Page 1

Installation, Operation and Maintenance Manual for

Blanket Gas Regulator

Series 3000

ISO 9001

Groth Corporation 1993

IOM 3000.0

JULY 1993

IOM 3000.0

REV. A 12541

Page 2

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE NO.

A MAIN SECTION

INTRODUCTION

GENERAL

INFORMATION

SAFETY

INSTALLATION

OPERATION &

MAINTENANCE

DRAWINGS & BILL

OF MATERIAL

B LIST OF FIGURES*

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

C LIST OF TABLES

No.

1

2

3

4

5

6

7

8

9

Regulator Design, Function & Operation

Regulator Function - Flowing/Shut-off Condition

General Instructions

Inspection & Installation

Operation: Pressure Setting

Operation: Flow Capacity Setting

Blanketing the Tank

Recommended Spare Parts

Troubleshooting Guide

Preventive Maintenance & Disassembly

Assembly

Recommended Testing & Setting Procedure

Exploded View - Drawing

Bill of Material

Cross-Sectional - Drawing

Model Identification & Product Limited Warranty

DESCRIPTION

Tank Installation - Safety Equipment

Regulator Function - Flowing Condition

Regulator Function - Shut-off Condition

Blanketing Regulator Installation

Orifice Sleeve Orientation

Spring Bonnet Assembly

Piston/Body Assembly

Piston Assembly - "Exploded"

Orifice Sleeve Orientation

Orifice Sleeve Orientation

Piston Assembly - "Exploded"

Piston/Body/ Diaphragm Assembly

Spring Bonnet Assembly

Blanketing Regulator - "Exploded" Assembly

Blanketing Regulator - Cross-Sectional Assembly

DESCRIPTION

3000 Series Regulator Specifications

Flow Capacity

Model 3000 Spring Table

Model 3010 Spring Table

Model 3020 Spring Table

Orifice Selection

Recommended Spare Parts

Recommended Bolt Torque

Bill of Material - 3000 Series Regulator

1

2

3

4

5

6

7

8

8

9

10 - 11

12 - 13

14

15

16

17

18

1

3

3

5

7

10

10

11

11

12

12

13

13

15

17

2

2

6

6

6

7

8

13

16

IOM 3000.0

REV. A 12541

Page 3

*Note: Some Figures are duplicated for the convenience of the reader

P

INTRODUCTION

The gas blanketing regulator is one of the principal

components typically installed on a storage tank to

protect the tank and its contents. It is a precision

regulator that is capable of maintaining a very low

gas pressure (1/2" WC minimum) in the tank by

controlling the flow of a high pressure (200 PSI

maximum) blanketing gas. It maintains a positive

tank pressure when fluid is pumped out or as fluid

temperature decreases.

Typically nitrogen or another compatible gas is used

to displace the tank product vapors. This reduces

product evaporation and prevents atmospheric

contaminants, including moisture, from entering the

tank, minimizing internal tank corrosion and product

contamination. The use of inert blanketing gas

minimizes air pollution due to leakage or emergency

venting.

