Page 1

ARK High Voltage Battery System

Download

Manual

Shenzhen Growatt New Energy Co., Ltd

4-13/F,Building A,Sino-German(Europe) Industrial Park,

Hangcheng Ave, Bao'an District, Shenzhen, China

T

+86 755 2747 1942

service@ginverter.com

E

www.ginverter.com

W

GR-UM-223-A-02

Growatt New Energy

User Manual(A1)

Page 2

About this Document

Symbol

Description

Indicates a potentially hazardous situation, if not avoided, could re su lt

in serious injury or death.

This document describes the installation, electrical connection, operation, commission,

maintenance and troubleshooting of ARK High Voltage Battery System. Before i ns ta ll in g

and operating ARK High Voltage Battery System, ensure that you are f am il ia r wi th

product feature s, f un ct io ns , an d sa fe ty p recautions provided in this document.

1 Product Overview

Contents

1.1 Intended Use

1.2 Appearance

1.3 Working Principle and Function

WARNING

2 Safety

3 Storage and Transportation

4 Installation

5 Power on/off Battery system

6 Maintenance Guide

2.1 Basic security

2.2 Safety Precautions

2.3 War ning Labels

2.4 Emergency Responses

3.1 Storage Requirements

3.2 Tran sp or ta ti on R eq ui rement

4.1 Basic Installation Requirements

4.2 Installation Required Tools

4.3 Installation Procedures

4.4 Electrical Connection

5.1 Power on Battery system

5.2 Power off battery system

6.1 Preparation

6.2 Battery pack or high voltage

controller re pl ac em en t

6.3 System fault information and

suggestions

7 Technical Specifications

Appendix I

Appendix II

7.1 System Data

7.2 Battery System designation

7.3 HVC 60050-A1

7.4 ARK 2.5H-A1

Page 3

1 Product Overview

Location

Port

Function

1

PCS

Communication with PCS

2

Link-In

Battery system parallel communication entrance

3

Pressure relief valve

Pressures i ns id e is released via the vent

4

Link-Out

Battery system parallel communication export

5

BMU

Communication with battery module

6

Module+/ Module-

Connect to the power terminal of the battery string

7

Ground terminal

8

PCS+/PCS-

The output from battery system to the PCS

9

Ground terminal

10

USB interface

USB communication interface

11

LED

SOC and working status indication of the system

12

Breaker

Breaker to turn on/off the whole battery system

13

Power button

Wak e up t he b at te ry s ys te m

Location

Port

Function

1

Link0

Communicate with the previous module Link1

2

Link1

Communicate with the next module Link0

3

Module-

Connect to the positive terminal of the adjacent

module

4

Module+

Connect to the negative terminal of the adjacent

module

5

Ground terminal

6

Pressure relief valve

Pressures i ns id e is released via the vent

7

Ground terminal

1.1 Intended Use

The entire ARK Hig h Voltage Ba tt er y System in cl ud es a HVC 60050-A1(high voltage

controller) and multiple ARK 2.5H-A1 (battery pack).

Each ARK 2.5H-A1 consists of 50A h c el ls wh ic h form 51.2V voltage battery pack via one

parallel and s ix te en s er ia l co nn ec ti on (1P16 S) . Two to ten ARK 2. 5H -A 1 ca n be connected

in serial to extend the capacity and power of energy storage system.

The ARK battery system powers the loads th rough PCS at nighttime without solar; when

solar b ec om es available du ri ng daytime, solar energy powers t he loads as a priority and

store res id ua l so la r po we r in to t he A RK b at te ry s ys te m.

1.2 Appearance

1.2.1 HVC 60050-A1 (high voltage controller)

The high voltage control le r is com po se d of bat te ry co ntrol unit, DC brea ke r, power

supply and communication terminals. The appearance of the product is shown as below.

