Page 1

Installation, Operation and Maintenance Manual for

Pilot Operated Valves

Models 1400, 1420, 1430, 1460

IOM1400.0

January 2, 2014

REV A 12393

REF. ID 98136

IOM1400.0

REV. A 12541

Page 2

TABLE OF CONTENTS

DESCRIPTION PAGE

Introduction

Pilot Valve Design and Function

Safety Warnings

Shipping, Inspection and Storage

Installation

Maintenance

Disassembly

Assembly

Figures and Tables

Troubleshooting Guide

Customer’s Notes

How to Order

Product Limited Warranty

LIST OF FIGURES

1. Tank Installation - Safety

Equipment

2. Groth Nameplate

3. Valve Port Identification

4. Available Seat Configurations

5. Model 1400

6. Model 1420

7. Model 1430

8. Model 1460

LIST OF TABLES

1. 1400 Series Pilot Operated Valve

Models

2. Body Flange Gasket Dimensions

3. Recommended Min. Torque Values

4. Notes for Figure 4 Thru Figure 7

5. Part no. for Vacuum Pallet Assy.

6. Lubricants – Specifications

7. Troubleshooting Guide

8. Abbreviations

NOTE:

For a list of abbreviations used in this manual, refer to Table 8.

1

3

3

4

4

5

5

6

6

12

13

14

14

2

2

6

7

8

9

10

11

2

4

4

6

7

12

12

12

INTRODUCTION

Pressure and/or vacuum relief valves are used

on liquid storage tanks and other process

vessels or systems to prevent structural damage

due to excess internal pressure or vacuum.

Storage tanks are pressurized when liquid is

pumped in, compressing the existing vapor or

when increasing temperature causes increased

evaporation or expansion of existing vapor.

Conversely, a vacuum may be created when

pumping out or due to decreasing temperature.

To prevent damage, vapor must be allowed to

escape or enter the tank at a specified pressure

or vacuum condition. The volume rate of

venting depends upon the tank size, volatility of

the contents, the pumping rate and the

temperature. See API Standard 2000 for the

procedures to determine venting requirements.

The pilot operated relief valve has two principal

advantages over other types of relief valves:

1) It is bubble tight to set pressure.

2) It achieves the full open position at 10%

above set pressure.

