Page 1

www.groupdynamics-laundry.com

sales@groupdynamics.lv

INDUSTRIAL TUMBLE DRYERS

55kg

77kg

BASIC INSTALLATION / OPERATION

70421501R3EN

Publication date: Jan 2012

Page 2

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Page 3

sic Installation/Operation

FOR YOUR

SAFETY, the information in

this manual must be followed to minimize

the risk of fire or explosion or to prevent

property damage, personal injury or

death.

W033

•

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

– Do not try to light any appliance.

– Do not touch any electrical switch; do

not use any phone in your building.

– Clear the room, building or area of all

occupants.

– Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

– If you cannot reach your gas supplier,

call the fire department.

• Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

W052

WA

RNING

FOR YOUR SAFETY

Do not sto

re or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

W053

T

o reduce the risk of fire, electric shock,

serious injury or death to persons when

using the tumbler unit, follow these basic

precautions:

• Read all instructions before using

tumbler.

• DO NOT tamper with controls.

• DO NOT bypass any safety devices.

• Always follow the fabric care

instructions supplied by the garment

manufacturer.

• Remove laundry immediately after the

tumbler stops.

• DO NOT reach into tumbler if cylinder is

revolving.

To avoid creating any flammable vapors

which may explode, ignite or cause

corrosive damage, DO NOT dry the

following materials:

• Articles that have been cleaned in,

soaked in, washed in or spotted with

gasoline, dry-cleaning solvents or other

flammable/explosive substances.

• Plastics or articles containing foam

rubber or similarly textured rubberlike

materials.

• Articles that have traces of flammable

substances like cooking oil, machine

oil, flammable chemicals or thinner.

• Articles containing wax or cleaning

chemicals.

• Fiberglass curtains or draperies (unless

the label says it can be done).

W440R1

WA

RNING

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Ba

Installation mus

t conform with local codes.

IMPORTANT: Information must be obtained from

a local gas supplier on instructions to be followed if

the user smells gas. These instructions must be

posted in a prominent location. Step-by-step

instructions of the above safety information must

be posted in a prominent location near the tumbler

for customer use.

©

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT70421501 (EN)

1

Page 4

sic Installation/Operation

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Ba

Table of

Contents

Introduction...

Model Identification ............................................................................. 3

Wiring Diagram Location..................................................................... 3

Serial Plate Location............................................................................. 4

Safety Information.............................................................................. 5

Important Safety Instructions ............................................................... 5

Installation........................................................................................... 7

Specifications and Dimensions............................................................. 7

120 Pound Tumble Dryer Dimensions and Exhaust

Outlet Locations ............................................................................. 8

170 Pound Tumble Dryer Dimensions and Exhaust

Outlet Locations ............................................................................. 9

Electric and Gas Connection Locations for Gas Models ................. 10

Electric and Steam Connection Locations for Steam Models ......... 11

Electric Connection Location for Electric Models .......................... 12

Position and Level the Tumble Dryer................................................... 13

Fire Suppression System....................................................................... 14

Water Requirements......................................................................... 14

Water Connections........................................................................... 14

Electrical Requirements ................................................................... 14

Auxiliary Alarm ............................................................................... 15

Gas Requirements................................................................................. 15

Natural Gas and Liquefied Petroleum.............................................. 15

European Gas ................................................................................... 15

General Information......................................................................... 16

Exhaust Requirements .......................................................................... 18

Make-Up Air.................................................................................... 18

Venting............................................................................................. 18

Electrical Requirements........................................................................ 19

Grounding Instructions .................................................................... 19

Steam Requirements ............................................................................. 20

Thermal Oil Prep .................................................................................. 20

...................................................................................... 3

© Pub

lished by permission of the copyright owner

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

2

Operation............................................................................................. 23

Emergency Stop Button........................................................................ 23

Operating Instructions .......................................................................... 23

Step 1: Clean Lint Screen/Compartment ......................................... 23

Step 2: Load Laundry....................................................................... 23

Step 3: Determine Control Type and Temperature Setting ............. 23

Step 4: Remove Laundry ................................................................. 23

Control Instructions .............................................................................. 24

Dual Digital Timer Control.............................................................. 24

Electronic OPL Control ................................................................... 25

LED OPL Control ............................................................................ 27

UniLinc Control ............................................................................... 28

Ignition Control Operation ................................................................... 29

Disposal of Unit................................................................................... 30

7

0421501 (EN)© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

Page 5

Model Identification

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Introduction

sic Installation/Operation

Ba

Informati

on in this manual is applicable to these models.

Gas

120 Pound

170 Pound

GU120L

GU120N

HU120L

HU120N

KU120L

KU120N

LU120L

LU120N

PU120L

GU170L

GU170N

HU170L

HU170N

KU170L

KU170N

LU170L

LU170N

PU170L

PU120N

SU120L

SU120N

UU120L

UU120N

XU120L

XU120N

YU120L

YU120N

PU170N

SU170L

SU170N

UU170L

UU170N

XU170L

XU170N

YU170L

YU170N

Includes models with the following control suffixes:

GU120S

GU120T

HU120S

HU120T

KU120S

KU120T

LU120S

LU120T

PU120S

GU170S

GU170T

HU170S

HU170T

KU170S

KU170T

LU170S

LU170T

PU170S

Steam/Thermal Oil Electric

PU120T

SU120S

SU120T

UU120S

UU120T

XU120S

XU120T

YU120S

YU120T

PU170T

SU170S

SU170T

UU170S

UU170T

XU170S

XU170T

YU170S

YU170T

HU120E

SU120E

UU120E

YU120E

Not Applicable

RE – reversing

LED OPL

RM – reversing OPL Micro

iring Diagram Location

W

Th

e wiring diagram is located in the junction or

RQ – reversing dual digital timer

RU – reversing UniLinc OPL

contactor box.

©

70421

501 (EN)

