ground logic PATHFINDER, PATHFINDER XC, PAT-12012-2, PAT-22016-2, Rover Operator's Manual

...Page 1

PATHFINDER, PATHFINDER XC

OPERATOR’S MANUAL

S/N: 20180360140 & Above

Congratulations on the purchase of your Ground Logic, Inc. machine.

This product has been carefully designed and manufactured to be a dependable piece of equipment that will provide years of trouble-free operation.

BEFORE OPERATING YOUR MACHINE, CAREFULLY READ AND UNDERSTAND THIS MANUAL IN ITS ENTIRETY.

For future reference, place the serial number of the machine and date of

purchase below:

Serial Number: ________________

Date of Purchase: _____________

GROUND LOGIC, INC.

PAT-12012-2/PAT-22016-2

1 5105862_-_HI

Page 2

1. MACHINE SPECIFICATIONS

TABLE OF CONTENTS

1.1 Table of Specications

1.2 Operator Controls

2. GENERAL OPERATIONAL SAFETY

2.1 Proposition 65 Statement

2.2 Operating Safely

2.3 Chemical Safety

2.4 Training

2.5 Preparation

2.6 Children

2.7 Safe Handling of Gasoline

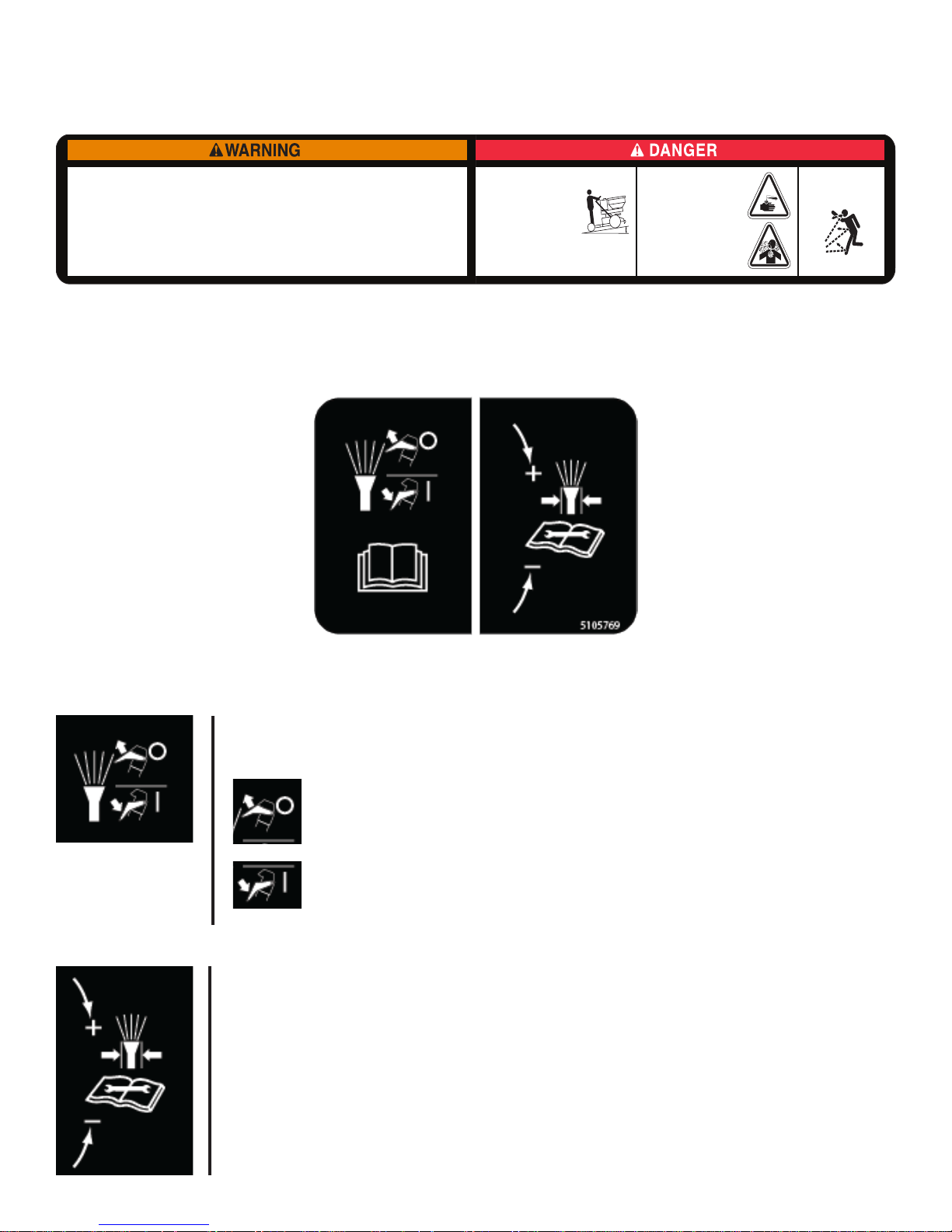

3. SAFETY AND INSTRUCTIONAL DECALS

3.1 Introduction to Safety Alert Symbols and Signal Words

3.2 Safety Icons and Warning Decals

3.3 Instructional Decals

3.4 Honda Engine Decals and Engine Controls

4. OPERATING INSTRUCTIONS

4.1 Operation

4.2 User Controls

4.3 Before First Time Operation

4.4 Pre-Start

4.5 Starting the Machine

4.6 Stopping the Machine

4.7 Transporting the Machine

4.8 Operating the Spreader

4.9 Operating the Sprayer

3-4

4

4

5

5-6

6

6-7

7

8

8

8-9

10-11

12

13

14

14-15

15

15

16

16

16

17

5. SLOPE OPERATIONAL SAFETY

5.1 Slope Identication Guide

5.2 Slope Operation

5.3 Operating on Slopes

6. CALIBRATION

6.1 Spreader Flow Rate Calibration

6.2 Centering the Spread Pattern

6.3 Calibrating the Spray Flow Rate

7. MAINTENANCE, STORAGE, AND SERVICE

7.1 Maintenance and Storage Safety

7.2 Periodic Service Intervals

8. FAULT ISOLATION

8.1 Machine Does Not Start

8.2 Spreading System Operates Incorrectly

8.3 Spraying System Operates Incorrectly

9. WARRANTY INFORMATION

18

19-20

20-21

21-22

22-23

23

24-25

25-26

27

28

29

30-31

2

Page 3

1. MACHINE SPECIFICATIONS

1.1 TABLE OF SPECIFICATIONS

PATHFINDER PATHFINDER XC

MODEL NUMBER

ENGINE

FUEL SYSTEM

TRANSMISSION

This manual is for model number 5901725

(PAT-12012-2).

• Engine Model: GX200-RT2RMG2

• Engine specications: See your Honda

engine owner’s manual.

• RPM: Full speed: 3750 rpm (no load) Idle:

1400 rpm.

• 2:1 gear reduction with wet clutch.

• Capacity: 2.5 gal (9.5 L).

• Type of fuel: Regular unleaded gasoline,

87 octane or higher.

• Fuel shut-off valves: Located on engine.

• Transmission Model: Peerless 855 Series.

• Gear selections: 2 forward, 1 reverse,

neutral.

• Speed: 3.5 mph (5.6 km/hour) low gear,

5.0 mph (8.0 km/hour) high gear.

This manual is for model number 5901726

(PAT-22016-2).

• Engine Model: GX200-RT2RMG2

• Engine specications: See your Honda engine

owner’s manual.

• RPM: Full speed: 3750 rpm (no load) Idle:

1400 rpm.

• 2:1 gear reduction with wet clutch.

• Capacity: 2.5 gal (9.5 L).

• Type of fuel: Regular unleaded gasoline, 87

octane or higher.

• Fuel shut-off valves: Located on engine.

• Transmission Model: Peerless 855 Series.

• Gear selections: 2 forward, 1 reverse, neutral.

• Speed: 3.5 mph (5.6 km/hour) low gear, 5.0

mph (8.0 km/hour) high gear.

TIRES AND

WHEELS

SPREADER

SPRAYING

SYSTEM

• Front tires: 18 x 950 – 8, RV antifreeze

added for ballast and traction.

• Rear tires: 13 x 650 – 6

• Spreader model: Spyker 120 Series.

• Capacity: 120 lb.

• Spray Pump: 2.0 GPM mechanically driven diaphragm pump.

• Tank: 12.0 gallon (45.4 L) capacity.

• Nozzles: Turbo FloodJet TF-VS5 (broadcast), Turbo TeeJet TT11004VP (trim).

