Page 1

Installation, Operation and Maintenance

Manual for Flame Arrester

Models 7618, 7628

©2011 Groth Corporation

IOM-7618

Rev. D 12233

Ref. ID: 96056

Page 2

Page 2 of 16

Table of Contents

I. INTRODUCTION 3

II. INSPECTION AND INSTALLATION 4

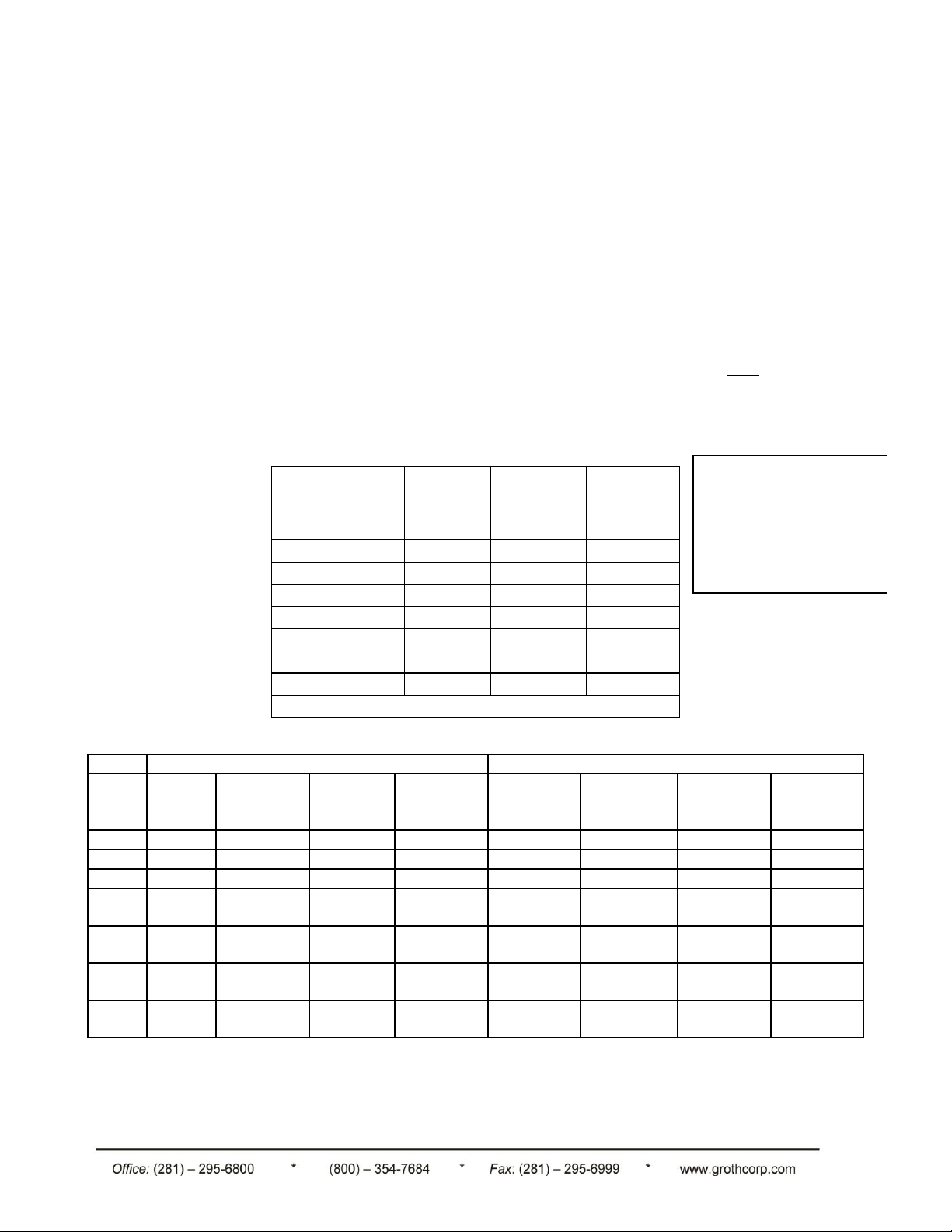

1. TABLE 1 – FLAME ARRESTER MAWP 4

2. TABLE 2 – HOUSING AND FLANGE BOLT TORQUE 4

III. MAINTENANCE 6

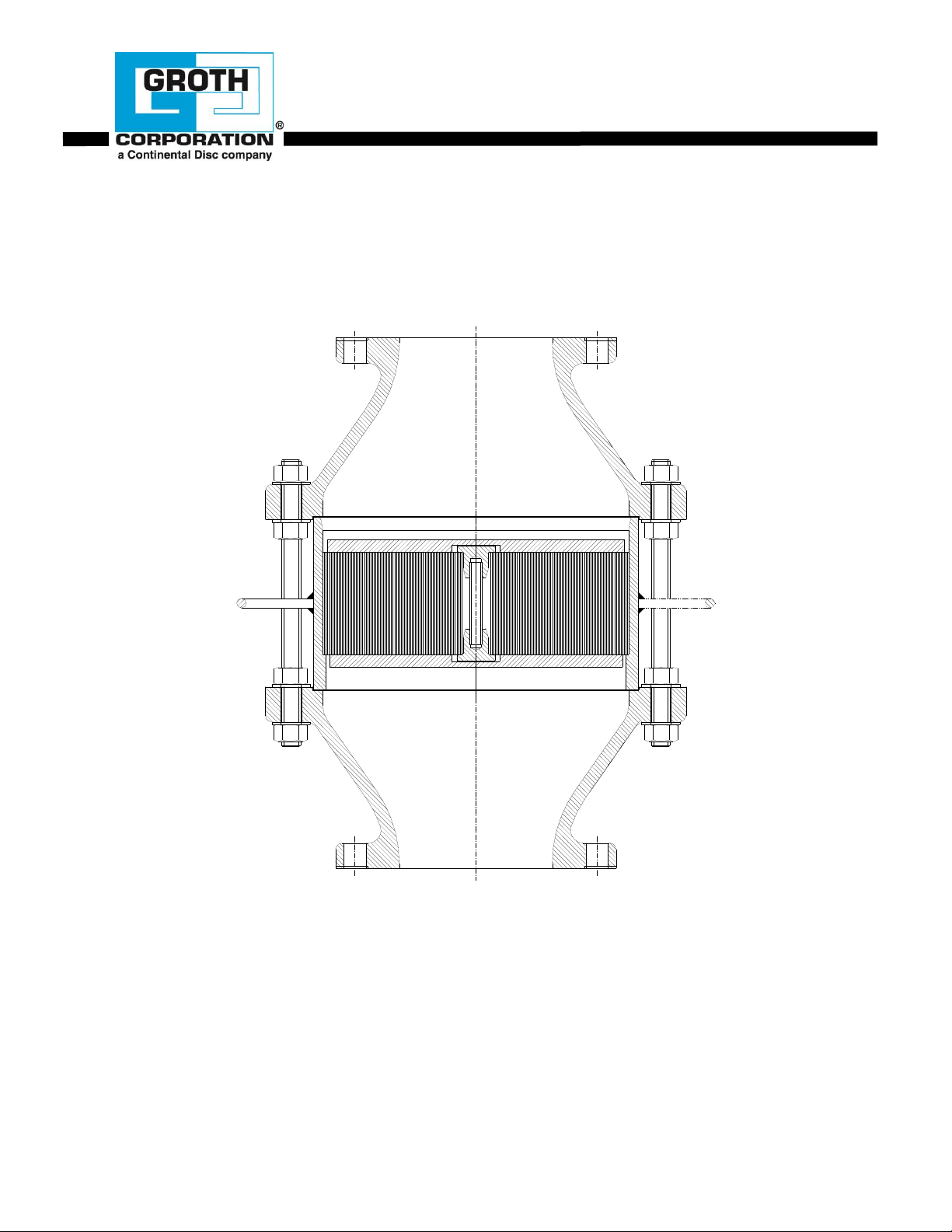

1. FIGURE 1 – TYPICAL MODEL 7618 FLAME ARRESTER 6

2. TABLE 3 – ELEMENT HOUSING WEIGHT 7

3. TABLE 4 – FLAME ARRESTER ASSEMBLY WEIGHT 7

IV. SPARE PARTS 9

1. TABLE 5 – FLAME BANK ASSEMBLY KIT 10

2. TABLE 6 – GASKET KIT 10

V. MODEL IDENTIFICATION 11

APPENDIX A – MODEL 7618 FLAME ARRESTER (2"-12") 12

APPENDIX B – MODEL 7618 END OF LINE FLAME ARRESTER (2"-12") 13

APPENDIX C – MODEL 7618 FLAME ARRESTER (14" and Larger) 14

APPENDIX D – MODEL 7628 FLAME ARRESTER (2"-12") 15

APPENDIX E – MODEL 7628 FLAME ARRESTER (14"and Larger) 16 15

Page 3

Page 3 of 16

For information not contained in this manual, please contact:

Groth Corporation

13650 N. Promenade Blvd.

Stafford, TX, 77477 USA

Phone: 281-295-6800

Fax: 281-295-6999

www.grothcorp.com