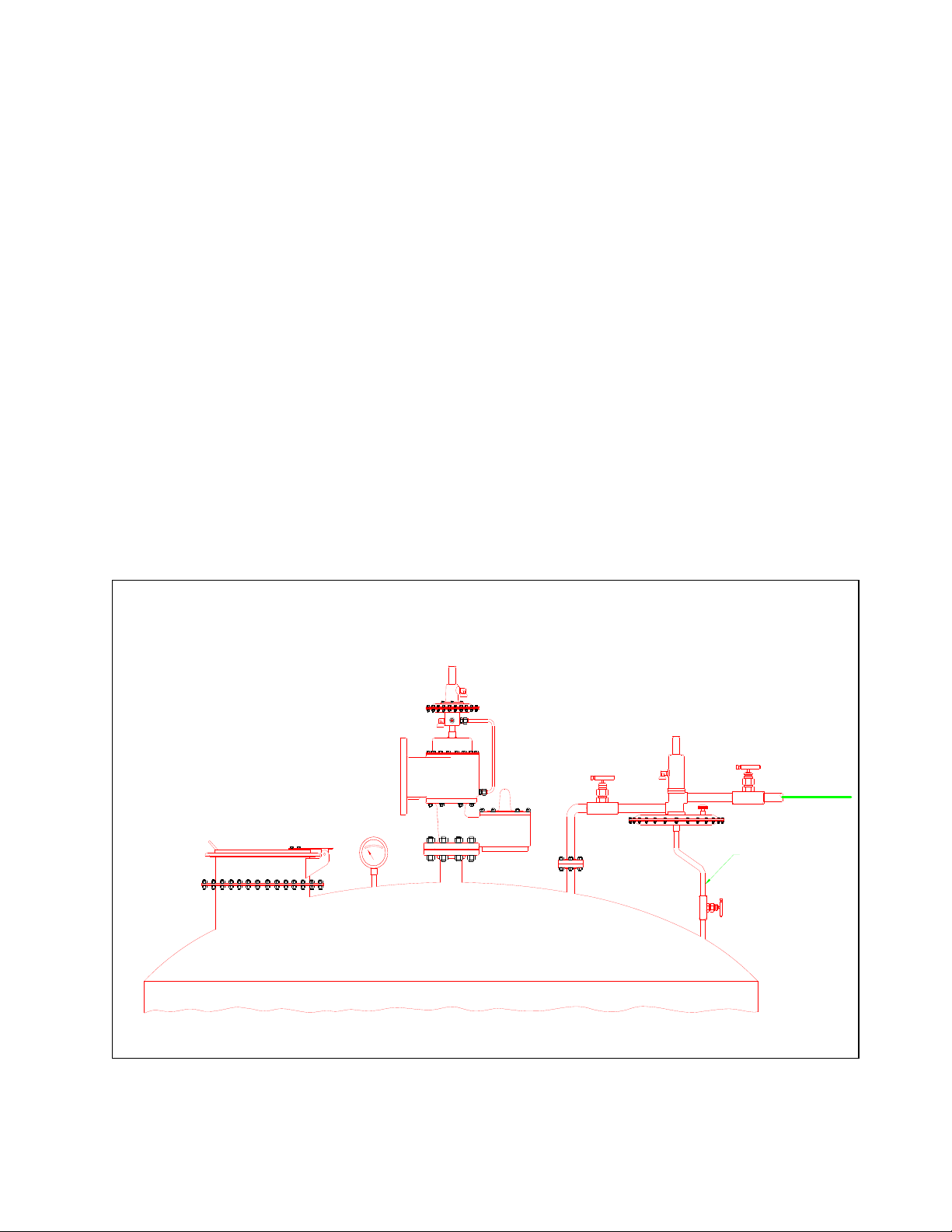

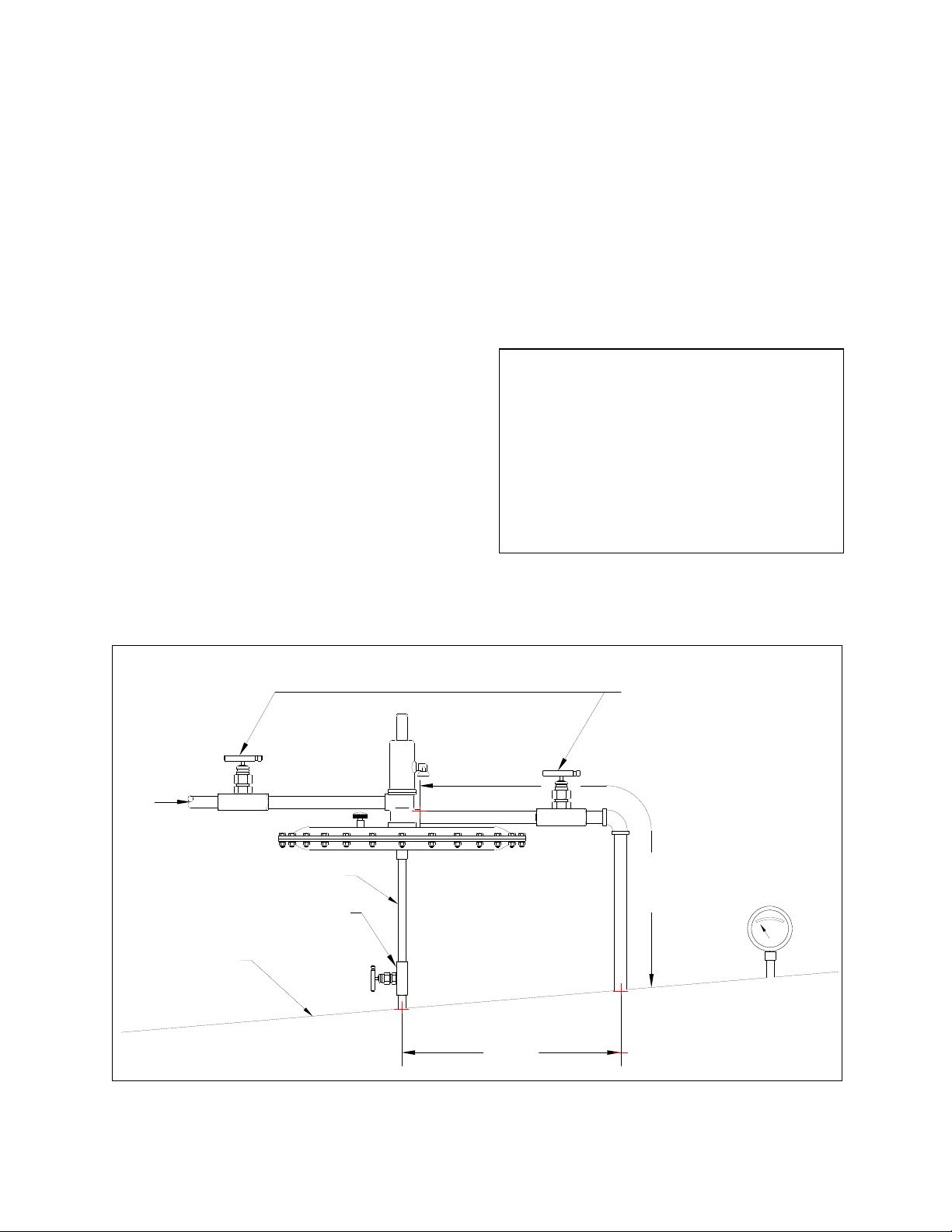

Figure 1: Tank Installation - Safety Equipment

In addition to the blanketing regulator, a tank must be

protected from structural damage by pressure and

vacuum relief valves. A typical tank installation is

shown in Figure 1 which includes the regulator, a

pressure vacuum relief valve and an emergency

pressure relief valve. Groth Corporation

manufacturers all of these devices.

The regulator must be carefully maintained by a

knowledgeable valve technician. It should only be

assembled under clean conditions, preferably in a

shop environment. Carefully read and understand

this manual before attempting to adjust set pressure

or flow capacity, or repair the regulator. Groth

Corporation offers repair services for all products

manufactured by the Tank Protection Division.

RESSURE/VACUUM

RELIEF VALVE

GROTH MODEL 1420

GAS BLANKET REGULATOR

GROTH MODEL 3000

BLANKET

GAS

EMERGENCY RELIEF VALVE

GROTH MODEL 2400

GAUGE

SENSE LINE

SUPPLY

IOM 3000.0

REV. A 12541

Page 4

REGULATOR DESIGN, FUNCTION &

OPERATION

The Groth Model 3000 Regulator is a high capacity

spring operated, diaphragm type, balanced piston

regulator design for tank blanketing applications.

The regulator controls the flow of blanketing gas to

the vapor space in the storage tank. When the

internal pressure of the tank is at or above set

pressure, the diaphragm force exceeds the spring

force and the regulator is shut off bubble tight.

When the tank pressure falls below the set point, the

spring force opens the regulator and blanket gas

flows into the tank (See Figures 2 and 3).

The regulator must be sized to provide sufficient

blanket gas to prevent the loss of tank pressure due to

liquid discharge or decreased ambient temperature.

Table 2 lists the maximum flow capacity of the

regulator for various blanketing gases. Actual

system flow will depend on supply system piping,

tank connection piping and position of the internal

orifice sleeve. Set pressure is the pressure at which

the regulator begins flowing when tank pressure is

decreasing and stops flowing when tank pressure is

increasing.

This manual is intended to provide recommended

procedures and practices for installation, operation,

and maintenance of the Groth Series 3000 Regulator.

Any standard procedures and practices developed in

a specific plant or process should supersede this

manual. Although this manual cannot cover all

possible contingencies, following these guidelines

should provide safe regulator performance.

For information not contained in this manual, please

contact:

Groth Corporation

Groth Products Group

P. O. Box 15293

Houston, TX. 77220

713-675-6151 (phone)

713-675-6739 (fax)

Note that throughout this manual, the item numbering

is listed in [ ] after the part description. Refer to the

exploded assembly drawing on page 15 and the parts

list on page 16.

TABLE 1

REGULATOR SPECIFICATIONS

3000 3010 3020

Flow

Coefficient

(CV)

Inlet/Outlet 1" NPT (F)

Supply Pressure 200 PSI

Tank Pressure 2" WC to

Max. Tank

MAWP

12.5 12.5 12.5

or

1"150# RF

Flange

2.0 PSI

25 PSI 10 " WC 150 PSI

1" NPT (F)

or

1" 150# RF

Flange

200 PSI

1/2" WC to

2" WC

1" NPT (F)

or

1" 150# RF

Flange

200 PSI

1 PSI to

10 PSI

TABLE 2

FLOW CAPACITY *

3000 SERIES REGULATOR SCFH

Supply

Pressure

PSI

5

10

15

20

30

40

50

60

80

100

120

140

160

180

200

Nitrogen Natural

Gas

0.6 G

5700

8700

11300

13800

18600

23200

27700

32100

40700

49300

57900

66500

75100

83700

92300

5800

8800

11500

14000

18900

23600

28200

32600

41300

50100

58800

67500

76300

85000

93700

Air

7400

11300

14600

17900

24000

30000

35800

41500

52600

63700

74800

85900

97000

108100

119200

Internal orifice sleeve installed in 100% flow capacity

*

position.

