Grower Select HS583 Installation Manual

Ventilation Systems

HS583 Curtain/Vent Machine Installation Manual

General Installation Notes:

Make sure that power is disconnected from system prior to servicing.

Installation of this equipment and related OEM equipment should be in accordance with these

instructions, OEM’s installation instructions and local codes (if applicable). Failure to follow specified

instructions may cause damage to equipment and/or personal injury or death.

Take special note of any Warnings or Safety Decals on the equipment and in manuals.

Always wear protective clothing and any applicable Personal Protective Equipment (Safety Glasses

and/or Ear Plugs) when working with the equipment.

Discarded materials, equipment and boxes should be recycled in accordance with local and national

codes.

Note: Actuator Assembly is to be wired in accordance with all applicable local and national electrical wiring codes. All

wiring sizes and fuse capacities are to be sized according to applicable electrical code specifications or other regulations.

SAFETY INSTRUCTIONS:

Read all safety messages in this manual and on equipment safety decals. Follow recommended

precautions and safe operating practices.

Ground all electrical equipment for safety.

Ground all non-current carrying metal parts to guard against electrical shock.

Always keep safety decals in good condition and replace missing or damaged decals.

Hog Slat Inc. Newton Grove, NC USA September 2014

1

Ventilation Systems

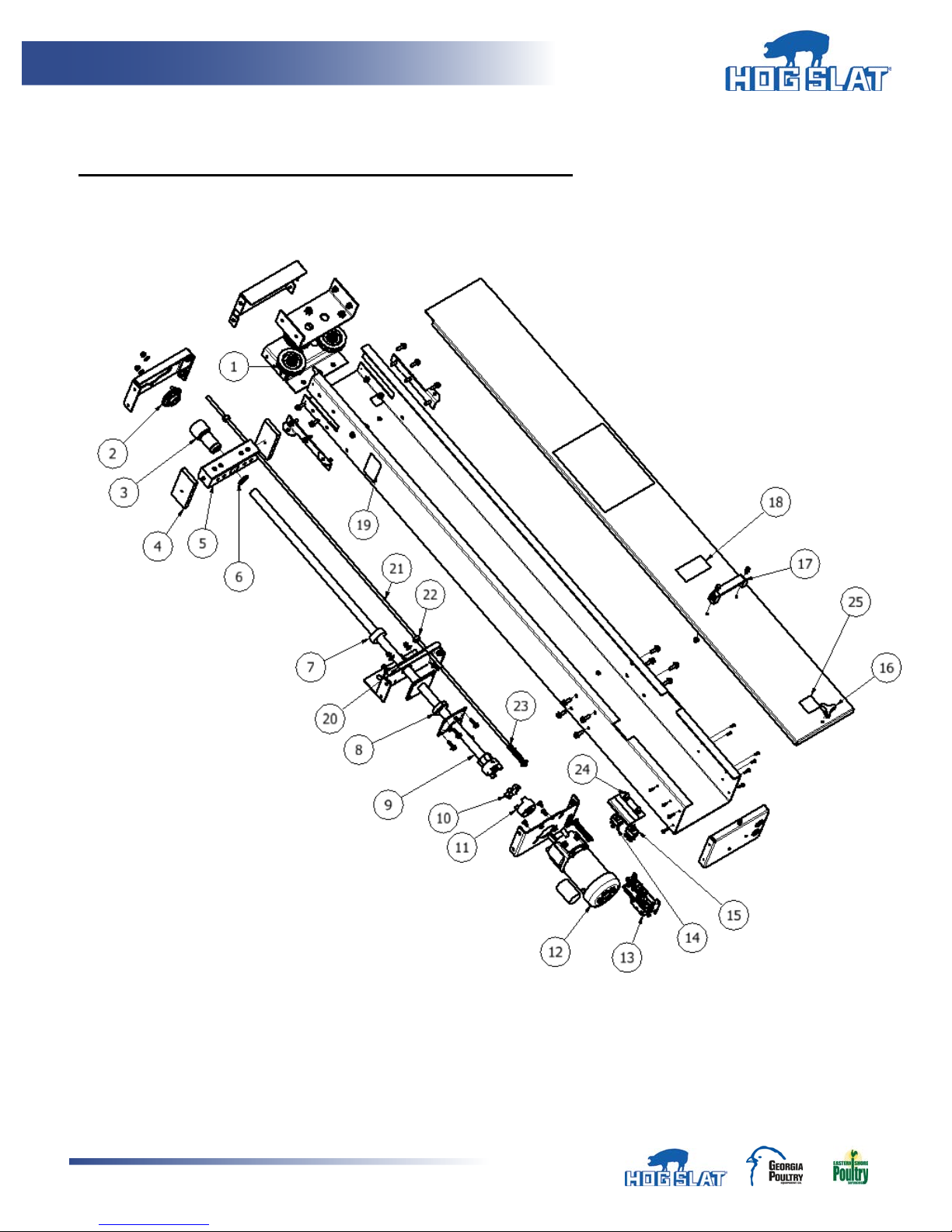

COMPONENT LAYOUT (SERVICE REPLACEMENT PARTS)

Hog Slat Inc. Newton Grove, NC USA September 2014

2

Ventilation Systems

ITEM #

PART #

QTY PER

DESCRIPTION

1

HS583-34

3

Pulley, Cast 3-1/2" with double ball bearings

2

HS583-42

1

Bearing Flange 1" I.D

3

HS583-8-2

1

Load Nut, nylon

4

HS583-9

2

Slide, load block

5

HS583-8

1

Load block assembly with load nut & cotter pins

6 1

1 ¼” External snap ring, supplied with HS583-8-2

7

HS583-41

2

Threaded collar, seal thrust bearing nylon

8

HS583-12

1

Thrust bearing, 1” ID, D9

9

HS583-11A24

1

ACME screw, 24” machine

HS583-11A36

1

ACME screw, 36” machine

HS583-11A48

1

ACME screw, 48” machine

10

HS613

1

Spider Gear-spacer Hytrel (white) L090/L095

11

LOV38146

1

Coupling Jaw L095 5/8" bore with keyway

12

HS9050

1

Motor 1/8 HP, 115V AC, 60 Hz, 1.9A FL, 28RPM

HS9051

1

Motor 1/8 HP 230V AC, 50/60Hz, 0.75/0.90A FL, 24/29 RPM

HS9052

1

Motor 1/8 HP, 115V AC, 60 Hz, 1.65A FL, 16RPM

13

HS583-31

1

Switch assembly with (6) EL1135 micro switches

14

EL1001

1

Switch, Toggle SPDT , 10A @ 250 Volt, CTR OFF

15

EL1005

1

Switch, Toggle DPDT , 10A @ 250 Volt, CTR OFF

16

HS612

1

Knob, tri-handle, ¼-20 insert

17

HS583-45

1

Handle, Front door

18

HSLABEL-084

1

Label, “Caution Automatic Equipment”

19

HSLABEL-083

2

Label, “Warning Moving Parts”

20

HSLABEL-087

1

Label, “Grease Location”

