Page 1

Installation, Operation and Maintenance Manual for

Back Pressure Regulator

Model 8860

IOM-8860

Rev. B 12541

©2009 Groth Corporation

Ref. ID: 95565

Page 2

IOM -8860

Page 2 of 13

Table of Contents

I. INTRODUCTION 3

II. DESIGN AND FUNCTION 4

III. SAFETY WARNINGS 5

IV. INSPECTION AND STORAGE 5

V. INSTALLATION 6

a. 6

b. 6

VI. MAINTENANCE 7

a. FIGURE 4 – 7

b. TABLE 3 – 8

VII. VALVE TESTING PROCEDURE 8

VIII. MODEL IDENTIFICATION 9

APPENDIX A – MODEL 1200A PRESSURE/VACUUM RELIEF VALVE 10

APPENDIX B – MODEL 1220A PRESSURE/VACUUM RELIEF VALVE 11

APPENDIX C – MODEL 1260A PRESSURE RELIEF VALVE 12

APPENDIX D – MODEL 1300A VACUUM RELIEF VALVE 13

APPENDIX E – MODEL 1360A VACUUM RELIEF VALVE 14

APPENDIX F – MODEL 2300A PRESSURE RELIEF VALVE 15

13650 N. Promenade Blvd. * Stafford, TX 77477

Office: (281) – 295-6800 * (800) – 354-7684 * Fax: (281) – 295-6999 * www.grothcorp.com

Page 3

IOM -8860

Page 3 of 13

I. INTRODUCTION

The Groth Model 8860 Back Pressure Regulator controls upstrea m pressure in a process line such as

an anaerobic digester gas control system. The pressure setting is obtained by adjustable spring

compression and opening is caused by upstream pressure acting on a large diaphragm. A visible scale

indicates approximate set pressure. Springs are available for various standard and special set

pressure ranges.

The regulator must be maintained by a knowledgeable valve technician. It should only be assembled

under clean conditions, preferably in a shop environment. Carefully read and understand this manual

before attempting to adjust set pressure or flow capacity, or repair the regulator.

For information not contained in this manual, please contact:

Groth Corporation

13650 N. Promenade Blvd.

Stafford, TX, 77477 USA

Phone: 281-295-6800

Fax: 281-295-6999

www.grothcorp.com

13650 N. Promenade Blvd. * Stafford, TX 77477

Office: (281) – 295-6800 * (800) – 354-7684 * Fax: (281) – 295-6999 * www.grothcorp.com

Page 4

IOM -8860

Page 4 of 13

II. DESIGN AND FUNCTION

The Groth Model 8860 Back Pressure regulator is a high capacity, low pressure in-line pressure relief

valve. It controls upstream pressure by discharging excess vapor downstream.

When the diaphragm force, due to upstream pressure, equals the spring compression, the regulator

begins to open. Opening is controlled to accommodate the required vapor flow. Full capacity is

achieved at 15-25% over-pressure [above set pressure]. When system pressure returns to set

pressure or below, the regulator closes.

Upstream vapor pressure, acting on a large diaphragm, forces the regul ator open at the specified set

pressure. For best performance, set pressure should be sensed at a remote location at least ten pipe

diameters upstream from the regulator. The upstream pressure acts on the lower surface of the

diaphragm. The upper side of the diaphragm must be vented to atmosphere.

Set pressure is determined by the compression of the spring; the greater the compression of the

spring, the higher line pressure required to overcome the spring force. The scale located on the

regulator is a close approximation of the set pressure. A manometer is recommended for a high

accuracy reading of the set pressure. The manometer should be plumbed upstream of the Back

Pressure Regulator, at lease ten pipe diameters.

The seat and disc are lapped flat surfaces with metal to metal contact.

III. SAFETY WARNINGS

This section is intended as an overview of safety guidelines that should be followed during the

installation, operation and maintenance of the Groth Model 8860 Back Pressure Regulator. To

understand the context of these warnings and instructions, read and understand this complete manual.

In the event of an actuator diaphragm failure, the regulator will fail in the CLOSED position.

Vapor flow will be shut off. WITHOUT PROPER PIPELINE PRESSURE SENSING, EXCESSIVE

PRESSURE CAN BE REACHED.

Regulator flow capacity is based on a fully open regulator flowing air or a vapor with SG=0.7.

Consult factory for capacity under other conditions.

DO NOT attempt to re-adjust the set pressure beyond the limits specified in Table 3.

The regulator is to be connected to the upstream line with a minimum .31" ID tubing sense line.

This line must be kept open and unobstructed to ensure that the regulator senses the actual

line pressure. Long sense lines may require a larger diameter and care must be taken DURING

INSTALLATION to assure that the line is self-draining.

DO NOT attempt to remove the regulator from the line or perform field repairs in line without

first isolating the regulator from both upstream and downstream systems.

The regulator body and actuator housing are exposed to process vapors. Observe all safety

precautions as specified on the Material Safety Data Sheet(s) for the prod uct(s) that are in the

system.

The vent on the upper actuator housing must be clean and open to the atmosphere and SHALL

be inspected periodically.

The recommended set pressure range of the regulator spring is stamped on the namep l ate.

Never adjust a spring for a set pressure beyond its design range as specified in Table 3.