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

3

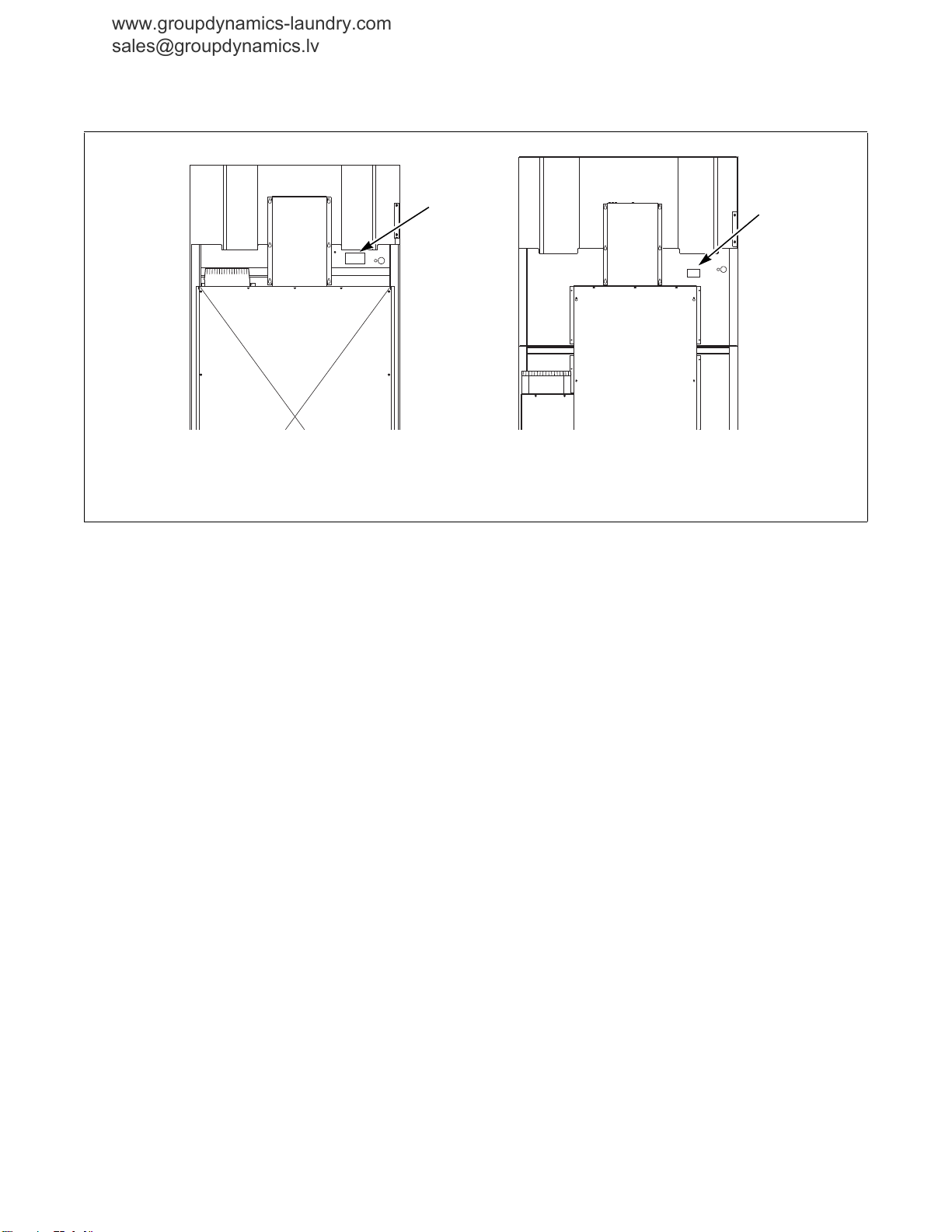

Page 6

sic Installation/Operation

TMB2288N

1

1

1

20 POUND TUMBLE DRYER

170

POUND TUMBLE DRYER

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Ba

Serial Plate Location

1 Serial Plate

TMB2288N

©

4

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

7

0421501 (EN)

Page 7

Safety Information

Haza

rdous Voltage. Can cause shock, burn

or cause death. Allow machine power to

remain off for two minutes prior to working

in and around AC inverter drive.

W359

WA

RNING

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Save These Instructions

sic Installation/Operation

Ba

Import

1.

2. Refer to the GROUNDING INSTRUCTIONS

3. Do not dry articles that have been previously

4. Do not allow children to play on or in the tumble

5. Before the tumble dryer is removed from service

6. Do not reach into the tumble dryer if the cylinder

7. Do not install or store the tumble dryer where it

8. Do not tamper with the controls.

9. Do not repair or replace any part of the tumble

10. Do not use fabric softeners or products to

11. To reduce the risk of fire, DO NOT DRY plastics

70421

ant Safety Instructions

Read all instructions before using the tumble

dryer.

for the proper grounding of the tumble dryer.

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, or other

flammable or explosive substances, as they give

off vapors that could ignite or explode.

dryer. This appliance is not intended for use by

young children or infirm persons without

supervision. Young children should be

supervised to ensure that they do not play with

the appliance.

or discarded, remove the door to the drying

compartment and the door to the lint

compartment.

is revolving.

will be exposed to water and/or weather.

dryer, or attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that you understand and have the

skills to carry out.

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

or articles containing foam rubber or similarly

textured rubberlike materials.

©

501 (EN)

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

12. Always clean the lint filter daily.

13. Keep area around the exhaust opening and

adjacent surrounding area free from the

accumulation of lint, dust and dirt.

14. The interior of the tumble dryer and the exhaust

duct should be cleaned periodically by qualified

service personnel.

15. If not installed, operated and maintained in

accordance with the manufacturer’s instructions

or if there is damage to or mishandling of this

product’s components, use of this product could

expose you to substances in the fuel or from fuel

combustion which can cause death or serious

illness and which are known to the State of

California to cause cancer, birth defects or other

reproductive harm.

16. Tumble dryer will not operate with the loading

door open. DO NOT bypass the door safety

switch to permit the tumble dryer to operate with

the door open. The tumble dryer will stop

tumbling when the door is opened. Do not use the

tumble dryer if it does not stop tumbling when

the door is opened or starts tumbling without

pressing or turning the START mechanism.

Remove the tumble dryer from use and call for

service.

17. Tumble dryer will not operate with lint panel

open. DO NOT bypass lint panel safety switch to

permit the tumble dryer to operate with the lint

panel open.

18. Do not put articles soiled with vegetable or cooking

oil in the tumble dryer, as these oils may not be

removed during washing. Due to the remaining

oil, the fabric may catch on fire by itself.

19. To reduce the risk of fire, DO NOT put clothes

which have traces of any flammable substances

such as machine oil, flammable chemicals,

thinner, etc. or anything containing wax or

chemicals such as in mops and cleaning cloths, or

anything dry-cleaned at home with dry-cleaning

solvent in the tumble dryer.

20. Use the tumble dryer only for its intended

purpose, drying fabrics.

21. ALWAYS disconnect and lockout the electrical

power to the tumble dryer before servicing.

Disconnect power by shutting off appropriate

breaker or fuse.

5

Page 8

sic Installation/Operation

WA

RNING

T

o reduce the risk of serious injury, install

lockable door(s) to prevent public access

to rear of tumble dryers.

W055R1

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Ba

Install this tumble dryer according to the

22.

INSTALLATION INSTRUCTIONS. All

connections for electrical power, grounding, and

gas supply must comply with local codes and be

made by licensed personnel when required.

23. Remove laundry immediately after tumble dryer

stops.

24. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of reach of children at all times

(preferably in a locked cabinet).

25. Do not tumble fiberglass curtains and draperies

unless the label says it can be done. If they are

dried, wipe out the cylinder with a damp cloth to

remove particles of fiberglass.

26. Always follow the fabric care instructions

supplied by the garment manufacturer.

27. Never operate the tumble dryer with any guards

and/or panels removed.

28. DO NOT operate the tumble dryer if it is

smoking, grinding, has missing or broken parts.

29. DO NOT bypass any safety devices.

30. Solvent vapors from dry-cleaning machines

create acids when drawn through the heater of the

drying unit. These acids are corrosive to the

tumble dryer as well as to the laundry load being

dried. Be sure make-up air is free of solvent

vapors.

