INLINE

DE-IONIZATION FILTER REMOVES LAST BIT OF PPM.

REPLACEMENT PARTS

PRODUCT TYPE MSRP SYSTEM NOTES

SPECIALTY FILTRATION, ACCESORIES & REPLACEMENTS

ALK-Inline Alkaline 99.00 All RO systems Raises ph, adds cal/mag mineral.

ALK-Cart Alkaline 99.00 All RO systems Raises ph, adds cal/mag mineral.

RM-Inline Re-Mineralize 67.00 All RO systems Adds cal/mag minerals.

RM-CART Re-Mineralize 67.00 All RO systems Adds cal/mag minerals.

DI-Inline De-Ionization 31.00 All RO systems Removes remaining TDS after RO (aquarium, lab)

DI-Cart De-Ionization 34.00 All RO systems Removes remaining TDS after RO (aquarium, lab)

UV-1530 Ultraviolet 149.00

UV-6010 Ultraviolet 215.00

UV-LB Ultraviolet 443.00

UV-XL Ultraviolet 538.00

All RO, Scrubber

systems, tank

storage

All RO, Scrubber

systems, tank

storage

All RO, Scrubber

systems, tank

storage

All RO, Scrubber

systems, tank

storage

Kills 99.9% bacteria

Kills 99.9% bacteria / viruses

Kills 99.9% bacteria / viruses

Kills 99.9% bacteria / viruses

PRODUCT TYPE APPLICATION / SYSTEM MSRP CAPACITY NOTES

REPLACEMENTS FOR ALL WATER FILTERS 400 GPD AND UNDER

SF-2510-PL Sediment Pleated EX100/200/400/400-Tall, GX200/300/400, Mini Scrub 14.50 Depends on feed water piping/supply Stock on GX Series

SF-2510-SP Sediment Spun EX100/200/400/400-Tall, GX200/300/400, Mini Scrub 10.75 Depends on feed water piping/supply Stock on EX Series

CF-2510-CC Economy Coco Carbon EX100/200/400/400-Tall, GX200/300/400, Mini Scrub 12.00

CF-2510-GB Green Carbon EX100/200/400/400-Tall, GX200/300/400, Mini Scrub 16.50

CF-2510-KDF Premium Carbon EX100/200/400/400-Tall, GX200/300/400, Mini Scrub 39.00 8,000 Gallons Total 2,700 Gallons RO Water Must for well water and chloramine removal

GXM-100 Standard Membrane 100+ GPD membrane for EX100 83.00 Depends on feed water quality Fits most other RO systems

GXM-200-HF

BP-1530 Booster Pump Booster pump for all RO systems 600 GPD and under. 227.00 12,000 Hrs brush life Booster pump for all RO systems 600 GPD and under

High Flow Cold Water

Membrane

200+ GPD High Flow Cold Water Membrane for EX100/200/400/400-Tall,

GX200/300/400

REPLACEMENTS FOR EX400HF-TALL AND SLIMSCRUB

SF-2520-SP Sediment Spun EX400-tall, Slim Scrub 10.75 Depends on feed water piping/supply

CF-2520-CC Economy Coco Carbon EX400-tall, Slim Scrub 24.00

CF-2520-KDF Premium Carbon EX400-tall, Slim Scrub 71.00

CF-4520-KDF Premium Carbon EX600/1000-Tall, XL Scrub 127.00

www.growonix.com toll free 888.406.8521, oce 818.510.0264, sales@growonix.com

7,500 Gallons Total

2,500 Gallons RO Water

7,500 Gallons Total

2,500 Gallons RO Water,

99.00 Depends on feed water quality Fits most other RO systems

16,000 Gallons Total

5,300 Gallons RO Water

17,000 Gallons Total

5,700 Gallons RO Water

34,000 Gallons Total

17,000 Gallons RO

Stock on EX Series

Stock on GX Series

Must for well water and chloramine removal

Must for well water and chloramine removal

5

GROWONIX EX 600/1000 ACCESORIES

ELECTRIC SHUT OFF KIT

An essential add-on to almost any

water lter! Shuts down feed water

before the water lter. Controls on/

o cycling of high pressure booster

pumps. The electric shuto kit

consists of a oat switch and solenoid

valve. Mount the oat switch in your

water tank or nutrient storage tank.

