Page 1

MODEL T30027

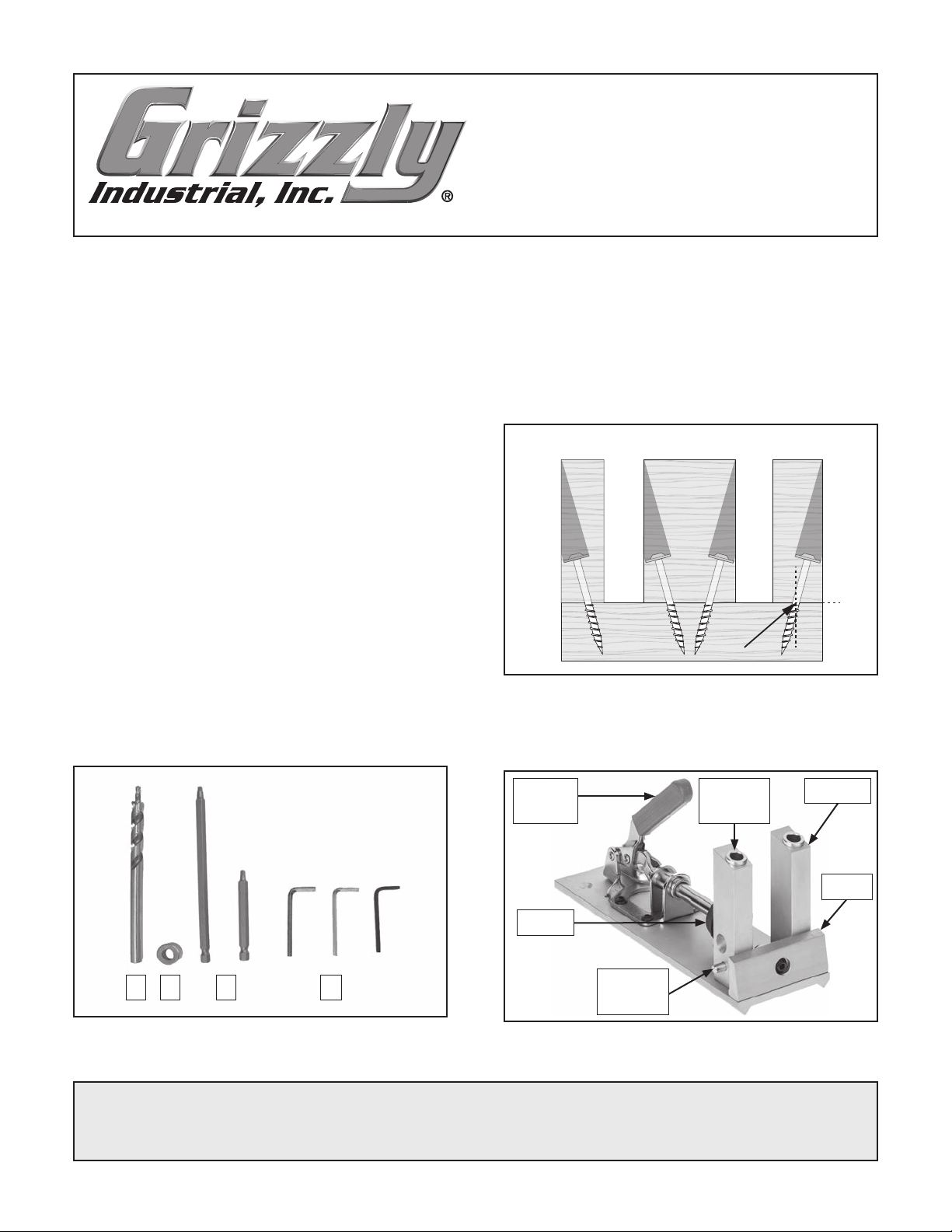

OptimalMinimum

Center Point

Maximum

POCKET HOLE GUIDE

INSTRUCTIONS

For questions or help with this product contact Tech Support at (570) 546-9663 or techsupport@grizzly.com

Introduction

The T30027 Pocket Hole Guide is a jig for creating

quick, incredibly strong joints. It can be attached

to a workpiece or mounted to a bench. Including

everything needed to get started, this jig creates

post and rail, curve, edge-to-edge, mitered frame

corner, square corner, and T joints. The T30027

comes fully assembled.

Specifications

Step Drill Bit Size .............................................3⁄8"

Optimal Workpiece Thickness

Workpiece Thickness Range

Pocket Hole Center Spacing Range

.........................3⁄4"

..................5⁄8"–11⁄2 "

........11⁄8"–3"

Inventory

Description Qty

A. Step Drill Bit 3⁄8" .......................................... 1

Stop Collar 3⁄8" ............................................ 1

B.