These characteristics permit operating

pressures nearer to the maximum allowable

working pressure of the tank. High operating

pressures reduce evaporation and total venting

volume, thereby reducing product loss and the

cost of processing emissions. A tank may also

have provisions for emergency pressure relief

due to fire exposure and/or inert gas blanketing

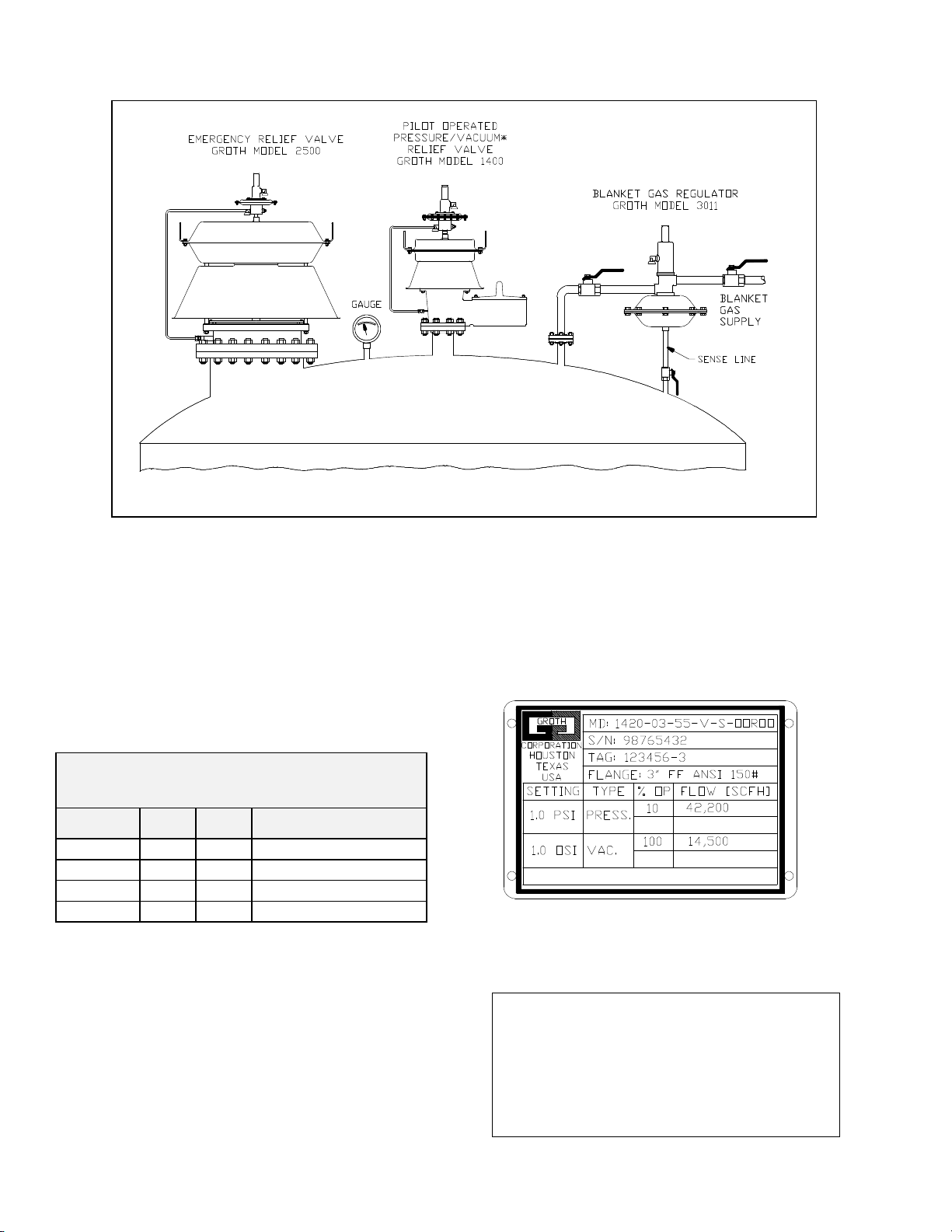

of the vapor space. A typical tank installation is

shown in Figure 1 which includes a 1400 Pilot

Operated Pressure/Vacuum Relief Valve, a Gas

Blanketing Regulator (Model 3011) and a 2500

Emergency Pressure Relief Valve which

provides protection under fire or other abnormal

conditions. Groth Corporation manufactures all

of these devices.

A Pilot Operated Valve (POV) must be carefully

maintained by a qualified valve technician. It

should only be assembled under clean

conditions, preferably in a service shop

environment. Carefully read and understand

this manual before attempting to repair a 1400

series POV. Groth Corporation provides repair

services for all products manufactured by the

Groth Products Group.

.

1

Page 3

FIGURE 1: TANK INSTALLATION - SAFETY EQUIPMENT

*Pressure relief is pilot operated, vacuum relief is weight loaded.

The 1400 Series Pilot Operated Valves are

designed to provide pressure and/or vacuum

relief for API 620 and 650 tanks. Several

configurations are available; these are

summarized in Table 1 below. Each type is

available with either a standard FEP film or with

an O-Ring pallet. A variety of material options

are available depending on the type of service.

