Page 1

MODEL T32716

To reduce your risk of

serious injury, read this

entire manual BEFORE

8" BENCHTOP

METAL SHEAR/BRAKE

INSTRUCTIONS

For questions or help with this product contact Tech Support at (570) 546-9663 or techsupport@grizzly.com

Introduction

The Model T32716 8" Benchtop Metal Shear/

Brake is designed to both bend and shear sheet

metal with one compact tool.

using machine.

Inventory

Description Qty

A. Benchtop Shear/Brake (Not Shown) .......... 1

Handle ........................................................ 1

B.

Hex Bolts M10-2 x 70 ................................. 4

C.

Flat Washers 10mm ................................... 4

D.

Hex Nuts M10-2 .......................................... 4

E.

Hex Wrenches 3, 4mm .........................1 Ea.

F.

Fingers

G.

Seating Tool................................................ 1

H.

B

3

⁄8", 9⁄16", 13⁄16", 19⁄16" ..................1 Ea.

C

D

E

G

F

H

Figure 1. Model T32716 8" Benchtop Metal

Shear/Brake.

Needed for Setup

• Safety Glasses ....................................1 Pair

• Cleaner/Degreaser ..................... As Needed

• Disposable Shop Rags ............... As Needed

• Disposable Gloves ..................... As Needed

• Open-End Wrench 17mm ........................... 1

• Wrench or Socket 17mm ............................ 1

COPYRIGHT © MAY, 2021 BY GRIZZLY INDUSTRIAL, INC.

NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

(FOR MODELS MFD. SINCE 05/21) #CS21863 PRINTED IN CHINA

Figure 2. Inventory.

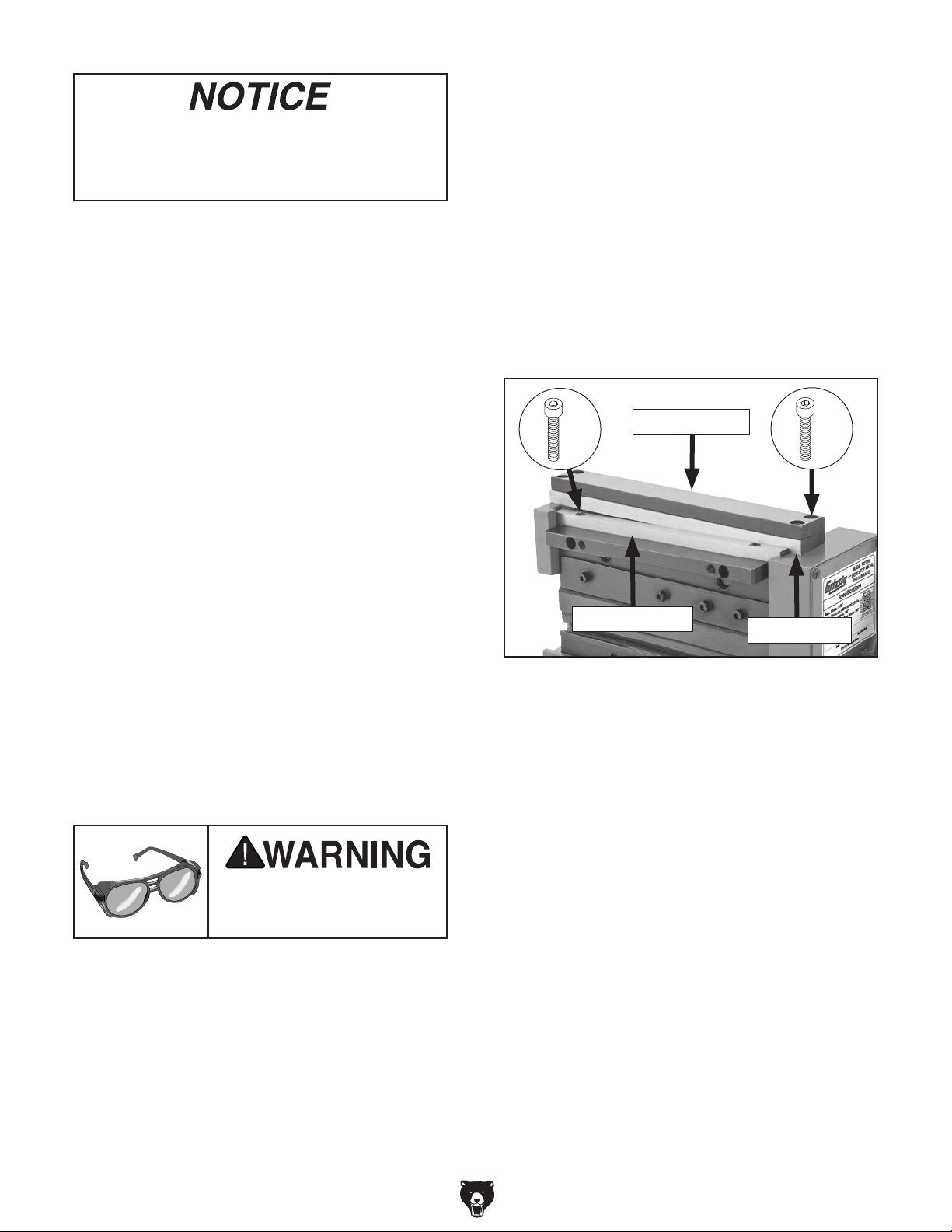

NOTICE

If you cannot find an item on this list, carefully check around/inside the machine and

packaging materials. Often, these items get

lost in packaging materials while unpacking or they are pre-installed at the factory.

V1.05.21

Page 2

MACHINE DATA

SHEET

Customer Service #: (570) 546-9663 · To Order Call: (800) 523-4777 · Fax #: (800) 438-5901

MODEL T32716 8" BENCHTOP METAL SHEAR/BRAKE

Product Dimensions:

Weight................................................................................................................................................................ 26 lbs.

