Grizzly T27577 Owner's Manual

MODEL T27577

PICTURE FRAMING

MACHINE/UNDERPINNER

OWNER'S MANUAL

(For models manufactured since 3/16)

COPYRIGHT © APRIL, 2016 BY GRIZZLY INDUSTRIAL, INC.

WARNING : NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#JH18073 PRINTED IN CHINA

V1. 0 4.16

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property damage

from negligence, improper training, machine modifications or misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State

of California to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Table of Contents

INTRODUCTION ............................................................................................................................... 2

Machine Description ................................................................................................................... 2

Contact Info ................................................................................................................................ 2

Manual Accuracy ........................................................................................................................ 2

Identification ............................................................................................................................... 3

Controls & V-Nail Components .................................................................................................. 4

Machine Data Sheet ................................................................................................................... 5

SECTION 1: SAFETY ....................................................................................................................... 6

Safety Instructions for Machinery ............................................................................................... 6

SECTION 2: SETUP ......................................................................................................................... 7

Needed for Setup ....................................................................................................................... 7

Unpacking .................................................................................................................................. 7

Inventory ..................................................................................................................................... 8

Cleanup ...................................................................................................................................... 9

Site Considerations .................................................................................................................... 9

Assembly .................................................................................................................................. 10

SECTION 3: OPERATIONS ........................................................................................................... 11

Operation Overview.................................................................................................................. 11

V-Nail Size & Placement .......................................................................................................... 12

Changing V-Nails ..................................................................................................................... 13

Clamp Settings ......................................................................................................................... 13

Removing Jammed V-Nail ....................................................................................................... 14

SECTION 4: ACCESSORIES ......................................................................................................... 15

SECTION 5: MAINTENANCE......................................................................................................... 17

Schedule .................................................................................................................................. 17

Cleaning & Protecting .............................................................................................................. 17

Replacing V-Nail Driver ............................................................................................................ 18

Adjusting Driver Indicator ......................................................................................................... 19

Replacing Battery ..................................................................................................................... 19

SECTION 6: SERVICE ................................................................................................................... 20

Troubleshooting ........................................................................................................................ 20

Wiring Diagram......................................................................................................................... 21

SECTION 7: PARTS ....................................................................................................................... 22

Pedestal Breakdown ................................................................................................................ 22

Table Breakdown ..................................................................................................................... 24

Labels Breakdown & Parts List ................................................................................................ 26

WARRANTY & RETURNS ............................................................................................................. 29

Model T27577 (Mfd. Since 3/16)

We stand behind our machines! If you have questions or need help, contact us with the information

below. Before contacting, make sure you get the

serial number

machine ID label. This will help us help you faster.

We want your feedback on this manual. What did

you like about it? Where could it be improved?

Please take a few minutes to give us feedback.

We are proud to provide a high-quality owner’s

manual with your new machine!

We

instructions, specifications, drawings, and photographs

in this manual. Sometimes we make mistakes, but

our policy of continuous improvement also means

that

you receive is

slightly different than shown in the manual

If you find this to be the case, and the difference

between the manual and machine leaves you

confused or unsure about something

check our

website for an updated version. W

current

manuals and

on our web-

site at

Alternatively, you can call our Technical Support

for help. Before calling, make sure you write down

the

from

the machine ID label (see below). This information

is required for us to provide proper tech support,

and it helps us determine if updated documentation is available for your machine.

INTRODUCTION

Machine Description

The Model T27577 Underpinner is a foot-operated device for assembling picture frames using

varying V-nail lengths to secure each corner.

The correct V-nail length used depends on V-nail

placement in workpiece (see V-Nail Placement

on Page 12) and workpiece thickness. V-nails

work best when used in combination with adhesive to secure each corner.

Contact Info

Email: techsupport@grizzly.com

Grizzly Documentation Manager

and manufacture date from the

Grizzly Technical Support

1815 W. Battlefield

Springfield, MO 65807

Phone: (570) 546-9663

P.O. Box 2069

Bellingham, WA 98227-2069

Email: manuals@grizzly.com

Manual Accuracy

made every effort to be exact with the

sometimes the machine

.

,

e post

manual updates for free

www.grizzly.com.