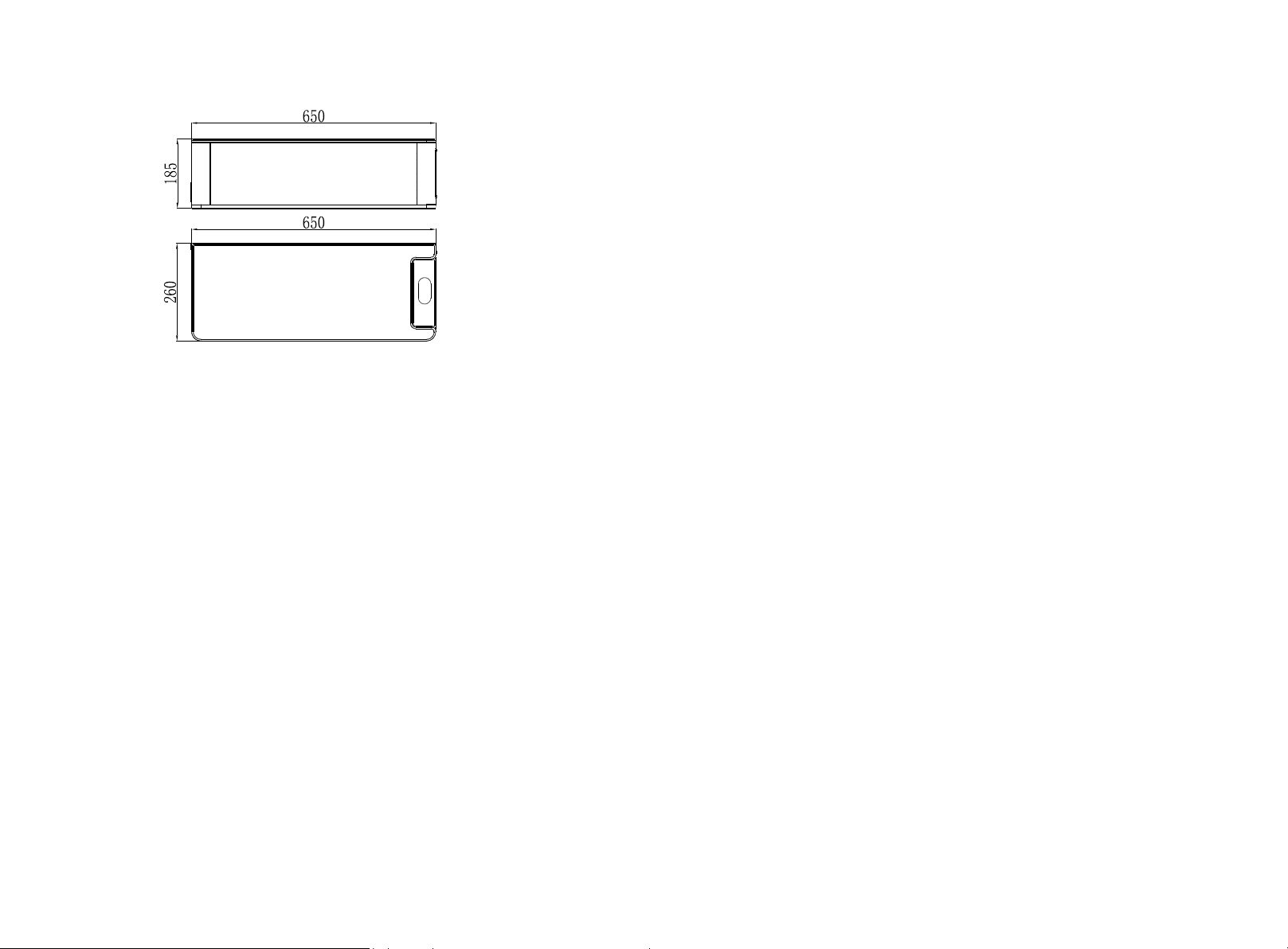

Dimension (unit: mm)

1.2.2 ARK 2.5H-A1 (battery pack)

ARK 2.5H-A1 consists of battery module (including cell and mechanical parts), Battery

management unit (BMU) as well as power and communication terminals. Product

appearance is shown as below.

Fig 1.1: Schematic diagram of power panel

Fig 1.2: Dimension of HVC 60050-A1

Fig 1.3: Schematic diagram of power panel

1

2

Page 4

Dimension (unit: mm)

Fig 1.4: Dimension of ARK 2.5H-A1

1.3 Working Principle and Function

The ARK high voltage battery system is composed of a high voltage controller HVC

60050-A1 and battery pack ARK 2.5H-A1 in series. It contains electrochemical batteries,

battery control units, battery management units, power and signal terminals, and

mechanical parts.

Compared with other battery systems, it has better charging and discharging

performance, higher charging and discharging efficiency, more accurate status monitor,

longer cycle life and less self-discharge loss.

A single cluster system can connect 2 to 10 packs in series to increase the capacity and

power of the battery system. The entire battery system communicates with the inverter

through CAN communication, and the operation stability is high.

Ø Monitoring: voltage, current and temperature de te ct io n of b ot h si ng le c el ls a nd

battery system.

Ø Protection and Alarm: pro te ct io n an d al ar m wh en o ve rv ol ta ge , un de r vo lt ag e, o ve r

current, over temperature o r un de r te mp er at ure occurs. See Appendix I for the details.

Ø Report: report all alarm and status data to PCS.

Ø Series connection: support two to ten packs in Series connection.

Ø Power failure triggered b y fa ul t: 1 0 mi nu te s af te r th e ba tt er y sy st em a nd P CS

communication is disconnected or 15 minutes after undervoltage protection.

Safety 2

When installing or using a b at te ry s ys te m, t he s af et y inform at io n contained in this

section m us t always be followed. Fo r safety reasons, it is the installer's responsibility to

be familiar with this manual and all war ni ng s be fo re installation.

2.1 Basic security

The battery system has been designed and tested in accordance with strict rules with

intern at io na l sa fe ty c er ti fi ca ti on requirements. Before a ny i ns ta ll at io n or u se o f th e

battery system, please read all safety instructions caref ul ly a nd a lw ay s fo ll ow t he relevant

rules. Growatt is not res po ns ib le f or a ny c on se qu en ce s resulting from violation of the

following regulations:

Ÿ Damage occurred during transportation.

Ÿ Incorrect transportation, storage, installation and use, or customer fails to convey the

correct information about transportation, storage, installation and use to terminal.

customers.

Ÿ Non-professional installation.

Ÿ Failure to obey the rules of this operation instructions and safety pre ca ut io ns i n th is

document.

Ÿ Unauthorized modifications or removal of the software p ac ka ge .

Ÿ The product's tamper label is damaged or the prod uc t la ck s an y pa rt s (e xc ep t

authorized disassembly parts).

Ÿ Operation in extreme enviro nm en ts w hi ch a re not allowed in this document .

Ÿ Repair, di sa ss em bl e, o r ch an ge p ac ks w it ho ut a ut ho ri za ti on a nd c au se f ai lu re.

Ÿ Damage to shell labels or modifies date of production.

Ÿ Packs fail to be charge for more than six months.

Ÿ Damages due to force majeure (s uc h as l ig ht ni ng , ea rt hq ua ke s, f ire, and storms).

Ÿ War ra nt y ex pi ra ti on .

2.2 Safety Precautions

2.2.1 Environment req ui rements

Ø Do not expose the battery to temperature above 50℃ or heat sourc es .

Ø Do not install or use the battery in wet locations, moisture, corro si ve g as es o r li qu id s,

such as bathroom.

Ø Do not expose the battery to direct sunlight for extended periods of time.

Ø Place battery in safe place away from childre n an d an im al s.

Ø Battery power terminals shall not touch conductive objects such as wires.

Ø Do not dispose the batteries in fire, which may cause an explosion.

Ø The battery system shall not come in contact with liquids.

3

4

Page 5

2.2.2 Operation Precautions

Symbols

Description

Do not dispose in trash

Lithium ion battery can be recycled

Certification in European union are a

Electric shock hazard

Explosive gas

May leak corrosive electrol yt e

Heavy enough to cause severe injury

Keep the Pack away from childre n

Make sure the battery polarity well connected

Do not expose to fire

Operate as the Manual

The performance will be limited

when the temperature is below

0°C.

Ø Do not touch the battery system with wet hands.

Ø Do not disassemble the battery system without permission.

Ø Do not crush, drop or pierc e th e ba tt er y pa ck a nd h ig h vo lt ag e co nt roller.

Ø Dispose the batteries according to local safety reg ul at io ns .

Ø Store and rec ha rg e ba tt er y in a cc ordance with this manual.

Ø Ensure the connection of grou nd w ire reliable.

Ø Remove all metal objects such as watches and rings that could cause a short-circuit

before installation, re pl ac em en t an d ma in te na nc e.

Ø The pack shall be repaire d, replaced or maintained by skilled personal that has been

recognized.

Ø When storing or handling batteries ,do not stack batteries without package.

Ø Do not broke the battery, the released electrol yt e ma y be t ox ic a nd i s ha rm fu l to s ki n

and eyes.

