Page 1

User Manual

Off Grid Solar Inverter

SPF 5000 ES

Version: 1.0

Page 2

Table Of Contents

Information on this Manual ............................................................................................................................ 1

Validity ...................................................................................................................................................... 1

Scope ......................................................................................................................................................... 1

Target Group ............................................................................................................................................. 1

Safety Instructions ................................................................................................................................... 1

Introduction ................................................................................................................................................... 2

Features .................................................................................................................................................... 2

Product Overview ...................................................................................................................................... 3

Installation ..................................................................................................................................................... 4

Unpacking and Inspection ........................................................................................................................ 4

Mounting the Unit ..................................................................................................................................... 4

Battery Connection ................................................................................................................................... 5

Lead-acid Battery Connection ............................................................................................................... 5

Lithium Battery Connection ................................................................................................................... 6

AC Input/Output Connection .................................................................................................................. 10

PV Connection ......................................................................................................................................... 11

Communication Connection .................................................................................................................... 12

Dry Contact Signal .................................................................................................................................. 12

Operation ...................................................................................................................................................... 13

Power ON/OFF ........................................................................................................................................ 13

Operation and Display Panel ................................................................................................................... 13

LCD Display Icons ................................................................................................................................ 14

LCD Setting .......................................................................................................................................... 16

Display Information ................................................................................................................................ 21

Operating Mode Description ................................................................................................................... 22

Parallel Installation Guide ............................................................................................................................ 23

Introduction ............................................................................................................................................ 23

Parallel Board Installation ...................................................................................................................... 23

Parallel Operation in Single Phase .......................................................................................................... 26

Parallel Operation in Three Phase........................................................................................................... 29

PV Connection ......................................................................................................................................... 32

LCD Setting and Display .......................................................................................................................... 32

Fault Reference Code ................................................................................................................................... 34

Warning Indicator ........................................................................................................................................ 34

Battery Equalization ..................................................................................................................................... 36

Specifications ............................................................................................................................................... 37

Trouble Shooting .......................................................................................................................................... 40

Page 3

1

Information on this Manual

Validity

This manual is valid for the following devices:

SPF 5000 ES

Scope

This manual describes the assembly, installation, operation and troubleshooting of this unit. Please read

this manual carefully before installations and operations.

Target Group

This document is intended for qualified persons and end users. Tasks that do not require any particular

qualification can also be performed by end users. Qualified persons must have the following skills:

Knowledge of how an inverter works and is operated

Training in how to deal with the dangers and risks associated with installing and using electrical

devices and installations

Training in the installation and commissioning of electrical devices and installations

Knowledge of the applicable standards and directives

Knowledge of and compliance with this document and all safety information

Safety Instructions

WARNING: This chapter contains important safety and operating instructions.

Read and keep this manual for future reference.

1.

Please be clear which kind of battery system you want, lithium battery system or lead-acid battery system, if

you choose the wrong system, energy storage system can’t work normally.

2.

Before using the unit, read all instructions and cautionary marking on the unit, the batteries and all

appropriate sections of this manual. The company has the right not to quality assurance, if not according to

the instructions of this manual for installation and cause equipment damage.

3.

All the operation and connection please professional electrical or mechanical engineer.

4.

All the electrical installation must comply with the local electrical safety standards.

5.

When install PV modules in the daytime, installer should cover the PV modules by opaque materials,

otherwise it will be dangerous as high terminal voltage of modules in the sunshine.

6.

CAUTION-To reduce risk of injury, charge only deep-cycle lead-acid type rechargeable batteries and

lithium batteries. Other types of batteries may burst, causing personal injury and damage.

7.

Do not disassemble the unit. Take it to a qualified service center when service or repair is required.

Incorrect re-assembly may result in a risk of electric shock or fire.

8.

To reduce risk of electric shock, disconnect all wirings before attempting any maintenance or cleaning.

Turning off the unit will not reduce this risk.

9.

NEVER charge a frozen battery.

10.

For optimum operation of this inverter, please follow required spec to select appropriate cable size. It’s very

important to correctly operate this inverter.

11.

Be very cautious when working with metal tools on or around batteries. A potential risk exists to drop a tool

to spark or short circuit batteries or other electrical parts and could cause an explosion.

12.

Please strictly follow installation procedure when you want to disconnect AC or DC terminals. Please refer to

INSTALLATION section of this manual for the details.

13.

GROUNDING INSTRUCTIONS -This inverter should be connected to a permanent grounded wiring system.

Be sure to comply with local requirements and regulation to install this inverter.

14.

NEVER cause AC output and DC input short circuited. Do NOT connect to the mains when DC input short

circuits.

15.

Make sure the inverter is completely assembled, before the operation.

Page 4

2

Introduction

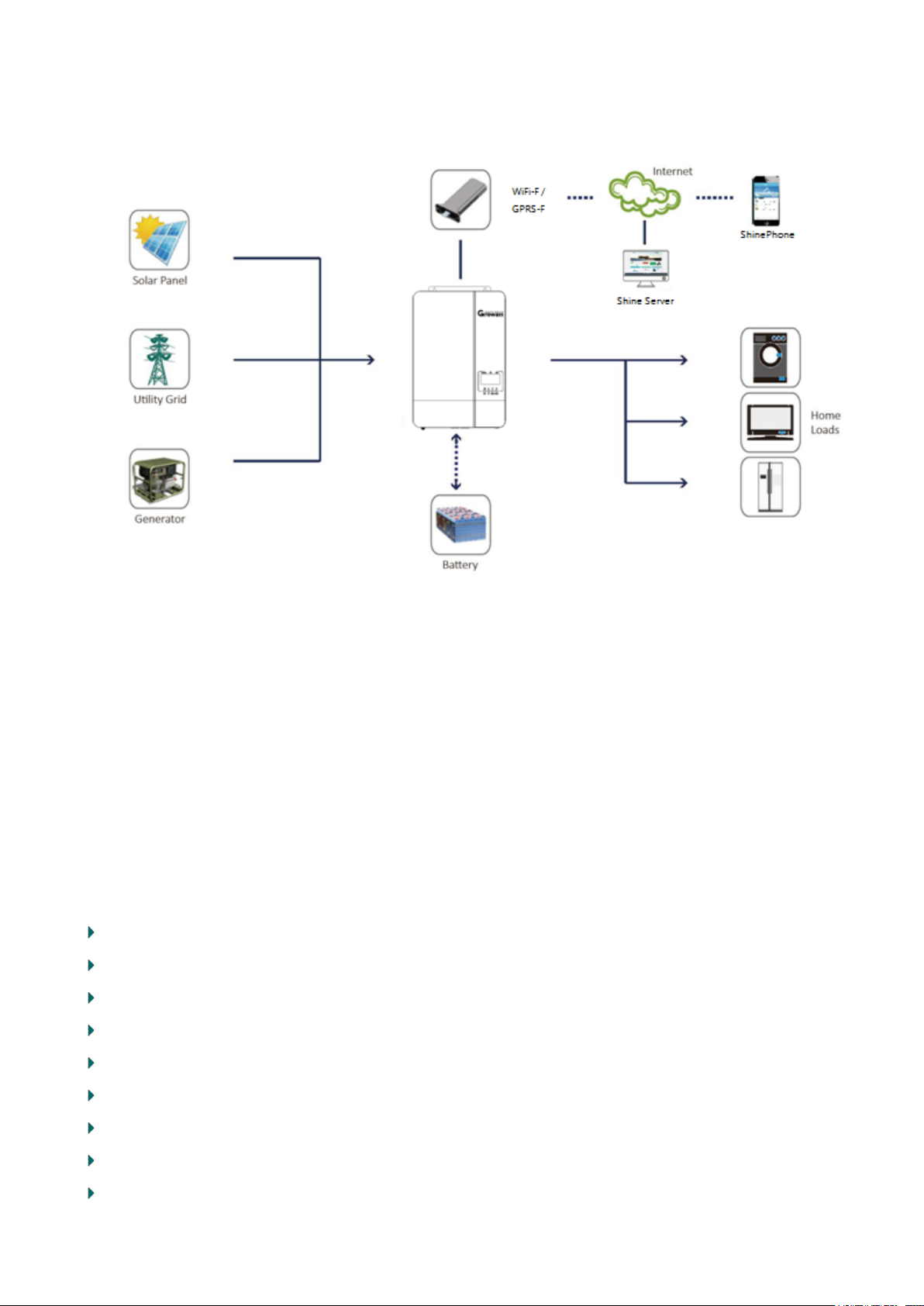

Hybrid Power System

This is a multifunctional off grid solar inverter, integrated with a MPPT solar charge controller, a high

frequency pure sine wave inverter and a UPS function module in one machine, which is perfect for off grid

backup power and self-consumption applications. This inverter can work with or without batteries.

The whole system also need other devices to achieve complete running such as PV modules, generator, or

utility grid. Please consult with your system integrator for other possible system architectures depending on

your requirements. The WiFi / GPRS module is a plug-and-play monitoring device to be installed on the

inverter. With this device, users can monitor the status of the PV system from the mobile phone or from the

website anytime anywhere.

Features

Rated power 5KW, power factor 1

MPPT ranges 120V~430V, 450Voc

High frequency inverter with small size and light weight

Pure sine wave AC output

Solar and utility grid can power loads at the same time

With CAN/RS485 for BMS communication

With the ability to work without battery

Parallel operation up to 6 unit

WIFI/ GPRS remote monitoring (optional)