21

HS583-27-24

1

Limit rod, 24” machine

HS583-27-36

1

Limit rod, 36” machine

HS583-27-48

1

Limit rod, 48” machine

22

HS583-28

2

Collar, steel 3/8'' w/ set screw

23

HS583-29

2

Spring, limit rod

24

EL1083

2

Rubber cover, toggle switch

25

HSLABEL-008

1

Label, Warning-Shock Hazard

Hog Slat Inc. Newton Grove, NC USA September 2014

3

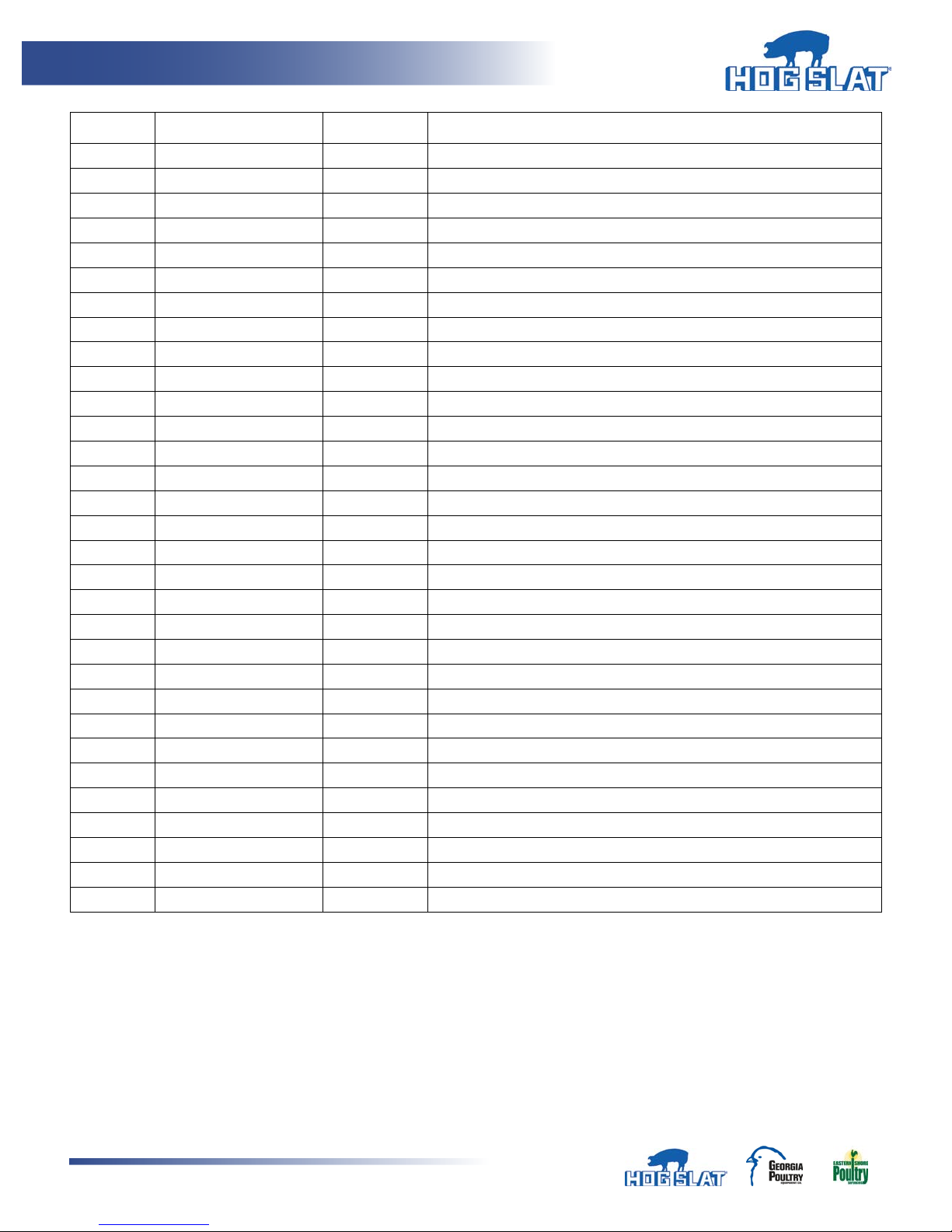

Ventilation Systems

15 & 28

4,000 lbs

2,000 lbs

1,000 lbs

60

2,000 lbs

1,000 lbs

500 lbs

Located on front door of machine

Located on side of cabinet near

cable/chain exits.

Located at bottom of front door

SAFETY DECALS AND WARNING LABELS

near removal point.

SPECIFICATIONS:

Maximum Load: Ratio : Machine travel : vent/ curtain travel

Example: 2:1 = 2” machine travel : 1” vent/curtain travel

Refer to Figures 6 and 7

RPM 2:1 pulley ratio 1:1 pulley ratio 1:2 pulley ratio

Hog Slat Inc. Newton Grove, NC USA September 2014

4

Ventilation Systems

Door slides under lip at

top of machine

Lift up from bottom

to remove.

