Page 1

Installation, Operation and Maintenance Manual for

Emergency Pressure Relief Valves

Model 2100

IOM 2100.0

REV. A 12541

Page 2

TABLE OF CONTENTS

IOM 2100.0

February 2005

INTRODUCTION

DESCRIPTION PAGE

Introduction

Emergency Valve Design & Function

Safety Warnings

Shipping, Inspection and Storage

Installation

Routine Maintenance

Tools

Disassembly

Assembly

Troubleshooting Guide

Certified Drawing Bill of Materials

How to Order

Product Limited Warranty

LIST OF FIGURES

1. Tank Installation - Safety Equip.

2. 2100 Certified Drawing

1

2

3

3

3 - 4

4

5

5

5

6

7 - 8

9

9

2

7

LIST OF TABLES

1. Body Flange Gasket Dimensions

2. Flange Bolt Torque

3. Troubleshooting Guide

4. O-Rings - 2100 Cover (Pressure)

4

4

6

6

Pressure relief valves are used on liquid storage

tanks and other process vessels or systems to

prevent structural damage due to excess

internal pressure.

Storage tanks are pressurized when liquid is

pumped in, compressing the existing vapor or

when increasing temperature causes increased

evaporation or expansion of existing vapor. To

prevent damage, vapor must be allowed to

escape or enter the tank at a specified pressure

condition. The volume rate of venting depends

upon the tank size, volatility of the contents, the

pumping rate and the temperature. See API

Standard 2000 for the procedures to determine

venting requirements.

The 2100 Spring Loaded Emergency Relief

Valve provides pressure relief. Emergency

pressure relief provides protection for fire

exposure and/or failure of the inert gas

blanketing system. The valves can be set for

pressure relief in the range of 1 - 15 PSIG.

High operating pressures reduce evaporation

and total venting volume, thereby reducing

product loss and the cost of processing

emissions.

All valves must be carefully maintained by a

qualified valve technician. They should only be

assembled under clean conditions, preferably in

a service shop environment. Carefully read and

understand this manual before attempting to

repair a 2100 Emergency Pressure Relief Valve.

5. Abbreviations

6. Pressure Spring - Set Ranges

7. Bill of Material (C-91768 Drawing)

6

7

8

1

Page 3

FIGURE 1: TANK INSTALLATION - SAFETY EQUIPMENT

EMERGENCY RELIEF VALVE DESIGN

AND FUNCTION

The 2100 Series Emergency Relief Valve is

designed to provide pressure relief for API 620

and 650 tanks.

This series of valve is available with a standard

O-Ring seat. Depending on application, it is

available in a wide range of material options.

Each application must be reviewed to ensure

material compatibility of all metal and soft good

This manual is intended to provide

recommended procedures and practices for

installation, operation, and maintenance of the

Groth 2100 Emergency Relief Valve. Any

standard procedures and practices developed

for a specific plant or process may supersede

this manual. Although this manual cannot cover

all possible contingencies, following these

guidelines should provide safe, reliable valve

performance.

components. Consult factory for special

requirements. (See Table 7 for a complete

standard material list.)

The Emergency Relief Valve is set at the factory

to comply with the specification on the purchase

order. The range of adjustment (for pressure

relief) is shown in Table 6. The pressure setting

may be changed within the design range in a

service shop.

For information not contained in this manual,

please contact:

Groth Corporation

A Continental Disc Company

13650 North Promenade Blvd.

Stafford, TX 77477

281-295-6800 [phone]

281-295-6999 [fax]

2

Page 4

SAFETY WARNINGS

This section is an overview of safety guidelines

that should be followed during the installation,

operation and maintenance of Groth Pressure

Emergency Relief Valves. To understand the

context of these instructions and warnings, it is

necessary to completely read and understand

the contents of this manual.

The purpose of an Emergency Relief Valve

(ERV) is to prevent excessive pressure in a tank

or process system. The valve must be designed

for the proper MAWP and flow requirements of

the system. Consult API Standard 2000 for tank

protection sizing procedures. An improperly

specified or functioning relief valve may result in

structural damage to the tank or system.

SHIPPING, INSPECTION AND

STORAGE

The ERV is normally bolted to a pallet during

shipping. When received inspect the valve for

any sign of damage that may have occurred in

shipment and report this to the carrier.

