Growatt MIN 2500TL-X, MIN 3600 TL-X, MIN 3000 TL-X, MIN 4600 TL-X, MIN 5000 TL-X Installation & Operation Manual

...Page 1

1

MIN 2500TL-X

MIN 3000 TL-X

MIN 3600 TL-X

MIN 4200 TL-X

MIN 4600 TL-X

MIN 5000 TL-X

MIN 6000 TL-X

Installation & Operation Manual

Page 2

2

Manual Introduce and Copyright

Copyright © 2018 Growatt New Energy Technology Co., Ltd All rights reserved.

No part of this document may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, electronic, mechanical, photographic,

magnetic or otherwise, without the prior written permission of Growatt New Energy

Technology Co., Ltd.

Growatt New Energy Technology Co., Ltd makes no representations, express or

implied, with respect to this documentation or any of the equipment and/or software it

may describe, including (with no limitation) any implied warranties of utility,

merchantability, or fitness for any particular purpose. All such warranties are

expressly disclaimed. Neither Growatt New Energy Technology Co., Ltd nor its

distributors or dealers shall be liable for any indirect, incidental, or consequential

damages under any circumstances.

(The exclusion of implied warranties may not apply in all cases under some statutes,

and thus the above exclusion may not apply.)

Specifications are subject to change without notice. Every attempt has been made to

make this document complete, accurate and up-to-date. Readers are cautioned,

however, that Growatt reserves the right to make changes without notice and shall not

be responsible for any damages, including indirect, incidental or consequential

damages, caused by reliance on the material presented, including, but not limited to,

omissions, typographical errors, arithmetical errors or listing errors in the content

material.

All trademarks are recognized even if these are not marked separately. Missing

designations do not mean that a product or brand is not a registered trademark.

Growatt New Energy Technology CO.,LTD

1st East & 3rd Floor,Building 5,Jiayu Industrial Zone,Xibianling,Shangwu Village,Shiyan,

Baoan District,Shenzhen,P.R.China

Page 3

3

Index

Index ................................................................................................................................................. 3

1 Notes on this manual ...................................................................................................................... 5

1.1 Validity ................................................................................................................................ 5

1.2 Target Group ....................................................................................................................... 5

1.3 Additional information ........................................................................................................ 5

1.4 Symbols in this document ................................................................................................... 6

1.4.1 Warnings in this document ....................................................................................... 6

1.4.2 Markings on this product.......................................................................................... 6

1.5 Glossary .............................................................................................................................. 8

2 Safety ............................................................................................................................................. 9

2.1 Intended Use ....................................................................................................................... 9

2.2 Qualification of skilled person ............................................................................................ 9

2.3 Safety instruction .............................................................................................................. 10

2.4 Assembly Warnings ........................................................................................................... 10

2.5 Electrical Connection Warnings ........................................................................................ 11

2.6 Operation Warnings ........................................................................................................... 11

3 Product description ...................................................................................................................... 12

3.1 TL-X Overview ................................................................................................................. 12

3.2 Type label .......................................................................................................................... 13

3.3 Size and weight ................................................................................................................. 15

3.4 Storage of Inverter............................................................................................................. 15

3.5 The advantage of the unit .................................................................................................. 16

4 Unpacking and inspection ............................................................................................................ 16

5 Installation .................................................................................................................................... 18

5.1 Safety instructions ............................................................................................................. 18

5.2 Selecting the installation location ..................................................................................... 19

5.3 Mounting the Inverter ....................................................................................................... 22

5.3.1 Mounting the Inverter with bracket ........................................................................ 22

5.3.2 Fixed the inverter on the wall ................................................................................. 23

6 Electrical connection .................................................................................................................... 24

6.1 Safety ................................................................................................................................ 24

6.2 Wiring AC Output ............................................................................................................. 24

6.3 Connecting the second protective conductor..................................................................... 28

6.4 Connecting the PV Array (DC input) ................................................................................ 28

6.4.1 Conditions for DC Connection ............................................................................... 28

6.4.2 Connecting the PV Array (DC input) ..................................................................... 29

6.5 Connecting signal cable .................................................................................................... 30

6.6 Grounding the inverter ...................................................................................................... 32

6.7 Active power control with smart meter , CT or ripple control signal receiver .................. 32

6.8 Inverter demand response modes (DRMS) ....................................................................... 33

6.8.1 8Pin socket pin assignment .................................................................................... 33

Page 4

4

6.8.2 Method of asserting demand response modes ........................................................ 33

7 Commissioning ............................................................................................................................ 33

7.1 Start the inverter ................................................................................................................ 34

7.1.1 Touch control .......................................................................................................... 34

7.1.2 Country setting ....................................................................................................... 34

7.2 General setting .................................................................................................................. 35

7.2.1 Set inverter display language ................................................................................. 35

7.2.2 Set inverter COM address ...................................................................................... 35

7.2.3 Set inverter date & time ......................................................................................... 36

7.3 Advanced setting ............................................................................................................... 37

7.3.1 Reset Country ......................................................................................................... 37

7.3.2 Export limitation setting ......................................................................................... 37

7.3.3 Reset factory........................................................................................................... 37

7.3 Communications ....................................................................................................................... 38

7.4 RS485 ................................................................................................................................ 38

7.5 USB-A ............................................................................................................................... 38

8 Start-Up and shut down the inverter ............................................................................................ 39

8.1 Start-Up the inverter .......................................................................................................... 39

8.2 Turn-off the Inverter .......................................................................................................... 39

9 Maintenance and Cleaning ........................................................................................................... 39

9.1 Checking Heat Dissipation ................................................................................................ 39

9.2 Cleaning the Inverter ......................................................................................................... 40

9.3 Checking the DC Disconnect ............................................................................................ 40

10 Trouble shooting ..................................................................................................................... 40

10.1 Error Messages displayed on OLED ............................................................................... 40

10.2 System fault ..................................................................................................................... 41

10.3 Inverter warning .............................................................................................................. 43

10.4 Inverter fault .................................................................................................................... 43

11 Manufacturer Warranty .............................................................................................................. 45

12 Decommissioning ....................................................................................................................... 45

12.1 Dismantling the Inverter ................................................................................................. 45

12.2 Packing the Inverter ........................................................................................................ 45

12.3 Storing the Inverter ......................................................................................................... 45

12.4 Disposing of the Inverter ................................................................................................. 45

13 Technical Data ............................................................................................................................ 46

13.1 Specification .................................................................................................................... 46

13.2 DC &AC connector info .............................................................................................. 49

13.3 Torque ............................................................................................................................. 49

13.4 Accessories ...................................................................................................................... 49

14 Compliance Certificates ............................................................................................................. 50

15 Contact ....................................................................................................................................... 50

Page 5

5

1 Notes on this manual

1.1 Validity

This manual describes the assembly, installation, commissioning and maintenance of

the following Growatt Inverter model:

MIN 2500 TL-X

MIN 3000 TL-X

MIN 3600 TL-X

MIN 4200 TL-X

MIN 4600 TL-X

MIN 5000 TL-X

MIN 6000 TL-X

This manual does not cover any details concerning equipment connected to the MIN

TL-X( e.g. PV modules). Information concerning the connected equipment is

available from the manufacturer of the equipment.

1.2 Target Group

This manual is for qualified personnel. Qualified personnel have received training and have

demonstrated skills and knowledge in the construction and operation of this device. Qualified

Personnel are trained to deal with the dangers and hazards involved in installing electric devices.

1.3 Additional information

Find further information on special topics in the download area at www.ginverter.com

The manual and other documents must be stored in a convenient place and be

available at all times. We assume no liability for any damage caused by failure to

observe these instructions. For possible changes in this manual, GROWATT NEW

ENERGY TECHNOLOGY CO.,LTD accepts no responsibilities to inform the users.