Page 5

3

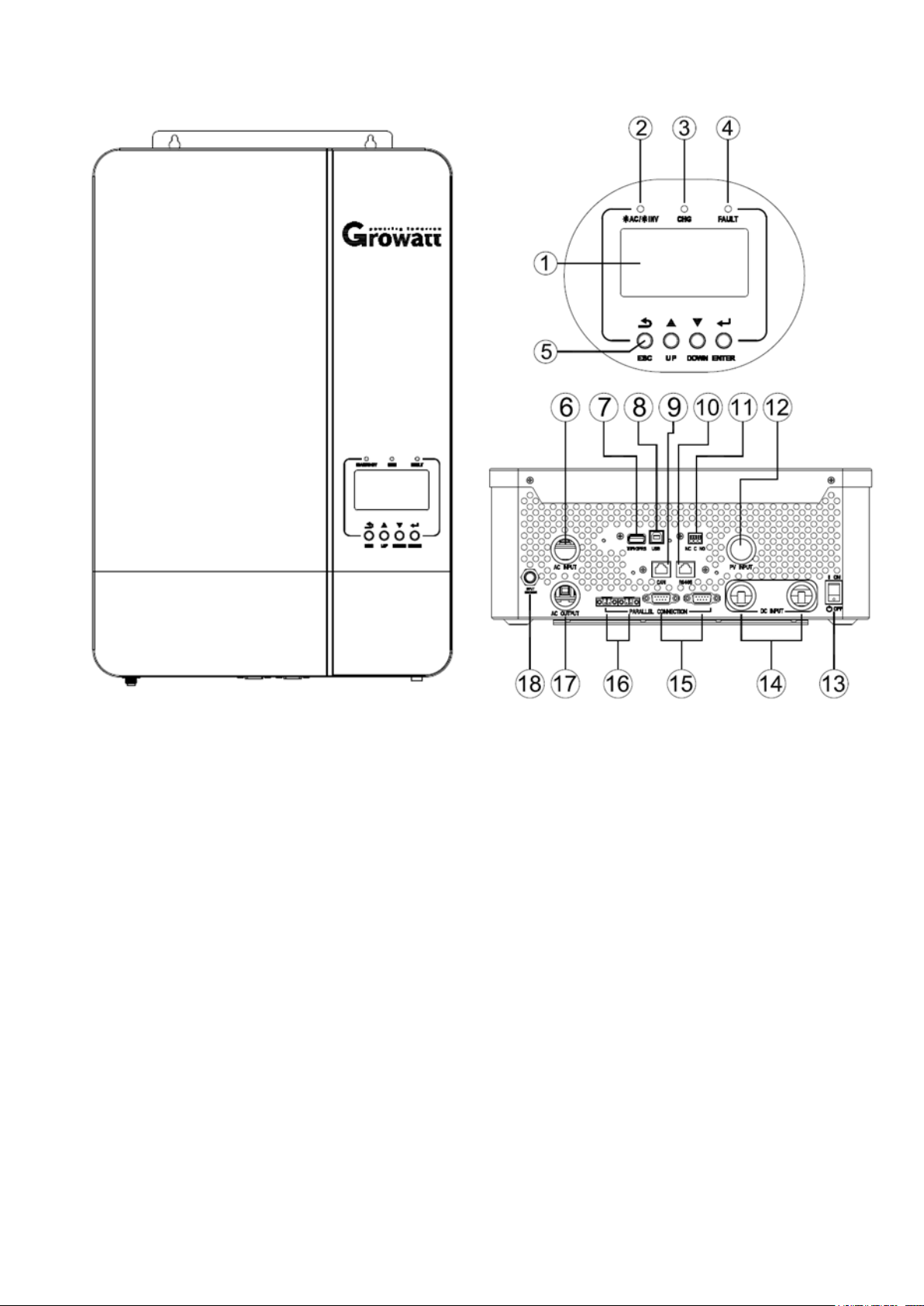

Product Overview

1. LCD display

2. Status indicator

3. Charging indicator

4. Fault indicator

5. Function buttons

6. AC input

7. WiFi/GPRS communication port

8. USB communication port

9. CAN communication Port

10. RS485 communication Port

11. Dry contact

12. PV input

13. Power on/off switch

14. Battery input

15. Parallel communication ports

16. Current sharing ports

17. AC output

18. Circuit breaker

Page 6

4

Installation

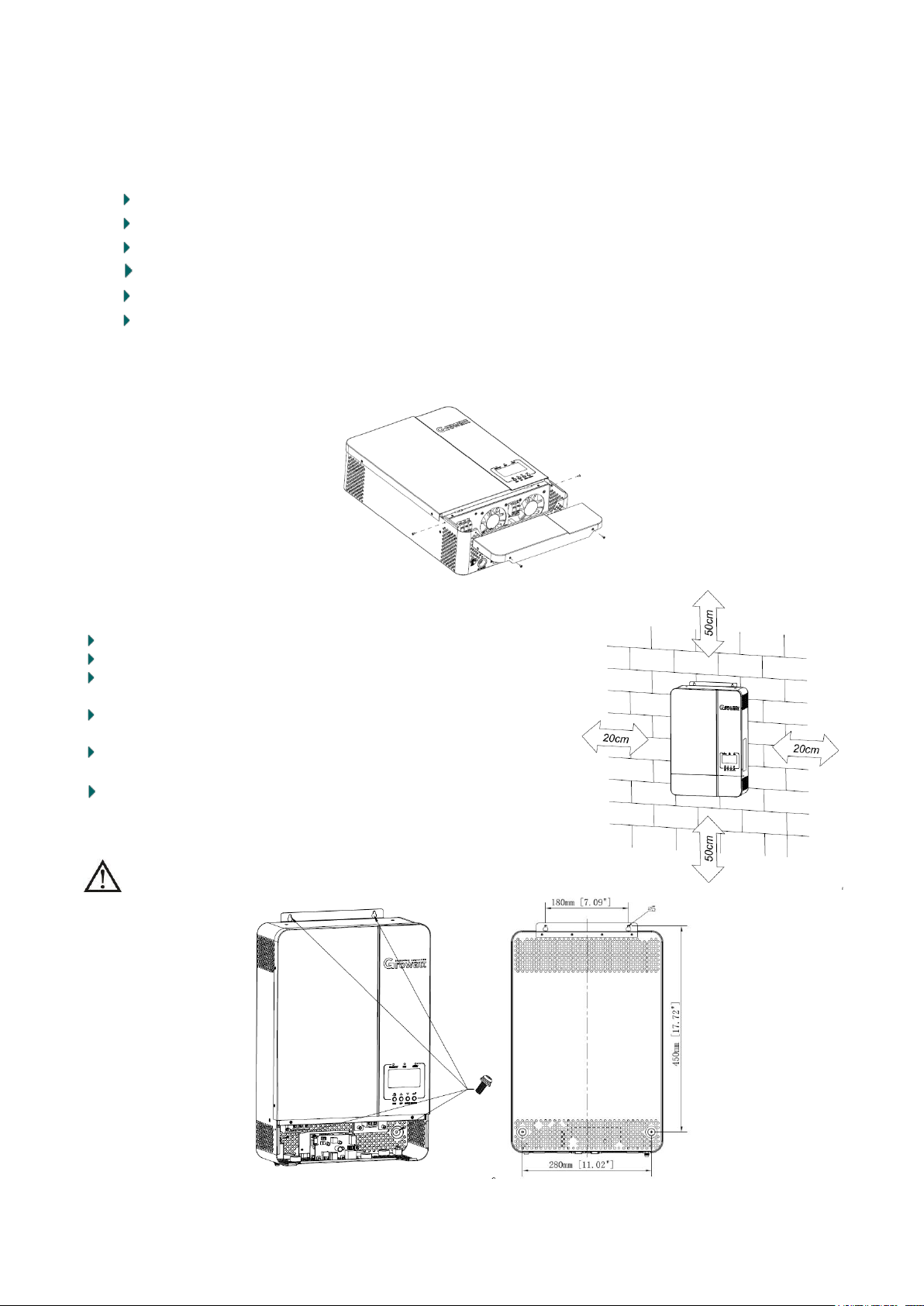

Unpacking and Inspection

Before installation, please inspect the unit. Be sure that nothing inside the package is damaged. You should

have received the following items in the package:

The unit x 1

User manual x 1

Communication cable x 1

Software CD x 1

Current sharing cable x 1

Parallel communication cable x 1

Preparation

Before connecting all wiring, please take off bottom cover by removing two screws as shown below.

Mounting the Unit

Consider the following points before selecting where to install:

Do not mount the inverter on flammable construction materials.

Mount on a solid surface

Install this inverter at eye level in order to allow the LCD display

to be read at all times.

The ambient temperature should be between 0°C and 55°C to

ensure optimal operation.

The recommended installation position is to be adhered to the

wall vertically.

Be sure to keep other objects and surfaces as shown in the right

diagram to guarantee sufficient heat dissipation and to have

enough space for removing wires.

SUITABLE FOR MOUNTING ON CONCRETE OR

OTHER NON-COMBUSTIBLE SURFACE ONLY.

Install the unit by screwing three screws.

It’s recommended to use M4 or M5 screws.

Page 7

5

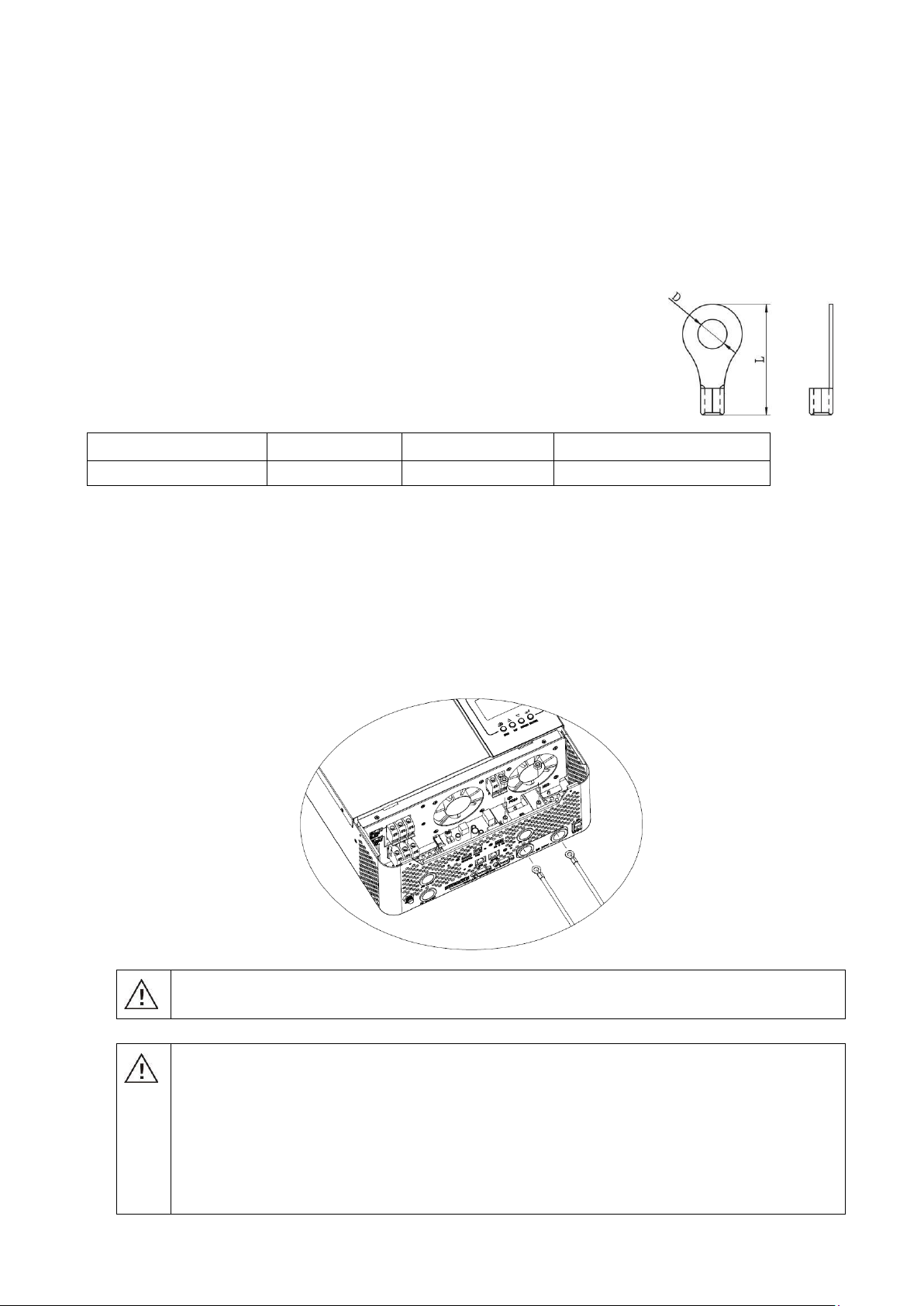

Battery Connection

Model

Wire Size

Cable (mm

2

)

Torque value(max)

SPF 5000 ES

1 x 2AWG

35

2 Nm

WARNING: Shock Hazard

Installation must be performed with care due to high battery voltage in series.

