Page 1

Atmospheric Connectionless

Steamers

SERVICE MANUAL

Models

VRC-3E • VRC-6E

Page 2

1

Call 1-800/676-9040 for Technical Support

i

SECTION 1

INTRODUCTION

Table of Contents

Page

1.1 THE GROEN SERVICE CONCEPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 GROEN CERTIFIED SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 WARRANTY AND NON-WARRANTY REPAIRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.4 SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.5 GLOSSARY OF TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.6 TOOLS AND SUPPLIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.6.1 Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.6.2 Recommended Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.6.3 Helpful Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.6.4 Recommended Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.7 HOW TO USE THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.7.1 Technical Bulletins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Page 3

1

Call 1-800/676-9040 for Technical Support

1

INTRODUCTION

1.1 The Groen Service Concept

Since 1907 Groen has been in the business of designing and

manufacturing the finest commercial appliances for the food

service industry. Chefs, cooks and kitchen support personnel

have come to depend upon the quality of construction and

the reliability of operation.

Groen, in turn, depends upon our service centers and their field

service personnel to keep the equipment in top operating condition. In order to do this, our designs are made with service and

reliability in mind.

Once the Groen equipment is sold, manufactured, delivered and

installed, our reputation is clearly in your hands. As part of our

team, we value your efforts and input to our product design.

We will do all we can to make your job of keeping the equipment in perfect working order as easy as we can. Together, we

will keep our customers satisfied.

1.2 Groen Certified Service

The Vortex Connectionless Steamer has been carefully designed

to provide many years of efficient and reliable service. Part of the

quality program is Groen Certified Service.This includes:

• Groen certifies that all equipment delivered to our customers

has been inspected and tested for compliance with the

specifications.

• Groen certifies that all parts required for service and

maintenance will be readily available.

• Groen certifies that this manual will be updated by means of

periodic service bulletins to provide the most up-to-date

information for field maintenance and service personnel.

1.3 Warranty & Non-Warranty Repair

Groen Warranty provisions are clearly presented in the

customer’s Operator Manual.

Certain procedures for the cleaning and/or adjustment

of the Vortex Connectionless Steamer are presented in this manual for reference, but not warranty related.

This non-warranty symbol is used throughout the

manual to tell you which items and activities are

NOT covered by the equipment warranty.

1.4 Safety

The Groen Vortex Connectionless Steamer has been designed

from the start with safety in mind. This includes safety to the

operating and maintenance personnel, safety to the facility in

which the equipment is installed and safety to the equipment

itself.

The steamer has been designed to the highest industry standards

and has been certified by the National Sanitation Foundation

Testing Laboratory (NSF) and the Underwriters Laboratory (UL)

to assure strict compliance.

The steamer contains several devices, which are specifically used

to prevent unsafe conditions. If they are disconnected, make sure

they are reinstalled properly and tested before the steamer is

operated.

The safety precautions in this manual are in accordance with

ANSI 535 Standard. Three different signal words alert you to a

hazardous situation:

DANGER,WARNING,AND CAUTION

DANGER:

The signal word DANGER indicates that a

hazardous situation is about to happen and, if not avoided,

will result in death or serious injury.

• Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

• When you open the steamer door, be very careful to avoid

escaping steam. Steam can cause burns.

• After removing the fan baffle partition, do not put your

hands or other object into the cooking cavity until the fan

comes to a complete stop. Rotating fan blades can cause

severe injury!

Page 4

1

Call 1-800/676-9040 for Technical Support

2

INTRODUCTION

WARNING: The signal word WARNING tells you that a

possibly hazardous situation is about to take place which, if not

avoided, could cause death or serious injury.

• Always turn off the steamer power before removing

and partitions or panels.

• Disconnect the steamer from the power source before

performing and internal service work.

CAUTION: The signal word CAUTION warns you of a

hazardous situation which, if not avoided, may result in minor

or moderate injury.

• Steamer may be hot. Take precautions to prevent any contact

with hot surfaces.

• Be sure all interior partitions have been installed before

operating the steamer.

• All steamer operators and service personnel should be

familiar with correct and safe operating procedures.

• Be sure steamer drain is not blocked as this could result in

improper steamer operations.

Two other signal words, not directly related to personal safety,

are also used in this manual:

NOTICE and IMPORTANT.

NOTICE

is used to alert you to hazards that may result in

component and/or equipment damage.

IMPORTANT is used to highlight an operating or maintenance

tip or suggestion.

1.5 Glossary of Terms

The following abbreviations and terms are used in this manual:

BTU British Thermal Unit

GPM Gallons Per Minute

LED Lighting Emitting Diode

MM Millimeter

NEC National Electric Code

N.P.T. National Pipe Thread

NSF National Sanitation Foundation

PSI Pounds per Square Inch (Pressure)

U.L. Underwriter’s Laboratory, Inc.

1.6 Tools and Supplies

This Section identifies the tools, instruments and supplies which

will be required and useful in the inspection, repair and testing

of the equipment described in this manual.

Most likely many of these tools and supplies are already in your

tool kits and are used in everyday maintenance. Make sure to

use only the specified sealants, compounds and dressings.

CAUTION: Care should be taken in using the correct tool as

indicated. Using the wrong tool may inflict damage to the part

being removed, installed and/or adjusted. Make sure that the

calibrations on instruments are periodically checked for accuracy.

1.6.1 Required Tools

• Screw Drivers: Flat Blade No. 1 and No. 2

• Phillips No. 1 and No. 2

• Socket Wrenches: 1/4” through 7/8” (Magnetic)

• Nutdrivers (metric and inches)

• Open Ended Wrenches: 1/4” through 7/8”

• Pipe Wrenches: 6” and 8” size

• Allen Wrenches: 1/16” through 1/4”

• Slip Joint Pliers: ChannelLock or Equivalent

• Wire Crimpers

1.6.2 Recommended Instruments

• Digital Multimeter: Fluke Model 77

1.6.3 Helpful Hardware

• Extension Mirror

• Screw Starter

• Level: 18” Model

• Fuse Puller

Page 5

3

Call 1-800/676-9040 for Technical Support

1

INTRODUCTION

1.6.4 Recommended Supplies

• Pipe Thread Compound: Brand: LACO PipeTite Stik

No. 11176 or equivalent

• Motor Sealant Grease: Bel-Ray

• 2” Aluminum Duct Tape

• Removable Thread Locker:

Locktite Type 242 (Door)

Locktite Type 222 (Exterior)

• Clear Silicone Sealant:

Dow Coming Type 732

• Silicone Heat Sink Compound:

Non-Fluid Oil Corp., Chemplex 1381

• High Temperature Anti-Seize and Lubricating Compound

Bostix NEVER SEEZ NSBT-16

1.7 How To Use This Manual

Read this manual completely before attempting any disassembly

or repairs.

Please note the similarities and differences between the various

models described in the manual.

Before making repairs, you should have knowledge of the

steamer operation as described in the Operations Section of this

manual, and a good understanding of service techniques, as

presented by the Groen Service School.

This service manual should be taken with you on all service calls.

Use the correct tools in accordance with the procedures shown

and use only Groen Certified Replacement Parts when performing

steamer repairs.

1.7.1 Technical Bulletins

Technical bulletins are issued by Groen to provide additional and

specific technical information to this manual. The technical

Bulletin Section of this manual should be used to file all of the

Technical Bulletins sent to you from the factory.

When you receive a Technical Bulletin, insert the bulletin in the

Technical Bulletin Section of this manual, and write a note in the

margin of the page in this manual which is appropriate to the

subject covered by the bulletin.

Page 6

2

Call 1-800/676-9040 for Technical Support

i

SECTION 2

OPERATION

Table of Contents

Page

2.1 CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 OPERATING PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Page 7

1

Call 1-800/676-9040 for Technical Support

2

2.1 Controls

Operator controls are on the front right of the unit.

The VRC-3E and VRC-6E control panels have the following touch

pads and indicator lights:

• The ON/OFF touch pad gets the Vortex™ ready for use,

or shuts it off.

• The HOLD indicator light shows that the cavity is at holding

temperature.

• The TIMING indicator light stays on when the timer is running.

• The low water probe signals the ADD H20 indicator light to

illuminate when it’s time to add water.

• The open and closed position of the drain valve allows the

unit to be filled with water or drained.This is also used to

manually reset the unit.

• If fitted with an optional water fill drain kit, the high water

probe will automatically control the water level.

• The HI TEMP indicator light comes on when the bottom of

the water reservoir becomes too hot.The unit will

automatically shut off, and cannot be turned on again until

the water reservoir cools down.

• The HI TEMP light will remain illuminated until the controls

are turned on and the unit temperature is low enough to

restart. Then reset the manual reset latch as indicated on the

bottom label.

• When power has been interrupted to the Vortex or the HI

TEMP light has come on, the RESET light will illuminate. The

drain handle will need to be momentarily opened or closed

to extinguish light.

The timer is used in three ways:

1. In the HOLD position the steam generator stays at a low boil

or “holding” temperature. Factory set at 180°F.

2. When a cook time is set, the timing light will illuminate.

The unit steams until the timer runs down to DONE.At that

time steaming stops, the DONE light illuminates and a

beeper sounds.

3. When the timer is turned to the ON position, the unit

steams continuously.The green ON light will stay illuminated.

OPERATION

Page 8

2.2 Operating Procedure

NOTE: When the unit is first installed, or anytime incoming

power is interrupted, the RESET light will illuminate. Momentarily

turn the drain handle to open then back to close to reset the

unit and extinguish the RESET light.

1. With the cooking chamber water reservoir “empty” press

the ON/OFF touch pad. The ADD H20 light will illuminate

when the door is opened. Pour water into the reservoir

through the door.When the water level comes up to the

hi probe the reservoir is full and 3 beeps will sound. Close

door.The fan and contactor will turn on after 15 seconds.

2. Set the time knob to the ON position. The contactor can be

heard cycling to pulse energy into the heating elements.The

unit will be ready in about 20 minutes.

3. Load food into pans in uniform layers. Pans should be filled

to about the same levels, and should not be mounded.

4. Open the door and slide the pans onto the supports. If you

will only be steaming one pan, put it in the middle position.

Some foods will cause foam. When cooking foods that

foam, such as shrimp, put an empty solid 2” deep pan in

the bottom slot of the pan racks.

5. Close the door and take one of the following steps:

• If you want to steam the food for a certain length of time,

set the timer for that period. The timer will automatically run

the steamer for the set time and then turn it off. A beeper

will sound. Steam productions stops. The red DONE light will

illuminate.

• If you want to steam continuously, turn the timer to the

manual ON position. The green ON light will illuminate.

