SERIES 200

MIXER OWNER'S MANUAL

4310 N. 126th Street, Brookfield, WI 53005

Phone (262) 781-5020 Fax (262) 781-8120

TABLE OF CONTENTS

About this Manual.......................................................................................................... 2

Read this Owner's Manual Prior to Using Your Grovhac Mixer..............................2

Important Safety Terminology.................................................................................. 2

Mixer Installation............................................................................................................. 3

Handling...................................................................................................................... 3

Mounting..................................................................................................................... 3

Set-up.......................................................................................................................... 4

Mixers with Air Motors....................................................................................................... 4

Mixers with Electric Motors............................................................................................... 4

Before Operating Your Grovhac Mixer....................................................................... 5

Operating Your Grovhac Mixer.................................................................................... 6

Mixers with Air Motors....................................................................................................... 6

Mixers with Electric Motors............................................................................................... 6

Mixer Maintenance....................................................................................................... 7

Motor Maintenance & Service................................................................................. 7

Air Motors.......................................................................................................................... 7

Electric Motors.................................................................................................................. 8

Removing the Mixer's Motor..................................................................................... 9

Direct Drive Mixers............................................................................................................ 9

Tools and Materials Required................................................................................................... 9

To Remove the Motor............................................................................................................... 9

To Replace the Motor............................................................................................................... 9

Gear Drive Mixers........................................................................................................... 10

Tools and Materials Required................................................................................................. 10

To Remove the Motor............................................................................................................. 10

To Replace the Motor............................................................................................................. 10

Gear Box Maintenance & Service......................................................................... 10

Removing the Mixer's Gear Box..............................................................................11

Tools and Materials Required................................................................................................. 11

To Remove the Gear Box....................................................................................................... 11

To Replace the Gear Box....................................................................................................... 11

Notes............................................................................................................................. 13

1 www.grovhac.com

4310 N. 126th Street, Brookfield, WI 53005

Phone (262) 781-5020 Fax (262) 781-8120

ABOUT THIS MANUAL

Read this Owner's Manual Prior to Using Your Grovhac Mixer

Read all instructions prior to operating mixer. Injury to personnel, damage to property, or premature

equipment failure may occur if mixer is improperly installed or operated. Do not discard this manual;

keep this owner's manual for future reference.

Important Safety Terminology

Please see the following table regarding safety terminology used throughout this owner's manual. When

referring to this manual, read the information following each safety term carefully before proceeding.

Failure to follow the recommendations in this manual can result in personal injury or damage to

property.