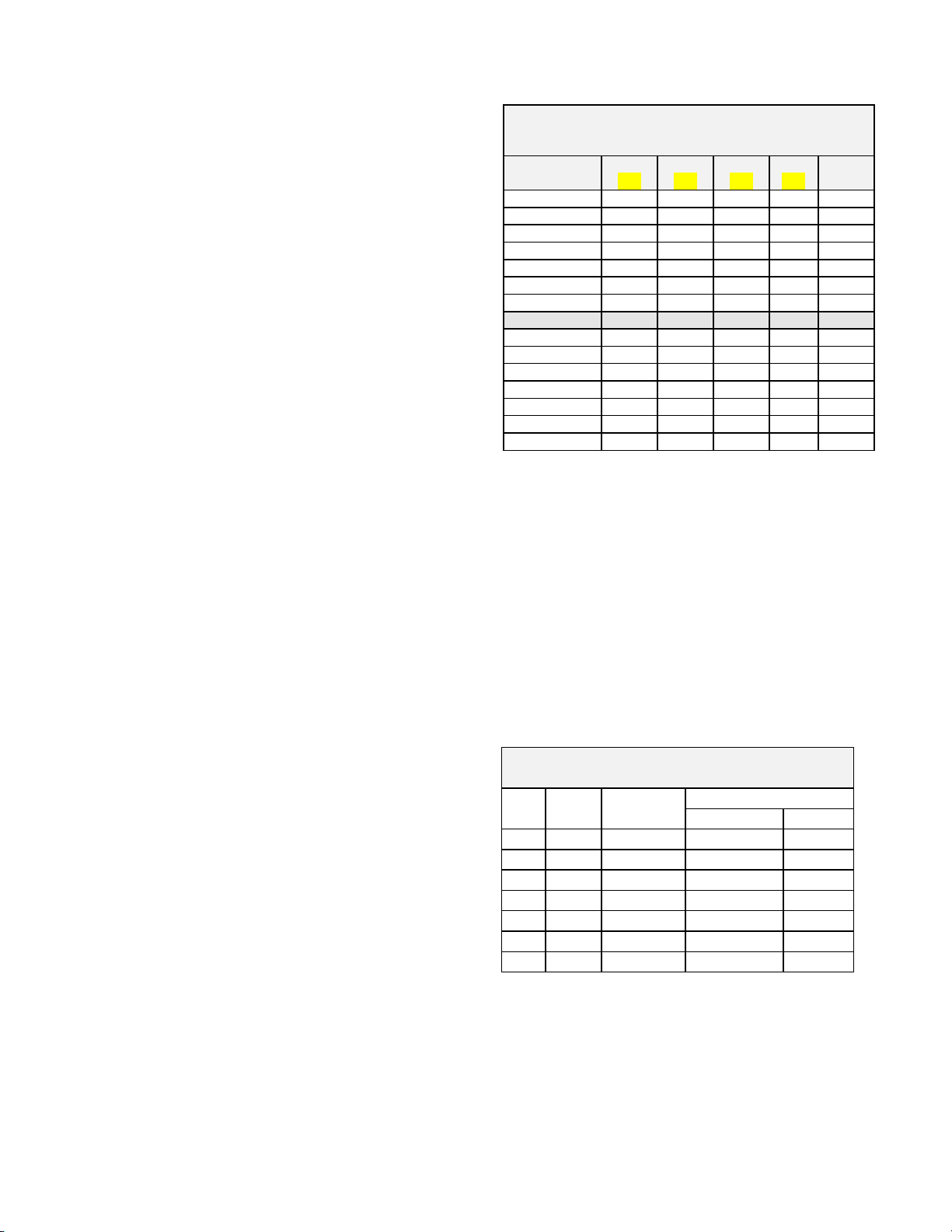

TABLE 1 : 1400 SERIES MODELS

(Pilot Operated Pressure Valves)

Model P V Vacuum Operation

1400

1420

1430

1460

The 1420 and 1460 POV are designed to be

used in header systems where the vapors are

piped away to a vapor recovery unit. The 1400

and 1430 POV’s vent to atmosphere.

Weight Loaded

Weight Loaded

Not Available

Not Available

The nameplate below shows the basic

information that is listed on each relief valve:

FIGURE 2: GROTH NAMEPLATE

For more information about these valves,

please contact:

Groth Corporation

13650 N. Promenade Blvd,

Stafford, Texas 77477

281-295-6800 (phone)

281-295-6995 (fax)

2

Page 4

PILOT VALVE DESIGN AND

FUNCTION

Each application must be reviewed to ensure

material compatibility of all metal and soft good

components with the service conditions. The

pallet assembly and wetted components are

available in Aluminum or 316 SS; they may be

upgraded to Alloy C276 or other alloys for

severe corrosive service. Diaphragms are all

FEP film; other soft goods can be specified as

Buna-N, FKM, or FFKM. The standard sense

tubing is 316 SS; it is available in PVDF for

severe corrosive chemicals.

The pilot valve is set at the factory to comply

with the specification on the purchase order.

The range of adjustment will depend on the

spring installed and will be stamped on the

nameplate. The pressure setting may be

SAFETY WARNINGS

This section is an overview of safety guidelines

that should be followed during the installation,

operation, and maintenance of your valve. To

understand the context of these instructions and

warnings, read and understand this complete

manual.

The purpose of a POV is to prevent excessive

pressure in a tank or process system. The valve

must be designed for the proper MAWP and flow

requirements of the system. Consult API

Standard 2000 for tank protection sizing

procedures. An improperly specified or

functioning relief valve may result in structural

damage to the tank or system.

In the event of an actuator diaphragm failure, the

valve will vent pressure to the atmosphere,

causing the pressure relief valve to fail in the

OPEN position. The valve will function like a

weight loaded valve under this condition with a

lower setting point, and will normally provide

rated flow capacity. Consult factory for any

questions related to this over-pressure condition.

POV relief pressure and blowdown are set at the

factory per purchase order specifications.