• Spray Patterns: 11’ wide pattern for

general spraying, 3’ narrow pattern for trim

spraying.

• Spray Pressure: Regulated to 25 psi (172

kPa) to match ground speed with tip output.

• Front tires: 18 x 950 – 8, RV antifreeze added

for ballast and traction.

• Rear tires: 13 x 650 – 6

• Spreader model: Spyker 220 Series.

• Capacity: 220 lb.

• Spray Pump: 2.0 GPM mechanically driven diaphragm pump.

• Tank: 16.0 gallon (60.6 L) capacity.

• Nozzles: Turbo FloodJet TF-VS5 (broadcast),

Turbo TeeJet TT11004VP (trim)

• Spray Patterns: 10’ wide pattern for general

spraying, 3’ narrow pattern for trim spraying.

• Spray Pressure: Regulated to 25 psi (172

kPa) to match ground speed with tip output

3 5105862_-_HI

Page 4

1. MACHINE SPECIFICATIONS CONTINUED

1.1 TABLE OF SPECIFICATIONS CONTINUED

PATHFINDER PATHFINDER XC

DIMENSIONS

ELECTRICAL SYSTEM

1.2 OPERATOR CONTROLS

• The handlebars provide access to most of the machine controls.

• Turning the handlebars while standing on the operator platform provides steering control.

• Squeezing the throttle lever on the right side of the handlebars provides speed control.

• Overall length: 54.0” (137 cm).

• Overall width: 35.5” (90 cm).

• Overall height: 49.0” (124 cm).

• Weight: 375 lb. (170 kg) dry, 600 lb.

(272 kg) full, 800 lb. (363 kg) full with

200 lb. (91 kg) rider.

• Charging system: N/A

• Charging capacity: N/A

• Safety interlock system: This machine is equipped with a neutral safety

start module. To start the engine, the

transmission must be in the neutral (N)

position.

• Overall length: 58.0” (147 cm).

• Overall width: 35.5” (90 cm).

• Overall height: 50.5” (128 cm).

• Weight: 450 lb. (204 kg) dry, 785 lb.

(356 kg) full, 985 lb. (447 kg) full with

200 lb. (91 kg) rider.

• Charging system: N/A

• Charging capacity: N/A

• Safety interlock system: This machine is equipped with a neutral safety

start module. To start the engine, the

transmission must be in the neutral (N)

position.

• Depressing the brake pedal on the operator platform provides braking control.

• The spray control lever controls liquid ow from the tank to the nozzles.

• The gate lever controls the ow of granular product out of the hopper.

• The engine ignition switch controls the operation or shutdown of the engine.

• The spray control knob controls liquid ow between the trim and broadcast spray nozzles.

• The spread control lever controls the center of the spread pattern of granular product.

• The gate stop on the front of the hopper controls the maximum gate opening for granular product.

2. GENERAL OPERATIONAL SAFETY

2.1 PROPOSITION 65 STATEMENT

WARNING

This product can expose you to chemicals including gasoline engine exhaust, which is known to the State of

California to cause cancer, and carbon monoxide, which is known to the State of California to cause birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control of the

unit, severe personal injury or death to you, or bystanders, or damage to property or equipment.

4

Page 5

2. GENERAL OPERATIONAL SAFETY CONTINUED

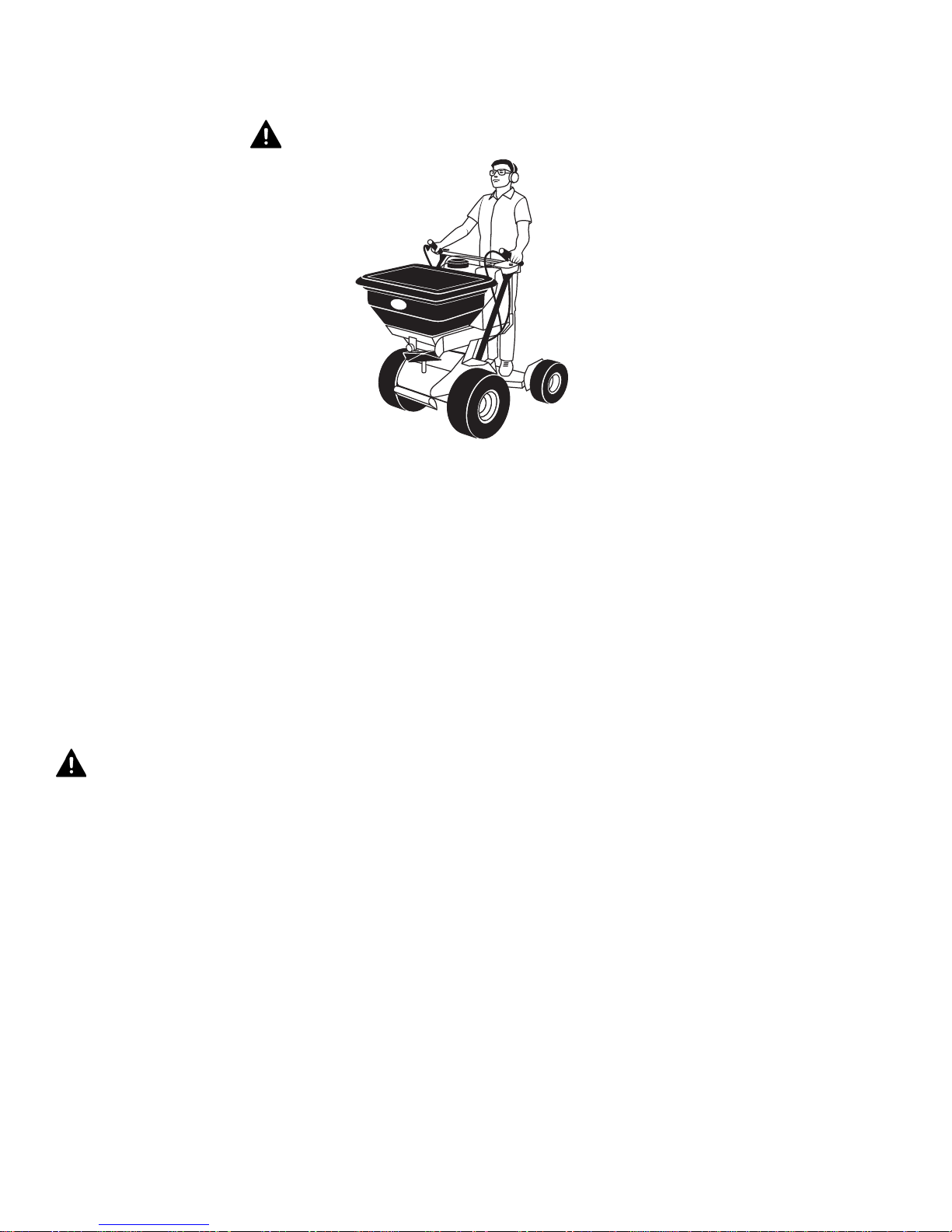

2.2 OPERATING SAFELY

The safety alert triangle ( ) in text signies important caustions or warnings which must be followed.

Figure 1

Congratulations on purchasing a superior-quality piece of lawn and garden equipment. Our products are designed and manufactured to meet or exceed all industry standards for safety.

Do not operate this machine unless you have been trained. Reading and understanding this operator’s manual

is a way to train yourself.

Keep both feet on the operator platform at all times. Power equipment is only as safe as the operator. If it is

misused, or not properly maintained, it can be dangerous! Remember, you are responsible for your safety and

that of those around you.

Use common sense, and think through what you are doing. If you are not sure that the task you are about to

perform can be safely done with the equipment you have chosen, ask a professional: contact your local authorized dealer.

2.3 CHEMICAL SAFETY

WARNING

Chemicals used in this machine such as herbicides and pesticides may be hazardous to apply and produce

gasses that are hazardous if inhaled or with contact to your skin. Caustic liquid or chemical burns could occur

if chemicals are not used properly.

• Read and follow all the instructions and warnings on Material Safety Data Sheets (MSDS) from manufacturer for all chemicals used.

• Become familiar with and follow all warnings, recommendations, instructions and procedures for: rst

aid measures, safe use, mixing, handling, applying, spills clean-up, storage and disposal of all chemicals as listed on the manufacturer’s label or MSDS of any herbicides, pesticides or other chemicals.

• Wear all personal protective equipment as recommended on the manufacturer’s label or MSDS of any

herbicides, pesticides or other chemicals. Personal protective equipment may include safety glasses

or goggles and/or face shields, chemical resistant gloves, rubber boots, and a respirator or air purifying

lter mask.