31. Failure to install, maintain, and/or operate this

machine according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

6

©

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

7

0421501 (EN)

Page 9

sic Installation/Operation

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Ba

Installation

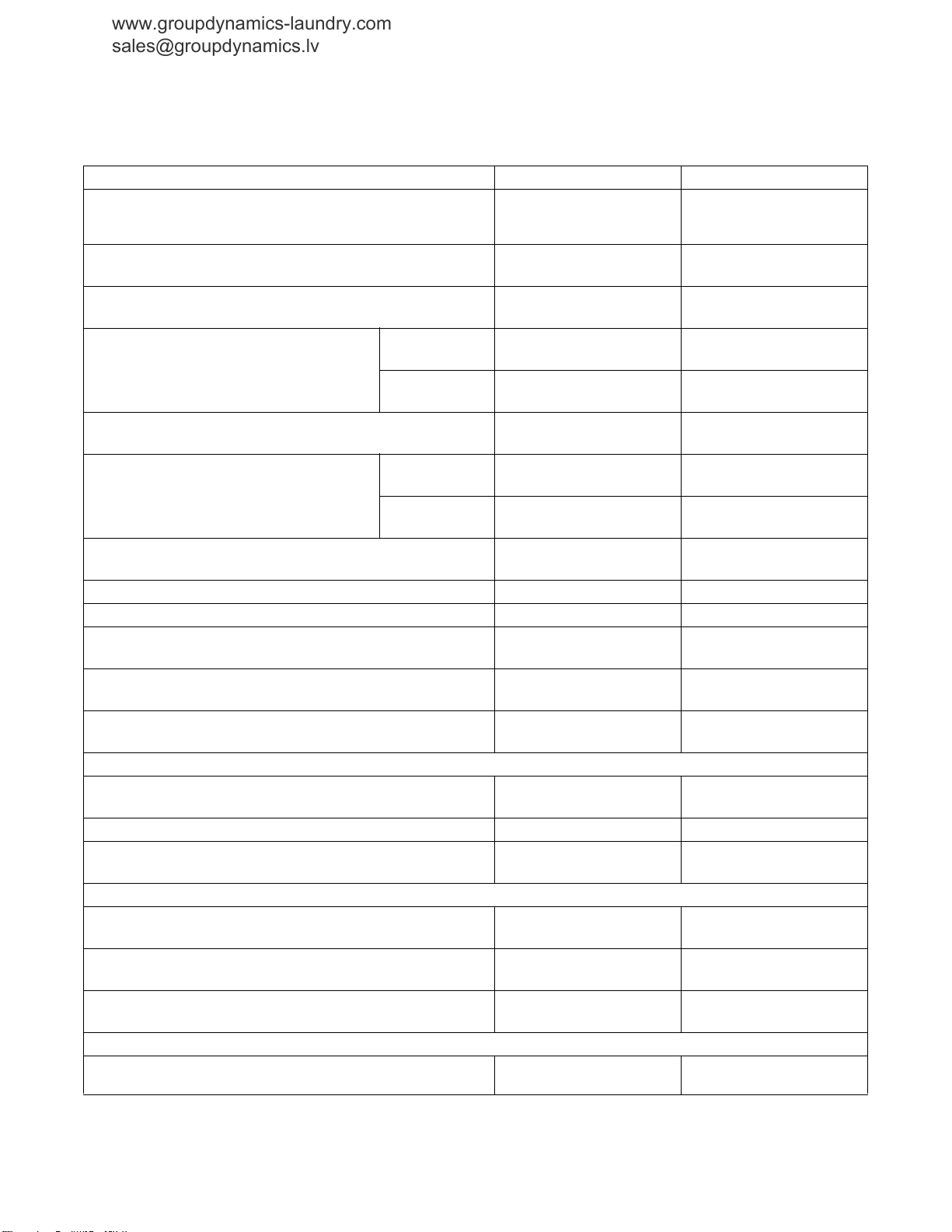

S

pecifications and Dimensions

S

pecifications 120 Pound 170 Pound

Noise level measured during operation at operator

position of 1 m (3.3 ft.) in front of machine and 1.6 m

(5.2 ft.) from the floor.

Cylinder Size:

mm (in.)

Cylinder Capacity dry weight:

kg (lbs.)

Gas and

Standard Packaging Weight:

kg (lbs.)

Standard Packaging Shipping

Dimensions: mm (in.)

Slat Crate Packaging Weight:

kg (lbs.)

Slat Crate Shipping Dimensions:

mm (in.)

Cylinder Motor Horsepower 3/4 3/4

Fan Motor Horsepower 13

Air Outlet Diameter:

mm (in.)

Maximum Static Back Pressure:

mbar (inches W.C.)

Maximum Airflow:

l/sec (C.F.M.)

Net Weight (approximate):

kg (lbs.)

Gas Connection 3/4 in. NPT 1 in. NPT

Gas Burner Rating:

Mj/hr. (Btu/hr.)

Net Weight (approximate):

kg (lbs.)

Steam Connection

Steam Coil Rating at 100 psig:

Boiler Horsepower (Btu/hr.)

Heating Element Rating:

Kilowatts (kW)

= Not Applicable

N/A

Electric

Steam

Gas and

Electric

Steam

Gas Models

Steam Models

Electric Models

66 dBA 66 dBA

1118 x 1041

(44 x 41)

54.4

(120)

607

(1338)

656

(1446)

1232 x 1829 x 2286

(48.5 x 72 x 90)

656

(1447)

702

(1547)

1308 x 1880 x 2305

(51.5 x 74 x 90.75)

254

(10)

0.8

(0.3)

755

(1600)

580

(1275)

316

(300,000)

625

(1375)

3/4 in. NPT 3/4 in. NPT inlet

11.7

(405,000)

60 kW N/A

1289 x 1080

(50.75 x 42.5)

77.1

(170)

756

(1667)

806

(1776)

1473 x 1892 x 2515

(58 x 74.5 x 99)

812

(1791)

858

(1891)

1549 x 1943 x 2534

(61 x 76.5 x 99.75)

300

(12)

(0.3)

1156

(2450)

716

(1575)

421

(395,000)

761

(1675)

1 in. NPT outlet

18.8

(648,000)

0.8

©

70421

501 (EN)