13650 N. Promenade Blvd. * Stafford, TX 77477

Office: (281) – 295-6800 * (800) – 354-7684 * Fax: (281) – 295-6999 * www.grothcorp.com

Page 5

IOM -8860

Page 5 of 13

Exceeding the spring upper limit may compress the spring to its solid height, and prevent the

regulator from opening. Setting it below the lower limit may prevent the regulator from closing

fully at the required pressure.

PROCESS PIPING IS TO BE CLEAN AND FREE OF WELD SLAG. WELD SLAG OR OTHER

DEBRIS COULD BLOCK THE SENSE LINE OR DAMAGE THE REGULATOR SEATING SURFACE.

DO NOT LIFT THE BACK PRESSURE REGULATOR FROM THE ADJUSTMENT SCREW. IF

LIFTED FROM THIS LOCATION, THE ADJUSTMENT SCREW MAY BE PERMANENTLY

DAMAGED.

USING AN IMPROPER PRESSURE SENSING LINE CAN RESULT IN LIMITED OR NO

FUNCTIONALITY OF THE REGULATOR. RECOMMENDED SIZE FOR THE PRESSURE SENSING

LINE IS AT LEAST .31”. THIS LINE MUST REMAIN FREE OF DEBRIS AND ANY TYPE OF

OBSTRUCTION.

IV. INSPECTION AND INSTALLATION

The regulator is packaged and supported to prevent damage or contamination during shipment. The

regulator shall also be protected during subsequent handling and storage. Always keep all ports

plugged to prevent intrusion of foreign materials. Before installation, inspect the unit visually. If there

are indications of physical damage or internal contamination, the regulator must be disassembled,

cleaned and inspected before installation. If factory set, the spring adjustment cap must be secure.

Report any shipping damage to carrier.

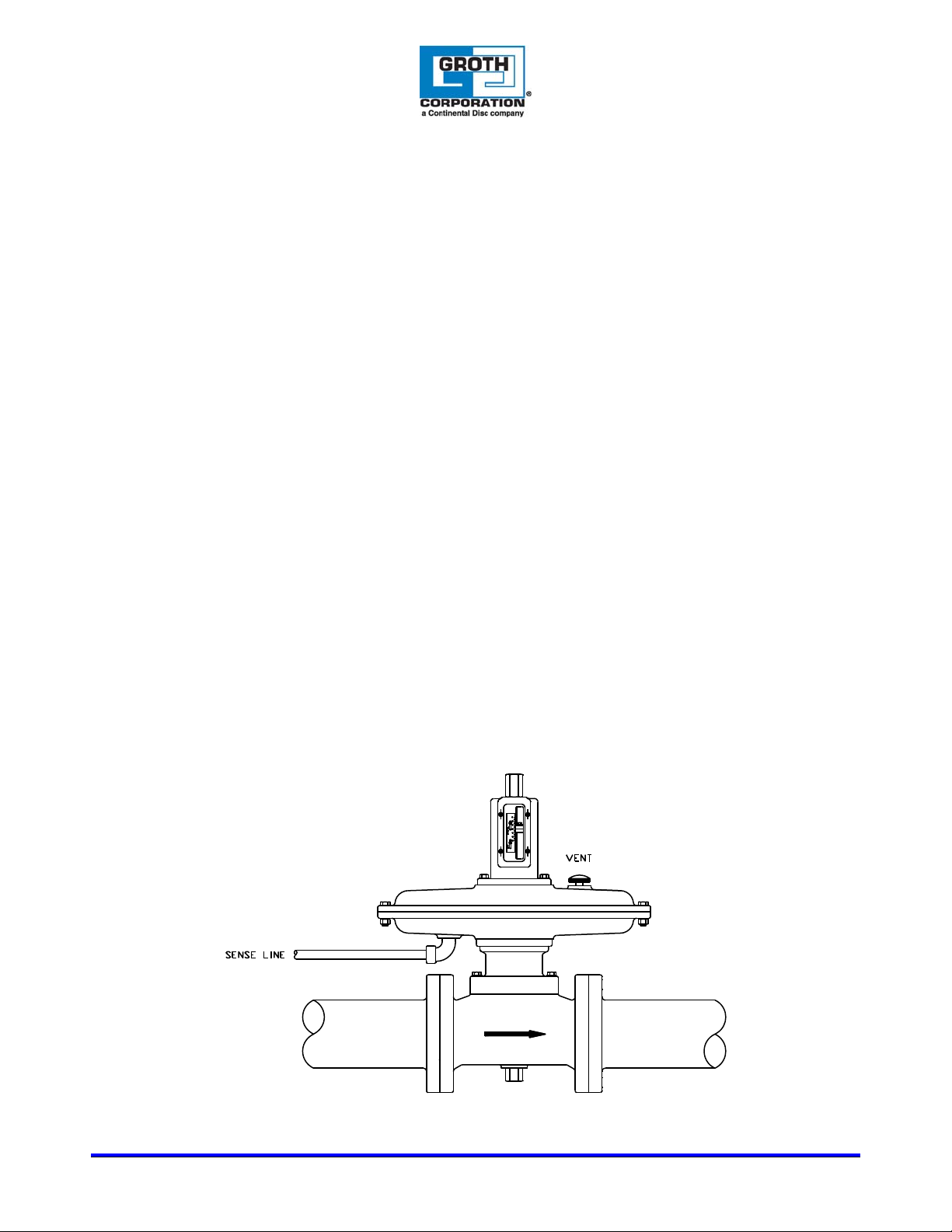

The regulator must be installed in a horizontal line as shown in Figure 1. Use the actuator housing or

valve body to lift and support the regulator at installation.