The set pressure and range of adjustability are

stamped on the pilot valve nameplate. DO NOT

attempt to readjust the set pressure beyond the

limit specified on the nameplate.

changed within the design range either while on

line or in a service shop. Observe the proper

setting and testing procedure in the appropriate

pilot valve manual.

This manual is intended to provide

recommended procedures and practices for

installation, operation, and maintenance of the

Groth Series 1400 Pilot Operated Valve (POV)

Series. Any standard procedures and practices

developed for a specific plant or process may

supersede this manual. Although this manual

cannot cover all possible contingencies,

following these guidelines should provide safe,

reliable pilot valve performance.

Note: This manual covers the operation and

maintenance of only the main valve; refer to the

appropriate manual for the pilot valve

instructions.

The pilot sense line is either 3/8" OD SS tubing,

or 1/2" NPT PVDF pipe. It must be kept open

and unobstructed to ensure that the pilot

"senses" actual tank pressure. For applications

where tank vapors may condense or

"polymerize" in the sense tube or pilot valve, a

nitrogen purge may be required to prevent

internal obstruction of the tube. Consult the

factory for recommendations.

DO NOT attempt to remove the pilot valve from

the main valve without removing or isolating the

relief valve from the system. ALTERNATIVE

MEANS OF PRESSURE RELIEF MUST BE

PROVIDED WHEN THE VALVE IS OUT OF

SERVICE. After isolating the relief valve, bleed

all pressure from both main and pilot valve

before removing the valve. Consult the pilot

valve manual before attempting to repair it. Both

the pilot valve and POV are exposed to process

vapors. Observe all plant procedures and

Material Safety Data Sheet recommendations

for the products in the system when inspecting,

adjusting or servicing the valves. Vents on the

body and spring bonnet of the pilot valve must

be clean and unobstructed for proper and safe

operation of the valve. These vents should be

inspected periodically, and cleaned or replaced,

if necessary.

3

Page 5

SHIPPING, INSPECTION AND

STORAGE

The POV is packed and supported to prevent

damage or contamination during shipping. It

should be similarly protected during subsequent

handling and storage. Always keep all ports

plugged to prevent intrusion of foreign materials.

Inspect the valve for any sign of damage that

may have occurred in shipment and report this

to the carrier. If there are indications of physical

damage or internal contamination, the valve

must be disassembled, cleaned and inspected

before installation. The spring adjustment cap

and blowdown screw locknut will be "car sealed"

to ensure that the factory pressure setting has

not been altered.

Inspect the valve for any sign of damage that

may have occurred in shipment and report this

to the carrier and Groth Corporation.

Lifting eyes are provided on the upper actuator

for handling the valve. To avoid damage to the

lower flange surface, set the valve on a soft

clean gasket material until it is ready to be

installed. It should be stored in a clean

environment until it is to be mounted on the tank.

The pilot pickup fitting is in the body and must

be kept completely free of all foreign materials.

DO NOT store the valve directly on the ground.

INSTALLATION

The 1400 Series valves are precision devices

that must be handled carefully to ensure seat

tightness.

1. At installation, the valve should be smoothly

lifted into position using the lifting eyes on

the actuator. Use the actuator housing to

align the valve directly over the tank nozzle.

Do NOT use the pilot valve or pickup line to

pull the valve into position.

2. Aluminum valve bodies should be

connected with flat faced 150# ANSI

flanges. A full faced gasket is

recommended. Mating flanges should be

flat within .020" and clean, free of scratches,

corrosion and tool marks.

3. Each valve is leak tested at the factory as

part of our standard inspection procedures.

4. Inspect the gasket; make sure that the

material is suitable for the service. Gasket

dimensions are listed below, Table 2. Full

gaskets must be used with flat face flanges.

Either full or ring gaskets may be used with

raised face flanges.

Table 2

Body Flange Gasket Dimensions

150# ANSI

Flange*

2” RF 4.12 2.38 --- --- --3” RF 5.38 3.50 --- --- --4" RF 6.88 4.50 --- --- --6” RF 8.75 6.62 --- --- ---

8” RF 11.00 8.62 --- --- --10” RF 13.38 10.80 --- --- --12” RF 16.12 12.80 --- --- ---

2" FF 6.00 2.00 4.75 0.75 4

3" FF 7.50 3.00 6.00 0.75 4

4” FF 9.00 4.00 7.50 0.75 8

6” FF 11.00 6.00 9.50 0.88 8

8” FF 13.50 8.00 11.75 0.88 8

10” FF 16.00 10.0 14.25 1.00 12

12” FF 19.00 12.0 17.00 1.00 12

* RF = Raised Face, FF = Flat Face

O.D.