Install the solenoid valve on the front

end of your water lter. When the tank

level decreases to the desired amount,

the oat switch opens the solenoid

valve, the booster pump (if installed)

powers on, and the water system

DDP-6

BP-6010

BP-6010-CH

FLOW BOXES

begins relling the storage tank.

The DDP-6 is the ultimate water

delivery pump. With a ow rate

of 6.5 GPM, the DDP-6 can move

water from on end of the garden

to the other in a ash. Integral as

a feed pump and return pump for

GrowoniX smaller nutrient top feed

systems, the DDP-6 can withstand

the most rigorous of duties. Built in

high pressure cuto allows for easy

use with solenoid valves, manual

shuto valves, watering wands, hose

sprayers, or faucets

DOUBLES pure water production for

the EX600,EX1000, EX600, EX1000

water lters. The pump only needs

30psi of incoming water pressure

to produce the full ow rate! Low

pressure cuto to safeguard the

pump against a loss of incoming water

pressure. Stainless steel liquid lled

300 psi system pressure gauge. Can

be controlled manually or with our

electric shuto kit.

DOUBLES pure water production for

the EX600 and EX1000 water lters.

Splash Guard™ chassis connects

directly to the EX600/EX1000. The

pump only needs 30psi of incoming

water pressure to produce the full ow

rate! Low pressure cuto to safeguard

the pump against a loss of incoming

water pressure. Stainless steel liquid

lled 300 psi system pressure gauge.

Can be controlled manually or with our

electric shuto kit.

GrowoniX FlowBox is a componential

add-on to any EX600/1000 or

EX600/1000 that utilizes a BP Series

booster pump. Equipped with highly

accurate liquid ow meters, the

FlowBox allows for custom tuning and

ne-tuning of the system ratio. Run

your system at any ratio from 3:1 to

1:1— whenever you want. System

ratios change throughout the year as

the weather temperatures change.

Keep a perfect 1:1 all year round with

a FlowBox. Flush the system with

a simple twist of the stainless steel

needle valve. Allows for removal of

the standard drain/ush assembly.

Mounts atop the EX series chassis for

easy viewing and adjusting. Easy wall

mounting as well.

6

GXMV INDUSTRIAL MEMBRANES

These Dow sheet, American made

membranes are the industries most

reliable and highest performing

reverse osmosis elements in the world.

Advanced membrane technology

and manufacturing processes ensure

superior quality and unmatchable

performance. Ultra low energy design

delivers high ow and high rejection at

only 80psi.

A must for cold water sources.

Always at an industry leading 1:1 ratio.

Flow Rate: 600 gpd high ow

membrane

Membrane replacement for EX600,

EX600, EX600T

Flow Rate:1000 gpd high ow

membrane

Membrane replacement for EX1000,

UV STERILIZATION

COCONUT CARBON / WHITE BLOCK

SEDIMENT SPUN

SEDIMENT PLEATED

KDF85/CATALYTYIC CARBON FILTER

EX10 00, EX1000T

Stainless steel ultraviolet ltration to

remove 99.9% of micro- organisms in

your water supply. A must for well water

treatment, whole house lter systems,

or anytime water will be stored.

Economy: High purity coconut shell

activated carbon lter. Excellent

cost to performance value.

Spun polypropylene: A true multistaged depth lter utilizing separate

layers of micron ltration. Constructed

spun polypropylene, these lters oer

superior dirt holding capacity at an

EXtremely economic price. Great lter

for changing frequently, especially in

well water applications, or with use in

GrowoniX scrubbers.

4.5”x9.75” Spun | 16000 gallons

High ow pleated Sediment lter: This

is a washable, reusable, and durable

sediment lter with very low pressure

drop. Bacteria and chemical resistant.

