Groppo Ferroli Domina Plus F 24-30 E Technical Manual

Supplied by HeatingSpares247.com

Wall-Mounting Gas

Boiler with antifreeze

for tap water

Airtight Chamber, for

Hot Water and Heating

TECHNICAL

DOMINA PLUS F 24-30 E

FERELLA EXTRA F 24-30 MEL

MANUAL

EDITION

092002

DOMINA PLUS F 24 - 30 E

Supplied by HeatingSpares247.com

FERELLA EXTRA F 24 - 30 MEL

1. Technical characteristics and data ........................................................ 3

1.1 Introduction .............................................................................................................. 3

1.2 Dimensions and connections .................................................................................. 4

1.3 General view and main components ....................................................................... 8

1.4 Technical data table ............................................................................................... 10

2. Hydraulic circuit - heating ................................................................... 11

2.1 Hydraulic circuit - heating ...................................................................................... 11

2.2 Hydraulic circuit - tap water ................................................................................... 15

2.3 Gas circuit .............................................................................................................17

2.4 Burner unit ............................................................................................................. 21

2.5 Fume circuit .......................................................................................................... 23

2.6 Electrical circuit ..................................................................................................... 27

3. Operation ............................................................................................ 30

3.1 Operating principle ................................................................................................ 30

3.2 Operating diagram................................................................................................. 32

3.3 Control panel ......................................................................................................... 33

3.4 Adjustments ........................................................................................................... 35

3.5 Operating parameter adjustment .......................................................................... 38

4. Unit self-diagnosis .............................................................................. 43

2

Version - 09.2002

DOMINA PLUS F 24 - 30 E

Supplied by HeatingSpares247.com

FERELLA EXTRA F 24 - 30 MEL

1. TECHNICAL CHARACTERISTICS AND DATA

1.1 Introduction

Our unit is a high-efficiency heat generator for heating and hot water production running on natural or liquefied

petroleum gas (configurable at the time of installation) and regulated by an advanced microprocessor control

system.

The boiler shell consists of a copper laminar exchanger whose particular shape guarantees high exchange

efficiency under all operating conditions and an open-flue burner equipped with electronic ignition and ionization

flame control.

The boiler is totally sealed off from the installation room: the air needed for combustion is drawn from outside

and the flue gases are expelled by a fan. The boiler outfit moreover includes a variable speed circulator,

expansion tank, flow meter, safety valve, filler cock, air pressure switch, water pressure switch, temperature

sensors, safety thermostat and an antifreeze thermostat with the relevant heating elements.

Thanks to the microprocessor control and adjustment system with advanced self-diagnosis, unit operation is

for the most part automatic. The power for heating is automatically governed by the control system according

to the indoor and outdoor characteristics (with an optional outdoor sensor installed), the characteristics of the

building and of its location. The power for hot water is automatically and continually governed to ensure a fast

delivery and comfort under all operating conditions.

The display continuously provides information on the unit's operating status and it is easily possible to obtain

additional information on the sensor temperatures, set-points, etc. or configure them. Any operating trouble

associated with the boiler or system is immediately signalled by the display and, if possible, corrected

automatically.

General Warnings

· Installation and maintenance must be carried out by professionally qualified personnel, according

to current regulations and the manufacturer's instructions.

· Incorrect installation or poor maintenance can cause damage or physical injury. The manufacturer

declines any responsibility for damage caused by errors in installation and use or by failure to

follow the manufacturer's instructions given in the instructions manual.

· Before carrying out any cleaning or maintenance operation, disconnect the unit from the electrical

power supply using the switch and/or the special cut-off devices.

Certification

The CE marking demonstrates that Ferroli gas units conform to the requirements contained in the

applicable European directives.

In particular, this unit complies with the following EU directives:

· Gas Appliance Directive 90/396 assimilated with Italian Presidential Decree DPR 15.11.96 no. 661

· Efficiency Directive 92/42 assimilated with Italian Presidential Decree DPR 15.11.96 no. 660

· Low Voltage Directive 73/23 (amended by 93/68)

· Electromagnetic Compatibility Directive 89/336 (amended by 93/68) assimilated with Italian