Page 6

6

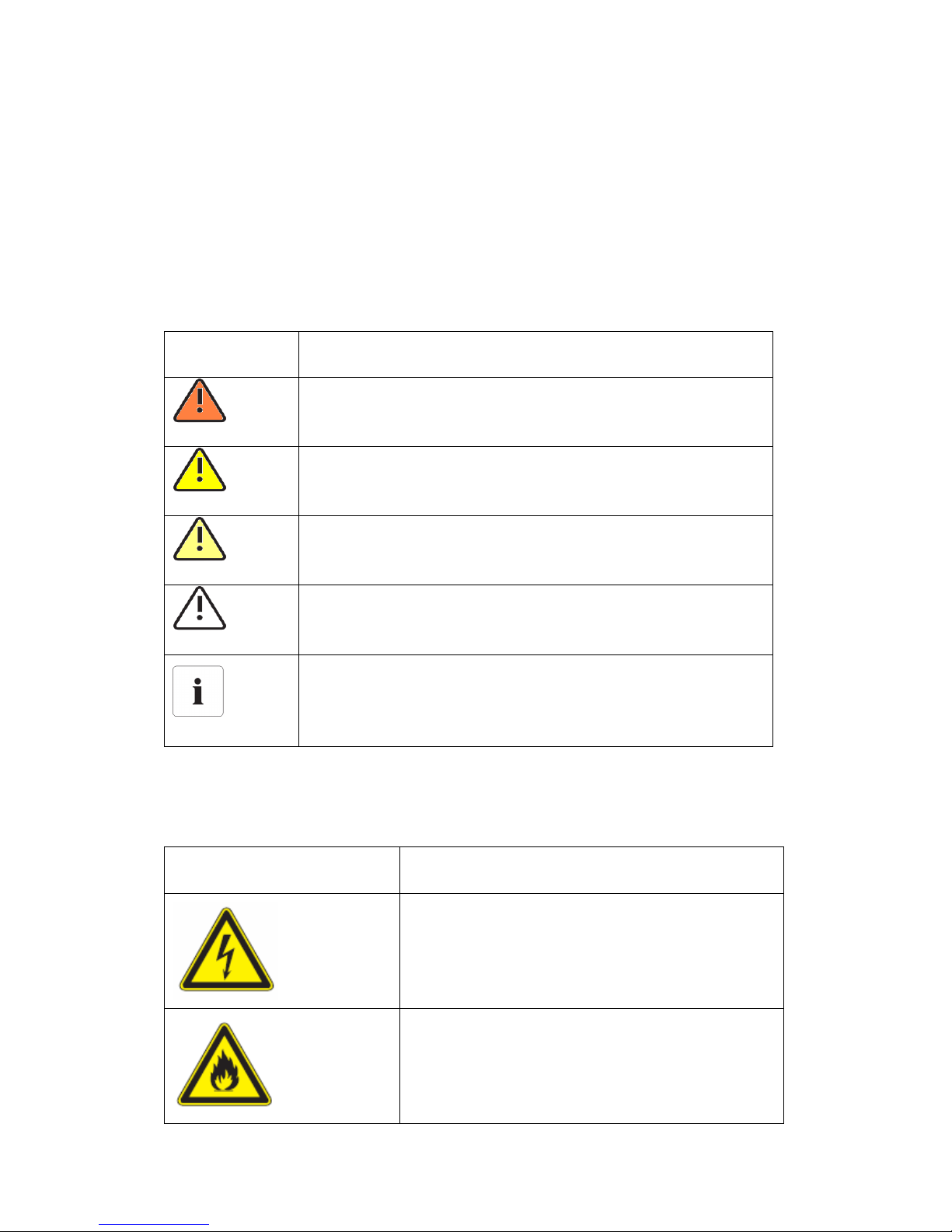

1.4 Symbols in this document

1.4.1 Warnings in this document

A warning describes a hazard to equipment or personnel. It calls attention to a

procedure or practice, which, if not correctly performed or adhered to, could result in

damage to or destruction of part or all of the Growatt equipment and/or other

equipment connected to the Growatt equipment or personal injury.

Symbol

description

DANGER

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to personal injury.

Information

Information that you must read and know to ensure optimal operation of

the system.

1.4.2 Markings on this product

Symbol

Explanation

Electrical voltage!

Risk of fire or explosion!

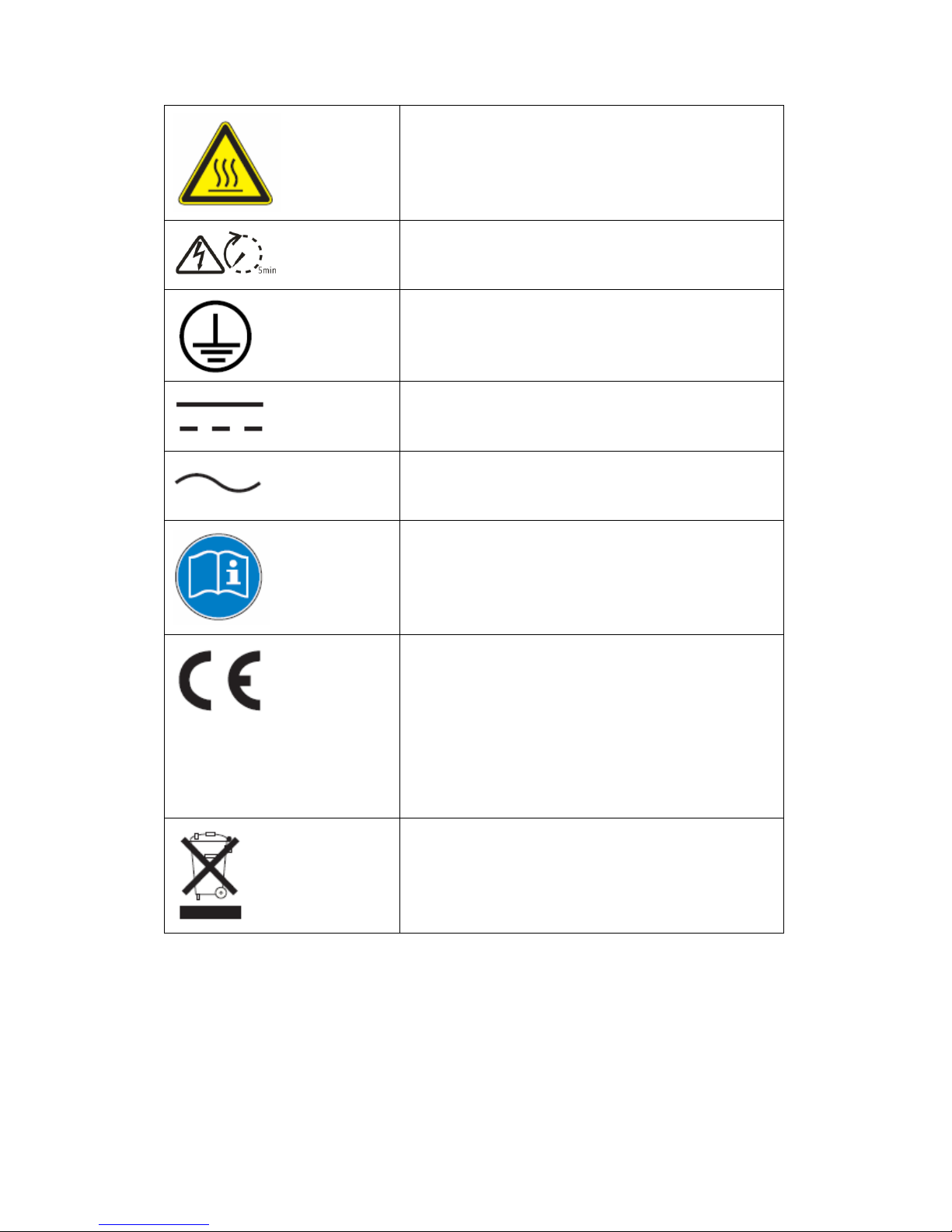

Page 7

7

Risk of burns

Operation after 5 minutes

Point of connection for grounding

protection

Direct Current (DC)

Alternating Current (AC)

Read the manual

CE mark.

The inverter complies with the

requirements of the applicable EC

guidelines.

The inverter must not be disposed of

with the household waste.

Page 8

8

1.5 Glossary

AC

Abbreviation for "Alternating Current"

DC

Abbreviation for "Direct Current"

Energy

Energy is measured in Wh (watt hours), kWh (kilowatt hours) or MWh (megawatt

hours). The energy is the power calculated over time. For example, your inverter

operates at a constant power of 4600 W for half an hour and then at a constant power

of 2300 W for another half an hour, it has fed 3450Wh of energy into the power

distribution grid within that hour.

Power

Power is measured in W (watts), kW (kilowatts) or MW (megawatts). Power is an

instantaneous value. It displays the power your inverter is currently feeding into the

power distribution grid.

Power rate

Power rate is the radio of current power feeding into the power distribution grid and

the maximum power of the inverter that can feed into the power distribution grid.

Power Factor

Power factor is the ratio of true power or watts to apparent power or volt amps. They

are identical only when current and voltage are in phase than the power factor is 1.0.

The power in an ac circuit is very seldom equal to the direct product of the volts and

amperes. In order to find the power of a single phase ac circuit the product of volts

and amperes must be multiplied by the power factor.

PV

Abbreviation for photovoltaic

wireless communication

The external wireless communication technology is a radio technology that allows the

inverter and other communication products to communicate with each other. The

external wireless communication does not require line of sight between the devices

and it is selective purchasing.

