Groove Tubes Glory Reference Manual

The Groove Tubes

Glory

Co mpressor

Reference Manual

5/16/2006 REV 6

Table of contents 1

Introduction 2

Safety Instructions 4

QUICK START guide 7

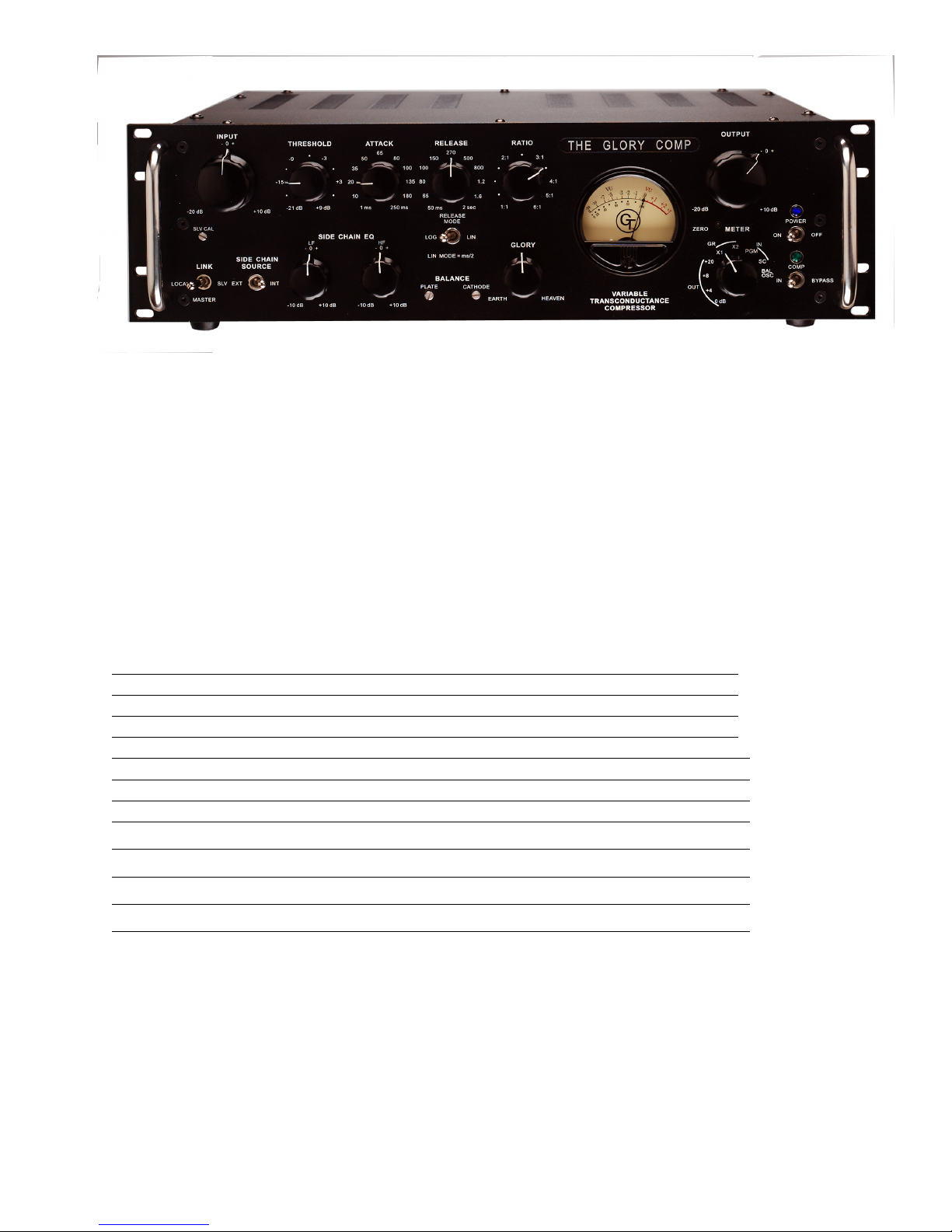

Front Panel Features and Controls _ 11

Other Recessed Controls 21

Rear Panel Features 22

Special Refinements Under the Hood 25

Unpacking and Inspection 32

Specifications 33

Obtaining Repair Service 36

Groove Tubes Limited Warranty 37

- 1 -

INTRODUCTION:

THANK YOU, for your purchase of the Groove Tubes Variable

Transconductance Glory Compressor.