1

Page 5

P

R

Figure 2: Regulator Function - Flowing Condition

VENT

INLET

HIGH PRESSURE

OUTLET

HIGH PRESSURE

BLANKETING GAS

BLANKETING GAS

VENT

SENSE PORT

LOW PRESSURE

PROCESS VAPOR

Figure 3: Regulator Function - Shut-off Condition

INLET

HIGH PRESSURE

OUTLET

LOW PRESSURE

PROCESS VAPOR

SENSE PORT

LOW PRESSURE

ROCESS VAPO

BLANKETING GAS

VENT

2

Page 6

SAFETY

GENERAL INSTRUCTIONS

This section is intended as an overview of safety

guidelines that should be followed during the

installation, operation and maintenance of Groth

Series 3000 Gas Blanketing Regulator. To

understand the context of these warnings and

instructions, read and understand this complete

manual.

The gas blanketing regulator is one of the principal

protection devices typically installed on a product

storage tank. It is a precision regulator that is

designed to maintain a positive pressure on the tank.

This will prevent product loss or contamination from

atmospheric air when pumping liquid out or when the

stored fluid cools.

WARNING

1. In the event of an actuator or body diaphragm

failure, the regulator will fail in the OPEN

position. Gas flow will NOT be shut off.

Operating and emergency pressure relief valves

must be sized to flow regulator capacity in

addition to normal and emergency venting

requirements.

2. Gas Blanket Regulator flow capacity is based on

tests conducted with five feet of 1" SCH. 40

discharge piping. Consult factory for capacity

data if regulator is to be installed with longer

pipe or numerous fittings or va lves between the

regulator and the tank it is blanketing.

3. The regulator is normally factory set at the

desired set pressure and orifice restriction.

These settings and spring range are stamped on

the nameplate. DO NOT attempt to readjust the

set pressure beyond the limits specified in Tables

3, 4 and 5.

4. The regulator is to be connected to the tank or

vessel with a minimum 0.300" ID tubing sense

line. This line must be kept open and

unobstructed to ensure that the regulator

"senses" the actual tank pressure. For some

applications, a nitrogen purge may be required

to ensure that this line remains open. Consult

factory for recommendations.

5. DO NOT attempt to remove the regulator from

the line or perform field repairs in line without

first isolating the regulator from both the tank

and the supply gas line. Bleed all pressure

before removing the spring bonnet or the flow

orifice locking screw, or opening up the actuator

cases.

6. Note the orifice sleeve position when

disassembling the regulator. It was factory set

according to the flow requirements listed on the

order and must be re-installed in the same

position to ensure the correct flow.

7. The regulator body and actuator case are

exposed to process vapors. Observe all safety

precaution as specified on the Material Safety

Data Sheet for the products that are in the tank.

8. The vents on the spring bonnet and upper case

must both be clean and open to the atmosphere

and should be inspected periodically.

3

Page 7

INSPECTION AND INSTALLATION

B

The regulator is packaged and supported to prevent

damage or contamination in shipping. It should be

similarly protected during subsequent handling and

storage. Always keep all ports plugged to prevent

intrusion of foreign materials. Before installation,

inspect the unit visually. If there are indications of

physical damage or internal contamination, the

regulator must be disassembled, cleaned and

inspected before installation. If factory set, the

spring adjustment cap and the orifice selector locking

screw must be secure. Report any shipping damage

to your carrier.

The regulator inlet and outlet connections are 1" NPT

(F) or 1" 150# RF ANSI flange. The regulator must

be installed level, the direction of the flow is marked

on the body. It is to be installed in accordance with

accepted piping practices. Full bore block valves

should be installed upstream and downstream of the

regulator and in the sense line to allow it to be

removed from the system for maintenance.

Figure 4: Blanketing Regulator Installation

The regulator discharge line must be as short as

possible to obtain the rated gas flow rate. It is not

recommended to exceed a 5' length of 1" SCH 40

pipe. Consult with the factory for piping

recommendations if it is necessary to install the

regulator a greater distance from the tank. The

supply line must be capable of providing the rated

flow at the minimum supply pressure. The sense line

should be minimum 300" ID tubing and is to be

connected to the tank at least 12" from the regulator

discharge line (See. Figure 4).

WARNING

Regulator flow capacity listed in Table 2 is based on

tests with 5' of 1" SCH. 40 discharge pipe and a 2"

supply hose reduced to 1" pipe at regulator supply

port. Depending on discharge line size, length and

number of fittings, regulator flow capacity may be

less than published curves. Supply and discharge

piping should be designed to minimize losses at

desired flow condition. Consult factory for nonstandard installation regarding flow capacity.

BLANKET

GAS

SUPPLY

BLOCK VALVE-1/2" MIN FULL BORE

TANK ROOF

(3)

SENSE LINE

(1)

12" MIN

(2)

LOCK VALVE-1" MIN FULL BORE

DISCHARGE

PIPING

5' MAX

LENGTH

TANK

PRESSURE

GAUGE

4

Page 8

OPERATION

PRESSURE SETTING

The regulator may be set at the factory or on the tank

or vessel when initially introducing blanketing gas.

A pressure gauge (or manometer) is required to show

the tank pressure.

Set pressure is adjusted by removing the valve cap

[1] and rotating the adjusting screw [2]. Back off the

jam nut [3] and turn the screw clockwise (tighten) to

increase set pressure. The Model 3000 Regulator

covers a range of set pressures from 2" WC to 2.0

PSI, using (7) different springs.