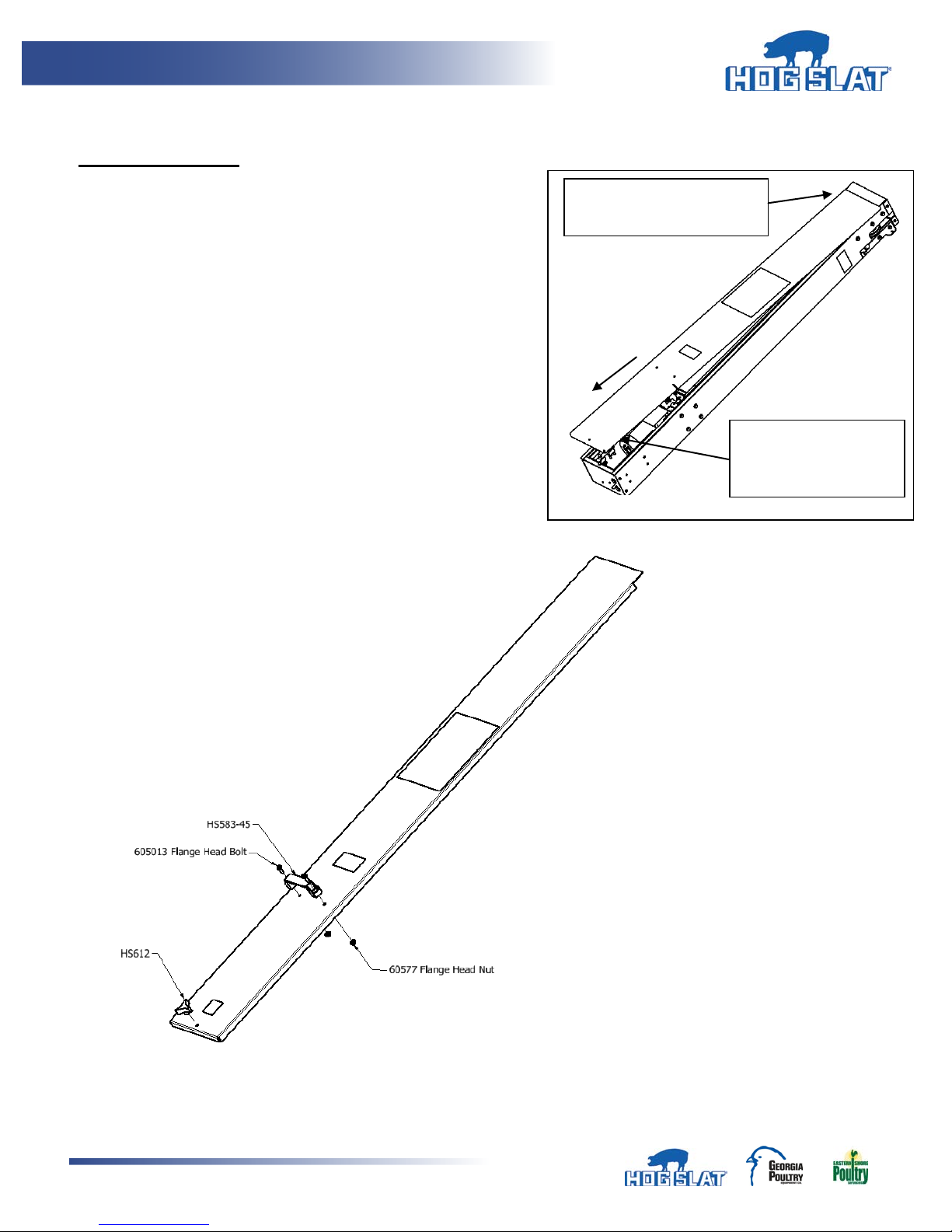

UNPACKING UNIT

Remove front cabinet door.

Packaged inside cabinet chassis:

1. HS583-50 Hardware Kit

a. Front cabinet door hardware

i. HS583-45 Handle

ii. (2) 605013 Flange head bolts

iii. (2) 60577 Flange nuts

iv. HS612 Tri-handle knob

b. Machine mounting hardware

i. (1) 3/8” x 3” Lag bolt

ii. (6) 3/8” x 2” lag bolts

iii. (2) 61646 liquid tight connectors

2. Installation manual

Assembly of Cabinet door with hardware supplied.

and slide door down

HS612 Tri-Handle Knob installs over threaded stud when cabinet door is placed on machine.