Presidential Decree DPR 15.11.96 no. 615

Version - 09.2002

3

DOMINA PLUS F 24 - 30 E

Supplied by HeatingSpares247.com

FERELLA EXTRA F 24 - 30 MEL

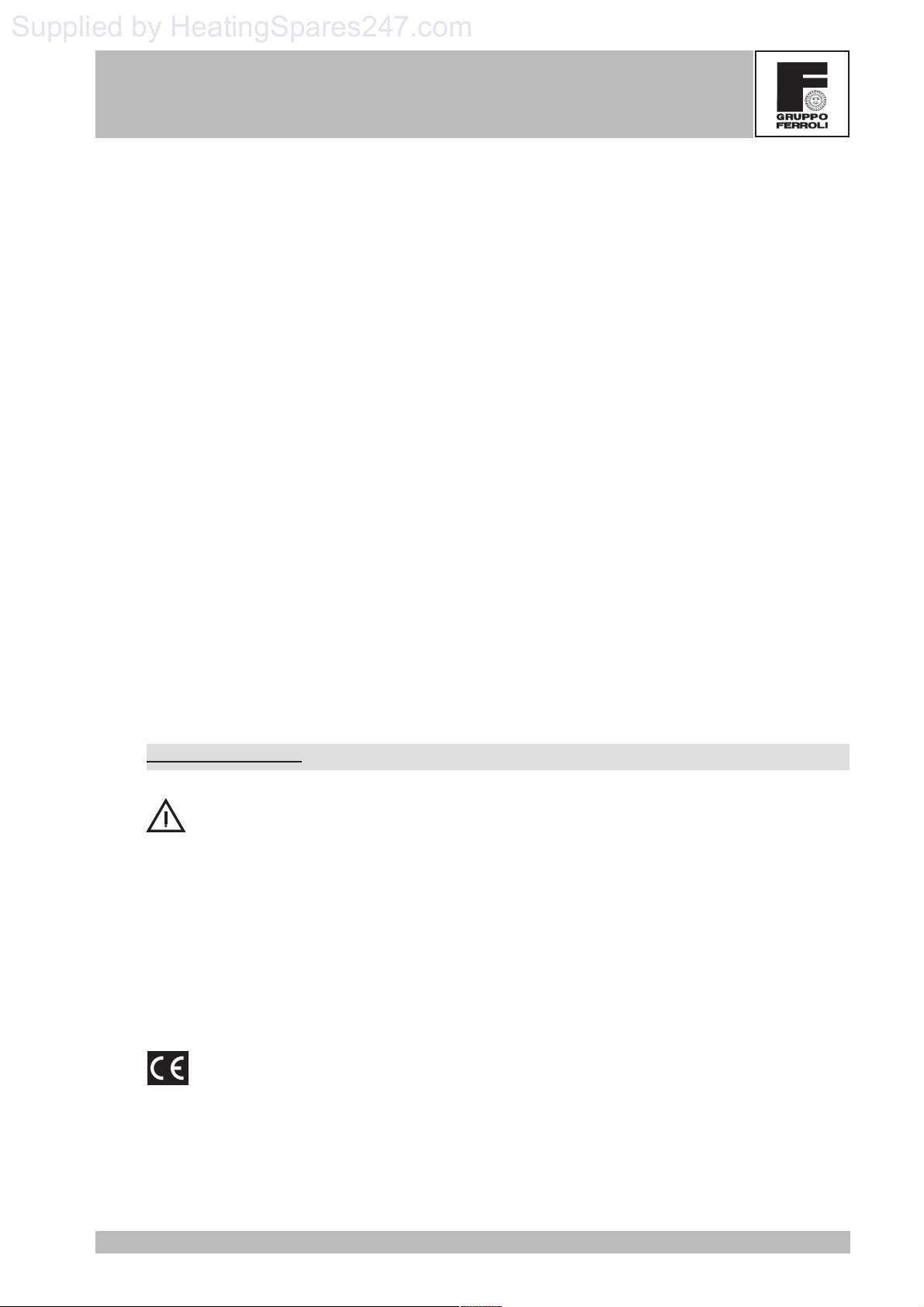

1.2 Dimensions and connections

Domina Plus F 24 E version

Top view

460

15012012070

110

10

725

Connections axis

Connections axis

100

270

720

80 80

80

175100

460

16025

Key

1 System delivery

2 Tap water outlet

3 Gas inlet

4 Tap water inlet

5 System return

4

100

1

2

Bottom view

1149560609536

4

3

5

Version - 09.2002

DOMINA PLUS F 24 - 30 E

Supplied by HeatingSpares247.com

FERELLA EXTRA F 24 - 30 MEL

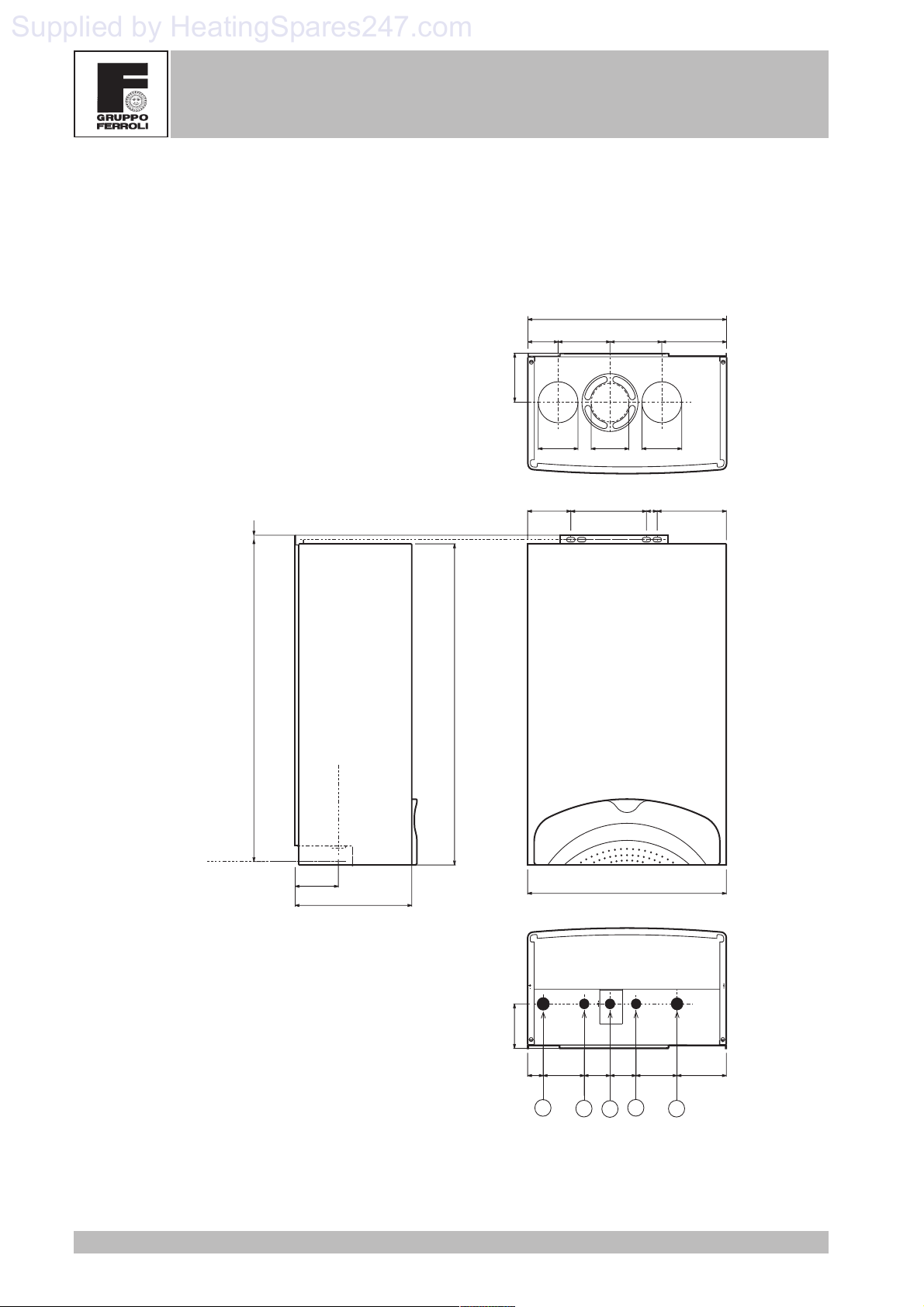

Ferella Extra F 24 MEL version

110

Top view

460

15012012070

10

725

Connections axis

Connections axis

100

270

720

80 80

80

175100

460

16025

Key

1 System delivery

2 Tap water outlet

3 Gas inlet

4 Tap water inlet

5 System return

Version - 09.2002

100

1

2

Bottom view

1149560609536

4

3

5

5

DOMINA PLUS F 24 - 30 E

Supplied by HeatingSpares247.com

FERELLA EXTRA F 24 - 30 MEL

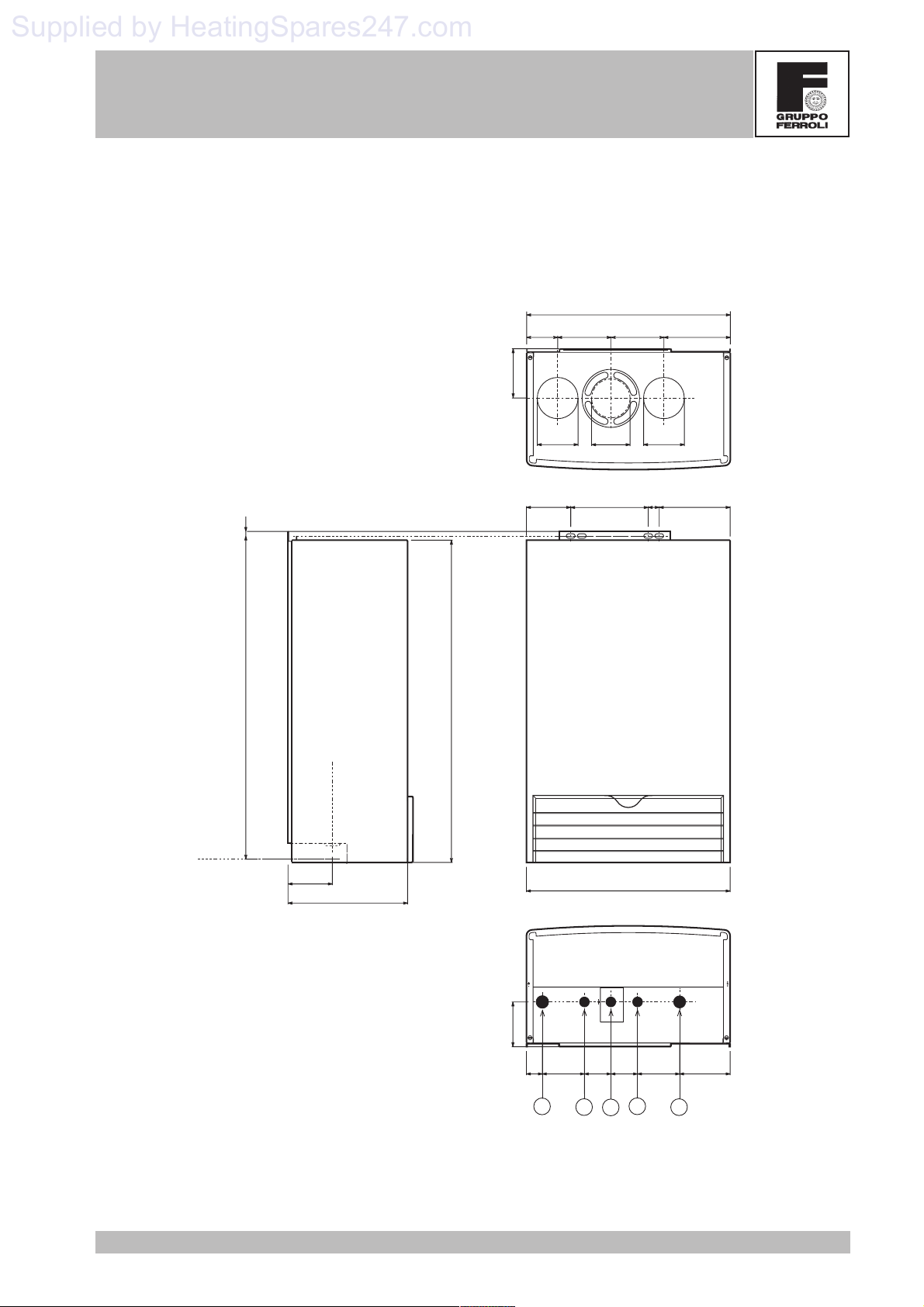

Domina Plus F 30 E version

200

Top view

460

120120110

110

14

733

