Page 1

MODEL T33448

THIN KERF RIVING KNIFE

FOR G1023RL SERIES

INSTRUCTIONS

For questions or help with this product contact Tech Support at (570) 546-9663 or techsupport@grizzly.com

Introduction

Install the Model T33448 on your G1023RL series

table saw for use with a thin kerf blade that matches the below specifications. The Model T33448 is

compatible with the existing table insert and will

reduce the risk of your workpiece pinching and

binding while performing non-through cuts that

require the removal of the blade guard.

• Riving knife MUST BE aligned with blade

and secured tightly. A misaligned riving

knife can cause workpiece to catch or

bind, increasing the risk of kickback.

• Use a riving knife for all non-through

operations, unless dado blade with less

than 10 in. diameter is installed.

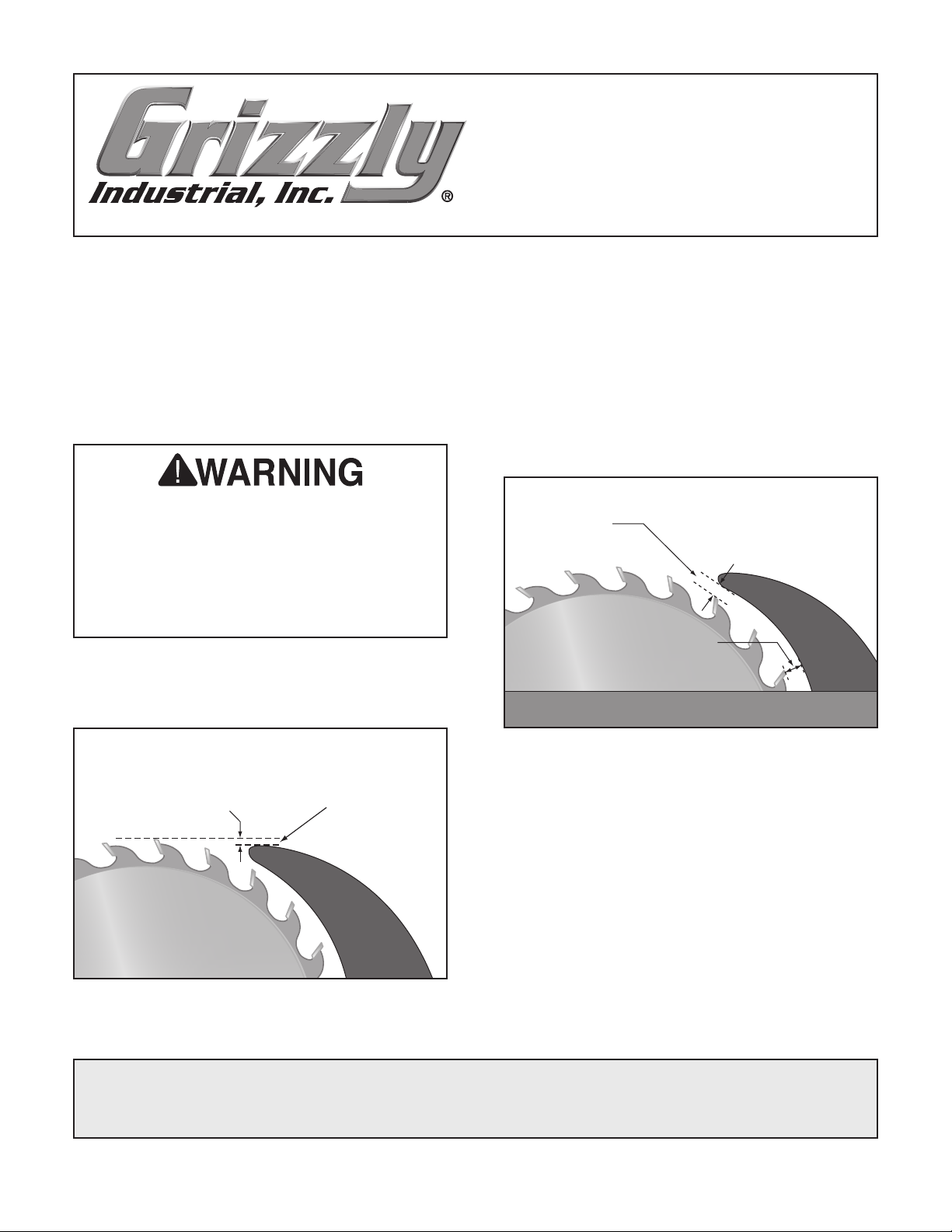

A riving knife mounts just below the blade's highest point of rotation, as shown in Figure 1.

