Page 1

MODEL T33949/T33950/T33951

CONCERT UKULELE KIT

OWNER'S MANUAL

(For models manufactured since 09/23)

COPYRIGHT © DECEMBER, 2023 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#JM22870 PRINTED IN CHINA

***Keep for Future Reference***

V1.12.23

Page 2

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State

of California to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Page 3

Table of Contents

INTRODUCTION ............................................................................................................................... 2

Contact Info

Description

Manual Accuracy

Identification

.................................................................................................................................2

..................................................................................................................................2

.........................................................................................................................2

................................................................................................................................3

SECTION 1: SAFETY

SECTION 2: SETUP

Unpacking

Planning & Preparation

Needed for Setup

Inventory

SECTION 3: SANDING

Body

Neck

Bridge

Fitting Neck to Body

SECTION 4: ASSEMBLY

Attaching Neck to Body

Installing Fretboard

Determining Bridge Location

Installing Nut

Preparing to Finish

Painting/Finishing

Installing Bridge

Fitting Bridge Pins

Installing Sound Hole Decal

Installing Tuning Machines

Installing Strings

Setting String Height

Tuning........................................................................................................................................21

Ukulele Setup

...................................................................................................................................5

......................................................................................................................................6

............................................................................................................................................7

............................................................................................................................................7

..........................................................................................................................................7

....................................................................................................................... 4

......................................................................................................................... 5

...............................................................................................................5

........................................................................................................................5

.................................................................................................................... 7

....................................................................................................................8

.................................................................................................................. 9

...............................................................................................................9

...................................................................................................................10

.....................................................................................................11

.............................................................................................................................13

....................................................................................................................14

......................................................................................................................14

.........................................................................................................................15

.....................................................................................................................16

......................................................................................................17

........................................................................................................18

........................................................................................................................18

.................................................................................................................19

............................................................................................................................21

SECTION 5: ACCESSORIES

SECTION 6: PARTS

...........................................................................................................................................23

Main

WARRANTY & RETURNS

....................................................................................................................... 23

.............................................................................................................. 25

......................................................................................................... 22

Page 4

INTRODUCTION

Contact Info

We stand behind our instruments! If you have

questions or need help, contact us using the information below. Before contacting, make sure you

gather all the information regarding your instrument. This will aid us in helping you faster.

Grizzly Technical Support

1815 W. Battleeld

Springeld, MO 65807

Phone: (570) 546-9663

Email: techsupport@grizzly.com

We want your feedback on this manual. What did

you like about it? Where could it be improved?

Please take a few minutes to give us feedback.

Grizzly Documentation Manager

P.O. Box 2069

Bellingham, WA 98227-2069

Email: manuals@grizzly.com

Description

Manual Accuracy

We are proud to provide a high-quality owner's

manual with your new instrument!

We make every effort to be exact with the instructions, specifications, drawings, and photographs

in this manual. Sometime we make mistakes, and

our policy of continuous improvement also means

that sometimes the instrument you receive is

slightly different than shown in the manual.

If you find this to be the case, and the difference

between the manual and instrument leaves you

in doubt, check our website (grizzly.com) for an

updated version. We post current manuals and

manual updates for free on our website.

Alternatively, you can call our Technical Support

for help. Before calling, gather all material and

instructions that came with your instrument for

easy reference. This will make providing you

proper technical support much easier. It also will

help us determine if updated documentation is

available for your instrument.

Grizzly ukulele kits are available in (3) different

veneer options:

—T33949 Hawaiian Koa

—T33950 Quilted Maple

—T33951 Fiddleback Maple

T33949

-2-

T33950

T33951

NOTICE

WE STRONGLY RECOMMEND that you read

books, review industry trade magazines,

or get formal training before beginning

any projects. Regardless of the content in

this Manual, Grizzly Industrial will not be

held liable for accidents caused by lack of

training.

Model T33949/50/51 (Mfd. Since 09/23)

Page 5

Identification

Become familiar with the names and locations of the features shown below to better understand the

instructions in this manual.

Sound

Board

Saddle

Bridge

Body

12th Fret

Sound Hole

Fret Inlay/

Markers

Headstock

Frets

Nut

Neck

Tuning

Machines

Fretboard

There is potential danger when operating

woodworking machinery. Accidents are frequently caused by lack of familiarity or failure to pay attention. Use any machines with

respect and caution to decrease the risk of

operator injury. If normal safety precautions

are overlooked or ignored, serious personal

injury may occur.

Strings

No list of safety guidelines can be complete. Every shop environment is different.

Always consider safety first, as it applies

to your individual working conditions. Use

tools and any machinery with caution and

respect. Failure to do so could result in serious personal injury, damage to equipment,

or poor work results.

Model T33949/50/51 (Mfd. Since 09/23)

-3-

Page 6

SECTION 1: SAFETY

Always wear safety glasses or goggles when operating equipment. Everyday glasses or reading glasses are not safety glasses. Be certain the safety glasses you wear meet the appropriate standards of

the American National Standards Institute (ANSI).

Because there are various ways to cut and join wood, you can make substitutions for the methods

stated in this plan. We try to suggest the easiest methods possible. However, only you know your skills

with each piece of machinery. Never compromise your safety by using a cutting method with which you

are not comfortable. Instead, find an alternative approach that will yield the same result.

These instructions assume that you are intimately familiar with the safe operation and use of woodworking machinery and woodworking tools, and understand the techniques used to reproduce this project.

If you do not qualify for both of these criteria, STOP building this project for your own safety. Read and

understand the owner’s manual for the machinery you intend to use, take a woodworking class or visit

your local library for more information. Woodworking machinery and tools are inherently dangerous,

because they use sharp edges that can and will cause serious personal injury including amputation

and death. Do not underestimate the ability of these tools and machinery to cause injury. Never operate any tool without all guards in place and always wear approved safety glasses. For your own safety,

please heed this warning.