Page 9

9

2 Safety

2.1 Intended Use

The unit converts the DC current generated by the photovoltaic (PV) modules to grid-compliant

alternating current and performs single-phase feed-in into the electricity grid.MIN

2500TL-X,MIN 3000TL-X,MIN 3600TL-X,MIN 4200TL-X,MIN 4600TL-X,MIN 5000TL-X

inverters are built according to all required safety rules. Nevertheless, improper use may cause

lethal hazards for the operator or third parties, or may result in damage to the units and other

property.

Principle of a PV plant with this MIN TL-X single-phase inverter

Position

Description

A

PV modules

B

DC load circuit breaker

C

Inverter

D

AC load circuit breaker

E

Energy meter

F

Utility grid

The inverter may only be operated with a permanent connection to the public power grid. The

inverter is not intended for mobile use. Any other or additional use is not considered the intended

use. The manufacturer/supplier is not liable for damage caused by such unintended use. Damage

caused by such unintended use is at the sole risk of the operator.

PV modules Capacitive Discharge Currents

PV modules with large capacities relative to earth, such as thin-film PV modules with cells on a

metallic substrate, may only be used if their coupling capacity does not exceed 1uF. During

feed-in operation, a leakage current flows from the cells to earth, the size of which depends on the

manner in which the PV modules are installed (e.g. foil on metal roof) and on the weather (rain,

snow). This "normal" leakage current may not exceed 50mA due to the fact that the inverter would

otherwise automatically disconnect from the electricity grid as a protective measure.

2.2 Qualification of skilled person

This grid-tied inverter system operates only when properly connected to the AC distribution

network. Before connecting the MIN TL-X to the power distribution grid, contact the local power

Page 10

10

distribution grid company. This connection must be made only by qualified technical personnel to

connect, and only after receiving appropriate approvals, as required by the local authority having

jurisdiction.

2.3 Safety instruction

The MIN TL-X Inverters is designed and tested according to international safety requirements

(IEC62109-1,CE,VDE0126-1-1, AS4777); however, certain safety precautions must be observed

when installing and operating this inverter. Read and follow all instructions, cautions and warnings

in this installation manual. If questions arise, please contact Growatt’s technical services at +86

(0)755 2747 1900.

2.4 Assembly Warnings

WARNING

Prior to installation, inspect the unit to ensure absence of any transport

or handling damage, which could affect insulation integrity or safety

clearances; failure to do so could result in safety hazards.

Assemble the inverter per the instructions in this manual. Use care

when choosing installation location and adhere to specified cooling

requirements.

Unauthorized removal of necessary protections, improper use,

incorrect installation and operation may lead to serious safety and

shock hazards and/or equipment damage.

In order to minimize the potential of a shock hazard due to hazardous

voltages, cover the entire solar array with dark material prior to

connecting the array to any equipment.

CAUTION

Grounding the PV modules:The MIN TL-X is a transformerless

inverter. That is why it has no galvanic separation. Do not ground the

DC circuits of the PV modules connected to the MIN TL-X. Only

ground the mounting frame of the PV modules.If you connect

grounded PV modules to the MIN TL-X, the error message "PV ISO

Low".

Comply with the local requirements for grounding the PV modules and

the PV generator. GROWATT recommends connecting the generator

frame and other electrically conductive surfaces in a manner which

ensures continuous conduction with ground in order to have optimal

protection of the system and personnel.

Page 11

11

2.5 Electrical Connection Warnings

2.6 Operation Warnings

DANGER

The components in the inverter are live. Touching live components can result

in serious injury or death.

Do not open the inverter except the wire box by qualified persons.

Electrical installation, repairs and conversions may only be carried out by

electrically qualified persons.

Do not touch damaged inverters.

Danger to life due to high voltages in the inverter

There is residual voltage in the inverter. The inverter takes 20 minutes to

discharge.

Persons with limited physical or mental abilities may only work with the

Growatt inverter following proper instruction and under constant supervision.

Children are forbidden to play with the Growatt inverter. Must keep the

Growatt inverter away from children.

WARNING

Make all electrical connections (e.g. conductor termination, fuses, PE

connection, etc.) in accordance with prevailing regulations. When working

with the inverter powered on, adhere to all prevailing safety regulations to

minimize risk of accidents.

Systems with inverters typically require additional control (e.g., switches,

disconnects) or protective devices (e.g., fusing circuit breakers) depending

upon the prevailing safety rules.

WARNING

Ensure all connectors are sealed and secure during operation.

Although designed to meet all safety requirements, some parts and

surfaces of Inverter are still hot during operation. To reduce the risk of

injury, do not touch the heat sink at the back of the PV-Inverter or nearby

surfaces while Inverter is operating.

Incorrect sizing of the PV plant may result in voltages being present

which could destroy the inverter. The inverter display will read the error

message “PV voltage High!”

Turn the rotary switch of the DC Disconnect to the Off position

immediately.

Contact installer.

CAUTION

All operations regarding transport, installation and start-up, including

maintenance must be operated by qualified, trained personnel and in

compliance with all prevailing codes and regulations.

Anytime the inverter has been disconnected from the power network, use

extreme caution as some components can retain charge sufficient to

Page 12

12

3 Product description

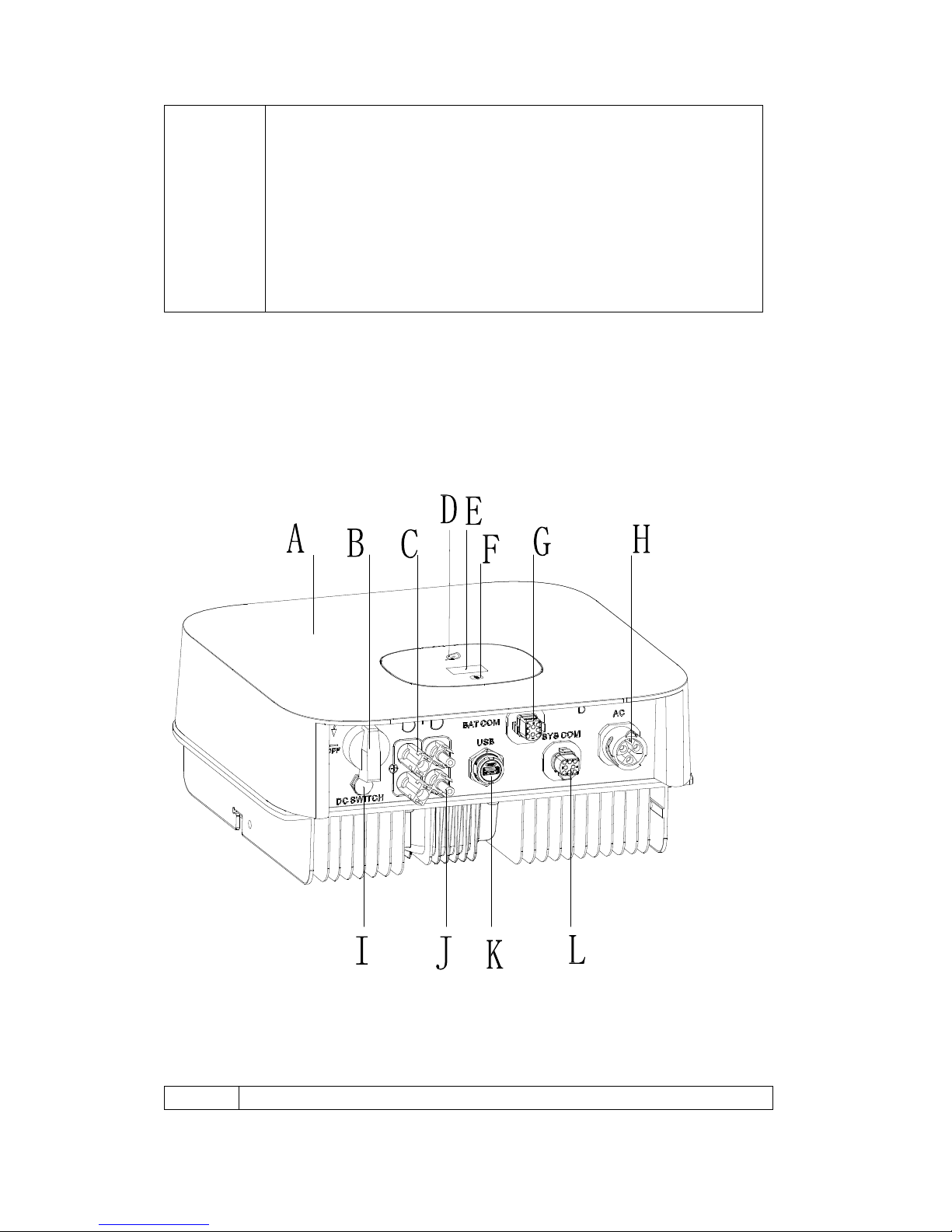

3.1 TL-X Overview

Position

Description

create a shock hazard; to minimize occurrence of such conditions,

comply with all corresponding safety symbols and markings present on

the unit and in this manual.