Great for high ow applications and

EXtended time between tler changes.

Comes standard in most GrowoniX

water lters.

4.5”x9.75” | 16000 gallons

KDF/CAT. Bacteriostatic media

controls growth of microorganisms.

Good for water soluble metals removal,

chlorine, chloramine, and scale. Highly

reactive catalytic carbon, EXtremely

porous and long lasting.

4.5”x9.75” | 16000 gallons

TABLE OF CONTENTS

EX 600/1000 FEATURES

2

SYSTEM SPECIFICATIONS

3

GROWONIX EX 1000 ACCESORIES

4

TABLE OF CONTENTS

5

INTRODUCTION

6

PRECAUTIONS

7

INFORMATION ON QUICK CONNECT FITTINGS

8

COMPONENT DIAGRAM

9

10

11

12

13

15

18

20

21

SETUP INSTRUCTIONS

FLUSHING THE KDF85 CARBON FILTER

FLUSHING THE MEMBRANE ELEMENT

REPLACING SEDIMENT AND CARBON PRE-FILTERS

REPLACING MEMBRANE ELEMENT

SPECIFICATIONS CHARTS

RO SYSTEM WARRANTY / RETURN POLICY

REPLACEMENT PARTS

www.growonix.com toll free 888.406.8521, oce 818.510.0264, sales@growonix.com

INTRODUCTION

OUR MISSION

Durability, Reliability, Eciency, Purity, and Conservation form the foundation on which we design

and build all of our products. Consistent and superior quality sets us apart from other manufacturers

and increases our value to you - our customer. Whether you are a hydroponics hobbyist, serious

enthusiast, or large-scale gardener, GrowoniX is committed to bringing you the best solution for

water purication systems.

WHAT IS REVERSE OSMOSIS?

Reverse osmosis (RO) is a ltration method that removes many types of large molecules and ions

from solutions by applying pressure to the solution when it is on one side of a selective membrane.

This ltering process ensures that the solute (waste water) is contained within the pressurized

chamber while the pure solvent (RO water) is allowed to pass freely through the membrane.

TUNED FOR GROWING - IN TUNE WITH OUR CUSTOMERS

Traditional RO systems have waste ratios of approximately 4:1, which means there are 4 gallons

of waste water produced for every 1 gallon of puried water. GrowoniX line of water lters achieve

waste ratios of 2:1 with the EX100 through GX400 and an astounding 1:1 ratio with the GX600 and

GX1000.

GrowoniX has created a complete product line that will address the needs of hydroponic operations

of all sizes. Our lters will signicantly reduce your water use while dramatically increasing your yields.

takes 4 gallons of waste water to produce 1 gallon of pure water

WASTE WATER

THE TRADITIONAL WAY

PURE WATER

THE GrowoniX WAY

WASTE WATER PURE WATER

8

PRECAUTIONS

• Do not use unit with inlet water pressure exceeding 80 psi. If inlet water pressure is too high,

install water pressure regulator before the unit. Regulators and pressure limiters are available at

www.Growonix.com or your local plumbing supply.

• Keep unit away from direct light.

Direct light can cause algae and other biologicals to grow inside of the lter housings.

• Do not install unit near electrical outlets or electrical devices.

• Do not install in places where a leak can cause damage.

• GrowoniX EX Series RO water lters are rated using supply water that is 77°F, 475ppm, at 70psi.

Slower performance may be noted in areas with colder temperatures, higher water salinity, or

lower inlet water pressure.

• A minimum of 40psi is recommended to operate GrowoniX water lters. If your inlet water

pressure is too low, booster pumps can be used to increase pressure.

Pumps are available at www.Growonix.com.

• Do not use a ow restrictor other than the one included with your unit.

• Flow restrictors help tune the unit for proper waste ratio.