1. Aluminum bodies should be connected with flat-faced 150# ANSI flanges using a full-faced gasket.

Mating flanges should be flat within .020", clean, free of scratches, corrosion and tool marks.

2. Steel bodies should be connected with raised-faced 150# ANSI flanges using a full-faced or ring

gasket. Mating flanges should be flat within .020", clean, free of scratches, corrosion and tool

marks.

3. Each valve is leak tested at the factory as part of our standard inspection procedures.

4. Inspect the gasket; make sure that the material is suitable for the service. Gasket dimensions are

listed in Table 1. Full gaskets must be used with flat face flanges. Either full or ring gaskets may be

used with raised face flanges.

Figure 1: Regulator

13650 N. Promenade Blvd. * Stafford, TX 77477

Office: (281) – 295-6800 * (800) – 354-7684 * Fax: (281) – 295-6999 * www.grothcorp.com

Page 6

IOM -8860

Page 6 of 13

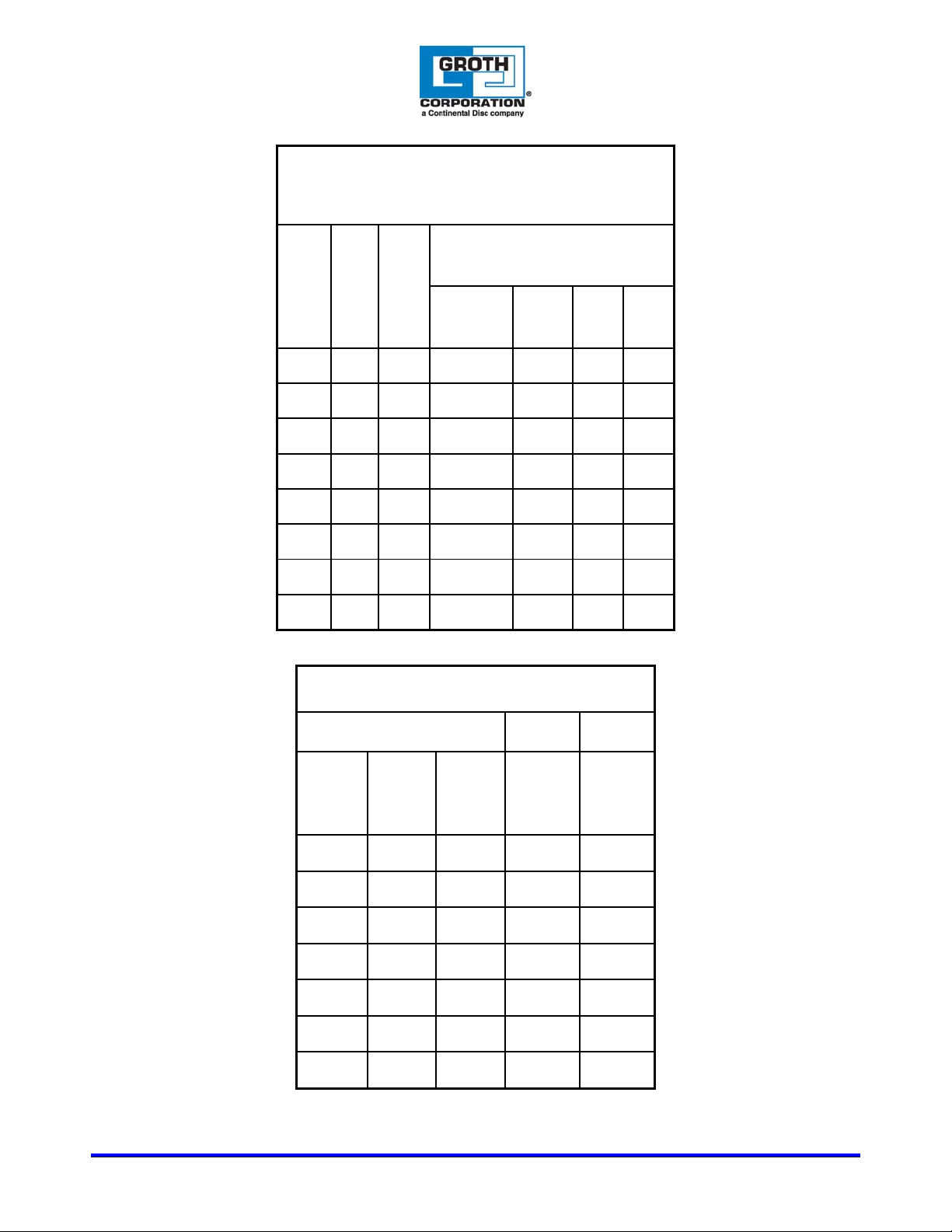

Table 1

Inlet/Outlet Flange Gasket Dimensions

Full Face Gasket

ANSI

150#

I.D.

Ring

O.D.