Square Drive Bits (#2 x 75, 150mm) .......... 2

C.

Hex Wrenches (2.5, 3, 4mm)...................... 3

D.

Pocket Hole Screws 11⁄4" (Not Shown) ... 100

E.

Pocket Hole Guide (Not Shown) ................ 1

F.

Workpiece Thickness

The optimal material thickness for the T30027

Pocket Hole Guide is

exit at the center point of the workpiece. It works

with a workpiece thickness range of

create a strong joint, thicker material may require

pocket holes on both sides.

5

⁄8"

Figure 2. Range of acceptable workpiece

3

⁄4". This allows screws to

5

⁄8" to 11⁄2 ". To

1

⁄2 "

1

3

⁄4"

thickness.

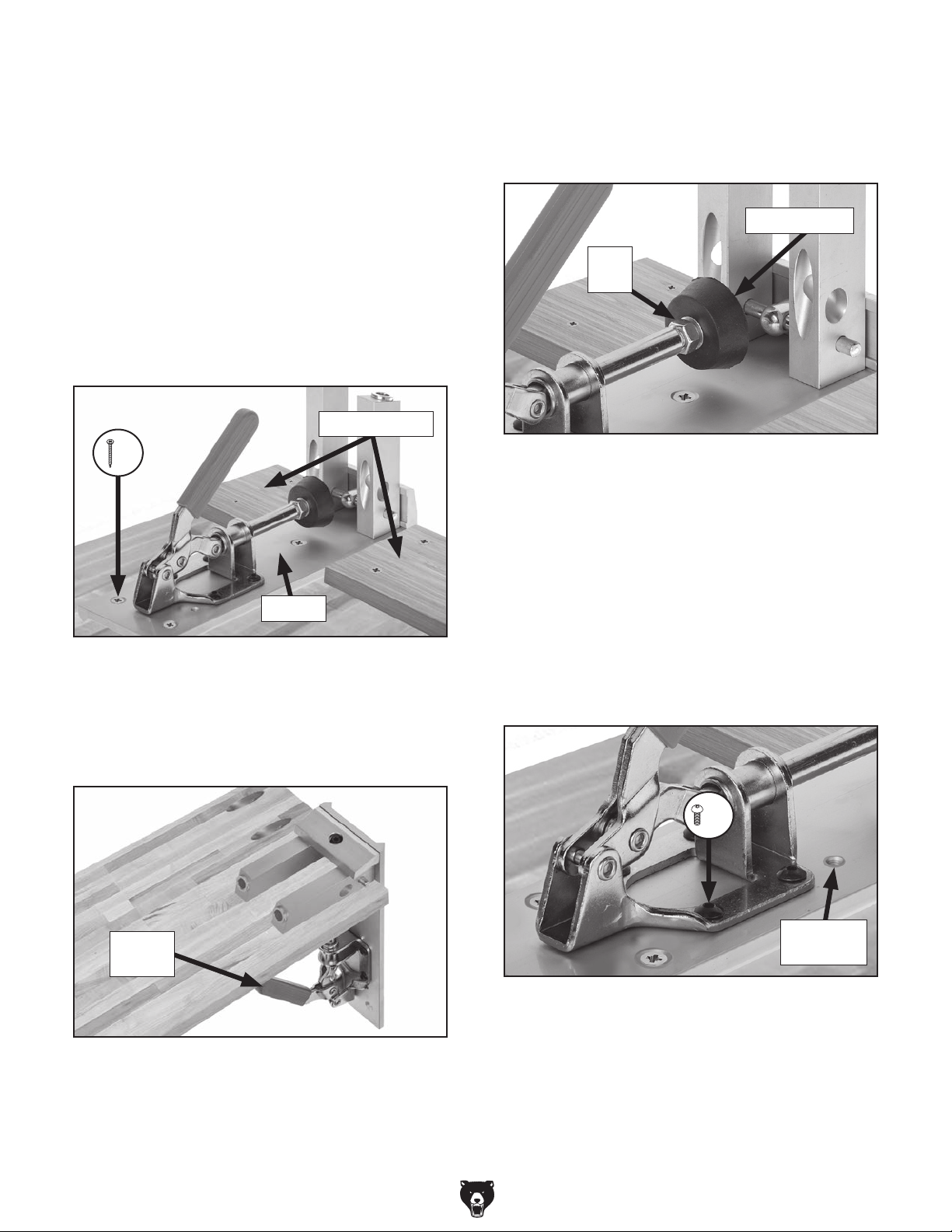

Identification

A B C D

Figure 1. Loose inventory.