• Before working on this machine, be sure the sprayer / valve system and hopper has been

thoroughly rinsed according to the recommendations of the chemical manufacturer (see MSDS and

product labels).

5 5105862_-_HI

Page 6

2. GENERAL OPERATIONAL SAFETY CONTINUED

2.3 CHEMICAL SAFETY CONTINUED

• Obtain the proper training before using or handling any chemicals. Follow all local, state and federal

requirements for the handling and spreading or spraying of chemicals.

• Be sure to verify there is an adequate supply of clean water and soap nearby and immediately wash

off any chemicals that may contact you.

• Handle chemicals in a well-ventilated area.

• Keep clean water available for immediate rinsing off and clean-up of any spilled chemicals, especially

when lling the sprayer tank.

• Do NOT attempt to clean spray nozzles by blowing through them or placing in or near your mouth.

• Never enter the spray tank or hopper with your unprotected hands, or place your mouth or face over

or into these openings. Chemicals and fumes may be hazardous to your health.

WARNING

• Reduce your speed and minimize the weight of your load (in the hopper and volume in the tanks)

when operating on hills or rough terrain to avoid possible instability, tipping or rollover of the machine.

• Liquid in the tanks and granular materials in the hopper may shift during operation. This is most

common while turning, going up, down or across hills, when suddenly changing speed, or operating on

rough terrain. This shift in load may cause possible instability, tipping or rollover of the machine. Reduce your speed in these situations.

2.4 TRAINING

• Read, understand, and follow all instructions in the manual and on the unit before starting. If the

operator(s) or mechanic(s) cannot read English it is the owner’s responsibility to explain this material to

them.

• Become familiar with the safe operation of the equipment, operator controls, and safety signs.

• All operators and mechanics should be trained. The owner is responsible for training the users.

• Only allow responsible adults, who are familiar with the instructions, to operate the unit.

• Never let children or untrained people operate or service the equipment. Local regulations may restrict

the age of the operator.

• The owner/user can prevent and is responsible for accidents or injuries occurring to themselves, other

people or property.

2.5 PREPARATION

• Evaluate the terrain to determine what accessories and attachments are needed to properly and

safely perform the job. Use only accessories and attachments approved by the manufacturer.

• Wear appropriate clothing including safety shoes, safety glasses and ear protection. Long hair, loose

clothing or jewelry may get tangled in moving parts.

• Inspect the area where the equipment is to be used and remove all objects such as rocks, toys and

wire, which can be thrown by the machine.

6

Page 7

2. GENERAL OPERATIONAL SAFETY CONTINUED

2.5 PREPARATION CONTINUED

• Use extra care when handling gasoline and other fuels. They are ammable and vapors are explosive.

• Use only an approved container for gasoline.

• Never remove fuel cap or add fuel with the engine running. Allow engine to cool before refueling. Do

not smoke. Never refuel or drain the machine indoors.

• Check that safety switches and shields are attached and functioning properly. Do not operate unlesss

they function properly.

• Become familiar with and follow all warnings, recommendations, instructions and procedures for safe

use, handling, applying, storage and disposal of all chemicals as listed on the manufacturer’s label of

any herbicides, pesticides or other chemicals.

• Wear all personal protective equipment as recommended on the manufacturer’s label or MSDS of any

herbicides, pesticides or other chemicals. Personal protective equipment may include safety glasses or

goggles and/or face shields, chemical resistant gloves, rubber boots and a respirator or lter mask.

WARNING

It is a violation of California Public Resource Code, Section 4442, to use or operate the engine on any forest-covered, brush-covered or grass-covered land unless the exhaust system is equipped with a spark arrest-

er, as dened in Section 4442, maintained in effective working order. Other states or federal jurisdictions may

have similar laws. Contact an Authorized Service Dealer to obtain a spark arrester designed for the exhaust

system installed on this engine.

• OSHA regulations may require the use of hearing protection when exposed to sound levels greater

than 85 dBA for an 8 hour time period

CAUTION

This machine produces sound levels in excess of 85 dBA at the operator’s ear and can cause hearing loss

though extended periods of exposure. Wear hearing protection when operating this machine.

2.6 CHILDREN

Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted to

the unit and the operating activity. Never assume that children will remain where you last saw them.

• Keep children out of the operating area and under the watchful care of another responsible adult.

• Be alert and turn unit off if children enter the area.

• Before and during reverse operation, look behind and down for small children.

• Never carry children, even with spreader spinner and sprayer pump off. They may fall off and be seriously injured or interfere with safe unit operation. Children who have been given rides in the past may

suddenly appear in the operation area for another ride and be run over or backed over by the machine.

• Never allow children to operate the unit.

• Use extra care when approaching blind corners, shrubs, trees, or other objects that may obscure

vision.

7 5105862_-_HI

Page 8

2. GENERAL OPERATIONAL SAFETY CONTINUED

2.7 SAFE HANDLING OF GASOLINE

To avoid personal injury or property damage, use extreme care in handling gasoline. Gasoline is extremely

ammable and the vapors are explosive.

• Extinguish all cigarettes, cigars, pipes, and other sources of ignition.

• Use only approved gasoline containers.

• Never remove the gas cap or add fuel with the engine running. Allow the engine to cool before

refueling.

• Never fuel the machine indoors.

• Never store the machine or fuel container where there is an open ame, spark, or pilot light such as

near a water heater or other appliance.

• Never ll containers inside a vehicle or on a truck bed with a plastic bed liner. Always place containers

on the ground away from your vehicle before lling.

• Remove gas-powered equipment from the truck or trailer and refuel it on the ground. If this is not

possible, then refuel such equipment on a trailer with a portable container, rather than from a gasoline

dispenser nozzle.

• Keep nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is

complete. Do not use a nozzle lock-open device.

• If fuel is spilled on clothing, change clothing immediately.

• Never over-ll the fuel tank. Replace gas cap and tighten securely.

• Use extra care in handling gasoline and other fuels. They are ammable and vapors are explosive.

• If fuel is spilled, do not attempt to start the engine but move the machine away from the area of spillage and avoid creating any source of ignition until fuel vapors have dissipated.

• Replace all fuel tank caps and fuel container caps securely.

3. SAFETY AND INSTRUCTIONAL DECALS

3.1 INTRODUCTION TO SAFETY ALERT SYMBOLS AND SIGNAL WORDS

Before operating your unit, read the safety decals. The cautions and warnings are for your safety. To avoid a

personal injury or damage to the unit, understand and follow all safety decals.

The safety alert symbol is used to identify safety information about hazards that can result in personal injury. A signal word (DANGER, WARNING, or CAUTION) is used with the alert symbol to indicate the likelihood

and the potential severity of injury. In addition, a hazard symbol may be used to represent the type of hazard.

DANGER indicates a hazard which, if not avoided, will result in death or serious injury.

WARNING indicates a hazard which, if not avoided, could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, could result in minor or moderate injury.

NOTICE indicates a situation that could result in damage to the product.

8

Page 9

3. SAFETY AND INSTRUCTIONAL DECALS CONTINUED

3.1 INTRODUCTION TO SAFETY ALERT SYMBOLS AND SIGNAL WORDS

WARNING

If any safety decals become worn or damaged, and cannot be read, order replacement decals from your local

dealer.