I. INTRODUCTION

Groth Corporation’s flame arresters are designed to inhibit flame propagation in gas piping systems

and to protect low pressure tanks containing flammable liquids. They protect low flash point liquids

from externally caused sources of heat and ignition, providing increased fire protection and safety.

The flame arresters consist of two main components, the arrester bases and the flame element

housing. The bases serve as the connecting interface to the piping system. The housing

accommodates the flame element and is instrumental in stopping the flame passage. The depth of the

flame element absorbs the heat from the vapor flow, cooling the vapor to prevent auto-ignition on the

protected side.

The flame element is comprised of small parallel triangular passageways aligned so that an

approaching flame front is slowed down and then quenched before it can propagate to the protected

side of the device.

Model 7618 and 7628 flame elements utilize spiral wound, crimped ribbon constructed of corrosion

resistant materials, to insure the best flame quenching performance with minimum pressure drop.

Depending on the design of the system in which it is used, the arrester bases can include optional

ports for temperature or pressure monitoring devices. These devices can activate warning or

shutdown systems if abnormal conditions are detected.

A flame arrester should be treated as a safety device and maintained by a knowledgeable repair

technician. Carefully read and understand this Manual before installing or servicing this product.

Page 4

The MAWP is different

from the approved preignition pressure.

Consult the factory for

pre-ignition pressure

limits for your

installation.

II. INSPECTION AND INSTALLATION

Size

Model

7618

Alum

Model

7618

CS/SS

Model

7628 Alum

Model

7628

CS/SS

2"

50 (345)

100 (690)

150 (1034)

275 (1965)

3"

50 (345)

100 (690)

140 (965)

275 (1965)

4"

50 (345)

100 (690)

140 (965)

275 (1965)

6"

50 (345)

100 (690)

140 (965)

275 (1965)

8"

50 (345)

100 (690)

90 (620)

200 (1379)

10"

50 (345)

100 (690)

75 (482)

150 (1034)

12"

50 (345)

100 (690)

75 (482)

150 (1034)

Sizes > 12" (7618 & 7628): MAWP = 15 PSIG

Flange*

Housing

Size

Raised

Face

Steel

Raised

Face

Aluminum

Flat

Face

Steel

Flat Face

Aluminum

Model

Steel 7618

Model

Steel 7628

Aluminum

Housing

7618

Aluminum

Housing

7628

2"

