Page 1

MODEL T32591

13" SPIRAL CUTTERHEAD

FOR DEWALT PLANERS

INSTRUCTIONS

For questions or help with this product contact Tech Support at (570) 546-9663 or techsupport@grizzly.com

Introduction

The T32591 13" Spiral Cutterhead is designed

to replace the straight-knife cutterhead on the

DeWalt DW735 and DW735X (T22222) Planers.

The total procedure for changing the cutterhead

and reassembling the planer takes approximately

three hours. Read these instructions thoroughly

before beginning. These instructions make reference to many procedures detailed in your planer

manual. Always consult your manual for these

procedures. We strongly recommend using the

new replacement bearings included with the

T32591, even if the existing bearings appear to be

in good condition. Call Technical Support at (570)

546-9663 if you need help.

The Model T32591 13" Spiral Cutterhead is

designed to be used only with the DeWalt

DW735 and DW735X (T22222) Planers. DO

NOT install the T32591 in any other planer

model or make. Doing so could result in

property damage or serious personal injury.

Recommended Tools

Description Qty

Open-End Wrenches 6, 24 mm ...................1 Ea.

Deep Well Sockets 32, 40mm

Retaining Ring Pliers (Internal and External)

Hex Wrench 4mm

Torx Driver T-30 (Included with DW735/X)

Phillips Screwdriver #2

Steel Hammer

Hex Bolt

Heavy Leather Gloves

Wood Board (Minimum 12" Length)

Scrap Cardboard

5

⁄16"-18 x 2 ........................................... 1

.............................................. 1

...................................... 1

................................................... 1

................................1 Pair

............................... As Needed

.....................1 Ea.

.... 1

....... 1

.................. 1

Inventory (Figure 1)

Description Qty

A. Ball Bearing 6202-2NSE ............................ 1

Ball Bearing 6204-2NSE ............................ 1

B.

Flat Hd Torx Screws T-25 10-32 x ½" ........ 5

C.

Indexable Inserts 15 x 15 x 2.5mm ............ 5

D.

T-Handle Torx Driver T-25 .......................... 1

E.

Helical Pinion Gear 8T ............................... 1

F.

Spiral Cutterhead 13" ................................. 1

G.

Specifications

Maximum Width of Cut

Cutterhead Diameter

Number of Cutter Rows

Total Number of Indexable Cutters

................................... 13"

..................................... 17⁄8"

..................................... 3

COPYRIGHT © MAY, 2021 BY GRIZZLY INDUSTRIAL, INC.

NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

(FOR MODELS MFD. SINCE 05/21) #KS21865 PRINTED IN TAIWAN

.................. 30

C

A B

F

E

Figure 1. Model T32591 Inventory.

D

G

V1.05.21

Page 2

Cutterhead knives and inserts are razor

sharp! Always wear heavy leather gloves

when handling cutterheads, and avoid

contact with knives and inserts whenever

possible. Failure to comply can result in

serious personal injury.

