Page 1

Installation, Operation and Maintenance Manual for

Low Pressure Pilot Operated 4-Way Valve

Model 1402

Low Pressure Pilot Operated 4-Way Valve

IOM 1402.1

August 2005

A CONTINENTAL DISC COMPANY

IOM 1402.1

REV. A. 12541

Page 2

The Groth Model 1402 pilot is a pressure

actuated 4-way valve that can be used to

control a single acting (push) or 2-way

(push-pull) pneumatic actuator. The pilot

can be actuated by pressure as low as 1.5

IN WC.

It is used with Groth pilot operated valves

(POV) when very low set pressure or a

non-flowing pilot is required. For further

information regarding the installation,

operation and maintenance of pilot

operated pressure/vacuum relief valves,

see the manuals for Groth 1660 or 1400

series valves.

The following section describes the use of

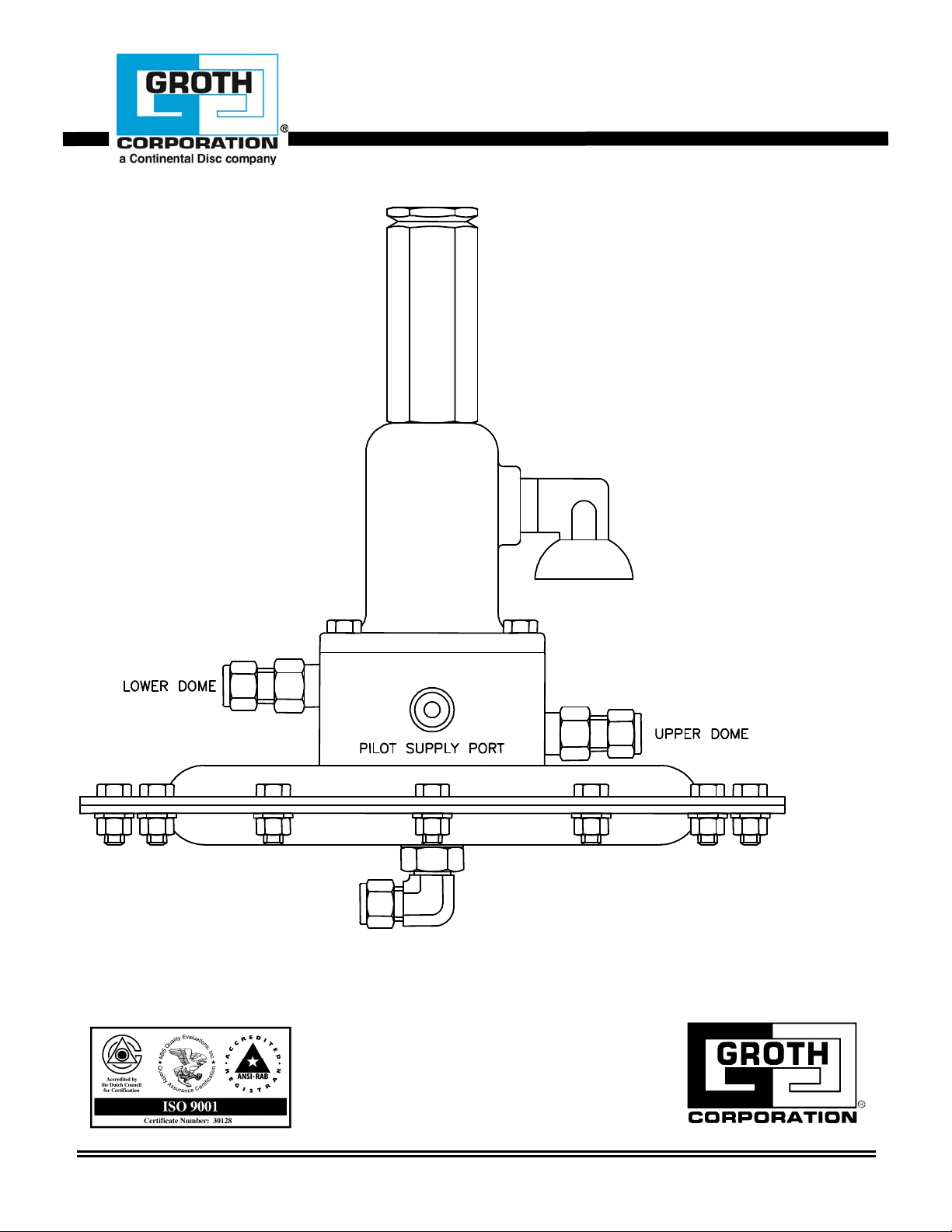

the 1402 pilot to control a 2-way (pushpull) actuator, see figure 1.

Tank pressure is sensed by connecting the

“sense” port to the pressure pick-up

fitting in the POV or directly to the tank

vapor space. If tank pressure is used to

operate the POV, this port will also be

connected to the pilot “supply” port by a

factory-installed tube.

actuator and the upper dome is vented

through the pilot spring bonnet vent. The

only emission from the pilot is that

required to vent the actuator chamber

during valve opening or closing.

The 1402 pilot can utilize an independent

supply (air, nitrogen, etc.) up to 1 PSI to

operate the POV. In this case, the

independent supply is connected to the

pilot “supply” port.

The “upper dome” port of the pilot is

connected to the upper dome or “push”

chamber of the actuator. The “lower

dome” port of the pilot is connected to the

lower dome or “pull” chamber of the

actuator.

When tank pressure is less than set

pressure, the pilot spool remains in the

lower position. Supply pressure is

applied to the upper dome of the valve

actuator and the lower dome is vented

through the pilot spring bonnet vent.

There is no emission from the pilot.

When tank pressure exceeds the set

pressure, the pilot spool moves to the

upper position. Supply pressure is

applied to the lower dome of the valve

Figure 1

1402revb.doc

1

Page 3