Manufacture Date and Serial Number

Manufacture Date

Serial Number

-2-

Model T27577 (Mfd. Since 3/16)

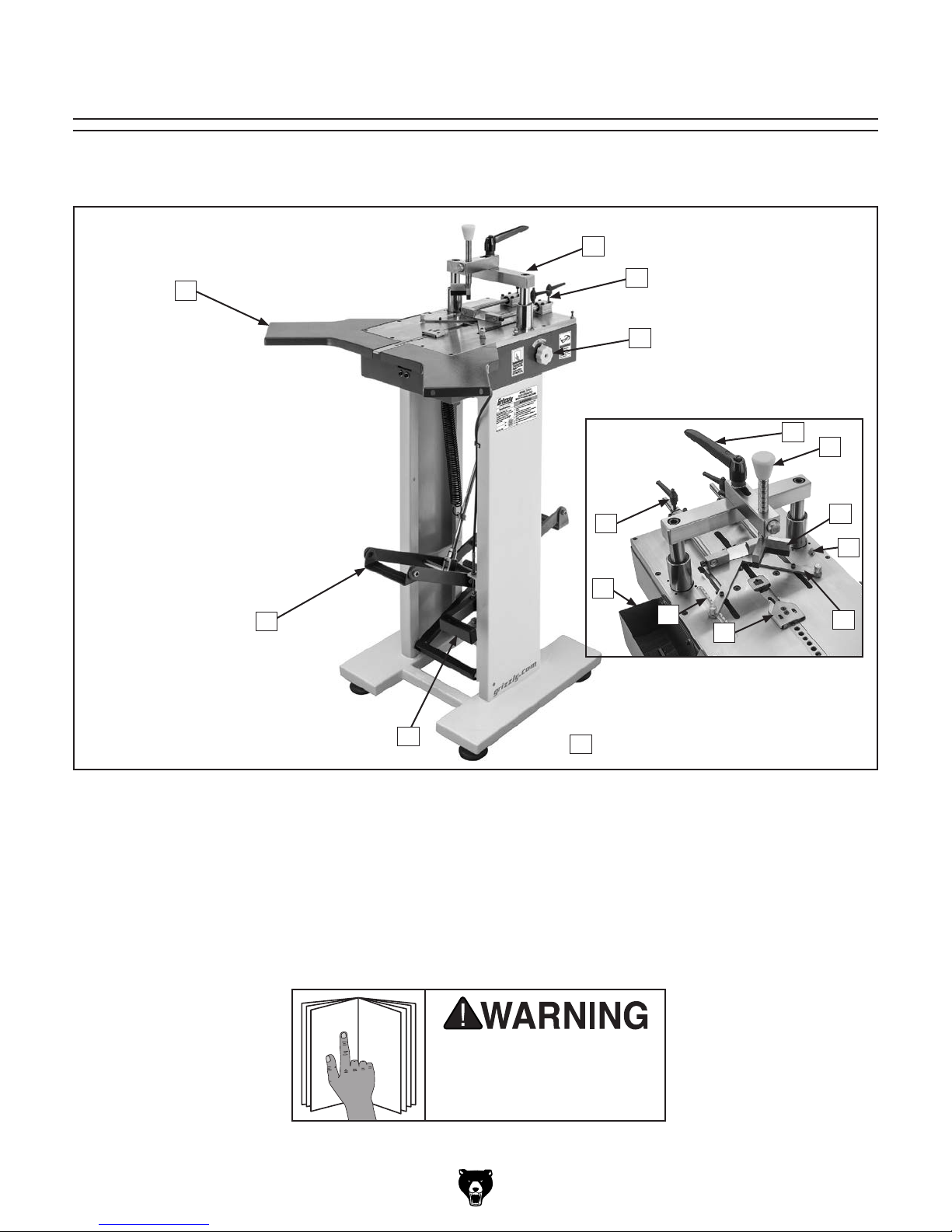

Identification

To reduce your risk of

serious injury, read this

entire manual BEFORE

Become familiar with the names and locations of the controls and features shown below to better understand

the instructions in this manual.

B

M

L

C

D

E

F

G

H

K

J

I

A

P

A. Extension Table

B. Pressure Bar Support

C. Rear Position Stop

D. V-Nail Height Dial

E. Pressure Bar Lock

F. Pressure Bar

G. Pressure Pad

H. V-Nail Depth Indicator Light

O

using machine.