Please read over this manual carefully as it contains

information essential to the proper operation and maximum

enjoyment of this dynamics controller.

The Glory Compressor is designed to provide suitable

downstream dynamics processing when paired with the GT VIPRE,

or any other professional audio source, and furnish maximized

sonic performance coupled with a generous ability to wrap

itself around the dynamic content of any signal source you may

wish to transform.

With the Glory Compressor’s feature compliment, you no longer

have to settle for what a given audio signal sounds like with

a low-headroom solid-state dynamics controller, or be boxed-in

by limited side-chain control options.

The Glory Compressor is designed to be flexible, and to adapt

to accommodate your situation, rather then the other way

‘round. To this end you will notice that it is the

anticipation of your compressor applications, which has driven

every detail of the Glory Compressor’s planning, engineering,

feature set, operating convenience and adaptability.

UNPACKING

Unpack the compressor carefully and make sure that all

supplied accessories are present. Examine all items for any

possibility of shipping damage. All seven tubes should be

standing at attention in their sockets. If the compressor is

damaged or fails to operate, notify the shipper and your

dealer or us immediately. Or if the compressor was shipped to

you directly, notify the shipping company without delay.

Your Glory Compressor was packed with the following

accessories:

A. 1 each rack-mount bracing kit.

L/R pair of rack mounting braces, which can be attached to the

sides of the Glory chassis, and rack mounted I RU above the

Glory front panel. This brace provides both rear chassis

- 2 -

support as well as insuring good ventilation for the top of

the Chassis.

B. 1 each 6 foot IEC 3-conductor power cable.

C. 1 each Owner’s manual.

Note: It is prudent to retain the shipping materials

for future use, as these materials are custom formed for

the Glory Compressor and will greatly minimize the

chance of shipping-related damage.

- 3 -

Important Safety

Instructions

Safety symbols used in this product:

This symbol alerts the user that there are important

operating and maintenance instructions in the literature

accompanying this unit.

This symbol warns the user of un-insulated voltage

within the unit that can cause dangerous electric shocks.

This symbol warns the user that output connectors

contain voltages that can cause dangerous electrical

shock.

Please follow these precautions when using this product:

1. Read these instructions.

2. Keep these instructions.

3.Heed all warnings.

4.Follow all instructions.

5.Do not use this apparatus near water.

6. Clean only with a damp cloth. Do not spray any liquid

cleaner onto the faceplate, as this may damage the front panel

controls or cause a dangerous condition.

7. Install in accordance with the manufacturer's

instructions.

8.Do not install near any heat sources such as radiators, heat

registers, stoves, or other apparatus (including amplifiers)

that produce heat.

9. Do not defeat the safety purpose of the polarized or

grounding-type plug. A polarized plug has two blades with one

wider than the other. A grounding-type plug has two blades

and a third grounding prong. The wide blade or the third

- 4 -

prong is provided for your safety. When the provided plug

does not fit into your outlet, consult an electrician for

replacement of the obsolete outlet.

10. Protect the power cord from being walked on or pinched,

particularly at plugs, convenience receptacles, and the point

where they exit from the apparatus.

11.Use only attachments or accessories specified by the

manufacturer.

12.Use only with a cart, stand, bracket, or table designed for

use with professional audio or music equipment. In

any installation, make sure that injury or damage

will not result from cables pulling on the

apparatus and it’s mounting. If a cart is used,

use caution when moving the cart/apparatus combination to

avoid injury from tip-over.

13. Unplug this apparatus during lightning storms or when

unused for long periods of time.

14. Refer all servicing to qualified service personnel.

Servicing is required when the apparatus has been

damaged in any way, such as when the power-supply

cord or plug is damaged, liquid has been spilled or

objects have fallen into the apparatus, the apparatus has been

exposed to rain or moisture, does not operate normally, or has

been dropped.

15. This unit produces heat when operated normally. Operate

in a well-ventilated area with at least six inches of

clearance from peripheral equipment.

16. This product, in combination with an amplifier and

headphones or speakers, may be capable of producing sound

levels that could cause permanent hearing loss. Do not

operate for a long period of time at a high volume level or at

a level that is uncomfortable. If you experience any hearing

loss or ringing in the ears, you should consult an

audiologist.

- 5 -

17. Do not expose the apparatus to dripping or splashing. Do

not place objects filled with liquids (flower vases, soft

drink cans, coffee cups) on the apparatus.