60 (82)

35 (47)

60 (82)

50 (68)

60 (82)

40 (54)

50 (68)

35 (47)

3"

60 (82)

35 (47)

60 (82)

50 (68)

60 (82)

40 (54)

50 (68)

35 (47)

4"

60 (82)

35 (47)

60 (82)

50 (68)

60 (82)

40 (54)

50 (68)

35 (47)

6"

105

(143)

60 (81)

105 (143)

90 (122)

105 (143)

105 (143)

90 (122)

90 (122)

8"

105

(143)

60 (81)

105 (143)

90 (122)

105 (143)

105 (143)

90 (122)

90 (122)

10"

140

(190)

100 (136)

170 (231)

140 (190)

170 (231)

220 (300)

140 (190)

170 (231)

12"

140

(190)

100 (136)

170 (231)

140 (190)

170 (231)

220 (300)

140 (190)

170 (231)

All Groth Corporation's flame arresters are bi-directional and the installation on a tank or piping system

depends to a great extent on the design of the system. The Model 7618 is recommended for vertical

installation in closed piping systems or venting to atmosphere. If a Model 7618 is installed in a

horizontal line, it should be equipped with drain ports for removal of condensation from the housing.

WARNING: Do not pipe both drainage connections to a common line as

this can provide a passage for flame to by-pass the flame arrester element.

The Model 7628 is designed for either vertical or horizontal installation.

These series of flame arresters have 150# ANSI PN 10 OR PN 16 flange drilling compatibility, [30" &

36" model 7618 & 7628 have API 650 drilling], and are pneumatically tested to 15 PSIG at the factory.

Follow the guidelines listed in Table 2 for flange make-up torque. The arresters are NOT rated for full

flange pressure and do not require high bolting torque. Recommended torque values are based on

pressures [MAWP] in Table 1. Consult factory for higher pressure applications.

Note:

TABLE 1: FLAME ARRESTER MAWP [PSIG (kPa)]

Page 4 of 16

*Torque values are for reference only and based on a nitrile binder synthetic gasket,

1/16" thick and unlubricated threads.

TABLE 2: BOLT TORQUE [ft-lbs (Nm)]

Page 5

Page 5 of 16

The following guidelines should be observed at installation:

WARNING: Groth Corporation's flame arresters have been tested by

Factory Mutual Research. To maintain the approval classification, all

arresters must be installed within 10 pipe diameters of the open end of the

vent pipe.

1. Remove any flange protectors and discard all packing material. Inspect flange faces and flame

element for damage or contamination.

2. Inspect the gasket seating surface of the tank nozzle or piping. It must be clean, flat, free of

scratches, corrosion and tool marks.

3. Aluminum flame arresters are furnished with flat face flanges; they should only be installed on

a mating flat face flange with a full face gasket.

WARNING: Installation of an aluminum arrester in piping with raised face

flanges can cause permanent distortion of the base flanges. This may

result in vapor leakage at the flange connection.

Adjacent piping must have appropriate structural support to prevent

excessive loads on the flame arrester flanges.

4. Inspect the gasket; make sure that the material is suitable for the application. Center the

gasket within the bolt circle.

5. Set the arrester between its mating flanges or on the nozzle. Position the lifting handles and

jacking nuts to facilitate future removal of the flame arrester housing (See Maintenance

Instructions section). Install the studs and tighten nuts hand tight.

WARNING: The handles on the arrester housing are to be used for

handling the element only during inspection and maintenance. DO NOT

use the handles to lift the entire flame arrester assembly.

Notes:

When installing Model 7628 in the horizontal position, the

eccentric portion of the housing must be positioned

upward (See Page 14). In this position condensation will

tend to move in the direction of flow and not collect in the

element.

Leave space behind mating pipe flange for insertion of

studs, as there may not be sufficient space to insert studs

from the flame arrester side.

