Grizzly T27338 Owner's Manual

COPYRIGHT © AUGUST, 2016 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#BL18231 PRINTED IN CHINA

MODEL T27338

3-IN-1 FLOORING NAILER

OWNER'S MANUAL

(For models manufactured since 01/15)

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property damage

from negligence, improper training, machine modifications or misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State

of California to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Model T27338 (Mfd. Since 01/15) -1-

SECTION 1: SAFETY

Safety Instructions for Pneumatic Tools

KEEP ALL SAFETY DEVICES IN PLACE

and in working order.

REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking to

see that keys and adjusting wrenches are

removed from tool before operation.

KEEP WORK AREA CLEAN. Cluttered

areas and benches invite accidents.

DO NOT USE IN DANGEROUS

ENVIRONMENT. Do not use pneumatic

tools in damp or wet locations, or where

any flammable or noxious fumes may

exist. Keep work area well lighted.

KEEP CHILDREN AND VISITORS

AWAY. All children and visitors should be

kept at a safe distance from work area.

MAKE WORKSHOP CHILD PROOF by

locking the shop and shutting off air

valves.

DO NOT FORCE TOOL. It will do the job

better and safer at the rate for which it was

designed.

USE THE RIGHT TOOL. Do not force tool

or attachment to do a job for which it was

not designed.

DO NOT USE UNDER INFLUENCE OF

DRUGS OR ALCOHOL.

For Your Own Safety Read Instruction Manual

Before Operating This Equipment

The purpose of safety symbols is to attract your attention to possible hazardous conditions. This manual uses a series of symbols and signal words which

are intended to convey the level of importance of the safety messages. The

progression of symbols is described below. Remember that safety messages by

themselves do not eliminate danger and are not a substitute for proper accident

prevention measures.

Indicates an imminent hazardous situation which, if

not avoided, WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, MAY result in minor or moderate injury.

It may also be used to alert against unsafe practices.

This symbol is used to alert the user to useful information about proper operation of the equipment.

NOTICE

Model T27338 (Mfd. Since 01/15)-2-

USE PROPER AIR HOSE for the tool.

Make sure your air hose is in good condition and is long enough to reach your work

area without stretching.

WEAR PROPER APPAREL. Do not wear

loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get

caught in moving parts. Non-slip footwear

is recommended. Wear a protective hair

covering to contain long hair.

ALWAYS USE SAFETY GLASSES. Also

use a face or dust mask if operation is

dusty. Everyday eyeglasses only have

impact resistant lenses, they are NOT

safety glasses.

WEAR APPROVED HEARING

PROTECTION. Air escaping from pneu-

matic tools can exceed safe exposure

limits and may cause hearing damage

with prolonged exposure.

AWKWARD POSITIONS. Keep proper

footing and balance at all times when

operating tool. Do not overreach! Avoid

awkward hand positions that make workpiece control difficult or increase the risk

of accidental injury.

REDUCE THE RISK OF

UNINTENTIONAL FIRING. Do not carry

tool with hand on trigger and always disconnect from air when not in use.

CHECK FOR DAMAGED PARTS.

Regularly inspect tool for any condition that may affect safe operation.

Immediately repair or replace damaged or

mis-adjusted parts before operating tool.

DISCONNECT TOOLS before servicing, changing accessories, or moving to

another location.

USE RECOMMENDED ACCESSORIES.

Consult this owner’s manual or the manufacturer for recommended accessories.

Using improper accessories will increase

the risk of serious injury.

NEVER LEAVE UNATTENDED TOOL

CONNECTED TO AIR. Disconnect the

air hose and do not leave tool until it is

relieved of any built up pressure.

NEVER ALLOW UNTRAINED

USERS TO USE THIS TOOL WHILE

UNSUPERVISED.

IF YOU ARE UNSURE OF THE

INTENDED OPERATION, STOP USING

TOOL. Seek formal training or research

books or magazines that specialize in

pneumatic tools.