In special cases, there may still be interference for the specified

application area despite maintaining standardized emission limit values

(e.g. when sensitive equipment is located at the setup location or when

the setup location is near radio or television receivers).In this case, the

operator is obliged to take proper action to rectify the situation.

Do not stay closer than 20 cm to the inverter for any length of time.

Page 13

13

A

Cover

B

DC SWITCH

C

PV INPUT +

D

LED

E

OLED

F

TOUCH BUTTON

G

DRM PORT

H

AC OUTPUT

I

VENTILATION VALVE

J

PV INPUT-

K

USB PORT

L

COM PORT

Symbol on the inverter

Symbol

Description

Explanation

Touch symbol

Touch button.We can switch the OLED display

and set parameter by touching.

Inverter status

symbol

Indicates inverter operation status:

Red:Fault.

Green:Nomal.

Red leaf flash:Warning or DSP Programming.

Green leaf flash:M3 Programming.

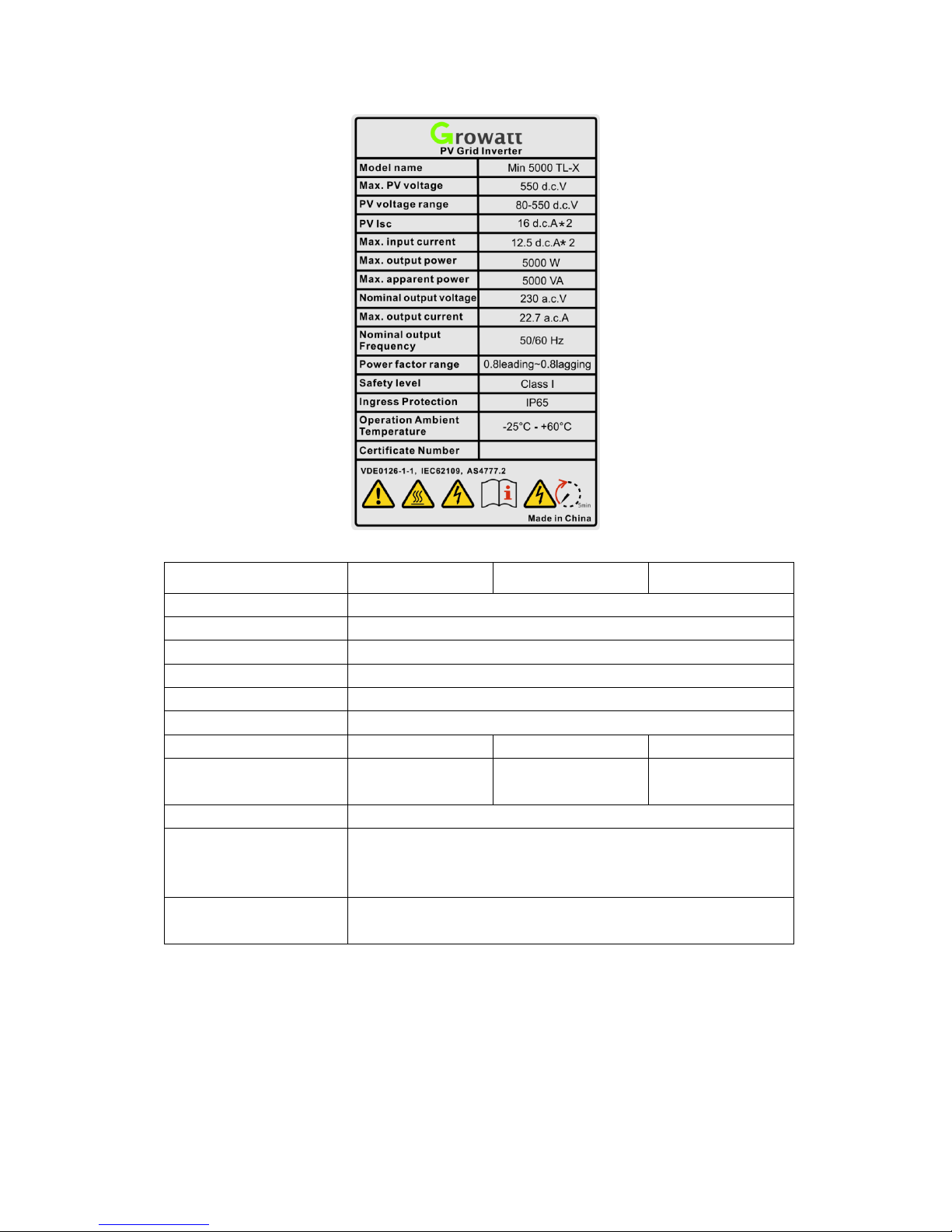

3.2 Type label

The type labels provide a unique identification of the inverter (The type of product,

Device-specific characteristics, Certificates and approvals). The type labels are on the

left-hand side of the enclosure.

Page 14

14

More detail about the type label as the chart below:

Model Name

MIN 2500 TL-X

MIN 3000 TL-X

MIN 3600 TL-X

Max input DC voltage

500V

Max input DC current

12.5A/12.5A

Start voltage

100V

MPP voltage range

80V~500V

AC nominal voltage

230V

AC grid frequency

50/60 Hz

Max. apparent power

2500VA

3000VA

3600VA

AC normal output

current

10.8A

13A

15.6A

Power factor

0.8leading…0.8lagging

Environmental

Protection

Rating

IP65

Operation Ambient

temperature

-25...+60℃ (-13...+ 140°F)

with derating above 45°C(113°F)

Page 15

15

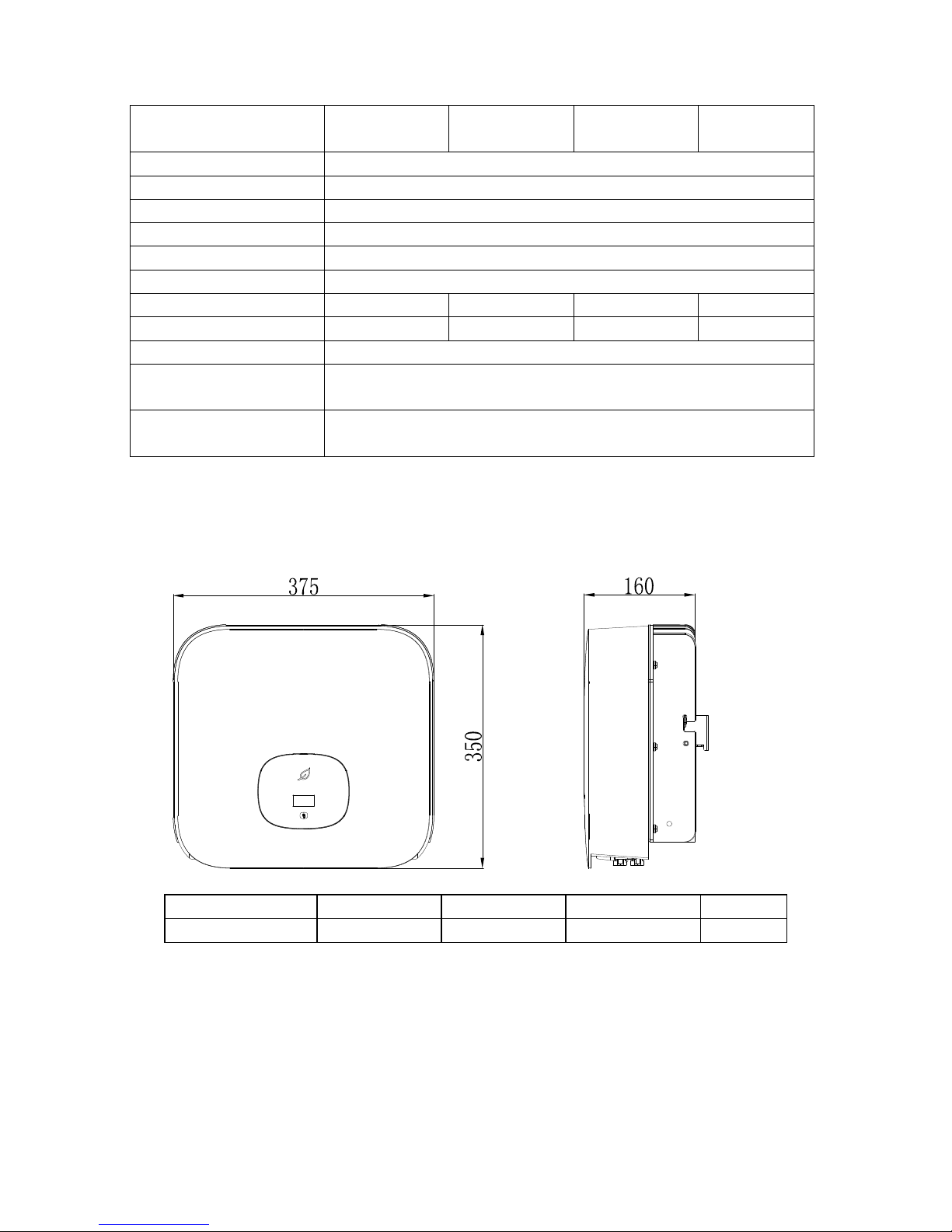

3.3 Size and weight

Dimensions and weight

Model

Height (H)

Width (W)

Depth (D)

Weight

MIN 2500-6000 TL-X

350mm 13.8inch

375mm 14.8inch

160mm 6.3inch

10.8kg

3.4 Storage of Inverter

If you want to storage the inverter in your warehouse, you should choose an

appropriate location to store the inverter.