Connections axis

420

80

8080

430362

189

Key

1 System delivery

2 Tap water outlet

3 Gas inlet

4 Tap water inlet

5 System return

189

6

460

1

23

36 95 60 60 155 54

4

5

Bottom view

175

Version - 09.2002

DOMINA PLUS F 24 - 30 E

Supplied by HeatingSpares247.com

FERELLA EXTRA F 24 - 30 MEL

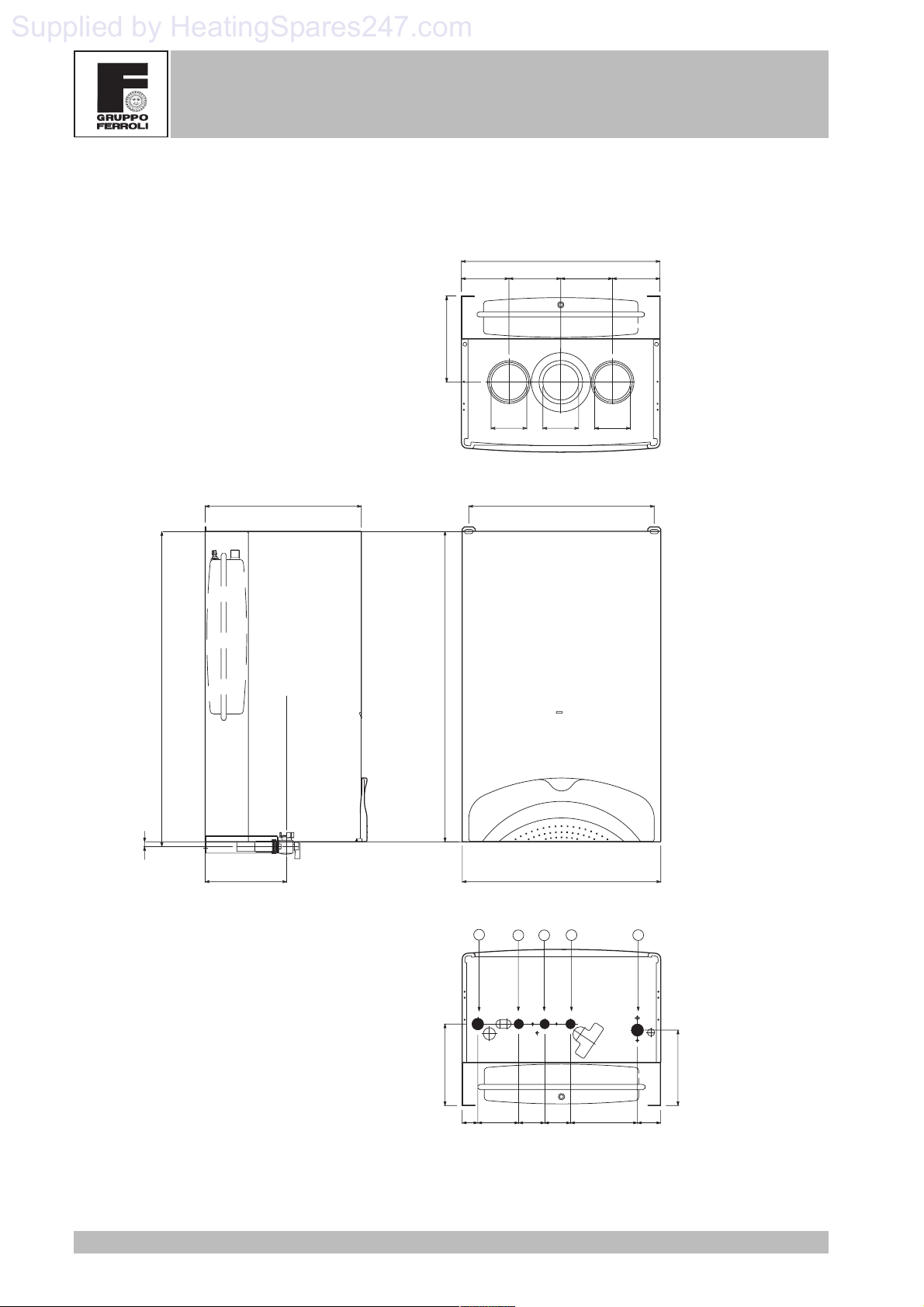

Ferella Extra F 30 MEL version

200

Top view

460

120120110

110

14

733

362

Connections axis

720

80

8080

430

189

Key

1 System delivery

2 Tap water outlet

3 Gas inlet

4 Tap water inlet

5 System return

Version - 09.2002

460

1

23

189

36 95 60 60 155 54

4

Bottom view

5

175

7

DOMINA PLUS F 24 - 30 E

Supplied by HeatingSpares247.com

FERELLA EXTRA F 24 - 30 MEL

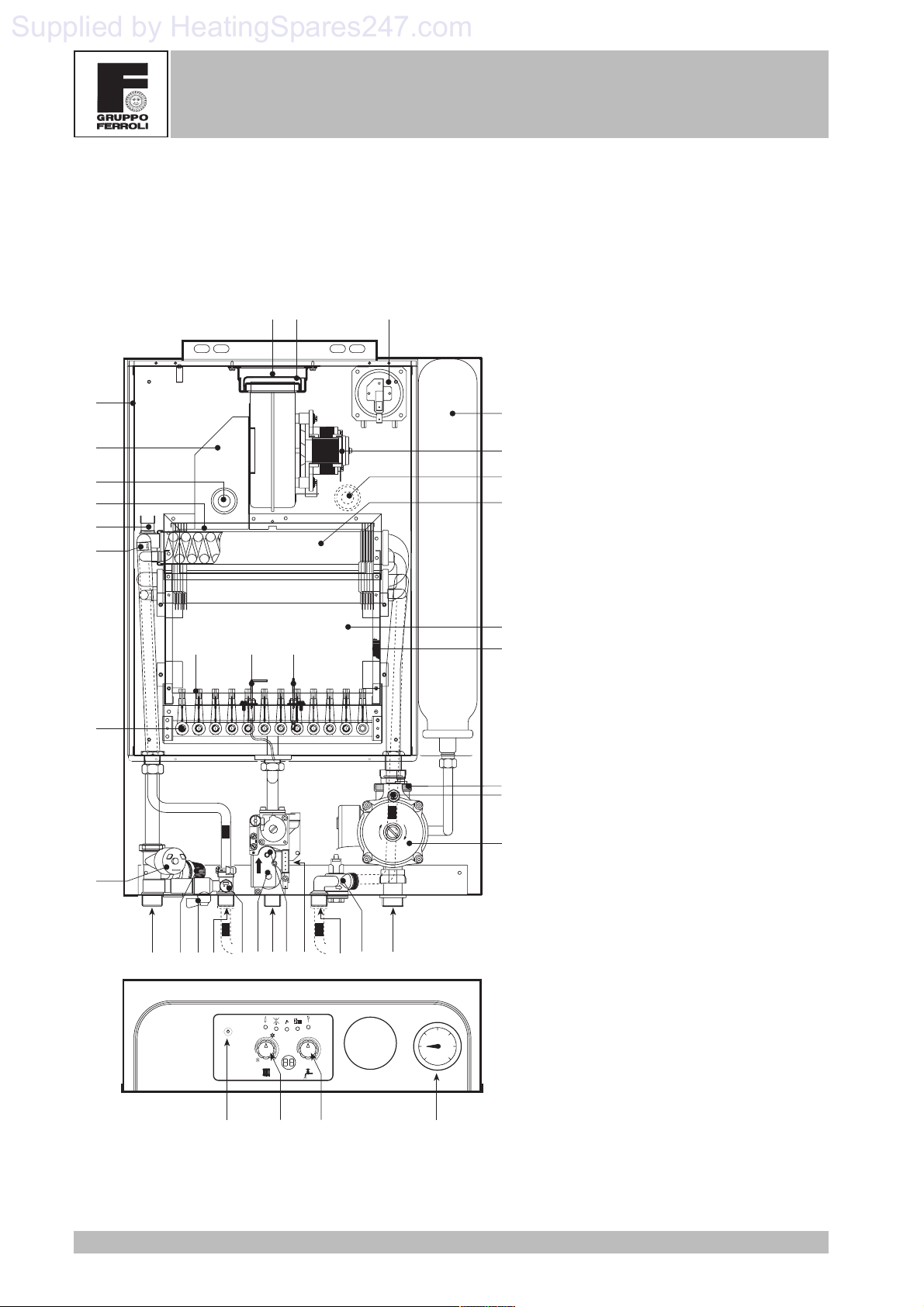

1.3 General view and main components

F 24 E/MEL version

29 43

187

5

28

90

132

49

34

81

8222

20

21

R4

3

4

2

1

5

0

6

114

OUT

R3

IN

MIN

R2

10 874 784 85 44

14 42 9 11

RESET

°C °C

R1

136

56

16

91

27

19

26

36

73

32

Key

5 Airtight chamber

7 Gas inlet

8 Tap water outlet

9 Tap water inlet

10 System delivery

11 System return

14 Safety valve

16 Fan

19 Combustion chamber