Outer

Diameter

Bolt

Circle

Hole

Size

Hole

Qty

2 2.38 4.12 6 4.75 0.75 4

3 3.5 5.38 7.5 6 0.75 4

4 4.5 6.88 9 7.5 0.75 8

6 6.62 8.75 11 9.5 0.88 8

8 8.62 11 13.5 11.75 0.88 8

10 10.8 13.4 16 14.25 1 12

12 12.8 16.1 19 17 1 12

16” 16 20.3 23.5 21.25 1.12 16

Flange

Size

(ANSI

150#)

Table 2: Bolt Torque

Flat Face & Raised Face Flange

Qty.

of

Bolts

Stud

Size

(UNC)

Flat

Face

Torque:

Foot-

Pound

(Kg*m)

Raised

Face

Torque:

Foot-

Pound

(Kg*m)

2” 4 5/8”-11 81 (11) 31 (4.3)

3” 4 5/8”-11 106 (15) 43 (6.0)

4” 8 5/8”-11 68 (9.4) 29 (4.0)

6” 8 3/4"-10 101 (14) 51 (7.1)

8” 8 3/4"-10 142 (20) 78 (11)

10” 12 7/8”-9 138 (19) 75 (10)

12” 12 7/8”-9 179 (25) 93 (13)

13650 N. Promenade Blvd. * Stafford, TX 77477

Office: (281) – 295-6800 * (800) – 354-7684 * Fax: (281) – 295-6999 * www.grothcorp.com

Page 7

5. Lubricate all studs and nuts with an appropriate thread lubricant. If stainless steel fasteners are

used, use an anti-seize lubricant such as moly-disulfide.

6. Align flanges and gaskets. Make sure the flow path is not restricted by valve or gasket

misalignment.

7. Install nuts and lock washers and torque all fasteners to half the value listed in Table 2 below in a

staggered, alternating pattern.

8. Make sure that the flanges are not distorted and that the gasket is evenly compressed.

9. Make up the final torque and check that no further nut rotation occurs at the specified torque value.

Regulator flow capacity is based on a fully open regulator flowing air or a vapor with SG=0.7. Consult

factory for capacity under other conditions.

The regulator sense line is to be connected to the process line at a location at least ten feet upstream

with a minimum of .31" ID tubing. The sense port on the regulator is on the lower surface of the

actuator housing (see Figure 1). This line must be kept open and unobstructed to ensure that the

regulator "senses" the actual line pressure. Long sense lines may require a larger diam eter and care

must be taken to assure that the line is self-draining. For some applications, a nitrogen purge may be

required to ensure that this line remains open. Consult the factory for recommendations for remote

installations or vapors that may cause line obstructions.

All system piping must be free of weld slag and other debris before installing the regulator.

V. OPERATION

The regulator is set at the factory. The pressure setting can be changed while installed in the pro ce ss

piping system. The purpose of the regulator is to maintain set pressure at some point upstream in the

process, such as in the anaerobic digester tank. System pressure shall be monitored at this point.

Set pressure is set at the factory according to purchasing specifications. The range of set pressure for

standard springs are shown in Table 3. Other ranges are available with special spring s. The factory

setting and spring range are shown on the nameplate. The regulator will not function properly if the

setting is outside this range. If higher or lower settings are required, the necessary component s can be

obtained from Groth Corporation.

For in-line adjustment, a visible scale shows the approximate set pressure. From this setting, small

adjustments can be made while observing upstream system pressure. Remove the cap [1] and turn the

adjusting screw counter-clockwise to increase pressure or clockwise to decrease pressure. Replace

the cap when adjustment is complete.

IOM -8860

Page 7 of 13

13650 N. Promenade Blvd. * Stafford, TX 77477

Office: (281) – 295-6800 * (800) – 354-7684 * Fax: (281) – 295-6999 * www.grothcorp.com