• Using bigger ow restrictors, or using the unit in areas with exceptionally dirty water,

will decrease membrane performance and longevity.

www.growonix.com toll free 888.406.8521, oce 818.510.0264, sales@growonix.com

9

INFORMATION ON QUICK CONNECT FITTINGS

O-RING

COLLET

TUBING

GROWONIX WATER FILTERS USE QUICK CONNECT FITTINGS

THAT ALLOW FOR EASY MAINTENANCE.

MAKE A CLEAN TUBE CUT

Cut the tube squarely and if using plastic tubing, ensure that the cut has not made the tube out of round.

Also ensure that the tube has a smooth outside diameter without any burrs or score marks

prior to inserting it into the tting

INSERT TUBE INTO FITTING

Push the tubing through the collet and dual o-rings until it bottoms out against the tube stop.

The collet holds the tube in place and the dual o-rings provide a leak resistant seal.

.

TEST AND INSPECT

Push and pull the tubing toward and away from the tting to ensure that it has been installed properly.

Test and inspect the installation for any leaks.

TUBE REMOVAL

Relieve pressure from the tubing and tting. Push uniformly around the collet ange against the

tting body while pulling the tubing away from the tting to release it.

PUSH COLLET IN

PULL TUBE OUT

10

3 2

COMPONENT DIAGRAM

6

109

13

1

8

14

11

12

15

45

7

19

18

16

1. SUPPLY WATER IN

2. INPUT SIDE PRESSURE GAUGE

3. OUTPUT SIDE PRESSURE GAUGE

4. SEDIMENT FILTER

5. CARBON FILTER

6. RO MEMBRANE HOUSING

7. RO MEMBRANE

8. O-RING

9. END CAP

www.growonix.com toll free 888.406.8521, oce 818.510.0264, sales@growonix.com

17

10. SNAP RING

11. FLUSH VALVE

12. FLOW RESTRICTOR

13. DRAIN/WASTE WATER OUT

14. AUTO-SHUTOFF VALVE

15. RO WATER OUT

16. DRAIN SADDLE CLAMP

17. IN-LINE SHUTOFF VALVE

18. FILTER WRENCH

19. RO AND DRAIN TUBING

11

SETUP INSTRUCTIONS

Important Tips:

• Always turn incoming water pressure o before servicing the unit.

• Always turn incoming water pressure on slowly, allowing all air to be discharged from

the system before full water pressure is restored.

• GrowoniX GX600 and GX1000 water lters are designed to be used with between 4080 psi of incoming water pressure. Do not exceed 80 psi of incoming water pressure

• If incoming water pressure is too high, install pressure regulator before unit.

• It is recommended to ush the membrane upon initial startup.

(see: Flushing Membrane Element)

1

Connect inlet water supply.

This example shows 3/4" garden hose

connected to supplied hose union.

Hose ttings can be removed to allow

for 3/4" NPT pipe connections.

3

2

Connect RO and waste / drain

assembly to membrane housing as

shown.

Make sure tubing is seated completely

4

waste / drain

RO

open position

Mount drain clamp to available drain

pipe. Connect other end of drain

tubing to included drain clamp.

5

12

BEFORE TURNING INCOMING WATER SUPPLY ON, REFER TO NEXT STEP “FLUSHING

THE KDF85 CARBON FILTER” ON THE NEXT PAGE

Make sure ush valve is in open

position as shown above. This position

is for ushing the RO membrane.

FLUSHING THE KDF85 CARBON FILTER

Growonix EX600 and EX1000 water lters can be upgraded with a KDF85 Catalytic Carbon Pre-Filter.

The "KDF" carbon lter is a superior blend of highly reactive catalytic carbon and KDF85 process

media used to remove/reduce iron, hydrogen sulde, chlorine, chloramine, bacteria, scale, and algae.

The catalytic carbon in these lters is in a loose form, and thus will discharge a small amount of carbon

dust upon initial startup. It is recommended to unhook the membrane input side and ush ten gallons

of water through the carbon lter before re-connecting to the RO membrane. This will ensure no dust

gets into the membrane causing premature fouling.

1 2

With system OFF and depressurized,

disconnect tting from membrane input.