6. Torque all fasteners to half the value listed in Table 2 in a staggered, alternating pattern to

provide an evenly compressed gasket joint.

7. Make up the final torque and check that no further nut rotation occurs at the specified torque

value.

Page 6

WARNING: After installation, all connections must be inspected for vapor

leakage. This may be accomplished by static pressure test, gas detector,

or "bubble" test using a liquid leak detector.

III. MAINTENANCE

For maximum operating efficiency the element of a flame arrester must be inspected for clogging at

regular intervals. Frequency of inspection and maintenance should be based on the experience

gained in each application. For ease of service, the flame element housing can be easily removed for

inspection and maintenance without removing the arrester from the line. It is recommended that the

arrester be removed for inspection of the element at least once per year or any time that one of the

following conditions occurs:

Excessive pressure drop is encountered at a known flow rate.

A flame front is detected.

Note:

Flame arresters equipped with a steam jacket can not be serviced in-line. The

arrester must be removed from the pipeline or tank nozzle for inspection and

maintenance.

1. Purge the line or tank with an inert gas before attempting to remove the arrester for maintenance.

CAUTION: The connecting pipeline must be free of all hazardous or flammable vapors before

inspection procedures begin. Before disassembling consult Material Safety Data Sheets

(MSDS) for all products that were exposed to in service. The components should be cleaned

according to MSDS procedures. Take appropriate safety precautions regarding eye protection,

skin contact & respiration.

2. Refer to Fig. 1 which illustrates a typical flame arrester with the element removed.

Page 6 of 16

FIGURE 1 - TYPICAL MODEL 7618 FLAME ARRESTER

Page 7

3. Loosen the housing nuts and remove only those studs necessary to withdraw the housing. Do not

Models 7618 / 7628

Size

Aluminum

Alum/SS

Steel

2"

5 (2)

10 (5)

15 (7)

3"

10 (5)

10 (5)

20 (9)

4"

15 (7)

20 (9)

35 (16)

6"

30 (14)

45 (20)

75 (34)

8"

45 (20)

70 (32)

115 (52)

10"

70 (32)

110 (50)

175 (80)

12"

95 (43)

160 (73)

250 (114)

Models 7618

Models 7628

Size

Aluminum

Alum/SS

Steel

Size

Aluminum

Alum/SS

Steel

2"

15 (7)

20 (9)

45 (70)

2"

25 (11)

30 (14)

70 (32)

3"

25 (11)

30 (14)

75 (34)

3"

35 (16)

40 (18)

95 (43)

4"

40 (18)

45 (20)

105 (48)

4"

50 (23)

60 (27)

105 (48)

6"

80 (36)

100 (45)

225 (102)

6"

85 (39)

100 (45)

225 (102)

8"

130 (59)

155 (70)

360 (164)

8"

150 (68)

175 (80)

360 (164)

10"

200 (91)

245 (111)

555 (252)

10"

235 (107)

280 (127)

555 (252)

12"

285 (130)

345 (157)

795 (361)

12"

320 (125)

385 (175)

795 (361)

remove studs with spreader nuts.

WARNING: The handles on the arrester housing are to be used for

handling the element only during inspection and maintenance. DO NOT

use the handles to lift the entire flame arrester assembly.

4. If the flame arrester is in a horizontal line, attach whatever lifting equipment is required to remove the

element [see weight table 3].

TABLE 3 - ELEMENT HOUSING WEIGHT [Lb. (kg)]

Page 7 of 16

TABLE 4 - FLAME ARRESTER ASSEMBLY WEIGHT [Lb. (kg)]

WARNING: If not supported, the element housing will drop onto the

remaining studs when the bases are separated. Be careful to avoid contact

with the housing while separating the bases.

Page 8

Page 8 of 16

5. On the remaining studs, loosen the housing nuts incrementally while advancing the spreader nuts to

separate the bases. When the bases are separated sufficiently to remove the housing, tighten the

housing nuts so the bases form a rigid assembly when the housing is removed.