BE AWARE OF HOSE LOCATION WHEN

USING PNEUMATIC TOOLS. Hoses can

easily become a tripping hazard when laid

across the floor or spread out in a disorganized fashion.

SECURE WORK. When required, use

clamps or vises to secure workpiece. A

secured workpiece protects hands and

frees both of them to operate the tool.

MAINTAIN TOOLS WITH CARE. Keep

tools lubricated and clean for best and

safest performance. Follow instructions

for lubricating and changing accessories.

Safety Instructions for Pneumatic Tools

Model T27338 (Mfd. Since 01/15) -3-

Additional Safety for Flooring Nailers

HAND AND FOOT INJURIES. Do not

place your hands or feet near or under

the nail point of entry. A nail/staple can

deflect and tear through the surface of the

workpiece, puncturing your hand or foot.

COMPRESSED AIR RATING. Do not

connect the nailer to compressed air that

exceeds 115 PSI.

ACTUATING MECHANISM. Be careful

not to bump actuating mechanism when

carrying or holding tool while connected

to air. If bumped, the tool may accidentally

shoot in dangerous direction.

SAFE HANDLING. Never point nailer at

others! Carry nailer only by handle, never

by any other part. Do not carry nailer by

air hose.

HOSE USAGE. Make sure your air hose

is designed for tool in use, is in good condition, and is long enough to reach your

work area without stretching. However, an

overly long air hose in the work area may

be a tripping hazard.

OPERATING QUESTIONS. If you are not

sure about intended operation, stop using

nailer. Seek formal training, or research

books or magazines that specialize in

pneumatic tools.

NAILING. Avoid driving one nail/staple on

top of another. The nail/staple may deflect

and cause injury.

AIR SOURCE. Disconnect air source

before installing nails/staples, clearing

jam, moving to another work area, performing maintenance, or when tool is

not in use. A nailer connected to air may

fire accidentally, causing serious personal

injury. DO NOT use check valve or any

other fitting that allows air to remain in

the tool.

COMBUSTIBLE GASES. Never connect

nailer to pressurized oxygen or other combustible gases as a power source. Only

use regulated compressed air.

CLEANING. Never use gasoline or other

flammable liquids to clean nailer; vapors

in nailer will ignite by a spark and cause

it to explode.

TOOL SERVICE. If nailer is leaking air,

damaged, or not working correctly, DO

NOT use before repairing.

HAMMER SAFETY. DO NOT use hammer

with damaged handle or loose head. Make

sure nobody is standing close enough to

be hit when you swing hammer.

No list of safety guidelines can be

complete. Every shop environment

is different. Always consider safety first, as it applies to your individual working conditions. Use this

and other tools with caution and

respect. Failure to do so could result

in serious personal injury, damage to

equipment, or poor work results.

Model T27338 (Mfd. Since 01/15)-4-

SECTION 2: INTRODUCTION

Manual Accuracy Contact Info

We stand behind our tools. If you have any

service questions, parts requests or general questions about the product, please

call or write us at the location listed below.

Grizzly Technical Support

1815 W. Battlefield

Springfield, MO 65807

Phone: (570) 546-9663

Email: techsupport@grizzly.com

We want your feedback on this manual.

What did you like about it? Where could it

be improved? Please take a few minutes to

give us feedback.

Grizzly Industrial, Inc.

C/O Technical Documentation Manager

P.O. Box 2069

Bellingham, WA 98227-2069

Email: manuals@grizzly.com

We are proud to offer this document with

your new tool! We've made every effort to

be exact with the instructions, specifications, drawings, and photographs of the

tool we used when writing this manual.

However, sometimes we still make an

occasional mistake.

Also, owing to our policy of continuous

improvement, your tool may not exactly

match the manual. If you find this to be

the case, and the difference between

the manual and tool leaves you in doubt,

immediately call our technical support for

updates or clarification.