Ø Packaged batteries should not be stacked more than specified number stipulated on

the packing case.

Ø Do not use damaged, failed or deformed batteries, which may lead to high

temperature or even dangero us a cc id en ts . Co nt in ue d op er at io n of d am ag ed b at te ry m ay

result in electrical shock, fire or e ve n wo rs e.

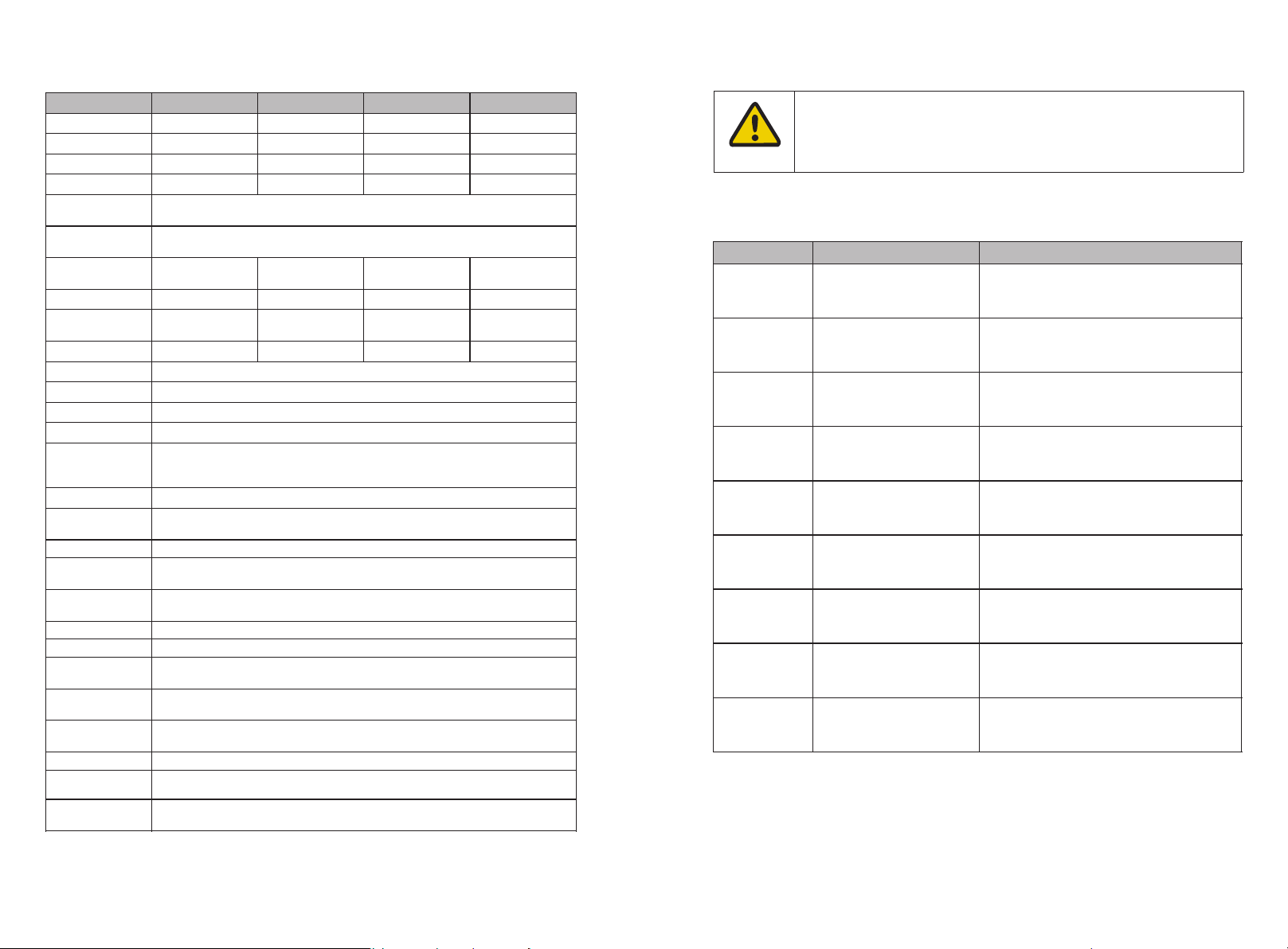

2.3 Warning Labels

Model

Nomin al/ Rated C apa ci ty

Nomin al/ Rated E ner gy

Rated C urr ent

Opera tin g Amb ien t

Temp eratu re

Fig 2.1: Nameplate

ARK H igh Volt age Bat tery Sy stem

ARK 5 .1H-A 1/102 .4V/

5.1 2kWh/ 4.6kW h

ARK 7 .6H-A 1/153 .6V/

7.6 8kWh/ 6.9kW h

ARK 1 0.2H- A1/20 4.8V/

10. 24kWh /9.2k Wh

ARK 1 2.8H- A1/25 6.0V/

Sys tem Mod el/

Nom inal Vol tage/

Nom inal En ergy/

Rat ed Ener gy

Hig h Voltag e

Con troll er Mode l

Pro tecti ve Clas s

Rat ed Curr ent

Nom inal/ Rated

Cap acity

Ing ress

Pro tecti on

Ope ratin gAmbi ent

Tempe ratur e

12. 80kWh /11.5k Wh

ARK 1 5.3H- A1/30 7.2V/

15. 36kWh /13.8 kWh

ARK 1 7.9H- A1/35 8.4V/

17. 92kWh /16.1 kWh

ARK 2 0.4H- A1/40 9.6V/

20. 48kWh /18.4 kWh

ARK 2 3.0H- A1/46 0.8V/

23. 04kWh /20.7 kWh

ARK 2 5.6H- A1/51 2.0V/

25. 6kWh/ 23.04 kWh

HVC 6 0050- A1

50A h/45A h

-10 °C ~ +50° C

ARK 2.5 H- A1

51.2V

50Ah/ 45 Ah

256 0Wh/230 0Wh

25A

-10°C ~ + 50 °C

Made In China

I

25A

IP6 5

WARNING

Do no t disas sembl e or alte r the PACK to a void he at ,exp losio n or fire .

Do no t use the PAC K beyon d speci fide co nditi ons.I t might c ause he at

gen erati on,da mage, or dete riora tion of i ts perf orman ce.

Do no t throw, drop, hit,d rive a na il in,s tamp on t he PACK.I t may cau se

hea t gener ation ,expl osion ,or fir e.