-4-

Model T33949/50/51 (Mfd. Since 09/23)

Page 7

SECTION 2: SETUP

Unpacking

This instrument was carefully packaged for safe

transport. When unpacking, separate all enclosed

items from packaging materials and inspect them

for shipping damage. If items are damaged,

please call us immediately at (570) 546-9663.

IMPORTANT: Save all packaging materials until

your are completely satisfied with the instrument

and have resolved any issues between Grizzly or

the shipping agent. You MUST have the original

packaging to file a freight claim. It is also extremely helpful if you need to return your instrument.

Wear safety glasses during

the entire setup process!

Planning &

Preparation

Total time building this instrument will vary on

many factors. Variables such as glue manufacturer's instructions and curing time, temperature and

humidity at the time of building, and your schedule

are just a few of the factors that can affect the

length of time spent on this project.

Perhaps the biggest determinant of time spent

completing this instrument will be the type of finish and the finishing process used. Finishing this

instrument can be as simple as applying a single

coat of stain or lacquer that can be done relatively quickly, up to a multi-coated finish that takes

weeks to harden.

Careful planning and budgeting ample time will

make this project easier and ensure you end up

pleased with your results. Good luck building your

instrument, and Grizzly hopes it turns out looking

and sounding great.

Needed for Setup

The majority of the wooden components in this kit

are fully machined from the factory and are ready

for assembly. A small amount of sanding and finishing is required to complete your ukulele.

Description Qty

• Safety Glasses (per person)....................... 1

• NIOSH-Approved Respirator (per person) ... 1

• Ratchet or Frame Clamp ............................ 1

• Hobby Knife or Chisel ................................ 1

• T-Handle Reamer (1⁄8" to 5⁄8") ..................... 1

• Drill Press or Cordless Drill w/Depth Stop .. 1

• Forstner Bit 5⁄32" .......................................... 1

• Sanding Block ............................................ 1

• Band Clamp ................................................ 1

• Fine Tooth Saw (Coping, Fret, or Curved) ..... 1

• Bridge Clamp (4" Minimum) ....................... 1

• Straightedge (18" Minimum) ....................... 1

• Small File (Fine) ......................................... 1

• 2" x 2" x 18" Wood Stock ........................... 1

• Pencil .......................................................... 1

• Phillips Head Screwdriver #0 ....................... 1

• Wire Cutters ............................................... 1

• Fine Ruler ................................................... 1

• Thread or Thin String ................ As Needed

• Disposable Nitrile Gloves ........... As Needed

• Wood Glue ................................. As Needed

• Super Glue ................................. As Needed

• Finishing Supplies ...................... As Needed

• Wood Filler/Putty ........................ As Needed

• Tack Cloth................................... As Needed

• Lint-Free Rags ............................ As Needed

• Sandpaper #180, #240, #320,

#800, #1000 ............................... As Needed

• Masking or Painter's Tape .......... As Needed

• C-Clamps (3" Minimum) ............. As Needed

• Masking Paper ........................... As Needed

• Rubber Bands ............................ As Needed

• Tuning Fork (Optional) ................................ 1

• Palm Sander (Optional) .............................. 1

• Binding Tape (Optional) .............. As Needed

Model T33949/50/51 (Mfd. Since 09/23)

-5-

Page 8

Inventory

The following is a list of items shipped with your

instrument. Before beginning assembly, lay these

items out and inventory them.

If any non-proprietary parts are missing (e.g.

strings, or tuning machine screws), we will gladly

replace them; or for the sake of expediency,

replacements can be obtained at your local music

shop.

Ukulele Components (Figure 2) Qty

C. Fretboard .................................................... 1

. Saddle Bridge ............................................. 1

D

. Nut .............................................................. 1

E

. Tuning Machine Screws ............................. 4

F

. Pins............................................................. 4

G

. Strings ........................................................ 4

H

. Bridge ......................................................... 1

I

. Tuning Machine Seats ................................ 4

J

. Tuning Machines ........................................ 4

K

. Decal .......................................................... 1

L

. Tuning Machine Washers ........................... 4

M

Body and Neck (Figure 1)

. Body ........................................................... 1

A

. Neck ........................................................... 1

B

A B

Qty

C

D

F

I

K

M

Figure 2. Ukulele components.

Bridge Template (Figure 3) Qty

Bridge Template ......................................... 1

N.

N

J

E

GH

L

Figure 1. Body and neck.

NOTICE

If you cannot find an item on this list, carefully check around/inside the machine and

packaging materials. Often, these items get

lost in packaging materials while unpacking or they are pre-installed at the factory.

-6-

Figure 3. Bridge template.

Model T33949/50/51 (Mfd. Since 09/23)

Page 9

SECTION 3: SANDING

Body

The ukulele body was assembled and rough

sanded at the factory. However, no finish has

been applied. The joint where the neck meets the

body and the sound hole should NOT be sanded.

For best appearance be careful not to round the

edges of the ukulele body.

To sand body:

1. Sand body with #180-grit aluminum-oxide

sandpaper until there is a consistent scratch

pattern on entire surface.

Note: When hand sanding, always sand in

same direction as wood grain.

Repeat Step 1 with #240-grit sandpaper.

2.

3. Repeat Step 1 with #320-grit sandpaper.

Neck

Like the ukulele body, most of the ukulele neck

has been machined and rough sanded at the

factory. However, the neck headstock can be customized to reflect personal taste. Additional cutting, inlay, or design work can give a ukulele that

personalized custom look that makes it unique.