WARNING

DISCONNECT TUBING

FROM PUMP INPUT

OR MEMBRANE INPUT

AND FLUSH 10 GALLONS

THROUGH

KDF CARBON FILTER

Position tting over drain or bucket

and slowly turn on incoming water

pressure. Allow ten gallons of water

to ush through carbon before

reconnecting to membrane input.

MAKE SURE WATER IS FREE

FROM CARBON FINES & DEBRIS

BEFORE RECONNECTION

TO MEMBRANE INPUT

www.growonix.com toll free 888.406.8521, oce 818.510.0264, sales@growonix.com

13

FLUSHING THE MEMBRANE ELEMENT

Growonix GX600 and GX1000 water lters come with a manual ush valve. Flushing the membrane

element after each use for approximately 3-5 minutes will remove standing salts from the membrane,

signicantly extending membrane life. Even weekly ushes will improve membrane life and system

performance.

The ush valve is located on the waste line of the RO membrane. To ush the membrane simply

turn the ush valve to the FLUSH position as seen in picture 1. High-pressure water will bypass the

ow restrictor and shuto valve and be sent down the drain, carrying membrane pollutants with it. If

using a oat valve and the system happens to be OFF due to valve engagement, opening the ush

valve will start the system again in ush mode, and the membrane will be cleaned.

1

While the system is running, turn the

ush valve to the OPEN position.

3

ush

position

closed position

(RO on)

2

Let system run for 3-5 minutes.

After ushing is complete, simply turn

ush valve to CLOSED position.

Membrane has been ushed.

14

REPLACING SEDIMENT AND CARBON PRE-FILTERS

GrowoniX EX600 and EX1000 pre-lters should be changed regularly to ensure maximum membrane element

life and system performance. When a 30% — 40% dierential between the gauges is reached and output

water pressure gauges is reached, pre-lters should be changed (i.e., when input gauge reads 80 psi and

output gauge reads approximately 50 psi, you have a 30% dierential—time to change pre-lters).

The pressure dierential is really “pressure drop” caused by dirty pre-lters.

IMPORTANT TIPS

• After changing lters, always turn incoming water pressure on slowly,

allowing air to be discharged before full water pressure is restored.

• Be careful not to lose the O-ring when removing each lter housing bottom.

OUTPUT INPUT

The table below displays pressure gauge readings that will assist you in knowing when to change

EX Series pre-lters. Pre lters should be changed when the output pressure gauge reads 30%

lower than input pressure gauge (30% pressure dierential).

Input Pressure Gauge Output Pressure Gauge Pressure Differential

80 56 30%

75 53 30%

70 49 30%

65 45 30%

60 42 30%

55 54 30%

50 35 30%

45 31 30%

40 28 30%

www.growonix.com toll free 888.406.8521, oce 818.510.0264, sales@growonix.com

15

REPLACING SEDIMENT AND CARBON PRE-FILTERS

1

Turn o incoming water supply.

Open ush valve to relieve

system pressure.

ush position

3

Carbon

Sediment

2

loosen

Loosen pre-lter housings using supplied

lter wrench. Empty standing water and

remove old pre-lters. Clean interior of

housings to remove standing sediment

and debris.

4

O-ring

Install new sediment & carbon

cartridges, making sure sediment

cartridge is installed in the housing

closest to the input side of the unit.

5

16

tighten

Grease O-rings with food grade

silicone grease

Tighten housings with supplied lter wrench. Close

ush valve and begin normal usage. If KDF85

carbon lter is being used, make sure to ush

carbon lter before connection to membrane input

(see section : Flushing The KDF85 Carbon FIlter)

REPLACING MEMBRANE ELEMENT

IMPORTANT TIPS

• Before servicing membrane element system must be de-pressurized. To de-pressurize the

EX600 and EX1000, turn incoming water supply completely OFF and open the ush valve.

• It is suggested that you replace sediment and carbon pre-lters as well

when replacing membrane element.

• After replacing membrane turn incoming water pressure on slowly,

allowing all air to be discharged before full water pressure is restored.