In ca se of ele ctrol yte lea kage, keep le aked el ectro lyte aw ay from

con tact wi th eyes o r skin. immed iatel y clean w ith wat er and se ek help

fro m a docto r.

Do no t put the PAC K into a fi re.Do n ot use it o r leave i t on a plac e

nea r fire, heate rs,or h igh tem perat ure sou rces. It may ca use ove r

tem perat ure,e xplos ion or fi re.

Do no t subme rge the PAC K in wate r,or wet t he prod uct.I t may cau se

hea t gener ation ,expl osion , or fire .

Do no t rever sely co nnect t he PACK pos itive (+)an d negat ive(- )term inal.

Do no t short c ircui t by lett ing the PAC K termi nals( +and -) conta ct a wire

or an y metal .

The u nit is he avy eno ugh to ca use sev ere inj ury.

Kee p out of re ach of ch ildre n or anim als.

X

Fig 2.2: Label

5

X

Fig 2.3: Nameplate

Made In China

Notice

6

Page 6

2.4 Emergency Responses

Situation Occurs

Description and action need

Leakage

Avoid touch of leaking liquid or gas. If you touch the leaking

electrolyte, do as below immediately.

Inhalation: Evacuate the contaminated area, and seek medical help.

Eye contact: Rinse eyes with flowing water for 15 minutes, and seek

medical help.

Skin contact: Rinse contacted area thorou gh ly w it h so ap a nd w at er,

and seek medical help.

Ingestion: Vomiting, and seek medical help.

On fire

It's hard for battery system ignite spontaneously. If the battery has

caught a fire, do not try to extinguish the fire bu t ev ac ua te p eo pl e

immediately.

Wet Packs

If the battery system is soaked or submerged in water, do no t ac ce ss

it. Contact Growatt or distributors immediately for technical

assistance.

Damaged shell

Damage to the shell is very dangerous, so special attention must be

paid. They are no longer suitable for use and may be dangerou s to

personnel. If the battery case is damaged, please stop using it and

contact Growatt or a distributor.

If not follow the above instructions for long-term storage, the battery

cycle life will be reduced or even damaged.

Manufacturer takes fore se ea bl e ri sk s ce na ri os i nt o co ns id er at io n an d is d es ig ne d to

reduce hazard s an d da ng er s. H ow ev er, if the following situation occurs, do as below:

Storage and Transportation 3

3.1 Storage Requirements

Ø Place the product follow the identification on the packing case during storage.

Ø Do not put the product upside down or sidelong.

Ø The defective product needs to be separated fro m ot he r product.

Ø The storage environment req ui rements are as follows:

Ÿ Place the product in a dry, clean and well ventilated place.

Ÿ The storage temperature for a short week(7 days) is between -20°C to 50℃.

Ÿ If you store the prod uc t ov er a l on g pe ri od o f si x mo nt hs , th e st or ag e te mp er at ure is

between -20°C to 40°C, relative humidity: 5%~95%RH.

Ÿ Place the product away from c or rosive and organic substances (including gas

exposure).

Ÿ Free from d irect exposure to sunlight and rain.

Ÿ At least two meters away from heat source s (s uc h as a r ad ia to r) .

Ÿ Free from e xp os ure to intensive infrared radiation.

Ø If the battery is stored for more t ha n si x mo nt hs , th e ba tt er y pa ck s ha ll b e recharged to

40% SOC every six months using a charger.

Notice

3.2 Transportation Requirement

Battery pack has been certified in UN38.3 (Section 38.3 of the sixth Revised Edition of the

Recommendations on the Tra ns po rt o f Da ng erous Goods: Manual of Tests and Criteria)

and SN/T 0370.2-2009 (Part 2: Performance Test of the Rules for the Inspection of

Packaging for Exporting Dangerous Goods). Battery pack is classified as category 9

dangerous goods.

Ø The battery pack shall not be transported with other inflammable, explosive or toxic

substances.

Ø Ensure the original Package and label complete and re co gn iz ab le .

Ø Prohibit dire ct e xp os ure to sunlight, rain, condensing water caused by temperature

differe nc e an d me ch an ic al d am ag es .

Ø Prohibit to pile up more th an s ix b at te ry p ac k.

Ø There will be a dro p in c ap ac it y du ri ng t ra ns po rt at io n an d st or ag e.

Ø Tran sp or ta ti on t em pe ra tu re is between -20°C to 40°C, relative humidity: 5%~95%RH.

7

8

Page 7

4 Installation

Ø The installation and use of batteries involve a lot of expertise.

Therefore , pl ea se e ns ure that technicians have obtained relevant

technical certificates before operation.

Ø Ensure to rea d th e Gu id an ce b ef ore installation in order to understand

product information and safety cautions.

Ø Operators should be well trained technicians and fully understand the

whole photovoltaic system, grid network, battery system, working

principle and national regional standards .

Ø Installers must use insulating tools and wear safety equipment.

Ø Device damages caused by failure to comply with storage,

transportation, installation and use requirem en ts s pe ci fi ed i n Gu id an ce

are not coved by Warranty.

Ø Do not install or use battery near explosive or inflammable substances.

Ø Use battery in well-ventilated environment with temperature r an gi ng

from -10℃ to 50℃.

Ø Maintain a minimum level of dust and dirt in the environment.

Ø Do not install battery in highly humid area such as bathroo m.

Ø Please make sure that all battery pack connected in series are from the

same batch, the same model and the same manufacturer. Do not mix old

batteries with new batteries. A battery pack that does not exceed 300

cycles is defined as a new battery.

Ø Before installing in series, make sure th at t he v ol ta ge d ifference of the

battery pack must be less than or equal to 0.5V.

Ø When installing the batteries, we recommend that the manufacturing

date of batteries in the same system should be within 3 months. The

manufacturing date of batteries can be interpreted thro ug h ba r co de

(refer to Appendix 1).

Do not place the battery pack upside down.

WARNING

Notice

4.1 Installation environment

Ø The battery system can be installed indoors or outdoors. The following conditions are

allowed:

9

Fig 4.1:Acceptable wall mounted installation

Fig 4.2:Acceptable floor standing installation

WARNING

Ø When installing outdoors, it is necessary to install sunshades and rain shelters to avoid

direct exposure t o su nl ig ht a nd r ai n.

Fig 4.3: Sunshades and rain shelters

10

Page 8

4.2 Installation Required Tools

Ø The high voltage controller (HVC 60050-A1) and the battery pack (ARK

2.5H-A1) are standard a cc es so ri es , pl ea se b e su re to purchase both, a

battery system only needs a high voltage controller (HVC 60050-A1),

battery pack (ARK 2.5H-A1) You c an f reely match the number within 2 to

10 .