Note: If you do choose to customize the neck

area, take your time with this sub-section and

consider testing ideas on scrap wood before performing the work on the actual headstock.

To sand neck:

1. Perform any custom cutting, inlay, or design

work to neck headstock.

2. Using sanding technique described in Body

section, sand ukulele neck.

Wipe body with a damp, lint-free cloth. Wiping

4.

workpiece with a damp cloth before final

sanding helps to "raise" wood grain; thus,

allowing "raised" grain to be sanded smooth.

Once body is dry, repeat Step 4.

5.

Wipe body with a tack cloth to remove all

6.

remaining sanding dust.

To reduce risk of eye injury from airborne

particles or lung injury from breathing dust,

always wear safety glasses and a respirator

when sanding.

Note: DO NOT sand fretboard mounting sur-

face. This will affect playability of ukulele and

could lead to irreparable damage.

Bridge

The bridge has been sanded and finished at the

factory. Sanding and finishing the bridge is not

nec essary.

Model T33949/50/51 (Mfd. Since 09/23)

-7-

Page 10

Fitting Neck to Body

4. Sand until neck profile matches ukulele body

profile (see Figure 6).

Attaching the neck to the ukulele body is the most

crucial part of the assembly process. Attaching

the neck incorrectly could result in difficult bridge

and string adjustments. Additionally, it can exert

stress on the instrument that could lead to irreparable damage.

The neck will need to be shaped by sanding

before it is ready to attach.

To sand neck:

1. Attach sandpaper with masking or painter's

tape at location shown in Figure 4 below.

Masking

Tape

Sandpaper

Note: DO NOT sand fretboard mounting sur-

face. Sanding fretboard mounting surface will

affect playability of ukulele and could lead to

irreparable damage.

Figure 6. Neck and body flush.

5. Wipe ukulele neck with a damp, lint-free cloth

and let dry.

Wipe ukulele neck with a tack cloth to remove

6.

all sanding dust.

. Test fit neck to body.

7

Figure 4. Body masked for neck sanding.

2. Lay body face down on flat, level surface.

3. Gently sand neck where it will mate with body

(see Figure 5).

Note: Keep neck aligned straight to body

when sanding.

Figure 5. Sanding neck.

— If neck is flush to body, sanding is complete.

Proceed to Assembly on Page 9.

— If neck is not flush to body, repeat

Steps 3–7 until a flush mount is achieved.

-8-

Model T33949/50/51 (Mfd. Since 09/23)

Page 11

SECTION 4: ASSEMBLY

Attaching Neck to

Body

As noted earlier, attaching the neck to the ukulele

body is the most crucial part of the assembly

process.

Make sure you have shaped the mounting surface of the ukulele neck as explained in Fitting

Neck to Body on Page 8 before attempting

to attach it to the ukulele body.

ALWAYS follow adhesive manufacturer's

instructions for your safety and best results.

To attach ukulele neck to body:

1. Place ukulele body and neck face down on

workbench.

2. Place layer of masking or painter's tape

lengthwise down center of back of ukulele

(see Figure 7), and trim flush at endpoints.

3. Repeat Step 2 for back of neck (see Figure 7).

5. Use a pencil to lightly draw center line over

masking tape on ukulele neck and back

(see Figure 7).

6. Apply a thin, even layer of wood glue to mat-

ing surfaces of ukulele body and neck.

Align center lines (see Figure 7).

7.

Masking

Tape

Ruler

Figure 7. Marking center line of ukulele body

and neck.