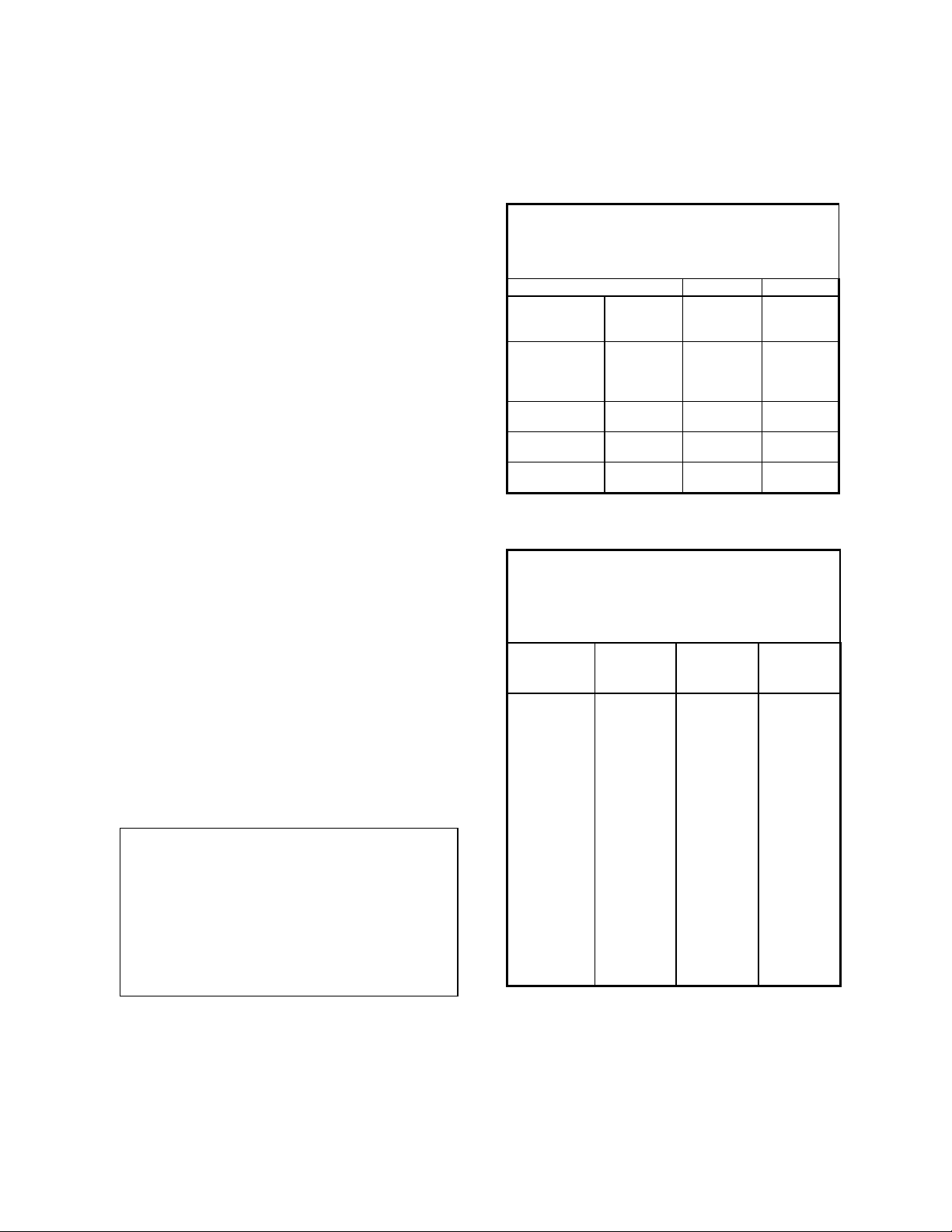

TABLE 3

SPRING TABLE

MODEL 3000

TANK BLANKETING REGULATOR

MEDIUM PRESSURE RANGE

SET PRESSURE RANGE: 2" WC - 2.0 PSIG

Spring

Range

1

2

3

4

5

6

7

Min.

Setting

11.0"

18.6"

2.0"

WC

3.4"

WC

6.3"

WC

WC

WC

1.00

PSI

1.38

PSI

Max.

Setting

10.9"

18.5"

27.7"

1.37 PSI 84209006

Spring

P/N

3.4"

84209001

WC

(Yellow) 83602015 83601005 4 PSI

6.3"

84209002

WC

(Green) 83602015 83601005 4 PSI

84209003

WC

WC

WC

2.0

PSI

(Pink)

84209004

(Blue)

84209005

(White)

(Gray)

84209007

(Black)

Support

Plate

83602015

83602025

83602025 83601025

83602025 83601025

83602025 83601035

Back-up

Plate

83601005 4 PSI

83601025

Tank

MAWP

25

PSI

25

PSI

25

PSI

25

PSI

WARNING

The recommended set pressure range of the regulator

spring is stamped on the nameplate. Never adjust a

spring for a set pressure above its upper design limit

as specified in Tables 3, 4 and 5. Exceeding the spring

rang may compress the spring to its solid height. If

this happens the regulator may not close and the tank

could be over-pressured if the relief valve capacity is

less than supply gas flow rate.

The model 3010 is required for set pressures from

1/2" WC to 2" WC, and model 3020 from 2.0 PSI to

10.0 PSI. In some cases, different actuator

components are also required, either to reduce the

weight for low settings or to withstand the forces due

to higher pressure. (See. Tables 3, 4 and 5).

The set pressure range with the original spring is

stamped on the valve nameplate. The regulator will

not function properly if the setting is not within this

range. If higher or lower settings are required, the

necessary components can be obtained from Groth

Corporation. They must be installed according to

instruction in the maintenance section of this manual.

Tables 3, 4 and 5 show standard set pressure ranges.

TABLE 4

SPRING TABLE

MODEL 3010

TANK BLANKETING REGULATOR

LOW PRESSURE RANGE

SET PRESSURE RANGE: 0.5" WC - 2.0" WC

Spring

Range

1

2

3

Min.

Settin

g

0.5"

WC

0.7"

WC

1.1"

WC

Max.

Setting

0.6"

WC

1.0"

WC

2.0"

WC

Spring

P/N

84209008

(Red)

84209001

(Yellow)

84209002

(Green)

Support

Plate

83602035 83601005

83602035 83601005

83602005 83601015

Back-up

Plate

Tank

MAWP

10"

WC

10"

WC

10"

WC

TABLE 5

SPRING TABLE

MODEL 3020

TANK BLANKETING REGULATOR

HIGH PRESSURE RANGE

SET PRESSURE RANGE: 1.0 - 10.0 PSIG

Spring

Range

1

2

3

4

Min.

Setting

1.0

PSI

1.81

PSI

3.08

PSI

5.22

PSI

Max.

Setting

1.80

PSI

3.07

PSI

5.21

PSI

10.0 PSI

Spring

P/N

84209002

(Green)

84209003

(Pink)

84209004

(Blue)

84209005

(White)

Support

Plate

84829005 N/A

84829005 N/A

84829005 N/A

84829005 N/A

Back-up

Plate

Tank

MAWP

150

PSI

150

PSI

150

PSI

150

PSI

5

Page 9

FLOW CAPACITY SETTING

Unless otherwise specified, the orifice selector sleeve

[34] is factory set at the 100% full open position. If

reduced capacity is specified on an order, the sleeve

is set at the appropriate restriction. Actual capacity at

any other position can be calculated by multiplying

the capacity value from Table 2 for a specific

pressure by the decimal fraction from Table 6.

Flow capacity can be adjusted by rotating the orifice

sleeve (See Warning). It has a series of indexing

holes, four of which are marked with the numbers 12-3-4 (See Figure 5). Two unmarked holes are used

to assist when rotating the sleeve. Adjustment can be

made by loosening and backing the lockdown screw

completely out of the body. The sleeve position can

then be viewed and the sleeve rotated by inserting a

small diameter wire into the holes.

Figure 5: Orifice Sleeve Orientation

34

3

2

2

36 35

WARNING

The adjustable orifice is located in a pressure

containing chamber. Close the supply valve and

release all pressure before making adjustments.

When replacing the locking screw, grease the O-Ring

[35] and slip it over the screw threads. Thread the

screw [36] into the body, finger tight, until the point

enters the sleeve and the head seats onto the O-Ring.