Width (side-to-side) x Depth (front-to-back) x Height........................................................................... 11 x 16 x 12 in.

Footprint (Length x Width)......................................................................................................................... 9-1/2 x 6 in.

Shipping Dimensions:

Type..................................................................................................................................................... Cardboard Box

Content........................................................................................................................................................... Machine

Weight................................................................................................................................................................ 29 lbs.

Length x Width x Height......................................................................................................................... 19 x 13 x 7 in.

Main Specifications:

Capacities

Maximum Width..................................................................................................................................... 7-7/8 in.

Maximum Thickness at Half Width Mild Steel..................................................................................... 20 Gauge

Maximum Thickness at Full Width Mild Steel..................................................................................... 22 Gauge

Aluminum............................................................................................................................................ 18 Gauge

Soft Brass........................................................................................................................................... 18 Gauge

Hard Copper....................................................................................................................................... 20 Gauge

Minimum Reverse Bend........................................................................................................................... 1/4 in.

Maximum Height of Pan/Box Brake Sides................................................................................................ 5/8 in.

Number of Fingers............................................................................................................................................ 5

Width of Fingers................................................................................................... 3/8, 9/16, 13/16, 1-9/16, 8 in.

Construction

Base..................................................................................................................................................... Cast Iron

Brake.................................................................................................................. Ground Steel, Hardened Edge

Fingers............................................................................................................... Ground Steel, Hardened Edge

Frame................................................................................................................................................... Cast Iron

Shear Blades................................................................................................ Precision-Ground Hardened Steel

Other Specifications:

Country of Origin ................................................................................................................................................ China

Warranty ........................................................................................................................................................... 1 Year

Approximate Assembly & Setup Time ........................................................................................................ 15 Minutes

Serial Number Location ................................................................................................................... Machine ID Label

Features:

Adjustable Brake & Shear Stops

Reversible Bending Prism w/2 V-Groove Sizes: 6 & 11mm Wide

Accessories Included:

Hex Wrenches 3, 4mm

Finger Seating Tool

-2-

T32716 (Mfd. Since 05/21)

Page 3

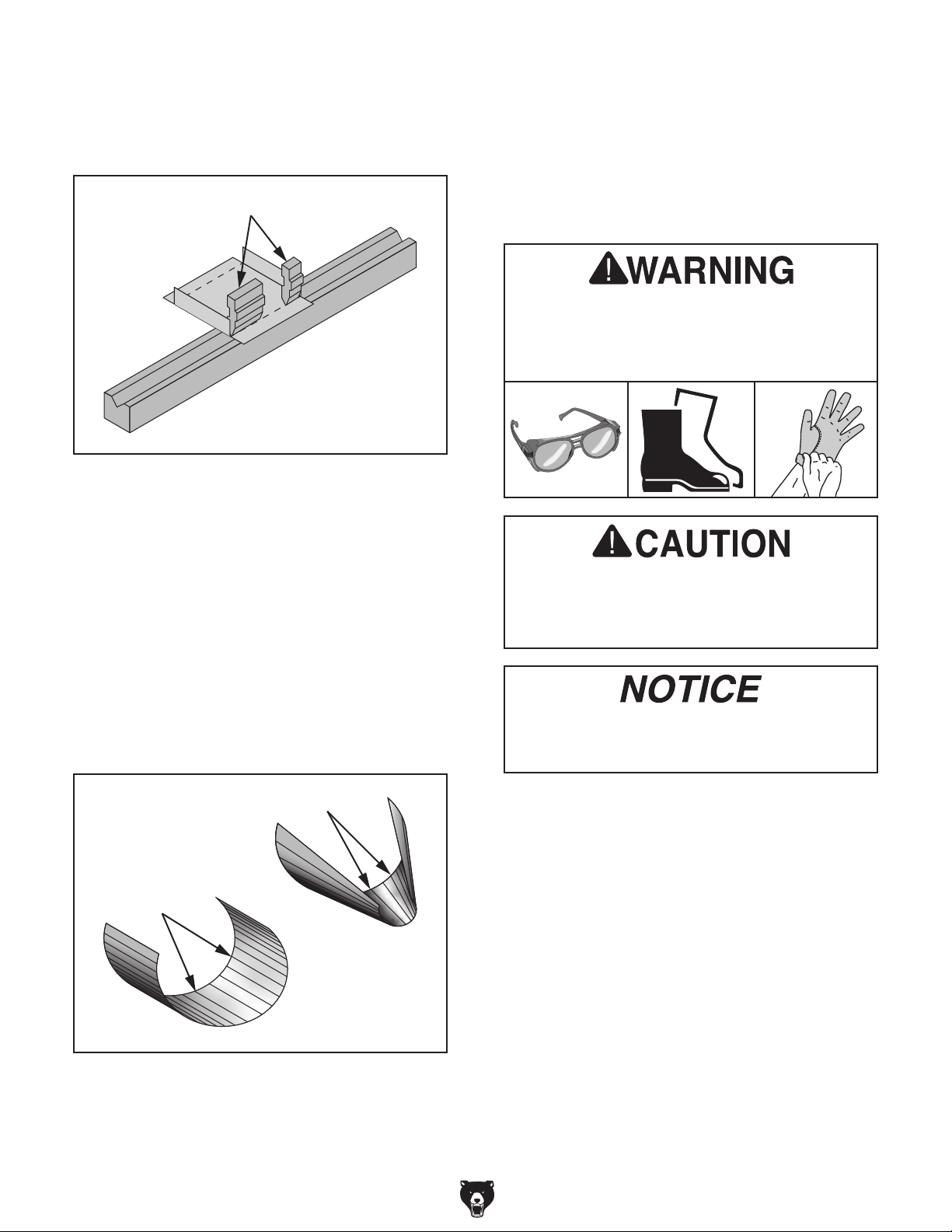

Another option is a "direct mount" (see example

below) where the machine is secured directly to

the workbench with lag screws and washers.