If the 1402 pilot is used to control a single

acting actuator, the “lower dome” port is

plugged and the pilot controls pressure to

the upper actuator chamber only.

The pilot must be maintained by a

knowledgeable valve technician. It

should only be assembled under clean

conditions, preferably in a shop

environment. Carefully read and

understand this manual before attempting

to adjust set pressure or repair the pilot.

For information not contained in this

manual, please contact:

Groth Corporation

13650 N. Promenade Blvd,

Stafford, TX, 77477

281-295-6800 (Phone)

281-295-6999 (Fax)

This manual is intended to provide

recommended procedures and practices

for installation, operation, and

maintenance of the Groth model 1402

pilot. Any standard procedures and

practices developed for a specific plant or

process should supersede this manual.

While this manual cannot cover all

possible contingencies, following these

guidelines should provide safe, reliable

valve performance.

SAFETY WARNINGS

This section is an overview of safety

guidelines that should be followed during

the installation, operation, and maintenance

of your valve. To understand the context of

these instructions and warnings, read and

understand this complete manual.

The purpose of a POV is to prevent

excessive pressure in a tank or process

system. The valve must be designed for the

proper MAWP and flow requirements of the

system. Consult API Standard 2000 for tank

protection sizing procedures. An

improperly specified or functioning relief

valve may result in structural damage to the

tank or system.

In the event of an actuator diaphragm

failure, the valve will vent pressure to the

atmosphere, causing the pressure relief

valve to fail in the OPEN position. The valve

will function like a weight loaded valve

under this condition and may require

additional over-pressure to provide rated

flow capacity. Consult factory for any

questions related to this over-pressure

condition.

POV relief pressure is set at the factory per

purchase order specifications. The set

pressure and range of adjustment are

stamped on the pilot valve nameplate. Do

not attempt to readjust the set pressure

beyond the limit specified on the

nameplate.