N

I. Fence

J. Front Clamp

K. Frame Size Scale

L. Tool Tray

M. Fence Lock Handle

N. Foot Pad

O. Front Clamp Foot Pedal

P. Top Clamp Foot Pedal

-3-

Model T27577 (Mfd. Since 3/16)

Controls & V-Nail

To reduce your risk of

serious injury, read this

entire manual BEFORE

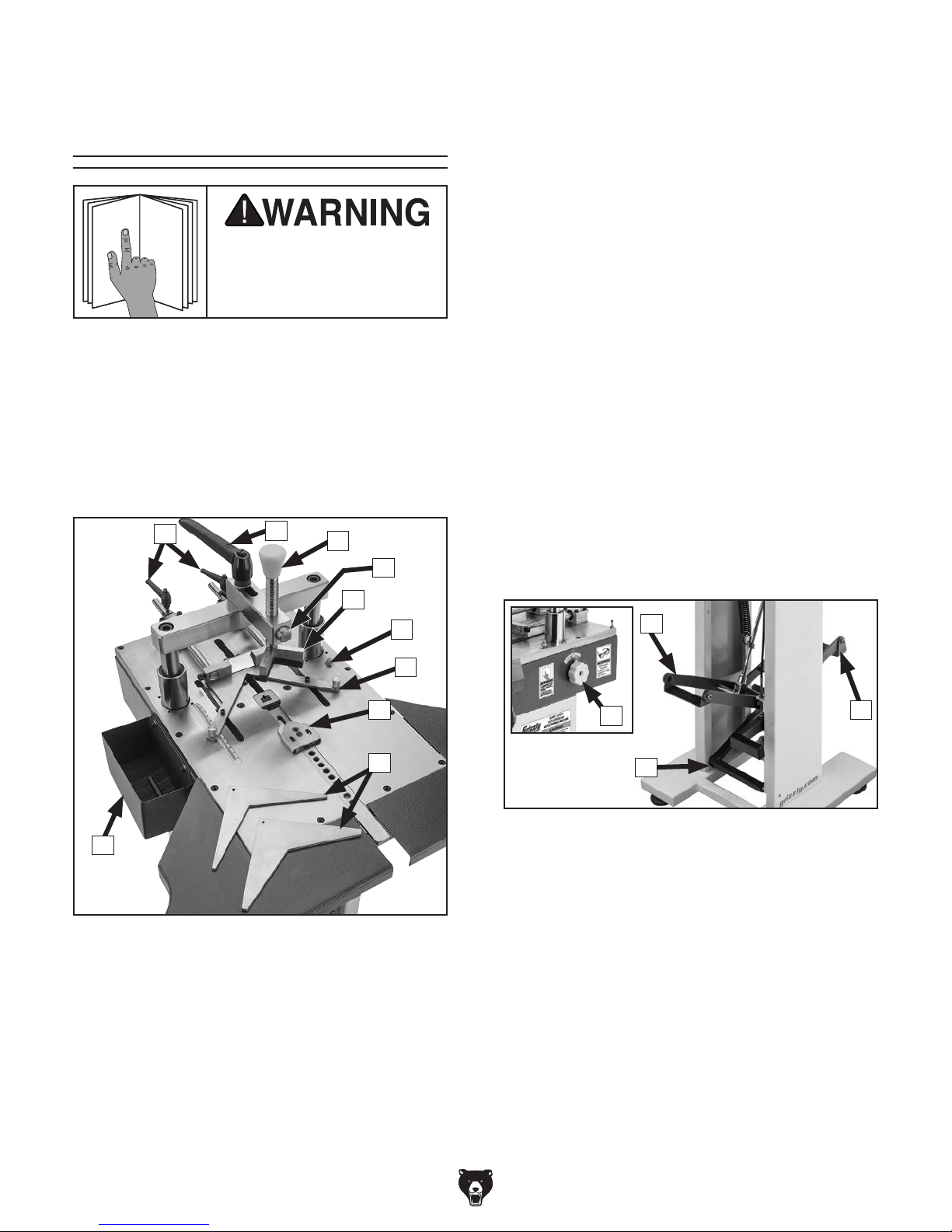

D. Quick-Release Button: Releases pressure

bar for fast height adjustment over workpiece.