Then wrench tighten the head firmly against the

body, compressing the O-Ring.

Sleeve position and valve capacity are shown in

Tables 2 and 6. These tables are based on the supply

pressure at the regulator inlet and piping as

recommended in the installation section.

WARNING

The regulator orifice sleeve is factory set at the

specified flow capacity. When repairing a

regulator, note the position of the indexing holes at

disassembly. The sleeve must be re-assembled in

the same position to ensure the proper flow

capacity. NEVER adjust the orifice sleeve position

without written instructions from your plant

operations group.

TABLE 6

ORIFICE CAPACITY

Orifice Sleeve

Position

1

2

3

4

Flow

Multiplier

1.0

0.75

0.50

0.25

6

Page 10

BLANKETING THE TANK

Before installing a new or replacement regulator, the

tank pressure must be below the desired set pressure

so the regulator setting can be verified. Sequentially

open the block valves in the following order: (1)

Sense Line, (2) Regulator Discharge Line and (3)

Regulator Supply (See Figure. 4).

If the regulator was set at the factory, blanket gas will

begin to flow immediately. The tank pressure must

be monitored closely to verify that the gas flow shuts

off within the specified limit above set pressure.

If the regulator was not set at the factory, make sure

that the adjusting screw [2] is backed out as far as

possible (no spring compression). When the blanket

gas supply valve is turned on, there will be no flow,

unless the tank pressure is very low. Now slowly

turn the adjusting screw to increase tank pressure and

the gas will begin to flow. The tank pressure can be

increased as gradually as desired until the correct

pressure setting is attained. When tank pressure is

reached, back out adjusting screw, if necessary, until

gas flow stops.

RECOMMENDED SPARE PARTS

When ordering spare parts, include model and serial number of regulator, pressure setting, and required material for

soft goods.

When adjusting the regulator on the tank, always be

sure that the sense line is open and unobstructed.

Monitor the tank pressure accurately.

In the event of actuator diaphragm [14] or piston

diaphragm [21] failure, the regulator will fail in the

OPEN position. Under this condition gas flow will

NOT be shut off by the regulator. The tank pressure

relief valve(s) must be sized to relieve the condition

of full regulator capacity, pump in rate; and thermal

expansion due to temperature rise. In the event of

blanket supply gas failure, the regulator will NOT

protect the tank from collapse due to a vacuum

condition. The operating relief valve should include

a vacuum breaker set according to the tank's design

vacuum capacity.

WARNING

WARNING

TABLE 7

RECOMMENDED SPARE PARTS

ITEM DESCRIPTION QUANTITY

14 Diaphragm, Actuator 2

21 Diaphragm, Piston 4

25 O-Ring, Piston 2

22 O-Ring, Guide Ring 2

35 O-Ring, Locking Screw 2

6 Spring 1

11 Vent, Case 1

7 Vent, Bonnet 1

39 Gasket, Actuator 2

7

Page 11

PROBLEM

Gas flowing at tank

pressure above

specified set point.

Gas not flowing at

tank pressure below

specified set point.

Gas leaking from

upper vent or bonnet

flange.

Gas leaking from

lower body seal or

case vent.

Process vapor leaks

from case flange or

vent.

Tank pressure above

or below specified

operating range

during pump out or

pump in.

Tank pressure or

vacuum exceeds vent

settings during pump

out or pump in.

TROUBLESHOOTING GUIDE

INSPECTION

Flow indicator in

blanket gas line.

Flow indicator in

blanket gas line.

Soap bubble test

and joining

surface or

emission

indication near

vent.

Soap bubble test at

joining surface or

emission

indication near

vent.

Soap bubble test at

joining surface or

emission

indication near

vent.

Observe tank

pressure indicator

during pumping

operations.

Observe tank

pressure indicator

during pumping

operations.

SUGGESTED CORRECTIVE ACTION

Damaged seat, O-Ring or diaphragm or pressure

setting too high. If original pressure setting has

not been disturbed, remove regulator and repair.

Damaged spring or pressure setting too low. If

original pressure setting has not been disturbed,

remove regulator and repair.

Damaged upper piston diaphragm. Remove

regulator from tank and replace diaphragm.

Diaphragm installed incorrectly. Reinforcement

fabric must be opposite to pressure (see page

13).

Damaged lower piston diaphragm. Remove

regulator from tank and replace diaphragm.

Diaphragm installed incorrectly. Reinforcement

fabric must be opposite to pressure (see page

13).

Damaged actuator diaphragm or loose case bolts.

Tighten bolts or remove regulator from tank and

replace diaphragm.

Excess or insufficient blanket gas flow. Check

flow orifice orientation. Refer to Tables 2 & 6

for flow capacity data. Check gas supply

pressure. Remove and repair regulator if other

conditions are correct.

Pressure/vacuum relief vent not functioning

properly. Inspect and repair or replace as

necessary.

8

Page 12

Figure 6: Spring Bonnet Assembly

1

2

3

5

WARNING

Before removing the regulator from the tank for

service, block supply pressure and vent all trapped

pressure. Never attempt to remove the regulator

from the line if it is pressurized.

WARNING

Do NOT attempt to remove the spring chamber [4],

flow orifice locking screw [36], or any pipe

connections from the body [20], while the regulator

is pressurized.

PREVENTIVE MAINTENANCE

Periodically, while in service, examine the regulator

for leakage at bolted connection, adjusting screws,

etc. Test for blanket gas or process vapor emissions

from vent caps.

DISASSEMBLY

All service on the regulator may be performed with

the following common tools:

7/16" thru 1" box end wrenches

3/8" open end wrench*

3/16" Allen key

*Wrench must be 16" long for flanged units.

Thread a 1/2" pipe nipple into the sense port on the

lower diaphragm case [15]. Use a vise and clamp

onto the pipe nipple. This makes a good holding

4

6

28729

fixture and provides some degree of rotation while

working on the regulator.

WARNING

Diaphragm actuator case and regulator body are

exposed to the process vapor(s). Observe all

standard safety precautions as specified on Material

Safety Data Sheets for the product(s) that are in the

tank. These precautions apply both during removal

of the regulator from the tank and while repairing

it.

Remove the adjustment screw cap [1] and loosen the

jam nut [3]. Turn the adjustment screw [2]

counterclockwise to completely relax the spring [6].

Remove the cap screws [28] and the lock washers

[29]. Remove the spring bonnet [4]. Remove the

spring upper button [5], the spring [6], the lower

spring button [5] and then the bonnet adapter ring

[10]. Use a 3/8" open end wrench and insert it

through the inlet port to hold onto the piston [24] at

the wrench flats. Remove the upper piston pin [8]

while holding onto the piston. Be careful not to let

the piston rotate during removal of the upper piston

pin. The piston diaphragms [21] can easily be torn if

care is not taken.

Figure 7: Piston/Body Assembly

20

WRENCH

FLATS

9

8

21

24

Remove the upper diaphragm retainer [9] and the

upper piston diaphragm [21].