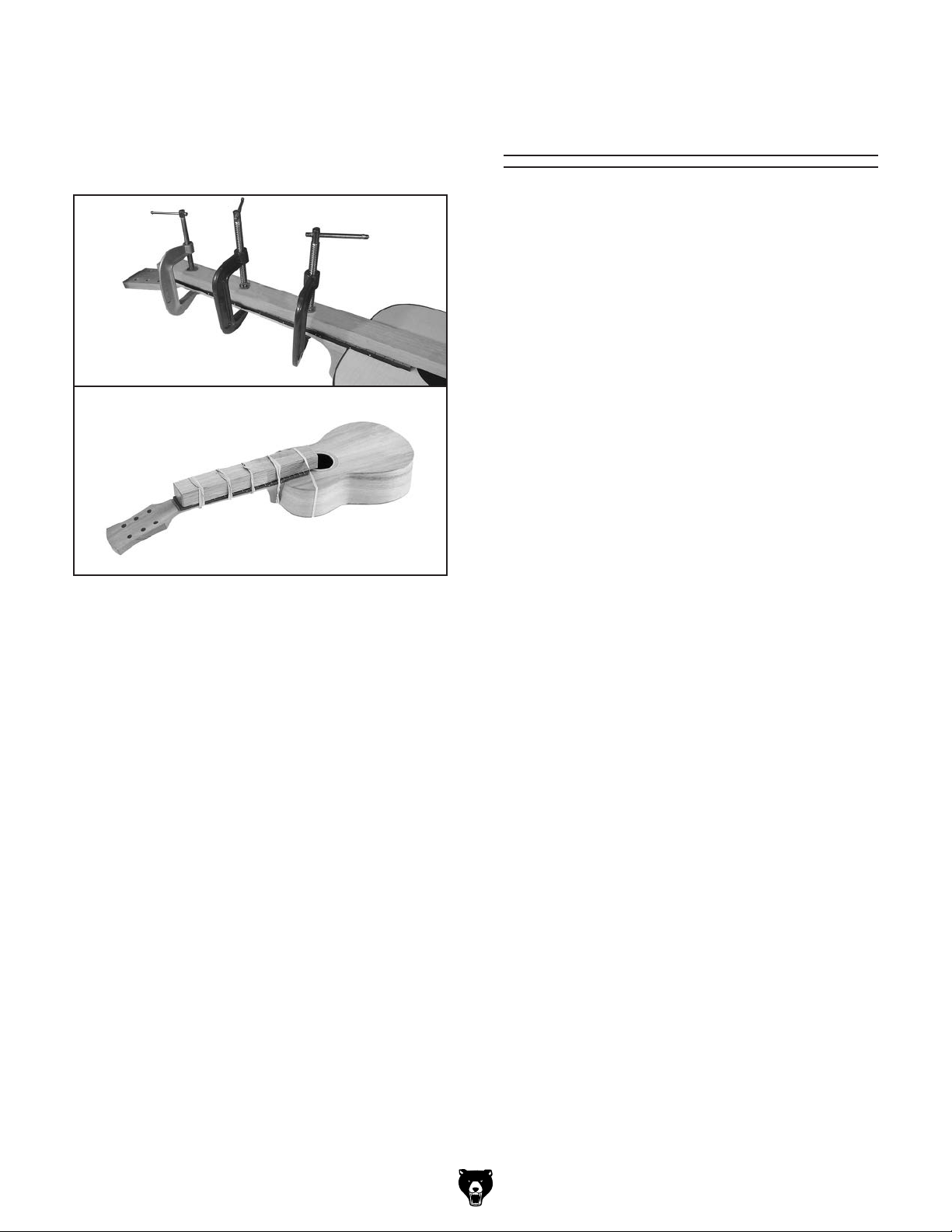

8. Use a ratcheting band clamp, or binding tape,

to secure ukulele body and neck together

(see Figure 8) and let assembly dry for at

least 24 hours.

Center Line

4. Using a ruler, measure to determine center line

of both ukulele back and neck (see Figure 7).

Model T33949/50/51 (Mfd. Since 09/23)

Note: If possible, clamp both ukulele and

neck in position on work surface, and wipe

away any excess glue immediately. Failure to

do so can mar finish in this area.

Figure 8. Neck and body secured with band

clamp.

-9-

Page 12

9.

Headstock

Use a fine tooth saw or hobby knife to remove

excess neck material that protrudes below

body of ukulele (see Figure 9).

Ukulele

Body

Figure 9. Excess neck material and cut line.

Neck

Cut Line

Excess Neck

Material

2. Lightly sand top face of neck with #120-grit

sandpaper.

Note: Try to avoid sanding body while sand-

ing top face of neck.

3. Remove sanding dust from both pieces with

tack cloth.

4. Apply a thin layer of wood glue to back of

fretboard and position it on neck.

5. Make sure fretboard is centered across width

of neck, and 14th fret is positioned over neckto-body joint (see Figure 10).

10. Using #320-grit sandpaper, sand bottom of

neck until smooth with bottom of ukulele.

11. Wipe bottom of ukulele neck with a damp,

lint-free cloth and let dry.

Wipe ukulele bottom and cut line with tack

12.

cloth to remove all remaining sanding dust.

Installing Fretboard

With the major components sanded, the fretboard

is ready to be installed on the neck and body.

To install fretboard:

1. Lay a sheet of #120-grit sandpaper on flat

surface and gently sand back of fretboard.

Nut Position

Fretboard

Neck-to-Body

Joint

Ukulele

Body

Figure 10. 14th fret position.

Top of Fretboard

14th Fret

-10-

Model T33949/50/51 (Mfd. Since 09/23)

Page 13

6. Secure fretboard in place with C-clamps or

rubber bands and wood stock, as shown in

Figure 11. Use wedges if necessary to

ensure a tight fit. Wipe off any glue overspill

with a damp, lint-free cloth.

Figure 11. Fretboard secured to neck.

7. Let glue dry a minimum of 24 hours, then

proceed to Step 8.

Determining Bridge

Location

The bridge is glued directly to the top of the body

at a distance that is consistent with the scale

length of the instrument. This instrument's scale

length is calculated by measuring the distance

from the bottom edge of the nut, where it butts

against the end of the fretboard, to the center of

the 12th fret, and then doubling that number.

It is important to leave an area of the sound board

unfinished that is slightly smaller than the footprint

of the bridge. This will increase the strength of the

glue joint that attaches the bridge to the sound

board. The reduced size of this area allows the

finish of the ukulele to be consistent around the

bridge.

A template has been provided for placement

of the bridge. In the event the template is

misplaced or damaged, contact Grizzly for a

replacement. However, it is possible to correctly

place the bridge without the template. Instructions

for attaching the bridge with or without the template are included.

8. Use #320-grit sandpaper or a fine file to sand

edge of neck flush with edge of fretboard. Do

this gently and slowly to avoid sanding

fretboard.

Locating Bridge With Template

1. Place template at top of fretboard

(see Figure 12 on Page 12), making sure

fretboard and sound hole are clearly visible

and properly aligned.

2. Remove template and place a layer of mask-

ing or painter's tape on instrument where

bridge will be located.

Note: Make sure taped area is larger than

bridge footprint.

3. Place template (see Figure 12 on Page 12)

back in position and use a pencil to lightly

trace top and side lines for bridge.

4. Remove template (see Figure 12

on Page 12) and place bridge according to

marks made on tape.

Model T33949/50/51 (Mfd. Since 09/23)

-11-

Page 14

Top of Fretboard

Headstock

Space for

Nut

Top of Fretboard

190mm

(7.50")

12th Fret

Bridge

Template

Bridge

Location

Figure 12. Using template for bridge placement.

5. Use a pencil to lightly mark bottom of bridge

on masking tape.

6. Use a hobby knife to gently cut tape at

marked location for bridge, then remove

excess tape.

14th Fret

190mm

(7.50")

Bridge

Scale Length for this Ukulele

380mm (15")

Figure 13. Example of determining scale length

and bridge positioning.