The unit must be stored in original package and desiccant must be left in the

Model Name

MIN 4200 TL-X

MIN 4600 TL-X

MIN 5000 TL-X

MIN 6000

TL-X

Max input DC voltage

550V

Max input DC current

12.5A/12.5A

Start voltage

100V

MPP voltage range

80V~550V

AC nominal voltage

230V

AC grid frequency

50/60 Hz

Max. apparent power

4200VA

4600VA

5000VA

6000 VA

AC normal output current

18.2A

20A

21.7A

26A

Power factor

0.8leading…0.8lagging

Environmental Protection

Rating

IP65

Operation Ambient

temperature

-25...+60℃ (-13...+ 140°F)

with derating above 45°C(113°F)

Page 16

16

package.

The storage temperature should be always between -25℃and +60℃. And the

storage relative humidity can achieve to 100%.

If there are a batch of inverters need to be stored, the maximum layers for original

carton is four.

After long term storage, local installer or service department of GROWATT

should perform a comprehensive test before installation.

3.5 The advantage of the unit

Maximum efficiency of 98.4%

Wide input voltage range from 80--550Vdc

Reactive power regulate

Integrated DC switch

Multi MPP controller

DSP controller

Touch control

Multi active power control mode

Easy installation

4 Unpacking and inspection

The inverter is thoroughly tested and inspected strictly before delivery. Our inverters

leave our factory in proper electrical and mechanical condition. Special packaging

ensures safe and careful transportation. However, transport damage may still occur.

The shipping company is responsible in such cases. Thoroughly inspect the inverter

upon delivery. Immediately notify the responsible shipping company if you discover

any damage to the packaging which indicates that the inverter may have been

damaged or if you discover any visible damage to the inverter. We will be glad to

assist you, if required. When transporting the inverter, the original or equivalent

packaging should be used, and the maximum layers for original carton is four, as this

ensures safe transport.

After opening the package, please check the contents of the box. It should contain the

following, Please check all of the accessories carefully in the carton. If anything

missing, contact your dealer at once.

Page 17

17

Object

Description

Quantity

A

Inverter 1 B

Mounting bracket

1

C

Quick Guide

1

D

Monitor(Optional)

1

E

Signal connector

1

DRED connector (only for Australia)

1

F

Self-tapping screws

3

G

Plastic expansion pipe

3

H

PV+/PV- terminal

2/2

I

PV+/PV- metal terminal

2/2

J

AC connector

1

K

Uninstall PV tool

1

L

Uninstall signal or AC connector tool

1

Page 18

18

5 Installation

5.1 Safety instructions

Danger to life due to fire or explosion

Despite careful construction, electrical devices can cause fires.

Do not install the inverter on easily flammable materials and

where flammable materials are stored.

Risk of burns due to hot enclosure parts

Mount the inverter in such a way that it cannot be touched

inadvertently.

Possible damage to health as a result of the effects of radiation!

In special cases, there may still be interference for the specified

application area despite maintaining standardized emission limit

values (e.g. when sensitive equipment is located at the setup

location or when the setup location is near radio or television

receivers).In this case, the operator is obliged to take proper

action to rectify the situation.

Never install the inverter near the sensitive equipment(e.g.

Radios, telephone, television, etc)

Do not stay closer than 20 cm to the inverter for any length of

time unless it is absolutely necessary.

Growatt assumes no responsibility for compliance to EMC

regulations for the complete system

All electrical installations shall be done in accordance with the local and national

electrical codes. Do not remove the casing. Inverter contains no user serviceable

parts. Refer servicing to qualified service personnel. all wiring and electrical

installation should be conducted by a qualified service personnel .

Carefully remove the unit from its packaging and inspect for external damage. If

you find any imperfections, please contact your local dealer.

Be sure that the inverters connect to the ground in order to protect property and

personal safety.

The inverter must only be operated with PV generator. Do not connect any other

source of energy to it.

Both AC and DC voltage sources are terminated inside the PV Inverter. Please

disconnect these circuits before servicing.

This unit is designed to feed power to the public power grid (utility) only. Do not

connect this unit to an AC source or generator. Connecting Inverter to external

devices could result in serious damage to your equipment.

Page 19

19

When a photovoltaic panel is exposed to light, it generates a DC voltage. When

connected to this equipment, a photovoltaic panel will charge the DC link

capacitors.

Energy stored in this equipment’s DC link capacitors presents a risk of electric

shock. Even after the unit is disconnected from the grid and photovoltaic panels,

high voltages may still exist inside the PV-Inverter. Do not remove the casing

until at least 5 minutes after disconnecting all power sources.

Although designed to meet all safety requirements, some parts and surfaces of

Inverter are still hot during operation. To reduce the risk of injury, do not touch

the heat sink at the back of the PV-Inverter or nearby surfaces while Inverter is

operating.

5.2 Selecting the installation location

This is guidance for installer to choose a suitable installation location, to

avoid potential damages to device and operators.

The installation location must be suitable for the inverter's weight and

dimensions for a long period time.

Select the installation location so that the status display can be easily viewed.

Do not install the inverter on structures constructed of flammable or

thermolabile materials.

Never install the inverter in environment of little or no air flow, nor dust

environment. That may derate the efficiency of the cooling fan of the

inverter.

The Ingress Protection rate is IP65 which means the inverter can be installed

outdoors and indoors.

The humidity of the installation location should be 0~100% without

condensation.

The installation location must be freely and safely to get at all times.

Vertically installation and make sure the connection of inverter must be

downwards. Never install horizontal and avoids forward and sideways tilt.

Page 20

20

Be sure that the inverter is out of the children’s reach.

Don’t put any things on the inverter. Do not cover the inverter.

Do not install the inverter near television antenna or any other antennas and

antenna cables.

Inverter requires adequate cooling space. Providing better ventilation for the

inverter to ensure the heat escape adequately. The ambient temperature

should be below 40°C to ensure optimum operation.

Do not expose the inverter to direct sunlight, as this can cause excessive

heating and thus power reduction.

Observe the Min. clearances to walls, other inverters, or objects as shown

below:

Ambient dimensions of one inverter

Page 21

21

Ambient dimensions of series inverters

There must be sufficient clearance between the individual inverters to

ensure that the cooling air of the adjacent inverter is not taken in.

If necessary, increase the clearance spaces and make sure there is enough

fresh air supply to ensure sufficient cooling of the inverters.

The inverter can’t install to solarization,drench,firn location. We suggest that the inverters should

be installed at the location with some cover or protection。

Please make sure the inverter is installed at the right place.The inverter

can’t install close to trunk。

Page 22

22

5.3 Mounting the Inverter

5.3.1 Mounting the Inverter with bracket

DANGER

In order to avoid electrical shock or other injury, inspect existing

electronic or plumbing installations before drilling holes.

Fix the mounting bracket as the figure shows. Do not make the screws to be

flush to the wall. Instead, leave 2 to 4mm exposed.

Page 23

23

5.3.2 Fixed the inverter on the wall

WARNING

Falling equipment can cause serious or even fatal injury, never

mount the inverter on the bracket unless you are sure that the

mounting frame is really firmly mounted on the wall after

carefully checking.

Type1:

Rise up the inverter a little higher than the bracket. Considered the weight

of them.During the process please maintain the balance of the inverter.

Hang the inverter on the bracket through the match hooks on bracket.

After confirming the inverter is fixed reliably, fasten one M6 safety-lock sockets

head cap screws on the right or left side firmly to prevent the inverter from being

lifted off the bracket.

Page 24

24

6 Electrical connection

Decisive Voltage Class (DVC) indicated for ports

Port Name

Class

AC C DC C DRMS

A

RS485&RS232

A

.