The pilot sense line is either 3/8" OD SS

tubing or larger. It must be open and

unobstructed to ensure that the pilot

"senses" actual tank pressure. For

applications where tank vapors may

condense or "solidify" in the sense tube or

pilot valve, a nitrogen purge may be

required to prevent internal obstruction.

Consult the factory for recommendations.

DO NOT attempt to remove the pilot valve

from the main valve without removing or

isolating the relief valve from the system.

ALTERNATIVE MEANS OF PRESSURE RELIEF

MUST BE PROVIDED WHEN THE VALVE IS

OUT OF SERVICE. After isolating the relief

valve, bleed all pressure from both main

and pilot valve before removing the valve.

Consult the pilot valve manual before

attempting to repair it. Both the pilot valve

and POV are exposed to process vapors.

Observe all plant procedures and Material

Safety Data Sheet recommendations for the

products in the system when inspecting,

adjusting or servicing the valves. Vents on

the body and spring bonnet of the pilot

valve must be clean and unobstructed for

proper and safe operation of the valve.

These vents should be inspected

periodically, and cleaned or replaced, if

necessary.

1402revb.doc

2

Page 4

Trouble Shooting

Any vapor emitted from the pilot should

be vented through the fitting [7] on the

spring bonnet.

There should be no emission when the

sensed tank pressure is less than 80% of

set pressure or greater than 110% of set

pressure.

The valve actuator upper dome should

receive tank pressure or vacuum or

independent supply pressure when the

sensed tank pressure is less than set

pressure. The lower dome should be

exposed to tank pressure when sensed

pressure is greater than 110% of set

pressure.

These conditions may be observed while

the valve is in service or during shop

testing. See test procedure on page 3. If

any of these conditions are not met, the

pilot must be disassembled, cleaned and

inspected. Replace all soft goods,

assemble and test according to the

following procedures.

Disassembly

Disconnect pilot at sense, upper dome and

lower dome ports. Remove tank pressure

supply tube. Invert the pilot and remove

hex bolts [22], lower actuator housing

[27], gasket [25], diaphragm [26] and

support plate sub-assembly. If the

diaphragm is damaged, it may be

replaced and the pilot may be tested

without further disassembly.

If further disassembly is required, remove

hex bolts [20] and upper actuator housing

[21].

Then invert pilot and remove the

adjustment screw cap [1], loosen the jam

nut [3], and back out the adjusting screw

[2] to release spring tension. Remove hex

bolts [8], the spring bonnet sub-assembly,

spring buttons [5 & 9], spring [6] and

retainer plate [10]. Remove the spool/seat

sub-assembly. This will require some

force to slide the O-Rings from the body.

Remove the upper and lower seat inserts

[13] from the spool [12]. Remove one

spool O-Ring [15], the seat [16] and the

other O-Ring [15]. Thoroughly clean and

inspect all parts. All seating surfaces

should be sharp but free of burrs or nicks.

Replace all O-Rings.

Note: Consult factory for soft goods kit

replacement for any valves sold prior

to March 2000.

Assembly

Lightly lubricate all O-Rings, removing

any excess lubricant. Slide the seat [16]

onto the spool [12] before installing the

final O-Ring [15]. Then position the seat

inserts and all O-Rings and slide the

spool/seat sub-assembly into the body.

Verify that the spool moves freely inside

the seats.

Position the retainer plate [10], the spring

[6] and spring buttons [5 & 9] and the

spring bonnet sub-assembly. Insert the

hex bolts and tighten uniformly. The thin

plate will be deformed as the bolts are

tightened, firmly clamping the seat inserts

in place. If necessary, remove the vent

fitting [7] to verify that the adjusting screw

is engaged with the upper spring button.

Final screw adjustment will be made after

assembly is complete.

Invert the pilot and position the support

plate sub-assembly, diaphragm [26],

gasket [25] and lower actuator housing

[27]. Insert the hex bolts [22], lock

washers [24] and nuts [23] and tighten

uniformly. Install tank pressure supply

tube. Test and adjust for set pressure

according to the following procedure.