The unit will continue steaming at a temperature of 203° F

or higher.

• If you want to maintain food at holding temperature turn

the timer to the “HOLD” position. The hold light will not

illuminate if the temperature is above 180 degrees. Open

door to cool.

WARNING

When you open the door,

stay away from the steam

coming out of the unit.

the steam can cause burns.

6. To remove pans from cavity, open the door. Remove the

pans from the steamer, using hot pads or oven mitts to

protect your hands from the hot pans.

7. To shut off the unit, press the ON/OFF touch pad.

8. To drain the remaining water in the water reservoir, move

the drain handle to the OPEN position.The drain pan will

not hold all of the water in the reservoir.Allow water to cool

before draining. Pull drain pan slowly from the unit to avoid

sloshing.

WARNING

Do not empty until water is cool.

Empty drain pan. Pan will not hold

all water from the reservoir.

Do not over fill drain pan.

Call 1-800/676-9040 for Technical Support

22

OPERATION

Page 9

Page 10

3

Call 1-800/676-9040 for Technical Support

i

SECTION 3

INSTALLATION, CLEANING

AND TESTING

Table of Contents

Page

3.1 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 INSTALLATION CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 CLEANING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Page 11

1

Call 1-800/676-9040 for Technical Support

3

INSTALLING, CLEANING AND TESTING

WARNING

GROUNDING INSTRUCTIONS

This appliance must be connected

to a grounded metallic, permanent

wiring system, or an equipment

grounding conductor must be run

with the circuit conductors and

connected to the equipment

grounding terminal on the station.

3.1 Installation and Start-up

CAUTION

DO NOT INSTALL THE UNIT WITHIN

2 INCHES OF A HEAT SOURCE

(SUCH AS A BRAISING PAN, DEEP FAT

FRYER, CHARBROILER, OR KETTLE).

Electrical Supply Connection – Observe all local, national, or

other applicable codes.

Three phrase models of the Vortex® Connectionless Steamer are

supplied with a cord set ready to be connected to a power

supply. See the chart below for the correct matching receptacle

(not supplied with the unit).

Single phase models are designed to be directly connected (hard

wired) to the electrical supply.Allow sufficient loop in the flexible

conduit to facilitate inspection, servicing, and cleaning.

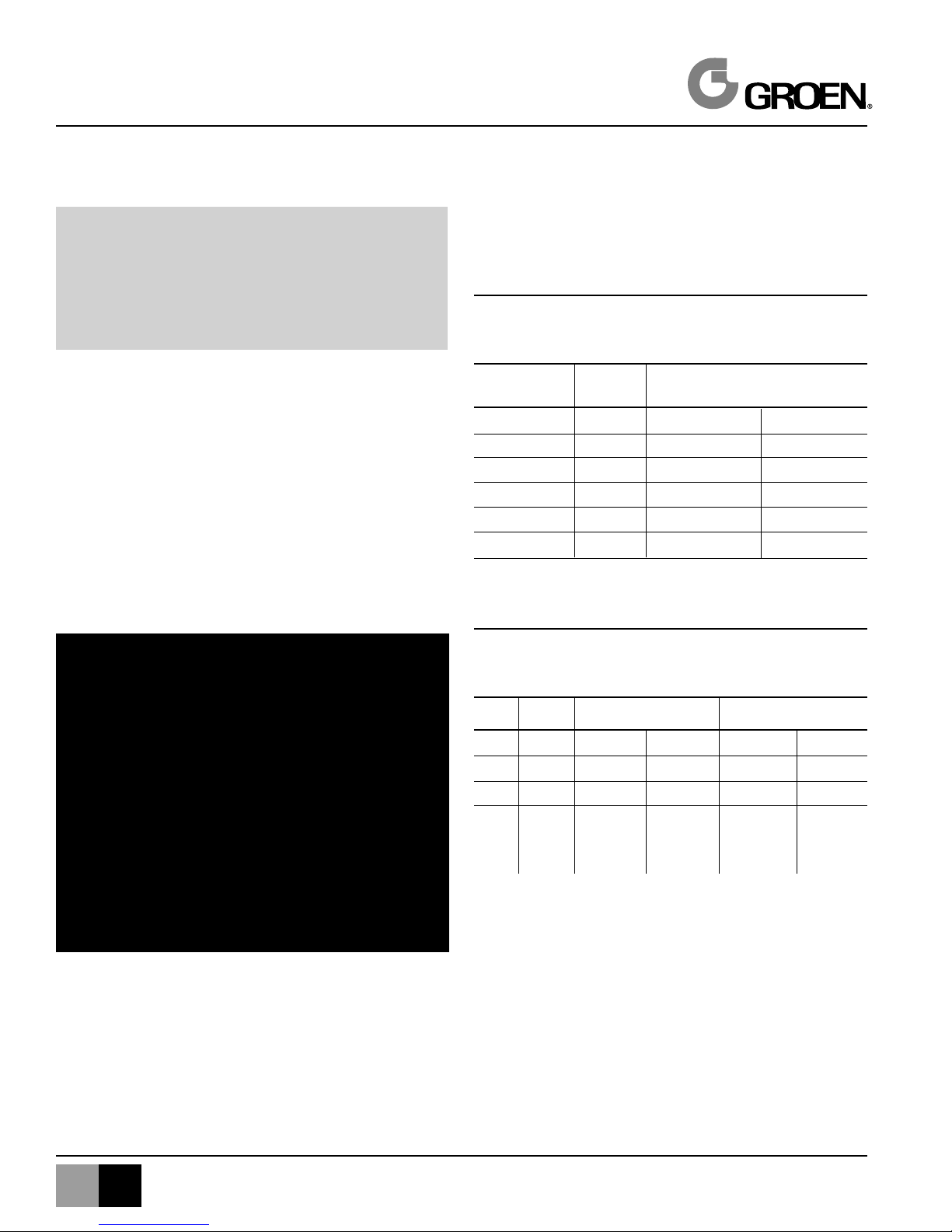

Branch Circuit Protection

Each Steamer, including individual units of stacked models,

should have its own branch circuit protection and ground wire.

Current and power demands for each unit are as shown below.

Field Wiring Table

Use copper wire only – insulation rating 90°C

Voltage Phase Rated Current

60 hz only Demand (amps)

VRC-3E VRC-6E

208 3 25 34

240 3 22 29

480 3 11 25

208 1 44 58

240 1 38 50

Plug & Receptacle Chart

Three Phase Only

Volts Phase Plug Receptacle

9 KW 12 KW 9 KW 12 KW

208 3 15-50P 15-50P 15-50R 15-50R

240 3 15-30P 15-50P 15-30R 15-50R

480 3 L16-20P CS8165C L16-20R CS8169

Hubbel or Hubbel or

Equivalent Equivalent

Page 12

3

INSTALLING, CLEANING AND TESTING

Call 1-800/676-9040 for Technical Support

2

Water Connections(s)

No water connection is needed.The water will be poured directly

into the water cavity reservoir.Avoid the use of any chemically

treated water, specifically filtered water.Instructions for connecting the optional auto-fill drain kit are included with the kit.Also,

in the Assembly/Disassembly section of the manual.

Drain Connection

The Vortex® Connectionless Steamer should be manually

drained to the bottom containment pan supplied by the factory.

If the unit is connected to a drain, do not connect more than

two units to one drain line or pressure from one unit will effect

the second unit.

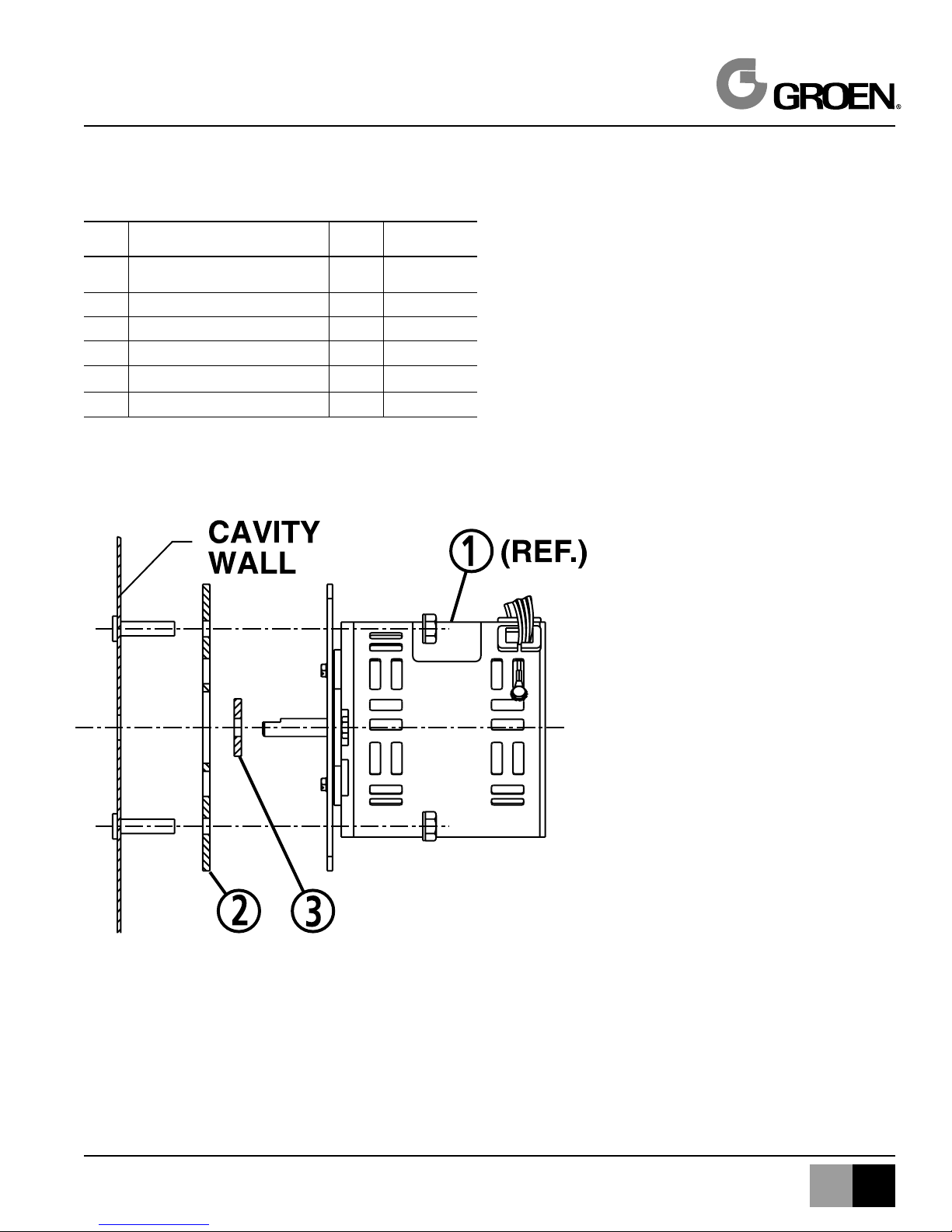

Steam Vent Assembly Instructions

Remove steam diverter assembly from literature bag which can

be found inside unit. Slide loose end as shown over unit steam

outlet, tighten worm gear clamp with flat head screw driver.