2. Double measurement to 380mm (15") to

determine scale length and placement of

bridge and saddle.

Note: Your measurement might vary depend-

ing on final placement of your fretboard.

3. Position bridge so front of saddle will be

380mm away from top of fretboard.

Front

of Bridge

Saddle

Tip: Angle knife inward as you cut.

Locating Bridge Without Template

1. Measure from top of fretboard to center of

12th fret. Measurement should be 190mm

(7.50") (see Figure 13).

-12-

Position bridge so front will be 190mm (7.50")

4.

from center of 12th fret (see Figure 13).

Model T33949/50/51 (Mfd. Since 09/23)

Page 15

5. To correctly center bridge, attach (2) pieces

of thread to 1st and 4th nut slots, then tape

opposite ends to corresponding holes in

bridge (see Figure 14).

. Center bridge so there is an equal amount of

6

space between fretboard edges and threads

(see Figure 14).

Equal

Distance

Installing Nut

The nut is located at the top of the fretboard and

holds the strings in place. The nut can be held in

place with string tension, or it can be spot glued

in place for more security.

If you prefer to glue, we recommend using wood

glue so that future adjustments can be made. For

a more permanent bond, super glue can be used,

but future adjustments will be more difficult.

Tape

Figure 14. Centering bridge.

. Place a layer of masking tape or painter's

7

tape on top of ukulele body where bridge will

be mounted.

. Place bridge back in original position and use

8

a pencil to lightly mark footprint of bridge on

masking tape.

. Use a hobby knife to gently cut tape at

9

marked location for bridge, then remove

excess tape.

Tip: Angle knife inward as you cut.

ALWAYS follow the adhesive manufacturer's instructions for your safety and best

results.

To install nut:

1. Test fit nut on top of fretboard.

Note: Curved part of nut should face head-

stock.

2. Apply a spot of glue to top of fretboard and

neck, then press nut in place and secure

(see Figure 15).

Glue Point

Glue Point

Model T33949/50/51 (Mfd. Since 09/23)

Nut Positioned

w/Curved Side Facing

Headstock

Figure 15. Fretboard installed.

3. Let glue dry a minimum of 24 hours, then

proceed to Preparing to Finish on Page 14.

-13-

Page 16

Preparing to Finish

Painting/Finishing

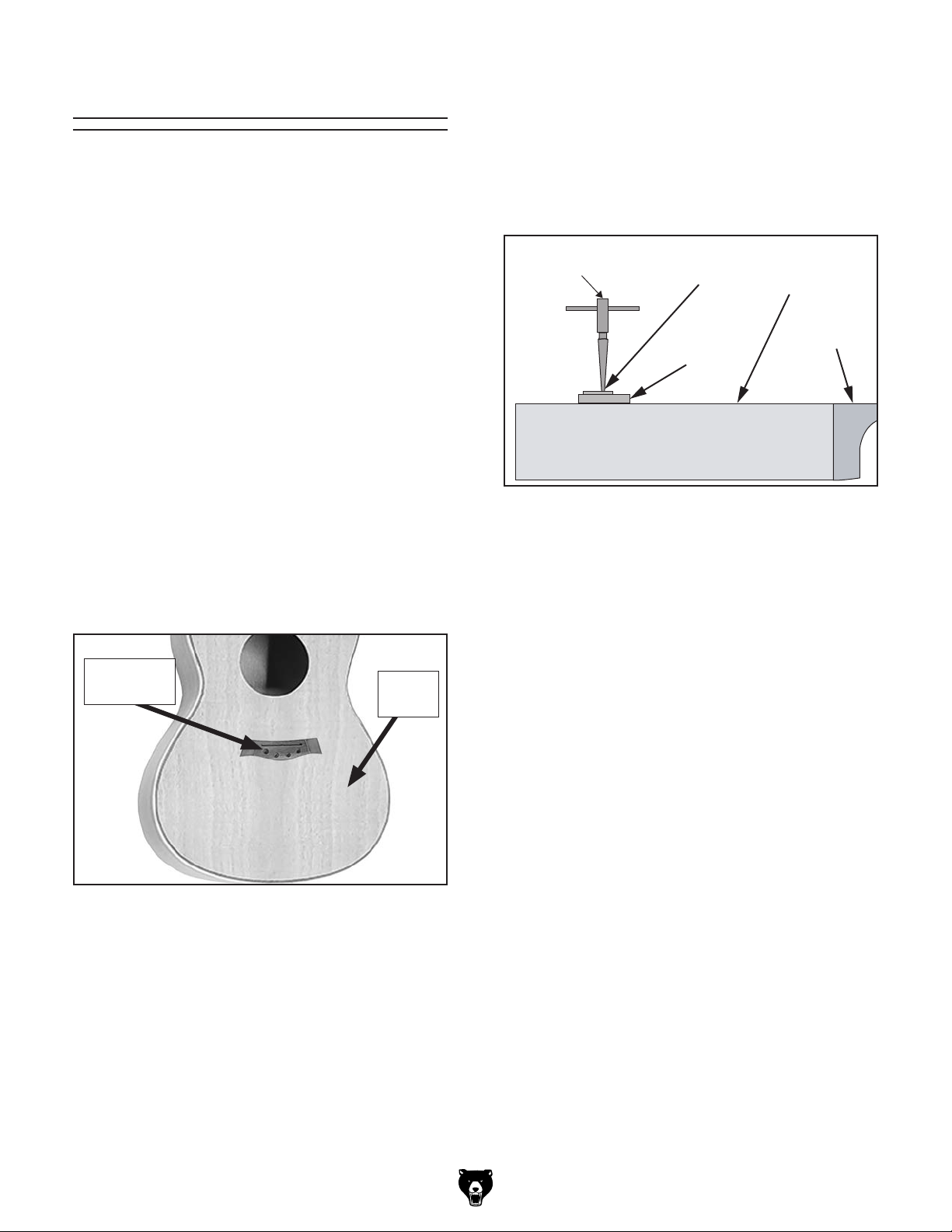

To prepare for applying the finish, cover the

fretboard, nut, and bridge footprint with masking

paper and secure it with masking tape, then fill the

sound hole with paper (see Figure 16).