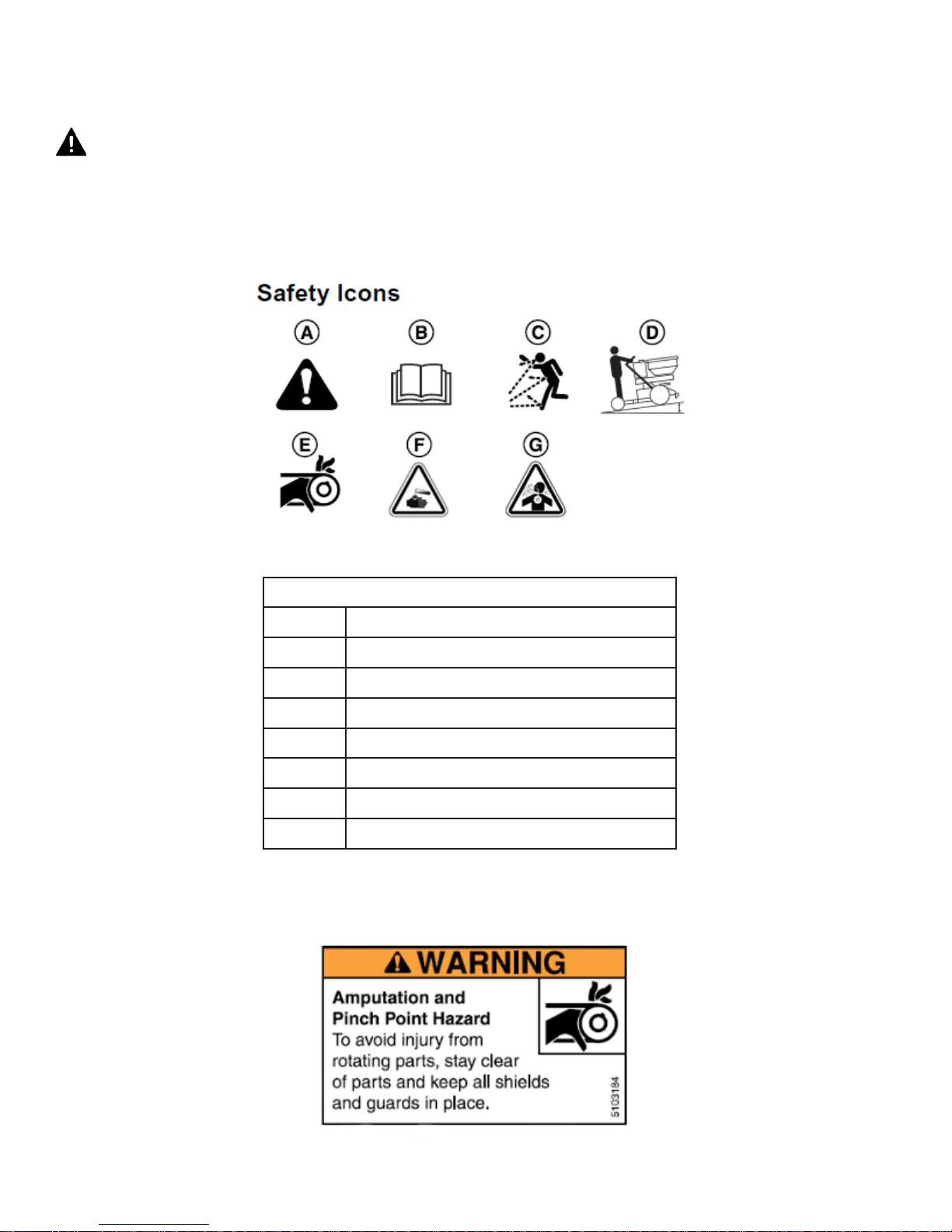

3.2 SAFETY ICONS AND WARNING DECALS

Figure 2: Safety Icons

Explanation of Icons in Figure 2

Callout Description

A Alert

B Read the Manual

C Thrown Objects

D Slope Direction for Safe Operation

E Amputation - Rotating Parts

F Caustic Liquid/Chemical Burn

G Gas Inhilation Hazard

Figure 3: Explanation of Icons in Figure 2

Figure 4: Amputation and Pinch Point Hazard Decal

9 5105862_-_HI

Page 10

3. SAFETY AND INSTRUCTIONAL DECALS CONTINUED

• Read and understand the operator’s manual before using

this machine.

• Do NOT operate unless trained to safely use this machine.

• Hearing protection is recommended.

• Do NOT operate without shields, guards, and safety

devices in place and working.

• Do NOT defeat the safety system.

• Stop engine and remove key before adjusting, servicing

or cleaning machine.

• Do NOT operate when people and pets are in the area.

• Do NOT carry passengers.

• Look behind and to the side before changing directions.

• Before leaving the operator’s position engage park brake

and stop engine.

To avoid serious injury or death:

Loss of Control:

Operating on slopes can be hazardous and

cause loss of control.

• Avoid sudden turns or rapid speed

changes.

• Go up and down slopes, NOT across.

• Reduce speed and use extreme caution

on slopes.

• If machine stops forward motion on a

slope, stop. Get o and walk the machine slowly o the

slope.

• Do NOT operate on slopes when grass is wet.

Caustic Liquid/Chemical

Burn and Gases Inhalation

Hazard:

• Follow instructions for handling

and wear all personal protective

equipment as recommended on the

manufacturer’s label of any herbicides,

pesticides, or other chemicals used.

Thrown Object Hazard:

• Do NOT operate when

people are nearby.

5105774

3.2 SAFETY ICONS AND WARNING DECALS CONTINUED

Figure 5: Warning and Danger Combination Decal

3.3 INSTRUCTIONAL DECALS

Figure 6: Sprayer Control Decal

Spray Control Lever: See section 4.2 CONTROLS for spray control lever

operating instructions.

When this lever is released, the spray valve is closed (OFF position)

When this lever is depressed, the spray valve is open (ON position)

Releasing the spray control lever will automatically close the sprayer valve

(OFF position)

Spray Pressure Relief Valve: See section 6.3 CALIBRATING THE SPRAY FLOW

RATE for Spray Pressure Relief Valve operating instructions.

Turning the knob clockwise increases spray pressure and turning the knob counter

clockwise decreases spray pressure.

10

Page 11

3. SAFETY AND INSTRUCTIONAL DECALS CONTINUED

3.3 INSTRUCTIONAL DECALS CONTINUED

Figure 7: Foot Brake Decal

Foot Brake Decal: See section 4.2 CONTROLS for brake pedal operating instructions.

Releasing the brake pedal disengages the band brakes on the rear wheels (OFF position).

Depressing the brake pedal engages the band brakes on the rear wheels (ON position).

Figure 8: Parking

Brake Decal

Figure 9: Explanation of Parking Brake Decal

11 5105862_-_HI

Page 12

3. SAFETY AND INSTRUCTIONAL DECALS CONTINUED

3.4 HONDA ENGINE DECALS AND ENGINE CONTROLS

Fuel valve

Throttle lever

Choke lever

Set lever to choke when starting cold.

Set lever to desired engine speed.

Move lever completely to the left to stop

engine.

12

Page 13

4. OPERATING INSTRUCTIONS

4.1 OPERATION

• Keep both feet on the operator platform at all times.

• Never run an engine in an enclosed area.

• Operate only in the daylight or with good articial light, keeping away from holes and hidden hazards.

• Be sure all drives are in neutral and parking brake is engaged before starting engine. Only start engine from the operator’s position.

• Be sure of your footing while using pedestrian controlled equipment, especially when backing up.

Walk, don’t run. Reduced footing could cause slipping.

• Slow down and use extra care on hillsides. Be sure to travel in the recommended direction on hillsides. Turf conditions can affect the machines stability. Use caution when operating near drop-offs.

• Do not Operate in reverse unless absolutely necessary. Always look down and behind before and

while traveling in reverse.

• Slow down and use caution when making turns and when changing directions on slopes.

• Never leave a running unit unattended. Always disengage the spreader spinner and sprayer pump, set

parking brake, stop engine, and remove keys before dismounting. Keep hands and feet away from the

rotating parts.

• Disengage the spreader spinner and sprayer pump when not operating.

• Never operate with guards not securely in place. Be sure all switches are attached, adjusted properly

and functioning properly.

• Do not change the engine governor setting or overspeed the engine.

• Stop on level ground, lower implements, disengage spreader spinner and sprayer pump, engage

parking brake, shut off engine before leaving the operator’s position for any reason.

• Look behind and down before backing up to be sure of a clear path.

• Never carry passengers and keep pets and bystanders away.

• Do not operate the unit while under the inuence of alcohol or drugs.

• Slow down and use caution when making turns and crossing roads and sidewalks. Disengage spreader spinner and sprayer pump if not operating.

• Use care when loading or unloading the machine into a trailer or truck.

• Use care when approaching blind corners, shrubs, trees or other objects that may obscure vision.

• To reduce re hazard, keep unit free of grass, leaves & excess oil. Do not stop or park over dry

leaves, grass or combustible materials.

13 5105862_-_HI

Page 14

4. OPERATING INSTRUCTIONS CONTINUED

4.2 CONTROLS

The user should become familiar with all controls before operating the machine.

• Handlebars: The handlebars provide steering control of the machine and should be grasped with the

hands at the location of the foam grips.

• Throttle lever: The throttle lever is located at the end of the right hand side of the handlebars.

Squeezing the throttle lever increases the speed of the engine. Releasing the throttle lever allows the

engine to return to idle speed. When the transmission is engaged in any position other than neutral,

squeezing the throttle will cause the machine to move relative to the gear that has been selected. The

more the lever is squeezed, the greater the speed of the machine.