Be sure steam outlet is pointing in the upward position.

(Shown below)

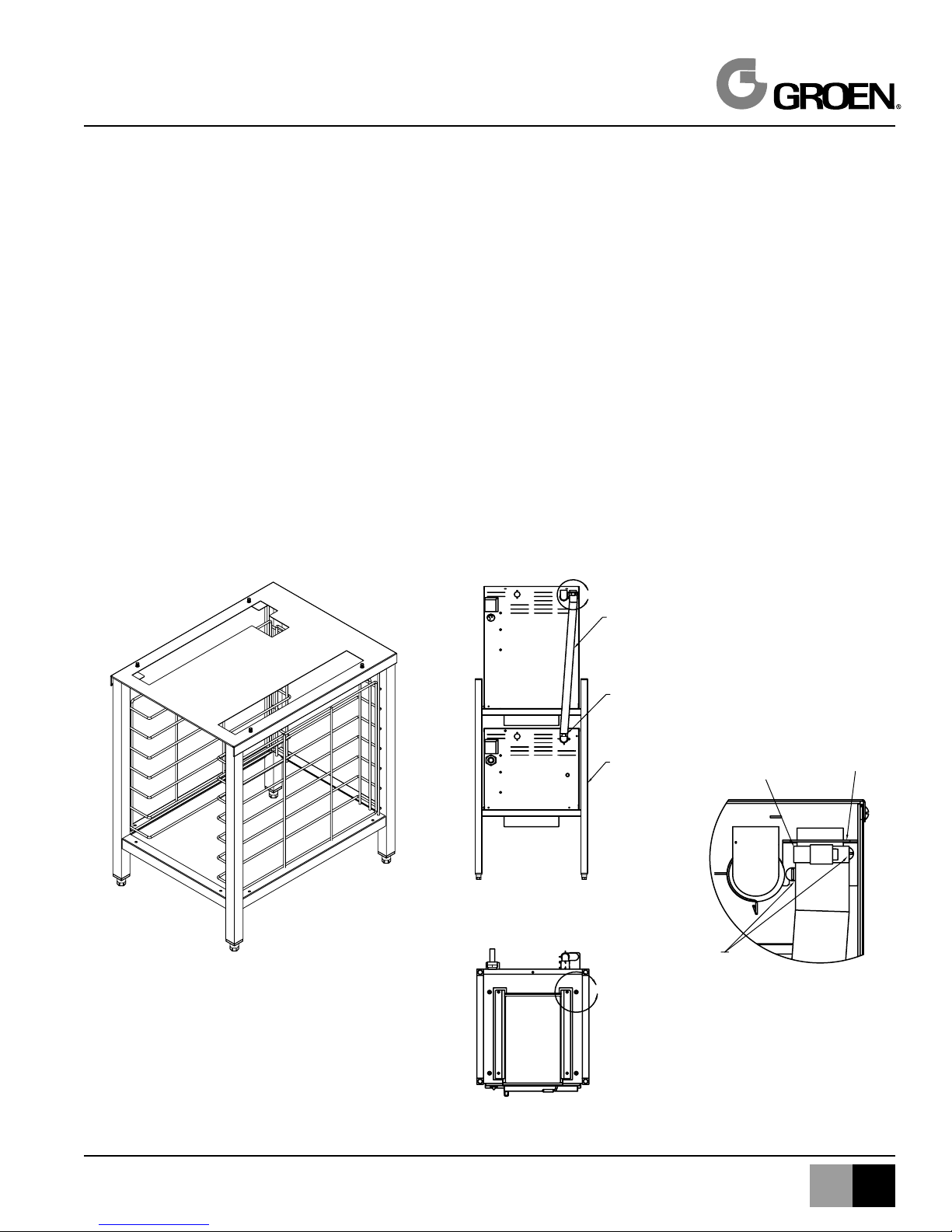

Stacking Units Instructions

Remove drain containment pan from the bottom of unit(s).

Unscrew to remove adjustable legs from base of Vortex unit(s).

Unfasten nuts and bolts on stand platform(s). Place Vortex

unit(s) on stand platform. Align the (4) leg holes with the holes

in the platform. Secure Vortex units(s) to stand platform(s) using

bolts and washers provided with stand, see drawing below.

For double stack units only:

By loosening the left screw and removing the right screw provided,

mount steam exhaust bracket assembly to the back panel of the

top Vortex unit as shown in detail “B” of Figure 1 on the next

page.Attach the steam exhaust hose from the bottom Vortex

unit’s steam outlet tube to the top Vortex unit’s steam exhaust

bracket assembly using hose clamps provided as shown in figure

2 on the next page. (Note: Steam exhaust hose may need to be

cut to fit.)

FIGURE 1

FIGURE 2

DETAIL B

SCALE 1 : 1

DOUBLE

STACK

STAND P/N

142363

HOSE

CLAMPS

P/N 073259

HOSE

CLAMPS

P/N 073259

DOUBLE STACK

STEAM

EXHAUST HOSE

DOUBLE STACK

STEAM EXHAUST

BRACKET

ASSEMBLY

P/N 143243

10-32 SCREW

P/N 004173

Page 13

3

Call 1-800/676-9040 for Technical Support

3

3.2 Installation Checklist

General

_____ Remove all packaging.

_____ Make sure there is a minimum of 2 inches of

free space around the steamer.

_____ Make sure the steamer is level or pitched

slightly to the rear.

_____ Check that the fan is clean and clear of

foreign material.

Electrical Checks

_____ Make sure the steamer is properly grounded.

_____ Verify that the electrical connections conform

to all local codes and the NEC requirements.

_____ Make sure the power supply branch circuit

conforms to the specifications indicated on

the steamer nameplate.

Steamer Door Check

_____ Make sure the door gasket is making good

contact with the cavity frame.

_____ Check that the operators are leaving the door open

when the steamer is shut down overnight or longer.

3.3 Cleaning

To keep your VRC-3E or VRC-6E Connectionless Steamer in

proper working condition, use the following procedure to clean

the unit.

A. Suggested Tools

• Mild detergent

• Stainless steel exterior cleaner such as Zepper“

• Cloth or sponge

• Plastic wood or a brush with soft bristles

• Spray bottle

• Measuring cup

• Nylon pad

• Towels

• Plastic disposable gloves

B. Procedure

Exterior Cleaning

a. Prepare a warm solution of the mild detergent as

instructed by the supplier.Wet a cloth with this solution

and wring it out. Use the moist cloth to clean the outside

of the unit. Do not allow freely running liquid to touch

the controls, the control panel, any electrical part, or on

the side or rear panels.

b. To remove material which may be stuck to the unit use

plastic wool, a fiber brush, or a plastic or rubber scraper

with a detergent solution.

c. Stainless steel surfaces may be polished with a recognized

stainless steel cleaner such as “Zepper“.

Interior Cleaning

Clean the unit daily or as residue builds upon the bottom of

the oven cavity.

a. Press ON/OFF to turn the steamer off. Open the door.

b. Drain the water from the unit into the drain pan and

allow the unit to cool before cleaning. (Note: If the cavity

is full of water, the drain pan will not hold the entire

amount and must be emptied more than once.)

c. After the unit has cooled, remove pan and pan racks

from the cavity.

d. Use a mild detergent to wipe down the steamer cavity, the

probes on the inside back panel wall, and the pan racks.

e. Rinse the unit to remove detergent.

f. Attach pan racks. Unit is ready for use.

INSTALLING, CLEANING AND TESTING

Page 14

WARNING

Keep water and cleaning solutions

out of controls and electrical

components. Never hose or steam

clean any part of the unit.

Even when the unit has been

shut off, don’t put hands or tools

into the cooking chamber until

the fan has stopped turning.

Don’t operate the unit unless the

removable partition has been put

back in its proper location.

Do not use any acidic cleanser,

delimer/descaler or chemical

products to clean the unit.

IMPORTANT

Do not use any metal material (such as metal sponges)

or metal implements (such as a spoon, scraper or

wire brush) that might scratch any stainless steel surface.

Scratches make the surface hard to clean and provide

places for bacteria to grow. Do not use steel wool,

which may leave particles imbedded in the surface which

could eventually cause corrosion and pitting.

Call 1-800/676-9040 for Technical Support

43

INSTALLING, CLEANING AND TESTING

Page 15

Call 1-800/676-9040 for Technical Support

INSTALLING, CLEANING AND TESTING

Notes

Page 16

4

SECTION 4

TROUBLESHOOTING

Table of Contents

Page

4.1 TROUBLESHOOTING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.1 - 4.5

Call 1-800/676-9040 for Technical Support

i

Page 17

1

Call 1-800/676-9040 for Technical Support

4

TROUBLESHOOTING

4.1 Vortex Troubleshooting Procedure

Each test procedure builds on the prior ones.Always start at the beginning of this procedure, and continue until the results indicate a

malfunction. Do not skip steps.

WARNING: Disconnect electrical power before servicing.

Measure input voltage and compare to rating plate.

Check input power to determine

if it is three phase or single phase

Open steamer door. Disconnect

then connect electrical power

(circuit breaker or plug)

Input voltage is within 10% of

rated voltage

Steamer wiring matches

incoming power

Reset light illuminates

Wrong model (voltage) installed

Wrong model ordered. Change

wiring at terminal block to

match incoming power.

(Perform Test 1 or 2)

Test 1. 12vdc led (light) on

circuit board is not illuminated

No line voltage

Blown 6 amp fuse F1 or F2

480v unit only-torroid

circuit breaker

480v unit only-torroid

transformer

10 volt transformer T2

Control board

Incorrect wiring

Test 2. 12vdc led (light) on

circuit board is illuminated

Control board

Hi-limit 2 (auto reset)

Incorrect wiring

Hi-limit 1 (auto reset)

Latching relay

Reset light

Incorrect wiring

Notify customer

When converting from three

phase to single phase, do not

exceed amperage of breaker or

power cord/plug

Standard test

Standard test

Reset breaker

Measure 480vac in and

208+/- 10%vac out

Measure 208 or 240vac in

and 12vac +/- 20% out

Substitute to test

Check wiring diagram

Measure from j7-pin 12 to

ground. If 12vdc +/- 20%,

control board is good

Continuity, normally closed

Check per wiring diagram

Hi-temp light will illuminate if

open

Continuity, from terminals

4 to 3, normally closed

Measure across light.