6. If a vertically mounted flame arrester is used to support a relief valve or similar equipment, tightening

the housing nuts after separating the bases will provide sufficient support for the relief valve.

7. Remove the housing assembly for inspection. Visually inspect the flame element and supporting grids

for damage or corrosion build-up from both sides. If the flame element appears to be damaged, it

should be replaced immediately.

WARNING: Failure to replace a damaged flame element can render the flame arrester ineffective

8. Verify that the element openings are not clogged by viewing a light source through the element

passages. If the flame element is dirty or clogged it can be cleaned by one of the following methods:

Compressed air

High pressure steam or water purge

Solvent wash followed by compressed air

WARNING: Never try to clean the element by inserting a sharp tool or

probe into the orifices. Any damage to the integrity of these passages can

render the flame arrester ineffective.

CAUTION: If compressed air, steam, or high pressure water jet is used to

clean clogged element passageways, restrict access to the area to prevent

injury from blown debris exiting the element. Use appropriate personal

safety equipment for the cleaning method used.

TIP: The best method of cleaning and frequency should be based on the

experience gained in each application.

9. Inspect the sealing gasket for damage and replace if necessary. (See Table 6 for replacement gasket

part numbers.

10. Install a gasket in the counter bore of each base. Position the element housing to align with the

counterbores. Insert the studs and torque all fasteners to half the value listed in Table 2 in a

staggered, alternation pattern to provide an evenly compressed gasket joint.

If the arrester is in high temperature service or stainless steel external studs and nuts are used, apply

an anti-seize compound such as moly-disulfide to all threaded components.

11. Make up the final torque and check that no further nut rotation occurs at the specified torque value.

The torque values are based on original gaskets supplied by Groth Corporation.

Page 9

IV. SPARE PARTS

Size

Housing

Material

Element

Material

Kit P/N

Size

Housing

Material

Element

Material

Kit P/N

2"

Aluminum

Aluminum

KFB76180211

8"

Carbon Steel

Aluminum

KFB76180831

3"

Aluminum

Aluminum

KFB76180311

10"

Carbon Steel

Aluminum

KFB76181031

4"

Aluminum

Aluminum

KFB76180411

12"

Carbon Steel

Aluminum

KFB76181231

6"

Aluminum

Aluminum

KFB76180611

2"

Carbon Steel

316 SS

KFB76180235

8"

Aluminum

Aluminum

KFB76180811

3"

Carbon Steel

316 SS

KFB76180335

10"

Aluminum

Aluminum

KFB76181011

4"

Carbon Steel

316 SS

KFB76180435

12"

Aluminum

Aluminum

KFB76181211

6"

Carbon Steel

316 SS

KFB76180635

2"

Aluminum

316 SS

KFB76180215

8"

Carbon Steel

316 SS

KFB76180835

3"

Aluminum

316 SS

KFB76180315

10"

Carbon Steel

316 SS

KFB76181035

4"

Aluminum

316 SS

KFB76180415

12"

Carbon Steel

316 SS

KFB76181235

6"

Aluminum

316 SS

KFB76180615

2"

316 SS

316 SS

KFB76180255

8"

Aluminum

316 SS

KFB76180815

3"

316 SS

316 SS

KFB76180355

10"

Aluminum

316 SS

KFB76181015

4"

316 SS

316 SS

KFB76180455

12"

Aluminum

316 SS

KFB76181215

6"

316 SS

316 SS

KFB76180655

2"

Carbon Steel

Aluminum

KFB76180231

8"

316 SS

316 SS

KFB76180855

3"

Carbon Steel

Aluminum

KFB76180331

10"

316 SS

316 SS

KFB76181055

4"

Carbon Steel

Aluminum

KFB76180431

12"

316 SS

316 SS

KFB76181255

6"

Carbon Steel

Aluminum

KFB76180631

Size

Part No.