• Brake pedal: The brake pedal is located in the middle of the operator platform. Depressing the brake

pedal engages the band brakes on the rear wheels and slows the motion of the machine.

• Spray control lever: The spray control lever is located near the left side of the handlebars and con-

trols the ow of liquid from the tank to the spray nozzles. When the lever is in the vertical position, the

valve is closed. When the lever is in the horizontal position (the lever can be either pushed forward or

pulled backward), the valve is open.

• Gate lever: The gate lever is located on the left side of the console and controls the opening at the

bottom of the hopper. Pushing forward on the gate lever causes the gate to close so that no granular

product will ow out of the bottom of the hopper. Pulling backward on the gate lever causes the gate to

open so that granular product will ow.

• Engine ignition switch: The engine ignition switch is located on the left side of the console and controls the ignition circuit of the engine. The engine will only start and run when the switch is in the “ON”

position. The engine will not start or will shut down if the switch is in the “OFF” position.

• Spray control knob: The spray control knob is located on the right side of the console and controls

which nozzle the liquid in the spray system is directed towards. When the knob is positioned in the wide

spray position, liquid is directed toward the broadcast nozzle. This nozzle will create a maximum spray

width of 11’. When the knob is positioned in the narrow spray position, liquid is directed toward the trim

nozzle. This nozzle will create a maximum spray width of 3’.

•Spread control lever: The spread control lever is located on the right side of the console and controls

the center of the granular spread. The lever controls the position of a bafe located below the gate of

the hopper. As this bafe is moved relative to the gate opening, the center of the dispensed material

changes. To operate, the lever is rst unlocked by rotating counterclockwise. The handle can then be

moved up and down to change the position of the bafe. Once the correct position is found, the handle

is rotated clockwise to lock the lever in place.

• Gate stop: The gate stop controls the maximum opening of the hopper gate and is located on the

front of the hopper. The knob is rotated one direction or the other until the desired maximum gate opening is obtained.

4.3 BEFORE FIRST TIME OPERATION

• Be sure to read all information in the Operator Safety and Operation sections before attempting to

operate this unit.

• Become familiar with all of the controls and how to stop the unit.

• Drive in an open area without operating the spreader and sprayer to become accustomed to the unit.

14

Page 15

4. OPERATING INSTRUCTIONS CONTINUED

4.3 BEFORE FIRST TIME OPERATION CONTINUED

WARNING

Never operate on slopes greater than 12°.

• Select slow ground speed before driving onto a slope. Use extra caution when operating on slopes

with any accessories attached to the unit.

• Operate up and down slopes, NOT across, use caution when changing direction on slopes and do

NOT start or stop on a slope.

4.4 PRE-START

• Fill the fuel tank. For best results use only fresh, clean regular grade unleaded gasoline with an octane rating of 87 or higher. Do not add oil to the gasoline.

• Do not overll the fuel tank. Never ll the fuel tank so that the fuel level rises above a level that is ½”

below the bottom of the ller neck. This will allow for fuel expansion and will help to prevent fuel

spillage.

• Understand the controls, their locations, their functions, and their safety requirements.

• Refer to Maintenance, Section 7, and perform all the necessary inspection and maintenance steps.

4.5 STARTING THE MACHINE

• Position the machine on a at and level surface.

• Ensure that the transmission is in the neutral (N) position and that the engine ignition switch is in the

“ON” position.

• Open the fuel shut-off valves located on the engine and below the fuel tank.

• If the engine is cold, activate the choke lever located on the engine. If the engine is warm, it may not

be necessary to activate the choke lever.

• Firmly grasp the handle of the start cord and pull the handle toward the rear of the machine.

Do not squeeze the throttle lever when starting the machine.

• Once the engine has started, gradually deactivate the choke lever.

• Carefully step onto the operator platform.

• Move the transmission lever to the desired location.

• Slowly squeeze the throttle lever to start the machine moving.

15 5105862_-_HI

Page 16

4. OPERATING INSTRUCTIONS CONTINUED

4.6 STOPPING THE MACHINE

• Position the machine on a at and level surface.

• Completely release the throttle lever.

• Move the transmission lever to the neutral (N) position.

• Move the engine ignition switch to the “OFF” position.

4.7 TRANSPORTING THE MACHINE

• Use a heavy-duty trailer or hitch-mounted rack to transport the machine. Securely fasten the machine

to the trailer or rack with straps, chains, cable, or ropes. Make sure that the trailer or rack has all of the

necessary lighting and markings that are required by law. If using a trailer, make sure that the safety

chains are secured.

• Use extreme caution when loading the machine on a trailer or rack. The ramps should be long enough

so that the angle between the ramp and the ground does not exceed 12°. A steeper angle may cause

the machine to lose traction and slide out of control.

• Always load the machine with the machine driving forward.

• Only use rst gear (1) when loading the machine.

• Keep the machine in gear once it has been properly loaded and shut off. This will help to minimize

movement of the machine on the trailer or rack during transportation.

• Move the transmission lever to the desired location.

4.8 OPERATING THE SPREADER

• The spreader has a pattern width of approximately 14 feet. By using passes with an approximate 7

foot width, the granular product will be evenly distributed with the proper amount of overlap. Note that

the sprayer also requires passes with an approximate 7 foot width. Sprayer operation details are noted

in the next section.

• Adjust the gate stop to the desired setting.

• Completely close the hopper gate and add fertilizer to the hopper.

• Install the hopper shower cap if necessary.

• Carefully step onto the operator platform.

• Place the gear selector in second gear (2).

• Squeeze the throttle lever to start the machine rolling forward.

• Slide the gate lever to the OPEN position.

• To stop the spreading operation, slide the gate lever to the CLOSED position, release the throttle

lever, and depress the brake pedal.

16

Page 17

4. OPERATING INSTRUCTIONS CONTINUED

4.9 OPERATING THE SPRAYER

• The sprayer has a pattern width of approximately 11 feet with the broadcast tip. The effective pattern

width is approximately 7 feet wide which allows the same pass width as the spreader. For this reason,

the spreader and spraying systems may be operated at the same time.

• Add the required materials to the spray tank.

• Note the direction of the wind and plan an application path that allows the spraying to occur downwind.

• Avoid spraying in windy conditions as the spray may carry to non-target areas.

• Carefully step onto the operator platform.

• Rotate the spray width knob to the desired setting.

• Place the gear selector in second gear (2).

• Squeeze the throttle lever to start the machine rolling forward.

• Activate the spray control lever (horizontal position).

• To stop the spraying operation, deactivate the spray control lever (vertical position), release the throttle lever, and depress the brake pedal.

17 5105862_-_HI

Page 18

5. SLOPE OPERATIONAL SAFETY

5.1 SLOPE IDENTIFICATION GUIDE

Figure 10

Measure the slope of a lawn surface with a smartphone or angle nder tool:

WARNING

Do not operate on slopes greater than 12 degrees.

1. Use a straight edge at least two (2) feet long (A, Figure 10). A 2x4 or a straight piece of metal works

well.

2. Angle nder tools.

a) Use your smartphone: Many smartphones (B, Figure 10) have an inclinometer (angle nder)

located under the compass application (app). Or, search an app store for an Inclinometer app.

b) Use angle nder tools: Angle nder tools (C & D,Figure 10) are available at local hardware

stores or online (also called inclinometer, protractor, angle meter, or angle gauge). Dial type (C)

or digital type (D) work, others may not. Follow user instructions with the angle nder tool.

3. Place the two (2) feet long straight edge along the steepest part of the lawn slope. Place the board

up and down the slope.

4. Lay the smartphone or angle nder tool on the straight edge and read the angle in degrees. This is

the slope of your lawn.

18

Page 19

5. SLOPE OPERATIONAL SAFETY CONTINUED

5.2 SLOPE OPERATION

Slopes are a major factor related to loss-of-control and tip-over accidents, which can result in severe injury or

death. All slopes require extra caution. If you cannot back up the slope or if you feel uneasy on it, do not drive

on it.

DANGER: LOSS OF CONTROL

Operating on slopes can be hazardous and cause loss of control.

• Avoid sudden turns or rapid speed changes.

• If machine stops forward motion on a slope, stop. Get off and walk the machine slowly off the slope.

• Go up and down slopes, NOT across.

• Reduce speed and use extreme caution on slopes.

• Do NOT operate on slopes when grass is wet.

• Do NOT operate on slopes over 12* degrees.