Page 8

Flange

Size

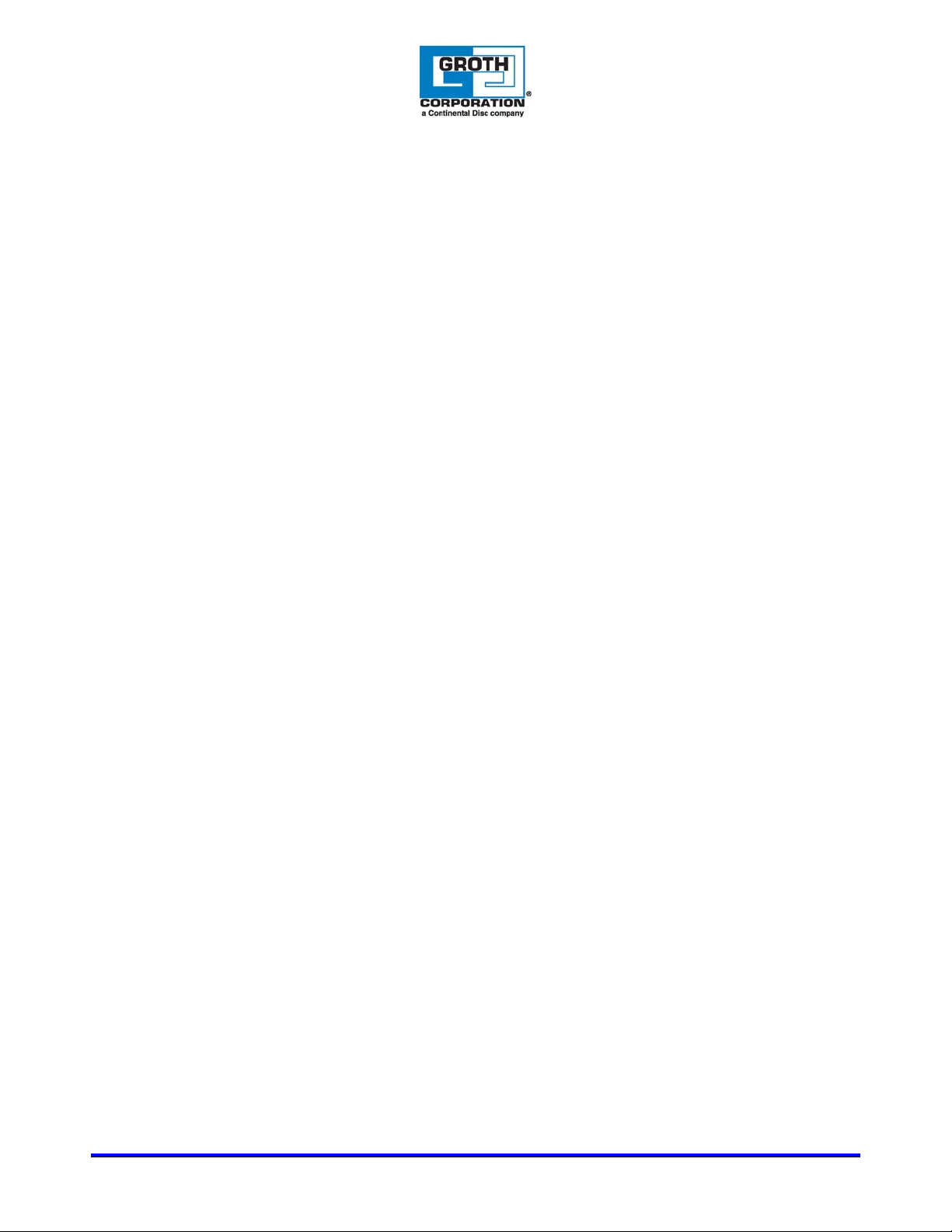

2” 2” WC 12” WC SPR8860020120 313000101

2” 8” WC 24” WC SPR8860020220 313000201

3” & 4” 2” WC 12” WC SPR8860030120 313000101

3” & 4” 8” WC 24” WC SPR8860030220 313000201

6” & 8” 2” WC 12” WC SPR8860060120 313000101

6” & 8” 8” WC 24” WC SPR8860060220 313000201

10” & 12” 2" WC 6” WC SPR8860100320 313000301

10” 5” WC 12” WC SPR8860100520 313000401

10” & 12” 10” WC 22” WC SPR8860100420 313000501

10” & 12” 20" WC 44” WC SPR8860100620 313000601

12" 3” WC 8” WC SPR8860100520 313000701

12" 5” WC 12” WC SPR8860120520 313000401

VI. TROUBLESHOOTING GUIDE

PROBLEM INSPECTION SUGGESTED CORRECTIVE ACTION

IOM -8860

Page 8 of 13

TABLE 3

SPRING TABLE: MODEL 8860

Min. Setting Max. Setting Spring P/N Scale P/N

Vapor flowing at line

pressure below specified

set point.

Vapor not flowing at line

pressure above specified

set point.

Gas leaking from upper

vent.

System pressure above

specified operating

range.

System pressure below

specified operating

range.

Flow indicator or vapor

discharge.

Flow indicator or vapor

discharge.

Emission indication

near the regulator.

Observe pressure

indicator during

operation.

Observe pressure

indicator during

operation.

VII. PREVENTATIVE MAINTANANCE

Periodically, while in service, examine the regulator for leakage at bolted connections, adjusting

screws, and vent. Test for process vapor emissions from vent caps.

Periodically, out of service, examine seat and pallet for a smooth surface to ensure proper seating and

sealing. Examine actuator diaphragm for cuts, or unusual wear.

VIII. RECOMMENDED SPARE PARTS

Spring; see Table 3 for correct part number

Vent part number 285320147 (1/4” NPT)

Soft Goods Kit; see Table 4 for correct part

numbers

Damaged seat/disc or setting too low.

If original pressure setting has not been disturbed, remove

regulator and repair.

Damaged diaphragm or pressure setting too high.

If original pressure setting has not been disturbed, remove

regulator and repair.

Inspect the bushings for debris or damage.

Damaged diaphragm.

Remove regulator and replace diaphragm.

Damaged diaphragm or pressure setting too high.

Vapor flow exceeds capacity of regulator.

Damaged seat/disc or setting too low.

Insufficient vapor production.

Table 4: Soft Goods Kits

Size Buna-N EPDM FKM

2”-4” KS886002B KS886002E KS886002V

6”-8” KS886002B KS886002E KS886002V

10”-12” KS886002B KS886002E KS886002V

13650 N. Promenade Blvd. * Stafford, TX 77477

Office: (281) – 295-6800 * (800) – 354-7684 * Fax: (281) – 295-6999 * www.grothcorp.com

Page 9

IOM -8860

Page 9 of 13

IV. MODEL INFORMATION

The nameplate on the Groth Model 8860 Back Pressure Regulator contains the model nu mber, serial

number, set pressure & set pressure range. The model number contains additional information about

material of construction, capacity and options. The following chart will assist in relating the model

number to the specifications of your regulator:

----- ------ -------------

Model Number Inlet/Outlet Soft

Body Goods

Material

13650 N. Promenade Blvd. * Stafford, TX 77477

Office: (281) – 295-6800 * (800) – 354-7684 * Fax: (281) – 295-6999 * www.grothcorp.com