If the valve is to be stored before installation, it

should be in a clean environment and protected

to prevent intrusion of foreign materials into the

body. Before installation inspect the unit

visually. If there is any indication of physical

damage or internal contamination, the valve

must be cleaned and inspected before

installation.

WARNING: The valve must be installed in a

vertical position as shown in Fig. 1. To

achieve nominal flow capacity, the tank nozzle

bore must be at least the same nominal

dimension as the relief valve body.

Lifting eyes are bolted to the upper body flange

and are to be used for handling the valve. To

avoid damage to the lower flange surface, set

the valve on a soft clean gasket material until it

is ready to be installed.

Do NOT attempt to remove the valve from the

tank or process vessel without first bleeding all

pressure from the system. ALTERNATIVE

MEANS OF PRESSURE RELIEF MUST BE

PROVIDED WHEN THE VALVE IS OUT OF

SERVICE.

The ERV is exposed to process vapors while in

service. Observe all plant procedures and

Material Safety Data Sheet (MSDS)

recommendations for the products in the system

when inspecting, adjusting or servicing the

valve. Take appropriate safety precautions

regarding eye protection, respiration and skin

contact.

SEE PAGES 4, 5, & 7 FOR ADDITIONAL

WARNINGS.

INSTALLATION

The 2100 ERV must be handled carefully to

ensure seat tightness.

1. At installation, the valve should be smoothly

lifted into position using the lifting eyes on

the body flange. Do NOT lift the valve by

the spring assemblies; this can damage the

seat and cause the valve to leak in service.

2. The mating flanges on the valve body and

tank nozzle should be the same type (i.e.

RF with RF and FF with FF). Mating flanges

MUST be flat within .015" and clean, free of

scratches, corrosion and tool marks.

3. Begin by inspecting the gasket; make sure

that the material is suitable for the service.

Gasket dimensions are listed in the Table 1

below. Center the gasket on the tank nozzle.