CAUTION!! Do not place anything between the flat part of the inverter terminal and the ring

terminal. Otherwise, overheating may occur.

CAUTION!! Do not apply anti-oxidant substance on the terminals before terminals are

connected tightly.

CAUTION!! Before making the final DC connection or closing DC breaker/disconnector, be sure

positive (+) must be connected to positive (+) and negative (-) must be connected to negative

(-).

Lead-acid Battery Connection

User can choose proper capacity lead acid battery with a nominal voltage at 48V. Also, you need to choose

battery type as “AGM(default) or FLD”

CAUTION: For safety operation and regulation compliance, it’s requested to install a separate DC over-current

protector or disconnect device between battery and inverter. It may not be requested to have a disconnect

device in some applications, however, it’s still requested to have over-current protection installed. Please refer

to typical amperage in below table as required fuse or breaker size.

WARNING! All wiring must be performed by a qualified person.

WARNING! It's very important for system safety and efficient operation to use

appropriate cable for battery connection. To reduce risk of injury, please use the

proper recommended cable and terminal size as below.

Ring terminal:

Recommended battery cable and terminal size:

Note: for lead acid battery, the recommended charge current is 0.2C(Cbattery capacity)

Please follow below steps to implement battery connection:

1.

Assemble battery ring terminal based on recommended battery cable and terminal size.

2.

Connect all battery packs as units requires. It’s suggested to connect at least 200Ah capacity battery for

SPF 5000 ES.

3.

Insert the ring terminal of battery cable flatly into battery connector of inverter and make sure the bolts are

tightened with torque of 2Nm. Make sure polarity at both the battery and the inverter/charge is correctly

connected and ring terminals are tightly screwed to the battery terminals.

Page 8

6

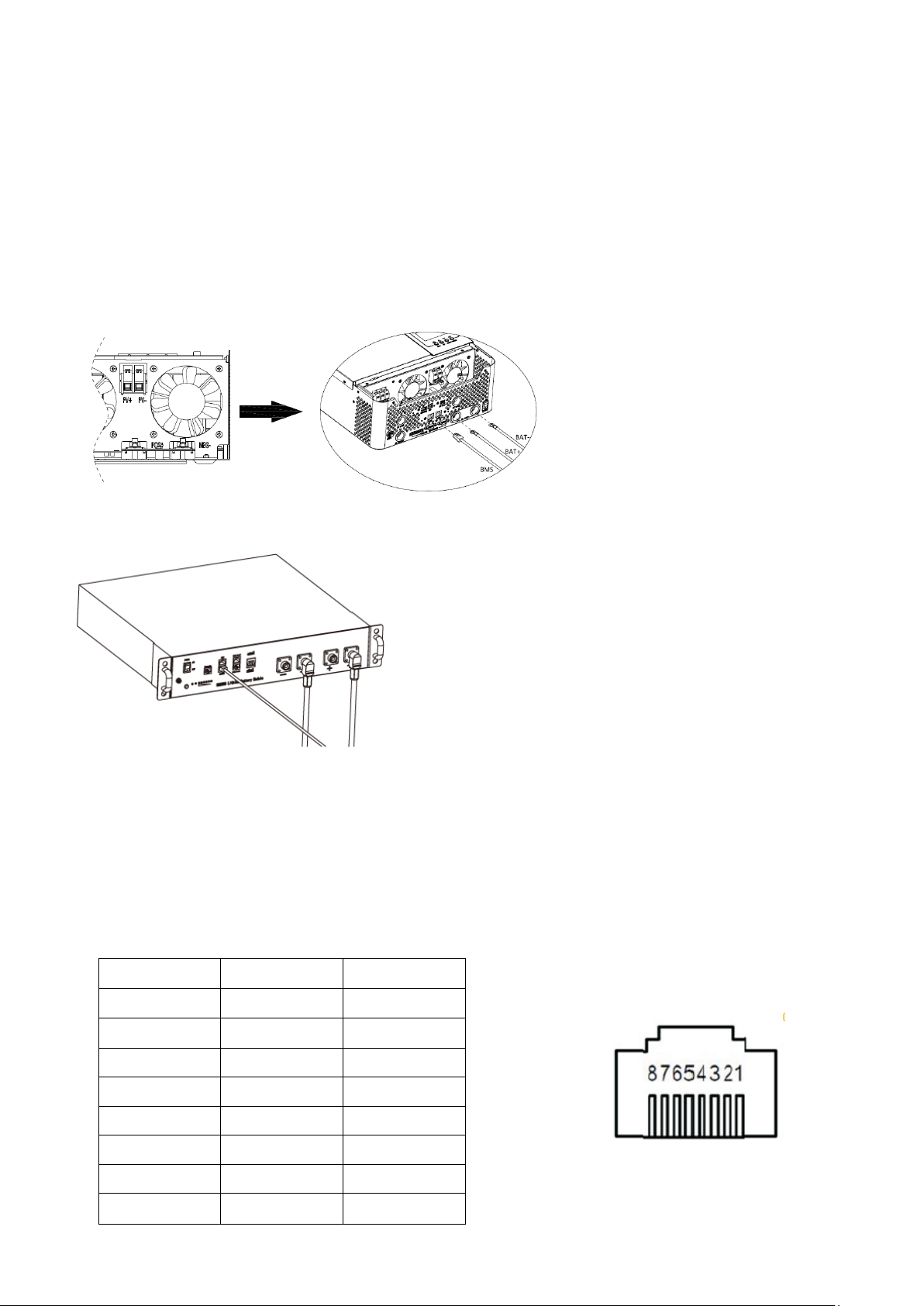

Lithium Battery Connection

Pin number

RS485 port

CAN port

1

RS485B

--

2

RS485A

--

3

--

--

4

--

CANH

5

--

CANL 6 --

-- 7 --

--

8

--

--

If choosing lithium battery for SPF 5000 ES, you are allowed to use the lithium battery only which we have configured.

There're two connectors on the lithium battery, RJ45 port of BMS and power cable.

Please follow below steps to implement lithium battery connection:

1. Assemble battery ring terminal based on recommended battery cable and terminal size (same as Lead acid, see

section Lead-acid Battery connection for details) .

2. Insert the ring terminal of battery cable flatly into battery connector of inverter and make sure the bolts are

tightened with torque of 2-3Nm. Make sure polarity at both the battery and the inverter/charge is correctly connected

and ring terminals are tightly screwed to the battery terminals.

3. Connect the end of RJ45 of battery to BMS communication port(RS485 or CAN) of inverter.

4. The other end of RJ45 insert to battery communication port(RS485 or CAN).

Note: if choosing lithium battery, make sure to connect the BMS communication cable between the battery and the

inverter. You need to choose battery type as “lithium battery”.

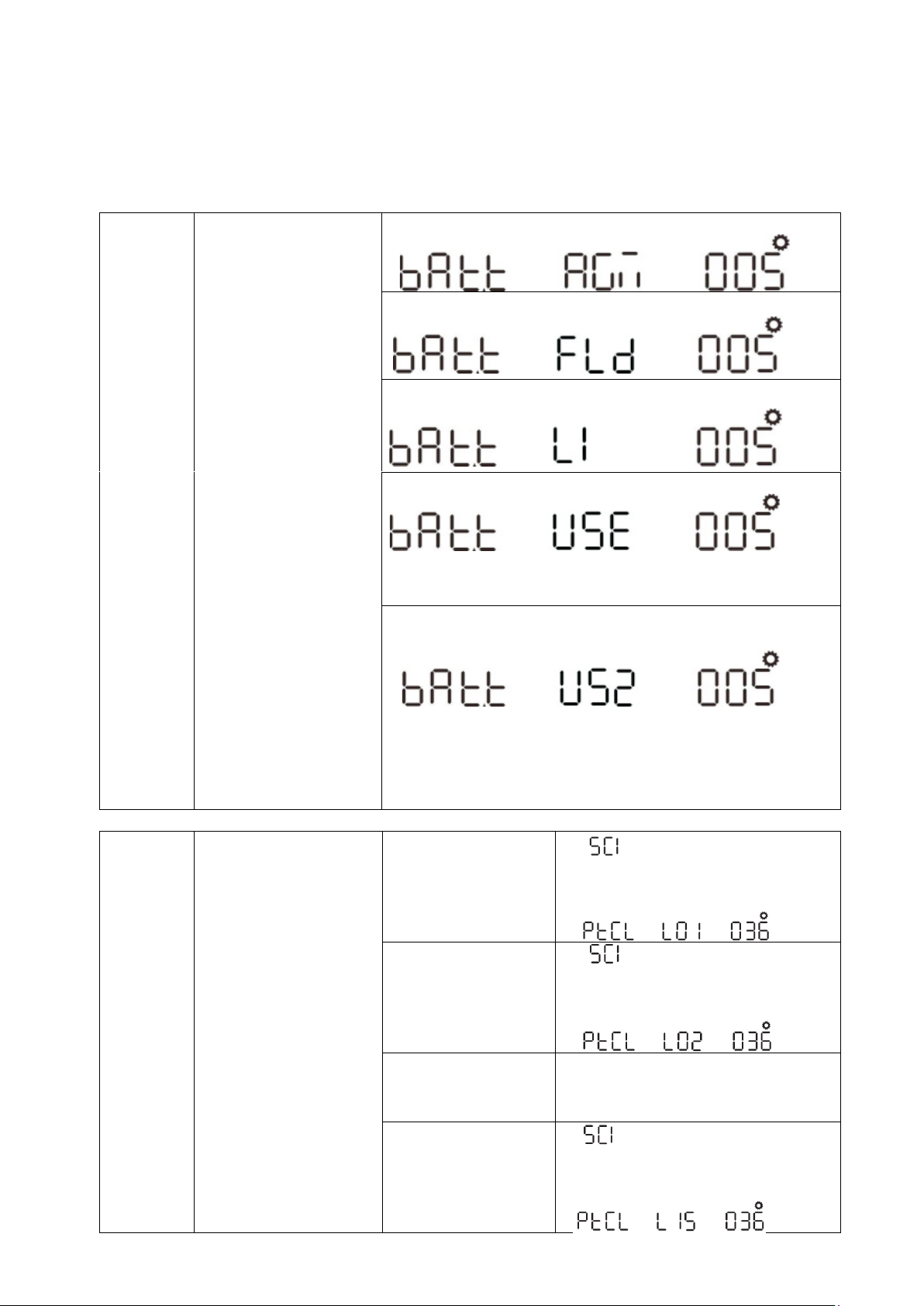

Lithium battery communication and setting

In order to communicate with battery BMS, you should set the battery type to “LI” in Program 5. Then the LCD will

switch to Program 36, which is to set the protocol type. There are several protocols in the inverter. Please get

instruction from Growatt to choose which protocol to match the BMS.