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

7

Page 10

sic Installation/Operation

TMB2326N

A

B

C

D

U

V

X

H

F

Z

Y

W

E

G

I

T

OP VIEW OF

EXHAUST

DUCT

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Ba

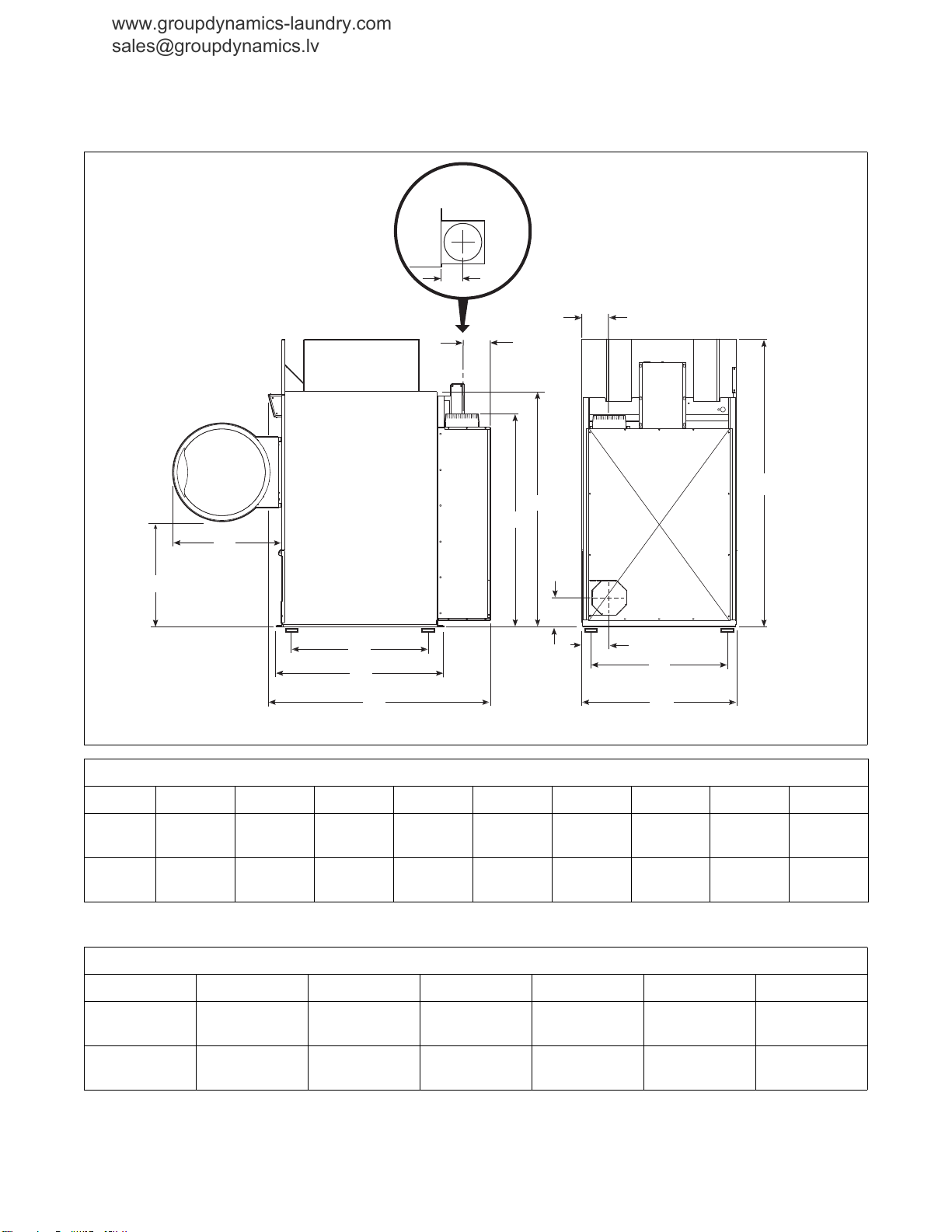

120 Pound Tumble Dryer Dimensions and

Exhaust Outlet Locations

binet Dimensions

ModelsABCDEFGH I

120L/N/E

120S

797 mm

(31.38 in.)

797 mm

(31.38 in.)

Refer to Position an

826 mm

(32.5 in.)

826 mm

(32.5 in.)

d Level the Tumbler to temporarily reduce the heights of these models.

1242 mm

(48.91 in.)

1242 mm

(48.91 in.)

Exha

Models U V W X Y Z

120L/N/E

120S

1612 mm

(63.45 in.)

1542 mm

(60.7 in.)

214 mm

(8.44 in.)

214 mm

(8.44 in.)

Ca

1268 mm

(49.91 in.)

1268 mm

(49.91 in.)

1725 mm

(67.92 in.)

1725 mm

(67.92 in.)

1153 mm

(45.38 in.)

1153 mm

(45.38 in.)

ust Outlet Dimensions and Locations

190 mm

(7.5 in.)

190 mm

(7.5 in.)

208 mm

(8.18 in.)

208 mm

(8.18 in.)

1178 mm

(46.38 in.)

1178 mm

(46.38 in.)

222 mm

(8.75 in.)

222 mm

(8.75 in.)

2177 mm

(85.7 in.)

2121 mm

(83.5 in.)

TMB2326N

1778 mm

(70 in.)

1778 mm

(70 in.)

208 mm

(8.18 in.)

208 mm

(8.18 in.)

©

8

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

7

0421501 (EN)

Page 11

170 Pound Tumble Dryer Dimensions and

A

B

C

D

W

H

F

Y

X

V

Y

T

OP VIEW OF

EXHAUST

DUCT

E

G

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Exhaust Outlet Locations

sic Installation/Operation

Ba

ModelsABCDEFGH

170L/N/S

860 mm

(33.86 in.)

Refer to Position an

826 mm

(32.5 in.)

d Level the Tumble Dryer to temporarily reduce the heights of these models.

Models V W X Y

170L/N/S

©

70421

501 (EN)

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

Exha

1076 mm

(42.38 in.)

Ca

1289 mm

(50.75 in.)

ust Outlet Dimensions and Locations

binet Dimensions

1314 mm

(51.75 in.)

1749 mm

(68.85 in.)

171 mm

(6.75 in.)

1324 mm

(52.12 in.)

222 mm

(8.75 in.)

1349 mm

(53.12 in.)

TMB2290N

2388 mm

(94 in.)

178 mm

(7 in.)

9

Page 12

sic Installation/Operation

A

C

C

A

B

D

B

D

120

L/N

17

0L/N

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Ba

Electric and Gas Connection Locations

for Gas Models

Mo

dels

120L/N

170L/N

NOTE: These

Electrical Connection Gas Connection

ABCDDiameter

466 mm

(18.34 in.)

533 mm

(21 in.)

1977 mm

(77.84 in.)

2057 mm

(81 in.)

figures are approximate dimensions only.

318 mm

(12.5 in.)

377 mm

(14.85 in.)

1791 mm

(70.5 in.)

1966 mm

(77.4 in.)

TMB2255N

3/4 in. NPT

1 in. NPT

©

10

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

7

0421501 (EN)

Page 13

Electric and Steam Connection Locations

A1

B1

12

0S 170S

A2

B2

D

E

F

A1

B1

B2

A2

D

E

F

C

C

www.groupdynamics-laundry.com

sales@groupdynamics.lv

for Steam Models

sic Installation/Operation

Ba

TMB2256N

f

fd

Steam Inlet

ls

Mode

Diameter A1 A2 F

120S

170S

120S

170S

3/4 in. NPT 911 mm

(35.875 in.)

3/4 in. NPT 956 mm

(37.625 in.)

Steam Outlet

Diameter B1 B2 D

3/4 in. NPT 879 mm

(34.625 in.)

1 in. NPT 1133 mm

(44.625 in.)

340 mm

(13.375 in.)

387 mm

(15.25 in.)

333 mm

(13.125 in.)

222 mm

(8.75 in.)

2102 mm

(82.75 in.)

2235 mm

(88 in.)

1740 mm

(68.5 in.)

1822 mm

(71.75 in.)

Electrical Connection

1977 mm

(77.84 in.)

2057 mm

(81 in.)

120S

170S

CE

466 mm

(18.34 in.)

533 mm

(21 in.)

©

70421

501 (EN)

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

11

Page 14

sic Installation/Operation

A

B

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Ba

Electric Connection Location for Electric

Models

els A B

Mod

120E

910 mm

(35.81 in.)

TMB2336N

2175 mm

(85.64 in.)

©

12

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

7

0421501 (EN)

Page 15

sic Installation/Operation

TMB2020N

4

1

5

6

7

3

WA

RNING

T

o reduce the risk of severe injury, clearance of tumble dryer cabinet from combustible

construction must conform to the minimum clearances.