Ø The battery base is only used for floor installation, and the wall bracket

is only used for wall installation .The battery base and wall bracket are

optional accessory, no t st an da rd accessory.

Ø You ne ed t o se pa ra te ly p urchase the connection cable from the high

voltage controller (HVC 60050-A1) to the PCS.

Ø If you want to install the same battery system in two lines, you need to

purchase a extension cable separately for connection.

Ø The installation method can be selected wall Mounted installation or

floor standing installation as required .

The following tools are req ui red to install the battery system:

4.3.1.2 Check the list of ARK 2.5H-A1

Drill

Pencil

Screw Driver

Tap Measure

Wre nc h

Multimeter

It is recommended to wear the following safety gear when dealing with the battery

system.

Insulated Glove

Safety Goggle Safety Shoes

4.3 Installation Procedures

4.3.1 Pre-installation Check

Ø Check the PACK package before op en i t. I f an y ab no rm it y is d et ec te d, d o no t op en t he

Package and contact your distributor.

Ø Check the quantity of all parts inside according to the package list. If there is a ny p ar t

missing or damaged, please contact your distributor.

4.3.1.1 Check the list of HVC 60050-A1

Se ri al c a bl e X1

Fig 4.5:compoents and parts ARK 2.5H-A1

4.3.1.3 Check the battery base and wall bracket

Ba t t er y b as e

Fig 4.6:Optional installation accessories

Notice

Fig 4.4:compoents and parts of HVC 60050-A1

11

Pl u g X1

12

Page 9

4.3.2 Wall Mounted Installation

Ø The number of wall-mounted installations should not exceed 4

(including high voltage controllers).

Ø If there are mo re than 4, please install them in two lines, and the

spacing should be greater than or equal to 300mm.

Ø If more than 4 batteries are us ed , b as e mo un ti ng i s recommended.

Ø For floor installation with base , the maximum stack number of the

battery is ten. But if the battery number is greater than six , we

recommend stacking them in two lines.

Ø The safety part needs to be installed at the top battery, ho we ve r, once

the number of the battery pack is higher than 7, one more safety part

should be installed in the middle battery which is shown the last step.

Ø Do not forget wear ESD wrist strap and gloves, safety gloves and

goggles.

4.3.3 Floor Standing Installation

Fig 4.8: Floor standing installation process

Ø Step 1: Place the battery base in the area to be installed, and mark the position of the

installation hole with a marker. The m in im um d is ta nc e be tw ee n th e wa ll a nd t he b at te ry

is 300mm.

Ø Step 2: Select an alloy drill with a diameter of 10mm and drill a mounting hole at least

60mm deep in the wall. Insert the expansion pipe into the hole and screw in the screw s to

secure the anti rol l ov er p la te .

Ø Step 3: Stack the battery on the base, connect the fixed connecting strip between the

battery packs.

Ø Step 4: Make sure the battery will not shake, and then lock the safety scre w.

Ø Step 1: Please make sure that the weight capacity of the wall should exceed 150kg.

Ø Step 2: Put bracket on wall and mark drilling spots. Keep a minimum distance of

300mm between the wall and bracket; a minimum distance of 500mm between bracket

and ground.

Ø Step 3: Choose an alloy drill with a diameter of 8mm, and drill at least 60mm mounting

holes in the wall. Clean the soil and insert the expansion tube into the hole, then screw in

the screw to fix the wall mount.

Ø Step 4: Fix the battery on the wall mount, make sure that the battery will not shake,

and then lock the safety screw.

Notice

13

Notice

4.4 Electrical Connection

Notice

14

Page 10

4.4.1 Definition of RJ45 communication port pin

No.

PCS

LINK_IN

LINK_OUT

BMU

1

RS485_B

Add_in

Add_out

\

2

RS485_A

Master

GND\3

GND

GND

Slaver

IMA_isoSPI

4

CAN_H

GND

GND

IPA_isoSPI

5

CAN_L

CANH

CANH

IMB_isoSPI

6

GND

CANL

CANL

IPB_isoSPI

7

WAK E-

GND

GND\8

WAK E+

Power_ON

Power_ON

\

No.

LINK 0

LINK 1

1

\

\

2

\

\

3

\

\4\

\

5

IMA_isoSPI

IMB_isoSPI

6

IPA_isoSPI

IPB_isoSPI

7

\

\8\

\

Ø When connecting the power line, it must be the same color terminal to

connect , otherwise there may be dangers such as short circ ui t .

Ø A DC circuit brea ke r ha s be en i ns ta ll ed i n th e hi gh v ol ta ge c on troller. If

you want to install a DC circuit brea ke r be tw ee n th e ba tt er y sy st em a nd

the PCS, you need to purchase it yourself accordi ng t o th e fo ll ow in g

specifications:

a. Voltage: 750Vdc/1000Vdc

b. Current: 63A

4.4.1.1 Communication port definition of HVC 60050-A1

4.4.2 System connection diagram

Notice

4.4.2.1 System connection diagram

4.4.1.2 Communication port definition of HVC 60050-A1

15

Fig 4.9: Single line installation

Note:

Ø The battery is not allowed to be installed in the running state. Tur n off th e sy st em

power before installation.

Ø To ensure system security, do not forget to install ground wire .

Ø Don't forget to connect the communication plug of the last battery pack, otherwise it

will cause system failure.

Ø When installing in two rows, please purch as e th e ex te nd ed s er ia l ca bl e.

Ø The cable connecting PCS can be purchased fro m GR OWATT.

Fig 4.10: Two li ne s installation

16

Page 11

4.4.2.2 Electrical wiring connection

Ø For a single battery system, the “Link-in” and “Link out” port of the

High Voltage Controller don't need to be connected, they are o nl y us ed

for parallel connection of the battery systems.

Ø Please pay attention to the connector color when connection the

power line. Only the same color of the connector could be connected

together.

Ø To ensure system security, do not forget to install ground wire .

Ø The battery module furthest from the HVC 60050-A1(high voltage

controller) is defined as the last battery module.

Ø Please pay attention to the connector color when connecting the

power line. Only the same color of the connector could be connected

together.

Ø The power lines between the battery modules are connected in series.

Be careful not to short-circu it t he b at te ry m od ul es d ur in g th e co nn ec ti on

process.