18. WARNING: To reduce the risk of fire or electric shock, do

not expose this apparatus to rain or moisture.

CE Declaration of Conformity

Manufacturer’s Name: Groove Tubes llc

Manufacturer’s Address: 1543 Truman Street

San Fernando, CA

91340

USA

declares, that the product:

Product Name: Glory Comp

Model Type: Variable

Transconductance Tube Compressor

conforms to the Standards for Safety and EMC for this product listed on

the Internet site:

www.groovetubes.com

- 6 -

Quick Start Guide

Step 1: Preliminary inspection.

Remove the Glory Compressor from the package and carefully

inspect the unit for outward signs of damage or distress. All

projecting controls and connectors should operate smoothly and

uniformly, and the enclosure’s surfaces should be free of

irregularities. All seven tubes should be standing at

attention in their sockets. Contact your dealer, the shipper

or us without delay if there is evidence of damage to the

unit.

Step 2: Park it.

Budget a suitable space to install the unit in an equipment

rack. Make sure there is at least 1U of breathing space above

and below the compressor, and that the airflow in the rack is

not constricted, since there will be about 95 Watts of power

dissipated by the unit. Keep cables and other objects away

from the rear panel and heat-sink since this panel will get

rather warm during operation.

Step 3: Hook it up, front panel control initial start-up

positions.

A. Route the target signal to either the INPUT XLR or TRS

jack. The TRS input jack will exhibit 6 dB more sensitivity

then the XLR input. Apply a 0 VU (+4 dBu, 1.23 Vrms) signal to

the XLR jack, or a -6 VU (-2 dBu, about 600 mVrms) signal to

the TRS jack. Using the TRS input jack will interrupt any

signal applied to the XLR input jack. Both jacks present

bridging loads to the line input signal, of about 10k and 20k

ohms respectively, and both are actively balanced.

B. Route the processed signal from the unit via the PROGRAM

OUTPUT XLR plug or TRS jack to suitable line-level monitoring

and/or recording gear. Be careful not to connect the

compressor outputs to any microphone-level inputs not capable

of handling large line-level signal levels. Damage to the misconnected microphone preamp may result.

C. Connect the compressor to the correct line voltage using

the supplied IEC power cable.

D. Turn the power on. Power lamp blinks during 30 second

warm-up period, and COMP relays hard-bypass the compressor

- 7 -

audio path by tying the like-format PROGRAM INPUT and OUTPUT

connectors together. The green COMP LED remains unlit until

the warm-up period is completed.

Notice that the relay-bypass circuit can only connect

like style PROGRAM connectors together, i.e., XLR in

to XLR out, and TRS in to TRS out. For example, if the

XLR PGM input is being used and the bypass mode is asserted,

no pass-through signal will be heard on the TRS PGM output

jack. In this case, the pass-through signal will be heard at

the XLR PGM output.

Step 4: front panel control initial start-up positions.

Position the front panel potentiometers and switches at the

following starting points:

INPUT = 0 Db,

THRESHOLD = -15 dB,

ATTACK = 35 ms,

RELEASE = 150 ms,

RELEASE MODE = LOG

RATIO = 1:1 (compression disabled),

OUTPUT = 0 dB,

METER = IN,PGM position,

COMPressor (hard-wire bypass switch) = IN,

LINK = LOCAL,

SIDE CHAIN SOURCE = INT,

SIDE CHAIN EQ LF = 0 dB, HF = 0 dB, and

GLORY = EARTH.

After the 30-second warm-up period, the compressor’s VU meter

should show PGM IN activity derived from the signal hitting

the PROGRAM INPUT jacks, and, if the COMP switch is in the

“IN” position, the green COMP LED will illuminate. Adjust the

INPUT control to get an average VU meter reading of 0 if need

be. It is OK if the meter gently hits the positive end-stops

on signal peaks; the compressor input circuitry has lots of

headroom. The uncompressed signal should be audible at the

PROGRAM OUTPUT jacks. Then:

A. Rotate the METER switch to the OUT, +8 position, or

whichever position best suits your production plant’s

operating level. The soon-to-be processed (output) signal

level should be visible on the VU meter and audible on any

attached outboard monitoring gear.

- 8 -

Notice that the output meter indication reflects the

actual signal present at the XLR PROGRAM OUTPUT plug, in

actual 600-ohm dBm units, when a 600 ohm load is present. The

reading will change somewhat depending on downstream load

conditions. If the load is light (say 10 k-ohms), the meter

will read at a somewhat higher level then if the load was

precisely 600 ohms. If the load is short-circuited, the meter

will read below -20 VU (no movement).