W056R1

8

2

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Ba

Position and Level the T

umble Dryer

OTE: Shaded areas indicate adjacent structure.

N

1 13 mm (0.5 in.) recommended between machines for removal or installation.

2 Allow 51-102 mm (2-4 in.) opening at top of machine to aid in removal or installation. A removable trim piece

may be used to conceal the opening; zero clearance allowed for trim.

3 102 mm (4 in.) maximum header thickness

4 Minimum clearance permitted for remainder: Gas 102 mm (4 in.), Steam 305 mm (12 in.)

5 Guard

6 Provision for Make-Up Air

7 610 mm (24 in.) minimum, 914 mm (36 in.) recommended for maintenance purposes

8 6 mm (0.25 in.) recommended for removal or installation purposes, zero clearance allowed

Figu

re 1

TMB2020N

©

501 (EN)

70421

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

13

Page 16

sic Installation/Operation

1

2

3

2

4

5

El

ectrical power must be provided to

tumbler at all times. The fire suppression

system will be inoperative if the main

electrical power supply is disconnected.

W690

W

ARNING

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Ba

Fire Suppression System

, H, K, S and U Models Only

G

Water Requirements

IMPOR

suppression system, or the fire suppression system

will not operate as intended.

Connection point to the electric water solenoid valve is

a 19 mm (3/4 inch) hose. The fire suppression system

equipped tumble dryer must be supplied with a

minimum water pipe size of 12.7 mm (1/2 inch) and be

provided with a

maximum of 827 kPa (120 psi) of pressure at all times.

Flowrate must be no less than, but approximately 57

liters (15 gallons) per minute.

NOTE: Water pressure under 138 kPa (20 pounds

per square inch) will cause low flow and water

leakage at water solenoid valve.

IMPORTANT: Temperature of the water supply

must be kept between 4.4° and 48.9°C (40° and

120°F). If water in the supply line or water solenoid

valve freezes, the fire suppression system will not

operate.

TANT: Water must be supplied to the fire

minimum o

f 138 kPa (20 psi) and a

Water Connections

TMB2008N

1 Lock

2 Hose Couplings

3 Y Valve

4 Inlet Hoses

5 Opening for Auxiliary Alarm Cable

igure 2

F

IMPOR

connections finger tight, then turn 1/4 turn with

pliers. Do not cross thread or overtighten

couplings.

TANT: Thread hose couplings onto valve

IMPORTANT: If temperature sensors inside the

tumble dryer register a temperature below 4.4°C

(40°F), the fire suppression system control will lock

out. This feature protects against operation of the

tumble dryer with a possible frozen water supply.

Only when the temperature sensors register a

temperature above 4.4°C (40°F) will the machine

reset for operation.

IMPORTANT: Flexible supply line/coupling must

be used. Solenoid valve failure due to hard

plumbing connections will void the warranty. It is

recommended that a filter or strainer be installed

in the water supply line.

IMPORTANT: Replace all hoses every five years.

NOTE: Longer inlet hoses are available (as

optional equipment at extra cost) if the hoses

supplied with the tumble dryer are not long enough

for installation. Order hoses as follows:

Part No. 20617 Inlet hose 2.44 m (8 feet)

Part No. 20618 Inlet hose 3.05 m (10 feet)

Electrical Requirements

No i

ndependent external power source or supply

connection is necessary. Power to operate the 24 Volt

fire suppression system is from the rear junction/

contactor box.

14

©

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

7

0421501 (EN)

Page 17

Auxiliary Alarm

T

o reduce the risk of fire or explosion, DO

NOT CONNECT THE GAS LINE TO THE

TUMBLE DRYER IF THE GAS SERVICE IS

NOT THE SAME AS THAT SPECIFIED ON

THE TUMBLE DRYER SERIAL PLATE! It

will first be necessary to convert the gas

burner orifice and gas valve. Appropriate

conversion kits are available.

W060R1

WA

RNING

T

o reduce the risk of fire or explosion, if

the tumble dryer is to be connected to

Liquefied Petroleum (L.P.) gas, a vent to

the outdoors must be provided in the room

where the tumble dryer is installed.

W062R1

WA

RNING

WA

RNING

T

o reduce the risk of electric shock, fire,

explosion, serious injury or death:

• Disconnect electric power to the

tumbler before servicing.

• Close gas shut-off valve to gas tumbler

before servicing.

• Close steam valve to steam tumbler

before servicing.

• Never start the tumbler with any guards/

panels removed.

• Whenever ground wires are removed

during servicing, these ground wires

must be reconnected to ensure that the

tumbler is properly grounded.

W002

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Duri

ng tumble dryer installation, you have the option

to connect a separate alarm system to this auxiliary

output. Use of the auxiliary output is not required for

the fire suppression system to operate, but may be

used for additional protection.

NOTE: The auxiliary output is activated during

fire suppression system maintenance test sequence.

Consider this fact prior to your system test every

three months. (Example: If the external system

uses the auxiliary output to call the fire

department, inform the fire department before and

after the fire suppression system maintenance test.)

sic Installation/Operation

Ba

NOTE: This manual is only a supplement. Refer to

installation/operation manual for full instructions.

European Gas

Gas Requirement

s

Natural Gas and Liquefied Petroleum

IMPOR

conversions must be made by the Manufacturer’s

Authorized Dealers, Distributors, or local service

personnel.

IMPORTANT: The tumble dryer must be isolated

fr

individual manual shut-off valve during any

pressure testing of the gas supply piping system at

test pressure equal to or less than 3.45 kPa,

34.5 mbar (0.5 psi).

TANT: Any product revisions or

om the gas supply piping system by closing its

IMPORTANT: The tumble dryer and its manually

operated appliance gas valve must be disconnected

om the gas supply piping system during any

fr

pressure testing of that system at test pressures in

excess

IMPORTANT: The installation must comply with

local codes.

70421

of

3.45 kPa, 34.5 mb

501 (EN)

ar (0.5 psi).

©

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

15

Page 18

sic Installation/Operation

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Ba

General Information

This information i

s to be used when installing gas

tumble dryers in countries, and/or on gases, different

than the machine’s factory configuration. Tumble

dryers are supplied from the factory for operation on

Natural Gas 8914 kcal/m

22,250 kcal/m

3

(2500 Btu/cu ft.) in

3

(1000 Btu/cu ft.) or L.P. Gas

the countries of

GB/IE/PT/ES/IT/GR/LU/CH. To install machines in

any other country or on any other gas requires some

level of modification.

Models are built in two different configurations:

• Regulated Natural Gas – Injector is sized for

Natural Gas, second family, group H (E) at

20 mbar inlet pressure. Regulator/governor is

operational. Gas valve CAN be field-converted

to a non-regulating type.

• Unregulated Liquefied Petroleum (L.P.) Gas –

Injector is sized for L.P. Gas, third family, group

3+ at 28.37 mbar inlet pressure. Regulator/

governor is blocked open. Gas valve CANNOT

be field-converted to a regulating type.

Serial plates supplied from the factory are configured

for the countries of GB/IE/PT/ES/IT/GR/LU/CH.

These instructions pertain to the situations when the

country of use or gas supply is different than that on

the serial plate.

NOTE: This manual is only a supplement. Refer to

installation/operation manual for full instructions.