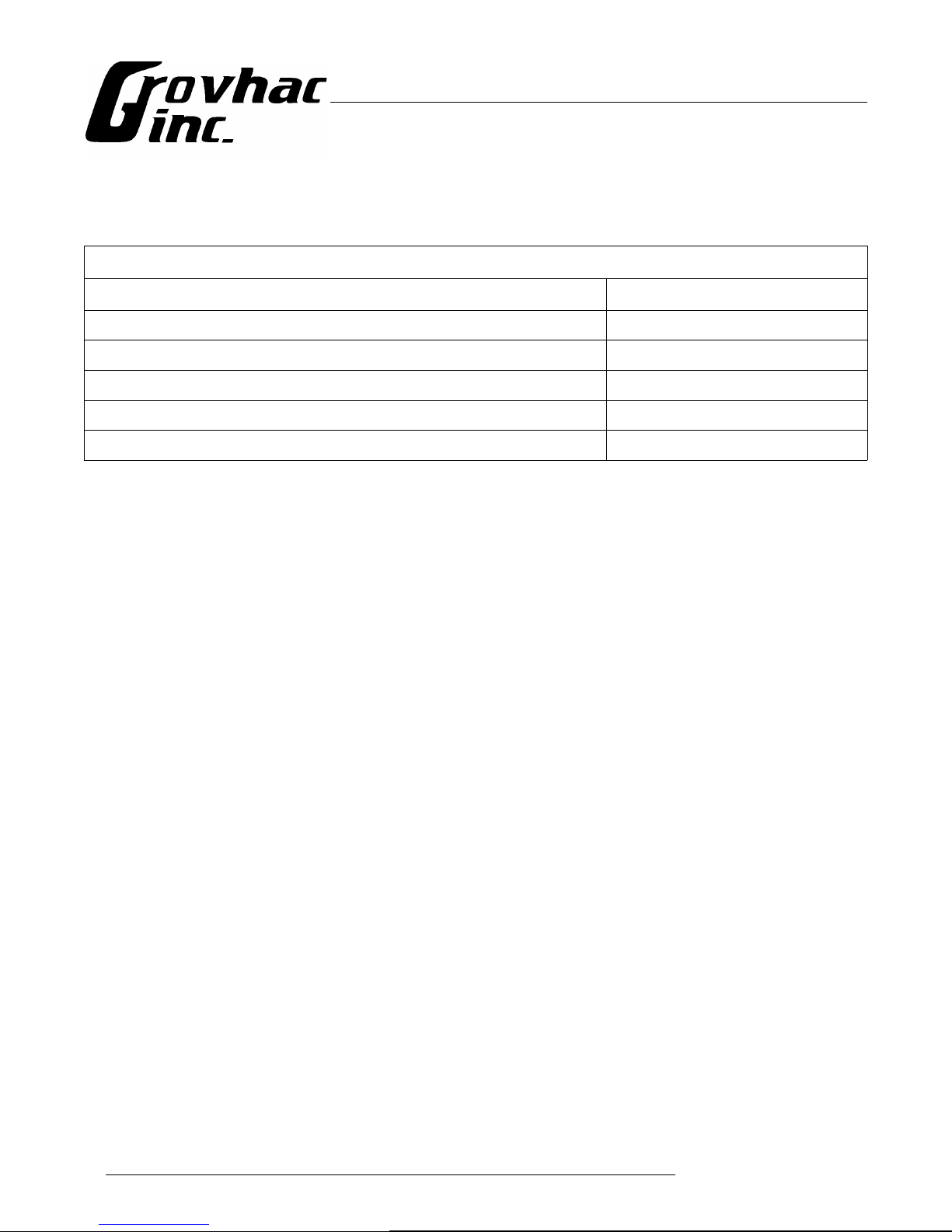

SAFETY TERMS

Result if recommendations are ignored

DANGER Severe personal injury or death will occur if hazard is ignored.

Warning Severe personal injury or death can occur if hazard is ignored.

Caution Minor injury or property damage can occur if hazard is ignored.

2 www.grovhac.com

4310 N. 126th Street, Brookfield, WI 53005

Phone (262) 781-5020 Fax (262) 781-8120

MIXER INSTALLATION

Handling

Never lift a mixer by its shaft. Grovhac mixers & agitators should be handled by lifting only on the

gearbox or drive unit, while also carefully supporting the mixer shaft & blades.

Mounting

Mount your mixer on a level tank surface and fasten securely; your mixer may fasten using bolts,

threaded bung, or clamps. For C-Clamp mixers, never use tools to tighten clamp; hand tighten only.