6.1 Safety

Danger to life due to lethal voltages!

High voltages which may cause electric shocks are present in the

conductive parts of the inverter. Prior to performing any work on the

inverter, disconnect the inverter on the AC and DC sides

WARNING

Danger of damage to electronic components due to electrostatic discharge.

Take appropriate ESD precautions when replacing and installing the

inverter.

6.2 Wiring AC Output

WARNING

You must install a separate single-phase circuit-breaker or other load

disconnection unit for each inverter in order to ensure that the inverter

can be safely disconnected under load.

NOTE :The inverter has the function of detecting residual current and

protecting the inverter against residual current. If your inverter has to equip

a AC breaker which has the function of detecting residual current ,you must

choose a AC breaker with the rating residual current more than 300mA.

You must install a separate single-phase circuit-breaker or other load disconnection

Page 25

25

unit for each inverter in order to ensure that the inverter can be safely disconnected

under load.

We suggest you choice the AC breaker rating current in this table:

MIN 2500 TL-X

16A/230V

MIN 3000 TL-X

16A/230V

MIN 3600 TL-X

20A/230V

MIN 4200 TL-X

25A/230V

MIN 4600 TL-X

25A/230V

MIN 5000 TL-X

32A/230V

MIN 6000 TL-X

32A/230V

The AC wiring step:

1. Uninstall the parts of the AC connection plug from the accessory bag.

2. Insert the stripped and bared cable through pressure screw, seal ring, threaded sleeve in

sequence, insert cables into connection terminal according to polarities indicates on it and

tighten the screws firmly. Please try to pull out the wire to make sure the it’s well connected.

Page 26

26

3. Push the threaded sleeve into the socket, Tighten up the cap on the terminal.

4. Finally, Push or screw the threaded sleeve to connection terminal until both are locked tightly

on the inverter.

Page 27

27

5:To remove the AC output terminal, press the bayonet out of the slot with a small screwdriver and

pull it out,or unscrew the threaded sleeve,then pull it out.

Wire suggestion length:

Conductor cross

section

Max. cable length

MIN 2500 TL-X

MIN 3000 TL-X

MIN 3600 TL-X

4 mm² 12AWG

48m

40m

33m

Page 28

28

5.2 mm² 10AWG

60m

50m

42m

Conductor cross

section

Max. cable length

MIN 4200 TL-X

MIN 4600 TL-X

MIN 5000 TL-X

MIN 6000 TL-X

5.2 mm² 10AWG

28m

26m

24m

6.6 mm² 9AWG

36m

33m

30m

6.3 Connecting the second protective conductor

In some installation countries, a second protective conductor is required to prevent a touch current

in the event of a malfunction in the original protective conductor.For installation countries falling

within the scope of validity of the IEC standard 62109, you must install the protective conductor

on the AC terminal with a conductor cross-section of at least 10 mm²Cu.Or Install a second

protective conductor on the earth terminal with the same cross-section as the original

protective conductor on the AC terminal. This prevents touch current if the original protective

conductor fails.

6.4 Connecting the PV Array (DC input)

6.4.1 Conditions for DC Connection

The inverter shall be used with IEC 61730 Class A rating PV module.

Please use the same brand male and female PV connectors.

Page 29

29

WARNING

The MIN TL-X single-phase inverter has 2 independent input : PV1 & PV2

Notice that the connectors are in paired (male and female connectors). The connectors

for PV arrays and inverters are VP-D4 connectors;

CAUTION

If the inverter is not equipped with a DC switch but this is mandatory in the

country of installation, install an external DC switch.

The following limit values at the DC input of the inverter must not be exceeded:

Types

Max current PV1

Max current input B

Max voltage

2500-3600 TL-X

12.5A

12.5A

500V

4200-6000 TL-X

12.5A

12.5A

550V

6.4.2 Connecting the PV Array (DC input)

DANGER

Danger to life due to lethal voltages!

PV array supplies d.c voltage to inverter when exposed to light,before connecting

the PV array, conver some light screens above PV arrays,ensure that the DC

switch and AC breaker are disconnect from the inverter. NEVER connect or

disconnect the DC connectors under load.

Make sure the maximum open circuit voltage(Voc) of each PV string is

less than the maximum input voltage of the inverter.

Check the design of the PV plant. The Max. open circuit voltage, which can

occur at solar panels temperature of -10℃, must not exceed the Max. input

Page 30

30

voltage of the inverter.

WARNING

Improper operation during the wiring process can cause fatal injury to operator or

unrecoverable damage to the inverter. Only qualified personnel can perform the

wiring work.

Please don’t connect PV array positive or negative pole to the ground, it could

cause serious damages to the inverter

Check the connection cables of the PV modules for correct polarity and make

sure that the maximum input voltage of the inverter is not exceeded.

Connection of PV terminal

6.5 Connecting signal cable

This series inverter has one 8 Pin signal connector(There are two connectors for

AS/NZS4777 model ) . Signal Cable Ports:

Page 31

31

Procedure

Step 1 Insert the stripped and bared cable through pressure screw, seal ring, threaded sleeve in

sequence, insert cables into connection terminal according to number indicates on it and tighten

the screws firmly. Please try to pull out the wire to make sure the it’s well connected.

Step 2 Push the threaded sleeve into the socket, Tighten up the cap on the terminal.

Step 3 Push the threaded sleeve to connection terminal until both are locked tightly on the

inverter.

Uninstall signal connector

Step 1 Press the fasteners and pull it out from the inverter.

Step 2 Insert the H type tool and pull it out from the socket.

Page 32

32

6.6 Grounding the inverter

The inverter must be connected to the AC grounding conductor of the power

distribution grid via the ground terminal (PE) .

WARNING

Because of the transformerless design, the DC positive pole and DC negative

pole of PV arrays are not permitted to be grounded.

6.7 Active power control with smart meter , CT or ripple

control signal receiver

Information

The position of export limitation CT or Meter must between the

Inverter & Load and gird.

This series inverter has integrated export limitation functionality. To use this function,

you can connect smart meter or CT. The smart meter model is Eastron

SDM230-Modbus. The CT Model is TOP 90-S10/SP4(LEM).The primary aperture is

10mm,output cable length is 5m . The arrow on the CT must pointing towards the

inverter.

Active power control with a ripple control signal receiver.

Page 33

33

6.8 Inverter demand response modes (DRMS)

This series inverter has the function of demand response modes, We use 8Pin socket

as inverter DRMS connection.

Information

DRMS application description

Only applicable to AS/NZS4777.2:2015.

DRM0, DRM5, DRM6, DRM7, DRM8 are available.

CAUTION

Damage to the inverter due to moisture and dust penetration

Make sure the cable gland has been tightened firmly.

If the cable gland are not mounted properly, the inverter can

be destroyed due to moisture and dust penetration. All the

warranty claim will be invalid.

6.8.1 8Pin socket pin assignment

Pin

Assignment for inverters capable

of both charging and discharging

1

DRM 5

2

DRM 6

3

DRM 7

4

DRM 8

5

RefGen

6

Com/DRM0

7

NC 8 NC

6.8.2 Method of asserting demand response modes

Mode

Socket Asserted

by shorting pins

Requirement

DRM 0

5

6

Operate the disconnection device

DRM 5

1

5

Do not generate power

DRM 6

2

5

Do not generate at more than 50% of rated power

DRM 7

3

5

Do not generate at more than 75% of rated power

AND Sink reactive power if capabie

DRM 8

4

5

Increase power generation (subject to constraints from

other active DRMs)

7 Commissioning

Page 34

34

DANGER

Do not disconnect the DC connectors under load.

WARNING

Improper operation during the wiring process can cause fatal injury to operator

or unrecoverable damage to the inverter. Only qualified personnel can perform

the wiring work.

CAUTION

Damage to the inverter due to moisture and dust penetration

Make sure the cable gland has been tightened firmly.

If the cable gland are not mounted properly, the inverter can be

destroyed due to moisture and dust penetration. All the warranty

claim will be invalid.

Requirements:

The AC cable is correctly connected.

The DC cable is correctly connected.

The country is set incorrectly.

7.1 Start the inverter

7.1.1 Touch control

Touch

Description

Single touch

Switch display or Number +1

Double touch

Enter or confirmation

Three touch

Previous menu

Hold 5s

Confirm country or recover

defaut value

7.1.2 Country setting

Information

Country setting

When the inverter start up,we need to select the right country,if

we don’t select any country, the inverter will run under

AS/NZS4777.2 as default for Australia,or run under

VDE0126-1-1 for other region after 30s.