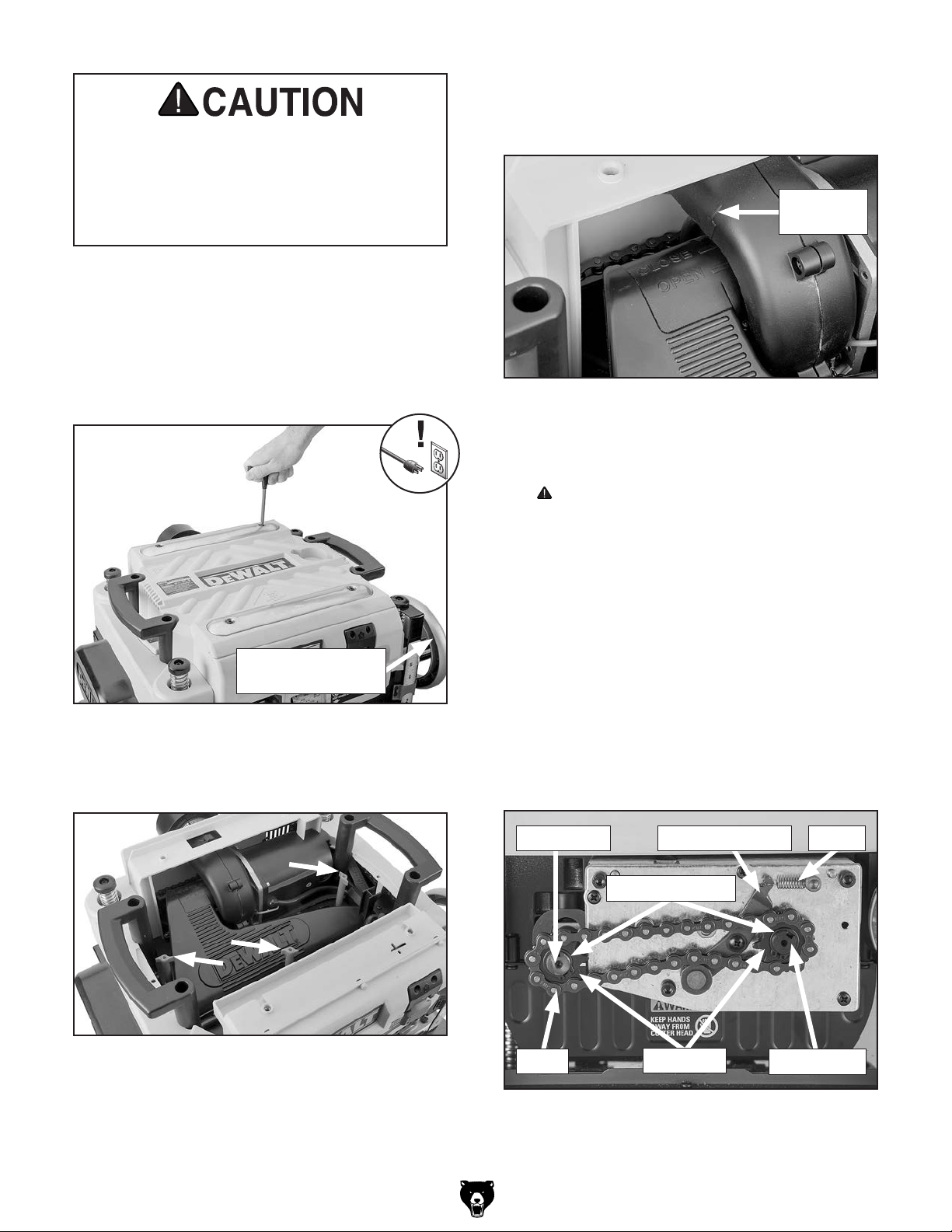

Removing Existing Cutterhead

1. DISCONNECT MACHINE FROM POWER.

2. Use T-30 Torx driver included with DW735/X

to remove screws holding top cover (see

Figure 2).

4.

Rotate dust shroud away from cutterhead so

alignment arrow on fan housing aligns with

OPEN line on dust shroud (see Figure 4).

Alignment

Arrow

Figure 4. Alignment arrow on dust shroud.

Pull dust shroud away from fan housing and

5.

remove.

CAUTION: Cutterhead will be exposed at

this time.

Depth Adjustment

Crank Handle

Figure 2. Removing top cover.

Remove red wing nuts holding dust shroud

3.

and set aside (see Figure 3).

. Remove gearbox cover located behind turret

6

lock on left side of planer.

Remove external retaining rings on front and

7.

rear rollers (see Figure 5).

Remove spring from chain tensioner (see

8.

Figure 5).

Remove sprockets and chain (see Figure 5).

9.

Remove spacer on front roller (see Figure 5).

10.

Rear Roller Spring

Retaining Rings

Chain Tensioner

-2-

Figure 3. Location of red wing nuts.