1. Connect the end of RJ45 of battery to BMS communication port of inverter

Make sure the lithium battery BMS port connects to the inverter is Pin to Pin, the inverter BMS port pin assignment

shown as below:

Page 9

7

LCD setting

05

Battery type

AGM (default)

Flooded

Lithium (only suitable when communicated with BMS)

User-Defined

If “User-Defined” is selected, battery charge voltage and low DC

cut-off voltage can be set up in program 19, 20 and 21.

User-Defined 2(suitable when lithium battery without BMS

communication)

If “User-Defined 2” is selected, battery charge voltage and low DC

cut-off voltage can be set up in program 19, 20 and 21. It is

recommended to set to the same voltage in program 19 and

20(full charging voltage point of lithium battery). The inverter will

stop charging when the battery voltage reach this setting.

36

RS485 communication type

Protocol 1

Protocol 2

.

.

.

.

.

.

Protocol 15

To connect battery BMS, need to set the battery type as “LI” in Program 05.

After set “LI” in Program 05, it will switch to Program 36 to choose communication type. There will be 2 options

under Program 36, first is the SCI communication type, and here will be 15 options(L01, L02…L15) under it; Second

is the CAN communication type, and here will be another 15 options(L51, L52…L65) under it.

Note: you can only use one communication type RS485 or CAN in a time

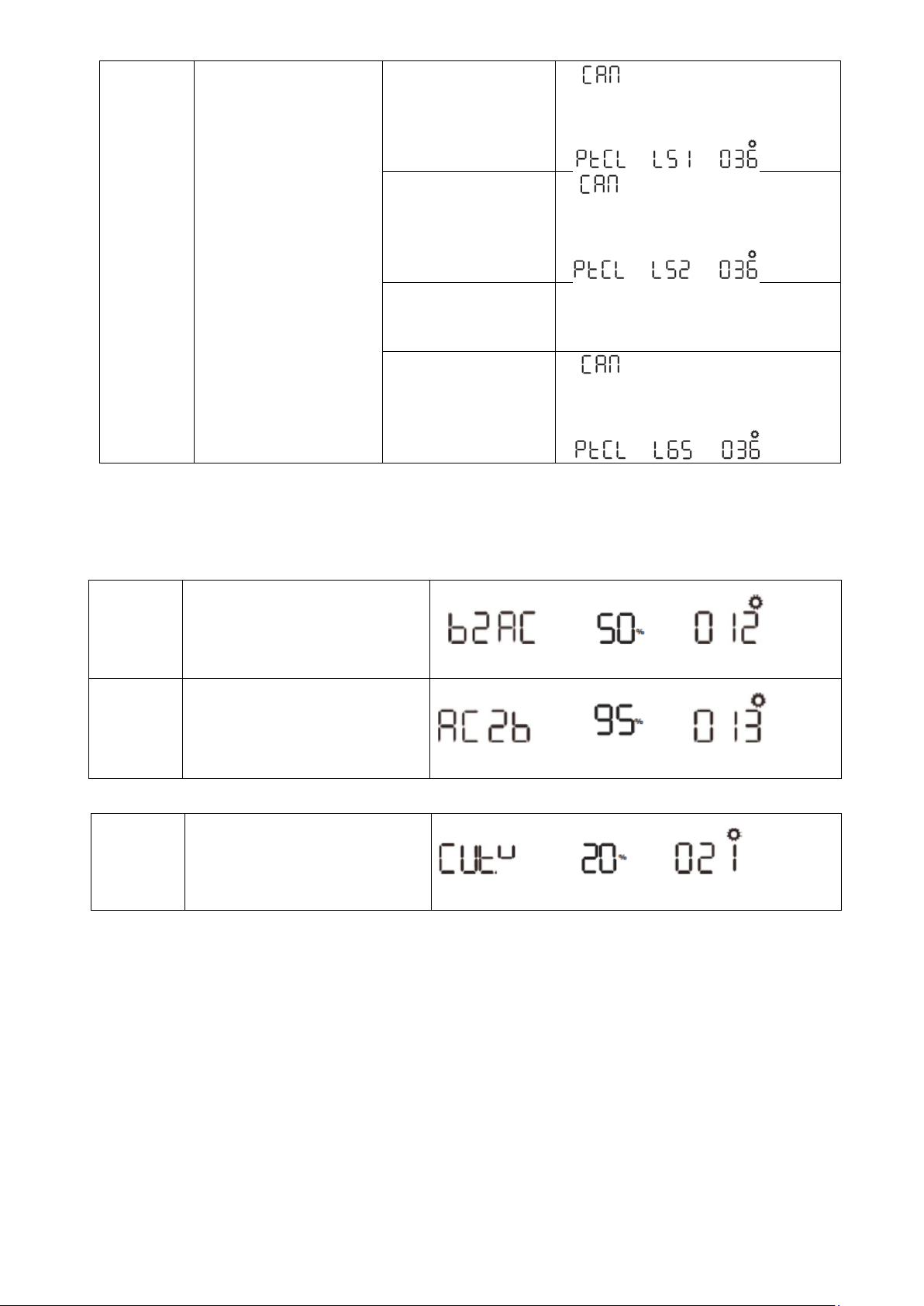

Page 10

8

CAN communication type

Protocol 51

Protocol 52

.

.

.

.

.

.

Protocol 65

12

Setting SOC point back to

utility source when selecting

“SBU priority” or “Solar first”

in program 01

Default 50%, 20%~50% Settable

13

Setting SOC point back to

battery mode when selecting

“SBU priority” or “Solar first”

in program 01

Default 95%, 60%~100% Settable

21

Low DC cut-off SOC

If “LI” is selected in program 5,

this program can be set up

Default 20%, 5%~30% Settable

Note: when the battery type set to Li, the setting option 12, 13, 21 will change to display percent.

Note: when the battery type set as “LI”, the Maximum charge current can't be modified by the user. When the

communication fail, the inverter will cut off output.

Note: any questions about communicating with BMS, please consult with Growatt.

Page 11

9

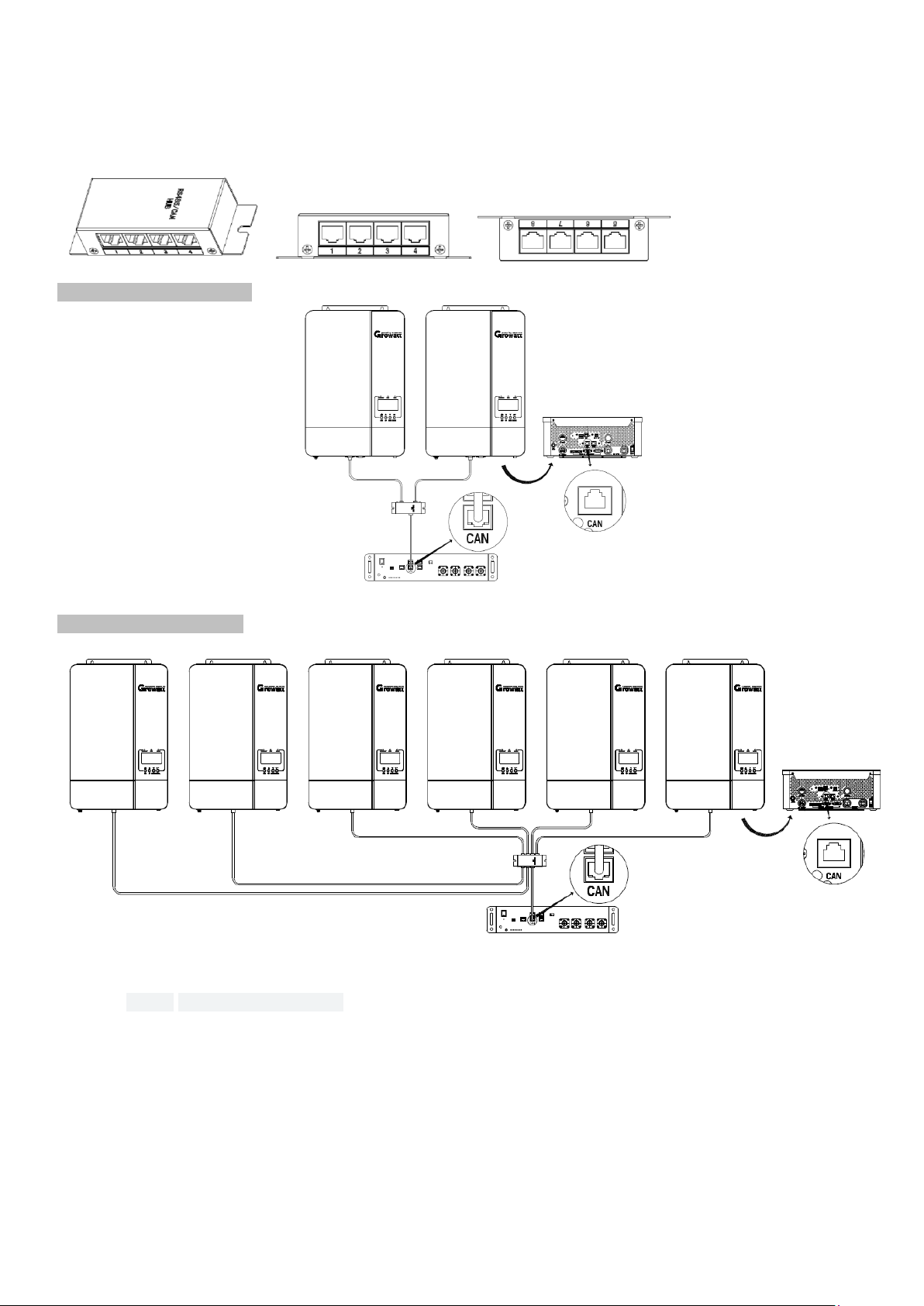

Communicating with battery BMS in parallel system

If need to use communicate with BMS in a parallel system, an external RS485/CAN HUB is needed to converge the

communication cables from the parallel inverters to lithium battery.

RS485/CAN Hub:

Two inverters in parallel:

Six inverters in parallel:

Note: if inverters parallel as 3 phase system, only need to connect L1-Phase inverters with lithium battery RJ45 port to

communicate with BMS. When inverters on L1-Phase are more than 2 units, it would need an extra RS485/CAN HUB to

converge inverters on L1-Phase to connect with battery RJ45 port to communicate with BMS.