• End caps can be dicult to re-install.

To aid in installation, apply continuous pressure to end cap.

Do not strike the end cap.

1 2

Turn incoming water supply OFF and

open ush valve to depressurize the

system.

3

ush position

4

Make sure to depress collet while pulling

stem outward.

Remove stem elbow from input side of

membrane housing.

www.growonix.com toll free 888.406.8521, oce 818.510.0264, sales@growonix.com

On the input side of the membrane

housing, remove the end-cap retaining

bolts.

17

REPLACING MEMBRANE ELEMENT

INPUT SIDE

5

Remove end clamp. Remove the end-cap

7

brine seal

6

and slide membrane out.

8

Pull used membrane element out towards

the input side of membrane housing.

9 10

Brine Seal

Prepare new membrane element by

applying food grade silicone grease

to the membrane brine seal and both

ends of the center tube.

brine seal

Clean inside of membrane housing

to remove buildup or debris.

Brine Seal

Insert membrane element into

membrane housing making sure that

the brine seal goes in last.

18

REPLACING MEMBRANE ELEMENT

INPUT SIDE

11 12

Newly seated membrane element. Grease brine seal and endcap center

hole with food grade silicone grease.

13

15

Seat end-cap back into input side of

membrane housing.

14

Replace end-clamp on input side of

membrane housing.

16

Tighten end-clamp retaining bolts evenly.

17

www.growonix.com toll free 888.406.8521, oce 818.510.0264, sales@growonix.com

Turn incoming water supply ON slowly, allowing air to be discharged, before full water

pressure is restored. Let system run in “Flush Mode” for 30 minutes to clear new membrane

element. After 30 minutes, close ush valve and begin normal usage. Enjoy.

19

ADDITIONAL SPECIFICATIONS CHARTS

Pleated Sediment Filter 4.5 “ Diameter

Materials of Construction:

• Filter Media

• End Caps

• Core

• Temperature Rating

• Non-woven Polyester

• Vinyl Plastisol

• Polypropylene

• 40˚F to 125˚F (4.4˚C to 51.7˚C)

Size Description:

• 4.5” X 10”

Initial AP (PSI) @ Flow Rate (GPM):

• 1 PSI @ 10 GPM (.01 bar @ 38 L/min)

PERCENT EFFICIENCY*

PARTICLE SIZE (MICRONS)

Filter Housings

Materials of Construction:

• Housing: Polypropylene

• Cap: Polypropylene

• Button Assembly: Stainless Steel,

EPDM & Polypropylene

• O-Ring: Buna-N

Maximum Dimensions:

• 13-1/2” X 7-1/4”

Initial AP (PSI) @ Flow Rate (GPM):

• 1 PSI @ 30 GPM

MEMBRANE HOUSINGS

Materials:

NSF Approved PVC Material

•

• NSF Approved GTX Material

• NSF Approved EPR O-Rings

• Available with 3/8”, 1/2”, 3/4”, & 1” Port

Sizes

PRESSURE DROP (PSID)*

FLOW RATE (GPM)

Specications:

• Maximum Operating Pressure: 225 PSI

• Maximum Operating Temperature: 110˚F

• Minimum Operating Temperature: 35˚F

20

ADDITIONAL SPECIFICATIONS CHARTS

Membrane Element

Operating Limits:

• Membrane Type: Thin lm

composite

• Maximum Operating Temperature: 110˚F

(43˚C)

• Minimum Concentrate Flow Rate: 5:1

• pH Range, Continuous Operation: 3-11

• pH Range, Short term cleaning (30 min):

1-12

• Maximum Feed Water Turbidity:

1 NTU

• Maximum Feed Silt Density IndEX (SDI):

5 SDI

• Chlorine Tolerance: 0 PPM

Features:

• High Flow (HF) Ultra Low Pressure

Membrane Material

• Tape Over Wrap

• Available Wet Tested

• Made in the U.S.A

Applied Pressure PSI (BAR)