COPYRIGHT © MARCH, 2019 BY GRIZZLY INDUSTRIAL, INC.

NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

(FOR MODELS MFD. SINCE 02/19) #RS20318 PRINTED IN TAIWAN

Handle

Drill Bit

Bushing

ColumnClamp

Scale

Clamp

Column

Pin

Figure 3. Pocket Hole Guide main components.

V1.0 3.19

Page 2

Mounting

The most common way to mount the jig is securing it to a bench. It can also be clamped directly

to the workpiece. The built-in clamp allows for

hands-free drilling during either procedure.

Operating Adjustments

The rubber foot on the clamp has a threaded shaft

and jam nut that can be used to adjust clamping

force against the workpiece (see Figure 6).

To mount guide to bench:

1. Secure jig to bench using (3) wood screws

(not included).

For additional workpiece support, attach

2.

scrap boards 7⁄16" thick flush with sides of jig

bed, as shown in Figure 4.

Scrap Boards

x 3

Jig Bed

Figure 4. Jig mounted to bench.

To clamp guide to workpiece:

Rubber Foot

Jam

Nut

Figure 6. Adjustable clamping components.

The clamp mechanism can be moved on the jig

bed to secure workpiece material up to 1

To move clamping mechanism:

1. Remove (4) button head cap screws that

secure clamp mechanism to jig bed (see

Figure 7).

2. Align clamp mechanism with threaded holes

in jig bed (see Figure 7).

1

⁄2 " thick.

1. Use clamp handle to clamp jig directly to

workpiece, as shown in Figure 5.

Clamp

Handle

Figure 5. Jig mounted to workpiece.

x 4

Threaded

Hole

Figure 7. Clamp placement on jig bed for thicker

workpieces.

3. Re-attach clamp mechanism with (4) button

head cap screws removed in Step 1.

-2-

T30027 Pocket Hole Guide (Mfd. 2/19+)

Page 3

Drill Bit Depth

When attached to the step drill bit, the stop collar is used to control pocket depth. This also

determines the length of screw that will join the

workpieces together.

4. Loosen set screw just enough to set step drill

bit tip 1⁄8" from jig bed, as shown in Figure 11.

To adjust stop collar:

1. Remove workpiece from jig, and ensure stop

collar set screw is flush with inside of stop collar using 2.5mm hex wrench (see Figure 8).

Set Screw

Stop

Collar

Hex Wrench

Figure 8. Set screw in stop collar.

2. Slide stop collar onto step drill bit and lightly

tighten 23⁄8" from end of shank (see Figure 9).

Shank

Tip

23⁄8"

Figure 9. Stop collar on step drill bit.

Step Drill Bit

Set

Screw

Jig

1

⁄8"

Bed

Figure 11. Step drill bit 1⁄8" from jig bed.

5.

Tighten set screw.

Note: The stop collar is now set for the

1

included 1

⁄4" pocket hole screws. Adjusting

the collar up or down the step drill bit will

allow for deeper or shallower pockets and

determine fastener length.

Eye injury hazard! Always

wear safety glasses when

using this tool.

3.

Insert step drill bit into drill bit bushing, allow-

ing stop collar to rest on top (see Figure 10).

Stop

Collar

Drill Bit

Bushing

Column

Figure 10. Stop collar resting on drill bit bushing.

Preparing Drill Bit Bushings

Before using the jig on a workpiece, create multiple pocket holes on a scrap board. This sets the

bushings flush with the columns and smooths

uneven surfaces between the stop collar and

drill bit bushings. This results in a consistent and

accurate drilling depth for this jig (see Figure 12).

Scrap

Before

After

Figure 12. Before and after preparing bushings.

Board

Receiving

Board

T30027 Pocket Hole Guide (Mfd. 2/19+)

-3-

Page 4

Adjusting Pocket Hole Spacing

The Pocket Hole Guide can provide approximately 1

centers while clamped in a single position.

To adjust spacing:

1. With 4mm hex wrench, loosen button head

1

⁄8" to 3" of spacing between pocket hole

cap screw beneath scale until columns slide

freely on column pin (see Figure 13).

Column

Pin

Button Head Cap Screw

2.

Move columns to desired measurement, as

referenced on the scale shown in Figure 14.

Inside

Columns

Scale

Figure 14. Inside of column against scale.

3. Tighten button head cap screw.

Figure 13. Button head cap screw location.

-4-

T30027 Pocket Hole Guide (Mfd. 2/19+)

Loading...

Loading...