Bridge

Footprint

Masked

Sound Hole

Filled With

Paper

Finishing supplies are not supplied with the ukulele kit.

There are many resources (books, videos, websites) that discuss ukulele finishing. Grizzly recommends consulting these sources before finishing your instrument.

Listed below are a few general tips that can be

helpful in finishing your instrument.

Painting/Finishing Tips:

• Always work in a well ventilated area when

using finishing materials.

• Wear an ANSI-approved respirator mask and

safety glasses when using finishing materials!

• Fabricate hooks from metal hangers to suspend ukulele components during finishing

process.

Masked Fretboard

and Nut

Figure 16. Masked fretboard and nut, filled sound

hole, and masked bridge position.

Carefully press all masking tape edges securely

to ukulele pieces. Finish can seep under these

edges, especially near corners, uneven edges,

and where frets meet fretboard.

Note: Failure to properly mask these areas could

result in irreparable damage to ukulele.

• Several thinner coats usually produce a nicer

finish than one heavy coat.

Note: Always follow finish manufacturer’s

instructions.

• Dust particles suspended in air will settle on

wet finishes, resulting in less than satisfactory results. To avoid this problem:

1. Have ukulele components positioned for

finish application upon entering room.

Leave room where finishing will take place

2.

completely undisturbed for 24 hours prior

to applying finish.

Avoid making unnecessary movements

3.

upon entering finish room.

Apply finish to desired ukulele parts and

4.

immediately leave finish room.

-14-

DO NOT return to room until specified dry-

5.

ing time has elapsed.

Model T33949/50/51 (Mfd. Since 09/23)

Page 17

Installing Bridge

Remove the tape from the masked areas in

preparation for installing the bridge. Refer to

Page 11 for the necessary measurements to

locate the bridge.

We recommend using wood glue so that future

adjustments can be made. For a more permanent

bond, super glue can be used, but future adjustments will be more difficult.

Installing Bridge with Clamp

1. Remove masking tape from bridge location.

Apply a thin, even layer of wood glue or super

2.

glue to bottom of bridge.

Position bridge on pre-determined bridge

3.

position and gently press bridge down making sure that bridge pin holes line up.

Installing Bridge with Wood Blocks

If a bridge clamp is not available, it is possible

to install the bridge using wood blocks and large

rubber bands.

1. Follow Steps 1–3 in Installing Bridge with

Clamp on this page.

. Carefully position wood blocks over bridge

2

and under back of ukulele, then secure with

rubber bands (see Figure 18).

Clamp bridge down with a bridge clamp or

4.

large depth C-clamp (see Figure 17).

Note: DO NOT overtighten clamp.

Figure 17. Bridge clamped in position.

5. Check to make sure bridge is still in correct

position and adjust if necessary.

Let dry for a minimum of six hours.

6.

Figure 18. Bridge secured with wood blocks.

Let dry for a minimum of six hours.

3.

4. Remove rubber bands, and wood blocks.

7. Remove clamps and place saddle in position.

Note: Saddle does not need to be glued in.

String tension will keep saddle in place.

Model T33949/50/51 (Mfd. Since 09/23)

-15-

Page 18

Fitting Bridge Pins

T-Handle

. Place T-handle reamer in (1) bridge pin hole

4

and gently twist reamer clockwise, making

one complete revolution (see Figure 20).

Now that the bridge is securely attached, it is time

to prepare the bridge for bridge pin fitting.

To protect the finish on your instrument you

should mask off the top of the ukulele around the

bridge before proceeding with these instructions.

Unless otherwise indicated, we strongly recommend using a drill press for the majority of drilling

to obtain the most precise results. However, an

electric/cordless drill fitted with a depth stop or a

drill stand can be used if you do not have a drill

press.

To fit bridge pins:

. Carefully drill (4) holes in bridge using 5⁄32"

1

Forstner bit at bridge pin hole locations

(see Figure 19).

Note: Be careful to keep drill straight, and

drill only until you break through to sound

chamber. Do not drill through back of ukulele.

Note: It is important to not take too much

material out of hole. Bridge pins should be

snug fitting.

Reamer

Figure 20. Reaming bridge pin holes.

5. Test fit bridge pin in reamed hole.

— If bridge pin does go into hole and fits

snugly, fitting is complete. Proceed to next

hole.

Bridge Pin

Holes

Bridge

Ukulele

Body

Ukulele

Neck

Bridge Pin

Holes

Figure 19. Bridge pin locations.

. Remove debris and sawdust from top and

2

make sure holes are free of debris.

. Test fit bridge pin.

3

Note: Bridge pin should not fit in hole at this

time.

Sound

Board

— If bridge pin does not go into hole, repeat

Step 4.

Note: As you get closer to fitting bridge pin, it

may be advisable to only rotate reamer

turn. This will avoid removing too much material and bridge pins fitting too loosely.

. Repeat Steps 3–5 for remaining bridge pin

6

holes.

1

⁄2

-16-

Model T33949/50/51 (Mfd. Since 09/23)

Page 19

Installing Sound

Hole Decal

The sound hole decal decorates the ukulele and

is easy to install.

To install sound hole decal:

1. Submerge decal sheet in water until decal

slides around easily with finger pressure. This

usually only takes a few minutes.