Note: the above diagrams described the parallel system communicate with lithium battery in CAN communication type,

and it is the same to the RS485 communication type.

Page 12

10

AC Input/Output Connection

Model

Gauge

Cable (mm2)

Torque Value

SPF 5000 ES

10 AWG

6

1.2 Nm

WARNING:

Be sure that AC power source is disconnected before attempting to hardwire it to the unit.

CAUTION!! Before connecting to AC input power source, please install a separate AC breaker between

inverter and AC input power source. This will ensure the inverter can be securely disconnected during

maintenance and fully protected from over current of AC input. The recommended spec of AC breaker is 32A

50A for SPF 5000 ES.

CAUTION!! There are two terminal blocks with “IN” and “OUT” markings. Please do NOT mis-connect input

and output connectors.

WARNING! All wiring must be performed by a qualified personnel.

WARNING! It’s very important for system safety and efficient operation to use appropriate cable for AC input

connection. To reduce risk of injury, please use the proper recommended cable size as below.

Suggested cable requirement for AC wires

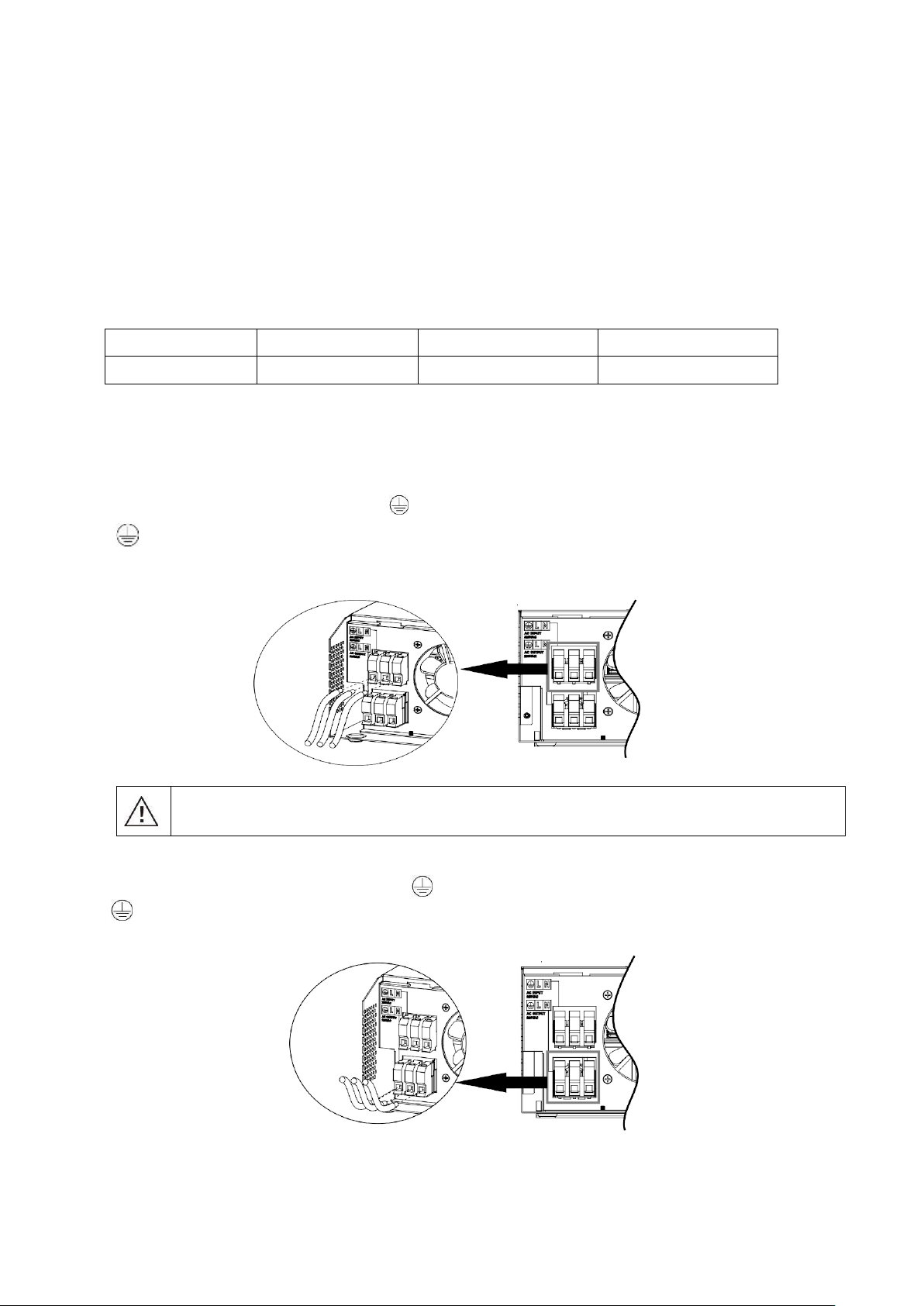

Please follow below steps to implement AC input/output connection:

1.

Before making AC input/output connection, be sure to open DC protector or disconnector first.

2.

Remove insulation sleeve 10mm for six conductors. And shorten phase L and neutral conductor N 3 mm.

3.

Insert AC input wires according to polarities indicated on terminal block and tighten the terminal screws. Be

sure to connect PE protective conductor first.

→Ground (yellow-green)

L→LINE (brown or black)

N→Neutral (blue)

4.

Then, insert AC output wires according to polarities indicated on terminal block and tighten terminal screws.

Be sure to connect PE protective conductor first.

→Ground (yellow-green)

L→LINE (brown or black)

N→Neutral (blue)

5.

Make sure the wires are securely connected.

CAUTION: Important

Be sure to connect AC wires with correct polarity. If L and N wires are connected reversely, it may cause utility

short-circuited when these inverters are worked in parallel operation.

Page 13

11

Model

Wire Size

Cable (mm2)

Torque value(max)

SPF 5000 ES

1 x 12AWG 4

1.2 Nm

INVERTER MODEL

SPF 5000 ES

Max. PV Array Open Circuit Voltage

450Vdc

PV Array MPPT Voltage Range

120Vdc~430Vdc

CAUTION: Appliances such as air conditioner are required at least 2~3 minutes to restart because it’s

required to have enough time to balance refrigerant gas inside of circuits. If a power shortage occurs and

recovers in a short time, it will cause damage to your connected appliances. To prevent this kind of damage,

please check with manufacturer of air conditioner that if it’s equipped with time-delay function before

installation. Otherwise, this off grid solar inverter will trigger overload fault and cut off output to protect your

appliance but sometimes it still causes internal damage to the air conditioner.

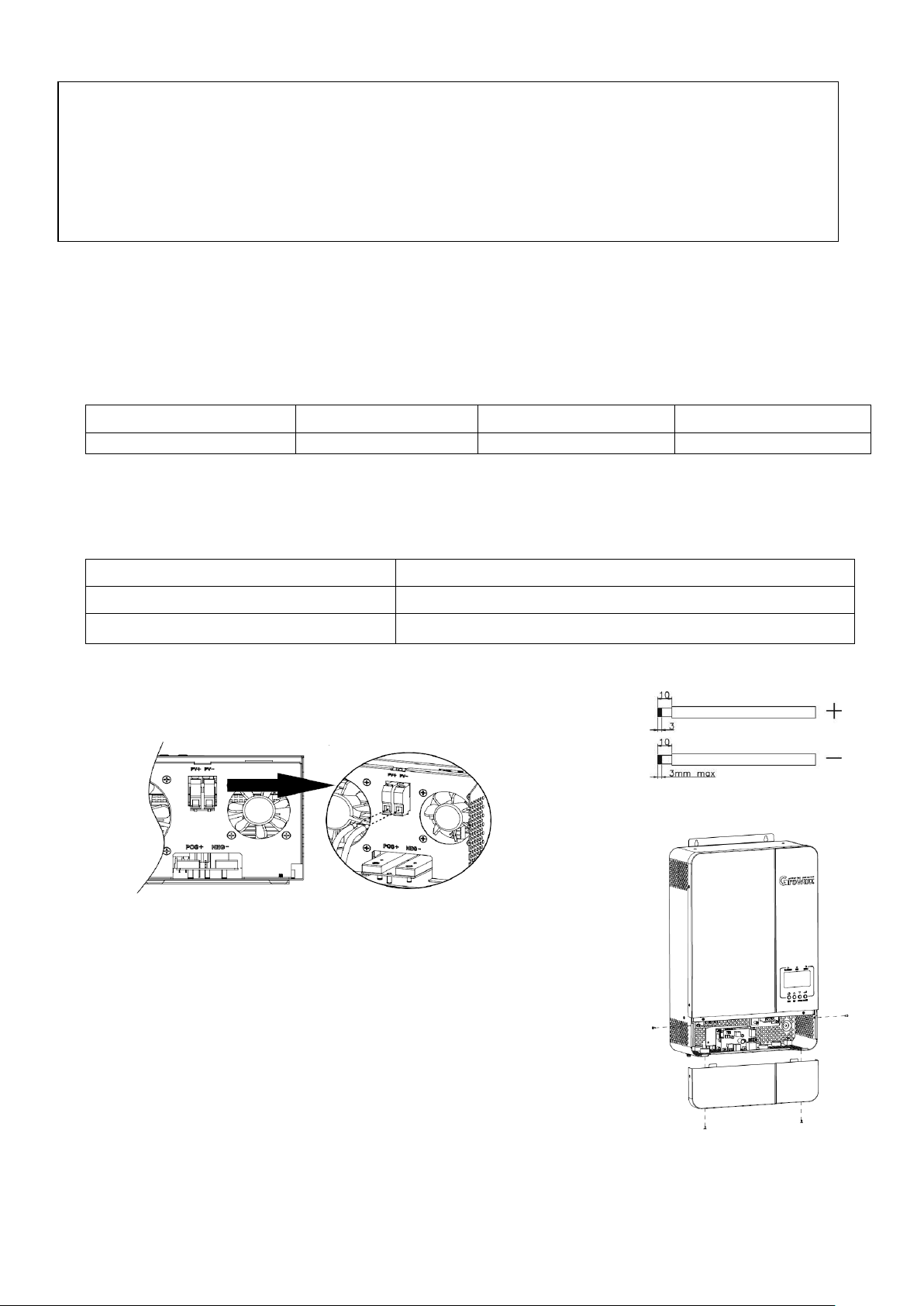

PV Connection

CAUTION: Before connecting to PV modules, please install separately a DC circuit breaker between inverter

and PV modules.

WARNING! All wiring must be performed by a qualified personnel.

WARNING! It'’ very important for system safety and efficient operation to use appropriate cable for PV module

connection. To reduce risk of injury, please use the proper recommended cable size as below.

PV Module Selection:

When selecting proper PV modules, please be sure to consider below parameters:

1.

Open circuit Voltage (Voc) of PV modules not exceeds max. PV array open circuit voltage of inverter.

2.