The height difference between the riving knife and

the blade allows the workpiece to pass over the

blade during non-through cuts (those in which the

blade does not cut all the way through the thickness of the workpiece.

The riving knife must also be kept within the range

shown in Figure 2. For these reasons, this riving

knife is only compatible with 10" blades, as listed

below in the Specifications.

Top Distance

Minimum 3mm

Maximum 8mm

Bottom Distance

Minimum 3mm

Maximum 8mm

Minimum 1mm

Maximum 5mm

Figure 1. Height difference between riving knife

and blade.

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

Height Difference

COPYRIGHT © FEBRUARY, 2023 BY GRIZZLY INDUSTRIAL, INC.

NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

(FOR MODELS MFD. SINCE 03/23) #CS22565 PRINTED IN TAIWAN

***Keep for Future Reference***

Figure 2. Allowable top and bottom distances

between riving knife and blade.

Specifications

• Riving Knife Thickness ......................... 2mm

• Required Blade Diameter .....................10 in.

• Required Blade Body Thickness ....... 1.8mm

• Required Blade Kerf Thickness......... 2.2mm

V1.02.23

Page 2

Installation

Items Needed Qty

Open or Closed-End Wrench 1⁄2 " ...................... 1

Straightedge 12"

Hex Wrenches 4, 5mm

To install thin kerf riving knife:

................................................ 1

................................1 Ea.

To reduce risk of shock or

accidental startup, always

disconnect machine from

power before adjustments,

maintenance, or service.