Chain

Figure 5. Gearbox area components.

Sprockets

Model T32591 (Mfd. 05/21)

Front Roller

Page 3

11.

Remove depth adjustment crank handle on

right side of planer.

Remove pulley cover.

12.

13. Remove chain tensioner assembly (see

Figure 6).

Remove sprockets and chain (see Figure 6).

14.

Chain Tensioner Assembly

Cutterhead Pulley

Press cutterhead lock lever and rotate

18.

cutterhead until T-30 Torx screws are visible

on knife clamp (see Figure 8).

Torx Screw

Figure 8. T-30 Torx screws on knife clamp.

Remove screws securing knife clamp.

19.

Sprockets

Figure 6. Pulley area components.

15. Press cutterhead lock lever down to allow

cutterhead to rotate (see Figure 7).

Cutterhead

Lock Lever

Figure 7. Cutterhead lock lever.

Remove drive belt by slowly rotating

16.

cutterhead pulley counterclockwise and pulling belt off. Use rear roller to secure belt after

removal.

Chain

Note: T-30 Torx driver included with DW735/X

has magnets built into handle.

Attract knife clamp with magnet and remove.

20.

21. Attract knife with magnet and remove.

22. Repeat Steps 18–21 until all three knives

have been removed from cutterhead.

Remove cutterhead lock lever and spring

23.

underneath that is hidden from view.

Note: Cutterhead lock lever is not compat-

ible with the Model T32591, but should be

retained in the event planer is ever returned

to original configuration.

Unfasten gearbox attachment screws (see

24.

Figure 9).

Cover table under cutterhead carriage with

17.

scrap cardboard to protect surface from

dropped parts/tools.

Model T32591 (Mfd. 05/21)

Figure 9. Gearbox attachment screws.

-3-

Page 4

25. While supporting gearbox, turn speed selector switch on front panel clockwise to release

(see Figure 10).

Note: Gearbox will separate from planer after

turning speed selector switch to speed "2".

Speed Selector

Switch

Remove helical pinion gear from cutterhead

28.

(see Figure 12).

Remove retaining ring (see Figure 12).

29.

Helical Pinion

Gear

Retaining

Ring

Figure 12. Helical pinion gear and retaining ring.

Figure 10. Supporting gearbox while turning

speed selector switch.

26.

Pull gearbox out and rest it on planer mount.

Note: Gearbox speed selection rod and posi-

tioning pin will prevent gearbox from being

completely removed from planer. Secure

gearbox to planer with tape or rope to prevent

it from shifting during disassembly.

Insert a wood board at least 12" in length

27.

between cutterhead and cutterhead carriage

(see Figure 11). Verify cutterhead no longer

rotates.

Remove 24mm hex nut from cutterhead pul-

30.

ley (see Figure 13).

Remove cutterhead pulley, key, and spacer

31.

(see Figure 13).

Spacer

Figure 13. Cutterhead pulley assembly.

32.

Remove retaining ring from right bearing

bore.

Key

Cutterhead

Pulley

24mm

Nut

Figure 11. Wood board between cutterhead and

carriage.

-4-

Model T32591 (Mfd. 05/21)

Page 5

33. Install 5⁄16"-18 x 2 hex bolt into helical pinion

gear threads (see Figure 14).

. Remove wood board and gently tap hex bolt

34

dead center with hammer until cutterhead is

unseated from carriage (see Figure 14).

Hex Bolt

Figure 14. Hex bolt in helical gear threads.

. Remove spiral cutterhead from packaging.

1

Lightly oil left and right bearing bore surfaces

2.

and remove any dust or dirt.

Lower cutterhead into carriage while guiding

3.

threaded end through right bearing bore (see

Figure 16).

Pull cutterhead through right bearing bore.

35.

36. Use a 32mm deep well socket or wood block

to remove left bearing from bore.