• Reduce your speed and minimize the weight of your load (in the hopper and volume in the tanks)

when operating on hills or rough terrain to avoid possible instability, tipping or rollover of the machine.

DANGER

Wet or soft slope hazard:

• Wet or soft slopes can cause sliding and loss of control

• Do NOT operate on slopes when grass is wet. Tires may lose traction and cause sliding and loss of

control.

• Do NOT operate on slopes when soil is soft (such as after heavy rains). Tires may lose traction and

cause sliding and loss of control.

DANGER

Water, retaining walls and drop-off hazard:

• Wheels dropping over edges may result in serious injury, death and drowning.

• Do NOT operate near water, retaining walls, drop-offs or embankments. The machine could suddenly

roll over if a wheel goes over the edge or the edge breaks away.

• Reduce your speed when operating over rough terrain or near these hazards.

• Give yourself a minimum of two machine widths of clearance around these hazards.

* This limit was determined per International Standard ISO 5395-3:2013, Section 4.6 and is based on the ISO 5395-3 Stability Test procedure described in Annex A. The 12 degree “limit of stability” is equal to 60% of the angle at which machine

lift-off occurred in static tests. Actual dynamic stability may vary depending on operating conditions.

19 5105862_-_HI

Page 20

5. SLOPE OPERATIONAL SAFETY CONTINUED

5.2 SLOPE OPERATION CONTINUED

Do:

• Operate up and down slopes, NOT across.

• Remove obstacles such as rocks, tree limbs, etc.

• Watch for holes, ruts, or bumps. Uneven terrain could overturn the unit. Tall grass can hide obstacles.

• Use slow speed. Choose a slow speed so that you will not have to stop or change speed while on the

slope.

• Use extra care with accessories. These can change the stability of the unit.

• Keep all movement on the slopes slow and gradual. Do not make sudden changes in speed or direction.

• See your authorized dealer for recommendations of available weights to improve stability.

Do NOT:

• Avoid starting, stopping, or turning on a slope. If tires lose traction (i.e. machine stops forward motion

on a slope), stop. Get off and walk the machine slowly off the slope.

• Do not turn on slopes unless necessary, and then, turn slowly and gradually uphill, if possible. Never

operate straight down slopes.

• Do not operate near drop-offs, ditches, or embankments. The operator could lose footing or balance

or machine could suddenly turn over if a wheel is over the edge of a cliff or ditch, or if an edge caves in.

• Do not operate on wet grass. Reduced footing or traction could cause sliding.

• Do not try to stabilize the unit by putting your foot on the ground (ride-on units).

• Do not operate excessively steep slopes.

• Do not operate on slopes if you cannot back up them.

5.3 OPERATING ON SLOPES

Learn how to operate the Pathnder on slopes and use your body position to improve traction and control of

the machine.

Operation on slopes can be dangerous. Slopes are a major factor related to accidents, which can result in severe injury or death. Using the unit on a slope that is too steep where you do not have adequate wheel traction

(and control) can cause sliding, loss of steering, control, and possible rollover. If you feel unsure about operating the unit on a slope, don’t do it. It’s not worth the risk.

• This machine has a high center of gravity and may become unstable on slopes. Always lean towards

the slope of a hill when operating on slopes and lean towards the center of turn when changing directions on slopes.

• Operation on wet grass especially when going across or down slopes can cause loss of traction, sliding, loss of steering, control,and possible rollover.

20

Page 21

5. SLOPE OPERATIONAL SAFETY CONTINUED

5.3 OPERATING ON SLOPES CONTINUED

Operate up and down slopes, NOT across:

• Operation down slopes can be dangerous and cause sliding, loss of steering, control, and possible

rollover. Do NOT operate down a slope unless absolutely necessary. Drive very slowly in the lowest

gear and be careful. Never make a sharp turn or sudden start or stop, as this can cause loss of trac-

tion, sliding, loss of steering, control and possible rollover. Apply the rear brakes rst to slow your speed

while descending a slope.

• Operate up the slope and lean your body forward (towards the control panel), while keeping a rm grip

on the handle bar. This body position helps keep the front wheels on the ground.

•Operate down the slope and lean your body rearward with your arms out-stretched, while keeping a

rm grip on the handlebar. This body position adds more weight to the rear wheels and improves traction, downhill braking, and control.

• Always be very gentle operating the controls, travel at a slower speed than normal.

• Do NOT accelerate quickly or change speed or direction suddenly while operating, as this may cause

the machine’s front wheels to come off the ground (up slopes) and to reduce the tendency to cause the

machine to slip and slide (down slopes).

Operate across slopes (only if you cannot operate up and down the slope):

• It is recommended to operate across the face of slopes only when you cannot operate up or down

the slopes. This may be the preferred technique for operating on very gentle slopes and to avoid going

down a slope.

• Lean your body slightly rearward and towards the uphill side drive wheel, while keeping a rm grip on

the handle bar. This body position adds more weight to the uphill side drive wheel to maximize traction

and control.

• Do NOT accelerate quickly, as this may cause the machine’s front wheels to come off the ground.

• Exert strong force and keep a rm grip on the handle bars to maintain control and resist the machine

tendency to turn uphill

6. CALIBRATION

6.1 SPREADER FLOW RATE CALIBRATION

• The following instructions provide a method for adjusting the ow of fertilizer from the hopper so that

the correct amount of fertilizer is applied to a 1000 ft2 area. The machine is designed to apply fertilizer

evenly by overlapping each pass by 50 percent. The spread width for most products is approximately

14 feet. This means that the center of each pass should be approximately 7 feet from the center of the

previous pass. The effective material spread width is 7 feet and is the basis for calibration.

• Measure a distance of 143 feet on a at paved surface. Using a paved surface will allow the fertilizer

to be recollected and will prevent burning the turf if the application rate is largely different from what is

intended. Traveling 143 feet with the machine equates to covering approximately 1000 ft2 with fertilizer

(7 ft x 143 ft = 1001 ft2).

21 5105862_-_HI

Page 22

6. CALIBRATION CONTINUED

6.1 SPREADER FLOW RATE CALIBRATION CONTINUED

• Set the gate stop to a setting of 5. This will be used as the starting setting for dialing in the correct

gate stop setting for the particular material that is being used. Note that the spreader will have to be

recalibrated for each different type of material that is spread. Make sure to record the nal gate stop

setting once the correct application rate has been achieved.

• Place the spreader gate lever in the CLOSED position. Place enough material in the hopper to cover

1000 ft2.

• Begin the spreading operation while moving toward the 143 foot marker. With the machine moving at

full speed, the hopper should just empty out as the machine passes the marker. If the hopper empties

before the marker is reached, turn the gate stop dial to a slightly lower setting and repeat the process.

If the hopper empties after the marker is reached, turn the gate stop dial to a slightly higher setting and

repeat the process. Continue this process until the proper dispensing rate is achieved.

• When the calibration is complete, collect the fertilizer that has been dispensed for reuse. Never leave

the fertilizer on the pavement where it can wash away in runoff.

6.2 CENTERING THE SPREAD PATTERN

• The following instructions provide a method for adjusting the center of the spread pattern so that

fertilizer is evenly distributed over the width of the spread area.

• Obtain the following items:

• Eleven collection pans, 3 to 4 inches tall and 12 inches square (e.g. aluminum roasting pans).

• Clear tube, ½” internal diameter, 4 inches tall. Use a permanent marker to mark the tube at

¼” increments all of the way up the tube. This will act as a measuring device for the collected

fertilizer prills.

• A ruler or tape measure.

• A method of recording the collection amounts.

• Set the gate stop to a setting of 5.

• Move the gate lever to the OPEN position (the hopper must initially be empty).

• Turn the spread control lever counterclockwise to release the lock and move the lever in or out so that

the bafe can be seen centered just below the opening of the gate in the bottom of the hopper. Turn the

spread control lever clockwise to lock into position.

• Move the gate lever to the CLOSED position.

• Load the hopper with the fertilizer to be used for calibration.

• Place the eleven collection pans on a at paved surface in a straight line on two-foot centers. Using a

paved surface will allow the fertilizer to be recollected and will prevent burning the turf if the application

pattern is largely different from what is intended.

• Make at least three passes traveling directly over the center pan in a path perpendicular to the row of

pans. NOTE: All of the passes must be made in the same direction.

• Pour the contents of the rst pan on the left into the graduated tube and record the amount of material

that is in the tube. Repeat this measurement for each of the eleven collection pans.

22

Page 23

6. CALIBRATION CONTINUED

6.2 CENTERING THE SPREAD PATTERN CONTINUED

• Add together all of the eleven numbers to nd the total material that was dispensed.