Components

using machine.

Refer to Figures 1–2 and the following descriptions to become familiar with the basic controls

and components of this machine. Understanding

these items and how they work will help you

understand the rest of the manual and stay safe

when operating this machine.

Table Controls

A

B

C

D

E. Pressure Pad: Holds workpiece firmly from

above as V-nail is inserted from underside of

table. Two pressure pads are included: round

and 90°. Pads thread into bottom of vertical

pressure bar and contact top of workpiece

while V-nail is inserted.

F. V-Nail Depth Indicator Light: Illuminates

when V-nail reaches proper depth.

G. Fence: Adjusts in or out depending upon

workpiece size. Fence angle is 90°.

H. Front Clamp: Secures inside angle during

V-nail insertion. Features two independently

adjustable gripping faces for securing oddshaped miters.

I. 120° & 135° Inserts: Place against fence for

clamping 6- and 8-sided frames.

J. Tool Tray: Holds tools and V-nails.

E

F

G

H

I

J

Figure 1. Table controls.

A. Fence Stop & Lock Handle: Locks fence

setting for consistent V-nail placement.

B. Pressure Bar Lock: Locks pressure bar

position over frame.

L

K

M

Figure 2. Stand controls and V-nail dial.

K. V-Nail Height Dial: Adjusts V-nail driver

depth depending upon size of V-nail used.

Turn dial clockwise for smaller V-nails. Turn

dial counterclockwise for larger V-nails.

L. Pressure Bar Foot Pedals: Controls down-

ward force of pressure bar.

M. Front Clamp Foot Pedal: Controls front

clamp pressure.

L

C. Pressure Bar: Adjusts height of pressure

pad over workpiece. Bar may be handturned, or the quick-release button can be

used for faster vertical bar adjustments.

-4-

Model T27577 (Mfd. Since 3/16)

Machine Data Sheet

MODEL T27577

PICTURE FRAMING MACHINE / UNDERPINNER

Product Dimensions:

Weight ...........................................................................................................................................................................104 lbs.

Width (side-to-side) x Depth (front-to-back) x Height .......................................................................... 28-1/2 x 30 x 48-1/2 in.

Foot Print (Length/Width) ...........................................................................................................................................18 x 15 in.

Shipping Dimensions:

Type ........................................................................................................................................................................ Wood Crate

Weight ............................................................................................................................................................................121 lbs.

Length/Width/Height .....................................................................................................................................43 x 19-1/2 x 23 in.

Must Ship Upright .................................................................................................................................................................Yes

Electrical:

Power Requirement ...................................................................................................................................................9V Battery

Main Specifications:

Capacities

Minimum Frame Width ............................................................................................................................................1/4 in.

Frame/Moulding Width Range ................................................................................................................... 1/4 – 3-5/16

Frame/Moulding Thickness Range .............................................................................................................. 1/4 – 3-1/2

V-Nail Sizes ....................................................................................................................................... 5, 7, 10, 12, 15 mm

Fence Templates .................................................................................................................................. 90, 120, 135 deg.

V-Nail Channel Capacity ................................................................................................................................350 V-Nails

Table Information

Table Length ............................................................................................................................................................18 in.

Table Width ..............................................................................................................................................................12 in.

Table Thickness ......................................................................................................................................................5/8 in.

Ext. Table Width .................................................................................................................................................13-3/4 in.

Ext. Table Length ...............................................................................................................................................13-3/4 in.

Ext. Table Thickness ...............................................................................................................................................1/8 in.

Floor-to-Table Height .........................................................................................................................................37-1/2 in.

Construction

Main Table .................................................................................................................................................................Steel

Ext. Tables ................................................................................................................................................................Steel

Body ..........................................................................................................................................................................Steel

Stand .........................................................................................................................................................................Steel

Paint Type/Finish ......................................................................................................................................Powder Coated

Other Specifications:

Country of Origin ............................................................................................................................................................... China

Warranty ........................................................................................................................................................................... 1 Year

Approximate Assembly & Setup Time ......................................................................................................................20 Minutes

Serial Number Location ................................................................................................................................................ ID Label

ISO 9001 Factory ...................................................................................................................................................................No

CSA Certified .........................................................................................................................................................................No

in.

in.