9

Page 13

Remove the hex nuts, lockwashers, and hex bolts

(items 18, 17, & 16 respectively). Remove the upper

diaphragm case assembly [12] straight up.

Loosen the vise and remove the lower diaphragm

case with the pipe nipple still intact. Turn the upper

diaphragm case assembly upside down and use a vise

to hold on to the body [20].

Insert the 3/8" open end wrench through the inlet port

and hold on to the piston at the wrench flats while

loosening the countersunk screw [37] (See Figure

12).

Figure 8: Piston Assembly - "Exploded"

24

25

31

Remove the lift stop ring [33] from the groove by

expanding the ring slightly; and slide it over the

piston with care. Do not overexpand the ring.

Remove the retaining ring [32] with retaining ring

pliers. Expand retaining ring just enough to slide

over the piston. Be careful not to scratch the piston

surface. Remove the O-Ring retainer [31] and the oring [25].

Figure 9: Orifice Sleeve Orientation

34

3

2

32

33

Remove the washer [38], the diaphragm [14], the

diaphragm support plate [13] and then the back-up

plate [19].

Use a 3/16" Allen hex key and remove the

countersunk screws [30]. Remove the upper

diaphragm case [12].

Lift the piston sub-assembly [24] straight up and

remove from the body for disassembly. Lay the

piston subassembly horizontally on a clean flat

surface. Hold the piston at the wrench flats and

remove the lower pin [26], the diaphragm retainer

[9], the diaphragm [21], the O-Ring [22] and then the

guide ring [23].

Remove the piston sub-assembly from the body.

2

36 35

Refer to "FLOW CAPACITY SETTING" and

warnings before disassembling lockdown screw [36]

from body. Loosen and screw the lock down screw

[36] completely out of the Body. Before removing

the orifice selector sleeve [34], make note of its

position by looking through the 1/2" lock down

screw port. There will be a number stenciled on the

sleeve indicating the position of the sleeve. Note this

number for re-assembly. Refer to Tables 2 & 6 to

determine flow capacity of the regulator at a specific

open position.

All components should be examined for damage or

wear. Replace all seals and diaphragms. Prior to

reassembly, make sure all components are clean and

free of contamination.

10

Page 14

ASSEMBLY

Before assembly note the following material and tool

requirements:

1. Diaphragms, O-Rings, gasket, vents and

spring as listed in Table 7:

Recommended Spare Parts on page 8.

2. Lubricants & Thread Sealants

A. Silicone Grease

Dow Corning No. 33

B. Anti-Galling Lubricant

Dow Corning G-N Metal

Assembly Spray

C. Thread Sealant

Loctite Threadlocker No. 222

D. Fluoropolymer tape

3. Assembly Tools

A. 7/16" - 1" box end wrenches

B. 3/8" open end wrench*

C. 3/16" Allen key

* Wrench must be 16" long for flanged units.

All screw threads and static O-Ring should be lightly

greased with silicone grease. Lubricate the piston

OD at both ends and the spring adjusting screw with

an anti-galling spray. If the greases listed above are

not compatible with the tank vapors, use equivalent

lubricants for that media. All pipe threads are to be

wrapped with Fluoropolymer tape or suitable pipe

thread sealant applied sparingly.

Before installing the orifice selector sleeve, read the

section entitled "FLOW CAPACITY SETTING" and

related warnings on page 7. Install the orifice

selector sleeve [34] into the regulator body. Observe

the sleeve position locking hole by looking in the

locking screw hole in the body. The hole in the

sleeve should be exactly centered in the screw hole.

If the holes do not line up exactly, invert the sleeve

and reinstall. The position indicating numbers will

also be seen through the screw hole.

These numbers indicate % open and flow capacity

according to Tables 2 and 6. Make sure that the

sleeve position is on the same number as when

disassembled, or on the number that provides the

specified flow requirements.

Figure 10: Orifice Sleeve Orientation

34

3

2

2

36 35

Grease the locking screw O-ring [35] and slip it over

the screw threads. Thread the locking screw [36]

into the body, finger tight, until the point enters the

sleeve and the head seats onto the O-ring. Then

wrench tighten the head firmly against the body,

compressing the O-ring.

Note: Damage to the sleeve will occur if force is

applied with the point of the locking screw.

Figure 11: Piston Assembly - "Exploded"

24

25

31

32

Assemble the piston sub-assembly according to

Figure 11. Install the O-Ring [25] from the top end

of the piston. Do not rotate the o-ring, but stretch it

just enough to clear the piston diameter. When

installing the retaining ring [31], snap ring [32] and

lift stop ring [33] expand the rings just enough to

33

11

Page 15

clear the piston without scratching the piston or

permanently deforming the rings.

Secure the body in a vise with the bottom surface

facing upward and the inlet port accessible (See

Figure 12). Spray the piston sub-assembly with an

anti-galling lubricant and insert it and the guide ring

[23], into the body. Install the body O-Ring [22].

Set the piston diaphragm into the upper actuator

housing with reinforcing fabric away from the piston

(opposite to the supply pressure). Refer to Figure 12.

Attach the upper diaphragm case [12] to the body,

being sure that the piston wrench flats are accessible

through the inlet port before tightening the

countersunk screws [30].

Figure 12: Piston/Body/Diaphragm

38

37

13

26

34

33

32

31

21

19

21

22

23

24

25

WRENCH

FLATS

Attach the sense diaphragm [14], support plate [13],

back-up plate [19] and washer [38] (See Figure 15).

Clean thread surfaces thoroughly and apply Loctite

Threadlocker No. 222 to countersunk screw [37].

Align diaphragm and case holes and hold piston with

a 3/8" wrench through inlet port while tightening the

countersunk screw [37].

Attach the gasket [39] and lower diaphragm case [15]

with hex bolts, lockwashers and nuts [16, 17, & 18].

TABLE 8

RECOMMENDED BOLT TORQUE

[FT. - LB.]

Screw Size 1/4" 5/16" 3/8" 7/16" 1/2"

Torque

6

11 20

32

44

Clean all surfaces before assembly and tighten bolts

uniformly; refer to Table 8 for recommended torque.

Reposition the assembly in the vise. Install the upper

piston diaphragm [21], retainer [9] and pin [8]. Hold

piston with 3/8" wrench through inlet port while

tightening pin. Install the bonnet adapter ring [10],

spring [6], spring buttons [5] and spring bonnet [4].

Attach bonnet to body with hex bolts [28] and

lockwashers [29]. Tighten bolts uniformly; refer to

Table 8 for recommended torque.

Figure 13: Spring Bonnet Assembly

1

2

3

5

4

6

28729

Thread set pressure adjusting screw [2] into bonnet

until it engages the upper spring button. Tighten lock

nut [3] and replace cap [1].

Note: See Recommended Testing and Setting

Procedure.

WARNING

Replace bonnet vent [7] or case vent [11] if

damaged or restricted. A plugged case vent could

prevent the regulator from closing. This could

cause an over-pressure condition in the tank. A

plugged bonnet vent would prevent the release of

supply pressure from the bonnet. This could cause

personal injury when disassembling.