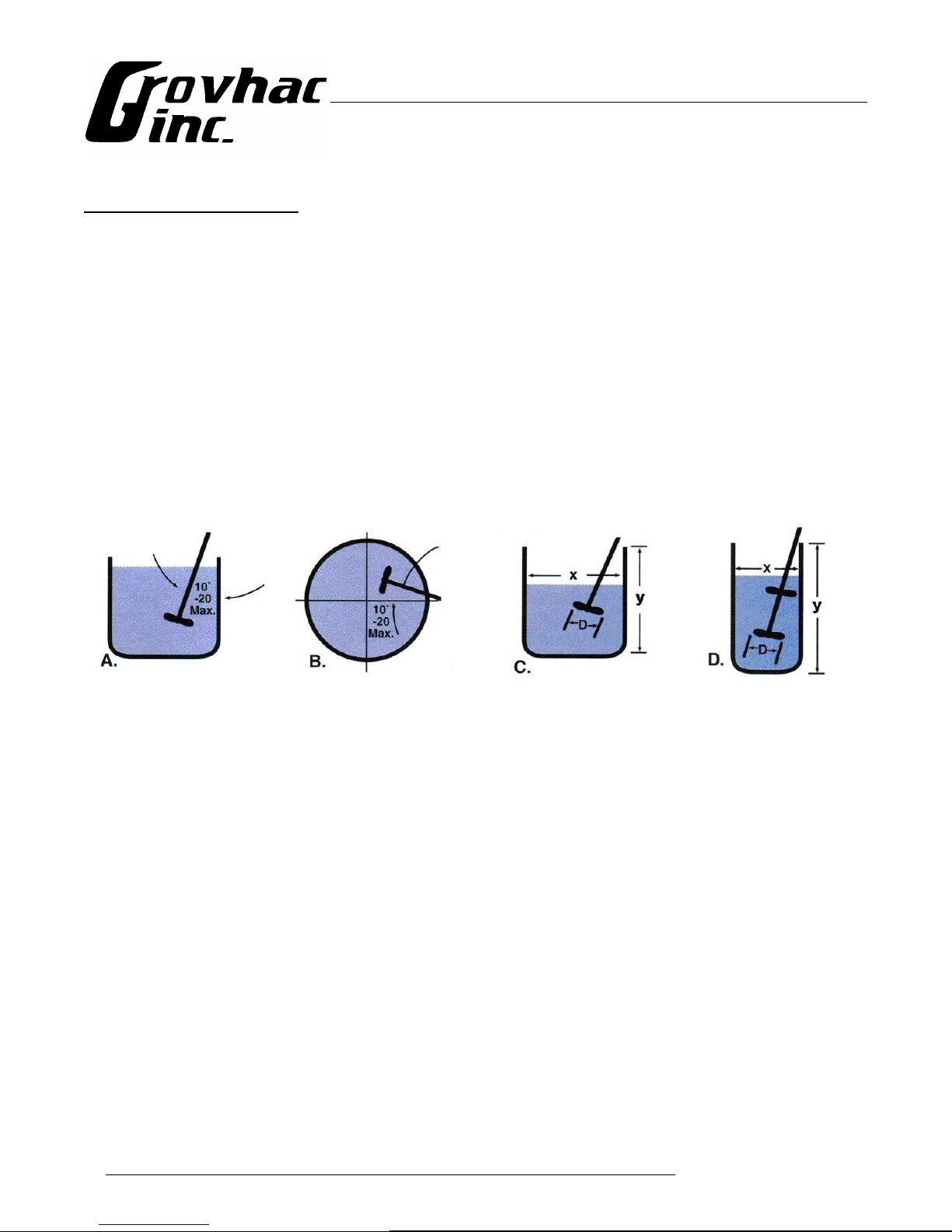

The following illustrations show recommendations for mounting mixers and number of propellers

required.

For proper mixing action in tanks without baffles, mixer

shafts should be mounted 10º to 20º off vertical and 10º to

20º off the tank center line, as shown in Illustrations A & B.

If the depth of the liquid (y) is approximately equal to the

diameter of the tank (x), a single propeller may be used, as

shown in Illustration C. Dual propellers are usually

specified when the liquid depth (y) is 1.5 times (or greater)

the diameter of the tank (x), as shown in Illustration D. The

bottom propeller should be placed 1 to 2 propeller

diameters from the bottom of the tank.

3 www.grovhac.com

4310 N. 126th Street, Brookfield, WI 53005

Phone (262) 781-5020 Fax (262) 781-8120

Set-up

Mixers with Air Motors

Install your air motor using air lines the same size or the next size larger than the intake port of the

motor.

It is recommended that you install a moisture trap and filter/lubricator in the air line ahead of the motor.

Excessive moisture in the air line can cause rust formation in the motor and might also cause ice to form

on the muffler (due to expansion of air through the motor). Lubrication is necessary for the bearings,

shaft seals, and to prevent rust formation.

Note: allowing excess moisture or foreign particles from the air line to enter the motor will nullify any

warranties.

If operating the motor intermittently without automatic air line oiler, place motor in accessible position

for easy lubrication.

A non-reversing motor will operate properly in one direction only; a reversible motor will work equally

well in both directions; all Grovhac mixers are designed to run clockwise when viewed from the top of

the motor.

When coupling or connecting the motor to a driven member, avoid any end or side thrust and never

hammer on the shaft.

Mixers with Electric Motors

For electric motors without electrical plugs, check local codes for wiring instructions.

Before making electrical power connections, check for proper grounding of motor and application. All

electrical contacts and connections must be properly insulated and enclosed. Prior to connecting to the

power line, check nameplate for proper voltage and rotation connection. All Grovhac mixers are

designed to run clockwise when viewed from the top of the motor.

Caution: Your electric motor should be installed in compliance with the National Electric Code,

OSHA, and any other applicable codes, Voltage at motor not to exceed + or – 10% of nameplate

voltage. Authorized person should make all electrical connections.