(IN)

I.D.

(IN)

B.C.

(IN)

Hole

(IN)

Qty

5. Lubricate all studs and nuts with an

appropriate thread lubricant. If stainless

steel fasteners are used, use an anti-seize

lubricant such as moly-disulfide (Table 6).

6. Center the gasket within the bolt circle of

the tank nozzle flange.

7. Set the valve carefully on the nozzle.

8. Install nuts and lock-washers and torque all

fasteners to half the recommended value in

a staggered, alternating pattern. Consult

with Plant and/or Maintenance Personnel

for appropriate practices and standards.

Table 3

Recommended Minimum Torque Values*

Size

10” 12 7/ 8” - 9 75 138

12” 12 7/ 8” - 9 93 179

*Note: Torque values are based on a gasket factor m = 3.5,

gasket factor y = 4000 psi, operating pressure = 30 psi

Qty

Holes

2” 4 5/ 8” - 11 31 81

3” 4 5/ 8” - 11 43 106

4” 8 5/ 8” - 11 29 68

6” 8 3/ 4” - 10 51 101

8” 8 3/ 4” - 10 78 142

Bolt

(UNC)

Torque (lb-ft)

Raised Face Flat Face

9. Make sure that the flanges are not distorted

and that the gasket is evenly compressed.

10. Make up the final torque and check that no

further nut rotation occurs.

11. Normally, the pilot sense is integral to the

valve assembly. However, if the optional

4

Page 6

remote sense connection is specified, an

external sense line must be installed. See

the appropriate manual or attached tag for

recommendations. If the valve utilizes a

1402 Pilot Valve, there will be two

connections to the tank. The connections

can only be combined (with a tee) at the

tank connection.

4. Body - nozzle flange joint gasket

Refer to the troubleshooting section of this

manual or the pilot valve manual for probable

causes for these type of problems.

The main and pilot valve actuator housings,

valve bodies, pallet assemblies and other

components are exposed to the process vapor.

MAINTENANCE

Safety Warning

If the valve must be removed from the tank for

any reason, make sure that all pressure has

been released before the flange fasteners are

loosened. Refer to your company procedures

before venting the tank pressure and when

handling toxic or otherwise hazardous materials.

Observe all standard safety precautions as

specified on Material Safety Data Sheets for the

product(s) in the system while removing the

valve and when repairing it.

The 1460 POV does not require routine

lubrication or adjustments. It should be checked

periodically, at least twice a year, to confirm that

the valve is functioning properly and that the set

point is correct. Test connections can be

provided to facilitate testing the valve in the field.

The pilot valve is designed to function in a failsafe manner. The failure of a seal or diaphragm

will cause pressure to be vented to the

atmosphere; the resulting loss in pressure will

cause the main valve to open under rising

pressure.

Periodic inspection for seat tightness should be

done to ensure compliance with local air

pollution control requirements. If the valve

relieves to the atmosphere, this may

accomplished with a gas detector calibrated for

the principle product in the system.

The valve will need to be periodically removed

from the tank for inspection of diaphragms,

gaskets and seals. When this is done, the valve

must be handled carefully using the lifting eyes

on the actuator housing.

Refer to handling instructions listed in the

Installation section of this manual.

If a vapor leak is detected, it will likely be from

one of the following sources:

1. Pilot valve

2. Main valve actuator

3. Main valve diaphragm

DISASSEMBLY

The 1400 series valves can be simplified into

three modules. These modules can be seen in

the figures below:

Weatherhood (with Pilot)

Outlet (with Pilot)

Vacuum (integral with body)

Before any disassembly or assembly, make sure

that there is NO PRESSURE (positive or

negative) in the system.

Outlet/ Weatherhood Disassembly

1. Disconnect the tubing connections (pilot to

main valve).

2. Remove the pilot valve. Refer to appropriate

pilot valve manual for disassembly

instructions.

3. Remove all fasteners holding the actuator

housings together.

4. Carefully lift the upper housing to avoid

damaging the actuator diaphragm.

5. Remove the housing gaskets.

6. Remove the actuator diaphragm and the

screw holding the support plate.

7. Remove the actuator support plate.

8. Remove the fasteners holding the lower

housing to the body (Models 1420 & 1460),

or weatherhood posts (Models 1400 &

1430).

9. Lift lower housing and stem guide assembly.

This assembly will slide over the stem.