Open circuit Voltage (Voc) of PV modules should be higher than min. battery voltage.

Please follow below steps to implement PV module connection:

1.

Remove insulation sleeve 10 mm for positive and negative conductors.

2.

Check correct polarity of connection cable from PV modules and PV input

connectors. Then, connect positive pole (+) of connection cable to positive

pole (+) of PV input connector. Connect negative pole (-) of connection

cable to negative pole (-) of PV input connector.

3.

Make sure the wires are securely connected.

Final Assembly

After connecting all wiring, please put bottom cover back by screwing

two screws as shown below.

Page 14

12

Communication Connection

Unit Status

Condition

Dry contact port:

NC & C

NO & C

Power Off

Unit is off and no output is powered.

Close

Open

Power On

Output is powered from Utility.

Close

Open

Output is

powered

from

Battery or

Solar.

Program 01

set as Utility

Battery voltage < Low DC warning

voltage

Open

Close

Battery voltage > Setting value in

Program 13 or battery charging

reaches floating stage

Close Open

Program 01

is set as

SBU or

Solar first

Battery voltage < Setting value in

Program 12

Open

Close

Battery voltage > Setting value in

Program 13 or battery charging

reaches floating stage

Close Open

Unit Status

Condition

Dry contact port:

NC & C

NO & C

Power Off

Unit is off and no output is powered.

Close

Open

Power On

Unit works in standby mode, line mode or fault mode

Close

Open

Unit works in battery mode or power saving mode

Open

Close

Please use supplied communication cable to connect to inverter and PC. Insert bundled CD into a computer and

follow on-screen instruction to install the monitoring software. For the detailed software operation, please

check user manual of software inside of CD.

Dry Contact Signal

There is one dry contact available on the rear panel. When program 24 is set as “disable”, it could be used to

deliver signal to external device when battery voltage reaches warning level. When program 24 is set as

“enable” and the unit is working in battery mode, it could be used to trigger the grounding box to connect

neutral and grounding of AC output together.

When program 24 is set as “disable” (default setting):

When program 24 is set as “enable”:

Page 15

13

Operation

LED Indicator

Messages

Green

Solid On

Output is powered by utility in Line mode.

Flashing

Output is powered by battery or PV in battery mode.

Green

Solid On

Battery is fully charged.

Flashing

Battery is charging.

Red

Solid On

Fault occurs in the inverter.

Flashing

Warning condition occurs in the inverter.

Button

Description

ESC

To exit setting mode

UP

To go to previous selection

DOWN

To go to next selection

ENTER

To confirm the selection in setting mode or enter setting mode

Power ON/OFF

Once the unit has been properly installed and the batteries are connected well, simply press On/Off switch

(located on the button of the case) to turn on the unit.

Operation and Display Panel

The operation and display panel, shown in below chart, is on the front panel of the inverter. It includes

three indicators, four function keys and a LCD display, indicating the operating status and input/output

power information.

1. LCD display

2. Status indicator

3. Charging indicator

4. Fault indicator

5. Function buttons

LED Indicator

Function Buttons

Page 16

14

LCD Display Icons

Icon

Description

AC Input Information

AC input icon

Indicate AC input power, AC input voltage, AC input frequency, AC input

current

Indicate AC power loads in bypass

PV Input Information

PV input icon

Indicate PV power, PV voltage, PV current, etc

Output Information

Inverter icon

Indicate output voltage, output current, output frequency, inverter

temperature

Load Information

Load icon

Indicate power of load, power percentage of load

Indicate overload happened

Indicate short circuit happened

Battery Information

Indicate battery level by 0-24%, 25-49%, 50-74% and 75-100% in battery

mode and charging status in line mode.

Indicate battery voltage, battery percentage, battery current

Indicate SLA battery

Indicate lithium battery

Indicate charging source priority: solar first, solar and utility, or only solar

Other Information

Indicate output source priority: solar first, utility first, SBU mode or SUB mode

Indicate warning code or fault code

Indicate a warning or a fault is happening

Indicate it’s during setting values

Indicate the alarm is disabled

Page 17

15

In battery mode, battery icon will present Battery Capacity

Load Percentage

Battery Voltage

LCD Display

Load >50%

< 1.717V/cell

1.717V/cell ~ 1.8V/cell

1.8 ~ 1.883V/cell

> 1.883 V/cell

50%> Load > 20%

< 1.817V/cell

1.817V/cell ~ 1.9V/cell

1.9 ~ 1.983V/cell

> 1.983

Load < 20%

< 1.867V/cell

1.867V/cell ~ 1.95V/cell

1.95 ~ 2.033V/cell

> 2.033

In AC mode, battery icon will present Battery Charging Status

Status

Battery voltage

LCD Display

Constant Current

mode / Constant

Voltage mode

<2V/cell

4 bars will flash in turns.

2 ~ 2.083V/cell

Bottom bar will be on and the other three bars

will flash in turns.

2.083 ~ 2.167V/cell

Bottom two bars will be on and the other two bars

will flash in turns.

> 2.167 V/cell

Bottom three bars will be on and the top

bar will flash.

Floating mode. Batteries are fully charged.

4 bars will be on.

Page 18

16

LCD Setting

Program

Description

Setting Option

01

Output source priority: To

configure load power

source priority

Solar first

Solar energy provides power to the loads as first priority.

If solar energy is not sufficient to power all connected loads, battery energy

will supply power the loads at the same time.

Utility provides power to the loads only when any one condition happens:

-

Solar energy is not available

-

Battery voltage drops to either low-level warning voltage or the setting

point in program 12.

Utility first (default)

Utility will provide power to the loads as first priority.

Solar and battery energy will provide power to the loads only when

utility power is not available.

SBU priority

Solar energy provides power to the loads as first priority.

If solar energy is not sufficient to power all connected loads, battery will

supply power to the loads at the same time.

Utility provides power to the loads only when battery voltage drops to

either low-level warning voltage or the setting point in program 12.

SUB priority

Solar energy provides power to the loads as first priority.

If solar energy is not sufficient to power all connected loads, solar and

utility will power loads at the same time.

Battery provides power to the loads only when solar energy is not

sufficient and there is no utility.

02

Maximum charging current:

set total charging current for

solar and utility chargers.

(Max. charging current =

utility charging current +

solar charging current)

Default 60A, 10A~100A Settable

03

AC input voltage range

Appliance (default)

If selected, acceptable AC input voltage range will be within 90~280VAC

UPS

If selected, acceptable AC input voltage range will be within 170~280VAC

Generator

If selected, acceptable AC input voltage range will be within 90~280VAC

In this mode, the MAX. charging current is 30A

After pressing and holding ENTER button for 3 seconds, the unit will enter setting mode. Press “UP” or “DOWN”

button to select setting programs. Then press “ENTER” button to confirm the selection or ESC button to exit.

Page 19

17

04

Power saving mode

enable/disable

Saving mode disable (default)

If disabled, no matter connected load is low or high, the on/off status of

inverter output will not be effected.

Saving mode enable

If enabled, the output of inverter will be off when connected load is pretty

low or not detected.

05

Battery type

AGM (default)

Flooded

Lithium (only suitable when communicated with BMS)

User-Defined

If “User-Defined” is selected, battery charge voltage and low DC cut-off

voltage can be set up in program 19, 20 and 21.

User-Defined 2(suitable when lithium battery without BMS

communication)

If “User-Defined 2” is selected, battery charge voltage and low DC cut-off

voltage can be set up in program 19, 20 and 21. It is recommended to set to

the same voltage in program 19 and 20(full charging voltage point of lithium

battery). The inverter will stop charging when the battery voltage reach this

setting.

06

Auto restart when overload

occurs

Restart disable (default)

Restart enable

07

Auto restart when over

temperature occurs

Restart disable (default)

Restart enable

08

Output voltage

*This setting is only

available when the inverter

is in standby mode (Switch

off).

230V (default)

220V

240V

208V

09

Output frequency

*This setting is only

available when the inverter

is in standby mode (Switch

off).

50Hz (default)

60Hz

10

Number of series

batteries connected

(e.g. Showing batteries are connected in 4 series)

Page 20

18

11

Maximum utility charging

current

Note: If setting value in

Program 02 is smaller

than that in Program 11,

the inverter will apply

charging current from

Program 02 for utility

charger

Default 30A, 10A~80A Settable

12

Setting voltage point back

to utility source when

selecting “SBU priority” or

“Solar first” in program 01

Default 46.0V, 44.0V~51.2V Settable

13

Setting voltage point back

to battery mode when

selecting “SBU priority”

or “Solar first” in program

01

Default 54.0V, 48.0V~58.0V Settable

14

Charger source priority:

To configure charger

source priority

If this off grid solar inverter is working in Line, Standby or Fault mode,

charger source can be programmed as below:

Solar first

Solar energy will charge battery as

first priority.

Utility will charge battery only when

solar energy is not available.

Solar and Utility

Solar energy and utility will both

charge battery.

Only Solar

Solar energy will be the only charger

source no matter utility is available

or not.

If this off grid solar inverter is working in Battery mode or Power saving

mode, only solar energy can charge battery. Solar energy will charge battery

if it's available and sufficient.

15

Alarm control

Alarm on (default)

Alarm off

16

Backlight control

Backlight on (default)

Backlight off

17

Beeps while primary

source is interrupted

Alarm on (default)

Alarm off

18

Overload bypass:

When enabled, the unit

will transfer to line mode

if overload occurs in

battery mode.

Bypass disable (default)

Bypass enable

19

Bulk charging voltage (C.V

voltage). If self-defined is

selected in program 5, this

program can be set up

Default 56.4V, 48.0V~58.4V Settable

Page 21

19

20

Floating charging voltage.

If self-defined is selected in

program 5, this program

can be set up

Default 54.0V, 48.0V~58.4V Settable

21

Low DC cut-off voltage.

If self-defined is selected

in program 5, this program

can be set up

Default 42.0V, 40.0V~48.0V Settable

23

AC output mode

*This setting is only

available when the inverter

is in standby mode (Switch

off).

Note: Parallel forbidden

without battery

Single:

Parallel:

L1 Phase:

L2 Phase:

L3 Phase:

When the units are used in parallel with single phase, please select “PAL” in

program 23.

It requires 3 inverters to support

three-phase equipment, 1 inverter in each phase.

Please select “3P1” in program 23 for the inverters connected to L1 phase,

“3P2” in program 23 for the inverters connected to L2 phase and “3P3” in

program 23 for the inverters connected to L3 phase.

Be sure to connect share current cable to units which are on the same phase.

Do NOT connect share current cable between units on different phases.

Besides, power saving function will be automatically disabled.

24

Allow neutral and

grounding of AC output

is connected together:

When enabled, inverter

can deliver signal to

trigger grounding box to

short neutral and

grounding(for expansion)

Disable: Neutral and grounding of AC output is disconnected.

(Default)

Enable: Neutral and grounding of AC output is connected.