Motor should be located in a clean and dry area with adequate ventilation. Motor must be protected from

the weather, if installed outdoors.

Warning: use only explosion-proof motors for applications with explosive gases or materials

present.

4 www.grovhac.com

4310 N. 126th Street, Brookfield, WI 53005

Phone (262) 781-5020 Fax (262) 781-8120

BEFORE OPERATING YOUR GROVHAC MIXER

✔ Remove all packaging materials, especially those fastened to the mixing equipment for transit.

✔ Always make sure mixer is properly supported.

✔ Always place mixer shaft in liquid before operating.

✔ Never use for flammables or combustibles without having an approved explosion-proof motor.

✔ Always properly ground mixer when mixing flammables or combustibles.

✔ Always wear protective clothing, eyewear, and follow standard safety procedures.

5 www.grovhac.com

4310 N. 126th Street, Brookfield, WI 53005

Phone (262) 781-5020 Fax (262) 781-8120

OPERATING YOUR GROVHAC MIXER

Mixers with Air Motors

Your air motor is a precision built rotary-type motor and is designed to be driven by compressed air

only. The air motor must not be driven by fluids, particles, solids, or any substance mixed with air,

particularly combustible substances likely to cause explosions.

Warning: solid or liquid material exiting the air motor can cause eye or skin damage – keep away

from air stream.

Warning: some air motor models may exceed 85dB sound level – hearing protection is

recommended.

The stalled or starting torque of your air motor is less than the running torque and will vary depending

on the position at which the vanes stop in relation to the air intake port. Operate motor well below

available line pressure so that full line pressure can be called upon for overloads on motor. The speed

and torque can be regulated by using a pressure regulator or a simple shut-off valve.

Caution: do not allow the air motor to "run free" at high speeds with no loads – excessive internal

heat build-up, loss of internal clearances, and rapid motor damage will result.

Mixers with Electric Motors

Warning: be careful when touching the exterior of an operating motor – it may be hot enough to

cause injury. Normal operating temperature of motor may be high enough to be uncomfortable or to

cause injury if touched.

6 www.grovhac.com

4310 N. 126th Street, Brookfield, WI 53005

Phone (262) 781-5020 Fax (262) 781-8120

MIXER MAINTENANCE

Motor Maintenance & Service

Air Motors

Warning: always disconnect the air supply before servicing.

Use SAE10 oil to lubricate your air motor. For moderate speeds or intermittent operation, one squirt of

oil in bearing oilers per day will suffice. If the duty is continuous or speed is high, use an automatic air

line oiler set to feed one drop per minute. The bearings will receive oil from the rotor chamber during

automatic oiling.

If the motor is sluggish or inefficient, try flushing with a non-combustible solvent. Always flush in a

well ventilated area. To flush with solvent, disconnect the air line and muffler and add several

teaspoons or spray solvent directly into motor. Rotate the shaft by hand in both directions for a few

minutes, re-connect the air line and apply pressure slowly until there is no trace of solvent in the exhaust

air. Warning: wear eye protection and keep face away from exhaust air – foreign material exiting

the air motor can be hazardous. Check the muffler felts or elements for grease, dirt, or other

contaminants. If dirty, wash them in a solvent. Replace the felts or elements and reconnect the muffler.

Re-lubricate the motor with a squirt of oil in the chamber and bearing oilers.

The motor's vanes take up their own wear and will last between 5,000-15,000 hours depending on speed,

method of oiling, operating pressure, and precautions taken in maintaining the motor. If the vanes need

replacing, or if foreign particles are present in the motor chamber, an experienced mechanic may remove

the end plate opposite the drive shaft end. Do not pry open with a screwdriver; prying will dent the

surface of the plate and body, which can cause leaks. A puller tool should be used which will remove the

end plate while maintaining the position of the shaft. New vanes should have the edge with the corners

cut on angle (notched edge if reversible air motor) towards the bottom of the vane slot. New gaskets

should be the proper thickness (similar to onion skin), otherwise the motor will operate inefficiently and

waste air. The end plates should be replaced carefully using an arbor press with a pusher acting on both

races of the bearing while supporting the opposite (drive) end of the shaft. This will eliminate the risk of

stress fatigue and misalignment of the rotor.