20 Burner assembly

21 Main nozzle

22 Burner

26 Combustion chamber insulation

27 Copper exchanger for heating and

tap water

28 Fume manifold

29 Fume outlet manifold

32 Heating circulator

34 Heating temp. sensor

36 Automatic air vent

42 Tap water temperature sensor

43 Air pressure switch

44 Gas valve

49 Safety thermostat

56 Expansion tank

63 Heating temperature setting

73 Antifreeze thermostat

74 System filler cock

81 Ignition electrode

82 Detection electrode

84 1st gas valve operator

85 2nd gas valve operator

90 Fume detection point

91 Air detection point

98 Off-On-Reset switch

114 Water pressure switch

132 Fume deflector

136 Flow meter

145 Water gauge

157 Tap water temperature setting

187 Fume diaphragm

R1-R2-R3-R4 Antifreeze heating elements

98 63 157

145

8

Version - 09.2002

DOMINA PLUS F 24 - 30 E

Supplied by HeatingSpares247.com

FERELLA EXTRA F 24 - 30 MEL

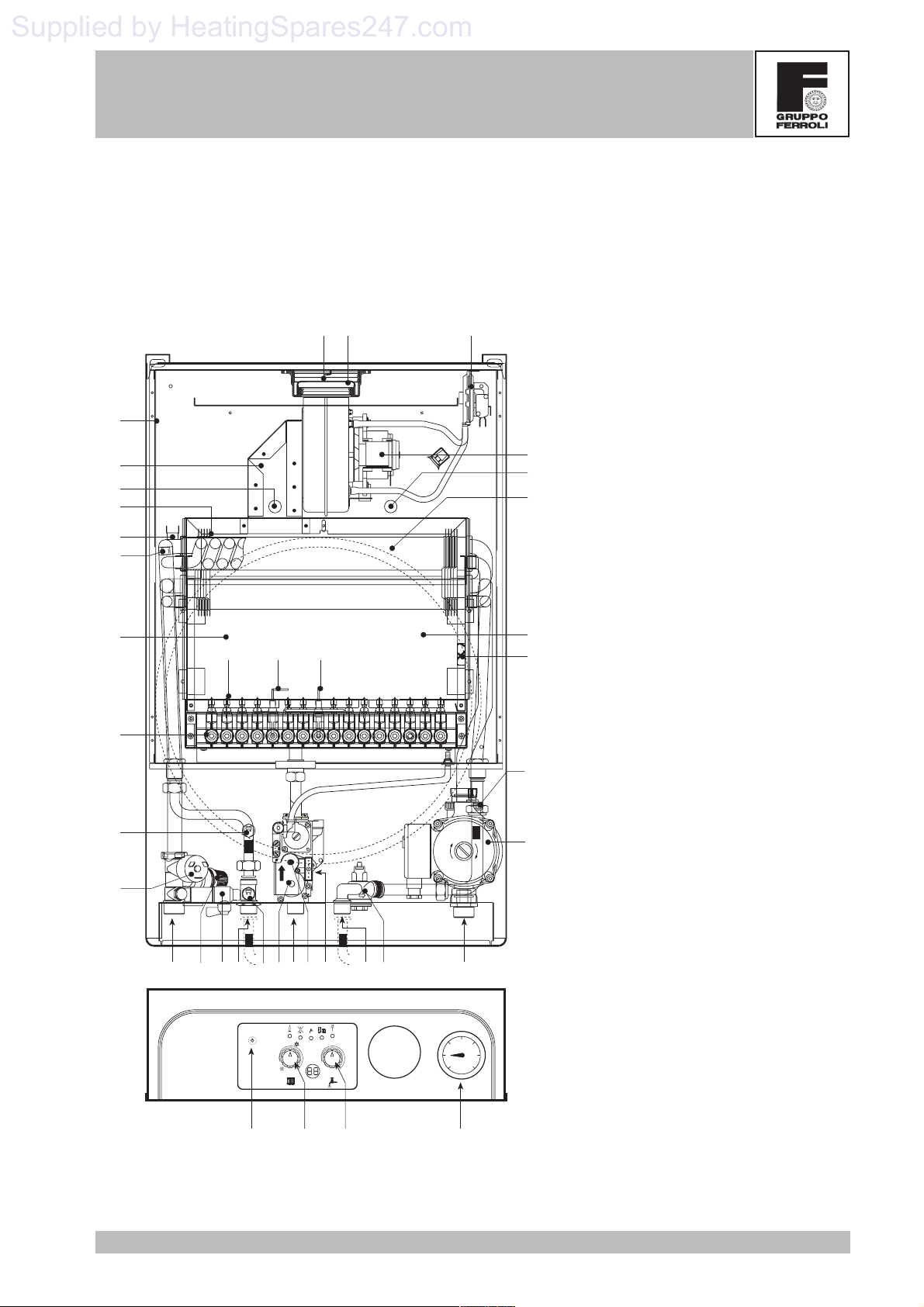

F 30 E/MEL version

28

90

132

49

34

56

20

21

73

114

29 43187

Key

5 Airtight chamber

7 Gas inlet

8 Tap water outlet

5

16

91

27

9 Tap water inlet

10 System delivery

11 System return

14 Safety valve

16 Fan

19 Combustion chamber