-5-

Model T27577 (Mfd. Since 3/16)

SECTION 1: SAFETY

For Your Own Safety, Read Instruction

Manual Before Operating This Machine

The purpose of safety symbols is to attract your attention to possible hazardous conditions.

This manual uses a series of symbols and signal words intended to convey the level of importance of the safety messages. The progression of symbols is described below. Remember that

safety messages by themselves do not eliminate danger and are not a substitute for proper

accident prevention measures. Always use common sense and good judgment.

Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury. It may also be used to alert

against unsafe practices.

This symbol is used to alert the user to useful information about

NOTICE

proper operation of the machine.

Safety Instructions for Machinery

OWNER’S MANUAL. Read and understand this

owner’s manual BEFORE using machine.

TRAINED OPERATORS ONLY. Untrained operators have a higher risk of being hurt or killed.

Only allow trained/supervised people to use this

machine.

DANGEROUS ENVIRONMENTS. Do not use

machinery in areas that are wet, cluttered, or have

poor lighting. Operating machinery in these areas

greatly increases the risk of accidents and injury.

DAMAGED PARTS. Regularly inspect machine

for damaged, loose, or mis-adjusted parts—or

any condition that could affect safe operation.

Immediately repair/replace BEFORE operating

machine. For your own safety, DO NOT operate

machine with damaged parts!

AWKWARD POSITIONS. Keep proper footing

and balance at all times when operating machine.

Do not overreach! Avoid awkward hand positions

that make workpiece control difficult or increase

the risk of accidental injury.

FORCING MACHINERY. Do not force machine.

It will do the job safer and better at the rate for

which it was designed.

MAINTAIN WITH CARE. Follow all maintenance

instructions and lubrication schedules to keep

machine in good working condition. A machine

that is improperly maintained could malfunction,

leading to serious personal injury or death.

USE RECOMMENDED ACCESSORIES. Consult

this owner’s manual or the manufacturer for recommended accessories. Using improper accessories will increase the risk of serious injury.

-6-

Model T27577 (Mfd. Since 3/16)

SECTION 2: SETUP

This machine was carefully packaged for safe

transport. When unpacking, separate all enclosed

items from packaging materials and inspect them

for shipping damage.

,

please

IMPORTANT:

you are completely satisfied with the machine and

have resolved any issues between Grizzly or the

shipping agent. You MUST have the original pack-

aging to file a freight claim. It is also extremely

helpful if you need to return your machine later.

Keep children and pets away

from plastic bags or packing

materials shipped with this

Wear safety glasses during

the entire setup process!

Needed for Setup

The following items are needed, but not included,

for the setup/assembly of this machine.

Description Qty

• Additional People ....................................... 1

• Safety Glasses ........................................... 1

• Cleaner/Degreaser ..................... As Needed

• Disposable Shop Rags ............... As Needed

• Straightedge 24" ......................................... 1

• 9V Battery ................................................... 1

Unpacking

If items are damaged

call us immediately at (570) 546-9663.

Save all packaging materials until

SUFFOCATION HAZARD!

machine. Discard immediately.

-7-

Model T27577 (Mfd. Since 3/16)

Inventory

The following is a list of items shipped with your

machine. Before beginning setup, lay these items

out and inventory them.

If any non-proprietary parts are missing (e.g. a

nut or a washer), we will gladly replace them; or

for the sake of expediency, replacements can be

obtained at your local hardware store.

NOTICE

If you cannot find an item on this list, carefully check around/inside the machine and

packaging materials. Often, these items get

lost in packaging materials while unpacking or they are pre-installed at the factory.