3

Page 5

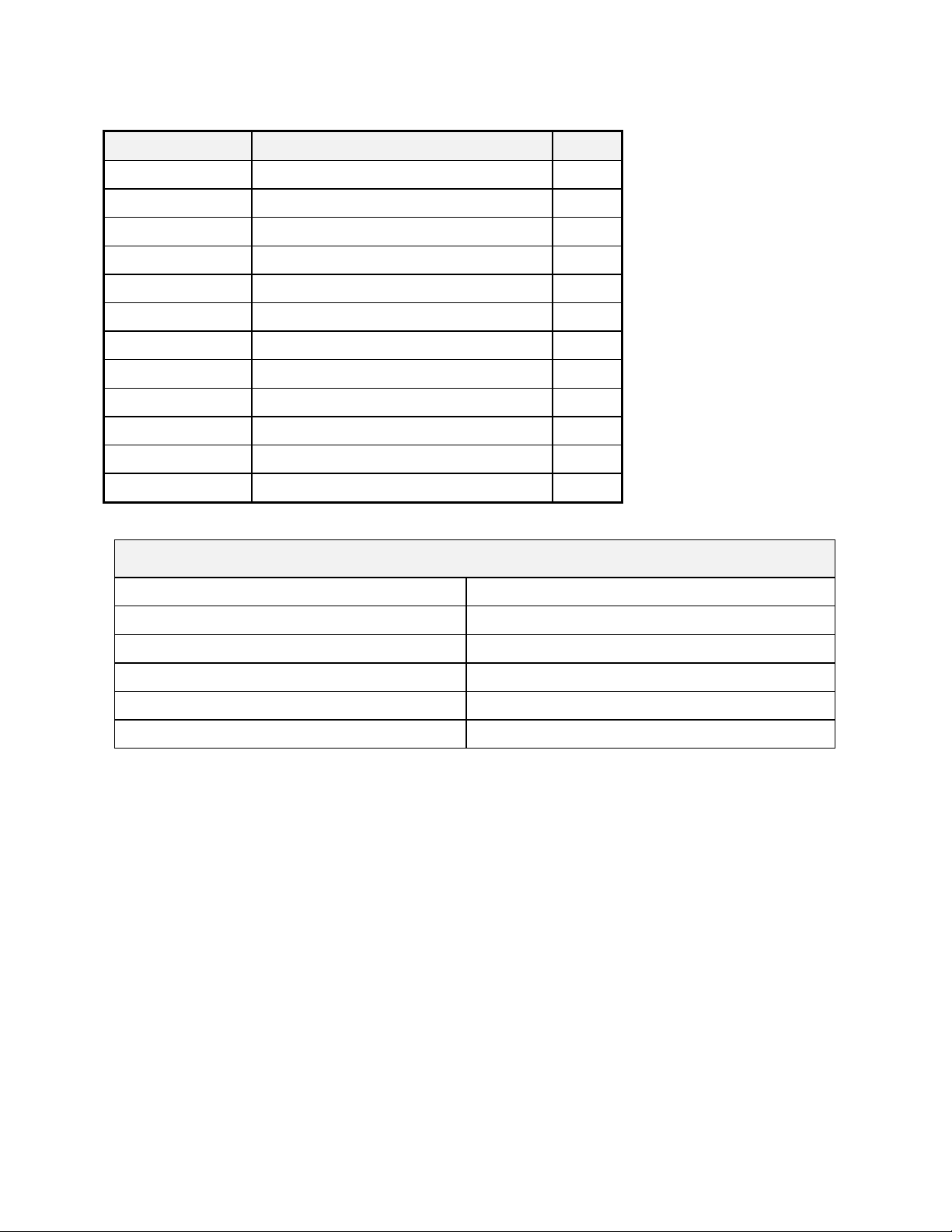

Table 1

Body Flange Gasket Dimensions

150# ANSI Flange

Size OD ID BC Hole No.

16" FF 23.50" 15.25" 21.25" 1.13" 16

20" FF 27.50" 19.25" 25.00" 1.25" 20

24” FF 32.00" 23.25" 29.50" 1.38" 20

16" RF 18.50" 15.25" --- --- --20" RF 23.00" 19.25" --- --- --24” RF 27.25" 23.25" --- --- ---

API 650# Flange

Size OD ID BC Hole No.

20" 26.00" 19.25" 23.50" 0.75" 16

24” 30.00" 23.25" 27.50" 0.75" 20

5. Set the valve carefully on the nozzle

6. Lubricate all studs and nuts with an

appropriate thread lubricant. If stainless

steel fasteners are used, use an anti-seize

lubricant such as moly-disulfide.

7. Install the studs in the valve body and

tighten nuts hand tight.

8. Torque all fasteners to half the value listed

in Table 2 in a staggered, alternating pattern

or follow appropriate Plant Maintenance

guideline standards.

9. Make sure that the flanges are not distorted

and that the gasket is evenly compressed.

API 650# Flange (2 PSIG MAWP)

20" 16 0.63" 22

24” 20 0.63" 25

ROUTINE MAINTENANCE

The 2100 ERV does not require routine

lubrication or adjustments. It should be checked

periodically, at least once a year, to confirm that

the valve is functioning properly and that the set

point is correct.

Periodic inspection for seat tightness should be

done to ensure compliance with local air

pollution control requirements. This may be

accomplished with a gas detector calibrated for

the principle product in the system.

The valve will need to be periodically removed

from the tank for inspection of the main cover

seal. When this is done, the valve must be

carefully lifted using the lifting eyes on the body

upper flange.

Refer to handling instructions listed in the

Installation section of this manual.

If a vapor leak is detected, it will be from one of

the following sources:

1. Cover Seal.

2. Body - nozzle flange joint gasket.

Refer to the Troubleshooting section (p. 6) of

this manual for probable causes for these type

of problems.

10. Make up the final torque and check that no

further nut rotation occurs at the specified

torque value.

Table 2

Flange Bolt Torque [Ft. Lb.]

150# ANSI Flange (30 PSI MAWP)

ANSI

Flange

16" FF 16 1.00” 330

20" FF 20 1.13” 410

24” FF 20 1.25” 630

16" RF 16 1.00” 225

20" RF 20 1.13” 320

24” RF 20 1.25” 500

Number

of Studs

Stud

Size

Torque

TOOLS

Most service, adjustment and assembly of the

2100 valve may be performed with the following

open end wrench sizes:

15/16”, 1-1/8”, 1-1/2", 1-11/16” & 1-7/8”

DISASSEMBLY

Note that throughout this manual, numbers in [ ]

after the part descriptions are item numbers

which refer to the drawings and bills of material.

They apply only to drawing C-91726 [on page 7].