Hog Slat Inc. Newton Grove, NC USA September 2014

5

Ventilation Systems

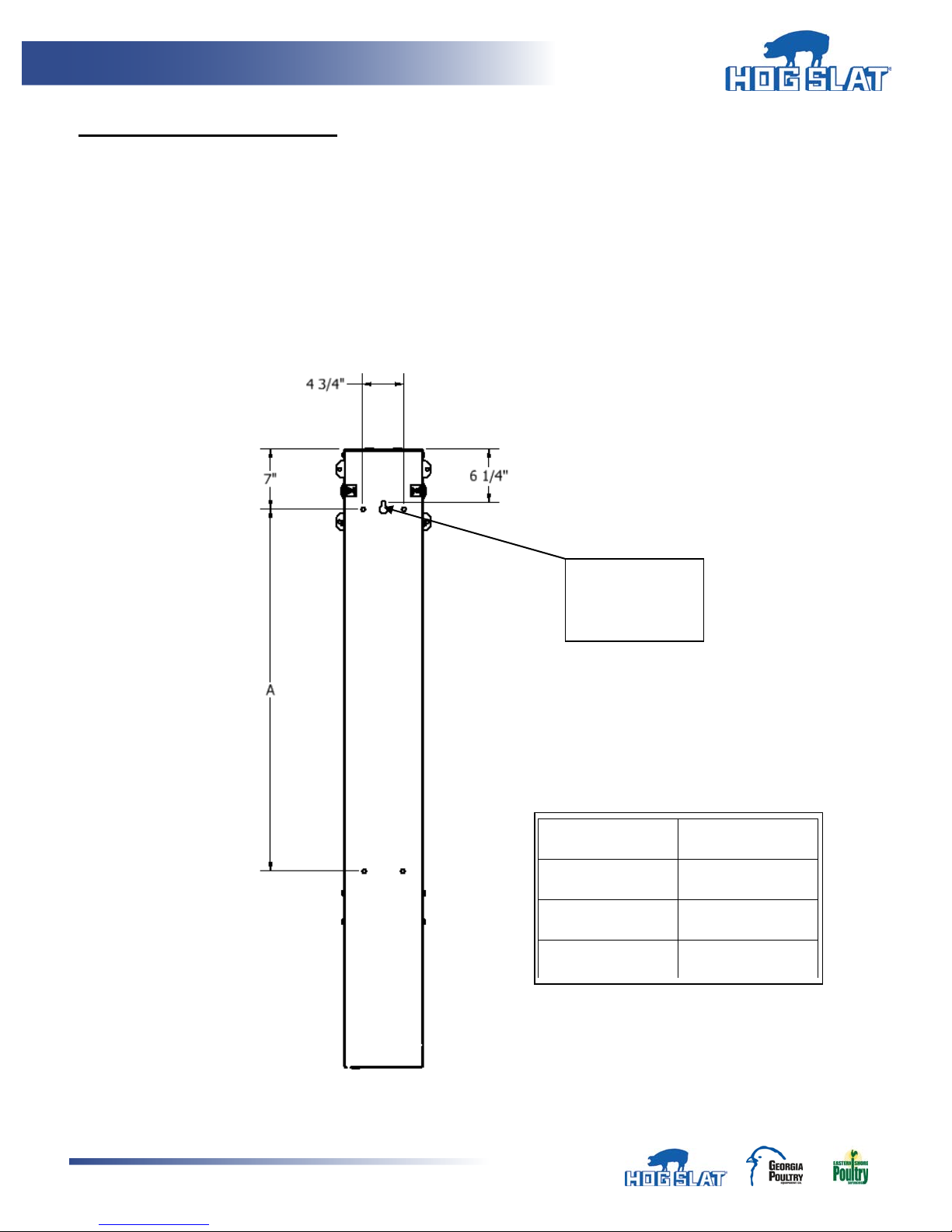

Keyhole

location

MODEL LENGTH

“A”

24”

30 3/8”

36”

42 3/8”

48”

54 3/8”

INSTALLATION / OPERATION

1. The HS583 Curtain/Vent machine is equipped with a key hole slot for easy installation as well as

(6) locations to secure unit to a wall.

2. Install (1) 3/8” X 3” Lag bolt (supplied) in the wall of the building in the desired location leaving

bolt out approximately ¼”. Lag bolt location to be center line of the machine and installed 6 1/4”

below the height of the top of the machine. Allow a minimum of 1” clearance above machine

from any structure in order to provide adequate clearance for hanging machine on keyhole lag

bolt.