7 www.grovhac.com

4310 N. 126th Street, Brookfield, WI 53005

Phone (262) 781-5020 Fax (262) 781-8120

Please see the following chart for motor top clearance (between rotor and bore) and total end clearance

(between the sides of the rotor and the end plates).

AIR MOTOR CLEARANCE CHART

Models Total End Clearance (in / mm) Top Clearance (in / mm)

1101, 1111, 1111-15, 1UP 0.0020" / 0.0508mm 0.0015" / 0.0381mm

1102, 1302 0.0025" / 0.0635mm 0.0015" / 0.0381mm

1103, 1223, 1303 0.0035" / 0.0889mm 0.0015" / 0.0381mm

1104, 1224, 1304 0.0035" / 0.0889mm 0.0015" / 0.0381mm

1225, 1305 0.0048" / 0.1219mm 0.0015" / 0.0381mm

In many cases, it is quicker and more cost effective to send the motor back to the factory for repair. For

more information on air motor repairs, please contact your Grovhac representative.

Electric Motors

Warning: always disconnect the power source before working on or near a motor or its connected

load.

Warning: use approved non-explosive and non-flammable materials when cleaning electrical

equipment. Do not attempt to clean the motor while electrical power is connected.

Your electric motor is supplied with pre-lubricated ball bearings, lubricated for life of the bearing. Do

not attempt to lubricate the motor's bearings.

Direct current (DC) motors have motor brushes that need periodic inspection and replacement as wear

indicates. Brush wear is greatly influenced by individual application. It is recommended that brush wear

be checked at early intervals of operation in order to determine future required inspection. Standard

motor brushes have an initial length of 1¼". When the brushes are worn to a length of 5/8" they should

be replaced.

If mechanical or electrical failure occurs, first check for proper electrical connections, fusing, or unusual

binding of mechanical connections. If unable to correct the problem, please contact your Grovhac

representative, describe the problem, and include complete motor nameplate data.

8 www.grovhac.com

Removing the Mixer's Motor

Direct Drive Mixers

Tools and Materials Required

✔ 9/16" box wrench or adjustable wrench

✔ 5/8" box wrench or adjustable wrench

✔ 5/16" Allen wrench

✔ Two (2) 7/16"-14 bolts, approximately 3" long

✔ LOCTITE® or similar thread bonding agent

✔ Emery paper or similar light abrasive

4310 N. 126th Street, Brookfield, WI 53005

Phone (262) 781-5020 Fax (262) 781-8120

To Remove the Motor

1) Remove the four (4) 3/8"-16 x 1" bolts and lock washers that secure the motor's C-face to the

bearing housing.

2) Thread two (2) 7/16"-14 bolts (not supplied) into the 7/16" threaded holes of the bearing

housing face. Alternately tighten the two bolts to push the motor off the bearing housing

evenly (note: stainless steel shaft coupling will normally come off with motor)

3) Use a 5/16" Allen wrench to loosen the hollow set-screw in the shaft coupling. Remove the

shaft coupling.

To Replace the Motor

1) Clean the inside diameter of the bearing in the bearing housing. Clean the outside of the

stainless steel shaft coupling.

2) Remove the hollow set-screw and its set key from the shaft coupling.

3) Slide the shaft coupling onto the motor shaft. Align the hole in the shaft coupling with the

keyway on the motor shaft. Insert the set key into the hole of the shaft coupling while

aligning the keyway with the motor shaft. You may need a large screwdriver to adjust the set

key so it lines up with the motor shaft.

4) Place a few drops of LOCTITE or similar thread bonding agent on the threads of the hollow

set-screw. Thread the hollow set-screw into the coupling and fully tighten using a 5/16"

Allen wrench.

5) Slide the bearing housing assembly over the shaft coupling (note: due to close tolerances

and thread locking compound build-up, you may need to clean the shaft coupling with emery

paper or a similar light abrasive for it to fit inside the bearing).

9 www.grovhac.com

4310 N. 126th Street, Brookfield, WI 53005

Phone (262) 781-5020 Fax (262) 781-8120

6) Replace the four (4) 3/8"-16 x 1" motor bolts and lock washers, but do not yet fully tighten.

7) Start motor and, while the motor is running, alternately tighten the four (4) motor bolts until

they are secure (note: motor bolts must be tightened in this manner to ensure proper

alignment of the coupling and bearing housing components).