If 12vdc, light is bad

Check per wiring diagram

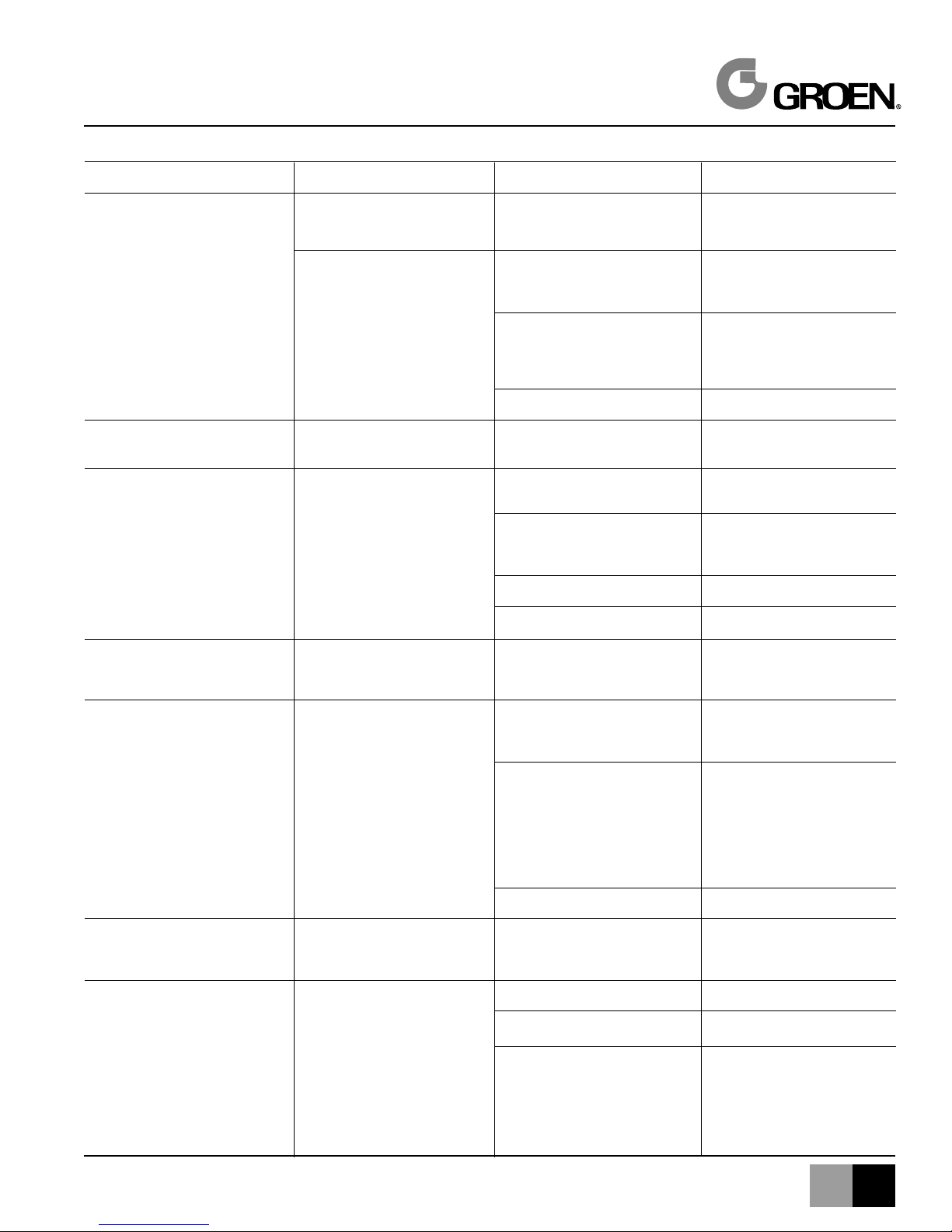

SETUP EXPECTED RESULTS PROBABLE DEFECT TEST or COMMENTS

Page 18

4

Call 1-800/676-9040 for Technical Support

2

TROUBLESHOOTING

Momentarily rotate drain handle

to reset

Press on\off switch to on

Add water to cover low water

(bottom) probe. Close door

Open door, add water to cover

top probe.

Reset light goes out

24vac led (light) on control board

illuminates

H20 light goes out

Unit beeps 3 times when water

reaches top probe

Reset switch adjustment

Reset switch

Latching relay

Incorrect wiring

Breaker on 24 Volt transformer

24 volt transformer T1

Overtemp shutdown control K1

Control board

Incorrect wiring

Low water probe

Temperature probe

Water level board

Incorrect wiring

High water probe

Control board

Incorrect wiring

Standard test

Measure from 1 to 4.

Normally open. Press switch

closed, measure continuity.

Measure from 1 to ground

while rotating reset handle.

If 12vdc and relay does not energize, relay is bad.

Check per wiring diagram

Reset breaker

Measure 208 or 240vac in and

24vac +/- 20% out

Measure across K1coil terminals

0 to 1. If 12vdc and relay does

not energize, K1 is bad

Substitute to test

Check per wiring diagram

Probe measures open to ground

without water. Short probe wire

to ground to simulate water.

About 550 ohms at room

temperature. 500 +\- 2 ohms

in ice bath.

Red light indicates power to

board. Bypass to test. Disconnect

wire to L1, move wire from NO-2

to NC-2, remove wire from H and

NO-1 and jumper these two

wires together.

Check per wiring diagram

Probe measures open to ground

without water. Short probe wire

to ground simulate water.

Substitute to test

Check per wiring diagram

SETUP EXPECTED RESULTS PROBABLE DEFECT TEST or COMMENTS

Page 19

3

Call 1-800/676-9040 for Technical Support

4

TROUBLESHOOTING

Optional water fill kit.

Close door.

Close door and set timer

to 30 minutes

Look for temperature rise on

the dial temperature guage

Water fills to high water probe

Power light illuminates.

After 15 seconds timing light illuminates and fan operates

Heats to 200 + degrees in

22 +/- 5 minutes

High water probe

Control board

Water fill solenoid valve

Incorrect wiring

If no power light or timing

light, but fan operates;

check door switch

If no power light or timing

light, but fan operates;

check control board

If fan does not operate with

power light and timing light

illuminated, check items below

Start capacitor

Internal thermal protector on

fan motor

Fan Motor

Control board

Incorrect wiring

Hi-limit 2 (auto reset)

Water level board

Contactor K3

Probe measures open to ground

without water. Short probe wire

to ground to simulate water.

Substitute to test

Valve is normally closed.

When water is below High

probe, 24vac is applied to coil

of valve and it opens.

When water reaches high

probe, coil de-energizes.

Check per wiring diagram

Measure from J9 pin 1 to 2.

12vdc with door open, zero (low)

voltage with door closed. If voltage is not zero, check door

switch, door magnet,

light & timer board, wiring.

Substitute to test

Standard test

Measure black to white motor

leads. 35 +/- 20% ohms

Measure orange to brown motor

leads. 35 +/-20% ohms. Red to

blue 42 +/- 20% ohms

Substitute to test

Check per wiring diagram

Measure for continuity

normally closed

Red light indicates power to

board. Bypass to test. Disconnect

wire to L1, move wire from NO-2

to NC-2, remove wire from H and

NO-1 and jumper these two

wires together.

Verify 24vac across K3 Coil.

Measure amperage through

heater wires and compare to

chart on Page 6.

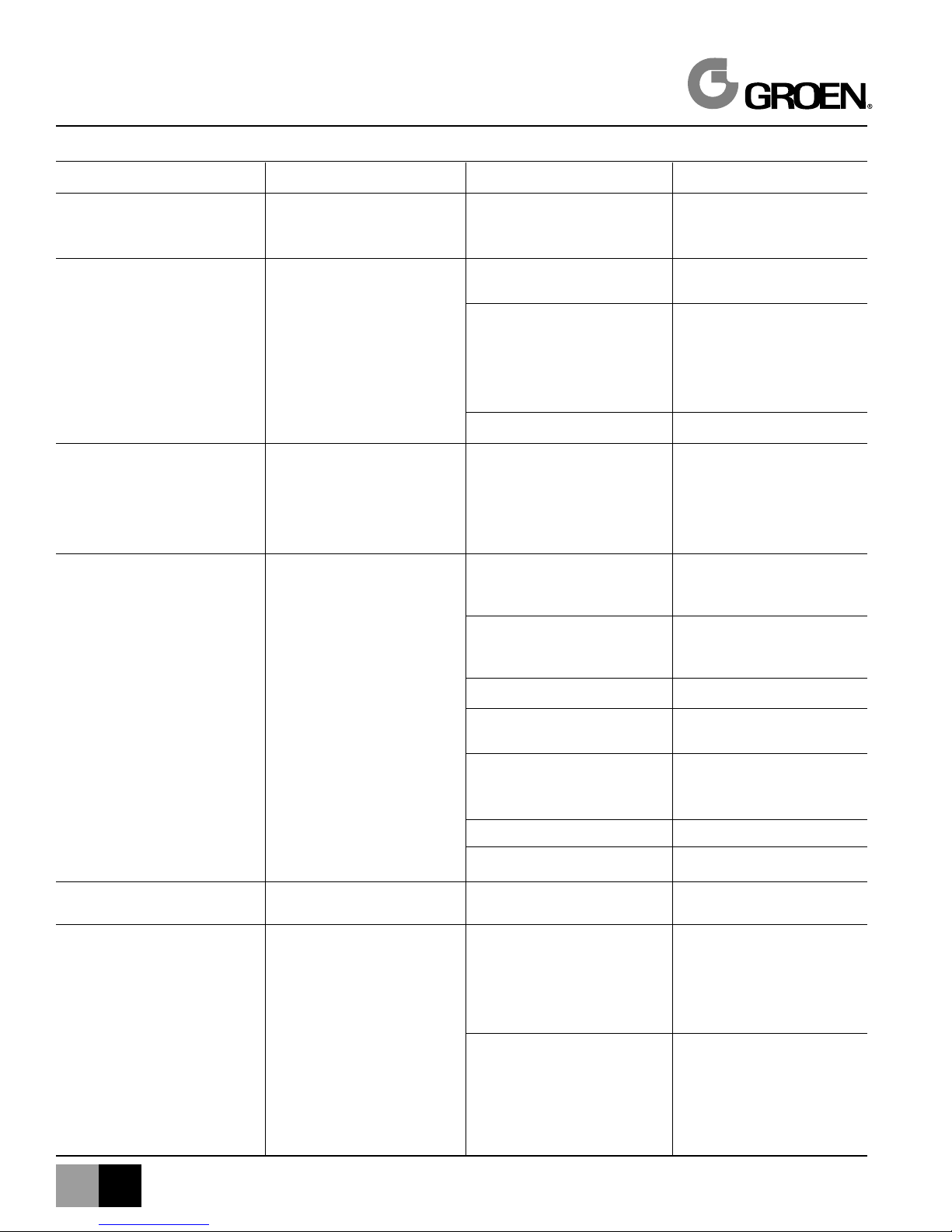

SETUP EXPECTED RESULTS PROBABLE DEFECT TEST or COMMENTS

Page 20

4

Call 1-800/676-9040 for Technical Support

4

TROUBLESHOOTING

Look for temperature rise on the

dial temperature guage

Set timer to one minute

Set timer to on

Cool to slightly below 180

degrees and set timer to hold

*Specials may have hold temps

from 150 to 200 degrees

Heats to 200 + degrees in

22 +/- 5 minutes

No defect found but customer

complaint is that unit is slow

to heat

Timer times out, done light

illuminates, and unit beeps

until door is opened or timer is

changed to another setting

On light illuminates

When the temperature is

180 =/-5 degrees, the hold

light illuminates

Heater element

Incorrect wiring

Customer may be opening

door frequently to add or remove

food

Timing mode heats fastest.