2"

KS761802

3"

KS761803

4"

KS761804

6"

KS761806

8"

KS761808

10"

KS761810

12"

KS761812

Synthetic-Non-Asbestos Fiber sheet material with

a nitrile binder. For special applications or chemical

compatibility please contact factory.

Flame Bank Kits are available upon request. Kits include the flame arrester element and two nonasbestos gaskets. Kits are based on Model Number, Size, and Material. The kits only apply to

arresters manufactured since 1992; consult factory for sizes greater than 12". To procure appropriate

kit, please contact Groth Corporation with the Serial Number, Model Number, Size, and Material.

TABLE 5 – FLAME BANK ASSEMBLY KITS

Page 9 of 16

.

TABLE 6 - GASKET KIT PART NUMBERS

Page 10

Page 10 of 16

-----

------

-------------

V. MODEL NUMBER IDENTIFICATION

The nameplate on the Flame Arrester contains the Model Number, Serial Number, set pressures and

flow capacity at a specified over-pressure. The Model Number contains additional information about

materials of construction, soft goods and options. The following chart will assist in relating the Model

Number to the characteristics of your valve:

7618 02 Element O = No Specials

7628 03 1=Aluminum Z = Special Option

04 Body 5=316 SS O = No Jacket

06 1=Aluminum Z=Special J = Steam Jacket

08 3=CS

10 5=316 SS

12 Z=Special

F = Flanged Outlet

W = Weatherhood

EXAMPLE: Model 7618-04-11-FOO indicates a 4" Model 7618 with an Aluminum body an Aluminum flame

element, flanged inlet/outlet connections, and no special options.

Page 11

Page 11 of 16

ITEM DESCRIPTION

STANDARD MATERIALS OF CONSTRUCTION

ALUMINUM

CARBON STL

316 SS

1

BASE

AL (356 T6)

CS (WCB)

316 SS (CF-8M)

2

HANDLE

ALUM

CS

SS

3 SPREADER HEX NUT

SS

SS

SS

4

HEX NUT

SS

SS

SS

5

STUD

SS

SS

SS

6

ELEMENT PLUG

SS

SS

303 SS

7

ELEMENT ROD

SS

SS

316 SS

8

ELEMENT GRID

ALUM

316 SS

316 SS

9 * ELEMENT HOUSING

ALUM

CS

316 SS

10 PIPE PLUG (OPTIONAL)

ALUM

CS

316 SS

11 COUPLING (OPTIONAL)

ALUM

CS

316 SS

12

*

GASKET

NON-ASB

NON-ASB

NON-ASB

13 * FLAME ELEMENT

ALUM (1)

316 SS

316 SS

APPENDIX A: Model 7618 Flame Arrester (2"-12")

(1) Available in 316 SS

* Recommended Spare Parts

Page 12

Page 12 of 16

ITEM DESCRIPTION

STANDARD MATERIALS OF CONSTRUCTION

ALUMINUM

CARBON STL

316 SS

1

BASE

AL (356 T6)

CS (WCB)

316 SS (CF-8M)

2

HANDLE

ALUM

CS

SS

3

HEX NUT

SS

SS

SS

4

STUD

SS

SS

SS

5

ELEMENT PLUG

SS

SS

303 SS

6

ELEMENT ROD

SS

SS

316 SS

7

ELEMENT GRID

ALUM

316 SS

316 SS

8 * ELEMENT HOUSING

ALUM

CS

316 SS

9 COUPLING (OPTIONAL)

ALUM

CS

316 SS

10 PIPE PLUG (OPTIONAL)

ALUM

CS

316 SS

11

*

GASKET

NON-ASB

NON-ASB

NON-ASB

12 * FLAME ELEMENT

ALUM (1)