3. Hang machine on bolt aligning keyhole slot located near top of the machine. (Figure 1)

mounting

Figure 1

Hog Slat Inc. Newton Grove, NC USA September 2014

6

Ventilation Systems

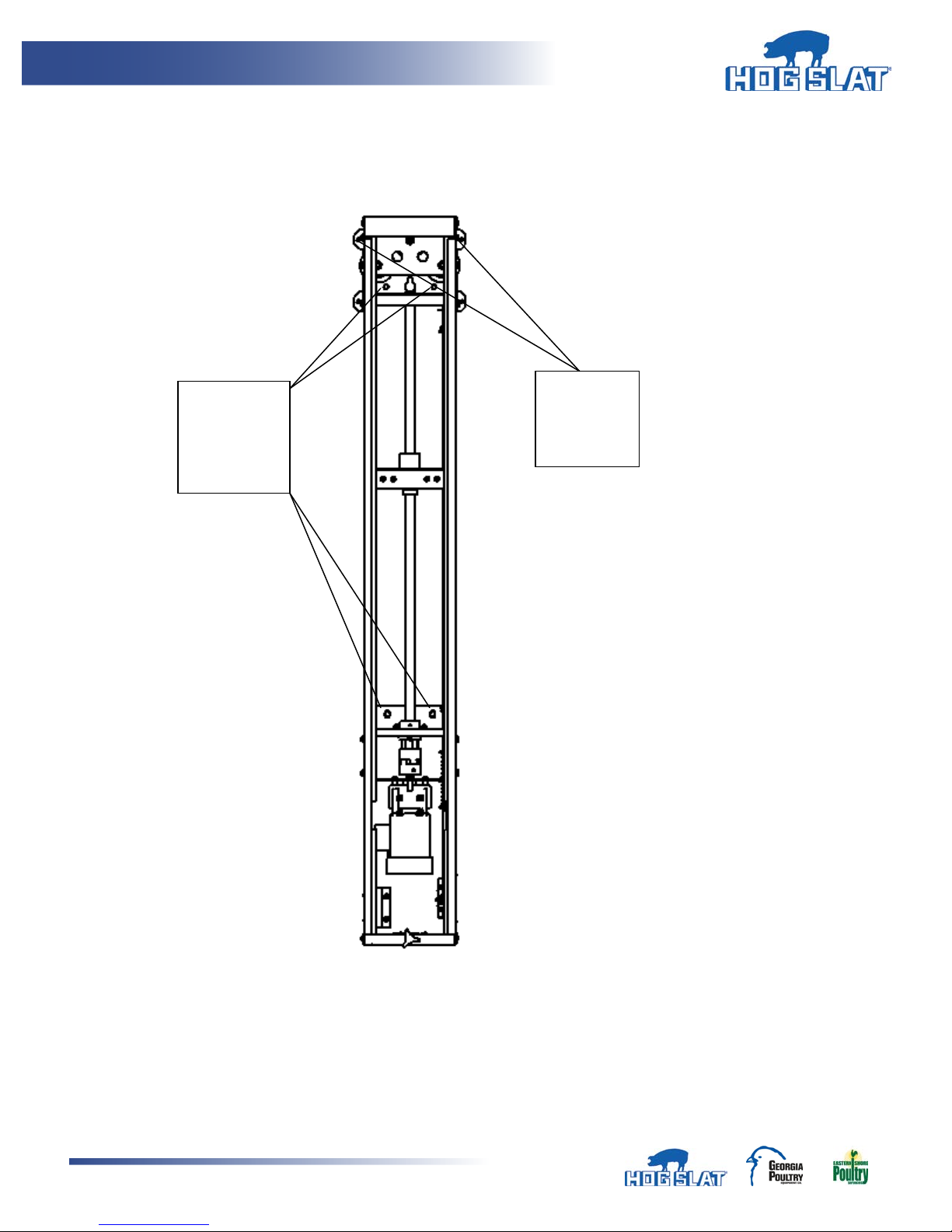

(4) Inside

(2) External

4. DO NOT OPERATE MACHINE while hanging on this bolt. Level machine and secure machine

using 3/8” x 2” Lag bolts (supplied) in the (6) mounting locations. (Figure 2)

chassis

mounting

locations

Mounting

Locations

5. When connecting cables, the load nut should be near the “Closed” position to allow enough

cable for manual winch connection.