The base of this machine has mounting holes

Cleanup

The unpainted surfaces of your machine are

coated with a heavy-duty rust preventative that

prevents corrosion during shipment and storage.

This rust preventative works extremely well, but it

will take a little time to clean.

Workbench Mounting

Mounting hardware has been included with the

Model T32716. However, you can use different

hardware with a 10mm diameter if your workbench

or surface requires a different size or type.

Be patient and do a thorough job cleaning your

machine. The time you spend doing this now will

give you a better appreciation for the proper care

of your machine's unpainted surfaces.

There are many ways to remove this rust preventative, but the following steps work well in a wide

variety of situations. Always follow the manufacturer’s instructions with any cleaning product you

use and make sure you work in a well-ventilated

area to minimize exposure to toxic fumes.

Before cleaning, gather the following:

• Disposable rags

• Cleaner/degreaser (WD•40 works well)

• Safety glasses & disposable gloves

• Plastic paint scraper (optional)

Basic steps for removing rust preventative:

Put on safety glasses.

1.

2. Coat the rust preventative with a liberal

amount of cleaner/degreaser, then let it soak

for 5–10 minutes.

Wipe off the surfaces. If your cleaner/

3.

degreaser is effective, the rust preventative

will wipe off easily. If you have a plastic paint

scraper, scrape off as much as you can first,

then wipe off the rest with the rag.

that allow it to be fastened to a workbench or

other mounting surface to prevent it from moving

during operation and causing accidental injury or

damage.

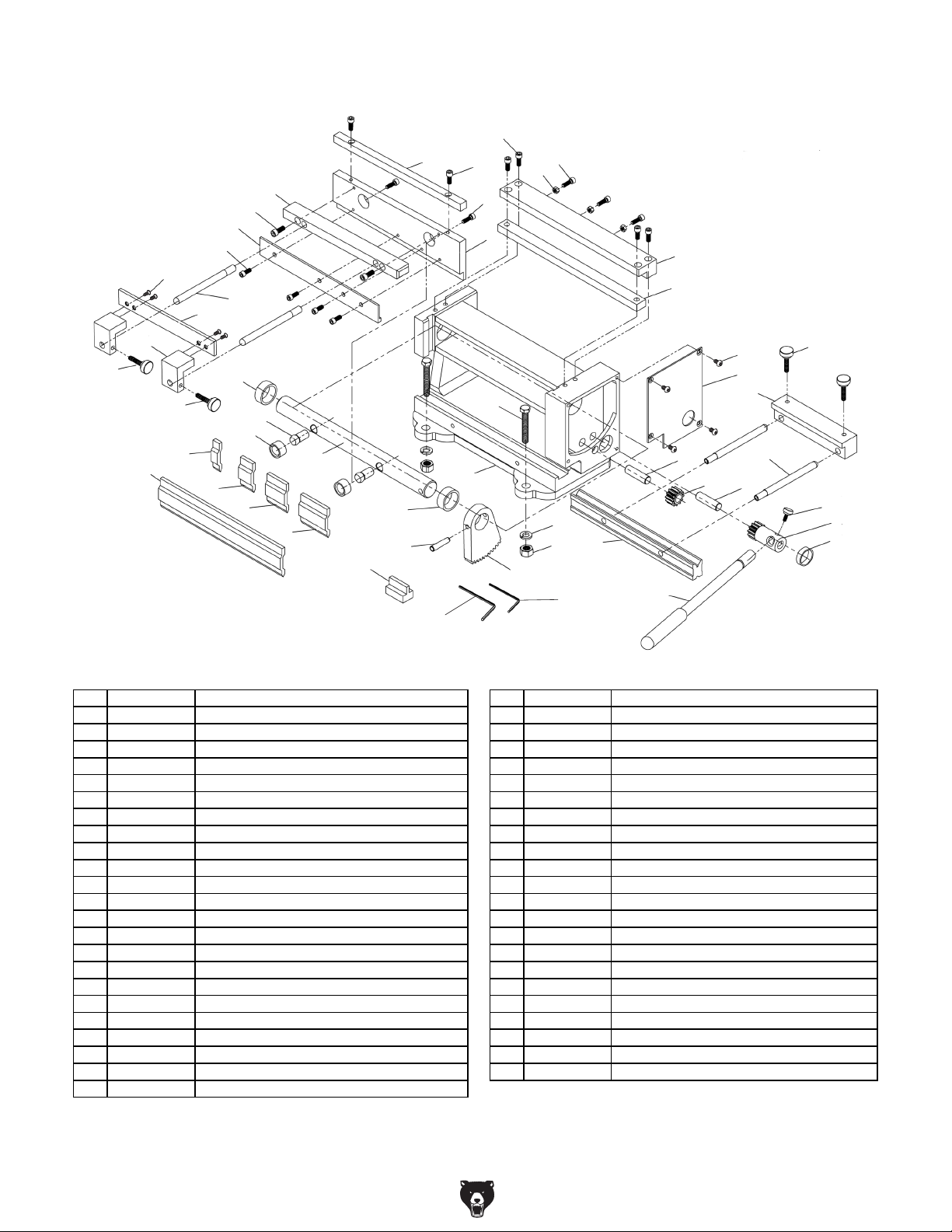

The strongest mounting option is a "Through

Mount" (see example below) where holes are

drilled all the way through the workbench—and

hex bolts, washers, and hex nuts are used to

secure the machine in place.

Hex

Bolt

Flat Washer

Machine Base

Workbench

Flat Washer

Lock Washer

Hex Nut

Figure 3. "Through Mount" setup.

Repeat Steps 2–3 as necessary until clean,

4.

then coat all unpainted surfaces with a quality

metal protectant to prevent rust.

NOTICE

Avoid harsh solvents like acetone or brake

parts cleaner that may damage painted surfaces. Always test on a small, inconspicuous location first.

