Grove Gear E Series Right Angle User Manual

Ironman E Series

Installation, Lubrication and

Maintenance Instructions

A Regal Brand

Important Selection Information

Read ALL instructions and safety precautions prior to operating

unit. Injury to personnel or unit failure may be caused by improper

installation, maintenance, or operation.

Check to verify that the application does not exceed the capacities

published in the current catalog.

Written authorization from Grove Gear is required to operate or use

gear units in man lift or people moving devices.

The system of connected rotating parts must be free from critical

speed, torsional, or other type vibration, regardless of how induced.

The responsibility for this system analysis lies with the purchaser of

the gear unit.

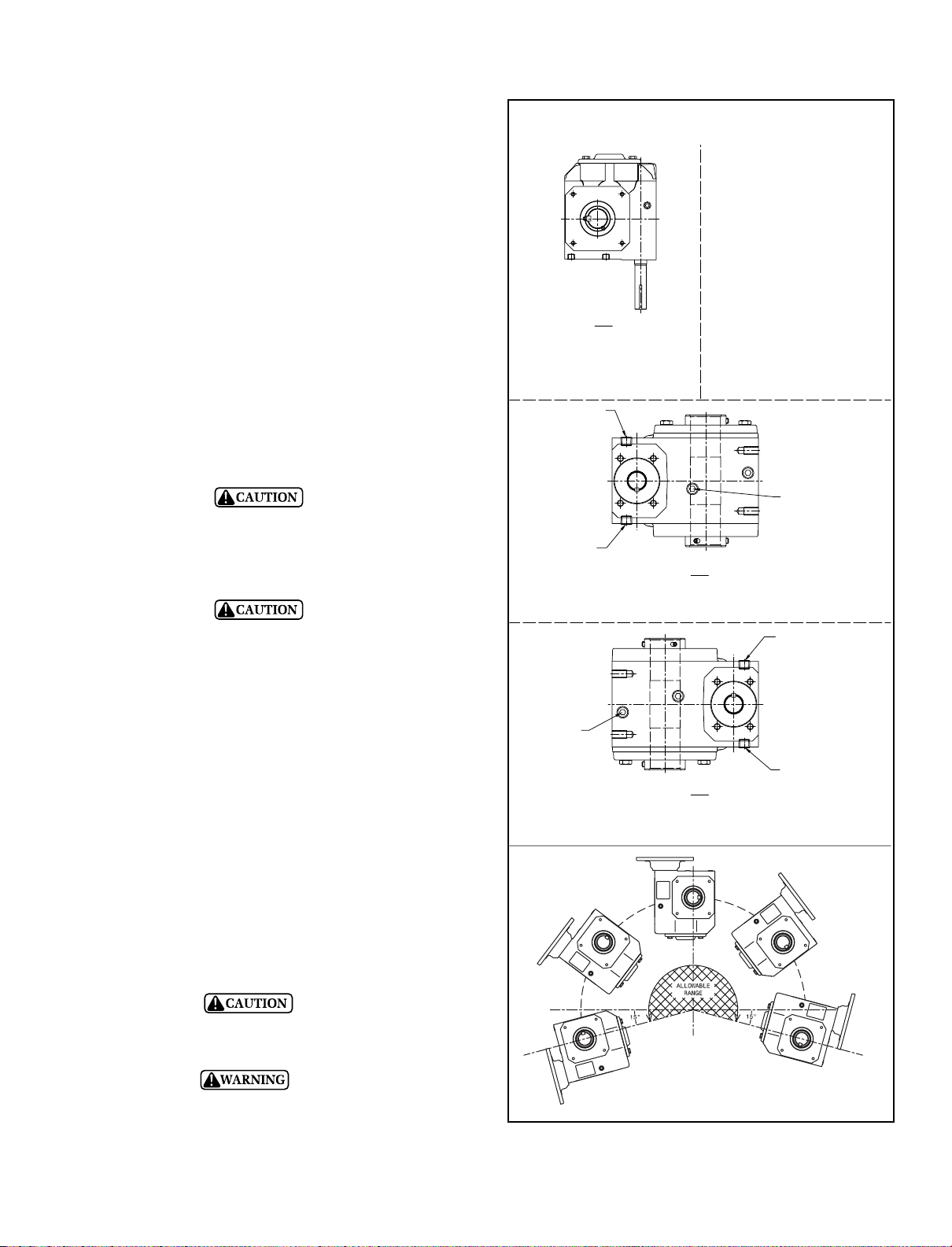

Figure 1

MOUNTING POSITION FIGURES FOR

GROVE GEAR E SERIES REDUCERS

Buyer shall be solely responsible for determining the adequacy of the

product for any and all uses to which the buyer shall apply the product.

The application by buyer shall not be subject to any implied warranties

of merchantability or fitness for a particular purpose.

Grove Gear E Series Reducer Models

These instructions apply to all Grove Gear E Series Reducer Models

18HE to 60HE.

Lubrication

All Grove Gear E Series Reducers are splash lubricated. The

unique design of the reducers permits nearly universal mounting by

placing a fill, drain and oil level plug at the proper location for mounting positions. See mounting figures on this page.

Review the approved mounting positions and lubrication levels

identified in the Mounting Position Figures in Figure 1. Do not

deviate from the mounting positions or lubrication levels shown

without contacting Factory.

After selecting the position that the unit will be mounted but before

operating: Remove Fill Plug, clean threads on the removed plug and

the plug hole with degreaser. Install Breather Plug securely in gear

case. Note — Plug with breather must always be installed on top most

plug hole of gear case, opposite Drain Plug.

Variations From Normal Conditions

Input speeds higher than 1800 RPM may require an adjustment in oil

level. For vertical output, factory modifications (grease pack and nilos

ring) are required. For input speeds up to 1150 RPM, the high oil level

can be used, without factory modifications. This level, as specified in

the oil capacity chart will be at the center of the top bearing. It can

be checked with a dipstick to obtain the level specified in the chart

from the top housing face.

-INPUT VERTICAL/DOWN-

B6

OUTPUT HORIZONTAL

NOT RECOMMENDED

POSITION

(FACTORY MODIFICATIONS REQUIRED)

FILL & VENT PLUG

LEVEL

DRAIN

V5

-OUTPUT VERTICAL, COVER SIDE UP-

INPUT HORIZONTAL

(FACTORY MODIFICATIONS REQUIRED)

FILL & VENT PLUG

LEVEL

DRAIN

V6

-OUTPUT VERTICAL, COVER SIDE DOWN-

INPUT HORIZONTAL

(FACTORY MODIFICATIONS REQUIRED)

Lubricant

Use only Mobil PAG Synthetic oil.

Oil should be changed with regular frequency if unit is used in a severe

environment such as dusty or humid.

Oil, housings, and other components can reach high temperatures

during operation, and can cause severe burns. Use extreme care

when removing lubrication plugs and vents while servicing the unit.

ALLOWABLE MOUNTING ORIENTATION

(WITHOUT FACTORY MODIFICATION)

Loading...

Loading...