10. Lift the stem and pallet assembly out of the

valve, invert it, and hold the stem in a soft

chuck vise (to avoid damage to the stem).

11. Remove the nut, to disassemble the pallet

assembly.

5

Page 7

Vacuum Disassembly

1. Remove the nuts from the cover.

2. Lift the cover.

3. Remove the gasket.

4. Lift the stem-pallet assembly. (Make note of

the weights. The valve must be

reassembled with the weights in the same

location to achieve the specified settings.)

5. Invert the assembly.

6. Remove the nut holding the assembly

together.

ASSEMBLY

Inspect all guides for corrosions, damage or

product build up. Also inspect the vacuum cover

guide bore. Check the metal seating surfaces

for pitting, corrosion or product build up. It is

recommended to replace ALL soft goods

including diaphragms, O-Rings and cover

gaskets. Note, the stem guide has internal

Fluoropolymer bushings.

TABLE 4 : NOTES FOR FIGURE 5 THROUGH FIGURE 8

NOTE DESCRIPTION

1 Pallet Diaphragms & O-Rings. These soft goods should be replaced each time the valve is

disassembled. Standard material options include FEP, Buna, FKM, & FFKM.

2 Gaskets: Non-Asbestos Fiber. These should be replaced each time the valve is

disassembled.

3 Bushing Guides: Fluoropolymer. At assembly, inspect stem travel through guides. The

stem should slide smoothly with minimal drag. Replace as required.

4 Actuator Diaphragms & Gaskets. Replace each time valve is disassembled they are

available only in FEP.

FIGURE 3: VALVE PORT IDENTIFICATION

If the seats are damaged they must be lapped

using a flat ground metal disc with fine grit

emery cloth attached and lapping compound.

Wipe the seating surface clean before assembly.

To assemble a valve, reverse the disassembly

procedure.

FIGURES AND TABLES

The following figures are to assist in identifying

components during disassembly and assembly

of the Groth 1400 Series valves. The actual

configurations might vary because of special

applications and customers’ request, but the

operation and function is similar.

Figure 5 through Figure 8 include a NOTE

column. For an explanation of the NOTES, see

Table 4 below.

For Lubricants suggested, see Table 6.

For Troubleshooting Guide, see Table 7.

For Abbreviations, see Table 8.

6

Page 8

ITEM DESCRIPTION

1 Pallet*

2 Seat**

3

Diaphragm (Fig 4.1)

O-ring (Fig 4.2)

FIGURE 4 : AVAILABLE SEAT CONFIGURATIONS

FIGURE 4: AVAILABLE SEAT CONFIGURATIONS

Fig. 4.1 Fig 4.2

* Actual pallet may not resemble drawing. Pallet design varies with operation.

** Seat can be integral (machined into body), or a ring insert. (Depends on the body material).

TABLE 5 : PART NUMBERS FOR VACUUM PALLET ASSEMBLIES

Component

2" 3" 4" 6" 8" 10" 12"

FEP Diaphragm, 10 mil

FEP Diaphragm, 20 mil

Gasket, Outlet (bottom)

Gasket, Cover (top)

O-Ring (plate pallet) -FKM

Setting < 4 OSI 4 - 8 OSI 8 - 12 OSI 12 - 16 OSI

Diaphragm 10 mil 20 mil 10 mil 20 mil 10 mil 20 mil 10 mil 20 mil

Quantity 1 --- --- 1 1 1 --- 2

80040162 80040362 80040562 80040762 80040962 80041162 80041362

80040154 80040357 80040568 80040761 80040963 80041167 80041354

80040159 80040359 80040559 80040759 80040959 80041159 80041359

80040158 80040358 80040558 80040758 80040958 80041158 80041358

89107010 ( #010 70 durometer) 89107012 ( #012 70 durometer)

Valve Size

* Please provide the valve serial number and pressure/vacuum settings when ordering replacement parts.