B. Rotate the METER switch to the GR, X1 position.

The meter should rest at the zero VU mark after 10 – 15

minutes of warm-up time (or you may adjust zero-trim at powerup if desired, but it may need to be touched up on the way to

temp stabilization), and now indicates the amount of gain

reduction, in dB, which should be zero since the RATIO switch

is still at the 1:1 position. The 1:1 ratio is included in

order to allow an audition of the signal path without dynamics

processing.

Notice that the zero-trim interacts with the GR meter

circuits only, and not the on-line audio signals.

The GR X2 position doubles the VU meter’s indicated amount of

GR, where a reading of -5 becomes -10 and so forth.

Rotate the RATIO switch slowly clockwise, stopping at 3:1.

The meter should deflect downward away from the zero mark,

depending on the volume of signal exceeding the THRESHOLD

setting of -15 dB. Notice that the THRESHOLD switch

calibration marks are referred exclusively to the IN-PGM VU

meter zero mark. In this case, compression will begin for

signal levels that exceed -15 VU when the METER switch is in

the IN-PGM level-reading position.

Notice that the VU meter, in typical fashion, may not

show large amounts of downward deflection when

responding to compression of fast or staccato signals,

such as rim-shots and the like. Also, the total amount of GR

displayed will be reduced by long ATTACK or short RELEASE

time, since these types of settings reduce the magnitude of

the control voltage produced by the side-chain circuitry.

At this point, the compressor should be actively reducing the

amplitude of the target signal. The user may now begin to

- 9 -

explore the various control settings, and arrive at those

which best suit the signal to be processed.

Note: Gain Reduction meter stabilization (GR x1 and x2)

Glory needs about 30 minutes of warming before the GR meter

will stabilize to read “0”. When turned on, the meter will

typically read a dB or so more than “0” until it fully warms

and stabilizes. Meanwhile, this temporary condition will not

affect Glory’s audio performance in any way OR affect the

operational mode of the meter when showing gain reduction. You

may wait for the meter to net itself in as the unit warms up,

or of course it is possible to continually trim the meter to

“0” until fully warmed up. Unless time pressure prevents it,

we suggest that you trim the GR “0” setting when the Glory is

fully warmed up, and let the meter reach “0” during future

sessions.

- 10 -

Front Panel Features and

Controls

A brief description of the control functions follows. The

fundamental ideas will be well-known to those who have spent

time with dynamics controllers used for audio production, but

there are a number of new twists and features that make an

examination of this section profitable.

The usual suspects

The Glory Compressor incorporates many familiarly labeled

controls, as may be found when comparing the control family

with those appearing on recent models of solid-state dynamics

processors. Indeed, the attractive and flexible dynamicscontrol array found on modern and certain vintage compressors

did in part inspire the control complement for the Glory Comp.

The feature twist here is the objective of providing userselectable parametric time and level control flexibility in an

all-tube compressor. Tough, but do-able.