316 SS

316 SS

13

EYE NUT

CS

CS

316 SS

14

HEX NUT

SS

SS

SS

15 WEATHERHOOD

ALUM

CS

316 SS

16

BIRD SCREEN

SS

SS

SS

17 ADAPTER PLATE

CS

CS

316 SS

APPENDIX B: Model 7618 End-of-Line Flame Arrester (2"-12")

(1) Available in 316 SS

* Recommended Spare Parts

Page 13

APPENDIX C: Model 7618 Flame Arrester (14" and Larger)

ITEM DESCRIPTION

STANDARD MATERIALS OF CONSTRUCTION

ALUMINUM

CARBON STL

316 SS

1

BASE

AL (356 T6)

CS (WCB)

316 SS (CF-8M)

2

SPACER

ALUM

CS

316 SS

3 * FLAME ELEMENT

ALUM (1)

316 SS

316 SS

4 * ELEMENT HOUSING

ALUM

CS

316 SS

5

STUD

SS

SS

SS

6

HEX NUT

SS

SS

SS

7

ELEMENT GRID

ALUM

316 SS

316 SS

8 ELEMENT SHAFT

SS

SS

316 SS

9

*

GASKET

NON-ASB

NON-ASB

NON-ASB

10

LIFTING LUG

ALUM

CS

316 SS

11 PIPE PLUG (OPTIONAL)

ALUM

CS

316 SS

12 COUPLING (OPTIONAL)

ALUM

CS

316 SS

13 SPREADER HEX NUT

SS

SS

SS

Page 13 of 16

(1) Available in 316 SS

* Recommended Spare Parts

Page 14

Page 14 of 16

ITEM DESCRIPTION

STANDARD MATERIALS OF CONSTRUCTION

ALUMINUM

CARBON STL

316 SS

1

BASE

AL (356 T6)

CS (WCB)

316 SS (CF-8M)

2

*

GASKET

NON-ASB

NON-ASB

NON-ASB

3 * FLAME ELEMENT

ALUM (1)

316 SS

316 SS

4

ELEMENT PLUG

SS

SS

303 SS

5

ELEMENT ROD

SS

SS

316 SS

6

HANDLE

ALUM

CS

SS

7 SPREADER HEX NUT

SS

SS

SS

8 PIPE PLUG (OPTIONAL)

ALUM

CS

316 SS

9

HEX NUT

SS

SS

SS

10

STUD

SS

SS

SS

11 COUPLING (OPTIONAL)

ALUM

CS

316 SS

12

ELEMENT GRID

ALUM

316 SS

316 SS

13 * ELEMENT HOUSING

ALUM

CS

316 SS

APPENDIX D: Model 7628 Flame Arrester (2"-12”)

(1) Available in 316 SS

* Recommended Spare Parts

Page 15

Page 15 of 16

ITEM DESCRIPTION

STANDARD MATERIALS OF CONSTRUCTION

ALUMINUM

CARBON STL

316 SS

1 * ELEMENT HOUSING

ALUM

CS

316 SS

2

BASE

AL (356 T6)

CS (WCB)

316 SS (CF-8M)

3 * FLAME ELEMENT

ALUM (1)

316 SS

316 SS

4 COUPLING (OPTIONAL)

ALUM

CS

316 SS

5 RETAINER ELEMENT

ALUM

316 SS

316 SS

6 ELEMENT SHAFT

SS

316 SS

316 SS

7

STUD

SS

SS

SS

8

HEX NUT

SS

SS

SS

9

*

GASKET

NON-ASB

NON-ASB

NON-ASB

10

LIFTING LUG

ALUM

CS

316 SS

11 PIPE PLUG (OPTIONAL)

ALUM

CS

316 SS

12

GUIDE ROLLER

ALUM

CS

316 SS

APPENDIX E: Model 7628 Flame Arrester (14" and Larger)

(1) Available in 316 SS

* Recommended Spare Parts

Page 16

Page 16 of 16

Loading...

Loading...