For your convenience, we post all available documentation on our website at

www.grizzly.com. Any updates to this document will be reflected on our website as

soon as complete.

Weight ......................................................................................................................11.2 lbs.

Length x Width x Height ................................................................................20 x 3

1

⁄2 x 23 in.

Operating Pressure ............................................................................................. 70–115 PSI

Magazine Capacity ................................................................ 100 Cleat Nails or 120 Staples

Fastener Length ........................................................................................................11⁄2–2 in.

Fastener Size ....16-Ga. T-Cleat Nails, 16-Ga. L-Cleat Nails, 15.5 Ga. 1⁄2 in. Crown Staples

Specifications

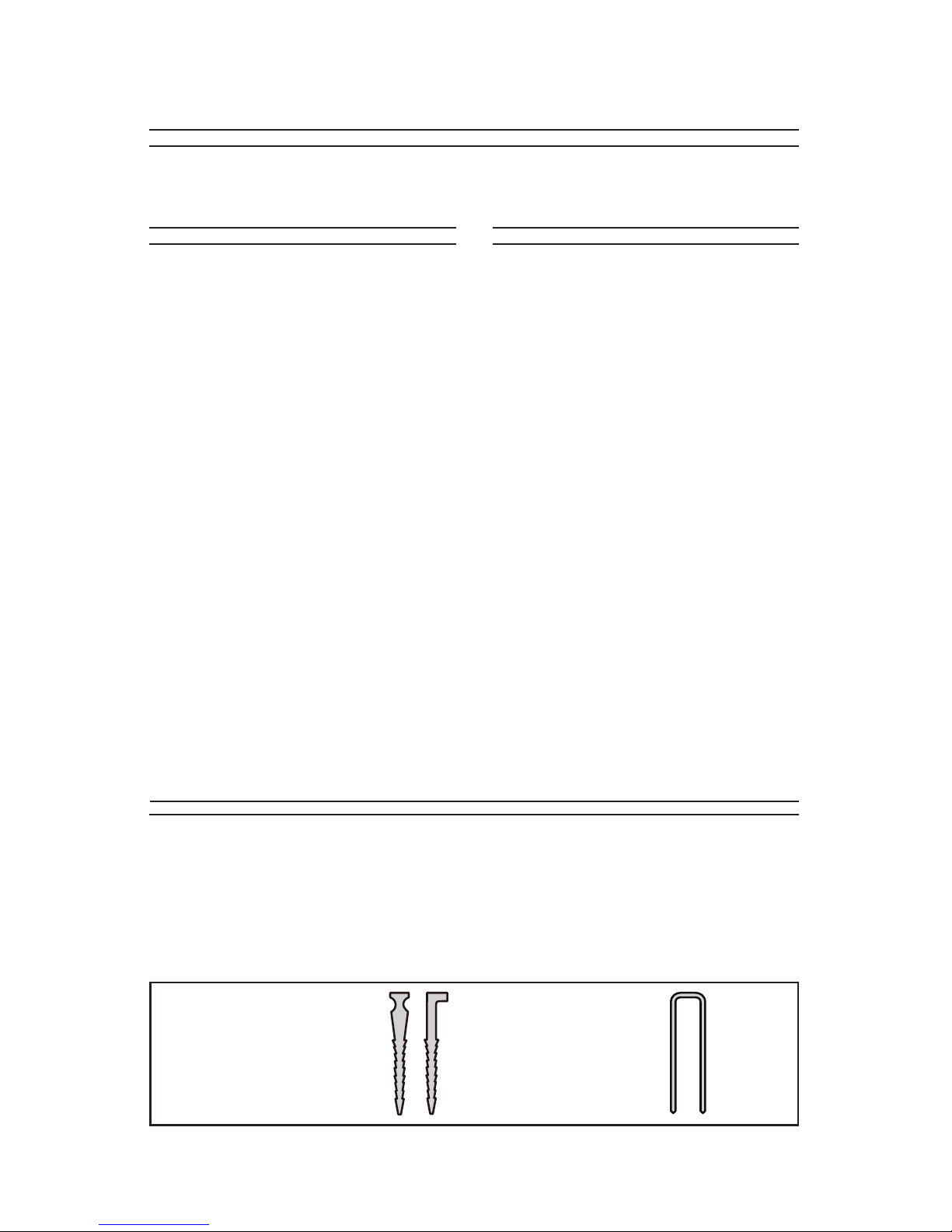

16 Ga.

L- or T-Cleat Nail

1

1

/2"–2" Long

(100 Pc. Capacity)

15.5 Ga.

1

/2" Crown Staple

1

1

/2"–2" Long

(120 Pc. Capacity)