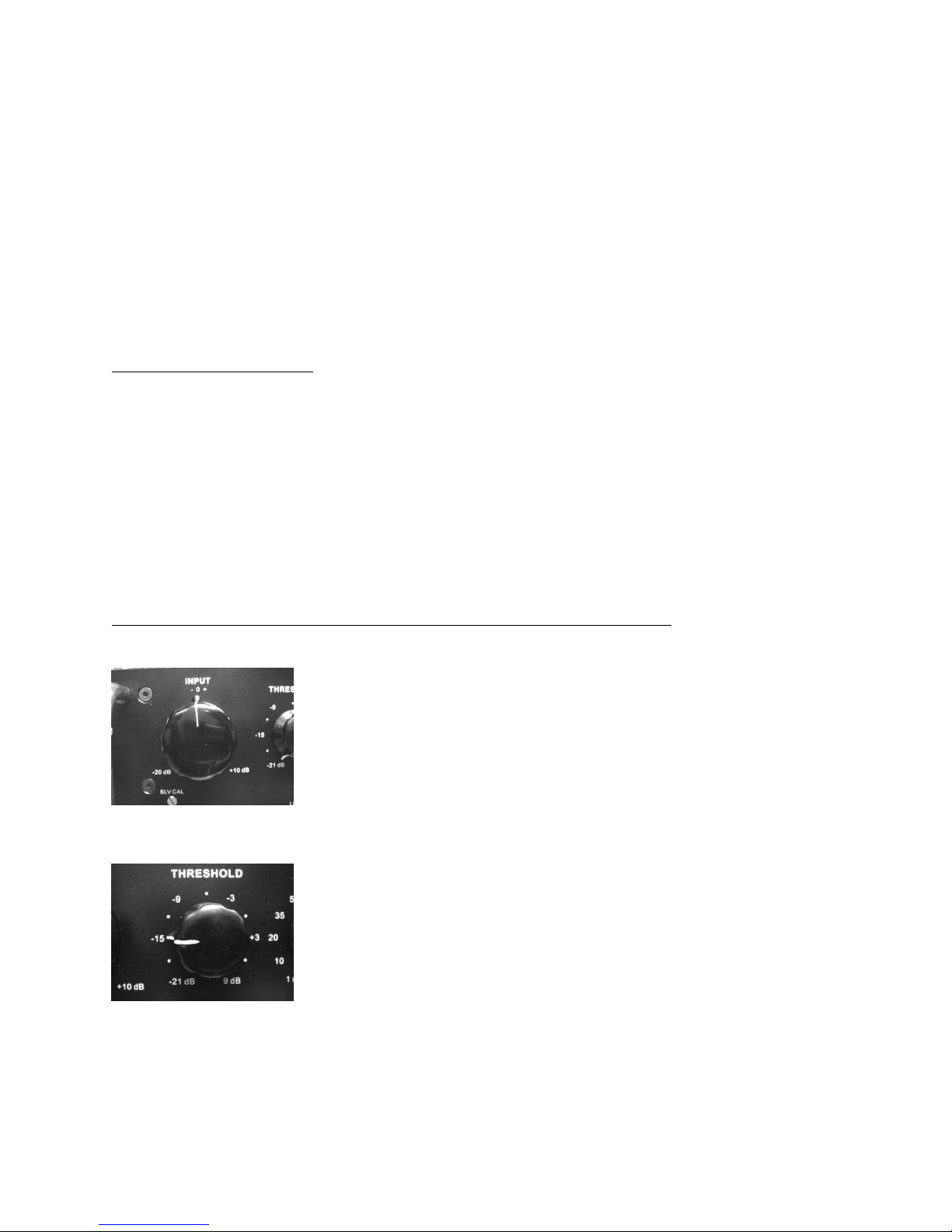

INPUT potentiometer and THRESHOLD rotary switch.

Do just what they say. The INPUT control

provides program signal input level scaling,

from –20 dB of attenuation, to +10 dB of

gain. It is used to adjust the program input

level, until the average level provides

ample input INput-ProGraM VU meter

deflection with averages hovering about the

0 dB mark.

The THRESHOLD control may then be used to

set the level of the compression knee, with

compression effects commencing when input

signals exceed the chosen knee voltage. The

control’s calibration is referenced to the

PGM meter zero VU deflection mark. Unlike

most modern fixed-knee compressor designs,

the separate THRESHOLD compression knee control permits

flexibility over the indicated range, independent of the Input

control setting. Notice that the chosen compression ratio will

be reached at a signal level at about 2 dB over that indicated

by the THRESHOLD switch setting.

- 11 -

The independent RATIO and THRESHOLD controls permit

interesting and subtle application of the compressor, by, for

example, setting the knee at very low signal levels (-21 dB),

and applying very shallow compression RATIOs of, say, 1.5:1.

The user may then reach deeply under the peak dynamic events

in the program signal, and give subtle added thickness to

material starting at more than 20 dB BELOW the peak program

operating level. Useful for raising foreground sound minutiae

and elevating room ambience details.