When inverter powered on, OLED will light automatically. Once the PV power is

sufficient, OLED displays the following:

Growatt

PV inverter

Set Country

XXXX

Page 35

35

Press the touch key once a second to scroll through the different Country, showing on

the screen will constantly change.For example, if you want to choose Newzealand,

press the control key until the OLED display shows “Newzealand” as below:

Set Country

Newzealand

Press the touch key 5S, the OLED shows Country setting is complete.

Set OK

7.2 General setting

7.2.1 Set inverter display language

This series inverter provides multi languages.

Single touch to switch different language.

Double touch to confirm you setting.

Set the language as described below:

Set Language

English

General

Advanced

Set parameter

7.2.2 Set inverter COM address

The default COM address is 1.We can change COM address as described below:

Single touch to switch display or make the number +1.

Hold 5s ,the COM address become 001.

Double touch to confirm you setting.

Page 36

36

Set Comaddr

001

Set Language

English

General

Advanced

Set parameter

7.2.3 Set inverter date & time

Single touch make the number +1.

Double touch to confirm you setting.

Hold 5s recover defaut value.

Set Date

2018-12-14

Set Time

12:30:30

Set Date

2018-12-14

Set Date

2018-12-14

Set Time

12:30:30

Set Time

12:30:30

Set OK Set OK

Set Comaddr

001

Set Language

English

General

Advanced

Set parameter

Page 37

37

7.3 Advanced setting

7.3.1 Reset Country

Single touch to switch display or make the number +1.

Double touch to confirm you setting.

The password of advanced setting is 123.

Set Country

VDE0126

Set Country

xxxxxxx

Set OK

Set parameter

General

Advanced

Password

123

7.3.2 Export limitation setting

Single touch to switch display or make the number +1.

Double touch to confirm you setting.

Exporlimit

OFF ON

Meter

CT

Set OK

Set parameter

General

Advanced

Password

123

7.3.3 Reset factory

Information

Perform this operation with caution because all configured parameters

except the current date,time, and model parameters will be restored to

their factory defaults.

Page 38

38

Single touch to switch display or make the number +1.

Double touch to confirm you setting.

Reset factory

NO

YES

Set OK

Set parameter

General

Advanced

Password

123

7.3 Communications

7.4 RS485

This series inverter provides two RS485 ports. You can monitor one or more inverters

by RS485.Another RS485 port is for smart meter(Export limitation functionality.).

7.5 USB-A

USB-A port is mainly for connecting monitor or firmware updage:

Through USB connection,we can connect external optional monitor ,for

example :Shine WIFI-X,Shine 4G-X, Shine LAN-X,ect.

And also you can quickly update the software by U disk.

We can monitor as below:

Make sure the △ on the front side, then insert the monitor,

fasten the screw.

NO.

Definition

NO.

Definition

1

+12V Power Supply(<1W)

2

COM

3

RS485A1 signal for

communication

4

RS485B1 signal for

communication

5

CT-P 6 CT- N

7

RS485A2 signal for

Smart Meter

8

RS485B2 signal for Smart

Meter

Page 39

39

8 Start-Up and shut down the inverter

8.1 Start-Up the inverter

1. Connect the AC breaker of the inverter.

2. Turn on the dc switch, and the inverter will start automatically when the input

voltage is higher than 70 V.

8.2 Turn-off the Inverter

DANGER

Do not disconnect the DC connectors under load.

Turn-off the inverter step:

1. Disconect the line circuit breaker from single-phases grid and prevent it from

being reactivated.

2. Turn off the dc switch.

3. Check the inverter operating status.

4. Waiting until LED, OLED have go out, the inverter is shut down.

9 Maintenance and Cleaning

9.1 Checking Heat Dissipation

If the inverter regularly reduces its output power due to high temperature,

please improve the heat dissipation condition. Maybe you need to clean the

heat sink.

Page 40

40

9.2 Cleaning the Inverter

If the inverter is dirty, turn-off the AC breaker and DC switch ,waiting the

inverter shut down ,then clean the enclosure lid, the display, and the LEDs

using only a wet cloth. Do not use any cleaning agents (e.g. solvents or

abrasives).

9.3 Checking the DC Disconnect

Check for externally visible damage and discoloration of the DC Disconnect

and the cables at regular intervals.If there is any visible damage to the DC

Disconnect, or visible discoloration or damage to the cables, contact the

installer.

Once a year, turn the rotary switch of the DC Disconnect from the On

position to the Off position 5 times in succession. This cleans the contacts

of the rotary switch and prolongs the electrical endurance of the DC

Disconnect.

10 Trouble shooting

Our quality control program assures that every inverter is manufactured to accurate specifications

and is thoroughly tested before leaving our factory. If you have difficulty in the operation of your

inverter, please read through the following information to correct the problem.

10.1 Error Messages displayed on OLED

An error message will be displayed on the OLED screen when a fault occurs. The faults consist of

system fault and inverter fault.

You may be advised to contact Growatt in some situation, please provide the following

information.

Information concerning the inverter:

Serial number

Model number

Error message on OLED

Short description of the problem

Grid voltage

DC input voltage

Can you reproduce the failure? If yes, how?

Page 41

41

Has this problem occurred in the past?

What was the ambient condition when the problem occurred?

Information concerning the PV panels:

Manufacturer name and model number of the PV panel

Output power of the panel

Voc of the panel

Vmp of the panel

Imp of the panel

Number of panels in each string

If it is necessary to replace the unit, please ship it in the original box.

10.2 System fault

System fault (system faults are mainly caused by system instead of inverter, please check the

items as instructed below before replacing inverter).

Error message

Description

Suggestion

Residual I High

Error: 201

Leakage current too high

1.Restart the invert.

2. If error message still exists, contact

Growatt.

PV Voltage High

Error: 202

The DC input voltage is exceeding

the maximum tolerable value.

1. Disconnect the DC switch immediately.

2. Check the voltage of each PV string

with multimerter.

3. If the voltage of PV string is lower than

550V, contact Growatt.

PV Isolation Low

Error: 203

Insulation problem

1. Check if panel enclosure ground

properly.

2. Check if inverter ground properly.

3. Check if the DC breaker gets wet.

4. Check the impedance of PV (+) & PV (-)

between ground (must be more than 25 KΩ

or 550 KΩ(VDE 0126)). If the error message

is displayed despite the above checking

passed, contact Growatt.

AC V Outrange

Error: 300

Utility grid voltage is out of

permissible range.

Please switch off DC switch.

Check AC wiring, especially neutral and

ground wire.

Check grid voltage is complied with local

grid standard. Restart inverter, if problem

still exist, Contact Growatt.

Page 42

42

No AC connection

Error: 302

No AC connection

Check AC wiring.

Check the status of AC breaker

AC F Outrange

Error: 303

Utility grid frequency out of

permissible range.

Please switch off DC switch.

Check AC wiring, especially neutral and

ground wire.

Check grid frequency is complied with local

grid standard. Restart inverter, if problem

still exist, Contact Growatt.

PE abnormal

Error: 304

Voltage of Neutral and PE above

30V.

1. Check the voltage of Neutral and PE.

2. Check AC wiring.

3. Restart inverter, if error message still

exisits,contact Manufacturer

Auto Test Failed

Error: 407

Auto test didn’t pass.

Restart inverter, repeat Auto Test, if

problem still exist, contact Growatt.

Page 43

43

10.3 Inverter warning

Warning code

Meanings

Suggestion

Warning202

DC SPD function abnormal

1.After shutdown,Check the DC SPD.

2.If error message still exists,contact

manufacturer.

Warning 203

PV1 or PV2 Circuit short

Check the PV panel polarity.

Restart the inverter. If the warning still

exist, please contact Growatt customer

service to replace the POWER board.

Warning204

Dryconnect function abnormal

1.After shutdown,Check the dry

Dryconnect wiring.

2.If the error message still exists, contact

manufacturer.

Warning 205

PV1 or PV2 boost broken

Restart the inverter. If the warning still

exist, please contact Growatt customer

service to replace the power board.

Warning207

USB over-current

1: Unplug the U disk or monitor.

2: Re-access U disk or monitor after

shutdown.

3.If the error message still exists, contact

manufacturer.

Warning 401

Inverter communicates with

Meter abnormal

1: Check if the meter is on

2: Check the inverter and the meter

connection is normal

Warning404

EEPROM abnormal

Restart the inverter. If the warning still

exist, please contact Growatt customer

service to replace the M3 board.

Warning405

Firmware version is not

consistent

Uptate the right version firmware

10.4 Inverter fault

Error code

Meanings

Suggestion

Error: 402

Output High DCI

Restart inverter, if problem still exist,

Contact Growatt.

Error: 404

Bus sample fault

Restart inverter, if problem still exist,

Contact Growatt.

Error: 405

Relay fault

Restart inverter, if problem still exist,

Contact Growatt.