This function is only available when the inverter is working with external

grounding box. Only when the inverter is working in battery mode, it will

trigger grounding box to connect neutral and grounding of AC output.

37

Real time setting---Year

Default 2018, range 2018~2099

38

Real time setting---Month

Default 01, range 01~12

39

Real time setting---Date

Default 01, range 01~31

40

Real time setting---Hour

Default 00, range 00~23

41

Real time setting---Minute

Default 00, range 00~59

42

Real time setting---Second

Default 00, range 00~59

Page 22

20

43

Battery equalization

Battery equalization enable

Battery equalization disable(default)

If “Flooded” or “User-Defined” is selected in program 05, this program can

be set up.

44

Battery equalization

voltage

Default 54.0V, 48.0V~58.4V Settable

45

Battery equalized time

Default 60min, 5min~900min

Settable

46

Battery equalized timeout

Default 120min, 5min~900min

Settable

47

Equalization interval

Default 30days, 1 days~90 days

Settable

48

Equalization activated

immediately

Equalization activated immediately on

Equalization activated immediately

off(default)

If equalization function is enabled in program 43, this program can be setup.

If “On” is selected in this program, it’s to activate battery equalization

immediately and LCD main page will shows “ ”. If “Off” is selected, it will

cancel equalization function until next activated equalization time arrives

based on program 47setting. At this time, “ ” will not be shown in LCD

main page.

49

Utility charging time

0000(default)

Allow utility to charge the

battery all day run.

The time allows utility to charge the battery.

Use 4 digits to represent the time period, the

upper two digits represent the time when

utility start to charge the battery, setting

range from 00 to 23, and the lower two

digits represent the time when utility end to

charge the battery, setting range from 00 to

23.

(eg: 2320 represents the time allows utility

to charge the battery is from 23:00 to the

next day 20:59, and the utility charging is

prohibited outside of this period)

50

AC output time

0000(default)

Allow inverter to power the

load all day run.

The time allows inverter to power the load.

Use 4 digits to represent the time period, the

upper two digits represent the time when

inverter start to power the load, setting

range from 00 to 23, and the lower two

digits represent the time when inverter end

to power the load, setting range from 00 to

23.

(eg: 2320 represents the time allows inverter

to power the load is from 23:00 to the next

day 20:59, and the inverter AC output power

is prohibited outside of this period)

Page 23

21

Display Information

Setting Information

LCD display

① AC Input voltage

② Output voltage

③ Load percentage

④ PV input voltage

⑤ Battery voltage

⑥ Battery charging stage

(Default Display Screen)

① AC Input frequency

② Output frequency

③ Load power in VA

④ PV energy sum in KWH

⑤ Battery percentage

⑥ Battery charging stage

① AC Input current

② Output current

③ Load percentage

④ PV input current

⑤ Battery charging current

⑥ Battery charging stage

① AC input power in Watts

② Inverter temperature

③ Load power in Watts

④ PV energy sum in KWH

⑤ Battery percentage

⑥ Battery charging stage

Firmware version

(CPU1: 040-00-b21; CPU2:041-00-b21)

Time

(15:20:10, December 15, 2018)

The LCD display information will be switched in turns by pressing “UP” or “DOWN” key. The selectable

information is switched as below order: voltage, frequency, current, power, firmware version.

Page 24

22

Operating Mode Description

Operation mode

Description

LCD display

Standby mode / Power saving

mode

Note: *Standby mode: The

inverter is not turned on yet but

at this time, the inverter can

charge battery without AC

output.

*Power saving mode: If

enabled, the output of inverter

will be off when connected load

is pretty low or not detected.

No output is

supplied by the

unit but it still

can charge

batteries.

Charging by utility and PV

energy.

Charging by utility

Charging by PV energy

No charging

Fault mode

Note:

*Fault mode: Errors are caused

by inside circuit error or

external reasons such as over

temperature, output short

circuited and so on.

PV energy and

utility can

charge batteries.

Charging by utility and PV

energy

Charging by utility

Charging by PV energy

No charging

Line Mode

The unit will

provide output

power from the

mains. It can

also charge the

battery at line

mode.

Charging by PV energy

Charging by utility

No battery connected

Battery Mode

The unit will

provide output

power from

battery and PV

power.

Power from battery and PV energy

Power from battery only

Page 25

23

Parallel Installation Guide

Introduction

This inverter can be used in parallel with two different operation modes.

1.

Parallel operation in single phase with up to 6 units.

2.

Maximum 6 units work together to support 3-phase equipment. Four units support one phase maximum.

NOTE: If the package includes share current cable and parallel cable, the inverter is default supported parallel

operation. You may skip section 3. If not, please purchase parallel kit and install this unit by following

instruction from professional technical personnel in local dealer.

Package Contents

In parallel kit, you will find the following items in the package:

Parallel board Parallel communication cable Current sharing cable

Parallel Board Installation

Step 1: Remove wire cover by unscrewing all screws.

Step 2: Remove WiFi/GPRS communication board and CAN/RS485 communication board by unscrewing

screws as below chart.

Page 26

24

Step 3: Remove two screws as below chart and remove 2-pin and 14-pin cables. Take out the board under the

communication boards.

Step 4: Remove two screws as below chart to take out cover of parallel communication.

Step 5: Install new parallel board with 2 screws tightly.

Step 6: Re-connect 2-pin and 14-pin to original position.

Parallel board WiFi/GPRS communication board CAN/RS485 communication board

Step 7: Put communication boards back to the unit.

Step 8: Put wire cover back to the unit. Now the inverter is providing parallel operation function.

Page 27

25

Mounting the Unit

Model

Wire Size

Cable (mm2)

Torque value

(max)

SPF 5000 ES

1 x 2AWG 35

1.2 Nm

Model

Gauge

Cable (mm2)

Torque Value

SPF 5000 ES

10 AWG

6

1.2 Nm

Model

1 unit*

SPF 5000 ES

150A / 60VDC

Model

2 units

3 units

4 units

5 units

6 units

SPF 5000 ES

100A/230VAC

150A/230VAC

200A/230VAC

250A/230VAC

300A/230VAC

When installing multiple units, please follow below chart.

NOTE: For proper air circulation to dissipate heat, allow a clearance of approx. 20cm to the side and approx. 50 cm

above and below the unit. Be sure to install each unit in the same level.

Wiring Connection

The cable size of each inverter is shown as below

Recommended battery cable and terminal size for each inverter: Ring terminal:

WARNING: Be sure the length of all battery cables is the same. Otherwise, there will be voltage difference between

inverter and battery to cause parallel inverters not working.

You need to connect the cables of each inverter together. Take the battery cables for example: You need to use a

connector or bus-bar as a joint to connect the battery cables together, and then connect to the battery terminal.

The cable size used from joint to battery should be X times cable size in the tables above. “X” indicates the number

of inverters connected in parallel.

Regarding AC input and output, please also follow the same principle.

Recommended AC input and output cable size for each inverter:

CAUTION!! Please install the breaker at the battery and AC input side. This will ensure the inverter can be

securely disconnected during maintenance and fully protected from over current of battery or AC input.

Recommended breaker specification of battery for each inverter:

*If you want to use only one breaker at the battery side for the whole system, the rating of the breaker should be X

times current of 1 unit. “X” indicates the number of inverters connected in parallel.

Recommended breaker specification of AC input with single phase:

Page 28

26

Note1: You can use 40A breaker (50A for 5KVA) for only 1 unit, and each inverter has a breaker at its AC input.

Inverter parallel numbers

2 3 4 5 6

Battery Capacity

400AH

600AH

800AH

1000AH

1200AH

Note2: Regarding three phase system, you can use 4 poles breaker, the rating is up to the current of the

phase which has the maximum units. Or you can follow the suggestion of note 1.

Recommended battery capacity

WARNING! Be sure that all inverters will share the same battery bank. Otherwise, the inverters will transfer to

fault mode.

Parallel Operation in Single Phase

WARNING! All inverters must be connected to the same batteries and ensure each group of cables from the

inverters to the batteries in the same length.

Two inverters in parallel:

Power Connection

Communication Connection

Page 29

27

Three inverters in parallel:

Power Connection

Communication Connection

Four inverters in parallel:

Power Connection

Communication Connection

Page 30

28

Five inverters in parallel:

Power Connection

Communication Connection

Six inverters in parallel:

Power Connection

Communication Connection

Page 31

29

Parallel Operation in Three Phase

WARNING! All inverters must be connected to the same batteries and ensure each group of cables from the

inverters to the batteries in the same length.

One inverter in each phase:

Power Connection

Communication Connection

Two inverters in one phase and only one inverter for the remaining phases:

Power Connection

Communication Connection

Page 32

30

Two inverters in two phases and only one inverter for the remaining phase:

Power Connection

Communication Connection

Three inverters in one phase and only one inverter for the remaining two phases:

Power Connection

Communication Connection

Page 33

31

Two inverters in each phase:

Power Connection

Communication Connection

Three inverters in one phase, two inverters in second phase and one inverter for the third phase:

Power Connection

Communication Connection

Page 34

32

Four inverters in one phase and one inverter for the other two phases:

Power Connection

Communication Connection

WARNING: Do not connect the current sharing cable between the inverters which are in different phases.

Otherwise, it may damage the inverters.

PV Connection

Please refer to user manual of single unit for PV Connection on Page 11

CAUTION: Each inverter should connect to PV modules separate

LCD Setting and Display

Refer to Program 23 on Page 19

Parallel in Single Phase

Step 1: Check the following requirements before commissioning:

Correct wire connection

Ensure all breakers in Line wires of load side are open and each Neutral wires of each unit are connected

together.

Step 2: Turn on each unit and set “PAL” in LCD setting program 23 of each unit. And then shut down all units.

NOET: It’s necessary to turn off switch when setting LCD program. Otherwise, the setting can not be programmed.

Page 35

33

Step 3: Turn on each unit.

LCD display in Master unit

LCD display in Slave unit

LCD display in Master unit

LCD display in Slave unit

LCD display in L1-phase unit

LCD display in L2-phase unit

LCD display in L3-phase unit

LCD display in L1-phase unit

LCD display in L2-phase unit

LCD display in L3-phase unit

NOTE: Master and slave units are randomly defined.

Step 4: Switch on all AC breakers of Line wires in AC input. It’s better to have all inverters connect to utility at the

same time. If not, it will display warning 15.

Step 5: If there is no more fault alarm, the parallel system is completely installed.

Step 6: Please switch on all breakers of Line wires in load side. This system will start to provide power to the load.

Parallel in Three Phase

Step 1: Check the following requirements before commissioning:

Correct wire connection

Ensure all breakers in Line wires of load side are open and each Neutral wires of each unit are connected

together.

Step 2: Turn on all units and configure LCD program 23 as P1, P2 and P3 sequentially. Then shut down all units.

NOET: It’s necessary to turn off switch when setting LCD program. Otherwise, the setting can not be

programmed.

Step 3: Turn on all units sequentially.