©

16

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

7

0421501 (EN)

Page 19

Gases and Configurations

www.groupdynamics-laundry.com

sales@groupdynamics.lv

sic Installation/Operation

Ba

ry

Count

Code

DK/NO/

SE/FI/CZ/

EE/LV/LT/

SI/SK

DE**

NL

BE/FR*

GB/IE/PT/

ES/IT/GR/

LU/CH

Supply

Gas Type Group

Pressure,

mbar

Natural Gas E 20 8.9

Burner

Orifice

Pressure,

mbar

8.0

Capacity/

Model

120

170

L.P. Gas B/P 30 No Governor 120

170

Natural Gas E 20 8.9

8.0

L.P. Gas B/P 30 and No Governor or 26.4 or

50** and No Governor or 28.7

120

170

120

170

Natural Gas LL 25 12.0 120

170

L.P. Gas B/P 30 No Governor 120

170

Natural Gas E+ 20 or 25 No Governor* 120

170

L.P. Gas 3+ 28 or 37 No Governor 120

170

Natural Gas E 20 8.9

8.0

120

170

L.P. Gas 3+ 28 or 37 No Governor 120

170

Diameter,

mm

4.8

4.8

2.6

3.4

4.8

4.8

2.6

3.4

4.8

4.8

2.6

3.4

4.2

3.8

2.6

3.4

4.8

4.8

2.6

3.4

Quantity

3

4

3

3

3

4

3

3

3

4

3

3

3

4

3

3

3

4

3

3

Burner

Orifice

Part No.

M411372

M411372

M411376

M400997

M411372

M411372

M411376

M400997

M411372

M411372

M411376

M400997

M402995

M402997

M411376

M400997

M411372

M411372

M411376

M400997

Natural Gas E 20 8.9

AT**

L.P. Gas B/P 50** 26.4

CY/IS/MT

L.P. Gas B/P 30 No Governor 120

Natural Gas H 25 8.9

HU

L.P. Gas B/P 30 No Governor 120

Natural Gas H 20 8.9

PL

L.P. Gas 3P 37 No Governor 120

Bur

ner orifice information at 0-600 meters (0-2000 feet) altitude.

* For Natural Gas, Group E+ applications, convert using

L.P. Gas model and replace burner orifices.

** For L.P. Gas, Group B/P with 50 mbar supply pressure,

convert using Natural Gas model and appropriate burner

orifices.

8.0

28.7

8.0

8.0

Table 1

120

170

120

170

170

120

170

170

120

170

170

4.8

4.8

2.6

3.4

2.6

3.4

4.8

4.8

2.6

3.4

4.8

4.8

2.6

3.4

3

4

3

3

3

3

3

4

3

3

3

4

3

3

M411372

M411372

M411376

M400997

M411376

M400997

M411372

M411372

M411376

M400997

M411372

M411372

M411376

M400997

©

70421

501 (EN)

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

17

Page 20

sic Installation/Operation

A drying tum

ble dryer produces

combustible lint. To reduce the risk of fire,

the tumble dryer must be exhausted to the

outdoors.

W057R1

T

o reduce the risk of fire and accumulation

of combustible gases, DO NOT exhaust

tumbler air into a window well, gas vent,

chimney or enclosed, unventilated area

such as an attic, ceiling, crawl space under

a building, or concealed space of a

building.

W506

W

ARNING

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Ba

Exhaust Requirement

s

Make-Up Air

IMPOR

combustion and ventilation air.

A tumble dryer is forced air exhausted and requires

provisions for make-up air to replace the air exhausted

by the tumble dryer.

TANT: Do not obstruct the flow of

Venting

Proper size

operation. All elbows should be sweep type. Exhaust

ducts must be assembled so the interior surfaces are

smooth to prevent the accumulation of lint.

DO NOT use plastic, thin foil or Type B flexible ducts

– rigid metal ducts are recommended. Use exhaust

ducts made of sheet metal or other noncombustible

material. Use of duct tape or pop rivets on all seams

and joints is recommended, if allowed by local codes.

Verify that old ducts are thoroughly cleaned out before

installing new tumble dryer(s).

NOTE: The ducts must be equivalent in strength

and corrosion resistance to ducts made of

galvanized sheet steel not less than 0.495 mm

(0.0195 inches) thick.

IMPORTANT: For best performance, provide an

individual exhaust duct for each tumble dryer. Do

not install a hot water heater in a room containing

tumble dryers. It is better to have the water heater

in a separate room with a separate air inlet.

NOTE: This manual is only a supplement. Refer to

installation/operation manual for full instructions.

d exhaust ducts are essential for proper

ired Make-Up Air Opening

Requ

(to the outside) for Each Tumble Dryer

Models Opening

120 Pound

170 Pound

Table 2

2323 cm

3710 cm

Make-up air openings with louvers will restrict air

flow. The opening must be increased to compensate

for area taken up by louvers.

If it is necessary to duct make-up air to tumble

dryer(s), increase area of ductwork by 25% to

compensate for any restriction in air movement.

18

©

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

fr

fr

2

(360

ee air

2

(525

ee air

in

in

2

)

2

)

7

0421501 (EN)

Page 21

sic Installation/Operation

WA

RNING

To reduce the risk of electric shock, fire,

explosion, serious injury or death:

• Disconnect electric power to the tumbler

before servicing.

• Close gas shut-off valve to gas tumbler

before servicing.

• Close steam valve to steam tumbler

before servicing.

• Never start the tumbler with any guards/

panels removed.

• Whenever ground wires are removed

during servicing, these ground wires

must be reconnected to ensure that the

tumbler is properly grounded.

W002

T

o reduce the risk of fire and electric

shock, check with a qualified serviceman

for proper grounding procedures.

Improper connection of the equipment

grounding conductor may result in a risk of

electric shock.

W068

T

o reduce the risk of fire and electric

shock, if electrical supply is coming from a

three phase service, DO NOT connect a

“High Leg” or “Stinger Leg” to a single

phase machine. On a three phase machine,

if there is a “High Leg” or “Stinger Leg” it

should be connected to L3.

W069

All

electrical connections should be made

by a qualified electrician.

To reduce the risk of electrical shock, deenergize the electrical circuit being

connected to the tumble dryer before

making any electrical connections. Never

attempt to connect a live circuit.

W070R1

WA

RNING

Label all wi

res prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation. Verify

proper operation after servicing.

W071

CAUTION

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Ba

Electrical Requirement

s

• Metal conduit and/or BX cable is not considered

ground.

• Connecting the Neutral from the electrical

service box to the tumble dryer ground screw

does not constitute a ground.

• A dedicated ground conduit (wire) must be

connected between the electrical service box

ground bar and the tumble dryer ground screw.

Grounding Instructions

NOT

E: To ensure protection against shock, this

tumble dryer MUST be electrically grounded in

accordance with the local codes or, in the absence

of local codes, with the latest edition of the National

Electrical Code ANSI/NFPA No. 70.

In the event of malfunction or breakdown, grounding

will reduce the risk of electric shock by providing a

path of least resistance for electric current. This

tumble dryer must be connected to a grounded metal,

permanent wiring system; or an equipment grounding

conductor must be run with the circuit conductors and

connected to the appropriate ground location.