Then tighten the jam nut [3] and replace

the cap [1].

Test Procedure

Connect the pilot as shown in figure 2.

Increase the tank pressure very slowly.

Adjust the set pressure adjustment screw

as required to maintain the following

conditions.

1402revb.doc

3

Page 5

At tank pressure less than 80% of set

pressure, upper dome pressure should be

about equal to tank pressure and the vent

should be bubble tight. Minimal leakage

may occur between 80% and 90% of set

pressure.

At set pressure, the upper dome pressure

should be less than 50% of set pressure

and the vent should be flowing freely.

At 110% of set pressure, the lower dome

pressure should be greater than 75% of

set pressure, the upper dome should be

less than 10% and the vent should show no

leakage. The vent should be bubble tight

above 110% of set pressure.

Figure 2

When all conditions have been met, install

the pilot on the valve by connecting the

tubing to the sense, upper dome and

lower dome ports. When pressure is

applied to the valve, test all connections

with a soap solution.

# DESCRIPTION MATL

1 Cap, Adjustment Screw 316

2 Screw, Adjustment 316

3 Nut, Jam 316

4 Bonnet, spring 316

5 Button, spring 316

6 Spring 316

7 Vent Aluminum

8 Bolt, hex 316

9 Button, spring 316

10 Plate, retainer 316

11 Body 316

12 Spool 316

13 Seat insert 316

O-Ring Elastomer

14

O-Ring Elastomer

15

16 Seat 316

17 Rod, actuator HDPE

18 Rivet, pop 316

19 Plate, diaphragm 316

20 Bolt, hex 316

21 Actuator housing, upper 316

22 Bolt, hex 316

23 Nut, hex 316

24 Washer, lock 316

Gasket FEP

25

Diaphragm FEP

26

27 Actuator housing, lower 316

28 Elbow, male 316

29 Washer, flat 316

O-Ring Elastomer

30

31 Connector, male 316

32 Nut, jam 316

33 Spacer, diaphragm Nylon

= Included in Soft Goods Kit

Elastomer Soft Goods Kit

Buna-N K1402BP

EPR K1402EP

FFKM K1402KP

Fluoropolymer K1402VP

1402revb.doc

4

Page 6

Figure 3

PRODUCT LIMITED WARRANTY

A. Seller warrants that products which are manufactured by

Seller, are manufactured in accordance with published

specifications and free from defects in materials and/or

workmanship for a period of (12) twelve months. Seller, at

its option, will repair or replace any products returned

intact to the factory, transportation charges prepaid, which

Seller, upon inspection, shall determine to be defective in

material and/or workmanship. The foregoing shall

constitute the sole remedy for any breach of Seller's

warranty.

B. THERE ARE NO UNDERSTANDINGS, AGREEMENTS,

REPRESENTATIONS, OR WARRANTIES, EXPRESS OR

IMPLIED, (INCLUDING MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE REGARDING PRODUCTS )

UNLESS SPECIFIED IN THE SALES CONTRACT . THIS

CONTRACT STATES THE ENTIRE OBLIGATION OF SELLER.

Seller makes no warranties, either express or implied,

except as provided herein, including without limitation

1402revb.doc

thereof, warranties as to marketability, merchantability, for a

particular purpose or use, or against infringement of any

patent of products. In no event shall Seller be liable for any

direct, incidental or consequential damages of any nature, or

losses or expenses resulting from any defective new product

or the use of any such product, including any damages for

loss of time, inconvenience, or loss of use of any such

product.

C. The original Manufacturer shall be solely responsible for the

design, development, supply, production, and performance

of its products hereunder, and the protection of its trade

name or names, if any. It assumes no responsibility, for

products modified or changed in any way by its agent or

customer. Any such modifications or changes to products

sold by Seller hereunder shall make the product limited

warranty null and void.

D. The Manufacturer shall be under no obligation to

manufacture, sell, or supply, or to continue to manufacture,

sell or supply any of the Products

5

Loading...

Loading...