T32716 (Mfd. Since 05/21)

Lag Screw

Flat Washer

Machine Base

Workbench

Figure 4. "Direct Mount" setup.

-3-

Page 4

Assembly

Crushing hazard! Always

keep hands clear when

The machine must be fully assembled before it

can be operated. Before beginning the assembly

process, first clean any parts that are covered or

coated in rust preventative.

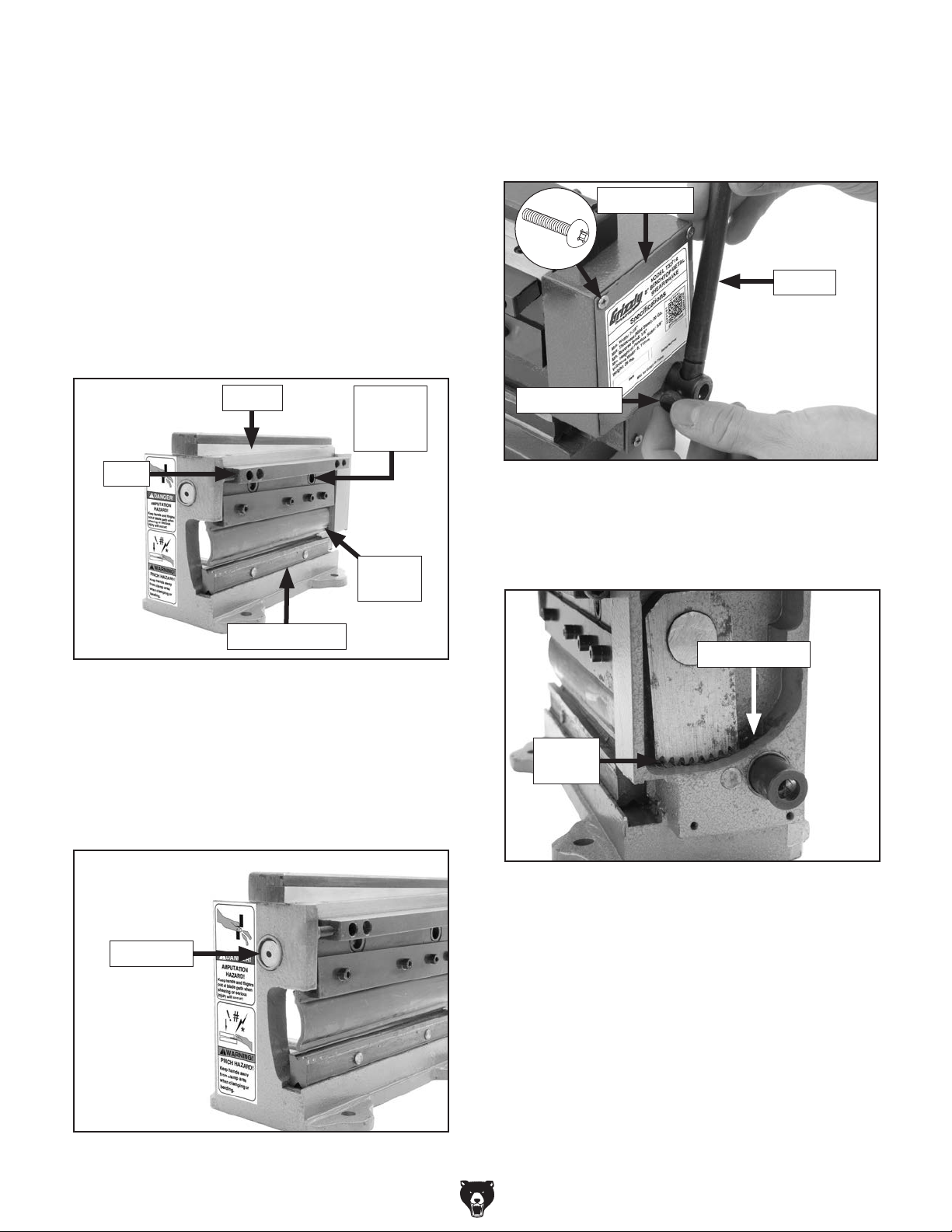

Remove unneeded fingers by sliding them

3.

left and out of gib (see Figure 6).

To assemble machine:

Insert handle into hub so tip of thumb knob

1.

fits in groove in handle and secure in place

with thumb knob (see Figure 5).

Handle

Groove

Hub

Thumb Knob

Figure 5. Installing handle.

Changing Fingers

The Model T32716 comes with five fingers of

various lengths:

sizes can be used to perform a variety of bending operations, including pan and box and radius

bending. Once you have planned your bend,

remove any installed fingers and replace them

with the finger (or fingers) needed for that bend.

3

⁄8", 9⁄16", 13⁄16", 19⁄16", and 8". These

x 4

Gib

Finger

Figure 6. Finger mounting components.

4.

Slide desired finger (or fingers) between gib

and bending prism in order necessary for

bending operation (see Figure 7).

using this machine.

5. Use handle to lower and press fingers against

bending prism to align them (see Figure 7).

Tool Needed Qty

Hex Wrench 4mm .............................................. 1

To change fingers:

Loosen (4) gib cap screws shown in Figure 6.

1.

Use handle to lift any installed fingers as high

2.

as possible (see Figure 6).

-4-

Fingers

Bending

Prism

Figure 7. Finger installation components.

6.

With finger (or fingers) still pressed against

bending prism, tighten cap screws from

Step 1.

T32716 (Mfd. Since 05/21)

Page 5

Flipping Bending Prism

The bending prism is what the fingers press a

workpiece up against to achieve a bend. This

prism can be turned over to reveal a shallower

V-groove with a smaller bending radius on the

other side.

To flip bending prism:

Typical Bending Operation

Use the following steps to perform a typical bend

on a workpiece. If needed, the brake stop can be

adjusted so more than one bend can be made at

the same location. For pan or box bending, refer

to Pan & Box Bending on Page 7. For bending

a cylinder or cone, refer to Radius Bending on

Page 8.