20 Burner assembly

21 Main nozzle

22 Burner

26 Combustion chamber insulation

27 Copper exchanger for heating and

tap water

28 Fume manifold

19

818222

26

29 Fume outlet manifold

32 Heating circulator

34 Heating temp. sensor

36 Automatic air vent

42 Tap water temperature sensor

43 Air pressure switch

44 Gas valve

49 Safety thermostat

56 Expansion tank

36

63 Heating temperature setting

73 Antifreeze thermostat

74 System filler cock

81 Ignition electrode

R3

OUT

IN

MIN

R4

GRUNDFOS

32

82 Detection electrode

84 1st gas valve operator

85 2nd gas valve operator

90 Fume detection point

91 Air detection point

98 Off-On-Reset switch

R2

R1

114 Water pressure switch

132 Fume deflector

10 8 784 85 44

74

14 42 9 11

136

136 Flow meter

145 Water gauge

157 Tap water temperature setting

187 Fume diaphragm

RESET

°C °C

3

4

2

1

5

0

6

R1-R2-R3-R4 Antifreeze heating elements

98 63 157

Version - 09.2002

145

9

FERELLA EXTRA F 24 - 30 MEL

Supplied by HeatingSpares247.com

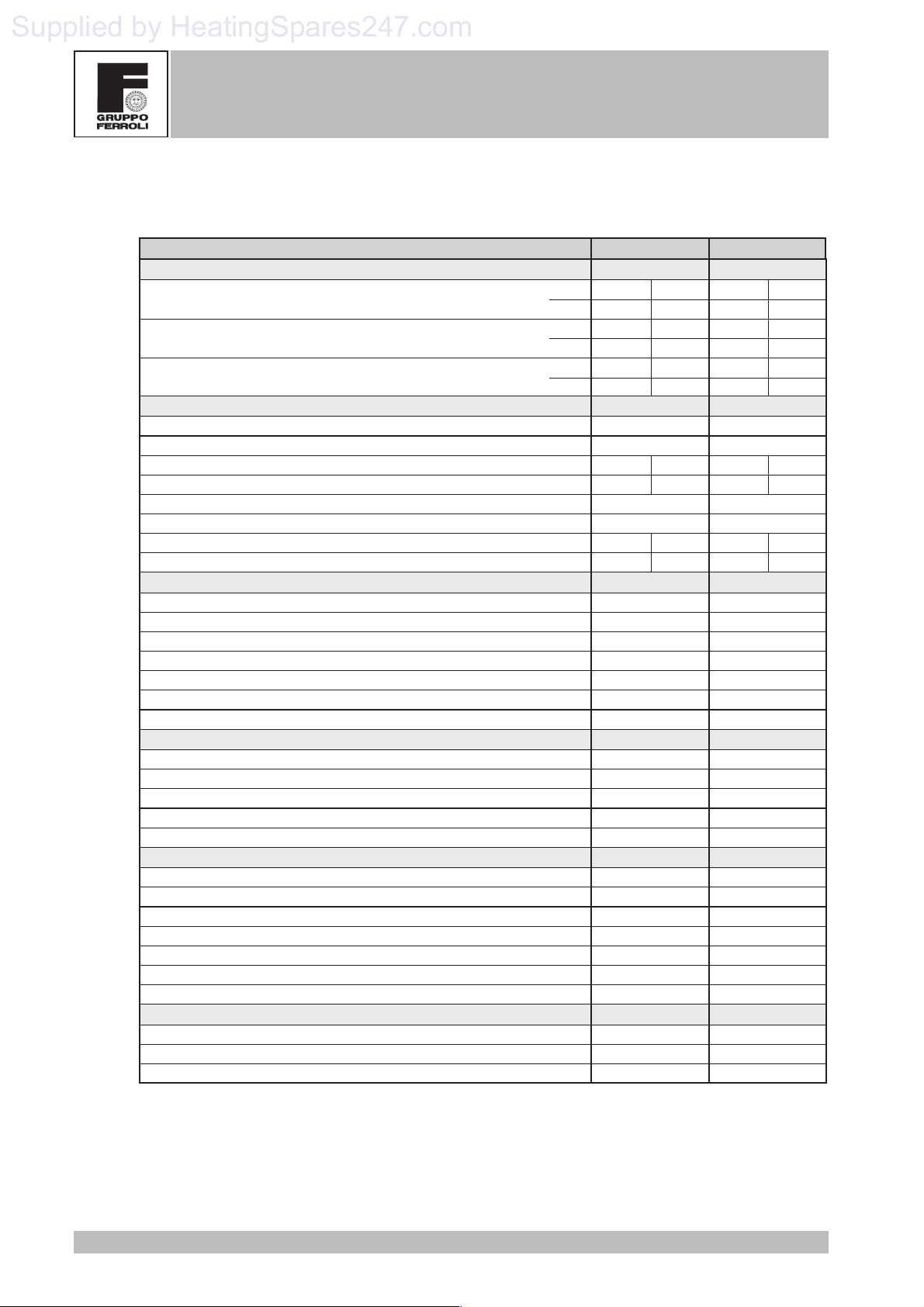

1.4 Technical data table

DOMINA PLUS F 24 - 30 E

DOMINA PLUS - FERELLA EXTRA

Powers Pmax Pmin

Heating Power (Net Heat Value - Hi)