A. HVC 60050-A1(High Voltage Controller) wiring

Step 1: Insert the power cable into the corresponding port, then there is c li ck s ou nd

indicating the connection is ok.

Step 2: Insert the communication cable into the "PCS" port and "BMU" port, and then

tighten the communication terminal clockwise. (“PCS” port connects to the PCS. “BMU”

port connects to the adjacent battery pack.)

Step 3: Connect to the PCS and adjacent battery pack using a 6mm2 grounding wire

through gro un di ng t er mi na l.

Fig 4.11: HVC60050-A1 Electrical wiring connection diagram

Notice

Step 1: Insert the power cable into the corresponding port, then there is c li ck s ou nd

indicating the connection is ok.

Step 2: Insert the communication cable into the "Link0" and "Link1" port, and then

tighten the communication terminal clockwise. (“Link0” connects to “Link1” of the

previous module. For the battery adjacent to the high voltage control le r, "link0" is

connected to the "BMU" of the high voltage controller. “Link1” connects to “Link0” of

the next module.)

Step 3: Insert a plug into the "Link1" port of the last battery module. The plug is an

annex of HVC 60050-A1 (high voltage controller).

Step 4: Connect to adjacent battery pack using a 6mm2 grounding wire th rough

grounding terminal.

Notice

B. ARK 2.5H-A1(Battery module) wiring

Fig 4.12: ARK 2.5H-A1 Electrical wiring connection diagram

17

18

Page 12

5 Power on/off Battery system

Ø The installation and use of batteries need to be operated by

professional technicians.

Ø Do not contact any positions with potential differe nc e.

Ø Prohibition sign should be hung on the battery: " Non - pro fe ss io na ls ,

do not touch.

Ø If any abnormalities occur during the startup phase, power off the

system immediately. Af te r problem confirmed, proceed again.

Ø Make sure the inverter is turned off before c he ck in g th e ba tt er y sy st em .

Power on the battery system by pressing power button(t>5S)

Serial

Procedures

Acceptation criteria

1

Connect the battery and PCS

Make sure the wiring harnesses are well

connected

2

Close the breaker of the battery

system

Make sure the bre ak er i s ON

3

Press POWER button for 5

seconds. Observe the LED

indication on panel..

1. If both RUN/ALM and SOC lights turn o n

normally, sy st em i s po we red on successfully.

2. If RUN/ALM light turn s red, there is a failure

and should solve it before power on again.

Error

Indication

Error

description

Error cause

Suggested actions

ALM

( ALM

Light

Flickers)

Discharge under

voltage

protection

Single cell voltage

below the threshold

for under-voltage

protection.

There is over discharge risk. User

should stop discharging and

arrange recharge

Charge over

voltage

protection

Single cell voltage

exceeding threshold

for protection

threshold.

1. There is no safety threa t;

2. User should stop charging.

Wai t fo r th e ba tt er y sy st em t o

automatically resolve the fault

Extern al C AN

Communication

failure

Communication loss

between PCS and

battery system.

1. There is no safety threa t an d

user should stop using battery.

2. Check if PCS and battery

communication terminal is well

connected.

3. If PCS and battery system

cannot communicate when the

communication wire is confirmed

well connected, user should

contact installer to repair battery.

Ø Before re pl ac in g th e ba tt er y, use the charger to charge the new battery

and the existing battery to full (SOC 100%).

Ø If the battery is not used, it is recommended to charge and discharge

the battery every 3 months to activate the chemical characteristics, and

the maximum interval shall not exceed 6 months.

Maintenance Guide 6

6.1 Preparation

Before maintenance, please make sure th at t he b at te ry s ys te m is p ow ered off and the DC

circuit bre ak er i s off.

Notice

5.1 Power on Battery system

Fig 5.1

Ø Before turning on the battery, ple as e ch ec k if t he c ab le i s properly connected.

6.2 Battery pack or high voltage controller replacement

Ø Wear safety gloves.

Ø Close the breaker and power off t he b at te ry s ys te m.

Ø Disconnect power lines and CAN communication lines of the battery system.

Ø Uninstall the safety screws on both sides of the battery pack or high voltage control le r.

Lift up the battery pack or high voltage controller.

Ø Put the battery pack or high voltage controller into the packing box accord in g to t he

repair proc ed ure and transport the battery pack or high voltage controller to the

designated repair site.

Ø Install new battery pack or high voltage controller based on proc ed ure specified in

Section 4.

Notice

6.3 System Failure Information List and Troubleshooting

Suggestions

5.2 Power off

19

Fig 5.2

Turn the DC brea ke r of t he H VC 6 00 50 A1(High Voltage Controller) to "Off" t o tu rn

off the entire ba tt er y sy st em .

20

Page 13

Interior

Communication

failure

Communication loss

between two packs

1.Check whether the

communication line between the

battery pack and the battery pack

is connected OK;

2.Check whether the

communication line between the

high voltage controller and the

battery pack is connected OK.

High

temperature

protection

The temperature

exceeds the

protection value

It is dangerous, please stop using

the battery immediately, wai t fo r

the battery temperature to drop ,

the fault will be automatically

resolved.

Low temperature

protection

The temperature is

below the

protection value

No safety risk, wait for the

temperature to rise, the fault will

be automatically resolved.

(ALM

Light on)

Discharge short

circuit

Extern al s ho rt c ircuit

of battery system

There is safety risk and user

should stop using battery.

User should contact installer to

repair PCS and battery.

Precharge short

circuit

Precharge

overtime

Voltage

sampling

anomaly

protection

BMS Voltage

sampling

failure

There is safety risk and user

should stop using battery.

User should contact installer to

repair battery.

Current

sampling fault

BMS current

sampling

failure

Main circuit fault

BMS main power

circuit failure

There is safety risk and user

should stop using battery.

User should contact installer to

repair battery.