On mode operates at a slightly

lower temperature. Hold mode

comes up to temperature more

slowly and maintains a

temperature of 180 degrees

Timer

Control board

Light and timer board

Incorrect wiring

Timer

Control board

Incorrect wiring

Timer

Control board

Hold resistor

Incorrect wiring

Measure amperage for each

leg and compare to the chart

on Page 6. If amperage is

incorrect, disconnect power,

measure heater resistance (cold),

and compare to the

chart below. If resistance is not

within 20% of specified,

replace heater element

Check per wiring diagram

Talk with customer

Talk with customer

Substitute to test

Substitute to test

Substitute to test

Check per wiring diagram

Substitute to test

Substitute to test

Check per wiring diagram

Substitute to test

Substitute to test

J8-3-4 100k ohms +/- 2%

Check per wiring diagram

SETUP EXPECTED RESULTS PROBABLE DEFECT TEST or COMMENTS

CONGRATULATIONS!

The unit is operating correctly.

Page 21

5

Call 1-800/676-9040 for Technical Support

4

TROUBLESHOOTING

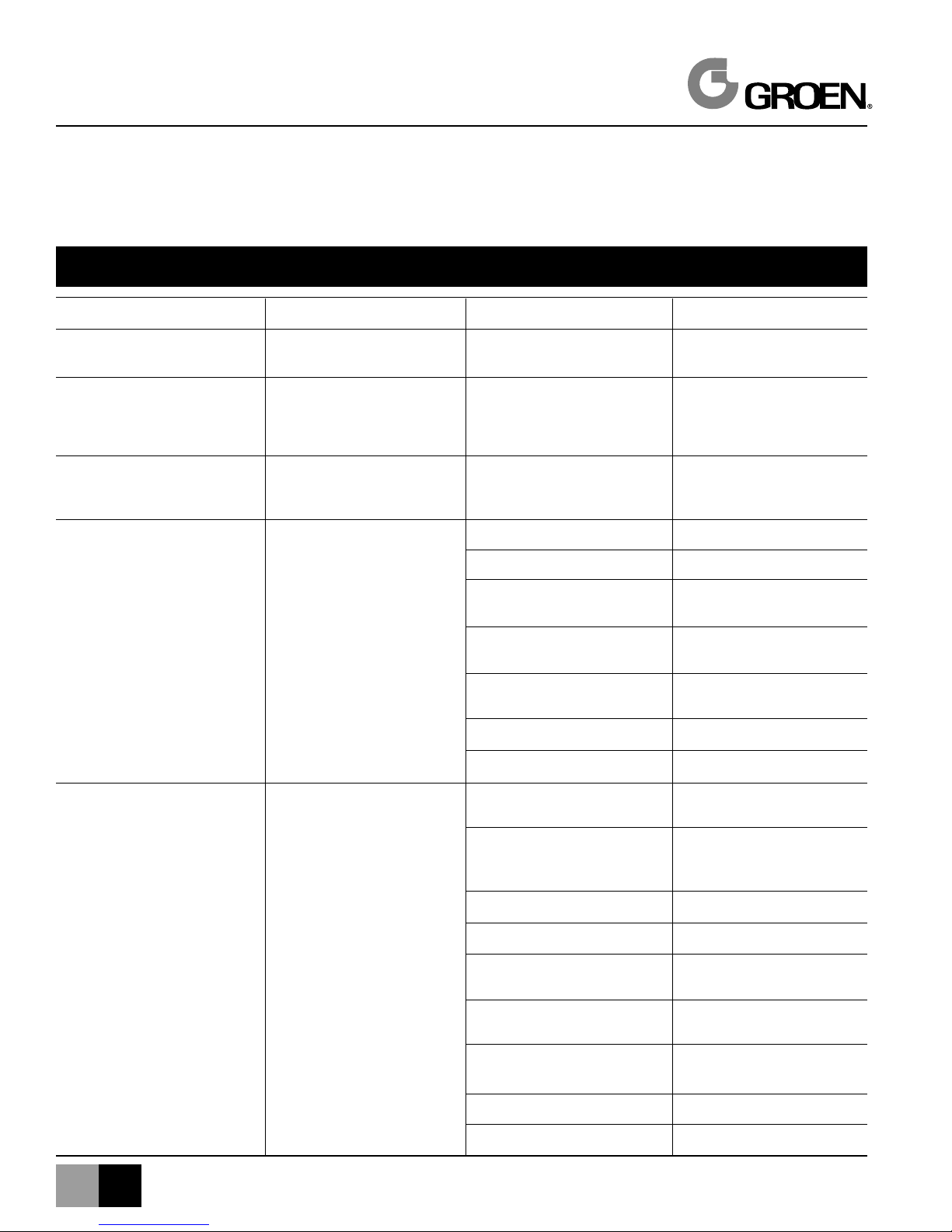

AMPERAGE / RESISTANCE CHART

Model / Voltage / Phase* Amperage Resistance

VRC-6E 208 Three Phase 33.3 10.5

VRC-6E 240 Three Phase 28.8 14.5

VRC-6E 480** Three Phase 14.4 19.5

VRC-6E 208 Single Phase 57.7 10.5

VRC-6E 240 Single Phase 50 14.4

VRC-3E 208 Three Phase 25 14.5

VRC-3E 240 Three Phase 21.7 19.5

VRC-3E 480 Three Phase 10.8 77

VRC-3E 208 Single Phase 43.2 14.5

VRC-3E 240 Single Phase 37.5 19.5

*Special units use VRC-6E elements in a VRC-3E and vice versa

** The voltage applied to the unit is 480, but the elements are wired so each operates on 277VAC

HOLD RESISTOR CHART

Hold Resistance

Temperature in K ohms

150 28.7

160 46.4

170 68.1

180 100

190 140

200 200

Page 22

5

Call 1-800/676-9040 for Technical Support

i

SECTION 5

ASSEMBLY / DISASSEMBLY

Table of Contents

Page

5.1 AIR TEMPERATURE PROBE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 CAVITY VENT ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3 CONTROL PC BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.4 DOOR REMOVAL/LNSTALLATION/ALIGNMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.5 DOOR SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.6 DOOR REVERSING PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.7 DOOR GASKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.8 DOOR SPRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.9 DOOR LOCKING PIN AND LOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.10 DRAIN VALVE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.11 FAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.12 HEATER ELEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.13 HI-LIMIT THERMOSTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.14 LEGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.15 LIGHT AND TIMER BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.16 MOTOR, FAN ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.17 MOTOR, STARTING CAPACITOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.18 PANEL BACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.19 PANEL LEFT SIDE / RIGHT SIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.20 PANEL,TOP COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.21 REMOTE READING THERMOMETER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.22 TIMER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.23 WATER LEVEL PROBES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.24 WATER FILL DRAIN KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Page 23

1

Call 1-800/676-9040 for Technical Support

5

5.1 Air Temperature Probe

Removal

1. Turn off the steamer power and disconnect the steamer

from the branch circuit.

Note: an incorrectly installed air

temperature probe MUST be replaced.Trying to operate the

steamer with a bent or crushed probe will result in improper

steamer operation.

2. Check to make sure the air temperature probe is not bent or

crushed and is installed through the opening in the probe

mounting bracket.There must be a 1/8”to 1/4" air gap

between the probe tip and the probe mounting bracket.

If the probe is bent, it must be replaced. If the probe tip

location is not within the 1/8" to 1/4" air gap required,

remove the air probe and correctly re-install it.

3. Remove the right and left covers from the steamer.

4. Disconnect the air temperature probe electrical leads from

the probe harness.

5. Loosen the probe compression nut.

6. Remove the air temperature probe. Note: Slide probe

through hole in rear cover to remove. lf the male fitting was

removed with the probe and compression nut, remove it

from the probe.The probe and compression nut are an

assembly.

Installation

7. If the air probe guard is not in place, one will have to be

installed. Order all of the component parts required using

the illustration shown.

8. lf a new guard assembly is being installed, install the guard

assembly, air temperature probe fitting, fiber washer,

stainless steel washer, and nut as shown in the illustration.

9. Install the new air probe and compression nut assembly.

Be careful not to bend the probe as you insert it through

the steamer wall and on through both ends of the

mounting bracket.

10. Connect the probe wires to the harness.

11. Replace the back, left and right covers.

12. Connect the steamer to the branch circuit.

13. Turn on the steamer power and test the steamer.

ASSEMBLY / DISASSEMBLY

WARNING

Be sure the steamer is disconnected from the branch circuit power

before performing any repair work.

Page 24

5

Call 1-800/676-9040 for Technical Support

2

ASSEMBLY / DISASSEMBLY

5.2 Cavity Vent Assembly

P/N 140867 - Pressure Relief Valve

Removal

1. Turn off the steamer power and disconnect the steamer

from the branch circuit.

2. Remove the left side panel.

3. Loosen the two (2) hose clamps.

4. Remove the hose from the hose fittings.

5. Unscrew the assembly from the nipple attached to the cavity.

Installation

6. Thread the new assembly onto the nipple attached to the

cavity.

7. Replace the hose and hose clamps.

8. Replace the left side panel.

5.3 Control PC Board - P/N 140792

Removal

1. Turn off the steamer power and disconnect the steamer

from the branch circuit.