Step 4: Switch on all AC breakers of Line wires in AC input. If AC connection is detected and three phases are

matched with unit setting, they will work normally. Otherwise, if will display warning 15/16 and they will not work in

the line mode.

Step 5: If there is no more fault alarm, the system to support 3-phase equipment is completely installed.

Step 6: Please switch on all breakers of Line wires in load side. This system will start to provide power to the load.

Note 1: To avoid overload occurring, before turning on breakers in load side, it’s better to have whole system in

operation first.

Note 2: Transfer time for this operation exists. Power interruption may happen to critical devices, which cannot bear

transfer time.

Page 36

34

Fault Reference Code

Fault Code

Fault Event

Icon on

01

Fan is locked

02

Over temperature

03

Battery voltage is too high

04

Battery voltage is too low

05

Output short circuited

06

Output voltage is too high.

07

Overload time out

08

Bus voltage is too high

09

Bus soft start failed

51

Over current or surge

52

Bus voltage is too low

53

Inverter soft start failed

55

Over DC voltage in AC output

56

Battery connection is open

57

Current sensor failed

58

Output voltage is too low

60

Negative power fault

61

PV voltage is too high

62

Internal communication error

80

CAN fault

81

Host loss

Warning

Code

Warning Event

Audible Alarm

Icon flashing

01

Fan is locked when inverter

is on.

Beep three times every

second

02

Over temperature

Beep once every second

03

Battery is over-charged

Beep once every second

04

Low battery

Beep once every second

07

Overload

Beep once every 0.5 second

10

Output power derating

Beep twice every 3 seconds

12

Solar charger stops due

to low battery

Beep once every second

Warning Indicator

Page 37

35

13

Solar charger stops due

to high PV voltage

Beep once every second

14

Solar charger stops due

to overload

Beep once every second

15

Parallel input utility grid

different

Beep once every second

16

Parallel input phase error

Beep once every second

17

Parallel output phase loss

Beep once every second

19

Battery disconnect

No beep

20

BMS communication error

Beep once every second

21

PV power insufficient

Beep once every second

22

Parallel forbidden without

battery

Beep once every second

33

BMScommunication loss

Beep once every second

34

Cell over voltage

Beep once every second

35

Cell under voltage

Beep once every second

36

Total over voltage

Beep once every second

37

Total under voltage

Beep once every second

38

Discharge over voltage

Beep once every second

39

Charge over voltage

Beep once every second

40

Discharge over temperature

Beep once every second

41

Charge over temperature

Beep once every second

42

Mosfet over temperature

Beep once every second

43

Battery over temperature

Beep once every second

44

Battery under temperature

Beep once every second

45

System shut down

Beep once every second

Page 38

36

Battery Equalization

Equalization function is added into charge controller. It reverses the buildup of negative chemical effects like

stratification, a condition where acid concentration is greater at the bottom of the battery than at the top.

Equalizationalso helps to remove sulfate crystals that might have built up on the plates. If left unchecked, this

condition, called sulfation, will reduce the overall capacity of the battery. Therefore, it’s recommended to equalize

battery periodically.

How to Apply Equalization Function

You must enable battery equalization function in monitoring LCD setting program 43 first. Then, you may apply this

function in device by either one of following methods:

1. Setting equalization interval in program 47.

2. Active equalization immediately in program 48.

When to Equalize

In float stage, when the setting equalization interval (battery equalization cycle) is arrived, or equalization is active

immediately, the controller will start to enter Equalize stage.

Equalize charging time and timeout

In Equalize stage, the controller will supply power to charge battery as much as possible until battery voltage raises

to battery equalization voltage. Then, constant-voltage regulation is applied to maintain battery voltage at the

battery equalization voltage. The battery will remain in the Equalize stage until setting battery equalized time is

arrived.

However, in Equalize stage, when battery equalized time is expired and battery voltage doesn’t rise to battery

equalization voltage point, the charge controller will extend the battery equalized time until battery voltage achieves

battery equalization voltage. If battery voltage is still lower than battery equalization voltage when battery

equalized timeout setting is over, the charge controller will stop equalization and return to float stage.

Page 39

37

INVERTER MODEL

SPF 5000 ES

Input Voltage Waveform

Sinusoidal (utility or generator)

Nominal Input Voltage

230Vac

Low Loss Voltage

170Vac± 7V (UPS); 90Vac± 7V (Appliances)

Low Loss Return Voltage

180Vac± 7V (UPS); 100Vac± 7V (Appliances)

High Loss Voltage

280Vac± 7V

High Loss Return Voltage

270Vac± 7V

Max AC Input Voltage

300Vac

Nominal Input Frequency

50Hz / 60Hz (Auto detection)

Low Loss Frequency

40± 1Hz

Low Loss Return Frequency

42± 1Hz

High Loss Frequency

65± 1Hz

High Loss Return Frequency

63± 1Hz

Output Short Circuit Protection

Circuit Breaker

Efficiency (Line Mode)

>95% ( Rated R load, battery full charged )

Transfer Time

<20ms @ Single

<30ms @ Parallel

Output power derating:

When AC input voltage drops to 170V,

the output power will be derated.

Output Power

Rated Power

20% Power

90V

170V

280V

Input Voltage

Specifications

Table 1 Line Mode Specifications

Page 40

38

Table 2 Inverter Mode Specifications

INVERTER MODEL

SPF 5000 ES

Rated Output Power

5KVA/5KW

Output Voltage Waveform

Pure Sine Wave

Output Voltage Regulation

230Vac± 5%

Output Frequency

50Hz

Peak Efficiency

93%

Overload Protection

5s@≥150% load; 10s@110%~150% load

Surge Capacity

2* rated power for 5 seconds

Nominal DC Input Voltage

48Vdc

Cold Start Voltage(Lead-Acid Mode)

46.0Vdc

Cold Start SOC(Li Mode)

30%

Low DC Warning Voltage

(Lead-Acid Mode)

44.0Vdc @ load < 20%

42.8Vdc @ 20% ≤ load < 50%

40.4Vdc @ load ≥ 50%

Low DC Warning Return Voltage

(Lead-Acid Mode)

46.0Vdc @ load < 20%

44.8Vdc @ 20% ≤ load < 50%

42.4Vdc @ load ≥ 50%

Low DC Cut-off Voltage

(Lead-Acid Mode)

42.0Vdc @ load < 20%

40.8Vdc @ 20% ≤ load < 50%

38.4Vdc @ load ≥ 50%

Low DC Cut-off Voltage (Li Mode)

42.0Vdc

Low DC Warning SOC (Li Mode)

Low DC Cut-off SOC +5%

Low DC Warning Return SOC

(Li Mode)

Low DC Cut-off SOC +10%

Low DC Cut-off SOC(Li Mode)

Default 20%, 5%~30% settable

High DC Recovery Voltage

56.4Vdc

High DC Cut-off Voltage

60.8Vdc

No Load Power Consumption

<60W

Page 41

39

Table 3 Charge Mode Specifications

Utility Charging Mode

INVERTER MODEL

SPF 5000 ES

Charging Algorithm

3-Step

Max. AC Charging Current

80Amp(@V

I/P

=230Vac)

Bulk Charging

Voltage

Flooded Battery

58.4Vdc

AGM / Gel Battery

56.4Vdc

Floating Charging Voltage

54Vdc

Charging Curve

MPPT Solar Charging Mode

Max. PV Array Power

6000W

Nominal PV Voltage

340Vdc

Start-up Voltage

100Vdc±10Vdc

PV Array MPPT Voltage Range

120Vdc~430Vdc

Max. PV Array Open Circuit Voltage

450Vdc

Max. PV Charging Current

100A

Max. Charging Current

(AC Charger Plus Solar Charger)

100A

INVERTER MODEL

SPF 5000 ES

Safety Certification

CE

Operating

Temperature

Range

0°C to 55°C

Storage temperature

-15°C~ 60°C

Humidity

5% to 95% Relative Humidity (Non-condensing)

Altitude

<2000m

Dimension(D*W*H), mm

485 x 330 x 135

Net Weight, kg

12

Table 4 General Specifications

Page 42

40

Trouble Shooting

Problem

LCD/LED/Buzzer

Explanation

What to do

Unit shuts down

Automatically during

startup process.

LCD/LEDs and buzzer will

be active for 3 seconds

and then complete off.

The battery voltage is too low .

(<1.91V/Cell)

1.Re-charge battery.

2.Replace battery.

No response after

power on.

No indication.

1.The battery voltage is far too

low. (<1.4V/Cell)

2.Battery polarity is connected

reversed.

1. Check if batteries and the wiring are connected

well.

2.Re-charge battery.

3.Replace battery.

Mains exist but the

unit works in battery

mode.

Input voltage is 0 on the

LCD and green LED is

flashing.

Input protector is tripped.

Check if AC breaker is tripped and AC wiring is

connected well.

Green LED is flashing.

Insufficient quality of AC power.

(Shore or Generator)

1. Check if AC wires are too thin and/or too long.

2. Check if generator (if applied) is working well or if

input voltage range setting is correct.

(UPS→Appliance)

Green LED is flashing.

Set “Battery First” or “Solar First”

as the priority of output source.

Change output source priority to Utility first.

When it’s turned on,

internal relay is

switching on and off

repeatedly.

LCD display and LEDs are

flashing

Battery is disconnected.

Check if battery wires are connected well.

Buzzer beeps

continuously and red

LED is on.

Fault code 01

Fan fault

Replace the fan.

Fault code 02

Internal temperature of component

is over 100°C.

Check whether the air flow of the unit is blocked or

whether the ambient temperature is too high.

Fault code 03

Battery is over-charged.

Return to repair center.

The battery voltage is too high.

Check if spec and quantity of batteries are meet

requirements.

Fault code 05

Output short circuited

Check if wiring is connected well and remove

abnormal load.

Fault code 06/58

Output abnormal (Inverter voltage

below than 190Vac or is higher

than 260Vac)

1.Reduce the connected load.

2.Return to repair center

Fault code 07

The inverter is overload 110% and

time is up.

Reduce the connected load by switching off some

equipment.

Fault code 08/09/53/57

Internal components failed.

Return to repair center.

Fault code 51

Over current or surge

Restart the unit, if the error happens again, please

return to repair center.

Fault code 52

Bus voltage is too low

Fault code 55

Output voltage is unbalanced

Fault code 56

Battery is not connected well

or fuse is burnt.

If the battery is connected well, please return to

repair center.

Fault code 60

Negative power fault

1. Check whether the AC output connected to the

grid input.

2. Check whether Program 8 settings are the same for

all parallel inverters

3. Check whether the current sharing cables are

connnected well in the same parallel phases.

4. Check whether all neutral wires of all parallel units

are connnected together.

5. If problem still exists, contact repair center.

Fault code 80

CAN fault

1. Check whether the parallel communication cables

are connected well.

2. Check whether Program 23 settings are right for the

parallel system.

3. If problem still exists, contact repair center

Fault code 81

Host loss

Loading...

Loading...