Loosen brake stop thumb screws and slide

1.

stop off its support rods if installed (see

Figure 8).

Thumb Screw

(1 of 2)

Brake Stop

Figure 8. Location of brake stop components.

2.

Use handle to lift fingers out of bending

prism, then remove prism from prism seat

(see Figure 9).

Support Rod

(1 of 2)

Tip: During a bending operation, workpiece scor-

ing may occur. To avoid these marks, keep the

bending prism free of burrs, and adhere a strip of

tape on the workpiece over the area that will be

bent.

Eye injury hazard! Always

wear safety glasses when

using bending function of

machine.

Do not operate unless machine has been

securely clamped or mounted to workbench.

Failure to secure machine before use could

result in crushing injuries.

Bending

Prism

Prism

Seat

Figure 9. Location of bending prism and seat.

3.

Turn bending prism over to reveal opposite

side and V-groove, then place prism in prism

seat.

Install brake stop removed in Step 1 for

4.

performing repeated bends (see Typical

Bending Operation for more information).

T32716 (Mfd. Since 05/21)

Only bend stock that falls within bending

capacity of this machine. Stock thicker than

20 gauge will damage machine when bent.

Items Needed Qty

Masking Tape .................................... As Needed

Marker/Pencil

Protractor

To perform bending operation:

Tape and mark workpiece with location of

1.

desired bend.

Install fingers and prepare bending prism for

2.

desired operation (see Changing Fingers on

Page 4 and Flipping Bending Prism).

Use handle to raise fingers.

3.

..................................................... 1

........................................................... 1

-5-

Page 6

Crushing hazard! Always

keep hands clear when

5.

While holding workpiece steady, use handle

to lower fingers and bend workpiece to

desired bend radius (see Figure 13).

using this machine.

4.

Rest workpiece on bending prism and use

handle to lower fingers enough to align mark

from Step 1 with finger tips (see Figure 11).

Desired Bend

Position

Workpiece

Figure 111. Example of aligning workpiece with

finger tips.

— If brake stop keeps workpiece from resting

flat on bending prism, loosen brake stop

thumb screws and remove brake stop (see

Figure 12).

Tip: Use protractor to measure bend angle.

Figure 13. Example of bent workpiece.

Raise fingers and remove workpiece.

6.

7. If reverse bend is required, repeat Steps 1–6

but with workpiece upside-down.

Note: Minimum reverse bend possible is 1⁄4"

(see Figure 14).

— If performing repeated bends, loosen brake

stop thumb screws and adjust brake stop

to edge of workpiece (see Figure 12).

Thumb Screw

(1 of 2)

Brake Stop

Figure 12. Location of brake stop and thumb

screws.

-6-

Figure 14. Example of reverse bend.

T32716 (Mfd. Since 05/21)

Page 7

Pan & Box Bending

When bending a piece of flat metal into a box, you

should be able to make the first two bends with

whichever fingers you like (see Figure 15).

Figure 15. Example of straight bending.

Use this information as well as the following steps

to bend a pan or box. Install the brake stop so the

pan height will be the same on all four sides.

Eye injury hazard! Always

wear safety glasses when

using bending function of

machine.

However, for the remaining bends, there needs to

be clearance for those first bends (see Figure 16).

8" Finger

!

Bending Prism

Figure 16. Insufficient clearance for first bends.

To provide the necessary clearance for the previous bends, the smaller fingers can be installed

like shown in Figure 17.

Do not operate unless machine has been

securely clamped or mounted to workbench.

Failure to secure machine before use could

result in crushing injuries.

Only bend stock that falls within bending

capacity of this machine. Stock thicker than

20 gauge will damage machine when bent.

Items Needed Qty

Masking Tape .................................... As Needed

Marker/Pencil

Protractor or Machinist's Square

To perform pan & box bending:

Follow Steps 1–6 of Typical Bending

1.

Operation beginning on Page 5 to perform

first two bends (see Figure 15).

Tape and mark workpiece with location of

2.

third bend.

..................................................... 1

....................... 1

Smaller Fingers

Bending Prism

Figure 17. Sufficient clearance for first bends.

T32716 (Mfd. Since 05/21)

Install fingers for third bend (see Changing

3.

Fingers on Page 4).

-7-

Page 8

Note: Fingers do not need to equal length of

bend. They can be placed with a small distance between them as long as outside length

equals workpiece bend (see Figure 18).

Fingers

Figure 18. Proper finger placement.

4.

Bend remaining sides.

Shearing Operation

In addition to bending metal, this machine also

consists of a set of reversible knives that shear up

to 20-gauge full width mild steel. A movable lower

knife passes next to the fixed upper knife, creating

a shearing action. For repetitive cuts at the same

dimensions, the shear stop can be used.

Always wear safety glasses, work boots,

and protective work gloves when shearing

and handling sheet metal. Sheared metal

can be sharp and easily cut.