2. Remove decal from water, letting excess

water run off.

3. Gently slide decal off decal sheet into position

around sound hole, as shown in Figure 21.

4. Lightly press down on decal with dampened

fingers and slowly slide decal sheet from

underneath decal (see Figure 22).

Figure 22. Pressing decal flat to body.

When decal sheet is completely removed,

5.

lightly press on decal with a dry cloth to

remove excess water trapped underneath.

Figure 21. Sliding decal onto body.

Let decal dry for at least eight hours.

6.

Model T33949/50/51 (Mfd. Since 09/23)

-17-

Page 20

Installing Tuning

Machines

The supplied tuning machines are mirrored pairs:

two for the left side of the headstock, two for the

right. Each tuning machine consists of the parts

shown in Figure 23.

Note: Unless otherwise indicated, we strongly rec-

ommend using a drill press for drilling in this manual to obtain the most precise results. However,

an electric/cordless drill fitted with a depth stop or

a drill stand can be used if you do not have a drill

press.

To install tuning machines:

1. Using a non-marring mallet, tap each of (4)

machine seats with washers into pre-drilled

holes on front of headstock.

2. From back of headstock, slide tuning machine

through headstock and seat (see Figure 23).

Checking

Tuning

Machine

Parallelism

from Side

to Side

x 4

Figure 24. Front and rear view of completed

headstock.

Installing Strings

Each string of the ukulele is a different diameter. Number the strings 1, 2, 3, and 4 —from the

smallest diameter to the largest diameter. Their

arrangement on the ukulele is shown in Figure 25.

To install ukulele strings:

Headstock

Tuning

Machine

Screw

Figure 23. Tuning machine components.

3. Position tuning machine buttons to outside of

headstock.

4. Set a straightedge across top of each pair of

machine tuners to ensure they are parallel

with each other from side to side,

as shown in Figure 24.

Tuning Machine Seat

Tuning Machine

Washer

Tuning Machine Peg

Tuning Machine

Button

Install saddle on bridge.

1.

Note: Saddle does not need to be glued in.

String tension will keep saddle in place.

Use a piece of tape and pen to designate

2.

each string number and tie a knot at one end

of each string.

In order shown in Figure 25, pull strings

3.

through bridge slots, over saddle, and over

string nut slots.

Ukulele Body

2

4

3

1

Secure each tuning machine to headstock

5.

with (1) tuning machine screw, as shown in

Figure 24.

-18-

Figure 25. Proper string arrangement.

Model T33949/50/51 (Mfd. Since 09/23)

Page 21

4. Set string knots in bridge pin slot and seat

bridge pins in bridge pin holes.

Setting String Height

Note: String knots should slide into groove

on bridge pins. Bridge pins should be snug

and not easily removed.

Route strings to inside of tuning pegs and

5.

through peg holes. Refer to Figure 26 for

proper string placement in tuning pegs.

Note: Provide enough string slack to allow

2–3 complete winds around tuning peg.

4

2

Headstock

Figure 26. String installation into tuning pegs.

3

1

Tuning Peg

The string height is the distance between the

top of the fret and the bottom of the string

(see Figure 27). Correct string height is crucial

for maximizing the playability of the ukulele.

Measurements are taken at the 1st and 12th frets.

You can use a variety of tools to check string

heights on ukuleles, including feeler gauges, a

fine ruler (

which are available at your local shop or online.

However, to set string height on a ukulele, all you

need is some pocket change.

1

⁄64" resolution), or string height gauges,

String

String Height

Fretboard

6. Turn tuning pegs counterclockwise to tighten

strings.

Note: DO NOT over-tighten strings at this

time. Final string tuning will be discussed

later in manual.

Use wire cutters to cut off excess string.

7.

Figure 27. String height measurement (side

view).

The string nut and saddle may come oversized

from the factory. Sizing them requires measuring, sanding, and re-measuring. Fix both the

nut and saddle until correct string heights are

reached. Hand-sanding prevents removing too

much material.

Items Needed Qty

Pennies .............................................................. 3

.................................................................. 1

Dime

Sandpaper #240-Grit or Fine File

..................... 1

Model T33949/50/51 (Mfd. Since 09/23)

-19-

Page 22

To set string height:

1. Using a dime as a gauge, measure string

height at each string along 1st fret

(see Figure 28).

— If string heights are approximately thick-

ness of a dime, then continue to Step 2.

— If string heights are more than height of a

dime at 1st fret, this is an indication that

height of nut needs to be reduced. Proceed

to Step 3.

2. Using a stack of three pennies, measure

string heights at 12th fret (see Figure 29).

— If string heights are approximately thick-

ness of three pennies, then continue to

Step 5.

— If string heights are more than height of

three pennies at 12th fret, this is an indication that height of saddle needs to be

reduced. Proceed to Step 3.

12th fret

Ukulele Body

Ukulele Body

1st Fret

Figure 28. Correct 1st fret string heights.

Dime

String Height

Nut

Pennies

String Heights

Figure 29. Correct 12th fret string heights.

3. Hand-sand base of string nut/saddle. DO

NOT remove too much material.

4. Test string nut/saddle by repeating Steps 1–2.

Congratulations! Construction of ukulele is

5.

now complete. Proceed to Tuning section to

tune instrument.

-20-

Model T33949/50/51 (Mfd. Since 09/23)

Page 23

Tuning

Tuning is the most important concept of playing

a ukulele. If the ukulele is not in tune with itself,

or the other instruments in an ensemble, the

resulting music will not sound pleasing to the ear.

Having a good understanding of tuning is essential to maximizing the full potential of any ukulele.

Important issues to consider when tuning a

ukulele:

• Get into the habit of tuning the ukulele every

time it is picked up to be played.