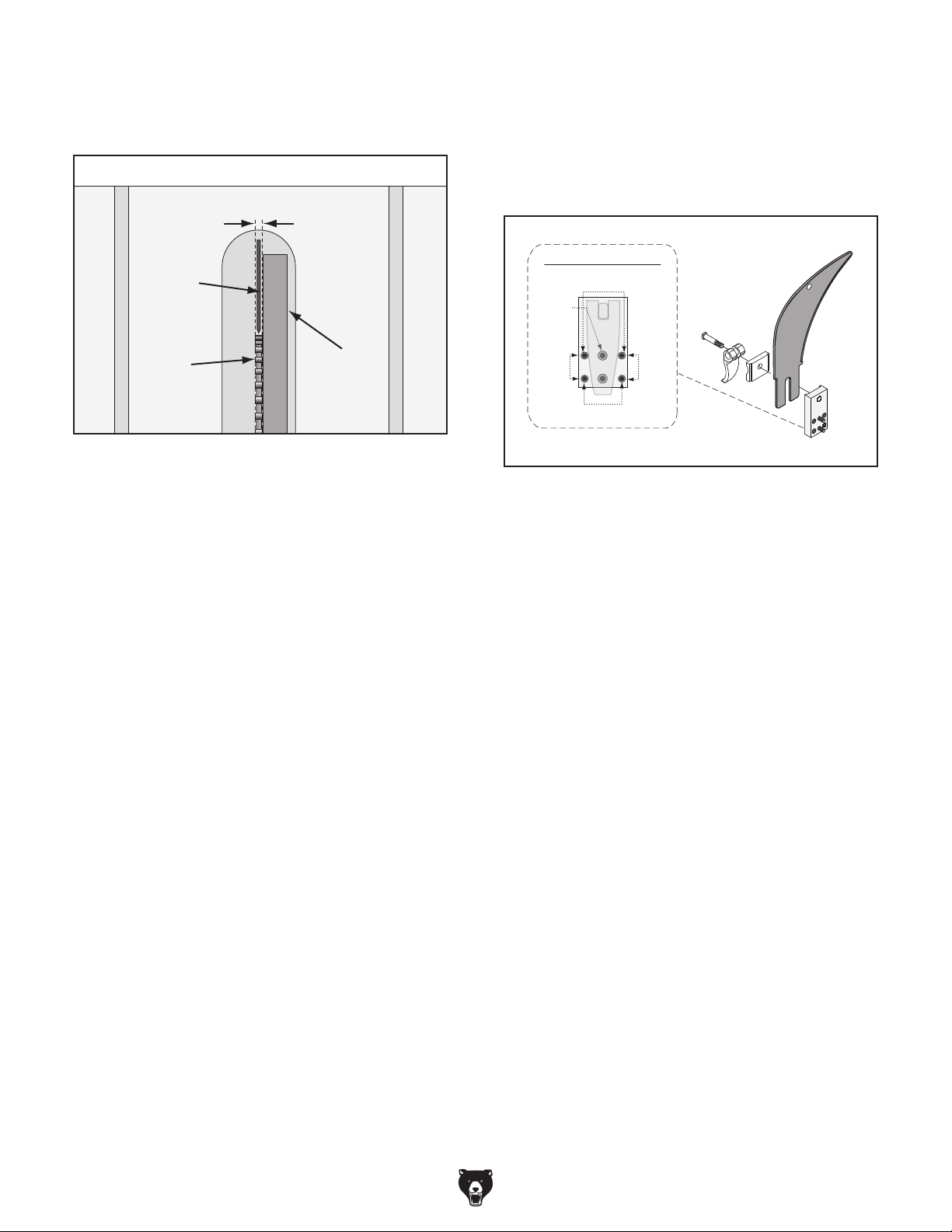

4. Fully tighten lock nut on lever assembly while

lever is in locked position (see Figure 4). Pull

riving knife up to verify it is locked.

Lock Nut

1. Install thin kerf blade (refer to Steps 1–4

of Blade Installation section of Owner's

Manual) meeting specification requirements

on Page 1 of this update, and tilt blade to 90°.

Open right access door.

2.

3. Flip quick-release lever up, insert riving knife

into spreader adjustment bracket, then push

lever down (see Figure 3).

Quick-Release

Lever

Spreader

Adjustment

Bracket

Figure 4. Location of lever assembly lock nut.

5. Check 90° stop bolt adjustment in Blade Tilt

Stops section of Owner's Manual.

Place straightedge against top and bottom of

6.

blade and riving knife, as shown in Figure 5.

Top Alignment

Bottom Alignment

Figure 5. Checking top and bottom riving knife

parallelism with blade.

Figure 3. Location of quick-release lever (viewed

from inside cabinet).

-2-

Model T33448 (Mfd. Since 03/23)

Page 3

Riving knife should be parallel with blade

along its length at both positions and should

be in "Alignment Zone," as shown in Figure 6.

Alignment

Zone

Riving

Knife

Blade

Straightedge

Figure 6. Riving knife alignment zone.

Flip quick-release lever up to remove riving

8.

knife.

Loosen (2) cap screws on mounting block,

9.

then adjust set screws on block to move it in

necessary direction (see Figure 7).

Mounting Block

Top Control

Cap

Screw

Control

Side

Side

Control

Bottom Control

— If riving knife is not parallel with blade

at either top or bottom, it may be bent.

Remove riving knife and place it on a flat

surface and check to see if riving knife

lays evenly along its length. If riving knife

does not lay evenly, proceed to Step 7.

— If riving knife is not parallel with blade or

is not inside alignment zone, proceed to

Step 8.

— If riving knife is parallel with blade and

inside alignment zone, close right access

door and install table insert. No additional

steps are necessary.

Bend riving knife by hand while installed or

7.

remove it to straighten it. Repeat Step 6 to

determine if riving knife is parallel with blade.

— I f riving knife cannot be straightened prop-

erly, replace it.

Figure 7. Mounting block controls.

10. Install riving knife, then repeat Step 6.

— If riving knife is in alignment zone, proceed

to Step 11.

— If riving knife is not in alignment zone,

continue adjusting set screws on mounting

block as necessary to correctly position

riving knife.

Remove riving knife, tighten (2) cap screws

11.

on mounting block to secure riving knife

adjustment, then install riving knife.

Close right access door and install table

12.

insert.

Model T33448 (Mfd. Since 03/23)

-3-

Page 4

Loading...

Loading...