2. Remove the three keps nuts and remove the clear plastic

control cover.

3. Unplug all the connectors attached to the control board.

4. Using a 1/4" socket, remove the 1-1/4" long standoffs at

the top and bottom of the board.

5. Using a 5/16" socket, remove the three 6/32 lock nuts and

remove the board from the five studs on the front panel.

6. Remove the voltage select jumper plug and save it for

installation on the new control board.

Installation

7. Install the voltage select jumper plug on the control board.

8. Position the control board on the five studs below the timer.

9. Thread the 1-1/4" long standoffs onto the studs at the top

and bottom of the board. Use a 1/4" socket to tighten them

in place.

10. Install the 6/32 lock nuts onto the other three studs. Use a

5/16" socket to tighten them in place.

11. Plug in the connectors. Press firmly to make sure the jack is

fully seated on the control board.

12. Install the clear plastic control panel cover over the timer

and control board and secure with the three 6/32 keps nuts.

13. Re-connect the branch circuit power supply.

13. Push the "ON" button and test the steamer.

5.4 Door Removal/lnstallation/Alignment

P/N 130858 Door Assembly for VRC-3E

P/N 140749 Door Assembly for VRC-6E

Removal

1. Turn the steamer "OFF" and allow it to cool.

2. Remove the door by supporting its weight and removing the

hinge pin.

3. Place the door on a flat surface gasket facing up. Be sure

not to scratch the door surface.

4. Inspect the door gasket for signs of cuts or other defects

that may impair its function. Replace if necessary.

Installation

5. To install the door, apply

NEVER-Seez lubricant to the

hinge pin. Align the door with

the hinge and insert the pin.

Apply serviceable Locktite 242

to the door-to-hinge bolts,

and then install the door and

mounting bolts. Do not tighten

the mounting bolts at this time.

Alignment

6. Place a piece of masking tape over the door pinhole in the

door channel.

7. Close the door until the door pin just penetrates the

masking tape.

8. If the door pin does not strike the center of the masking

tape, loosen the hinge-to-steamer bolts and align the door to

the door pin. Tighten the hinge-to-steamer mounting bolts.

9. You should be able to pull a dollar bill or comparable piece

of paper smoothly between the gasket and the steamer

cavity with the door closed. To adjust the hinge side, loosen

the door-to-hinge bolts and align the door gasket with the

steamer cavity.Tighten the door-to-hinge mounting bolts.

To adjust the door bullet side see page 5-14.

10. Turn the steamer "ON" and check for leaks.

Page 25

3

Call 1-800/676-9040 for Technical Support

5

5.5 Door Switch - P/N 096857

Removal

1. Turn off the steamer power and disconnect the steamer

from the branch circuit.

2. Remove the right side cover from the steamer.

3. Disconnect the door switch harness from the control board.

4. The switch is held in place by two slotted screws. Removing

these two screws will allow the removal of the switch.

5. If the door has been reversed, remove the left side cover

and follow the instructions above.

Installation

6. Secure the new switch with the two slotted screws.

7. Plug in the door switch harness into the control board.

8. Replace the side cover.

9. Reconnect the branch circuit power supply.

10. Turn “ON” the steamer and test for proper operation.

5.6 Door Reversing Procedure

1. Turn OFF the power to the steamer.

2. Support the door while removing the hinge-to-steamer

bolts.

3. Place the door, with the hinge on a flat clean table, and the

gasket face up.

4. Note the distance between the lock nut and the end of the

door-locking pin (bullet).This information will be needed

later on in step 6.

5. Loosen the lock nut, and then remove the door bullet and

lock nut.

6. Coat the bullet threads with a few drops of Locktite 242.

Install the bullet and lock nut directly across the steamer

cavity from the old bullet location. Install these two items

so that the lock nut to end of the bullet distance is

approximately the same as measured in step 4.

7. Remove the two screws from above and below the old

bullet location and install them above and below the new

bullet location.

8. Remove the screws and U-channel from the door.Take the

magnet and block assembly from the present location and

place it at the opposite end of the door channel, with the

magnet facing outward from the door.

9. Remove the two screws holding the door handle and cam.

10. Apply NEVER-SEEZ high temperature (1800 degree F)

anti-seize and. lubrication compound to the cam and a few

drops of Locktite 242 to the door handle screw threads.

11. Turn the handle and cam 180-degrees from their original

position and install them on the door with the screws. Be

sure the handle and can move smoothly.

12. Be sure the door handle and door cam are in the DOWN

position. Turn the U-channel 180-degrees from, its original

position, hold the door spring in the U-channel open with a

screw driver or similar tool, and install the U-channel being

sure the door spring is seated over the cam.

13. Check the operation of the cam. Push UP on the door handle

and check if the spring opens. If the spring does not open,

the cam and spring are NOT correctly aligned and the

problem must be corrected.

14. Apply a light amount of Locktite 242 to the screws, then

install them to hold the U-channel in place.

15. Apply Locktite 242 to the hinge-to-steamer bolts, and then

install the door and hinge mounting bolts. Do NOT tighten

the mounting bolts at this time.

16. Align the door to the steamer as described in the

“Alignment Procedure” page 5-7.

17. Replace the right side cover.

18. Turn on the power to the steamer.

19. Close the steamer door and operate the steamer. If the fan

does not operate, check the location of the door magnet

and be sure the alternative door switch was connected.

23. With the door closed and the steamer in the “ON” position,

or the timer running, the “READY”light should come on in

15 to 20 minutes.

24. Once the steamer is up to “READY” check for leaks. If there

are no leaks then the steamer is ready for operation. If there

are leaks, recheck the door alignment and gasket installation.

5.7 Door Gasket

P/N 124849 VRC-3E

P/N 140748 VRC-6E

Removal

1. Turn OFF the steamer and allow to cool.

2. Remove the door following the procedure for “Door Removal”.

3. Position the door on a clean flat surface.

4. Remove the inner door panel, using a flat blade screwdriver,

and remove the screws.

5. Remove and discard the old gasket.

6. Clean the back of the inner door panel and remove all of

the old sealant.

ASSEMBLY / DISASSEMBLY

Page 26

Call 1-800/676-9040 for Technical Support

45

ASSEMBLY / DISASSEMBLY

Installation

7. Apply a RTV 732 or equivalent, to the door spacers.

8. Install the new door gasket around the outer door panel on

the insulation board. Be sure the inner door panel flange is

fully inserted into the gasket groove.

9. Apply Locktite 242 to the threads of the inner door

mounting screws and tighten.

10. Align the door with the hinge and insert the pin or apply

Locktite 242 to the door-to-hinge bolts, then install the door

and mounting bolts. Refer to the section on “Door

Alignment” page 5-7.

5.8 Door Spring - P/N078911

Removal

1. Turn the steamer OFF and allow it to cool.

2. With a flat blade screwdriver, remove the two 8-32 truss

head screws on the door U-channel. Remove the U-channel

from the door.

3. Carefully remove the retaining ring from one end of the

spring support pin, and then remove the pin by moving the

pin to the left or to the right,

4. With a 3/8” nut driver, remove the 10-32-kep nut, lift the

square plate, then remove the spring.

Installation

5. Apply a high temperature anti-seize lubrication (Never-Seez

Apply Locktite 242 to the kep nut and install the kep nut.)

on the bottom of the U-channel surface that contacts the

spring.

6. Install the spring onto the brass roller, and then place the

square plate over the spring.

7. Apply Locktite 242 to the kep nut and install the kep nut.

8. Install the spring support pin, and then push the retaining

ring onto the pin, using a screwdriver.

9. Hold the door spring open with a screwdriver or similar tool,

hold the door handle in the down position and install the

U-channel, top end first, and then lower the channel into

position. Check that the spring opens when the door handle

is pushed up.

10. Apply Locktite 242 to the U-channel mounting screws and

install the screws.

5.9 Door Locking Pin

P/N 078914 Door Locking Pin

P/N 003823 Lock Nut

Removal

1. Turn off the steamer and allow it to cool.

2. Note and record the distance between the lock nut and the

door pin (bullet) from the front panel.

3. Loosen the lock nut and remove it and the door pin from

the front panel.

Installation

4. To install the door pin, coat the threads with a few drops of

Locktite 222.

5. Install the door pin with the lock nut to the front panel.

The lock nut to the end-of-the bullet distance should be

approximately the same as measured above, in step 2.

6. The position of the bullet should be such as to firmly retain

the door when closed.

7. The frictional force should be adjusted by turning the door

locking pin in or out accordingly.

8. The pressure should be such that a dollar bill or similar piece

of paper, when pulled out from between the door gasket

and the steamer cavity, requires some effort.

9. Tighten the lock nut down after the door tightness is

checked.

5.10 Drain Valve Assembly

WARNING

Be sure to drain all of the water

out of the water reservoir.

Removal

1. Turn off the branch circuit power to the steamer.

2. Remove the left side cover from the steamer.

3. Disconnect the drain actuator shaft from the drain

connection bracket, by removing the 3/8” hex nut.

4. Disconnect the drain connection bracket from the drain valve

by disconnecting the 1/4” hex nut from the valve stem.

5. Remove the drain valve by unthreading off the pipe nipple.

6. Remove the pipe extension from the drain valve.

Page 27

5

Call 1-800/676-9040 for Technical Support

5

ASSEMBLY / DISASSEMBLY

Installation

7. Attach the pipe extension to the drain valve.

8. Attach the drain valve to the pipe nipple attached to the

cavity.

9. Attach the connection bracket to the drain valve body, using

the 1/4” hex nut.

10. Attach the drain actuator shaft to the connection bracket,

using the 3/8” hex nut.

11. Fill the steamer water reservoir with water and check for

leaks.

12. Re-connect the steamer to the branch circuit power supply.

13. Turn “ON” the steamer and check for proper operation.

5.11 Fan - P/N 096790

Removal

1. Turn the steamer off and disconnected from the branch

circuit power, and open the door to allow it to cool before

proceeding.

2. Remove the support rack from in front of the fan.

3. With a 1/8”Allen wrench, loosen the setscrew that holds

the fan to the motor shaft.

4. Hold the fan and with a slight rocking motion, pull the fan

off the motor shaft.

Installation

5. Position the fan hub on the motor shaft so that the 1/8”

Allen set screw is over the flat on the motor shaft.

6. Slide the fan onto the motor shaft so that the motor shaft is

flush with the fan hub.

7. With a 1/8”Allen wrench, tighten the setscrew on the fan.

8. Turn the branch circuit power ON, and turn the steamer ON.

9. Install the support rack and check for any interference

between the fan and the support rack.