Model T27338 (Mfd. Since 01/15) -5-

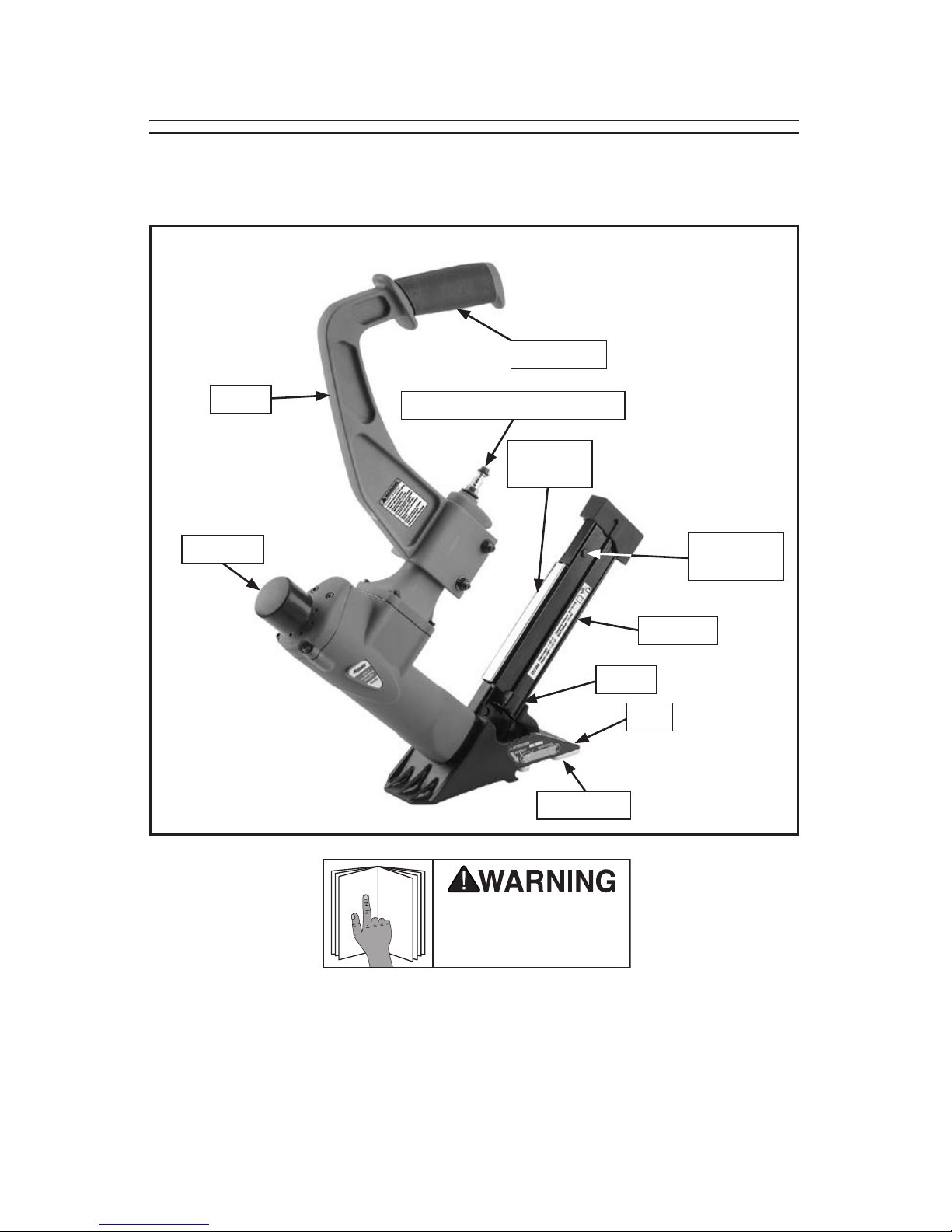

Identification

To reduce your risk of

serious injury, read this

entire manual BEFORE

using tool.

Become familiar with the names and locations of the controls and features shown below to

better understand the instructions in this manual.