12

Page 16

RECOMMENDED TESTING AND SETTING PROCEDURE

1.0) Equipment

1.1) A high pressure air (or inert gas) supply

system capable of maintaining supply pressure

at 0-200 PSI. Flow may be controlled by a

reducing regulator or valve.

1.2) A low pressure air (gas) supply system

capable of maintaining sense pressure at 1/2"

WC to 10 PSI. Pressure may be controlled by

a regulator or needle valve and a small

accumulator. If a needle valve is used, it will

require frequent adjustment because the

regulator consumes a significant volume of air

when operating.

1.3) A means of indicating or measuring air flow

with a capacity of approximately 30 SCFH.

1.4) A means of soap bubble shell testing the

assembly.

2.0) Test procedure and Acceptance Criteria.

2.1) Connect the high pressure air supply to the

regulator inlet port.

2.2) Connect the low pressure air supply to the

regulator sense port.

2.3) Connect a reduced size manual shut-off valve

to the outlet port.

2.4) Connect a small diameter hose or plastic tube

to the inlet of the flow indicator o r flow meter.

Use a hand held port cover to attach the flow

meter to the regulator outlet port. Never

connect the flow meter rigidly to the regulator

unless the flow meter is rated for full air

supply pressure.

2.5) Connect a small diameter hose or plastic tube

to the outlet of the flow indicating device so

the end may be immersed in a container of

water.

2.6) Close the outlet valve and set the supply air

pressure to the maximum available, but not

greater than 300 PSI. Soap bubble test the

entire assembly at this pressure. Open the

outlet valve and reduce the supply until a

minimum audible flow is observed.

2.7) Adjust the sense pressure to the specified

regulator set pressure. Adjust the regulator

screw to shut off (no audible flow). Now

increase the sense pressure to 2 times the

specified set pressure or 1.5 times the

specified tank MAWP, whichever is greater.

Soap bubble test the actuator housing.

2.8) Increase the supply pressure to the specified

system pressure (100 PSI if not specified).

2.9) Slowly decrease the sense pressure and adjust

the regulator screw until the air flow is 5-20

SCFH at the specified setting. Lock the

adjusting screw at this setting.

2.10) While immersing the outlet tube in water,

increase the sense pressure until the regulator

is bubble tight. If this pressure exceeds 15%

or 2" WC greater than the set pressure,

examine the seat and O-Ring. Do not adjust

the regulator screw to improve bubble

tightness.

2.11) Remove the bonnet vent. Shut off the supply

pressure. Slowly decrease the sense pressure

to zero, while observing the stroke of the

piston thru the bonnet vent port. The stroke

must be 0.18" minimum. Replace the bonnet

vent.

3.0) Test report data.

3.1) The following data should be recorded for

future reference:

Model, Tag & Serial numbers

Test media

Body & Actuator shell test pressure

Supply pressure

Set pressure

Bubble tight pressure

13

Page 17

Figure 14: Blanketing Regulator - "Exploded" Assembly

1

3

2

4

28

29

7

5

6

5

10

8

9

21

23

22

21

9

26

16

11

12

19

30

24

25

31

32

33

PISTON

SUB-ASSY

BODY & SPRING

BONNET ASSY

20

35

36

34

13

14

38

37

39

15

17

18

ACTUATOR & PISTON ASSY

14

Page 18

TABLE 9

BILL OF MATERIAL

3000 SERIES BLANKET GAS REGULATOR

MATERIALS OF CONSTRUCTION

ITEM QTY DESCRIPTION CARBON

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

36

36

36

1

1

2

1

1

1

1

1

1

4

4

4

1

1

1

1

1

1

1

1

1

Cap, Adjustment Screw

Screw, Pressure Adjustment

Nut, Hex

Bonnet, Spring

Button , Spring

Spring

Vent, Bonnet

Pin, Upper Piston

Retainer, Diaphragm

Adapter, Bonnet

Vent, Case

Case, Upper Actuator

Plate, Diaphragm Support

Diaphragm, Actuator

Case, Lower Actuator

Bolt, Hex

Washer, Lock

Nut, Hex

Plate, Back-Up

Body

Diaphragm, Piston

O-Ring, Guide Ring

Ring, Guide - Piston

Piston

O-Ring, Piston Seat

Pin, Lower Piston

Nameplate

Bolt, Hex

Washer, Lock

Screw, Flathead

Retainer, O-Ring Piston Seat

Retaining Ring

Stop, Lift

Sleeve, Orifice Selector

O-Ring, Lockdown Screw

Screw, Locking - Flow Orifice

Screw, Flathead

Washer, Countersunk

Gasket, Actuator

STEEL

CS

SS

SS

CS

CS

316 SS

PVC or Alum

316 SS

316 SS

CS

PVC or Alum

CS

316 SS

Fluoropolymer

CS

SS

SS

SS

316 SS

316 SS

BUNA-N

BUNA-N

316 SS

316 SS

BUNA-N

316 SS

316 SS

SS

SS

SS

316 SS

SS

SS

316 SS

BUNA-N

316 SS

316 SS

SS

Non-Asbestos

STAINLESS

STEEL

SS

SS

SS

316 SS

316 SS

316 SS

PVC or Alum

316 SS

316 SS

316 SS

PVC or Alum

316 SS

316 SS

Fluoropolymer

316 SS

SS

SS

SS

316 SS

316 SS

FKM

FKM

316 SS

316 SS

FKM

316 SS

316 SS

SS

SS

SS

316 SS

SS

SS

316 SS

FKM

316 SS

316 SS

SS

Non-Asbestos

15

Page 19

Figure 15: Blanketing Regulator - Cross-Sectional Assembly

28 29

25

24

23

22

21

PISTON DETAIL

20

30

19

21

31

32

33

34

26

REF

27

TOP VIEW

SHOWS TRUE

ORIENTATION

1

2

3

4

5

6

7

8

9

10

11

INLET

OUTLET

18

17

16

38

35

36

37

SENSE

PORT

12

13

14

39

15

16

Page 20

The nameplate on the Groth Series 3000 Tank Blanketing Regulator contains the model number, serial number, set

pressure & range and supply pressure. The model number contains additional information about material of

construction, capacity and options. The following chart will assist in relating the model number to the

specifications of your regulator:

3000 N 5 V 1 O

Connections

N

F

Z

1" NPT (F)

1"150# RF

Special

Material

3

5

Z

Carbon Stl

316 SS

Special

Soft Goods

B

V

E

Z

Buna-N

FKM

EPDM

Special

Orifice

1

2

3

4

100%

75%

50%

25%

Options

0 Z None

Special

Model 3000 2" WC to 2 PSI Pressure Range

Model 3010 1/2" WC to 2" WC Pressure Range

Model 3020 1 PSI to 10 PSI Pressure Range

A "Z" in the model number indicates a non-standard material or feature. Review your purchase specifications or

consult Groth Corporation for more details.