Error: 408

Over Temperature

If the ambient temperature of inverter is

Page 44

44

lower than 60°C , restart inverter, if error

message still exists, contact Growatt.

Error: 409

Bus over voltage

Restart inverter, if problem still exist,

Contact Growatt.

Error: 411

DSP communicates with M3

abnormal

Restart inverter, if problem still exist,

update the DSP&M3 firmware;

Change DSP board or M3 board, if problem

still exist, contact Growatt.

Error: 414

EEPROM fault.

Restart inverter, if problem still exist,

Contact Growatt.

Error: 417

The data sampled by the DSP and

redundant M3 is not the same.

Restart inverter, if problem still exist,

Contact Growatt.

Error: 420

GFCI fault.

Restart inverter, if problem still exist,

change power board, or contact Growatt.

Page 45

45

11 Manufacturer Warranty

Please refer to the warranty card.

12 Decommissioning

12.1 Dismantling the Inverter

1 Disconnect the inverter as described in section 8 .

2 Remove all connection cables from the inverter.

CAUTION

Danger of burn injuries due to hot enclosure parts!

Wait 20 minutes before disassembling until the housing has cooled down.

3 Screw off all projecting cable glands.

4 Lift the inverter off the bracket and unscrew the bracket screws.

12.2 Packing the Inverter

If possible, always pack the inverter in its original carton and secure it with tension

belts. If it is no longer available, you can also use an equivalent carton. The box must

be capable of being closed completely and made to support both the weight and the

size of the inverter.

12.3 Storing the Inverter

Store the inverter in a dry place where ambient temperatures are always between

-25°C and +60°C.

12.4 Disposing of the Inverter

Do not dispose of faulty inverters or accessories together with household

waste. Please accordance with the disposal regulations for electronic waste

which apply at the installation site at that time. Ensure that the old unit and,

where applicable, any accessories are disposed of in a proper manner

Page 46

46

13 Technical Data

13.1 Specification

Model

Specifications

2500TL-X

3000TL-X

3600TL-X

4200TL-X

Input data(DC)

Max. recommended PV

power(for module STC)

3500W

4200W

5040W

5880W

Max. DC voltage

500V

Start voltage

100V

Nominal voltage

360V

MPP voltage range

80-500

80-500

80-550

80-550

MPP voltage range at Full

Power

100V-450V

120V-450V

150V-500V

170V-500V

No. of MPP trackers

2

No. of PV strings per MPP

trackers

1

Max. input current per MPP

trackers

12.5A

Max. short-circuit current per

MPP trackers

16A

DC overvoltage category

Category II

Output data(AC)

AC nominal power

2.5kW

3kW

3.6kW

4.2kW

Max. AC apparent power

2.5kVA

3kVA

3.6kVA

4.2kVA

Nominal AC voltage/range*

230/

160~300V

230/

160~300V

230/

160~300V

230/

160~300V

AC grid frequency/range

50-60Hz/44-55Hz;54-65Hz

Max. output current

11.3A

13.6A

16A

19A

Inrush current

<10A

Max output fault current

53A

Max output overload protection

16A

16A

20A

25A

Backfeed current

0A

Power factor(@nominal power)

>0.99

Adjustable power factor

0.8leading… 0.8lagging

THDi

<3%

AC grid connection type

Single phase

AC overvoltage category

Category III

Efficiency

Page 47

47

Max. efficiency

98.2%

98.2%

98.2%

98.4%

Euro-eta

97.1%

97.1%

97.2%

97.2%

Protection devices

DC reverse-polarity protection

Integrated

DC switch

Integrated

DC Surge protection

Type II

Insulation resistance

monitoring

Integrated

AC surge protection

Type III

AC short-circuit protection

Integrated

Ground fault monitoring

Integrated

Grid monitoring

Integrated

Anti-islanding protection

Integrated

Residual-current monitoring

unit

Integrated

General data

Dimensions (W / H / D) in mm

375*350*160

Weight

10.8 kg

Operating temperature range

–25 °C ... +60 °C

Noise emission (typical)

≤ 25 dB(A)

Altitude

4000m

Internal consumption at night

<1W

Topology

transformerless

Cooling

Natural convection

Protection degree

IP65

Relative humidity

0~100%

DC connection

VP-D4/MC4(Optional)

AC connection

AC connector

Interfaces

Display

OLED+LED

RS485/USB

Integrated

WIFI/GPRS/4G/LAN/ RF

Optional

Warranty:5/10 years

Yes/ Optional

Model

Specifications

4600TL-X

5000TL-X

6000TL-X

Input data(DC)

Max. recommended PV

power(for module STC)

6440W

7000W

8100W

Max. DC voltage

550V

Start voltage

100V

Nominal voltage

360V

Page 48

48

MPP voltage range

80-550

80-550

80-550

MPP voltage range at Full

Power

185V-500V

200V-500V

235V-500V

No. of MPP trackers

2

No. of PV strings per MPP

trackers

1

Max. input current per MPP

trackers

12.5A

Max. short-circuit current per

MPP trackers

16A

DC overvoltage category

Category II

Output data(AC)

AC nominal power

4.6kW

5kW

6kW

Max. AC apparent power

4.6kVA

5kVA

6kVA

Nominal AC voltage/range*

230/

160~300V

230/

160~300V

230/

160~300V

AC grid frequency/range

50-60Hz/44-55Hz;54-65Hz

Max. output current

20.9

22.7A

27.2A

Inrush current

<10A

Max output fault current

53A

Max output overload protection

25A

32A

32A

Backfeed current

0A

Power factor(@nominal

power)

>0.99

Adjustable power factor

0.8leading… 0.8lagging

THDi

<3%

AC grid connection type

Single phase

AC overvoltage category

Category III

Efficiency

Max. efficiency

98.4%

98.4%

98.4%

Euro-eta

97.5%

97.5%

97.5%

Protection devices

DC reverse-polarity protection

Integrated

DC switch

Integrated

DC Surge protection

Type II

Insulation resistance

monitoring

Integrated

AC surge protection

Type III

AC short-circuit protection

Integrated

Ground fault monitoring

Integrated

Grid monitoring

Integrated

Anti-islanding protection

Integrated

Residual-current monitoring

Integrated

Page 49

49

unit

General data

Dimensions (W / H / D) in mm

375*350*160

Weight

10.8 kg

Operating temperature range

–25 °C ... +60 °C

Noise emission (typical)

≤ 25 dB(A)

Altitude

4000m

Internal consumption at night

<1W

Topology

transformerless

Cooling

Natural convection

Protection degree

IP65

Relative humidity

0~100%

DC connection

VP-D4/MC4(Optional)

AC connection

AC connector

Interfaces

Display

OLED+LED

RS485/USB

Integrated

WIFI/GPRS/4G/LAN/ RF

Optional

Warranty:5/10 years

Yes/ Optional

13.2 DC &AC connector info

DC connector

VP-D4/ MC4(opt)

AC connector

M-S30_SD03_S10 001U-A

VPAC06EP-3S(SC)5

VPAC06EW-3P(SC)

13.3 Torque

Enclosure lid screws

12kg.cm

AC terminal

6kg.cm

Signal terminal

4kg.cm

Safety screw

12kg.cm

Additional ground screws

12kg.cm

13.4 Accessories

In the following table you will find the optional accessories for your product. If

required, you can order these from GROWATT NEW ENERGY TECHNOLOGY

Page 50

50

CO.,LTD or your dealer.

Name

Brief description

Shine WIFI-X

WIFI monitor with USB interface

Shine 4G-X

4G monitor with USB interface

Shine RF-X

RF monitor with USB interface

Shine LAN-X

LAN monitor with USB interface

Shipped to a Growatt service centre for repair, or repaired on-site, or exchanged for a replacement

device of equivalent value according to model and age.

The warranty shall not cover transportation costs in connection with the return of defective

modules . The cost of the installation or reinstallation of the modules shall also be expressly

exclude as are all other related logistical and process costs incurred by all parties in relation to this

warranty claim.

14 Compliance Certificates

Certificates

With the appropriate settings, the unit will comply with the requirements specified

in the following standards and directives (dated: Dec./2018):

Model

Certificates

2500-6000TL-X

CE , IEC 62109, AS4777, G98,G99

15 Contact

If you have technical problems about our products, contact the GROWATT

Serviceline. We need the following information in order to provide you with the

necessary assistance:

Inverter type

Serial number of the inverter

Event number or display message of the inverter

Type and number of PV modules connected

Optional equipment

GROWATT NEW ENERGY TECHNOLOGY Co.,LTD

No.28 Guangming Road, Longteng Community, Shiyan,

Bao'an District, Shenzhen, P.R.China

www.ginverter.com

Serviceline

Tel: + 86 755 2747 1900

Email: service@ginverter.com

Page 51

51

Loading...

Loading...