Page 10

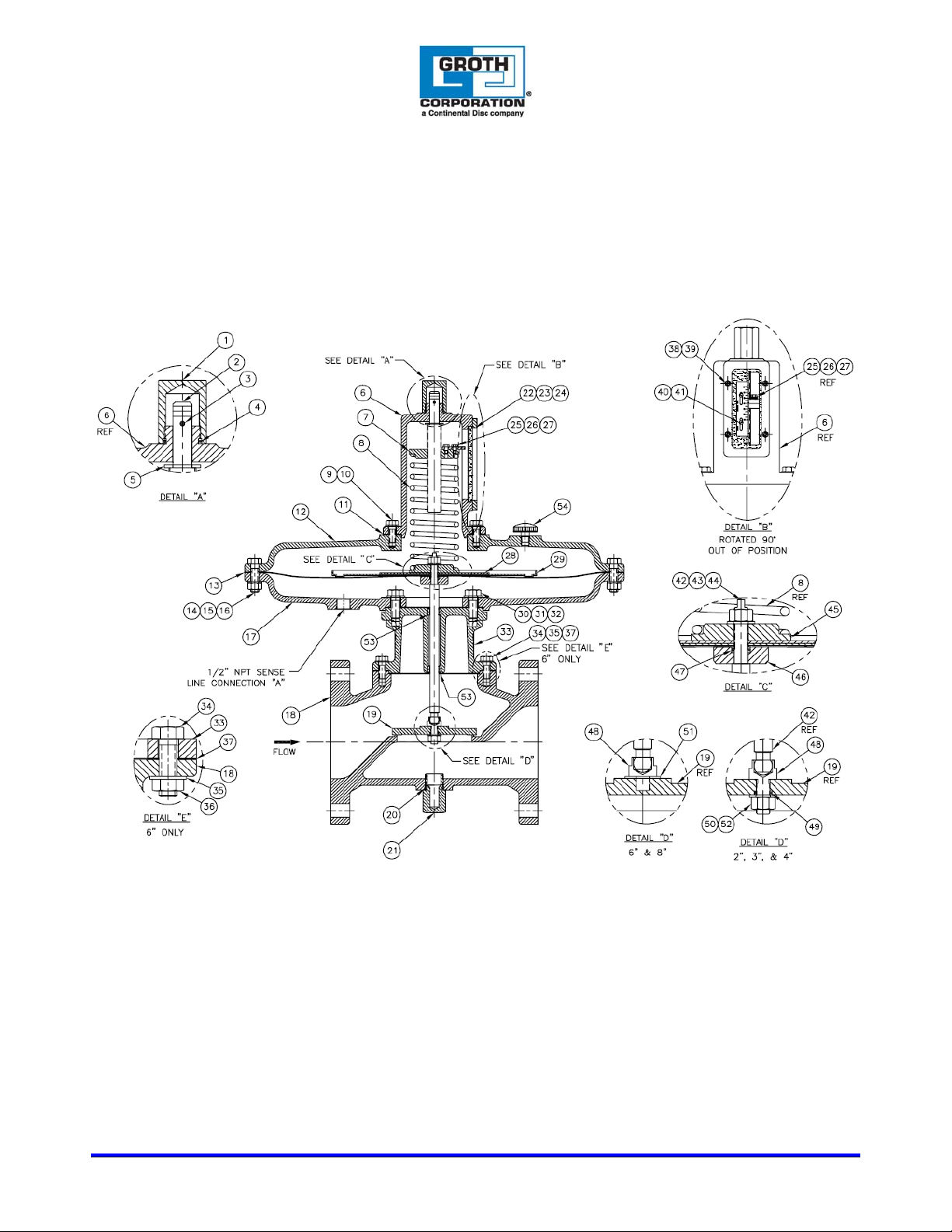

APPENDIX A – GROTH MODEL 8860 BACK PRESSURE REGULATOR (2”-8”)

IOM -8860

Page 10 of 13

Office: (281) – 295-6800 * (800) – 354-7684 * Fax: (281) – 295-6999 * www.grothcorp.com