Handle

Handle Grip

Air Inlet/Quick-Connect Fitting

Magazine

Cover

Magazine

Pusher

Base

Guide Plate

Head Cap

Magazine

Lock Button

Model T27338 (Mfd. Since 01/15)-6-

SECTION 3: SETUP

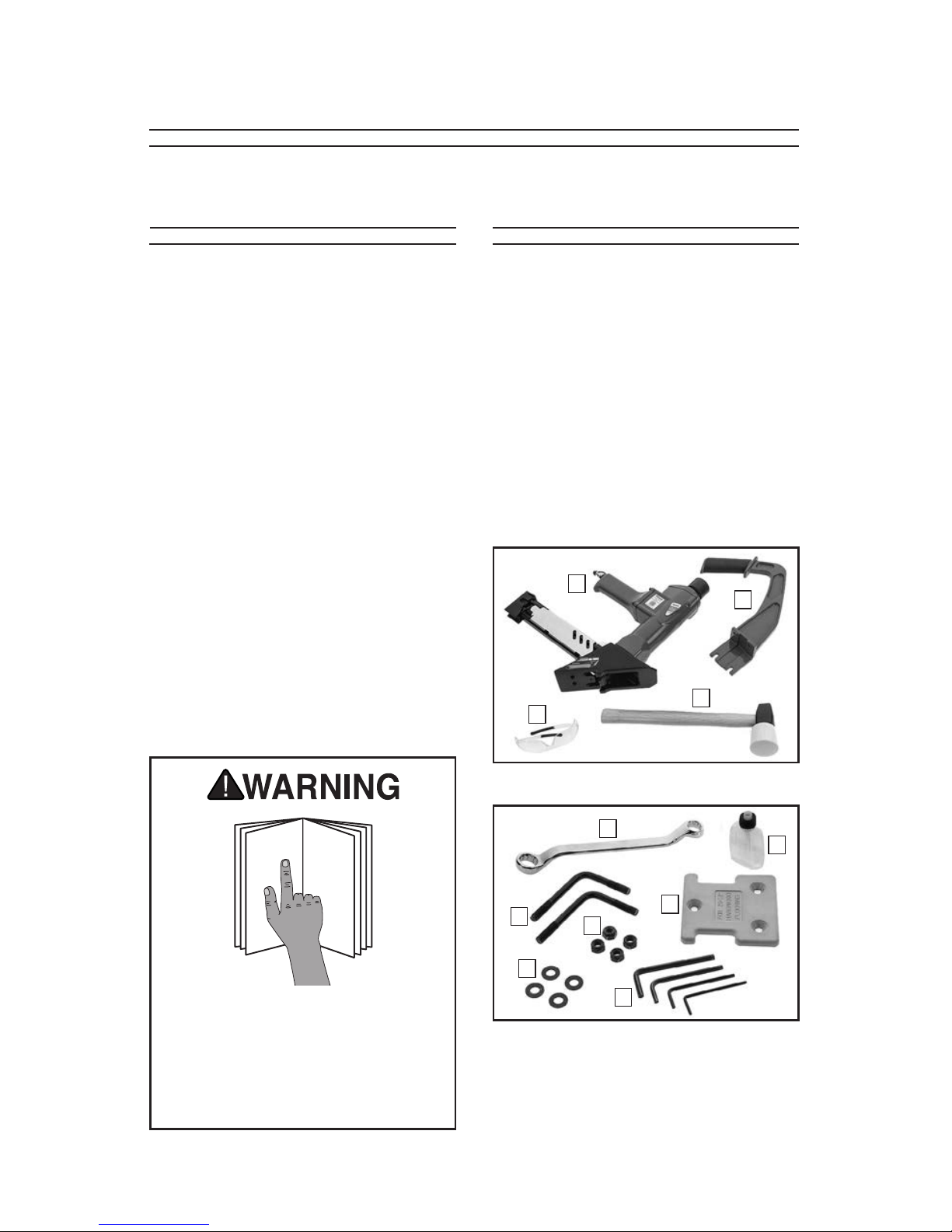

Unpacking Inventory

Model T27338 Inventory (Figures 1-2)

A. Flooring Nailer Body .......................... 1

B. Arm .................................................... 1

C. Safety Glasses ................................... 1

D. Hammer ............................................. 1

E. Closed-End Wrench 13/16mm ........... 1

F. Bottle for Oil ....................................... 1

G. L-Bolts M8-1.25 .................................. 2

H. Lock Nuts M8-1.25 ............................. 4

I. Guide Plate for 1⁄2" Hardwood Floors . 1

J. Flat Washers 8mm ............................. 4

K. Hex Wrenches 2.5, 3, 4, 5mm .....1 Ea.

Figure 1. Model T27338 inventory.

B

C

D

A

Figure 2. Model T27338 additional

inventory.

E

G

I

H

J

K

F

Your tool was carefully packaged for

safe transportation. Remove the packaging materials from around your tool and

inspect it. If you discover the tool is damaged, please immediately call Customer

Service at (570) 546-9663 for advice.

Save the containers and all packing materials for possible inspection by the carrier or its agent. Otherwise, filing a freight

claim can be difficult.

When you are completely satisfied with

the condition of your shipment, inventory

the contents.

If any non-proprietary parts are missing

(e.g., a nut or a washer), we will gladly

replace them; or for the sake of expediency, replacements can be obtained at

your local hardware store.

This tool presents serious injury

hazards to untrained users. Read

through this entire manual to

become familiar with the controls

and operations before starting the

tool!