• Always tune the strings "up." The final tuned

tension of each string should be reached

while tightening the string, not loosening it. If

the string is tensioned too far, loosen the tension and tune "up" again.

• The easiest way to tune a ukulele is using an

electronic tuner. There are a wide variety of

these available in music stores, or online with

a wide variety of prices as well. However, with

practice, you can learn how to tune a ukulele

by ear–a skill used by many accomplished

ukulele players.

Ukulele Setup

Congratulations – construction of your ukulele kit

is now complete!

At this point you may want to consider setting up

the ukulele to your own personal specifications.

"Setting up" your ukulele can be as simple as

swapping out the strings provided to the brand

that is your personal favorite.

• The goal when tuning is to make the strings

in tune with one another. Standard tuning is

shown in Figure 30.

Ukulele Body

G

C

E

A

Figure 30. Standard tuning notes.

Setting up your ukulele can also be a bit more

complicated and technical. You can modify or

adjust the ukulele to match your preference for not

only strings, but string height, or action, through

nut and saddle adjustments, and raising or lowering the bridge, to name just a few.

There are plenty of resources including books and

websites that will guide you through that process.

It is also possible to have your ukulele taken to a

music shop or licensed luthier and have them set

up the ukulele for you.

Again, congratulations and enjoy your new ukulele!

Model T33949/50/51 (Mfd. Since 09/23)

-21-

Page 24

ACCESSORIES

order online at www.grizzly.com or call 1-800-523-4777

SECTION 5: ACCESSORIES

NOTICE

Refer to our website or latest catalog for

additional recommended accessories.

H5332—Titebond Original Wood Glue

The industry standard for general woodworking

applications. Provides strong initial tack and fast

setting speed to reduce clamp time. Develops a

bond stronger than the wood itself.

H5890—Repairman's Taper Reamer.

This Repairman's Taper Reamer reams holes

1

from

for compact storage and 7 flutes for smooth

bores. Reamer measures 5" long. Handle measures 3

⁄8" to 5⁄8" and features a removable handle

1

⁄2 " long.

Figure 31. H5332 Titebond Original Wood Glue.

H0927—Insta-Cure+ 2 oz.

Insta-Cure+ is a powerful CA or Cyanoacrylate

adhesive in a two ounce bottle. Apply to one surface and then hold parts tightly together for about

5 to 15 seconds for a fast permanent bond.

Figure 32. H0927 Insta-Cure+ 2 oz.

Figure 33. H5890 Repairman's Taper Reamer.

T30674—Pony 15' Band Clamp.

This clamp is ideal for round, irregular or awkwardly-shaped projects. It features 15' of 1" width

high-strength nylon webbing and has a self-locking cam with quick release.

Figure 34. T30674 Pony 15' Band Clamp.

-22-

Model T33949/50/51 (Mfd. Since 09/23)

Page 25

SECTION 6: PARTS

We do our best to stock replacement parts when possible, but we cannot guarantee that all parts shown

are available for purchase. Call (800) 523-4777 or visit www.grizzly.com/parts to check for availability.

Main

1

2

3

10

13

6

11

14

8

5

7

4

8

9

12

REF P ART # DES CRIPTI ON REF P ART # DES CRIPTI ON

1 PT33949001 UKULELE BODY KOA 7 PT33949007 TUNING MACHINE SCREW M2-.4 X 9

1 PT33950001 UKULELE BODY QUILTED MAPLE 8 PT33949008 SADDLE

1 PT33951001 UKULELE BODY FIDDLEBACK MAPLE 9 PT33949009 NUT

2 PT33949002 NECK 10 PT33949010 TUNING MACHINE WASHERS 2MM

3 PT33949003 FRETBOARD 11 PT33949011 STRING SET

4 PT33949004 BRIDGE 12 PT33949012 BRIDGE PIN

5 PT33949005 TUNING MACHINE 13 PT33949013 SOUNDHOLE DECAL

6 PT33949006 TUNING MACHINE SEAT 14 PT33949014 BRIDGE TEMPLATE

Model T33949/50/51 (Mfd. Since 09/23)

BUY PARTS ONLI NE AT GRIZZLY.COM!

Scan QR code to visit our Parts Store.

-23-

Page 26

Page 27

WARRANTY & RETURNS

Grizzly Industrial, Inc. warrants every product it sells for a period of 1 year to the original purchaser from

the date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligence, accidents, repairs or alterations or lack of maintenance. This is Grizzly’s sole written warranty

and any and all warranties that may be implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited to the duration of this written warranty. We do not warrant or represent

that the merchandise complies with the provisions of any law or acts unless the manufacturer so warrants.

In no event shall Grizzly’s liability under this warranty exceed the purchase price paid for the product and

any legal actions brought against Grizzly shall be tried in the State of Washington, County of Whatcom.

We shall in no event be liable for death, injuries to persons or property or for incidental, contingent, special,

or consequential damages arising from the use of our products.

The manufacturers reserve the right to change specifications at any time because they constantly strive to

achieve better quality equipment. We make every effort to ensure that our products meet high quality and

durability standards and we hope you never need to use this warranty.

In the event you need to use this warranty, contact us by mail or phone and give us all the details. We will

then issue you a “Return Number,’’ which must be clearly posted on the outside as well as the inside of

the carton. We will not accept any item back without this number. Proof of purchase must accompany the

merchandise.

Please feel free to write or call us if you have any questions about the machine or the manual.

Thank you again for your business and continued support. We hope to serve you again soon.

To

you can

applicable information for

take advantage of this warranty, you must register it at https://www.grizzly.com/forms/warranty, or

scan the QR code below to be automatically directed to our warranty registration page. Enter all

the product.

WARRANTY

Page 28

Loading...

Loading...