5.12 Heater Element

P/N 141078 208 Volts 12 KW VRC-6E

P/N 141400 240 Volts 12 KW VRC-6E

P/N 141401 480 Volts 12 KW VRC-6E

P/N 141075 208 Volts 9 KW VRC-3E

P/N 141079 240 Volts 9KW VRC-3E

P/N 141080 480 Volts 9KW VRC-3E

Alternative Heater Elements for the VRC-3E

P/N 142501 240 Volts 9 KW VRC-3E

P/N 142502 480 Volts 9 KW VRC-3E

Removal

1. Remove all power connections, drains lines, and fill lines

(if applicable). A stacked unit must be removed from its

location (top or bottom) in order to change the element.

2. Disconnect the element wires connected to the terminal

block.

3. Due to the location of the element and the limited space

available, you must turn the unit upside down.

4. Remove the two side panels.

5. Remove the base of the unit. The base is held in 4 places

attached to the legs.

6. Remove drain lever.This can be done by removing the nut

on the coupling at the valve.

7. Remove the plate support.

8. Remove all the insulation and holding brackets.

9. Remove the press plate and the lower heat sink plate.

10. Remove element and the upper heat sink plate.

11. Once the upper plate is removed, scrape away ALL the

Thermal Paste material from the bottom of the cavity. In

order to do this effectively, use a putty knife.

Page 28

5

Call 1-800/676-9040 for Technical Support

6

ASSEMBLY / DISASSEMBLY

Installation

12. Assemble the plate assembly DRY to be sure the orientation

of the assembly is correct and the correct sides of the plates

are marked.There is not enough paste supplied with the kit

to do the assembly twice. Disassemble to apply the Thermal

Paste.

13. Apply the Thermal Paste evenly to the bottom of the cavity

or top of upper aluminum heat sink plate. See the figure on

page 5-17. Thickness should be about 1/4” inch. Place the

upper heat sink plate in place on the bottom of the cavity.

14. Spread the Thermal Paste over both sides of the element.

It is easiest if disposable gloves are used.

15. Carefully place the element on the upper aluminum plate.

Ensure correct orientation of he element.

16. Place the lower aluminum heat sink plate on the element.

This plate has orientation studs.

17. Place the press plate on the lower heat sink plate.

18. Re-install the support brackets and insulation.

19. Enclose the assembly with the plate support cover.

20. Reinsert the drain lever and check for orientation.

21. Wire elements per wiring diagram. Note: 6-pan 480v

3 phased must be wired in a Y-configuration.

5.13 Hi-limit Thermostat - P/N 141661

The thermostat is attached to the center heater support bracket,

and is held on with two 6-32 x 3/8” long screws.

Removal

1. Turn off the steamer power and disconnect the steamer

from the branch circuit.

2. Unplug the two wires from the thermostat to the wiring

harness.

3. Using a short flat blade screwdriver, remove the two 6-32

screws holding the thermostat to the heater support bracket.

Installation

4. Seat the thermostat on the heater support bracket and

fasten with the two screws.

5. Plug the two wires from the thermostat into the wiring harness.

5.14 Leg Assemblies - P/N 43121

The leg assemblies are screwed into weld nuts attached to the

base assembly.

Removal

1. Turn off the steamer power and disconnect the steamer

from the branch circuit.

2. Raise the steamer up and support the weight of the steamer

3. Unscrew the leg assembly

Installation

4. Line up the threaded stud on the leg assembly with the weld

nut attached to the base, and screw the leg in until tight

5. Lower the steamer onto all four legs

6. Check the level of the steamer

Page 29

7

Call 1-800/676-9040 for Technical Support

5

ASSEMBLY / DISASSEMBLY

5.15 Light and Timer PC Board - P/N 137233

Removal

1. Remove the three kep nuts and remove the clear plastic

control cover.

2. Unplug the connector attached to the Light and Timer board.

3. Using a 1/4” socket, remove the 3/4” long standoff securing

the top of the board.

4. Using a 5/16” socket, remove the two 6-32 locknuts, and

then remove the board from the three studs attached to the

front panel.

Installation

5. Position the board on the three studs.

6. Thread the 3/4” standoff onto the top stud and use a 1/4”

socket to tighten.

7. Install the 6-32 lock nuts on the other two suds and

tightened with a 5/16” socket.

8. Insert the connector by pressing firmly to make sure the jack

is fully seated on the board.

9. Install the plastic cover over the control panel and the Light

and Timer board and secure the three 6-32 kep nuts.

10. Re-connect the branch circuit power to the steamer and test

for proper operation.

5.16 Fan Motor Assembly

P/N 096740 Fan Motor

P/N 096868 Motor Shaft Seal

P/N 096831 Oil Slinger Washer

Removal

1. Turn off the steamer power and disconnect the steamer

from the branch circuit.

2. Remove the support rack from in front of the fan.

3. With a 1/8”Allen wrench, loosen the setscrew that holds

the fan to the motor shaft.

4. Hold the fan and with a slight rocking motion, pull the fan

off the motor shaft.

5. Using a 7/16” nut driver, remove the four 1/4”-20 kep nuts

holding the motor. Note that one of the nuts secures the

motor ground strap to the steamer.

6. Remove the motor mounting plate to which the motor is

attached.

Installation

7. Make sure the motor insulation is installed on the four

threaded studs to the cavity wall.

8. Apply lubrication on both sides of the steamer motor seal

and inside the hole.

9. Insert the steamer motor seal in the cutout of the insulator

board.

10. Slide the oil slinger washer onto the motor shaft, about 1/2”

down the shaft.

IMPORTANT

The oil slinger washer has a rubber

surface and a phenolic surface.

Make sure the phenolic surface is

facing the motor.

11. Install the seal holder plate onto the motor shaft. Carefully

slide the seal holder plate on the motor shaft until it

engages the oil slinger washer. Continue sliding the plate on

the motor shaft until it rests on the raised bosses of the

motor casing.

12. The rubber surface on the oil slinger washer should be in

contact with the seal holder plate and there should be

approximately 1/16” gap between the phenolic surface and

the motor.

13. Attach the motor mounting plate to the motor with the

6-32 screws.

14. The entire assembly can now be positioned on the four

mounting studs protruding from the cavity wall.Tighten the

motor assembly with the 1/4” kep nuts using a 7/16” nut

driver. Make sure the green ground strap is fastened by one

of the kep nuts securing the motor.

Page 30

5

Call 1-800/676-9040 for Technical Support

8

ASSEMBLY / DISASSEMBLY

5.17 Motor Starting Capacitor - P/N096813

Removal

1. Turn off the steamer power and disconnect the steamer

from the branch circuit.

2. Loosen the two screws holding the motor capacitor.

3. Loosen the rubber boot from the capacitor and pull the boot

clear of the wire terminals.

4. Unplug the two wires from the capacitor. Remove the

capacitor.

Installation

5. Install and tighten the two screws holding the capacitor to

the mounting plate.

6. Plug in the terminal wires to the capacitor, and slide the

rubber boot over the wire terminals.

7. Re-connect the branch circuit power and test the steamer

for proper operation.

5.18 Back Panel

P/N 140444 Back Panel VRC-3E

P/N 140764 Back Panel VRC-6E

Removal

1. Turn off the steamer power and disconnect the steamer

from the branch circuit.

2. Remove the right, left and top panels (as described in Items 5).

3. Then remove the single 10-32 screw holding the cavity vent

to the back panel and the two screws at the bottom of the

panel.

4. Support the electrical control assembly that is attached to

the back panel.

Installation

5. Hold the back panel in-place and replace the two 10-32

screws on the bottom edge of the panel.

6. Re-attach the cavity vent assembly with the single 10-32

screw.

7. Replace the top, left and right side panels.

8. Turn on the electrical power the steamer.

5.19 Right Side Panel and Left Side Panel

P/N 140447 Right Side Panel VRC-3E

P/N 140448 Left Side Panel VRC-3E

P/N 140761 Right Side Panel VRC-6E

P/N 140762 Left Side Panel VRC-6E

Removal

1. Turn off the steamer power and disconnect the steamer

from the branch circuit.

2. With a flat blade screwdriver remove the three 10-32

screws, two on the bottom edge and one on the top edge.

The panel is retained to the front edge of the steamer by a

tongue and groove and by a spring-like clamp on the back

and bottom edges.

3. Once the screws are removed slide the panel towards the

front with a lifting motion. Do not attempt to pry the panel.

Once the panel is free of the rear clips, the panel may be

lifted off.

Installation

4. When replacing the panel, press the rear edge inward so

that all of the spring-like clip will be retain the rear flange.

5. Make sure that the holes in the panel are in alignment with

the tapped holes in the steamer so that the replacement on

the screws will be easy and not damage the screws.

5.20 Top Panel

P/N 140760 Top Cover VRC-3E

P/N 123133 Top Cover VRC-6E

Removal

1. Turn off the steamer power and disconnect the steamer

from the branch circuit.

2. First remove the right and left side panels (as described in

item 5).

3. Remove the retaining bracket, which prevents the top from

sliding forward.

4. Slid the cover forward, and once clear of the spring-like clips

on the back and the front flange, the cover may be lifted off.

Installation

5. Hold down the center rear to engage the sprig-like clips and

slid the cover over the front flange.

6. Replace the two retaining brackets.

Page 31

9

Call 1-800/676-9040 for Technical Support

5

ASSEMBLY / DISASSEMBLY

5.21 Remote Reading Thermometer

P/N 141055 Remote Reading Thermometer

Removal

1. Turn off the steamer power and disconnect the steamer

from the branch circuit.

2. Remove the left and right side panels.

3. On the left side, remove the 5/8” compression hex nut

holding the capillary bulb in place.

4. Push the capillary bulb out from the inside of the cavity.

5. Pull the capillary over the top of the cavity to the right side.

6. With a small flat blade screw driver, remove the (3) pan

head 6-32 x 3/8” long screw that holds the face or the

thermometer to the front panel.

7. Pull the gauge and capillary out through the hole in the

front panel.

Installation

8. Pass the bulb, capillary and gauge through the opening in

the front panel.

9. Fasten the gauge to the front panel with the (3) pan head

6-32 x 3/8” long screw that holds the face of the

thermometer to the front panel.

10. Pass the bulb and capillary over the top of the cavity, and

insert the bulb into the fitting.

11. Tighten the compression nut to the bulb fitting.

12. Connect power and test operation, especially for leaks

around the capillary bulb.

5.22 Timer Assembly

P/N 141063 Timer

P/N 123100 Timer Knob

Removal

1. Turn off the steamer power and disconnect the steamer

from the branch circuit.