EXAMPLE 3000 N 5 V 1 0 Indicates a 3000 Series Regulator with

Set Pressure Range from 2" WC - 2 PSI, 1"

NPT Body Connections, 316 SS Construction,

FKM Elastomers, Full Capacity Orifice and

No Special Requirements.

PRODUCT LIMITED WARRANTY

A. Seller warrants that products which are manufactured

by Seller, are manufactured in accordance with

published specifications and free from defects in

materials and/or workmanship for a period of (12)

twelve months. Seller, at its option, will repair or

replace any products returned intact to the factory,

transportation charges prepaid, which Seller, upon

inspection, shall determine to be defective in material

and/or workmanship. The foregoing shall constitute

the sole remedy for any breach of Seller's warranty.

B. THERE ARE NO UNDERSTANDINGS,

AGREEMENTS, REPRESENTATIONS, OR

WARRANTIES, EXPRESS OR IMPLIED,

(INCLUDING MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE REGARDING

PRODUCTS) UNLESS SPECIFIED IN THE SALES

CONTRACT. THIS CONTRACT STATES THE

ENTIRE OBLIGATION OF SELLER.

Seller makes no warranties, either express or implied,

except as provided herein, including without

limitation thereof, warranties as to marketability,

merchantability, for a particular purpose or use, or

against infringement of any patent of products. In no

event shall Seller be liable for any direct, incidental or

consequential damages of any nature, or losses or

expenses resulting from any defective new product or

the use of any such product, including any damages

for loss of time, inconvenience, or loss of use of any

such product.

C. The original Manufacturer shall be solely responsible

for the design, development, supply, production, and

performance of its products hereunder, and the

protection of its trade name or names, if any. It

assumes no responsibility, for products modified or

changed in any way by its agent or customer. Any

such modifications or changes to products sold by

Seller hereunder shall make the product limited

warranty null and void.

D. The Manufacturer shall be under no obligation to

manufacture, sell, or supply, or to continue to

manufacture, sell or supply any of the Products.

17

Page 21

ADDENDUM A

Groth Corporation continually reviews and revises designs an d specifications to improve quality and performance of its

manufactured products. The specifications and procedures in this addendum supersede the applicable sections of the

TABLE 3

Spring Table

Model 3000

Set Pressure Range: 2" WC to 2.0 PSI

Tank MAWP: 25 PSI

Spring

Range

1

2

3

4

5

6

7

Spring

Range

8

1

2

Spring

Range

4 2.0 PSI 3.3 PSI

5 3.4 PSI 5.1 PSI

6 5.2 PSI 7.3 PSI

7 7.4 PSI 10.0 PSI

Min.

Setting

2.0

In WC

3.5

In WC

6.4

In WC

11.0

In WC

18.6

In WC

1.0

PSI

1.38

PSI

Set Pressure Range: 0.5" WC to 2.0" WC

Min.

Setting

0.5

In WC

0.7

In WC

1.1

In WC

Set Pressure Range: 2.0 PSI to 10.0 PSI

Tank MAWP: 25 PSI Standard 150 PSI Optional

Min.

Setting

Max.

Setting

3.4

InWC

6.3

InWC

10.9

InWC

18.5

InWC

27.6

InWC

1.37

PSI

2.0

PSI

TABLE 4

Spring Table

Model 3010

Tank MAWP: 10 In WC

Max.

Setting

0.6

In WC

1.0

In WC

2.0

In WC

TABLE 5

Spring Table

Model 3020

Max.

Setting

Spring

P/N

84209001

Yellow

84209002

Green

84209003

Pink

84209004

Blue

84209005

White

84209006

Gray

84209007

Black

Spring

P/N

84209008

Red

84209001

Yellow

84209002

Green

Spring

P/N

84209004

Blue

84209005

White

84209006

Gray

84209002

Green

manual for all Groth blanket gas regulators manufactured after

7/1/1994.

PRESSURE SETTING

All springs and spring ranges are the same, however, balance

springs have been added in some spring ranges. Refer to tables 3, 4

Balance

and 5 below.

Spr P/N

85493001

Yellow

Not

Required

Not

Required

Not

Required

Not

Required

Not

Required

Not

Required

FLOW CAPACITY SETTING

The setting procedure is the same, but additional flow restrictions

are available, down to 5% of full flow. Refer to table 6 below.

DISASSEMBLY

Some regulators utilize a balance spring inside the body (refer to

Tables 3 & 4 and Figure 12 on the reverse side of this page).

Hex bolts [28] are used in place of the countersunk screws [30] to

mount the body to the actuator housing. As the bolts are removed,

the internal spring [30] will force the guide ring [23] out of the

body. The force is not great enough to present a hazard, but caution

should be used to prevent damage to the ring. The spring can then

be removed as part of the piston sub-assembly. Proceed with

disassembly according to the manual.

ASSEMBLY

Prepare the body, piston sub-assembly and upper actuator housing

Balance

Spr P/N

85493001

Yellow

85493001

Yellow

Not

Required

according to the manual. Attach the piston diaphragm [21],

diaphragm retainer [9] and lower piston pin [26] to the piston subassembly. Note: The reinforced (rough) surface of the piston

diaphragm [21] must be facing away from the piston, ie: high

pressure on the smooth side. This is critical for the top (inlet)

piston diaphragm. Proceed with assembly according to the

manual, except where a balance spring is utilized, then proceed as

follows:

Slide the small end of the balance spring [30] over the piston subassembly until it seats on the retaining ring [32]. Insert this

piston/spring sub-assembly into the body. Fit the large end of the

balance spring into the groove in the guide ring [23] and compress

Balance

Spr P/N

Not

Required

Not

Required

Not

Required

Not

Required

the spring as you insert the guide ring and O-Ring [22] into the

body. Hold the guide ring as you position the actuator housing [12]

onto the body. The weight of the housing will maintain

compression of the spring. Install hex bolts [28] and lockwashers

[29] and tighten uniformly. Proceed with assembly according to the

manual.

See piston/body/diaphragm sub-assembly drawing (Figure 12) and

bill of materials on the next page.

Page 22

10

34

30

29 28 38 37 26 13

8

9

Figure 12

21

24

25

31

32

35

36

33

23

22

19

ITEM QTY DESCRIPTION

8

1

9

10

13

19

21

22

23

24

25

26

28

29

30

31

32

33

34

35

36

37

38

Pin, Upper Piston

2

Retainer, Diaphragm

1

Adapter, Bonnet

1

Plate, Diaphragm Support

1

Plate, Back-Up

1

Diaphragm, Piston

1

O-Ring, Guide Ring

1

Ring, Guide - Piston

1

Piston

1

O-Ring, Piston Seat

1

Pin, Lower Piston

4

Bolt, Hex

4

Washer, Lock

1

Spring, Balance

1

Retainer, O-Ring Piston Seat

1

Retaining Ring

1

Stop, Lift

1

Sleeve, Orifice Selector

1

O-ring, Lockdown Screw

1

Screw, Locking - Flow Orifice

1

Screw, Flathead

1

Washer, Countersunk

Loading...

Loading...