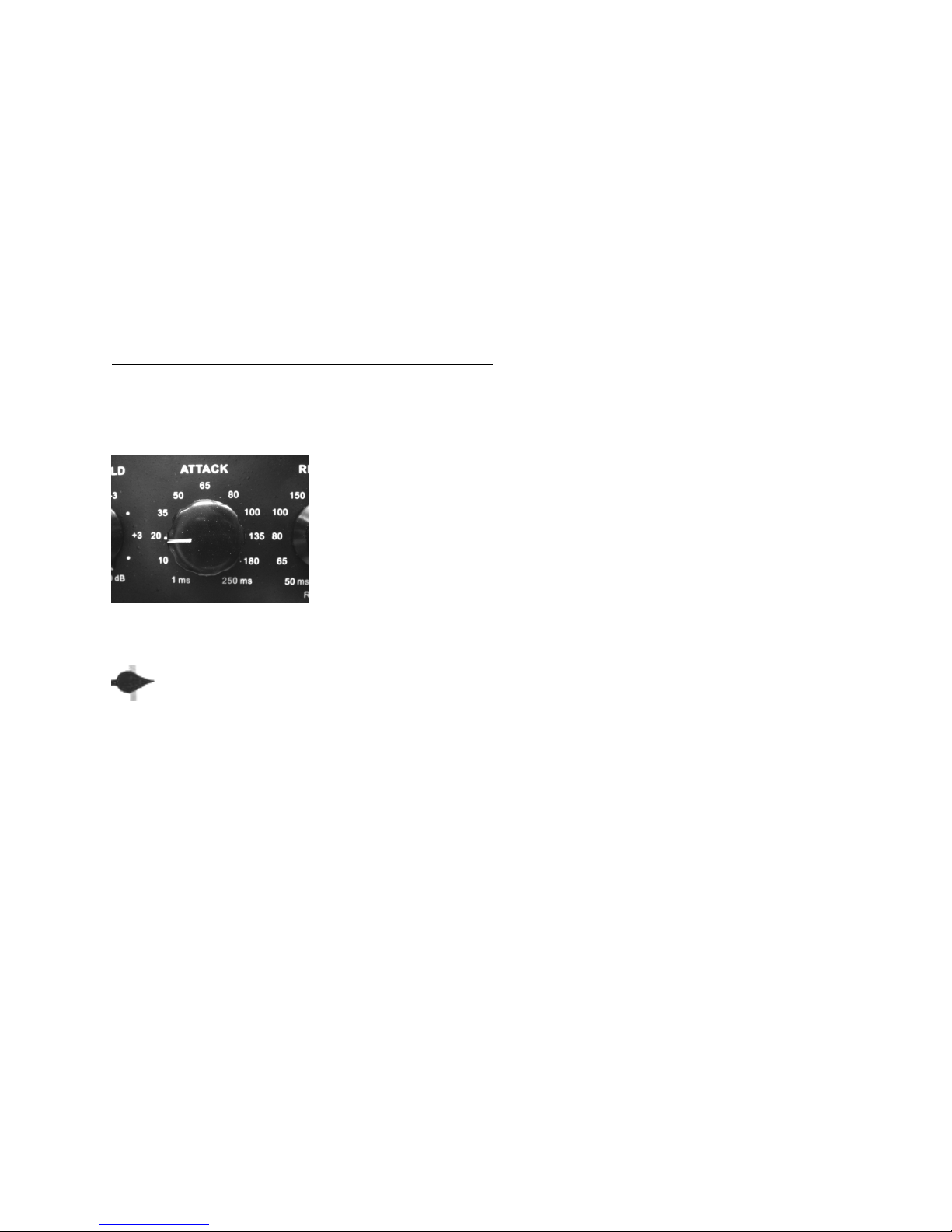

ATTACK and RELEASE rotary switches

ATTACK rotary switch

Each of these two controls function

conventionally, with separate time-constant

circuit stages dedicated to each control.

The ATTACK control sweeps through an

approximately 250:1 adjustable timeconstant range. The expanded 1 to 100 ms

mid-values correspond to the range of

average time intervals required for the

human ear to respond to an impulsive signal.

Note however that a 1 millisecond transient will

correspond to nearly 100 sound samples in a 96 kHz

digital system. Which means it will still be possible to clip

digital systems briefly, even with the ATTACK time set to

minimum. Occasional slight clipping of a 1 ms interval of

program material in a well designed digital system will be

inaudible, and may be avoided by modest drive level reduction

to the digital system.

The ATTACK and RELEASE controls are best set to values that

fit the particular musical situation. By “fit” it is meant

that, in general, faster A&R settings for percussive signals

where there is little sustain or ambient sound, and slower for

more ponderous acoustic events where there are long decay

intervals from an instrument or room reverberation. Initial

control-setting exploration will be necessary to fit the time

constant controls to the musical events at hand.

To minimize compression artifacts, it is best to keep the

ATTACK control set to time periods equal to ½ or less of the

RELEASE control setting, and both set to intervals longer then

- 12 -

Loading...

Loading...