Hog Slat Inc. Newton Grove, NC USA September 2014

7

Figure 2

Ventilation Systems

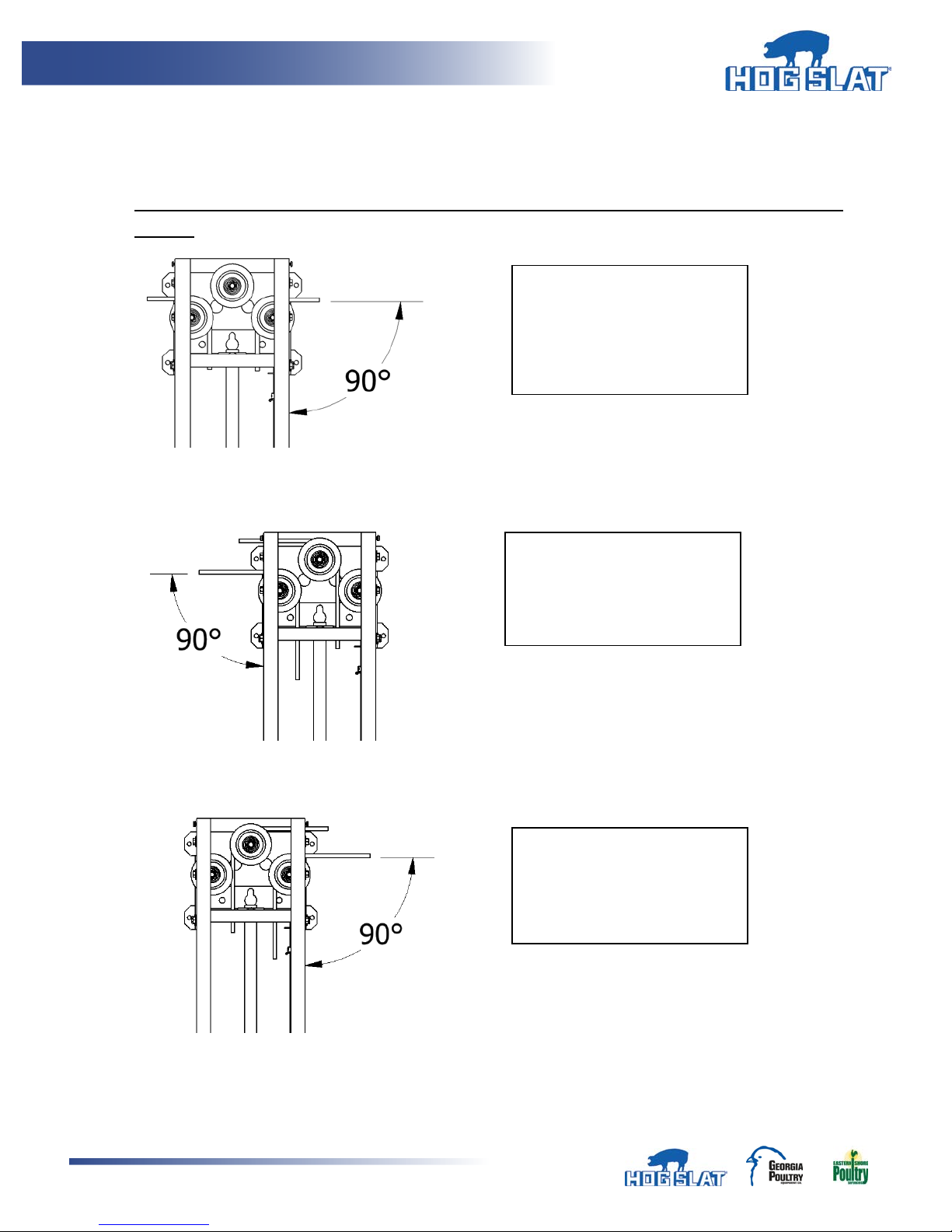

One machine used to pull two

One machine used to pull

One machine used to pull

6. Run cable ends through side of machine around pulley down to the load block. Route cables

around pulleys as shown in below figures that best suits the application.

7. Cables should exit 90 Degrees to cabinet side to ensure even load on both sides of load block.

Changing the exit angle will change force distribution on load block resulting in shorter load

nut life.

curtains from both sides, loop

cable around pulleys.

(Figure 3)

Figure 3

Figure 4

curtain from LEFT side, loop

cable around pulleys.

(Figure 4)

curtain from RIGHT side, loop

cable around pulleys.

(Figure 5)

Figure 5

Hog Slat Inc. Newton Grove, NC USA September 2014

8

Loading...

Loading...