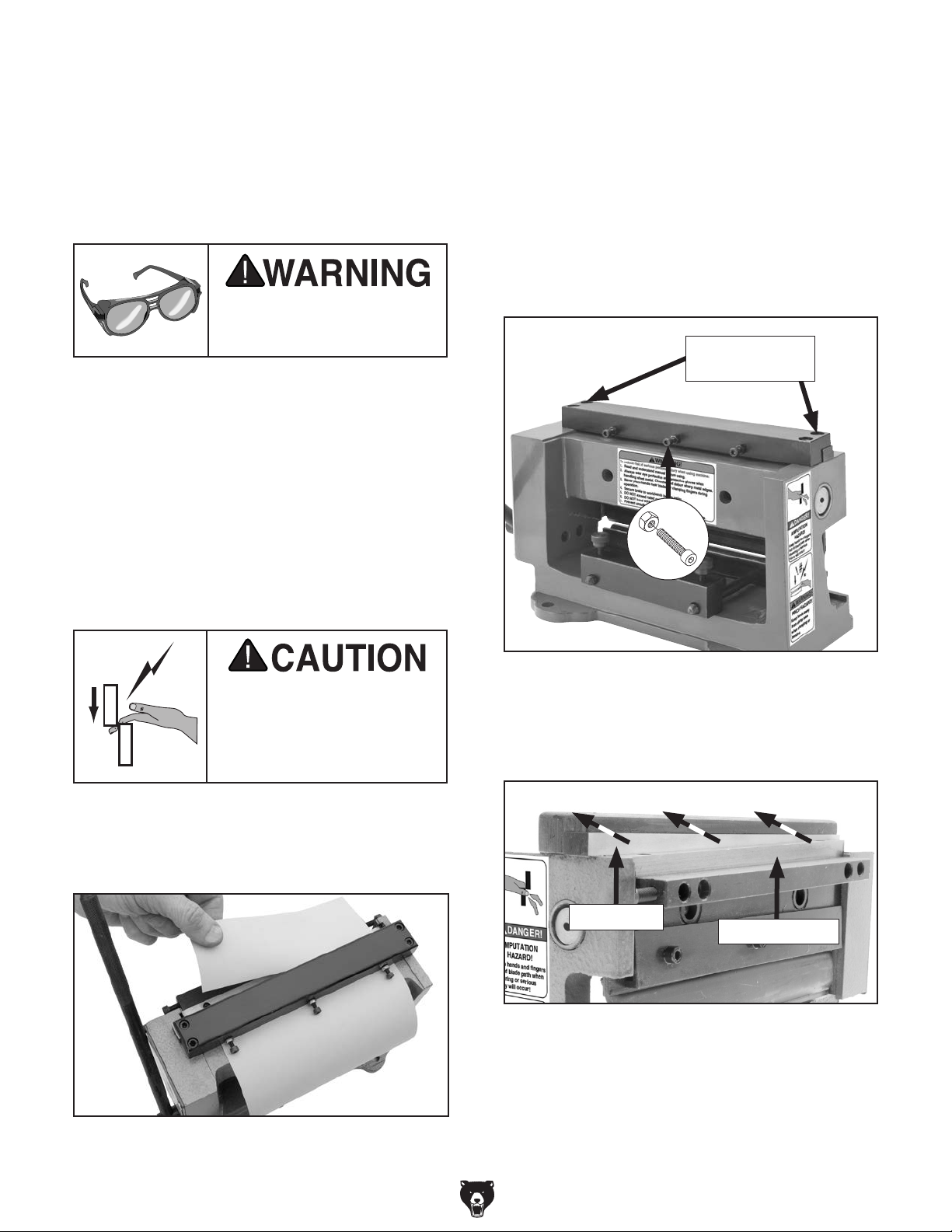

Radius Bending

Radius bending is most commonly used to make

cylinders and cones, both of which are formed by

making a series of small, closely-spaced bends in

the workpiece.

For cylinders, the bends are evenly spaced and

parallel to the workpiece edges while cones have

a series of uneven bends that are not parallel to

the edges (see Figure 19).

Uneven Bends

Even Bends

Do not operate unless machine has been

securely clamped or mounted to workbench.

Failure to secure machine before use could

result in crushing injuries.

Only shear stock that falls within capacity of

this machine. Stock thicker than 20 gauge

will damage machine when sheared.

Items Needed Qty

Safety Glasses .............................................1 Pr.

Work Boots

Protective Gloves..........................................1 Pr.

Marker/Pencil

To perform shearing operation:

Mark workpiece with location of desired cut.

1.

...................................................1 Pr.

..................................................... 1

Figure 19. A typical cylinder and cone.

Use this information as well as the steps listed in

Typical Bending Operation beginning on Page

5 to radius bend.

-8-

2. Use handle to lower shearing blade (see

Figure 20).

T32716 (Mfd. Since 05/21)

Page 9

Make sure no body part is

near knives when shearing

occurs. Failure to follow

this warning may result in

cut or pinch injuries.

3. Insert workpiece between blades through

rear of machine and align mark from Step 1

with fixed blade edge (see Figure 20).

Fixed Blade Edge

Shearing

Blade

Cleaning

Cleaning the Model T32716 is relatively easy.

Periodically wipe down the machine to remove

dust and oil.

Protect the unpainted cast iron surfaces of your

machine by applying regular applications of a

product that is designed to prevent rust and oxidation, or you can use products like those shown in

Figure 22.

G5562—SLIPIT® 1 Qt. Gel

G5563—SLIPIT

G2871—Boeshield

®

12 Oz. Spray

®

T-9 12 Oz. Spray

Figure 20. Workpiece aligned to fixed blade.

— If shear stop prevents aligning mark with

fixed blade, loosen shear stop thumb

screws and remove shear stop (see

Figure 21).

— If performing repeated cuts, loosen shear

stop thumb screws and adjust shear stop

to edge of workpiece (see Figure 21).

Shear Stop

Thumb Screw

(1 of 2)

Figure 22. Recommended products for protect-

ing unpainted cast iron/steel parts on machinery.

Lubrication

When lubricating this machine, first clean the

components. This step is critical because grime

and dust build up on lubricated components,

which makes them hard to move. Simply adding

more lubricant will not result in smooth moving

parts.

For lubricating, we suggest an ISO 68 equivalent

lubricant and a NLGI#2 grease (see Figure 23).

SB1365 —South Bend Way Oil-ISO 68

T26418 —Syn-O-Gen Synthetic Grease

Figure 21. Location of shear stop components.

4.

While holding workpiece steady, use handle

to raise shearing blade and cut workpiece.

T32716 (Mfd. Since 05/21)

Figure 23. Recommended products for machine

lubrication.