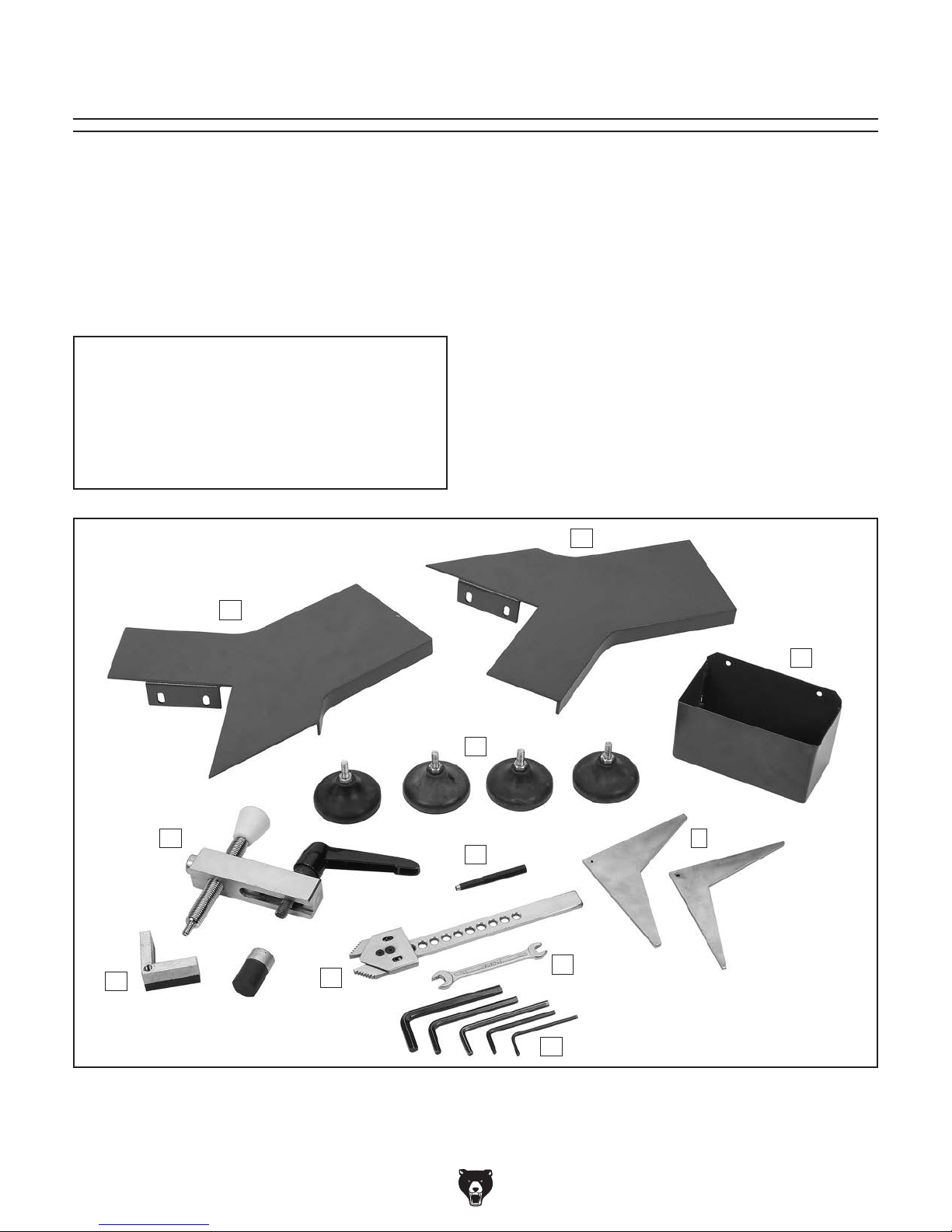

Inventory (Figure 3): Qty

A. Extension Tables ........................................ 2

B. Too l Tray ..................................................... 1

C. Rubber Feet ............................................... 4

D. Vertical Clamp Assembly ........................... 1

E. Magnetic Tool ............................................. 1

F. Angle Inserts: 120° & 135° ...................1 Ea.

G. Pressure Pad: Round & 90° .................1 Ea.

H. Front Clamp ................................................ 1

I. Open-End Wrench 8/10mm ........................ 1

J. Hex Wrench Set: 2.5, 3, 4, 5, 6mm ......1 Ea.

K. Hardware (not shown)

—Cap Screws M6-1 x 10 ......................... 10

—Flat Washers 6mm ............................... 10

A

G

A

B

C

D

E

I

H

J

F

-8-

Figure 3. Model T27577 inventory.

Loading...

Loading...