Useful Heating Power 80°C - 60°C

Tap Water Heating Power

Gas supply Pmax Pmin

Natural Gas main nozzles (G20) mm 12 x 1.30

Natural Gas supply pressure (G20) mbar 20.0

Pressure at Natural Gas burner (G20) mbar 11.8 2.5

Natural Gas delivery (G20) nm

LPG main nozzles (G31) mm 12 x 0.77

LPG supply pressure (G31) mbar 37.0

Pressure at LPG burner (G31) mbar 36.0 7.8

LPG delivery (G31) kg/h 2.00 0.89

Heating

Maximum working temperature in heating °C 90

Maximum working pressure in heating bar 3

Safety valve bar 3

Minimum working pressure in heating bar 0.8

Expansion tank capacity litres 7

Expansion tank pre-filling pressure bar 1

Boiler water content litres 0.8

Tap water

Maximum hot water production Dt 25°C l/min 13.6

Maximum hot water production Dt 30°C l/min 11.3

Maximum working pressure in hot water production bar 9

Minimum working pressure in hot water production bar 0.25

Hot water content litres 0.8

Dimensions, weights connections

Height mm 760

Width mm 460

Depth mm 272

Weight kg 38

Gas system connection inches 1/2

Heating system connections inches 3/4

Hot water circuit connections inches 1/2

Electrical power supply

Max electrical power absorbed W 125

Power voltage/frequency V/Hz 230/50

Electrical protection rating IP 44

kW 25.8 11.5

kcal/h 22,200 9,900

kW 23.8 9.7

kcal/h 20,400 8,300

kW 23.8 9.7

kcal/h 20,400 8,300

3

/h 2.73 1.22

24kW 30kW

Pmax Pmin

33.1 14.5

28,500 12,500

30.0 12.7

25,800 10,900

30.0 12.7

25,800 10,900

Pmax Pmin

16 x 1.25

20.0

13.0 2.5

3.50 1.53

16 x 0.75

37.0

35.5 7.0

2.60 1.14

90

3

3

0.8

10

1

1.5

17.2

14.3

9

0.25

0.8

760

460

363

48

1/2

3/4

1/2

125

230/50

44

10

Version - 09.2002

DOMINA PLUS F 24 - 30 E

Supplied by HeatingSpares247.com

FERELLA EXTRA F 24 - 30 MEL

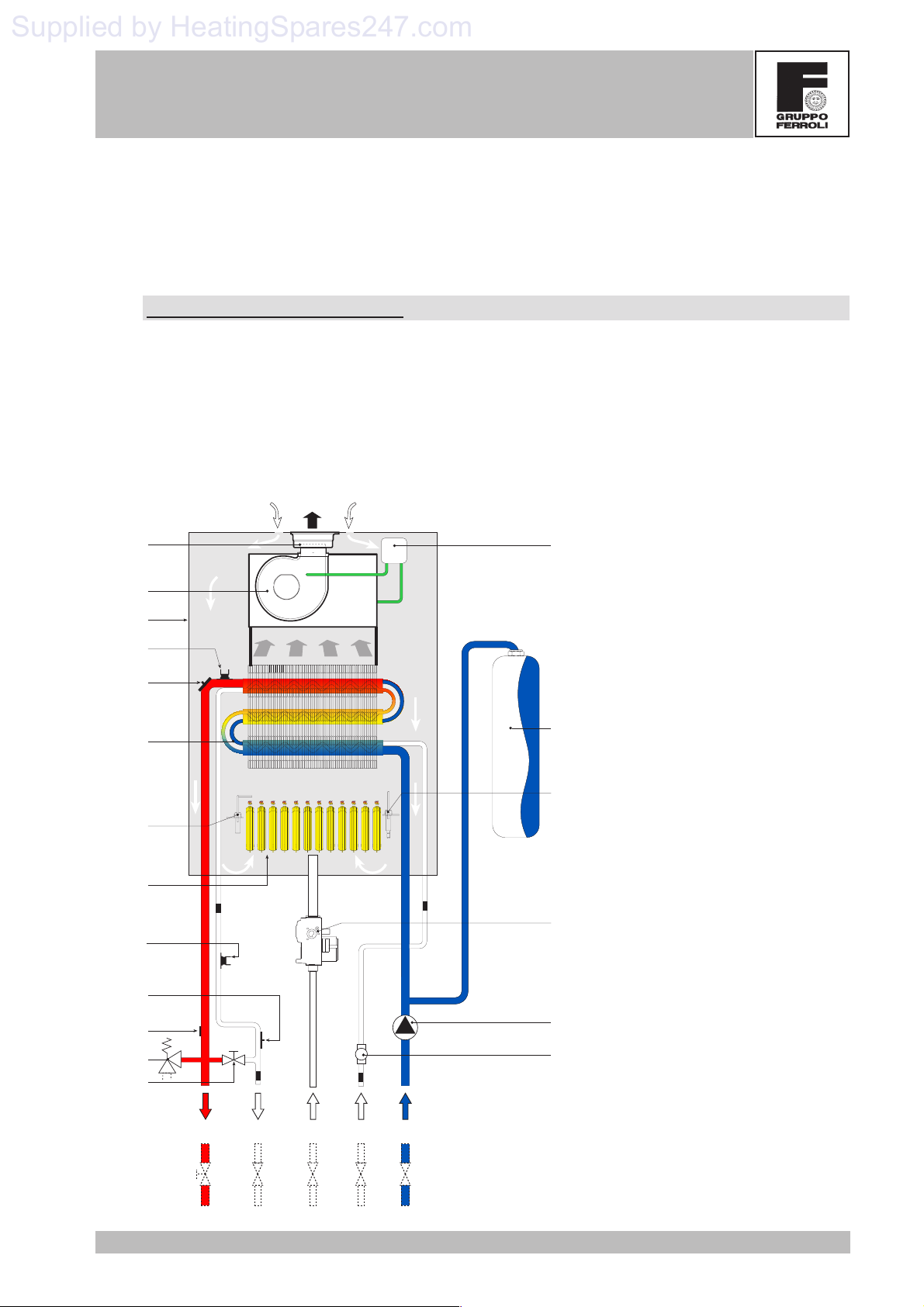

2. PRODUCT FRAMEWORK AND INTERNAL

COMPONENTS

2.1 Hydraulic circuit - heating

Hydraulic diagram for heating

When there is a call for heat, the room thermostat or control system make the burners ignite and the circulation