2. Pull to remove the timer knob from the timer. Under the

timer knob is the hex timer fastener nut, which holds the

timer to the steamer front panel. Note that there is a flat on

the timer shaft that corresponds to the frictional mounting

hole in the knob.

3. Remove the right side cover from the steamer.

4. Unplug the five terminal and two motor lead wires from the

timer.

5. With a 1/2”open ended wrench, remove the hex fastener

nut and remove the timer from inside of the electrical

compartment.

6.

Note: right below the timer shaft, the timer has a small round

plastic boss molded into the case.There is a corresponding

hole punched into the front panel. This hole may be seen

from the inside of the compartment when the timer is

removed.

Installation

7. Insert the new timer, with the round plastic boss fitted in the

hole in the front panel, and the timer shaft protruding

through the front panel.

8. Tighten the hex fastener nut, and align the flat in the timer

knob with the flat on the timer shaft and push the knob

firmly on the shaft until it is seated.

9. Attach the harness and motor wires.

10. Turn on the branch circuit power supply.

11. Turn ON the steamer and test.

5.23 Water Level Probes

Removal

1. Turn off the steamer power and disconnect the steamer

from the branch circuit.

2. Remove the right side cover from the steamer.

3. Disconnect the water level probe harness wire.

4. Loosen and remove the hex locking nut and washer.

5. Remove the water level probe from inside the cavity.

Installation

6. Insert the new water level probe through the opening from

inside the steamer cavity (be sure the o-ring seal is in place).

7. From the back, put on the washer and locking nut and

tighten to prevent any water leaks.

8. Attach the harness wire.

9. Turn on the branch circuit power supply.

10. Turn ON the steamer and test.

Page 32

Call 1-800/676-9040 for Technical Support

105

ASSEMBLY / DISASSEMBLY

5-24 WATER FILL-DRAIN KIT INSTALLATION

1. Remove all parts from shipping cartons.

2. Check-identify all parts as follow.

2.1 Water fill parts.

143122 Bulkhead fitting . . . . . . . . . . . . . . . . . . . . . .1

143123 Jam nut 5/8-18 . . . . . . . . . . . . . . . . . . . . . . .1

142562 Teflon washer . . . . . . . . . . . . . . . . . . . . . . . .1

142563 Elbow, 1/8NPT to 3/8” hose barb, brass . . . . .1

143148 Hose auto fill line 3/8”ID x 38” long . . . . . . .1

100934 Water valve . . . . . . . . . . . . . . . . . . . . . . . . .1

127523 Hose clamps . . . . . . . . . . . . . . . . . . . . . . . . .2

005764 Screw truss machine 8-32 thread . . . . . . . . . .2

2.2 Water Drain Parts

142549 Elbow 3/4 hose barb 90 deg . . . . . . . . . . . . .1

142550 Tee 3/4 hose barb . . . . . . . . . . . . . . . . . . . . .1

143246 Drain assembly, autodrain . . . . . . . . . . . . . . .1

143250 Hose long 3/4”ID x 10ft . . . . . . . . . . . . . . . .1

143254 Hose 3/8”ID x 30” long . . . . . . . . . . . . . . . .1

3 Water fill installation steps.

3.1 Turn off the steamer power and disconnect the steamer

from the branch circuit.

3.2 Remove left side panel from the unit.

3.3 Mark the hole center on the left side cavity wall. From the

thermometer bulb hole measure 2.5” down and 9.5” from

the rear of cavity as shown in the diagram.

3.3a Cut out a 3” square of insulation around the hole center.

3.4 Drill a 5/8” diameter hole. Note: make sure to remove all

burrs on both in and out side of the cavity, any burrs will

cause the fitting to leak.

3.4a Install bulkhead fitting and teflon washer from the inside

of the cavity, and thread jam nut from outside to hold in

place and seal, refer to drawing.

3.5 Thread brass elbow into the bulkhead fitting from outside

of the cavity with barb end pointing toward the back of the

unit as shown on the drawing.

3.6 On the back panel of the unit, locate the 1” diameter

pre-drilled hole and pop out the plug.

3.7 Install the water valve from inside of the unit with the 8-32

screws from outside thru the pre drilled holes.

3.8 Connect hose auto fill line to the outlet port on the valve

and to the brass elbow on the side of the unit thru the

hose clamps, see drawing. Use the tension hose clamps to

secure on both ends of the hose, one on the valve and the

other on the brass barb. Note, if you are installing the kit in

a span capacity unit cut hose to fit.

3.9 Connect the two hose electrical leads to the solenoid valve.

The leads are marked with WV-1 and WV-2.The wiring

harness has these two leads loose inside the unit.

4 Water drain installation steps.

4.1 The condensate drain line needs to be disconnected before

the left side cabinet panel can be replaced.

4.1a From the bottom of the unit just right of the drain valve

unscrew the condensate drip bracket.

4.1b From the inside, loosen the tension clamps and remove

the bracket from the hose and the hose from the

condensate line.

4.1c Slide the tension clamps off of the hose and use them on

next step.

4.1d Install one end of the supplied hose 3/8”ID x 30” long

on the condensate line where the condensate trap to

drain hose were installed before, pull the other end of the

hose through the hole where the bracket was mounted.

Reinstall the inside tension clamp.

4.2 Guide the hose loose end thru the uncovered hole to the

outside bottom of the unit as drawing shows.

4.3 Thread the hose drain assembly onto the unit drain valve,

see drawing.

4.4 Connect the 3/8” diameter x 30” long hose loose end to

the plastic barb fitting on the drain assembly and reuse

the other tension hose clamps.

4.4a If you are installing a kit on a 3 pan model cut this 3/8”

x 30” long hose to fit.

4.5 A 10ft piece of hose is supplied with this kit, it can be cut

to length and used with the elbow to help route the hose

to the proper drain location.

4.6 For single units cut the long hose to length as needed to

route it to facility drain. Note hose end must have at least

a 2” gap from the floor drain, do not use traps.

4.7 For double stack units, a 6.5” long piece of hose can be

cut to join the upper and lower cavities by using the

supplied tee on the bottom unit, the supplied elbow on

the top unit and a piece to connect the two cavities as

shown. Permit a 2” air gap from the floor drain. Do not

use traps.

5 Test to ensure the final assembly of the drain line

allows the water to flow freely.

Loops or kinks in the hose will cause back pressure which

may cause the door to pop open during draining.

Page 33

11

Call 1-800/676-9040 for Technical Support

5

ASSEMBLY / DISASSEMBLY

Item # Part # Description

1 142549 Elbow, 3/4” Hose Barb

2 141067 Chamber Assembly. Reference only

3 142550 Tee, 3/4” Hose Barb

4 140789 Back Panel - Reference Only.

5 143246 Drain Assembly, Autodrain Kit

6 143250 Hose, long 3/4”ID x 10 ft.

8 143123 Nut, Jam 5/8-18

9 142562 Washer, Teflon Autofill-drain Kit

Item # Part # Description

10 142563 Elbow, 1/8” NPT to 3/8”Hose Barb

11 143148 Hose, Autofill Line 3/8”ID x 38” long

12 100934 Water Valve

14 127523 Hose Clamp

15 005764 Screw, Truss Machine 8-32 Thread

16 143254 Hose, 3/8”ID x 30” long

17 143256 Bulkhead Fitting Assembly

A

CONNECT

TO WATER

SUPPLY

11

TO FACILITY

DRAIN

Page 34

6

Call 1-800/676-9040 for Technical Support

i

SECTION 6

PARTS IDENTIFICATION • VRC-3E

Table of Contents

Page

6.1 Cavity Vent Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Control Board and Wiring Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3 Door Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.4 Drain Valve Reset Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.5 Electrical Components 208 and 240 volts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.6 Electrical Components 480 volts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.7 Heater Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.8 Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.9 Probe Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.10 Interior & Exterior Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Page 35

No. Description Qty. Part No.

1* Pressure Relief Valve 1/2 PSI 1 140867

(Remove used plug if needing

to replace)

2 Fan Motor 1 96740

3 Exhaust Assembly 1 141512

4 Hose 1 142528

5 Constant Tension Band 2 127524

6 Clamp, Constant Tension 2 127523

7 Condensate Hose 9” 1 92124

8 Timer 60 Hz 90 Minute 1 141063

9 Drain Actuator Shaft 1 141074

10 High Probe 1 142689

11 Low Probe 1 142689

12 PC Control Board 1 140792

13 Air Temperature Probe 1 70187

14 Shaft Grip 1 141668

15 Remote Reading 1 141055

Dial Thermometer

*Not shown

1

Call 1-800/676-9040 for Technical Support

6

PARTS IDENTIFICATION • VRC-3E

6.1 Cavity Vent Assembly

Page 36

6

Call 1-800/676-9040 for Technical Support

2

PARTS IDENTIFICATION • VRC-3E

No. Description Qty. Part No.

1 Control Board 1 140792

2 Light and Timer Board 1 137233

3 Timer 1 141063

4 Timer Mounting Nut 1 101145

5 Timer Knob 1 123100

6* Standoff Male to Female

1-1/4” long 2 119827

7* Standoff Male to Female

3/4” long 1 119826

8* Washer, Nylon No. 6 8 126026

9 Control Panel Cover 1 119806

10 Lock Nut 6-32 5 119855

11 Door Switch 1 096857

12* Door Switch Harness 1 119878

13* Timer Motor Harness 1 123120

14* Pigtail Harness 1 125788

15* Voltage Selector Plug 1 123124

208/240 volts

16* Control Board to 1 123122

Display Board Jumper

17* Phase Jumper Wire 1 094155

3 Phase to 1 Phase

18* Transformer Jumper 1 123125

19* Fuses 6 amps 2 119823

*Not shown

6.2 Control Board and Wiring Harnesses

Page 37

3

Call 1-800/676-9040 for Technical Support

6

PARTS IDENTIFICATION • VRC-3E

No. Description Qty. Part No.

1 Outer Door Panel 1 130895

2 Gasket 1 124849

3 Inner Door Panel 1 130861

4 Truss Head Screws 6 005764

5* Hex Head Screws 2 005608

6 Door Handle 1 129723

7 Door Hinge 1 140755

8 Door Cam 1 074252

9 Latch Assembly 1 140752

10* Door Spacers 4 071206

11* Insulator Board 1 140754

12 Block and Magnet 1 069762

13* Never Seez Grease .01 oz. 074210

14* RTV 732 Sealant As Req’d 001711

15* Loctite 242 .01 oz. 073282

*Not shown

6.3 Door Assembly

Page 38

6

Call 1-800/676-9040 for Technical Support

4

PARTS IDENTIFICATION • VRC-3E

No. Description Qty. Part No.

1 Reset Switch 1 002982

2 Bracket, Micro Switch 1 142535