7.1 System Data

System Model

ARK 5.1H-A1

ARK 7.6H-A1

ARK 10.2H-A1

ARK 12.8H-A1

ARK 15.3H-A1

Nomin al e nergy

5.12kWh

7.68kWh

10.24kWh

12.8kWh

15.36kWh

Rated energy

4.608kWh

6.912kWh

9.216kWh

11.52kWh

13.82kWh

Rated Power

2.56kw

3.84kw

5.12kw

6.4kw

7.68kw

Max Power

4.915kw

7.372kw

9.83kw

12.288kw

14.745kw

Nominal

capacity

50Ah(@25℃)

Rated

capacity

45Ah(@25℃)

Nominal

voltage

102.4V

153.6V

204.8V

256V

307.2V

Voltage range

94.4V ~1 13.6V

141.6 V~ 170.4V

188.8 V~ 227.2V

236V-284 V

283.2 V~ 340.8V

Dimensions

(mm)

650/260/555

650/260/740

650/260/925

650/260/1110

650/260/1295

Weight

64kg

91kg

118kg

45kg

172kg

Rated current

25A(@25℃)

Max current

48A(@25℃)

Fault current

49A(@25℃)

DoD

90%

Operating

ambient

temperature

-10℃~50℃

RTE

≥95%

Battery pack

in series

Maximum support 10 units in series, series voltage differen ce △V≤0 .5 V

Humidity

5%~95%

Storage

temperature

﹣20℃~50℃/7 days; -20℃~40℃/6 months; 95%RH

cooling

method

Natural cooling

Installation

Wal l- mo un te d/ fl oo r st ac ki ng i ns ta ll at io n

Altitude

≤2000m

communicati

on method

CAN(to PCS)

Certified

product

IEC62619/IEC 62040/IEC 62477/VDE 2510-50 / RCM+ CEC /CE

Tran sp or t

certification

UN38.3

IP rating

IP65

Envir onmenta l

req ui remen ts

RoHS,Reach

Battery

System

Secondary Li-ion Battery System

Technical Specifications 7

21

22

Page 14

System Model

ARK 17.9H-A1

ARK 20.4H-A1

ARK 23.0H-A1

ARK 25.6H-A1

Nominal energy

17.92kWh

20.48kWh

23.04kWh

25.6kWh

Rated energy

16.13kWh

18.43kWh

20.74kWh

23.04kWh

Rated Power

8.96kw

10.24kw

11.52kw

12.8kw

Max Power

17.203kw

19.66kw

22.118kw

24.576kw

Nominal

capacity

50Ah(@25℃)

Rated capacity

45Ah(@25℃)

Nominal voltage

358.4V

409.6V

460.8V

512V

Voltage range

330.4V~397.6V

377.6V~454.4V

424.8V~511.2V

472V~568V

Dimensions

(mm)

650/260/1480

650/260/1665

650/260/1850

650/260/2035

Weight

199kg

226kg

253kg

280kg

Rated current

25A(@25℃)

Max current

48A(@25℃)

Fault current

49A(@25℃)

DoD

90%

Operating

ambient

temperature

-10℃~50℃

RTE

≥95%

Battery pack in

series

Maximum sup po rt 1 0 units in series, se ri es v oltage diff erence △V≤0. 5V

Humidity

5%~95%

Storage

temperature

﹣20℃~50℃/7 days; -20℃~40℃/6 months; 95%RH

cooling method

Natural cooling

Installation

Wal l- mo un te d/ fl oo r st ac ki ng i ns ta ll at io n

Altitude

≤2000m

communication

method

CAN(to PCS)

Certified

product

IEC62619/IEC 62040/IEC 62477/VDE 2510-50 / RCM+ CEC /CE

Tran sp or t

certification

UN38.3

IP rating

IP65

Envir onmenta l

req ui remen ts

RoHS,Reach

Battery System

Secondary Li-ion Battery System

Ø Method for calculating rated capacity:

Rated capacity of the measured module: 45 Ah

Number of modules connected in series: 2~10

Calculated rated capacity (Ah) = 45 Ah *1 =45Ah

Ø The performance will be limited when the temperature is below 0°C.

Notice

Model

Battery designation

Recommended charge instructions

ARK 5.1H-A1

IFpP/41/150/102/[(1P16S)

2S]M/-10+50/90

1.Constant current 25A charging to 108V;

2.Constant current 10A charging to 110V;

3.Constant current 2A charging to 110V;

ARK 7.6H-A1

IFpP/41/150/102/[(1P16S)

3S]M/-10+50/90

1.Constant current 25A charging to 162V;

2.Constant current 10A charging to 165V;

3.Constant current 2A charging to 165V;

ARK 10.2H-A1

IFpP/41/150/102/[(1P16S)

4S]M/-10+50/90

1.Constant current 25A charging to 216V;

2.Constant current 10A charging to 220V;

3.Constant current 2A charging to 220V;

ARK 12.8H-A1

IFpP/41/150/102/[(1P16S)

5S]M/-10+50/90

1.Constant current 25A charging to 270V;

2.Constant current 10A charging to 275V;

3.Constant current 2A charging to 275V;

ARK 15.3H-A1

IFpP/41/150/102/[(1P16S)

6S]M/-10+50/90

1.Constant current 25A charging to 324V;

2.Constant current 10A charging to 330V;

3.Constant current 2A charging to 330V;

ARK 17.9H-A1

IFpP/41/150/102/[(1P16S)

7S]M/-10+50/90

1.Constant current 25A charging to 378V;

2.Constant current 10A charging to 385V;

3.Constant current 2A charging to 385V;

ARK 20.4H-A1

IFpP/41/150/102/[(1P16S)

8S]M/-10+50/90

1.Constant current 25A charging to 432V;

2.Constant current 10A charging to 440V;

3.Constant current 2A charging to 440V;

ARK 23.0H-A1

IFpP/41/150/102/[(1P16S)

9S]M/-10+50/90

1.Constant current 25A charging to 486V;

2.Constant current 10A charging to 495V;

3.Constant current 2A charging to 495V;

ARK 25.6H-A1

IFpP/41/150/102/[(1P16S)

10S]M/-10+50/90

1.Constant current 25A charging to 540V;

2.Constant current 10A charging to 550V;

3.Constant current 2A charging to 550V;

7.2 Battery System designation

23

24

Page 15

7.3 HVC 60050-A1

No.

Items

Specification

1

Model

HVC 60050-A1

2

Input/output voltage range

90~585V

3

Rated current

25A

4

Operating ambient temperature

-10~50℃

5

IP rating

IP65

6

communication method

CAN2.0

7

Dimensions (W/D/H)

W650*D260*H185 mm ±2mm

8

Weight

8.5±1kg

9

Certification

CE-EMC

10

Environmental req ui rements

RoHS

No.