70421

©

501 (EN)

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

All manually operated models are factory-equipped

with an emergency stop button on the front panel.

NOTE: Activation of the emergency stop button

stops all machine control circuit functions, but

DOES NOT remove all electrical power from

machine.

NOTE: This manual is only a supplement. Refer to

installation/operation manual for full instructions.

19

Page 22

sic Installation/Operation

All

system components must have a

8.6 bar (125 psig) working pressure.

Shut-off valves must be installed upstream

of the steam solenoid valve and

downstream of each steam trap so

components can be isolated for

maintenance or emergency purposes.

All components (solenoid valve, traps)

must be supported to minimize loads on

the tumbler steam coil connections.

W701

WA

RNING

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Ba

team Requirements

S

Thermal Oil Prep

Obta

in specific steam service pipe sizes from the

steam system supplier or a qualified steam fitter.

• Refer to Figure 3 and Figure 4 for proper steam

pipe configurations.

• When tumble dryer is on the end of a line of

equipment, extend header at least 1.2 meters

(4 feet) beyond tumble dryer. Install shut-off

valve, union, check valve and bypass trap at end

of line. If the system has a gravity return to the

boiler, omit trap.

• Insulate steam supply and return line for safety of

operator and safety while servicing tumble dryer.

• Keep tumble dryer in good working condition.

Repair or replace any worn or defective parts.

It is t

he responsibility of the customer to install

appropriate coil and heating system for thermal oil

prep models. Manufacturer is not

responsible for the performance or safety of the

customer installed thermal oil system. To ensure

proper operation, refer to the Specifications and

Dimensions section for the BTU input of equivalent

steam models. Thermal oil systems that do not deliver

appropriate BTUs will dry slower. For solenoid valve

wiring connections, refer to the Wiring Diagram

supplied with tumble dryer.

NOTE: This manual is only a supplement. Refer to

installation/operation manual for full instructions.

20

©

Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

7

0421501 (EN)

Page 23

120 Pound Tumble Dryers

TMB2014N

2

12

6

3

5

1

13

10

9

8

6

7

4

11

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Basic Installation/Operation

120S

Figure 3

Steam Pressure

bar (PSI)

8.3 - 8.6 (120-125) 1 in. NPT 345

Minimum Pipe Diameter

4.1 - 8.3 (60-120) 1 in. NPT 345

Steam Trap Size*

(Pounds Condensate/Hour)

2.4 - 4.1 (35-60) 1-1/4 in. NPT 345

NOTE: Refer to Table 3 for sizing of steam lines. Piping must also be sized accordingly for length of runs and number

of elbows.

1 Supply 8 457 mm (18 in.) Drop

2 305 mm (12 in.) Riser 9 Solenoid Valve (Supplied with machine)

3 Shut-Off Valve 10 Steam Bonnet

4 Condensate Return Line from Supply Line 11 Flexible Line

5 Return 12 Union

6 Check Valve 13 Trap with Built-in Strainer

7 Vacuum Breaker (optional)

Model

*Based on maximum PSI.

Table 3

TMB2014N

70421501 (EN)

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

21

Page 24

Basic Installation/Operation

TMB2024N

SUPPLY

2

1

9

3

RETURN

2

3

7

10

4

5

8

6

www.groupdynamics-laundry.com

sales@groupdynamics.lv

170 Pound Tumble Dryers

NOTE: Refer to Table 4 for sizing of steam lines. Piping must also be sized accordingly for length of runs and number

of elbows.

1 Risers 305 mm (12 in.) 6 457 mm (18 in.) Drop

2 Shut-Off Valve 7 Steam Bonnet

3 Check Valve 8 Solenoid Valve (Supplied with machine)

4 Vacuum Breaker (optional) 9 Union

5 Condensate Return Line from Supply Line 10 Trap with Built-In Strainer

Model

170S

* Based on maximum PSI.

22

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

Figure 4

Steam Pressure

bar (PSI)

Minimum Pipe Diameter

Steam Trap Size*

(Pounds Condensate/Hour)

7.5 - 8.6 (110-125) 1 in. NPT 517

4.1 - 7.5 (60-110) 1-1/4 in. NPT 517

2.4 - 4.1 (35-60) 1-1/2 in. NPT 517

Table 4

TMB2024N

70421501 (EN)

Page 25

Operation

To reduce the risk of fire:

• DO NOT DRY articles containing foam rubber or similarly textured rubberlike materials.

• DO NOT DRY plastics, anything containing wax or chemicals such as mops and cleaning

cloths, or anything dry-cleaned at home with a dry-cleaning solvent.

• DO NOT TUMBLE fiberglass curtains and draperies unless the label says it can be done. If

they are dried, wipe out the cylinder with a damp cloth to remove particles of fiberglass.

W076

To reduce the risk of serious injury, allow cylinder to stop before cleaning lint screen.

W412

WARNING

1

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Basic Installation/Operation

Emergency Stop Button

All CE approved OPL tumble dryers are factoryequipped with an emergency stop button located on

the front panel. Refer to Figure 5.

TMB1665N

1 Emergency Stop Button

Figure 5

To operate emergency stop button:

a. Press red emergency stop button to stop all

action.

b. To restart machine, pull red emergency stop

button out and press START pad or button.

NOTE: Activation of the emergency stop button

stops all machine control circuit functions, but

DOES NOT remove all electrical power from

machine.

Operating Instructions

IMPORTANT: Clean lint screen and lint

compartment daily. Failure to clean the lint screen

daily will result in higher than normal

temperatures that may damage laundry.

Step 2: Load Laundry

Open loading door and load cylinder with laundry. DO

NOT OVERLOAD.

NOTE: Overloading causes slow drying and

wrinkling.

Close loading door. Tumble dryer will not operate with

the door open.

Step 3: Determine Control Type and

Temperature Setting

Refer to the various controls in the Control

Instructions Section, pages 24 - 28, determine

appropriate control and then follow the instructions.

The type of fabric being dried will determine the

temperature setting. Consult the fabric care label or

fabric manufacturer to determine proper temperature

setting.

IMPORTANT: Always follow the fabric care

instructions supplied by the garment

manufacturer.

Step 4: Remove Laundry

When the cycle is complete, open door and remove the

laundry.

Step 1: Clean Lint Screen/Compartment

Remove any accumulated lint from the lint screen and

compartment. Close panel tightly against tumble dryer

frame and lock panel securely, if applicable.

70421501 (EN)

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

23

Page 26

Basic Installation/Operation

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Control Instructions

Dual Digital Timer Control

RQ Control Suffix

1. Select HIGH, MED, LOW or NO HEAT by

turning the temperature knob.

TMB2147N

Figure 6

2. Set the HEAT TIME for the number of minutes

(from 0-60) desired.

TMB2148N

Figure 7

3. Set the COOL DOWN TIME for the number of

minutes (from 0-15) desired.

4. Select reversing or nonreversing cylinder rotation

settings, if applicable.

TMB2145N

Figure 9

5. Press and release START button to start tumble

dryer. Display will show minutes remaining

before end of cycle.

TMB2150N

Figure 10

IMPORTANT: To stop the tumble dryer at any

time during the cycle, OPEN DOOR. If the loading

door or lint panel door is opened during the cycle,

the heating system will shut off and the motor will

stop. To restart the cycle, both doors must be closed

and the START button must be pressed in.