The valve should be handled by the lifting eyes

attached to the main valve body upper flange. It

should be set on a flat surface.

4

Page 6

WARNING: Before disassembling a valve,

carefully read and understand the Safety

Warnings listed on page 3.

ASSEMBLY:

This valve is built with an integral body seat. If

construction is C.S., a 316 SS weld overlay was

used to build up the seat. Consult the factory

before machining this surface.

Measure the distance from the top of the

pressure upper spring button [4] and the top of

the adjustment screw [6]. This should also be

recorded. Remove the top hex nut [5] from each

adjustment screw and then back off the lower

nut [5], releasing spring compression. Use care

as the nut is removed from the adjustment

screw in case of spring pre-load. Loosen the

lower nuts [11] and remove the adjustment

screws [6]. Lift the springs [3] from the valve;

handle carefully to avoid bending them or

scratching the wire.

Lift the cover (using appropriate equipment) with

one of the lifting lugs [8] and turn it upside down,

exposing the cover seal [7]. Inspect the O-Ring

for signs of mechanical damage or deterioration

from product exposure and replace if necessary.

To install a new pressure O-Ring, the cover

should be turned upside down to provide access

to the groove. It must be cleaned and can be

lubricated with a small amount of grease. The

O-Ring should be started at three or four points

around the circumference to minimize the effect

of -O-Ring stretch. Use your finger or a smooth

tool to roll the O-Ring into the groove.

Using all four lifting lugs [8], carefully lift the

cover assembly onto the body [1]. Align the

adjustment screw holes in the cover with the

body. (Depending on size and set pressure

range there are either four or eight holes.)

Place an adjustment screw [6] into each of these

holes and lock into place using the two 3/4”-10

UNC hex nuts [11] and lock washers [10]. Slide

spring buttons [4] over each of the adjustment

screws [6] and then the springs [3]. Put a spring

button [4] on top and then tighten the two 1”-8

UNC hex nuts [5] until the desired spring

compression is achieved. [Refer to the

dimension that was recorded before the valve

was disassembled.]

TABLE 3: TROUBLESHOOTING GUIDE

PROBLEM INSPECTION SUGGESTED CORRECTIVE ACTION

Vapor leakage

between the

cover & valve

top flange

Vapor leakage

between the

valve body

and tank

nozzle

Visual, audible or

vapor detector

Visual, audible or

vapor detector

Leakage can occur at the cover O-Ring seal and valve body seat.

This will generally occur because of deterioration of the O-Ring,

but can also be caused by mounting the valve on a warped

flange. The seat can be distorted resulting in a leak path; the

tank nozzle must be machined or replaced to correct this

condition.

Leakage between the flanges may be corrected by tightening the

fasteners. Follow installation instructions listed on pages 3 - 4.

The gasket may have deteriorated due to the chemical

environment; replace if required. The tank nozzle may be

warped, corroded or scratched. This will require resurfacing of

the flange face.

5

Page 7

TABLE 4: O-RINGS - 2100 PRESSURE COVER:

Part Number Description SIZE

891A70384 O-Ring, 2100 ERV, 16”, Aflas, #384 16”

891A70388 O-Ring, 2100 ERV, 20”, Aflas, #388 20”

891A70392 O-Ring, 2100 ERV, 24”, Aflas, #392 24”

89102384 O-Ring, 2100 ERV, 16”, Buna N, #384 16”

89102388 O-Ring, 2100 ERV, 20”, Buna N, #388 20”

89102392 O-Ring, 2100 ERV, 24”, Buna N, #392 24”

891E70384 O-Ring, 2100 ERV, 16”, EPR, #384 16”

891E70388 O-Ring, 2100 ERV, 20”, EPR, #388 20”

891E70392 O-Ring, 2100 ERV, 24”, EPR, #392 24”

891V75384 O-Ring, 2100 ERV, 16”, FKM, #384 16”

89107388 O-Ring, 2100 ERV, 20”, FKM, #388 20”

89107392 O-Ring, 2100 ERV, 24”, FKM, #392 24”

TABLE 5: ABBREVIATIONS

API American Petroleum Institute PH Precipitation Hardened

CS Carbon Steel PSIG Pounds/Sq. Inch - Gauge

EPA Environmental Protection Agency QCP Quality Control Procedure

OSI Oz. per Square Inch SS Stainless Steel

MAWP Maximum Allowable Working Pressure VOC Volatile Organic Compounds

NPT National Pipe Thread WC Water Column

6

Page 8

Fig. 2: Model 2100 Certified Drawing - (C-91726)