Items

Specification

1

Battery pack Module

ARK 2.5H-A1

2

Nominal Capacity/Energy

50Ah/2.56kWh

3

Rated Capacity/Energy

45Ah/2.3 kWh

4

Nominal Voltage

51.2V

5

Operating Voltage

47.2 - 56.8V

6

Rated current(25℃)

25A

7

Battery Type

Cobalt Free Lithium Iro n

Phosphate (LFP)

8

Operating ambient temperature

-10~50℃

9

Storage conditions

10

Cooling

Natural cooling

11

Dimension (W/D/H)

W650*D260*H185 mm ±2mm

12

Weight

27±1kg

13

Installation

Wal l- mo un te d in st al la ti on /f lo or

standing installation

14

Ingress pro te ct io n

Ip6515Cell safety certification

IEC62619/UL1642

16

safety certification

IEC62619/IEC 62040/IEC

62477/VDE 2510-50 / RCM+ CEC

/CE

17

Tran sp or ta ti on t es t st an da rd

UN38.3

18

Environmental req ui rements

RoHS

19

Battery designation

IFpP/41/150/102/[1P16S]M/10+50/90

XXX X XXXX XXXX XXXX

The 13th to 16th di gits re prese nt t he s eria l n umbe r , ba se 34 ,

from 0001 to ZZZ Z , a utomat ical ly re turn t o 0 every w eek

The 9th t o 12th digits re prese nt t he produc tion date , a t otal of 4 digits ,

s uch as in t he 38th wee k of 2013 is 1338

The 5th t o 8th di gits re prese nt t he s upplie r . G ROWA TT is 0000 , other

outs ourcin g s upplie rs refer to the corres ponding rela tions hip of the suppl ier c ode

The 4th re pres ents t he softw are vers ion c ode , re fer t o G ROW ATT cont rolle d

"S oftwa re c ode hi story tabl e"

The 1th to 3th digi ts indica te the product code : refer to th e p roduct nam ing table and code

corre sponde nce tabl e for deta ils

Appendix I

Ø Barcode coding rules

Bar code number position:

7.4 ARK 2.5H-A1

25

﹣20℃~50℃/7 days; -20℃~40℃

/6 months; 95%RH

1. The 1th to 3th digits indicate the product code : re fe r to t he p roduct naming table and

code correspondence table for details.

2. The 4th repres en ts t he s of tw are version code , refer to GROWATT control le d

"Software code history table".

3. The 5th to 8th digits repres en t th e su pp li er c od e. G RO WATT i s 00 00 , th e su pp li er D i s

0001, and other outsourced suppliers are 00 02 /0 00 3. .. , a nd s o on , pl ea se refer to the

corresponding rel at io ns hi p ta bl e of t he s up pl ie r co de .

4. The 9th to 12th digits repre se nt t he p roduction date, which is repres en te d by 4 d ig it s,

the year is repre se nt ed b y th e fi rs t 2 di gi ts , an d th e we ek i s represented by the last 2

digits, for example, the 38th week of 2013 is 1338.

5. The 13th to 16th digits repres en t th e se ri al n um be r, 34 base , rep resented by 4 digits,

and the characters 0 to Z are used. I and O in the letters are di sc arded.

For example, the product number is SD00.0002100, the prod uc t co de i s AR J, t he

software version is 0, the supplier D is 0001, the prod uc ti on d at e is 2 1t h we ek i n 20 21 ,

and the first barcode of the work ord er i s AR J0 00 01 21 21 00 01 .

26

Page 16

Appendix II

LED light definition

Status

Items

SOC indication

RUN/ALM

Remark

LED1

LED2

LED3

LED4

LED5

Charge

SOC

0%-25%

(t=1S)

RUN/ALM light

on and one SOC

lights flicker

26%-50%

(t=1S)

51%-75%

(t=1S)

76%-99%

(t=1S)

100%

Discharge

SOC

100%-76%

75%-51%

50%-26%

25%-5%

5%-0%

(t=1S)

RUN/ALM light

flicker

Idle

100%-76%

75%-51%

50%-26%

25%-5%

5%-0%

(t=1S)

RUN/ALM light

flicker

Protection

Cell charge

overvoltage

alarm

LED1-LED4 indicates current

remaining capacity

(t=1S)

RUN/ALM light

flicker green

Cell charge

overvoltage

protection

(t=1S)

RUN/ALM light

flicker green

Cell

discharge

undervoltag

e alarm

(t=1S)

RUN/ALM light

flicker green

Cell

discharge

undervoltag

e protection

(t=1S)

RUN/ALM light

flicker green

Charge and

discharge

high

temperatur

e alarm

(t=1S)

RUN/ALM light

flicker green

Charge and

discharge

high

temperature

protection

(t=1S)

RUN/ALM light

flicker green

Charge and

discharge

low

temperature

alarm

(t=1S)

RUN/ALM light

flicker green

Charge and

discharge

low

temperature

protection

(t=1S)

RUN/ALM light

flicker green

PACK

charge

overvoltage

alarm

(t=1S)

RUN/ALM light

flicker green

PACK

charge

overvoltage

protection

(t=1S)

RUN/ALM light

flicker green

PACK

discharge

undervoltag

e alarm

(t=1S)

RUN/ALM light

flicker green

PACK

discharge

undervoltag

e protection

(t=1S)

RUN/ALM light

flicker green

High

temperature

environment

alarm

(t=1S)

RUN/ALM light

flicker green

High

temperature

environment

protection

(t=1S)

RUN/ALM light

flicker green

Cell Large

voltage

differe nc e

alarm

(t=1S)

RUN/ALM light

flicker green

Cell Large

voltage

differe nc e

protection

(t=1S)

RUN/ALM light

flicker green

LED indication Control Mechanism

27

28

Page 17

War ning of

high

temperature

differe nc e

of PACK

module

(t=1S)

RUN/ALM light

flicker green

Fault,perso

nnel

handling

require d

Discharge

short circuit

SOC indicates current rem ai ni ng

capacity

(t=1S)

RUN/ALM light

flicker red

Precharge

short circuit

(t=1S)

RUN/ALM light

flicker red

Precharge

overtime

circuit

(t=1S)

RUN/ALM light

flicker red

Extern al

CAN

communicat

ion failure

(t=1S)

RUN/ALM light

flicker red

Interior

communicat

ion failure

(t=1S)

RUN/ALM light

flicker red

Voltage

sampling

anomaly

protection

(t=1S)

RUN/ALM light

stays red

Current

sampling

fault

(t=1S)

RUN/ALM light

stays red

Main circuit

fault

(t=1S)

RUN/ALM light

stays red

Shenzhen Growatt New Energy Co., Ltd

4-13/F,Building A,Sino-German(Europe) Industrial Park,

Hangcheng Ave,Bao’an District, Shenzhen, China

T

+86 755 2747 1942

service@ginverter.com

E

www.ginverter.com

W

29

Loading...

Loading...