Note: Focus impact to bearing on outer race

(see Figure 15). Take care not to damage

rubber seal.

Outer Race

Rubber

Seal

Inner Race

Figure 15. Bearing outer race.

Figure 16. Example of guiding cutterhead.

. Install 5⁄16"-18 x 2 hex bolt into helical pinion

4

gear threads.

Seat 6202-2NSE ball bearing into left bearing

5.

bore using hex bolt as an alignment guide.

Use a 32mm deep well socket or wood block

6.

to gently tap bearing into bore until retaining

ring groove is visible. Bearing will be flush

with internal carriage wall when fully seated.

Note: If using a wood block to install bear-

ings, ensure that impact is evenly distributed

around outer race to prevent bearing tilt (see

Figure 17).

1

Installing T32591 Spiral Cutterhead

We strongly recommend using the new replacement bearings included with the Model T32591,

even if the existing bearings appear to be in good

condition.

Wrap the new bearings and place them in a freezer overnight. This will cause the bearing metal to

contract, making them easier to install.

Model T32591 (Mfd. 05/21)

4

3

Figure 17. Bearing impact distribution.

Re-install retaining ring into bearing bore

7.

groove.

2

-5-

Page 6

8. Seat 6204-2NSE ball bearing into right bearing bore using threaded cutterhead end as an

alignment guide.

Gently stretch drive belt over cutterhead pul-

17.

ley while slowly rotating pulley clockwise until

belt is centered.

Use a 40mm deep well socket or wood block

9.

to gently tap bearing into bore until retaining

ring groove is visible. Bearing will be flush

with internal carriage wall when fully seated.

Re-install retaining ring into bearing bore

10.

groove.

Insert a wood board at least 12" in length

11.

between cutterhead and cutterhead carriage.

Verify cutterhead no longer rotates.

Install spacer, key, and cutterhead pulley

12.

onto cutterhead end (see Figure 18).

Spacer

Key

Cutterhead

Pulley

24mm

Nut

Note: Drive belt and pulley wheels have

grooves along their surface for alignment.

Verify drive belt is centered on cutterhead

18.

and drive pulleys before re-installing drive

belt cover.

Turn speed selector switch clockwise to

19.

speed "2".

Re-install gearbox by aligning both locating

20.

pins on gearbox assembly with both alignment holes on planer (see Figure 20).

Alignment

Holes

Figure 18. Cutterhead pulley assembly.

Re-install 24mm hex nut on cutterhead pulley.

13.

14. Remove hex bolt and install helical pinion

gear.

Remove wood board.

15.

16. Remove drive belt cover located on right side

(see Figure 19) and verify that drive belt is

centered on drive wheel.

Locating

Pins

Figure 20. Gearbox locating pin alignment.

While installing gearbox, confirm that "U"

21.

bracket attached to speed selector switch

engages with positioning pin on gearbox

speed selection rod (see Figure 21).

Note: If gearbox does not fully seat during

Steps 20–21, slowly rotate cutterhead pulley

back-and-forth to re-align helical pinion gear

with gearbox.

"U"

Bracket

-6-

Figure 19. Drive belt cover location.

Speed

Selector Rod

Figure 21. Speed selector rod and "U" bracket.

Model T32591 (Mfd. 05/21)

Page 7

22. Turn speed selector switch counterclockwise

to speed "1" to grasp positioning pin with "U"

bracket.

Re-install screws removed from gearbox in

23.

Step 24 on Page 3 of Removing Existing

Cutterhead instructions.