FIGURE 5: MODEL 1400

7

Page 9

ITEM DESCRIPTION NOTE

1 Pilot Valve Assembly

2 Pipe Nipple

3 Upper Diaphragm Case

4 Lifting Eye

5 Gasket – Actuator 4

6 Hex Bolt

7 Hex Nut

8 Lock Washer

9 Weatherhood

10 Cover – Vacuum

11 Lock Washer

12 Hex Nut

13 Stud

14 Gasket – Cover 2

15 Body

16 Guide Rod – Vacuum

17 Pallet – Vacuum

18 Retainer Plate – Vacuum

19 Diaphragm – Vacuum 1

20 Stem – Vacuum

21 Hex Nut

22 Lock Washer

23 Tubing

24 Male Connector

ITEM DESCRIPTION NOTE

25 Connector

26 Weatherhood Post

27 Lock Washer

28 Hex Nut

29 Pallet – Pressure

30 Diaphragm, Pressure Pallet 1

31 Retainer Plate – Pressure

32 Swivel Fitting

33 Belleville Washer

34 Hex Nut

35 Seal - Guides 1

36 Stem Guide

37 Washer – Stem Guide

38 Hex Jam Nut

39 Bushing 3

40 Set Screw

41 Stem – Pressure

42 Screw

43 Support Plate

44 Diaphragm 4

45 Screen

46 Lower Diaphragm Case

47 Male Connector

8

Page 10

FIGURE 6: MODEL 1420

ITEM DESCRIPTION NOTE

1 Pilot Valve Assembly

2 Pipe Nipple

3 Button Head Cap Screw

4 Lifting Eye

5 Support Plate

6 Diaphragm, Actuator 4

7 Hex Bolt

8 Lock Washer

9 Set Screw

10 Outlet

11 Stem Guide

12 Bushing 3

13 Swivel Fitting

14 Pallet

15 Gasket 2

16 Vent – Cover

17 Stud

18 Lock Washer

19 Hex Nut

20 Gasket 2

21 Guide Rod

22 Stem

23 Body

24 Diaphragm – Vacuum Pallet 1

25 Retainer Plate

26 Seat Ring

27 Lock Washer

ITEM DESCRIPTION NOTE

28 Hex Nut

29 Pallet

30 Seat Ring

31 Retainer Plate

32 Hex Nut

33 Belleville Washer

34 Male Connector

35 Stud

36 Hex Nut

37 Lock Washer

38 Union Connector

39 Tubing

40 Drain Plug

41 Diaphragm, Pressure Pallet 1

42 Seal 1

43 Stem

44 Washer

45 Gasket 2

46 Lower Diaphragm Case

47 Gasket, Actuator 4

48 Hex Bolt

49 Hex Nut

50 Lock Washer

51 Upper Diaphragm Case

52 Hex Jam Nut

53 Male Connector

9

Page 11

FIGURE 7: MODEL 1430

ITEM DESCRIPTION NOTE

1 Pilot Valve Assembly

2 Male Connector

3 Pipe Nipple

4 Cap Screw

5 Support Plate

6 Hex Jam Nut

7 Stem Guide

8 Screen

9 Seal – Swivel Guide 1

10 Swivel Fitting

11 Tubing

12 Union Connector

13 Male Connector

14 Pick – up Fitting

15 Belleville Washer

16 Hex Nut – Swivel

17 Inlet

18 Weatherhood Post

19 Lock Washer

ITEM DESCRIPTION NOTE

20 Hex Nut

21 Seat Ring

22 Pallet

23 Diaphragm, Pressure Pallet 1

24 Retainer Plate

25 Stem

26 Bushing – Stem Guide 3

27 Weatherhood

28 Washer – Stem Guide

29 Lower Actuator Housing

30 Hex Bolt

31 Lock Washer

32 Hex Nut

33 Diaphragm – Actuator 4

34 Gasket – Actuator 4

35 Lifting Lug

36 Upper Actuator Housing

37 Set Screw

10

Page 12

FIGURE 8 : MODEL 1460

ITEM DESCRIPTION NOTE

1 Pilot Valve Assembly

2 Male Connector

3 Pipe Nipple

4 Lifting Eye

5 Cap Screw

6 Support Plate

7 Diaphragm, Actuator 4

8 Hex Bolt

9 Lock Washer

10 Set Screw

11 Stem Guide

12 Bushing – Guides 3

13 Swivel Fitting

14 Pallet - Pressure

15 Gasket 2

16 Lock Washer

17 Union Connector

18 Tubing

19 Male Connector

20 Hex Nut

ITEM DESCRIPTION NOTE

11

21 Belleville Washer

22 Inlet

23 Stud

24 Hex Nut

25 Drain Plug

26 Diaphragm, Pressure Pallet 1

27 Seal 1

28 Stem

29 Washer

30 Outlet

31 Gasket 2

32 Lower Diaphragm Case

33 Gasket 2

34 Hex Bolt

35 Hex Nut

36 Lock Washer

37 Upper Diaphragm Case

38 Hex Jam Nut

39 Bushing – Guides 3

Page 13

TABLE 6: LUBRICANTS – RECOMMENDATIONS

FASTENER LOCATION LUBRICANT – SEALANT MANUF. & PART NO.