13650 N. Promenade Blvd. * Stafford, TX 77477

Page 11

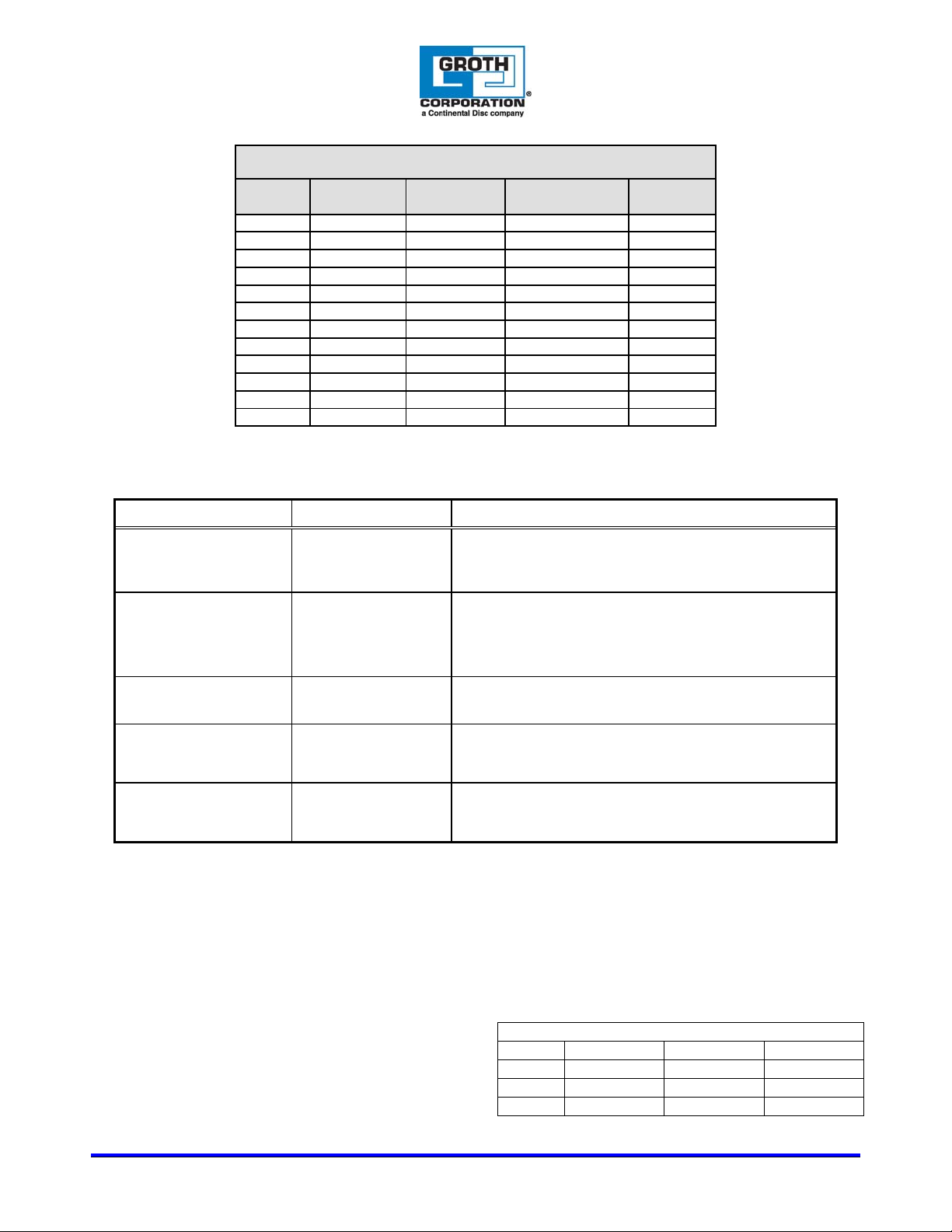

TABLE 5 – GROTH MODEL 8860 BACK PRESSURE REGULATOR (2”-8”)

BILL OF MATERIALS

ITEM DESCRIPTION ITEM DESCRIPTION

1 CAP-HOUSING 28 SUPPORT PLATE

2 ADJUSTMENT SCREW 29 RETAINER PLATE

3 ROLL PIN 30 HEX BOLT

4 * O-RING-UPPER HOUSING CAP 31 LOCK WASHER

5 WASHER 32 * GASKET-SPOOL LOWER CASE

6 SPRING HOUSING 33 SPOOL

7 SPRING BUTTON-UPPER 34 HEX BOLT

8 SPRING 35 LOCK WASHER

9 HEX BOLT 36 HEX NUT (6" ONLY)

10 LOCK WASHER 37 * GASKET-BODY

11 * GASKET-SPRING HOUSING 38 HEX BOLT

12 UPPER-DIAPHRAGM CASE 39 LOCK WASHER

13 * DIAPHRAGM 40 MACHINE SCREW

14 HEX BOLT 41 SCALE

15 LOCK WASHER 42 STEM

16 HEX NUT 43 HEX JAM NUT

17 LOWER-DIAPHRAGM CASE 44 BELLEVILLE WASHER

18 BODY 45 SPRING BUTTON-LOWER

19 PALLET 46 SPACER

20 * O-RING-LOWER CAP 47 * O-RING-SPACER

21 PLUG 48 SWIVEL FITTING

22 * GASKET-SIGHT GLASS 49 * O-RING-SWIVEL FITTING (2"-4" ONLY)

23 SIGHT GLASS 50 FLAT WASHER (2"-4" ONLY)

24 COVER-SIGHT GLASS 51 BELLEVILLE WASHER (6"-8" ONLY)

25 HEX BOLT 52 LOCK NUT (2"-4" ONLY)

26 LOCK WASHER 53 BUSHING

27 INDICATOR-PRESSURE 54 VENT

*spare parts

IOM -8860

Page 11 of 13

Office: (281) – 295-6800 * (800) – 354-7684 * Fax: (281) – 295-6999 * www.grothcorp.com