6. When the cycle is complete, open door and

remove the laundry.

Figure 8

24

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

TMB2149N

70421501 (EN)

Page 27

Basic Installation/Operation

HIGH

MEDIUM

MED LOW

LOW

NO HEAT

ON / SELECT

REVERSING

START

STOP/RESET

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Electronic OPL Control

H, L, P, S, U, X and Y Models with

RM Control Suffix

1. To use an Automatic Cycle, press an ON/

SELECT pad. Select HIGH, MEDIUM,

MED LOW, LOW or NO HEAT for items that

should not be dried with heat. A light to the left

of the selected pad lights up.

To use a Time Dry or Custom Cycle, refer to the

Programming Manual.

2. Select REVERSING or NON-REVERSING

cylinder rotation setting.

TMB1486N

Figure 13

3. Press START pad to start tumble dryer.

TMB1485N

Figure 14

NOTE: All pads can be pressed in any sequence

without damaging control or tumble dryer. To stop

the tumble dryer at any time, open the door or

press STOP/RESET.

TMB1483N

Figure 11

NOTE: Do not press directly on lights or the center

of pad. For proper selection, press on pad slightly

to the right of center. Refer to Figure 12.

TMB806N

Figure 12

TMB1484N

Figure 15

NOTE: The window display will flash. Press STOP/

RESET twice (within three seconds) to end the

cycle and reset the control to idle status. To restart

the tumble dryer, CLOSE door and press START

pad.

IMPORTANT: If the loading door or lint panel

door is opened during the cycle, the heating system

will shut off and the motor will stop. To restart the

cycle, both doors must be closed and the START

pad must be pressed.

4. When the cycle is complete, open door and

remove the laundry.

70421501 (EN)

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

25

Page 28

Basic Installation/Operation

www.groupdynamics-laundry.com

sales@groupdynamics.lv

G and K Models with RM Control Suffix

1. To use an Automatic Cycle, press a

TEMPERATURE pad. Select HIGH, MED,

LOW, DELICATE or NO HEAT for items that

should not be dried with heat. A light to the left

of the selected pad lights up.

To use a Time Dry or Custom Cycle, refer to the

Programming Manual.

Figure 16

2. Select REVERSING or NONREVERSING

cylinder rotation setting.

TMB2201N

3. Press START pad to start tumble dryer.

TMB2202N

Figure 18

NOTE: All pads can be pressed in any sequence

without damaging control or tumble dryer. To stop

the tumble dryer at any time, open the door or

press STOP.

TMB2203N

Figure 19

NOTE: The window display will flash. Press STOP

twice (within 3 seconds) to end the cycle and reset

the control to idle status. To restart the tumble

dryer, CLOSE door and press START pad.

IMPORTANT: If the loading door or lint panel

door is opened during the cycle, the heating system

will shut off and the motor will stop. To restart the

cycle, both doors must be closed and the PUSH TO

START button must be pressed in.

Figure 17

4. When the cycle is complete, open door and

remove the laundry.

TMB2206N

26

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

70421501 (EN)

Page 29

Basic Installation/Operation

PROGRAM REVERSING ENERGY

SAVER

HEATING

STOP

BACK

TMB1371R

START

S MODELS

H MODELS

U MODELS

TMB1346R

TMB1371R

TMB1345R

START

STOP

BACK

Y MODELS

TMB2370N

www.groupdynamics-laundry.com

sales@groupdynamics.lv

PROGRAM REVERSING ENERGY

BACK

SAVER

HEATING

STOP

START

TMB1345R

PROGRAM REVERSING ENERGY

BACK

SAVER

HEATING

STOP

START

TMB1346R

LED OPL Control

RE Control Suffix

1. Press the Up (↑) or Down (↓) keypad to change

2. Press Start ( ) to start selected cycle.

IMPORTANT: If the loading door or lint panel

door is opened during the cycle, the heating system

will shut off and the motor will stop. To restart the

cycle, both doors must be closed and the

Start ( ) pad must be pressed.

3. When the cycle is complete, open door and

cycles.

To customize a cycle, refer to the Programming

Manual.

remove laundry.

Figure 20

NOTE: This machine includes an anti-wrinkle/

extended tumble feature. After the drying cycle is

complete, the cylinder will tumble without heat

every few minutes. The intermittent tumbling will

continue for one hour or until the door is opened.

After an hour the machine enters delayed tumble

and will tumble for two minutes every hour for up

to 18 hours or until the door is opened.

70421501 (EN)

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

27

Page 30

Basic Installation/Operation

TMB1276C

www.groupdynamics-laundry.com

sales@groupdynamics.lv

TMB1276C

Figure 21

UniLinc Control

RU Control Suffix

1. Press the (←)or(→) keypad to change cycles. The

center highlighted position is the selected cycle.

To customize a cycle, refer to the Programming

Manual.

2. Press Start to start selected cycle.

IMPORTANT: If the loading door or lint panel

door is opened during the cycle, the heating system

will shut off and the motor will stop. To restart the

cycle, both doors must be closed and the Start

pad must be pressed.

3. When the cycle is complete, open door and

remove laundry.

NOTE: This machine includes an anti-wrinkle/

extended tumble feature. After the drying cycle is

complete, the cylinder will tumble without heat

every few minutes. The intermittent tumbling will

continue for one hour or until the door is opened.

After an hour the machine enters delayed tumble

and will tumble for two minutes every hour for up

to 18 hours or until the door is opened.

28

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

70421501 (EN)

Page 31

Ignition Control Operation

1

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Diagnostic LED (DGN LED) / Error Codes

The Diagnostic LED or DGN LED is located by the

power connector on the ignition control. Refer to

Figure 22. The Diagnostic LED will indicate the status

of the ignition control. Refer to Table 5 .

LED Color Description

Orange-Yellow Initialization

Green Standby / Normal Operation

Red Fault Indication Code

Table 5

The Diagnostic LED will flash error codes one half

second on and one half second off. Error codes are

separated by a one second pause before the code is

repeated.

Basic Installation/Operation

Error

Code

1

2

3

4

5

6

1 Diagnostic (DGN) LED

Red Ignition Control Internal Failure

2 Red Flashes Gas Valve Not Connected

3 Red Flashes Ignition/Flame Sense Failure

4 Red Flashes Reset Switch is Shorted

Slow Red and Green Flashes Low Voltage Detection

Fast Red and Orange Flashes Ignition Control is in Reset Delay

Figure 22

DGN LED status Fault Type

TMB2176N

70421501 (EN)

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

29

Page 32

Basic Installation/Operation

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Disposal of Unit

This appliance is marked according to the European

directive 2002/96/EC on Waste Electrical and

Electronic Equipment (WEEE).

This symbol on the product or on its packaging

indicates that this product shall not be treated as

household waste. Refer to Figure 23. Instead it shall

be handed over to the applicable collection point for

the recycling of electrical and electronic equipment.

Ensuring this product is disposed of correctly will help

prevent potential negative consequences for the

environment and human health which could otherwise

be caused by inappropriate waste handling of this

product. The recycling of materials will help to

conserve natural resources. For more detailed

information about recycling of this product, please

contact the local city office, household waste disposal

service, or the source from which the product was

purchased.

MIX1N

Figure 23

30

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT 70421501 (EN)

Loading...

Loading...