Model T27338 (Mfd. Since 01/15) -7-

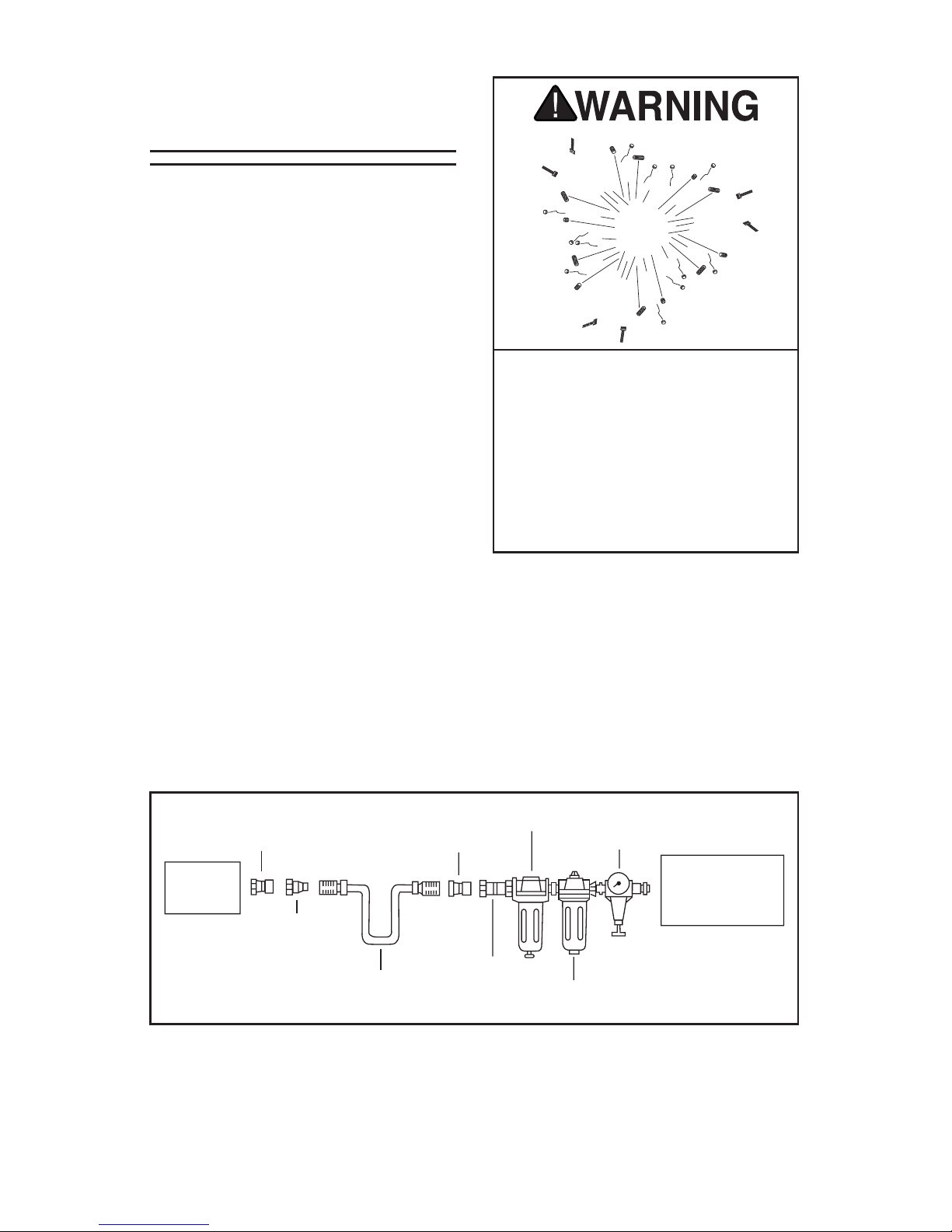

Compressed Air

System

The Model T27338 is designed to be operated at 70-115 PSI using clean, dry, regulated, compressed air. DO NOT exceed

the 115 PSI maximum operating pressure for your model. Before using, regu-

late the air pressure on your air compressor to 70 psi.

An in-line filter/lubricator/regulator unit,

depicted in Figure 3, can be installed and

should be located as close to the nailer as

possible.

The filter/lubricator/regulator unit will

protect your tool from damaging water

build-up, allow you to adjust and maintain

constant air pressure to your tool, and

save you the inconvenience of having to

manually lubricate your tool every time

you use it.

Check the current Grizzly catalog for availability of this unit. If you plan on installing a filter/lubricator/regulator unit in your

compressed air system, always follow the

connection instructions that come with

the unit.

Quick

Connector

Quick

Coupler

Air Hose

Quick

Coupler

Quick

Connector

Lubricator

Filter

Regulator

Air

Compressor

Your

Tool

Figure 3. Typical filter/lubricator/regulator installation order.

Exceeding maximum permissible

operating pressure may cause nailer

to explode, blowing metal fragments

in all directions. To protect yourself

and bystanders from serious personal

injury, DO NOT allow your air compressor to exceed the recommended pressure when connected to this

nailer!

Loading...

Loading...