TABLE 6: Pressure Spring - Allowable Set Pressure Ranges:

1 1.00 1.39

2 1.40 1.89

3 1.90 2.49

4 2.50 3.29

5 3.30 4.29

6 4.30 5.59

7 5.60 7.29

8 7.30 9.49

9 9.50 12.29

10 12.30 15.00

WARNING: Failure to properly set a spring loaded valve can result in a valve that is either set too high

or has insufficient lift to attain rated flow capacity. Under these conditions, the valve will not protect the

tank or system from rupturing due to changes in internal pressure. Tank failure can cause material

damage and loss and result in severe personal injury or death.

Range Min. Press.

(PSIG)

Max. Press.

(PSIG)

7

Page 9

TABLE 7: BILL OF MATERIAL: DRAWING C-91726

(Standard Materials of Construction)

ITEM DESCRIPTION CS 316 SS SPARE

1

BODY (1)

2 COVER CS 316 SS

3 SPRING CS 17-7 PH

4 BUTTON, SPRING CS 316 SS

5 NUT, HEX SS SS

6 SCREW, ADJUSTMENT 316 SS 316 SS

7

O-RING, COVER (2)

8 EYE, LIFTING CS 316 SS

9 BOLT, HEX SS SS

10 WASHER, LOCK SS SS

11 NUT, HEX SS SS

(1) 316 SS Seat Overlay on CS Body

(2) Elastomers Also Available in Aflas, Buna-N, EPR, & FFKM.

The nameplate on the Valve contains the Model Number, Serial Number, set pressures and flow capacity

at a specified over-pressure. The Model Number contains additional information about materials of

construction, soft goods and options. The following chart will assist in relating the Model Number to the

characteristics of your valve:

CS 316 SS

FKM FKM

X

MODEL SIZE MATERIAL OPTIONS

2 1 0 0 -- -- -----------------

16” 3 Carbon Steel O-Ring Material (Seat)

20” 5 316 SS A - Aflas

24” Z Special B - Buna N

E - EPR

V - FKM

1 - ANSI 150# Drilling

2 - API 650# Drilling

O - No Jacket

J - Steam Jacket

O - No Options

Z - Special Options

EXAMPLE: 2100-20-5-V2OO indicates a Model 2100 20” with 316 SS body and seat,

FKM cover O-Ring, API 650 Drilling and no special options.

8

Page 10

PRODUCT LIMITED WARRANTY

A. Seller warrants that products which are manufactured by Seller, are manufactured in accordance

with published specifications and free from defects in materials and/or workmanship for a period of

(12) twelve months. Seller, at its option, will repair or replace any products returned intact to the

factory, transportation charges prepaid, which Seller, upon inspection, shall determine to be

defective in material and/or workmanship. The foregoing shall constitute the sole remedy for any

breach of Seller's warranty.

B. THERE ARE NO UNDERSTANDINGS, AGREEMENTS, REPRESENTATIONS, OR

WARRANTIES, EXPRESS OR IMPLIED, (INCLUDING MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE REGARDING PRODUCTS) UNLESS SPECIFIED IN THE SALES

CONTRACT. THIS CONTRACT STATES THE ENTIRE OBLIGATION OF SELLER.

Seller makes no warranties, either express or implied, except as provided herein, including without

limitation thereof, warranties as to marketability, merchantability, for a particular purpose or use, or

against infringement of any patent of products. In no event shall Seller be liable for any direct,

incidental or consequential damages of any nature, or losses or expenses resulting from any

defective new product or the use of any such product, including any damages for loss of time,

inconvenience, or loss of use of any such product.

C. The original Manufacturer shall be solely responsible for the design, development, supply,

production, and performance of its products hereunder, and the protection of its trade name or

names, if any. It assumes no responsibility, for products modified or changed in any way by its

agent or customer. Any such modifications or changes to products sold by Seller hereunder shall

make the product limited warranty null and void.

D. The Manufacturer shall be under no obligation to manufacture, sell, or supply, or to continue to

manufacture, sell or supply any of the Products.

9

Loading...

Loading...