Actuator Fastener Dry Moly Film Crown #6080 or equal

Stem Guide MS

Lubricant Fel-Pro [Loctite] #51048 or equal

2

Stem/Swivel Fitting Silicone Lubricant Dow Corning #33 or equal

Note: Lubricant selection must consider process environment.

TABLE 7: TROUBLESHOOTING GUIDE

PROBLEM INSPECTION SUGGESTED CORRECTIVE ACTION

Pilot Valve

Leak

Main Valve

Actuator Leak

Visual, audible or

vapor detector

Visual, audible or

vapor detector

Consult troubleshooting guide in specific pilot valve manual

Leakage at the actuator flange may be corrected by tightening

the fasteners adjacent to the leak path. If this is not successful,

it will be necessary to install a new gasket. Refer to

instructions on page 6.

Vapor leakage

from the valve

body outlet.

Visual, audible or

vapor detector

Leakage can occur at the valve body seat - FEP film interface;

other leak paths are the swivel seal or a torn actuator

diaphragm. After removing the upper actuator housing, lift the

pallet assembly off the seat and inspect for damage to the film

or foreign debris buildup on the seat or film. Clean or replace

the pallet diaphragm as required. Refer to page 6.

Vapor leakage

between the

valve body and

tank nozzle

Visual, audible or

vapor detector

Leakage between the flanges may be corrected by tightening

the fasteners. Follow mounting instructions listed on page 4.

The gasket may have deteriorated due to the chemical

environment; replace if required. The tank nozzle may be

warped, corroded or scratched. This will require resurfacing of

the flange face; note that a flat faced flange is recommended to

avoid potential damage to an aluminum valve body.

TABLE 8: ABBREVIATIONS

ANSI American National Standards Institute NPT National Pipe Thread

API American Petroleum Institute POV Pilot Operated Valve

BOM Bill of Materials PSIG Pounds/Sq. Inch – Gauge

DPHGM Diaphragm PTFE Fluoropolymer

FEP Fluorocarbon Film (Fluoropolymer) SS Stainless Steel

MAWP Maximum Allowable Working Pressure WC Water Column

MS2 Moly – Disulfide

12

Page 14

The nameplate on the Groth Series 1400 Pilot Operated Valve contains the model number, serial

number, set pressure and flow capacity. The model number contains additional information about

materials of construction and options. The following chart will assist in relating the model number to the

specifications of your pilot operated valve:

Notes:

Include model number when ordering

For special options, consult factory.

EXAMPLE 1 4 6 0 - 0 6 - 3 1 - V - S - OORO

Indicates a 6" Model 1460 with Carbon Steel body, Standard Trim using FKM soft goods with remote pilot pickup and

no specials.

PRODUCT LIMITED WARRANTY

A. Seller warrants that products which are manufactured by Seller, are manufactured in accordance with published specifications and free

from defects in material and/or workmanship for a period of (12) twelve months. Seller, at its option, will repair or replace any product

returned intact to the factory, transportation charges prepaid, which Seller, upon inspection shall determine to be defective in material

and/or workmanship. The foregoing shall constitute the sole remedy for any breach of Seller's warranty.

B. THERE ARE NO UNDERSTANDINGS, AGREEMENTS, REPRESENTATIONS, OR WARRANTIES, EXPRESS OR IMPLIED (INCLUDING

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE REGARDING PRODUCTS) UNLESS SPECIFIED IN THE SALES

CONTRACT. THIS CONTRACT STATES THE ENTIRE OBLIGATION OF SELLER.

Seller makes no warranties, either express or implied, except as provided herein, including without limitation thereof, warranties as to

marketability, merchantability, for a particular purpose or use, or against infringement of any patent of products. In no event shall Seller be

liable for any direct, incidental or consequential damages of any nature, or losses or expenses resulting from any defective new product or

the use of any such product, including any damages for loss of time, inconvenience, or loss of use of any such product.

C. The original Manufacturer shall be solely responsible for the design, development, supply, production, and performance of its products

hereunder, and the protection of its trade name or names, if any. It assumes no responsibility, for product modified or changed in any way

by its agent or customer. Any such modifications or changes to products sold by Seller hereunder shall make the product limited warranty

null and void.

D. The Manufacturer shall be under no obligation to manufacture, sell, or supply, or to continue to manufacture, sell or supply any of the

Products.

13

Loading...

Loading...