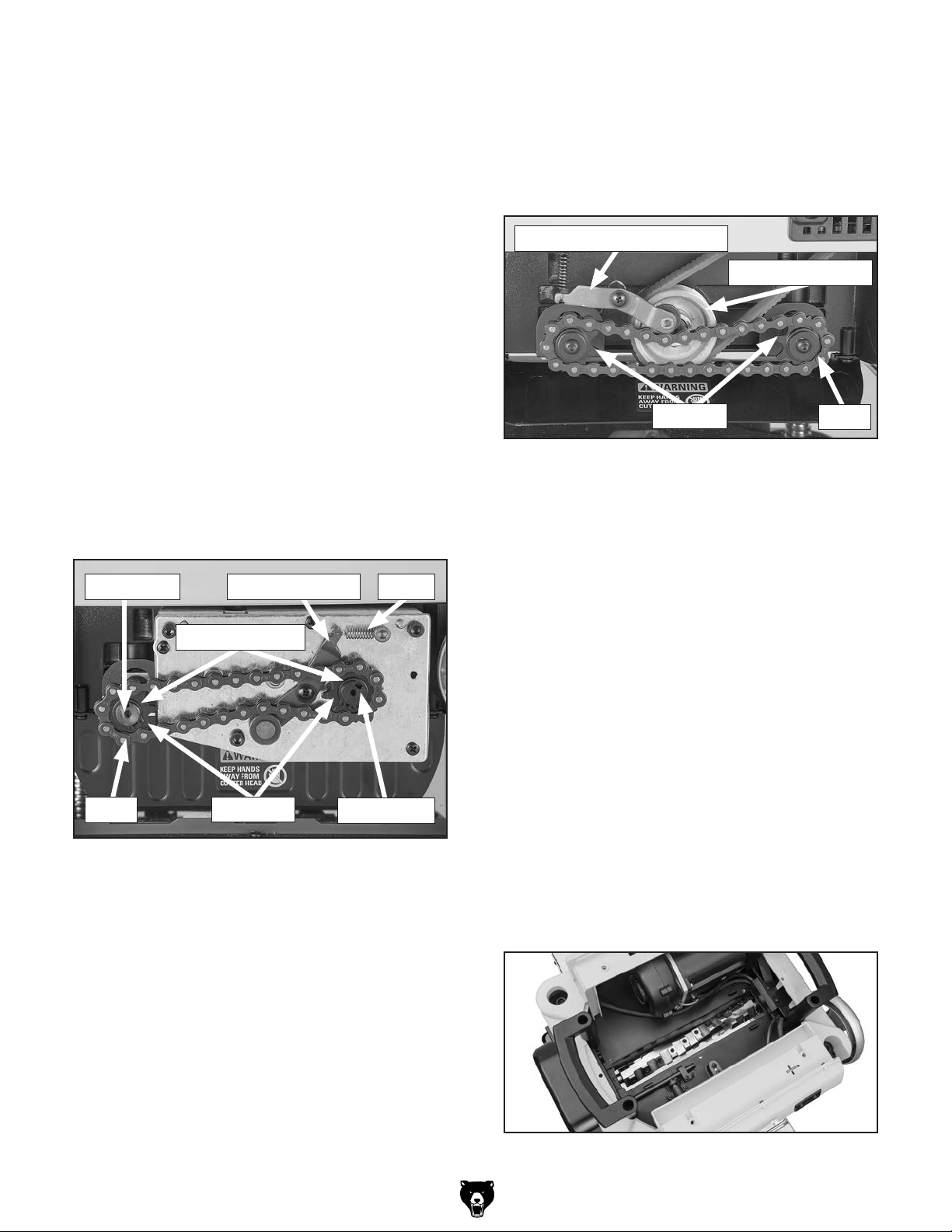

30.

Re-install sprockets and chain on front and

rear rollers in pulley area (see Figure 23).

Re-install chain tensioner and re-attach

31.

spring. Verify tensioner is engaged with chain

(see Figure 23).

Test for smooth operation of speed selection

24.

assembly by cycling speed selector switch

from "1" to "2" and then back to "1".

Re-install spacer on front roller.

25.

26. Re-install sprockets and chain on front and

rear rollers (see Figure 22).

Re-attach spring to chain tensioner. Verify

27.

tensioner is engaged with chain, as shown in

Figure 22.