• 600 GPD: 8.0 (5.52)

• 1000 GPD: 8.0 (5.52)

Maximum Pressure PSI (BAR)

• 600 GPD: 400 (27.58)

• 1000 GPD: 400 (27.58)

Permeate Flow rate GPD

• 600 GPD: 600

• 1000 GPD: 1000

Nominal Salt Rejection

• 600 GPD: 600

• 1000 GPD: 1000

Carbon Filter Cartridge

Materials:

• Filter Media: Granular activated carbon

• Outer Shell: Polyethylene

• End Caps: Polypropylene

• Gasket: Buna-N

• Inner Wraps/Core: Polypropylene

• Temperature Rating: 40 - 125˚F (4.4 - 51.7˚C)

Maximum Dimensions:

• 4 1/2” X 9 1/4”

Initial AP (PSI) @ Flow Rate (GPM):

• 0.90 PSI @ 4 GPM (.06 bar @ 15.1 L/m)

Chlorine, Taste, Odor

Reduction Capacity Flow

>70,000 gallons @ 4 GPM (265,000L @ 15.1

•

LPM)

Approximate Net Pressure Drop - psi (Bar)

Flow Rate - gpm (Lpm)

www.growonix.com toll free 888.406.8521, oce 818.510.0264, sales@growonix.com

21

GROWONIX REVERSE OSMOSIS SYSTEM WARRANTY

For a period of one year from the date of original purchase, we will replace or repair any part of the GrowoniX

reverse osmosis water system that we nd to be defective in operation du e to faulty materials or workmanship

with the EXception of the replaceable lters and membranes.

GENERAL CONDITIONS

Damage to any part of this reverse osmosis system because of misuse; misapplication; negligence; alteration;

accident; installation; or operation contrary to our instructions, incompatibility with accessories not installed

by GrowoniX, or damage caused by freezing, ood, re, or Act of God, is not covered by this warranty. In all

such cases, regular charges will apply. This limited warranty does not include service to diagnose a claimed

malfunction in this unit. This warranty is void if the claimer is not the original purchaser of the unit or if the unit

is not operated under normal municipal water or well water conditions.

GrowoniX assumes no liability in connection with this reverse osmosis system. GrowoniX assumes no liability

for any damages incurred through the use of this product. It is the responsibility of the end user to gauge the

safe use of this product in the environment where it is applied. We do not authorize any person or representative

to assume for us any other obligations on the sale of this reverse osmosis system. The information given out

in the manual we believe to be true, but are oered to you in good faith without guarantee because each

application of this product is dierent and beyond our control.

THE FOLLOWING STANDARD OPERATING CONDITIONS FOR RESIDENTIAL/COMMERCIAL REVERSE

OSMOSIS SYSTEMS MUST BE MET FOR WARRANTY TO BE VALID.

Water Pressure pH Range Maximum TDS Water Temp

Standard System 40-80 psi

2-11

2000 ppm 40-100 F

GROWONIX RETURN POLICY

MERCHANDISE RETURN DETAILS AND PROCEDURE:

If any merchandise was defective —we will refund the full purchase price upon receiving and reviewing the

merchandise returned in undamaged condition.

RMA NUMBER:

You must rst obtain a Return Merchandise Authorization (RMA) number from GrowoniX.com. Any products

sent to GrowoniX without an RMA number will not receive a refund and may be returned to the sender at their

expense.

All refund amounts will be based on the manufacturer’s warranty and GrowoniX return policy. Refunds will be

issued back using the payment method you used when you placed your order. Refunds take up to 3-5 business

days to process once we receive the return.

PACKAGING:

Please kindly re-pack the product in its original box, or a box of equivalent strength. The unit should be packed

in the same manner as it came to prevent damage in shipping. Please return everything that was in the original

box, including any free items if applicable. Be sure to drain out all water from wet systems and parts and wrap

them in plastic bags before packing.

RETURN TO:

We will provide you with an GrowoniX warehouse address for return merchandise when we issue the RMA number.

22

Loading...

Loading...