pump come into operation. The heat contained in the products of combustion is transferred to the water by the

system via the exchanger. For more details on the operating logic, refer to chap.3.

Key

29-187

16

49

34

27

82

20

73

5 Airtight chamber

-

+

5

R1

R2

43

7 Gas inlet

8 Tap water outlet

9 Tap water inlet

10 System delivery

11 System return

14 Safety valve

16 Fan

20 Burner assembly

27 Heat exchanger

29 Fume outlet collar

32 Heating circulator

56

34 Heating temperature sensor

42 Tap water temperature sensor

43 Air pressure switch

44 Gas valve

81

49 Safety thermostat

56 Expansion tank

73 Antifreeze thermostat

74 System filler cock

81 Ignition electrode

82 Detection electrode

114 Water pressure switch

136 Flow meter

44

187 Fume diaphragm

R1-R2-R3-R4 Antifreeze heating elements

42

114

14

74

Version - 09.2002

R3

8

7

R4

1110

9

32

136

11

DOMINA PLUS F 24 - 30 E

Supplied by HeatingSpares247.com

FERELLA EXTRA F 24 - 30 MEL

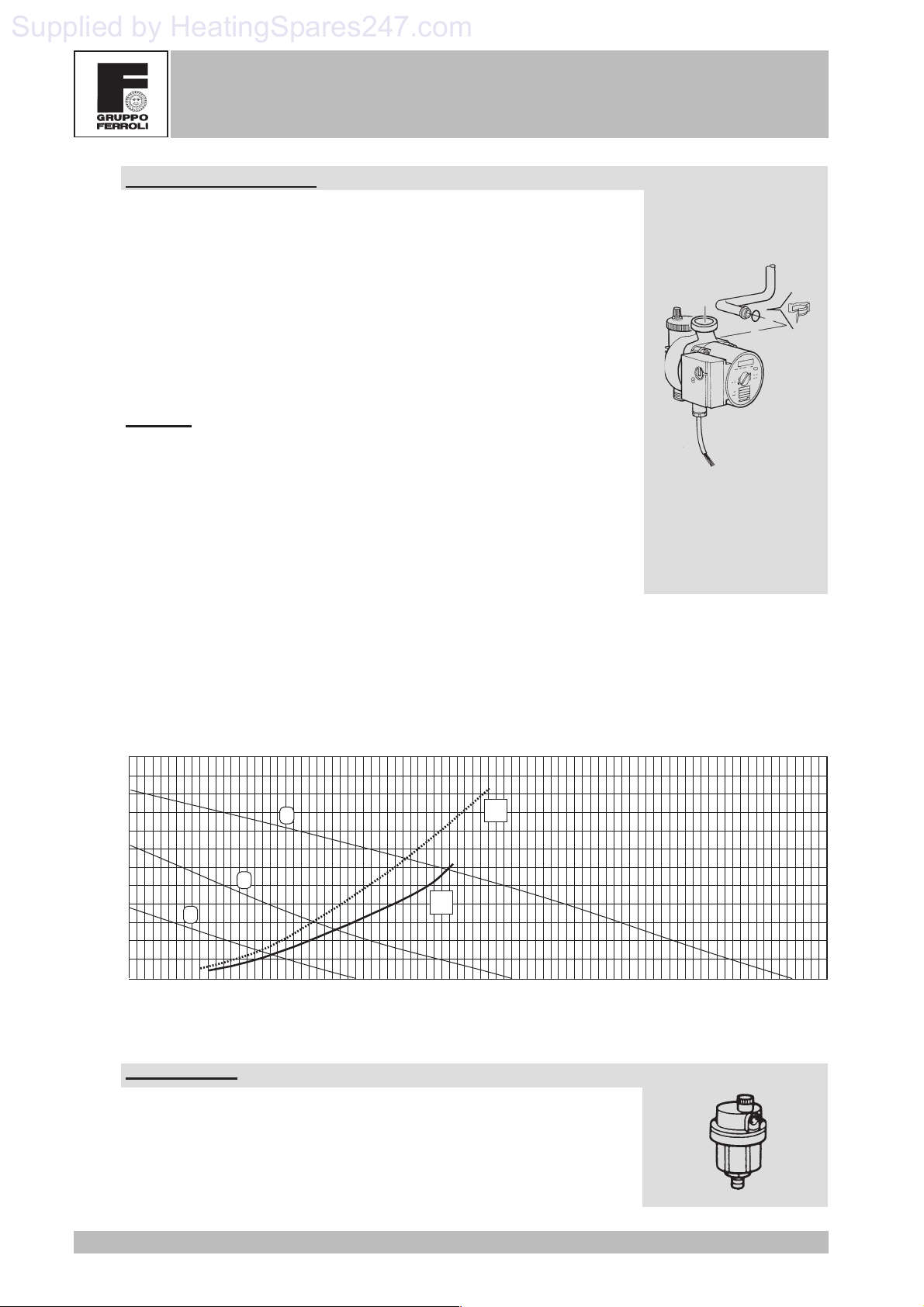

Circulator (230v/50Hz)

Located on the heating circuit return, it is connected directly to the exchanger

via special forks and connected to the system via a threaded brass section. It has

three delivery/head levels (see diagram). Changing the delivery/head changes

the speed of the water flowing through the boiler exchanger and as a result the

temperature difference (DT) between heating delivery and return. Clearly,

increasing the delivery of the circulator decreases DT and vice versa. If it is not

used for a long time, the impeller might "jam" due to debris in the water. With the

front screw it is possible to access the impeller, which can be freed with the aid

of a screwdriver. The connection to the expansion tank and the air separator is

installed on the pump casing.

Checks

If the pump doesn't work:

· Check that the impeller is free to turn by turning the screw on the front with a

screwdriver.

· Check that both the card and the pump connection are powered.