Gear Drive Mixers

Tools and Materials Required

✔ 9/16" box wrench, socket wrench, or adjustable wrench

✔ Small amount of light grease

To Remove the Motor

1) Remove the four (4) 3/8"-16 x 1" bolts w/ lock washers that secure the motor's C-face to the

bearing housing.

2) Slide the motor up and out of the gear box (note: ensure that the shaft key comes with the

motor).

To Replace the Motor

1) Place key in the motor shaft keyway. Lightly lubricate the motor output shaft and the keyway

with a light grease.

2) Slide the motor output shaft into the hollow shaft of the gear box (note: ensure that the key

stays on the motor shaft).

3) Align the holes of the gear box face with the holes on the motor C-face and replace the four

(4) bolts (3/8-16 x 1") w/ lock washers to secure the motor to the gear box.

Gear Box Maintenance & Service

Your Grovhac gear reducer has been tested and adjusted at the factory. Dismantling or replacement of

components will void the warranty.

The gear reducer is properly filled at the factory with sufficient lubricant for all mounting positions. The

reducer may be mounted in any supplier approved mounting position without modification or changing

oil level. The oil should be changed approximately every six (6) months or 2,300 hours; please see your

gear box's part sheet for instructions on changing gear box lubricant.

10 www.grovhac.com

Removing the Mixer's Gear Box

Tools and Materials Required

✔ 9/16" box wrench or adjustable wrench

✔ 5/8" box wrench or adjustable wrench

✔ 5/16" Allen wrench

✔ Two (2) 7/16"-14 bolts, approximately 3" long

✔ LOCTITE® or similar thread bonding agent

✔ Emery paper or similar light abrasive

To Remove the Gear Box

Note: Remove the mixer's motor from the gear box before attempting to remove the gear box

(see Removing the Mixer's Motor, Gear Drive Mixers, To Remove the Motor section).

4310 N. 126th Street, Brookfield, WI 53005

Phone (262) 781-5020 Fax (262) 781-8120

1) Remove the four (4) 3/8"-16 x 1" bolts and lock washers that secure the gear box's C-face to

the bearing housing.

2) Thread two (2) 7/16"-14 bolts (not supplied) into the 7/16" threaded holes of the bearing

housing face. Alternately tighten the two bolts to push the gear box off the bearing housing

evenly (note: coupling will normally come off with gear box)

3) Use a 5/16" Allen wrench to loosen the hollow set-screw in the shaft coupling. Remove the

shaft coupling.

To Replace the Gear Box

Note: Replace the mixer's motor on the gear box before attempting to replace the gear box (see

Removing the Mixer's Motor, Gear Drive Mixers, To Replace the Motor section).

1) Clean the inside diameter of the bearing in the bearing housing. Clean the outside of the

stainless steel shaft coupling.

2) Remove the hollow set-screw and its set key from the shaft coupling.

3) Slide the shaft coupling onto the gear box shaft. Align the hole in the shaft coupling with the

keyway on the gear box shaft. Insert the set key into the hole of the shaft coupling while

aligning the keyway with the gear box shaft. You may need a large screwdriver to adjust the

set key so it lines up with the gear box shaft.

4) Place a few drops of LOCTITE or similar thread bonding agent on the threads of the hollow

set-screw. Thread the hollow set-screw into the coupling and fully tighten using a 5/16"

Allen wrench.

11 www.grovhac.com

4310 N. 126th Street, Brookfield, WI 53005

Phone (262) 781-5020 Fax (262) 781-8120

5) Slide the bearing housing assembly over the shaft coupling (note: due to close tolerances

and thread locking compound build-up, you may need to clean the shaft coupling with emery

paper or a similar light abrasive for it to fit inside the bearing).

6) Replace the four (4) 3/8"-16 x 1" gear box bolts and lock washers, but do not yet fully

tighten.

7) Start motor and, while the motor is running, alternately tighten the four (4) gear box bolts

until they are secure (note: gear box bolts must be tightened in this manner to ensure proper

alignment of the coupling and bearing housing components).

12 www.grovhac.com

4310 N. 126th Street, Brookfield, WI 53005

Phone (262) 781-5020 Fax (262) 781-8120

NOTES

13 www.grovhac.com

Grovhac, Inc. Phone (262) 781-5020

4310 N. 126th Street Fax (262) 781-8120

Brookfield, WI 53005 USA www.grovhac.com

©2005 Grovhac, Inc.

Loading...

Loading...