-9-

Page 10

Items Needed Qty

Disposable Rags ............................... As Needed

Mineral Spirits

Model SB1365 or ISO 68 Equiv.

Wire Brushes

Phillips Head Screwdriver #1

Model T26419 or NLGI#2 Equiv.

.................................... As Needed

........ As Needed

..................................................... 2

............................. 1

....... As Needed

Loosen handle thumb knob and remove

4.

handle (see Figure 26).

Remove (4) Phillips head screws and remove

5.

gear cover (see Figure 26).

Gear Cover

To lubricate machine:

1.

Use rag and mineral spirits to clean away

grease and built up grime from surfaces

of fingers, bending prism, knuckle sockets,

slide, and shearing knives (see Figure 24).

Knives

Slide

Bending Prism

Figure 24. Lubrication locations.

Knuckle

Socket

(1 of 2)

Finger

(1 of 8)

x 4

Handle

Thumb Knob

Figure 26. Gear cover removal components.

6. Use mineral spirits, wire brush, and rags to

clean and dry rack and pinion gears and gear

housing (see Figure 27).

Gear Housing

2. Allow cleaned parts to dry before applying

ISO 68 lubricant with clean rag.

Apply a few drops ISO 68 lubricant to end

3.

shaft (see Figure 25) and pump handle to

work lubricant into machine body.

End Shaft

Figure 25. End shaft location.

Rack &

Pinion

Figure 27. Rack and pinion and gear housing

locations.

Brush heavy coat of NLGI#2 grease on gears

7.

with clean wire brush.

Install gear cover and secure with screws

8.

from Step 5.

Install handle and pump to disperse grease.

9.

-10 -

T32716 (Mfd. Since 05/21)

Page 11

Adjusting Fixed Knife

The fixed (top) knife should be positioned against

the shearing (bottom) knife to achieve a snug and

consistent knife rub without causing the knives to

bind at any location. Misalignment of the knives

can result in machine damage and poor cutting

results.

Eye injury hazard! Always

wear safety glasses when

servicing machine.

Items Needed Qty

Safety Glasses ...........................................1 Pair

Light Machine Oil............................... As Needed

Scrap Paper

Wrench or Socket 3mm

Hex Wrench 4mm

Protective Gloves........................................1 Pair

...................................... As Needed

..................................... 1

.............................................. 1

— If shear cuts paper without binding, no

adjustment is required.

— If shear cuts paper poorly or if knives bind,

proceed to Step 3.

Loosen (2) knife retaining cap screws shown

3.

in Figure 29.

Loosen (3) cap screws with jam nuts shown

4.

in Figure 29 a full turn.

Knife Retaining

Cap Screws

To adjust fixed knife:

Oil knives with light machine oil.

1.

Make sure no body part is

near knives when shearing

occurs. Failure to follow

this warning may result in

cut or pinch injuries.

2. While keeping fingers clear of knives, shear

sheet of paper to test shearing results (see

Figure 28).

x 3

Figure 29. Fixed knife adjustment components.

While wearing protective gloves, carefully

5.

push fixed knife back and away from shearing knife (see Figure 30).

Fixed Knife

Shearing Knife

Figure 28. Example of using paper to test

shearing results.

T32716 (Mfd. Since 05/21)

Figure 30. Location of knives and direction of

fixed knife travel.

-11-

Page 12

No part of fixed knife should contact or

overlap shearing knife for next step. If

knives overlap, knives or other machine

components may be damaged.

Use handle to lift shearing knife completely.

6.

Adjust cap screws from Step 4 until fixed

7.

knife is flush with shearing knife.

IMPORTANT: Shearing knife should still be

able to move past fixed knife without binding.

When fixed knife is aligned with shearing

8.

knife, tighten jam nuts from Step 4 without

moving cap screws to secure setting.

Tighten screws from Step 3.

9.

Repeat test from Step 2 to check adjustment.

10.

Items Needed Qty

Safety Glasses .............................................1 Pr.

Protective Gloves..........................................1 Pr.

Hex Wrenches 3, 4mm

Light Machine Oil............................... As Needed

To rotate or replace knives:

While wearing protective gloves, remove (4)

1.

knife retainer cap screws, knife retainer, and

fixed knife (see Figure 31).

Remove (2) shearing knife retaining cap

2.

screws and shearing knife (see Figure 31).

x 2

................................1 Ea.

Knife Retainer

x 4

Rotating/Replacing Knives

Both of the knives on the Model T32716 can be

removed and rotated to reveal one of the additional cutting edges. Both knives have four available

cutting edges. However, the position of the upper

and lower knives are not interchangeable. When

all edges on the knives have reached the end of

their usable life, they can be reground by using

wet grinding techniques for SK-4 metal or better.

If sharpening services are not available in your

area, replacement knives are available through

grizzly.com and must be replaced as a set.

Eye injury hazard! Always

wear safety glasses when

servicing machine.

Shearing Knife

Figure 31. Knife removal components.

Rotate or flip knives to expose new cutting

3.

edges, or replace knives.

Lubricate knives, then re-install shearing

4.

knife with (2) cap screws removed in Step 2.

Re-install fixed knife and secure in place with

5.

knife retainer and (4) cap screws removed in

Step 1.

Refer to Adjusting Fixed Knife on Page 11

6.

to ensure knives are adjusted correctly.

Fixed Knife

-12-

T32716 (Mfd. Since 05/21)

Page 13

45

Please Note: We do our best to stock replacement parts whenever possible, but we cannot guarantee that all parts shown here

are available for purchase. Call (800) 523 - 4777 or visit our online parts store at www.grizzly.com to check for availability.