· If there is no power supply, check the card.

· If there is power, change the pump.

Key

1 - 2 - 3 = Pump selector position

mC.A.

6

5.5

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

0 0.25 0.75 1.25 1.75 2.25 2.752.51.50.5 1 2 3

1

3

2

A

B

Air separator

This is used to expel the air in the heating circuit automatically. On boilers with

a twin heat exchanger, it is located on the pump casing. It is normally accessible

either via the fork or by simply unscrewing it from its seat.

A = Losses of head 24kW version

B = Losses of head 30kW version

3.2 3.4 3.6 3.8 4

3

m

/ h

12

Version - 09.2002

DOMINA PLUS F 24 - 30 E

Supplied by HeatingSpares247.com

FERELLA EXTRA F 24 - 30 MEL

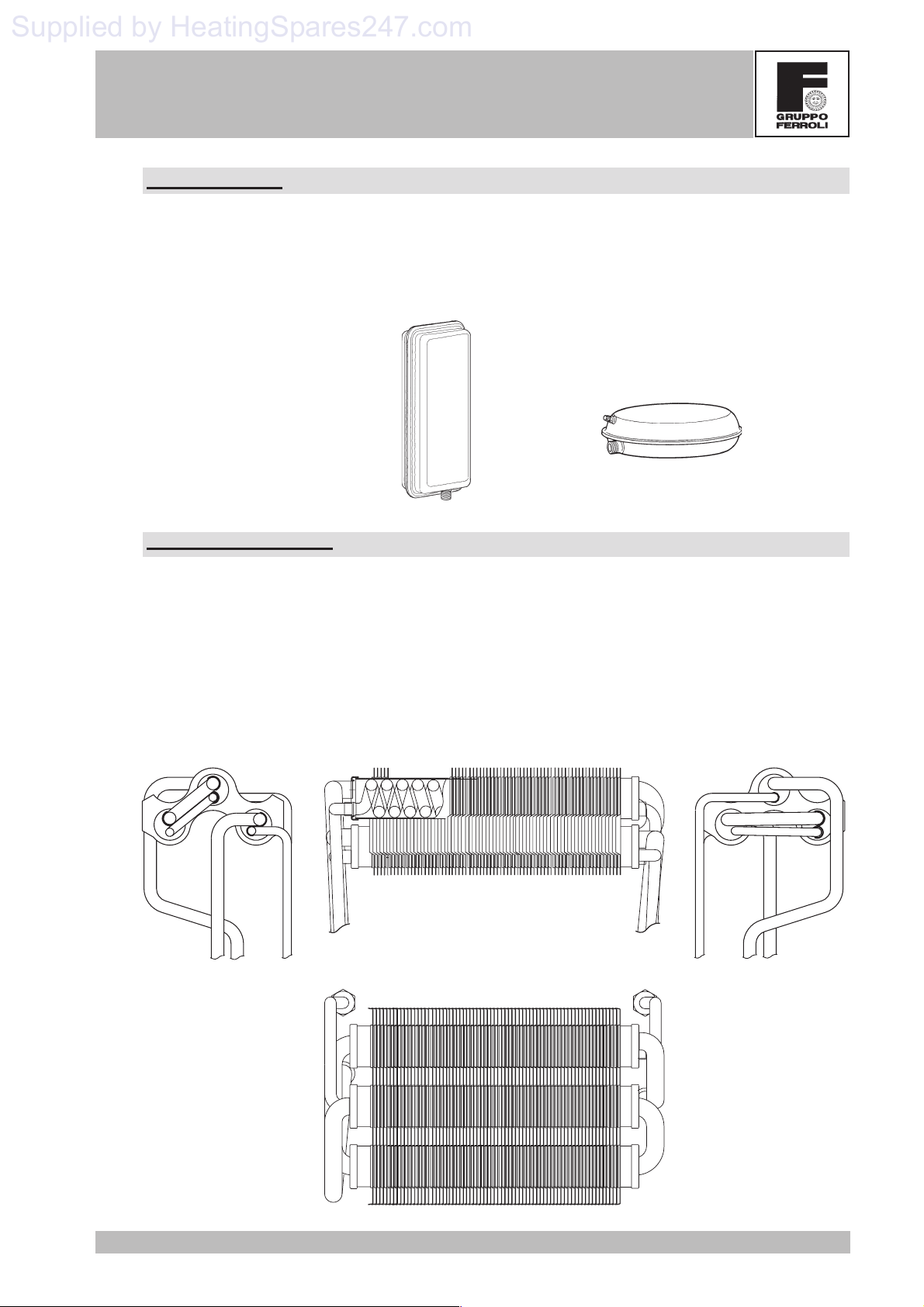

Expansion tank

It is connected to the pump casing via a pipe with a fork connection. On the 24kW version, it is located above

the pump, while on the 30kW version it is located behind the exchanger, inside the frame. The expansion tank

contains a diaphragm in contact, on one side, with the system water and, on the other side, with the air under

pressure (pre-loaded to 1 bar) inside the tank. By the expansion of the diaphragm and ensuing compression

of the air, the tank compensates for the thermal expansion of the water in the heating system.

Version 24kW

7 litre

Version 30kW

10 litre

Twin Heat Exchanger

The exchanger is a copper laminar assembly. It comprises a thickly finned portion, three circular pipes

containing the heating water and, inside them, another three pipes in the form of a spiral containing the tap water.

The heating water exchanges directly with the burnt gases, while the tap water does not have this kind of

exchange, it receives heat indirectly from the water in the three heating pipes. In this way, the surface of the

coil does not reach very high temperatures so less scale gets formed. In addition, being very small, it makes

the water speed very high over its entire section, making mineral deposits of any kind negligible. The typical

"omega" shape of the finning ensures an even distribution of the heat over all the finning, with consequent

benefits in terms of exchange efficiency and the life of the exchanger. A special surface treatment protects the

exchanger against oxidation and corrosion.

Version - 09.2002

13

DOMINA PLUS F 24 - 30 E

Supplied by HeatingSpares247.com

FERELLA EXTRA F 24 - 30 MEL

Hydraulic unit

This is a single piece of brass to which the exchanger

delivery is connected for ease of access. It

accommodates a number of safety and adjustment

components.

The hydraulic unit includes:

- safety valve

- water pressure switch

- heating sensor

- filler cock

- tap water sensor

- tap water check valve

Water pressure switch

It ensures a minimum pressure for the system. It is normally open (NO) and

closes the contact when the pressure exceeds 0.5 bar. It works on low voltage.

Safety valve

It opens if the pressure exceeds 3 bars, making boiler operation safer and

protecting it against overpressure. You are strongly recommended not to use this

valve to drain the system; once open, dirt could remain inside it, preventing it from

closing completely.

Check valve

This is necessary to ensure no water returns from the heating system to the tap

water circuit.

Filler cock

This is located between the heating delivery and the tap water outlet. It is not fitted

on the boiler for some markets such as the British and Belgian ones.

14

Version - 09.2002

Loading...

Loading...