13650 N. Promenade Blvd. * Stafford, TX 77477

Page 12

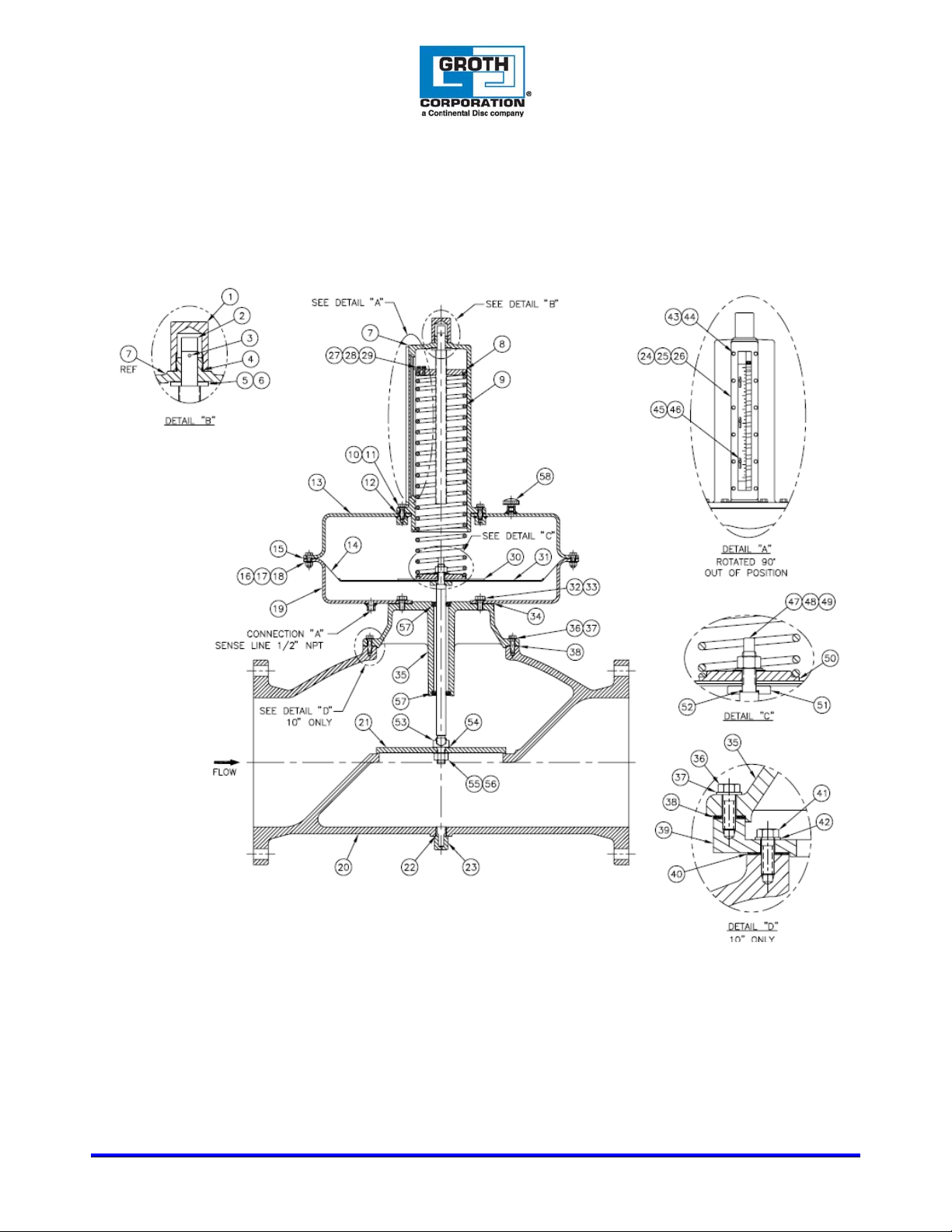

APPENDIX B – GROTH MODEL 8860 BACK PRESSURE REGULATOR (10”-12”)

IOM -8860

Page 12 of 13

Office: (281) – 295-6800 * (800) – 354-7684 * Fax: (281) – 295-6999 * www.grothcorp.com

13650 N. Promenade Blvd. * Stafford, TX 77477

Page 13

TABLE 5 – GROTH MODEL 8860 BACK PRESSURE REGULATOR (10”-12”)

ITEM DESCRIPTION ITEM DESCRIPTION

1 CAP-HOUSING 30 SUPPORT PLATE

2 ADJUSTMENT SCREW 31 RETAINER PLATE

3 ROLL PIN 32 HEX BOLT

4 * O-RING-UPPER HOUSING CAP 33 LOCK WASHER

5 WASHER 34 * GASKET-SPOOL LOWER CASE

6 WASHER 35 SPOOL

7 SPRING HOUSING 36 HEX BOLT

8 SPRING BUTTON-UPPER 37 LOCK WASHER

9 SPRING 38 * GASKET-BODY

10 HEX BOLT 39 ADAPTER PLATE (10" ONLY)

11 LOCK WASHER 40 * GASKET (10" ONLY)

12 * GASKET-SPRING HOUSING 41 HEX BOLT (10" ONLY)

13 UPPER-DIAPHRAGM CASE 42 LOCK WASHER (10" ONLY)

14 * DIAPHRAGM 43 HEX BOLT

15 * GASKET-DIAPHRAGM CASE 44 LOCK WASHER

16 HEX BOLT 45 MACHINE SCREW

17 LOCK WASHER 46 SCALE

18 HEX NUT 47 STEM

19 LOWER-DIAPHRAGM CASE 48 HEX JAM NUT

20 BODY 49 BELLEVILLE WASHER

21 PALLET 50 SPRING BUTTON-LOWER

22 * O-RING-LOWER CAP 51 SPACER

23 PLUG 52 * O-RING-SPACER

24 * GASKET-SIGHT GLASS 53 SWIVEL FITTING

25 SIGHT GLASS 54 * GASKET-SWIVEL FITTING

26 COVER-SIGHT GLASS 55 BELLEVILLE WASHER

27 HEX BOLT 56 HEX JAM NUT

28 LOCK WASHER 57 BUSHING

29 INDICATOR-PRESSURE 58 VENT

*spare parts

IOM -8860

Page 13 of 13

BILL OF MATERIALS

Office: (281) – 295-6800 * (800) – 354-7684 * Fax: (281) – 295-6999 * www.grothcorp.com

13650 N. Promenade Blvd. * Stafford, TX 77477

Loading...

Loading...