43

14

13

12

42

Parts Breakdown & List

1

7

11

10

3

4

9

2

8

6

21

44

25

34

33

21

22

21

5

36

46

15

16

17

18

19

31

41

25

24

39

32

37

38

47

29

20

23

30

40

29

28

35

REF PART # DES CRIP TI ON REF PART # DES CRIP TI ON

1 PT32716001 CAP SCREW M5-.8 X 25 25 PT32716025 SPACER 22 X 27 X 10

2 PT32716002 CAP SCREW M4-.7 X 25 26 PT32716026 SPACER 19 X 22 X 6

3 PT32716003 HEX NUT M4- . 7 27 PT32716027 P I NI O N GE AR HUB

4 PT32716004 CAP SCREW M5-.8 X 16 28 PT32716028 K NURLE D THUMB SCRE W M4- . 7 X 8, D1 2

5 PT32716005 BALL STUD 29 PT32716029 GEAR PIN 10 X 35

6 PT32716006 FIXED BLADE 30 PT32716030 GEAR

7 PT32716007 SHEARI NG BLADE 31 PT32716031 PI VOT ROD

8 PT32716008 FIXED BLADE RETAINER 32 PT32716032 RA CK A RM

9 PT32716009 SLIDE 33 PT32716033 GEAR COVER

10 PT32716010 CAP SCREW M4-.7 X 10 34 PT32716034 PHLP HD SCR M4-. 7 X 8

11 PT32716011 SHEAR STOP ANCHOR PLATE 35 PT32716035 HE X WRE NCH 4MM

12 PT32716012 CAP SCREW M5-.8 X 12 36 PT32716036 HEX BOLT M10-1.5 X 70

13 PT32716013 FI NG ER GI B 37 PT32716037 FLAT WASHER 10MM

14 PT32716014 CAP SCREW M5-.8 X 12 38 PT32716038 HEX NUT M10 -1. 5

15 PT32716015 FI NG ER 8" 39 PT32716039 BODY

16 PT32716016 FINGER 3/8" 40 PT32716040 BRAKE STOP ROD

17 PT32716017 FINGER 9/16" 41 PT32716041 FINGER SEATING TOOL

18 PT32716018 FINGER 13/16" 42 PT32716042 SHEAR STOP ROD

19 PT32716019 FINGER 1-9/16" 43 PT32716043 SHEAR STOP

20 PT32716020 BENDING PRI SM 44 PT32716044 SHEAR STOP MOUNTI NG BRACKET

21 PT32716021 K NURLE D THUMB SCRE W M5- . 8 X 20 , D16 45 PT32716045 FL AT HD S CR M5-. 8 X 8

22 PT32716022 BRAKE STOP 46 PT32716046 BUSHI NG

23 PT32716023 HA NDLE 47 PT32716047 HE X WRE NCH 3MM

24 PT32716024 TAPER PIN 6 X 40

27

26

T32716 (Mfd. Since 05/21)

-13-

Page 14

Labels & Cosmetics

REF PART # DES CRIPTION REF PART # DES CRIPTION

104

To reduce risk of serious personal injury when using machine:

1. Read and understand manual before using.

2. Always wear eye protection and protective gloves when

handling sheet metal. Chamfer and deburr sharp metal edges.

3. Never place hands near blades or clamping fingers during

operation.

4. Secure brake to workbench before using.

5. DO NOT exceed rated capacity of machine.

6. DO NOT bend wire or nails.

7. Prevent unauthorized use by children or untrained users.

WARN ING !

101

MODEL T32716

8" BENCHTOP METAL

SHEAR/BRAKE

Specifications

Max. Width: 7-7/8"

Max. Thickness (Mild Steel): 20 Ga.

Min. Reverse Bend: 1/4"

Max. Height of Pan/Box Sides: 5/8"

Min. Radius Bend: ??"

Weight: ?? lbs.

Date

Mfd. for Grizzly in China

Serial Number

102

DANGER!

AMPUTATION

HAZARD!

Keep hands and fingers

out of blade path when

shearing or serious

injury will occur!

103

PINCH HAZARD!

Keep hands away

from clamp area

when clamping or

bending.

101 PT32716101 MACHINE ID LABEL 103 PT32716103 TOUCH-UP PA I NT, GRI ZZLY GRE EN

102 PT32716102 AMPUTATI ON/PINCH LABEL 104 PT32716104 WARNING LABEL

Safety labels help reduce the risk of serious injury caused by machine hazards. If any label comes

off or becomes unreadable, the owner of this machine MUST replace it in the original location

before resuming operations. For replacements, contact (800) 523-4777 or www.grizzly.com.

-14-

T32716 (Mfd. Since 05/21)

Page 15

WARRANTY & RETURNS

Grizzly Industrial, Inc. warrants every product it sells for a period of 1 year to the original purchaser from

the date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligence, accidents, repairs or alterations or lack of maintenance. This is Grizzly’s sole written warranty

and any and all warranties that may be implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited to the duration of this written warranty. We do not warrant or represent

that the merchandise complies with the provisions of any law or acts unless the manufacturer so warrants.

In no event shall Grizzly’s liability under this warranty exceed the purchase price paid for the product and

any legal actions brought against Grizzly shall be tried in the State of Washington, County of Whatcom.

We shall in no event be liable for death, injuries to persons or property or for incidental, contingent, special,

or consequential damages arising from the use of our products.

The manufacturers reserve the right to change specifications at any time because they constantly strive to

achieve better quality equipment. We make every effort to ensure that our products meet high quality and

durability standards and we hope you never need to use this warranty.

In the event you need to use this warranty, contact us by mail or phone and give us all the details. We will

then issue you a “Return Number,’’ which must be clearly posted on the outside as well as the inside of

the carton. We will not accept any item back without this number. Proof of purchase must accompany the

merchandise.

Please feel free to write or call us if you have any questions about the machine or the manual.

Thank you again for your business and continued support. We hope to serve you again soon.

To

you can

applicable information for

take advantage of this warranty, you must register it at https://www.grizzly.com/forms/warranty, or

scan the QR code below to be automatically directed to our warranty registration page. Enter all

the product.

WARRANTY

Page 16

Loading...

Loading...