• Divide the amount caught in each pan by the total amount. This is the percentage that was caught in

each pan.

• The distribution should increase towards the center pan and decrease toward the outside pans. The

distribution should also be approximately the same on each side. If it appears that the left side is receiving more material, pull the spread control lever out slightly and repeat the process. If it appears that the

right side is receiving more material, push the spread control lever in slightly and repeat the process.

Only slight adjustments are needed to make spread pattern changes.

• Once the correct distribution is achieved, measure the distance from the console surface to the top of

the spread control lever. Record this measurement as the setting to be used for the particular fertilizer

being evaluated. Note that the spreader will have to be recalibrated for each different type of material

that is spread.

• When the calibration is complete, collect the fertilizer that has been dispensed for reuse. Never leave

the fertilizer on the pavement where it can wash away in runoff.

6.3 CALIBRATING THE SPRAY FLOW RATE

• The following instructions provide a method for adjusting the amount of ow being dispensed from the

spray nozzles.

• Fill the spray tank with water.

• Place a container in a position near the spray nozzles so that all of the spray being dispensed by the

nozzles can be captured in the container.

• Move the spray control knob to the desired spray width setting. The spray will ow through the broadcast tip (TF-VS5) on the wide spray setting. The spray will ow through the trim tip (TT11004VP) on the

narrow spray setting.

• Place the machine in neutral (N), squeeze the throttle lever to run the engine at full throttle, and adjust

the pressure relief valve so that the reading on the pressure gauge is 25 psi.

• Move the spray control lever to ON (horizontal position). Operate the spray system in the ON position

for exactly one minute.

• Measure the collected water. The amount collected for each tip should approximately be as follows:

• Broadcast tip (TF-VS5) = 100 ounces ± 10 ounces

• Trim tip (TT11004VP) = 40 ounces ± 4 ounces

• If the output from the nozzles is slightly different from the values listed above, adjust the pressure

relief valve slightly. Unscrewing the valve knob will decrease the system pressure and will decrease the

output from the tips. Screwing the valve knob in will increase the system pressure and will increase the

output from the tips.

• If the output from the nozzles is drastically different from the values listed above, there may be other

problems with the system. Refer to section 8, FAULT ISOLATION.

23 5105862_-_HI

Page 24

7. MAINTENANCE, STORAGE, AND SERVICE

7.1 MANTENANCE AND STORAGE SAFETY

• Always observe safe refueling and fuel handling practices when refueling the unit after transportation

or storage.

• Always follow the engine manual instructions for storage preparations before storing the unit for both

short and long term periods.

• Always follow the engine manual instructions for proper start-up procedures when returning the unit to

service.

• Never store the machine or fuel container inside where there is an open ame, such as in a water

heater. Allow unit to cool before storing.

• Shut off fuel while storing or transporting. Do not store fuel near ames or drain indoors.

• Keep all hardware tight and keep all parts in good working condition. Replace all worn or damaged

decals.

• Never tamper with safety devices. Check their proper operation regularly.

• Disengage spreader spinner and sprayer pump, set parking brake, stop engine and remove key or

disconnect spark plug wire. Wait for all movement to stop before adjusting, cleaning or repairing.

• Clean grass and debris from moving parts, drives, mufers, and engine to prevent res. Clean up oil

or fuel spillage.

• Let engine cool before storing and do not store near ame.

• Stop and inspect the equipment if you strike an object. Repair, if necessary, before restarting.

• Park machine on level ground. Never allow untrained personnel to service machine.

• Use jack stands to support components when required.

• Carefully release pressure from components with stored energy.

• Disconnect battery or remove spark plug wire before making any repairs. Disconnect the negative

terminal rst and the positive last. Reconnect positive rst and negative last.

• Keep hands and feet away from moving parts. If possible, do not make adjustments with the engine

running.

• Charge batteries in an open well ventilated area, away from spark and ames. Unplug charger before

connecting or disconnecting from battery. Wear protective clothes and use insulated tools.

• Check brake operation frequently. Adjust and service as required.

• Use only factory authorized replacement parts when making repairs.

24

Page 25

7. MAINTENANCE, STORAGE, AND SERVICE CONTINUED

7.1 MANTENANCE AND STORAGE SAFETY CONTINUED

• Always comply with factory specications on all settings and adjustments.

• Only authorized service locations should be utilized for major service and repair requirements.

• Never attempt to make major repairs on this unit unless you have been properly trained. Improper service procedures can result in hazardous operation, equipment damage and voiding of manufacturer’s

warranty.

• Units with hydraulic pumps, hoses, or motors: WARNING: Hydraulic uid escaping under pressure

may have sufcient force to penetrate skin and cause serious injury. If foreign uid is injected into the

skin it must be surgically removed within a few hours by a doctor familiar with this form of injury or gan-

grene may result. Keep body and hands away from pin holes or nozzles that eject hydraulic uid under

high pressure. Use paper or cardboard, and not hands, to search for leaks. Make sure all hydraulic uid

connections are tight and all hydraulic hoses and lines are in good condition before applying pressure

to the system. If leaks occur, have the unit serviced immediately by your authorized dealer.

• WARNING: Stored energy device. Improper release of springs can result in serious personal injury.

Springs should be removed by an authorized technician.

• Always disengage the sprayer pump and spreader spinner and close the hopper gate before maintaining or storage.

• Empty the sprayer tank and fertilizer hopper before lifting or tilting the machine for maintenance or

storage.

7.2 PERIODIC SERVICE INTERVALS

Daily Inspections:

• Check engine oil level. See the Engine Owner’s Manual.

• Check the reduction case oil level. See the Engine Owner’s Manual.

• Check the air lter. See the Engine Owner’s Manual.

• Spray the shaft bushing in the bottom of the hopper with a light oil lubricant such as WD-40.

• Check the entire machine for loose hardware or other problems. Resolve any issues before operating

the machine.

One Month or 20 Hour Maintenance Period:

• Change the engine oil the rst month or after 20 hours, whichever comes rst. Change the engine oil

every 100 hours after that. See the Engine Owner’s Manual.

• Change the reduction case oil the rst month or after 20 hours, whichever comes rst. Change the

reduction case oil every 100 hours after that. See the Engine Owner’s Manual.

25 5105862_-_HI

Page 26

7. MAINTENANCE, STORAGE, AND SERVICE CONTINUED

7.2 PERIODIC SERVICE INTERVALS CONTINUED

25 Hour Maintenance Interval:

• Check the tire pressure in all four tires. Inate the front drive tires to 10 psi. Inate the rear operator

platform tires to 15 psi.

• Clean debris from the engine and mufer.

• Inspect the spray system lter located right below the tank.

• Grease the wheel bearings on the operator platform.

• Wash the machine with low pressure water.

• Apply a light oil lubricant such as WD-40 to all moving parts except for belts and pulleys.

50 Hour Maintenance Interval:

• Clean the air lter. When operating in dusty conditions, the air lter may require more frequent

cleaning.

• Check the brakes. Adjust if necessary.

• Grease the operator platform pivot hub.

100 Hour Maintenance Interval:

• Change the engine oil. See the Engine Owner’s Manual.

• Change the reduction case oil. See the Engine Owner’s Manual.

• Clean the sediment cup on the engine. See the Engine Owner’s Manual.

• Check and adjust the spark plug. See the Engine Owner’s Manual.

• Clean the spark arrester on the engine. See the Engine Owner’s Manual.

• Inspect the fuel tank for debris. Clean if necessary.

• Inspect the fuel lter. Clean or replace as necessary.

• Inspect the belts. Replace if necessary.

• Flush and clean the spray tank.

• Check the spray system output rate. Replace spray tips and/or adjust pressure setting as necessary.

300 Hour Maintenance Interval:

• Replace the air lter. See the Engine Owner’s Manual.

• Replace the spark plug. See the Engine Owner’s Manual.

• Check the idle speed and adjust if necessary.*

• Check the valve clearance and adjust if necessary.*

• Check the gear oil level in the spinner right angle gearbox.

500 Hour Maintenance Interval:

• Clean the combustion chamber.*

*These items should be serviced by your Honda servicing dealer, unless you have the proper tools and are

mechanically procient. Refer to the Honda shop manual for service procedures.

26

Page 27

8. FAULT ISOLATION

This section provides a method for troubleshooting machine problems. Before utilizing the following procedures, check the machine for obvious signs of damage or failure. This includes missing or loose components,

components that have failed, or physical damage. Do not attempt to operate the machine until the machine has

been repaired.