Re-install retaining rings on front and rear

28.

rollers (see Figure 22).

Rear Roller Spring

Retaining Rings

Chain Tensioner

Chain Tensioner Assembly

Cutterhead Pulley

Sprocket

Figure 23. Pulley area components.

Re-install pulley cover.

32.

33. Re-install dust shroud into fan housing.

Note: DO NOT re-install cutterhead lock

lever! Cutterhead lock lever is not compatible

with the Model T32591.

Rotate dust shroud towards cutterhead.

34.

Verify alignment arrow on fan housing aligns

with CLOSED line on dust shroud.

Chain

Chain

Figure 22. Gearbox area components.

Re-install gearbox cover.

29.

Sprockets

Front Roller

Re-install red wing nuts on dust shroud.

35.

Re-install top cover.

36.

Remove any cardboard used to protect plan-

37.

er table.

Connect machine to power and follow all

38.

procedures outlined in your planer manual for

adjustment and calibration.

Figure 24. Cutterhead installed in planer.

Model T32591 (Mfd. 05/21)

-7-

Page 8

REF PART # DES CRIP TIO N

Please Note: We do our best to stock replacement parts whenever possible, but we cannot guarantee that all parts shown here

are available for purchase. Call (800) 523 -4777 or visit our online parts store at www.grizzly.com to check for availability.

Rotating/Replacing Indexable Inserts

Items Needed:

Heavy Leather Gloves ................................ 1 Pair

T-Handle Torx Driver T-25

T-30 Torx Driver (Included with DW735/X)

Torque Wrench 0–50 in.-lb.

Clean Shop Rags

Degreaser

.......................................... As Needed

.............................. As Needed

Light Machine Oil............................... As Needed

................................. 1

....... 1

............................... 1

Note: Proper cleaning is critical to achiev-

ing a smooth finish. Contaminants trapped

between the insert and cutterhead will slightly

raise the insert, making noticeable marks on

your workpieces the next time you plane.

Lubricate Torx screw threads with a light

5.

machine oil, wipe excess oil off threads, and

torque screw to 48–50 inch/pounds.

The Model T32591 is equipped with 30 indexable

carbide inserts. Each insert can be rotated to

reveal any one of its four cutting edges. If one

cutting edge becomes dull or damaged, rotate it

90˚ to reveal a fresh cutting edge (see Figure 25).

Reference Dot

Figure 25. Rotating indexable insert.

Each insert has a reference dot on one corner.

As the insert is rotated, the reference dot location

can be used as an indicator of which edges are

used and which are new. When the reference dot

revolves back to its starting position, the insert

should be replaced.

6. Return planer to its original configuration by

following Steps 34–39 on Page 7 of Installing

T32591 Spiral Cutterhead instructions.

Accessories

T32861—10 Pack of Indexable Carbide Inserts

Replacement indexable carbide inserts for T32591

13" Spiral Cutterhead.

Parts Breakdown & List

3

5

6

7

4

1

2

To rotate or replace an indexable insert:

DISCONNECT MACHINE FROM POWER.

1.

Gain access to cutterhead by perform-

2.

ing Steps 2–6 of Removing Existing

Cutterhead instructions.

Remove Torx screw and indexable insert.

3.

1 PT32591001 SPI RAL CUTTERHEAD 13"

2 PT32591002 CARBIDE INSERT 15 X 15 X 2.5MM (10PK)

3 PT32591003 FLAT HD TORX SCR T-25 10-32 X 1/2

4 PT32591004 BALL BEARING 6204-2NSE

5 PT32591005 T- HANDL E TO RX DRI VER T-25

6 PT32591006 HELICAL PINION GEAR 8T

7 PT32591007 BALL BEARING 6202-2NSE

4. Clean all dust and dirt off insert and cutterhead

pocket from which insert was removed, and

replace insert so a fresh, sharp edge is facing

outward.

-8-

Model T32591 (Mfd. 05/21)

Loading...

Loading...