8.1 MACHINE DOES NOT START

FAILURE MODE CAUSE OF PROBLEM CORRECTIVE ACTION

Machine does not start. The fuel level in the tank is low. Add fuel to the fuel tank.

The fuel shutoff valves are in the

closed position.

The fuel line is clogged. Clean the fuel line.

The fuel tank has contamination. Clean out the fuel tank and install

The choke setting is incorrect. Ensure that the choke setting is

The shift lever is not in the neutral

(N) position.

The ignition switch is in the “OFF”

position.

Make sure that the fuel shut off

valves are open. One valve is located below the tank and the other

valve is located on the engine.

fresh fuel.

correct for the starting conditions.

Cold starts will require the choke to

be activated while warm starts may

not require the choke.

Center the shift lever in the neutral (N) position. The transmission

must be in the neutral position to

start.

Move the ignition switch to the

“ON” position.

27 5105862_-_HI

Page 28

8. FAULT ISOLATION CONTINUED

8.2 SPREADING SYSTEM OPERATES INCORRECTLY

FAILURE MODE CAUSE OF PROBLEM CORRECTIVE ACTION

Spreader pattern is uneven or

spreader does not operate.

The gate opening in the bottom of

the hopper is blocked.

The spread control bafe is positioned incorrectly.

The input shaft of the spinner gearbox is not turning.

The shaft coupler is loose. Make sure that the coupler con-

The spinner is dirty, worn or damaged.

The spinner clip is damaged or

missing.

Remove the material from the

hopper and dislodge any clumps

around the gate opening. Inspect

the agitator wire and make sure

that it is not worn, damaged, or

missing.

Follow the procedure outlined

in Section 4.2 for centering the

spread pattern.

Inspect the tension of the drive

belts. Make sure that the idler

pulleys are maintaining pressure

on the belts. Inspect the belts for

severe wear or damage.

necting the spinner shaft to the

spinner gearbox is tightened correctly.

Inspect the spinner and clean or

replace if necessary.

Inspect the spinner clip on the bottom of the spinner. If it is damaged

or missing, the spinner may not

spin even though the spinner shaft

is rotating. Replace the spinner clip

if necessary.

28

Page 29

8. FAULT ISOLATION CONTINUED

8.3 SPRAYING SYSTEM OPERATES INCORRECTLY

FAILURE MODE CAUSE OF PROBLEM CORRECTIVE ACTION

Spraying pattern is

uneven or spraying

system does not operate.

The spray nozzle tips are out of

position.

The spray nozzles are out of

position.

The spray valve is not in the correct position.

The pressure relief valve is set

incorrectly.

The strainer or tip is clogged. Remove the spray nozzle tip and inspect the tip

The lter is clogged. Remove the sediment bowl from the lter

The spray pattern knob is incorrectly set.

Rotate the spray nozzle tips so that the tip ori-

ce is directed straight in front of the machine.

Verify that the lower nozzle (trim nozzle) is positioned approximately 30 degrees and the upper

nozzle (broadcast nozzle) is positioned straight

up and down.

Verify that the spray valve is in the horizontal

position when spraying. The valve lever can be

moved either forward or backward to the horizontal position to operate. The valve is “OFF” in

the vertical position.

Verify that the pressure gauge reads approximately 25 psi at full engine speed. Adjust the

pressure relief knob in or out to obtain this

pressure. Tighten the locking nut against the

pressure relief knob.

orice and the strainer to make sure they are

not clogged. Clean or replace these components as necessary.

housing and inspect the lter screen. Clean or

replace the screen as necessary.

Move the spray pattern knob all the way to side

of the desired pattern setting.

The spray tank volume is low. Rell the spray tank. Note that in very rough

The engine speed is too low. Operate the machine at full engine speed. The

The pump is worn or damaged. Loosen the suction tting on the pump to verify

The pump input shaft is not spinning.

or hilly conditions, the liquid in the spray tank

may slosh around and the tank discharge tube

may starve when the tank level is low. This can

cause poor spraying performance.

spray system is designed to operate most efciently at full engine speed.

that there is liquid ow to the pump. Tighten the

suction tting and loosen the discharge tting

to verify that the pump is operating correctly. If

there is no ow, replace the pump.

Verify that all of the belts are in good condition

and are tensioned properly. Verify that the pump

pulley is securely fastened to the pump shaft

with a setscrew.

29 5105862_-_HI

Page 30

9. WARRANTY INFORMATION

BRIGGS & STRATTON WARRANTY POLICY (November 2017) LIMITED WARRANTY

Briggs & Stratton warrants that, during the warranty period specied below, it will repair or replace,

free of charge, any part that is defective in material or workmanship or both. Transportation charges

on product submitted for repair or replacement under this warranty must be borne by purchaser. This

warranty is effective for and is subject to the time periods and conditions stated below. For warranty

service, nd the nearest Authorized Service Dealer in our dealer locator map at

www.groundlogicinc.com. The purchaser must contact the Authorized Service Dealer, and then make

the product available to the Authorized Service Dealer for inspection and testing.

There is no other express warranty. Implied warranties, including those of merchantability and tness

for a particular purpose, are limited to the warranty period listed below, or to the extent permitted by

law. Liability for incidental or consequential damages are excluded to the extent exclusion is permitted

by law. Some states or countries do not allow limitations on how long an implied warranty lasts, and

some states or countries do not allow the exclusion or limitation of incidental or consequential damag-

es, so the above limitation and exclusion may not apply to you. This warranty gives you specic legal

rights and you may also have other rights which vary from state to state or country to country.*

Covered Parts Standard Warranty Rental Warranty Period

Spreader-Sprayer and Spreaders 1 Year (12 Months) 90 Days

• Belts

• Tires

• Brake Pads

• Hoses

• Battery

Accessories 1 Year (12 Months) 90 Days

Engine* See Engine Operator’s Manual See Engine Operator’s Manual

* Emissions-related components are covered by the Emissions Warranty Statement.

The warranty period begins on the date of purchase by the rst retail or commercial customer. To

ensure prompt and complete warranty coverage, register your product at the website shown above or

at www.groundlogicinc.com/support/warranty-registration/, or mail the completed registration card (if

provided), or call 1-877-423-4340 (in USA).

Save your proof of purchase receipt. If you do not provide proof of the initial purchase date at the time

warranty service is requested, the manufacturing date of the product will be used to determine the

warranty period. Product registration is not required to obtain warranty service on Briggs & Stratton

products.

90 Days 90 Days

30

Page 31

ABOUT YOUR WARRANTY

Warranty service is available only through Ground Logic Authorized Service Dealers. This warranty only covers

defects in materials or workmanship. It does not cover damage caused by improper use or abuse, improper

maintenance or repair, normal wear and tear, or stale or unapproved fuel.

Improper Use and Abuse - The proper, intended use of this product is described in the Operator's Manual.

Using the product in a way not described in the Operator's Manual or using the product after it has been damaged will not be covered under this warranty. Warranty coverage will also not be provided if the serial number

on the product has been removed or the product has been altered or modied in any way, or if the product has

evidence of abuse such as impact damage, or water/chemical corrosion damage.

Improper Maintenance or Repair - This product must be maintained according to the procedures and schedules provided in the Operator's Manual, and serviced or repaired using genuine Briggs & Stratton parts or

equivalent. Damage caused by lack of maintenance or use of non-original or non-equivalent parts is not covered by warranty.

Normal Wear and Tear - Like all mechanical devices, the unit is subject to wear even when properly maintained. This warranty does not cover replacement or repairs when normal use has exhausted the life of a part

or the equipment. Except as noted in the warranty period, maintenance and wear items such as lters, belts,

and brake pads (except engine brake pads) are not covered by warranty due to wear characteristics alone,

unless the cause is due to defects in material or workmanship.

Stale or Unapproved Fuel - In order to function correctly, this product requires fresh fuel that conforms to the

criteria specied in the Operator's Manual. Engine or equipment damage caused by stale fuel or the use of

unapproved fuels (such as E15 or E85 ethanol blends) is not covered by warranty.

Other Exclusions - This warranty excludes damage due to accident, abuse, modications, alterations, im-

proper servicing, freezing or chemical deterioration. Attachments or accessories that were not originally packaged with the product are also excluded. This warranty does not include used, reconditioned, second-hand, or

demonstration equipment or engines. This warranty also excludes failures due to acts of God and other force

majeure events beyond the manufacturer's control.

31 5105862_-_HI

Loading...

Loading...