Page 1

MODELS T10502, T10556,

& T26300

TAPER ATTACHMENT

INSTRUCTIONS

For questions or help with this product contact Tech Support at (570) 546-9663 or techsupport@grizzly.com

Introduction

This taper attachment provides precision outside

and inside tapers up to 12" without having to offset the tailstock.

Another feature is the ability to use the attachment without disengaging the cross slide. This

allows the taper attachment to be functional at any

time by simply tightening the bed clamp bracket.

However, the taper attachment does not interfere

with other turning operations.

This taper attachment features scales at both

ends, reading inches-of-taper per foot and angle

of taper. An adjustment knob with fine threads

achieves precise control when setting tapers.

Identification

A

E

B. Slide Table: Connects to the bed clamp and

provides a stable platform for the pivot bar.

C. Body: Houses the pivot and slide blocks that

connect to the cross slide.

D. Taper Adjustment Knob: Adjusts the angle

of the pivot bar for the desired taper.

E. Pivot Bar: Provides an angled dovetail path

to guide the tooling for the desired taper.

Specifications

Model T10556 ...... for G4002, G4003, & G4003G

Model T10502 .......................................for G0709

Model T26300 ................................... for G0750G

Maximum Taper Length .................................... 9"

Taper Per Inch Range ..............................0"– ±3"

Inch Scale Divisions ........................................

Taper Angle Range ..................................0°– ±5°

Angle Scale Divisions ....................................... 1°

Construction ................................ Cast Iron, Steel

Shipping Weight ........................................60 lbs.

1

⁄2 "

B

C

Figure 1. Taper attachment identification.

A. Bed Clamp: Secures the taper attachment

to a specific position on the bedway and

enables the use of the taper attachment.

COPYRIGHT © JULY, 2013 BY GRIZZLY INDUSTRIAL, INC. REVISED JANUARY, 2018 (HE)

NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

FOR MODELS MANUFACTURED SINCE 3/13 #TS15756 PRINTED IN CHINA

D

This taper attachment is heavy! Get

assistance when installing it on the lathe.

To reduce the risk of crushing injuries, wear

boots with toe protection and keep hands

and fingers away from all pinch points.

Page 2

Inventory

This taper attachment was carefully packed when

it left our warehouse. If you discover the taper

attachment is damaged after you have signed

for delivery, please immediately call Customer

Service at (800) 523-4777 for advice.

Save the containers and all packing materials for

possible inspection by the carrier or its agent.

Otherwise, filing a freight claim can be difficult.

When you are completely satisfied with the condition of your shipment, you should inventory the

contents.

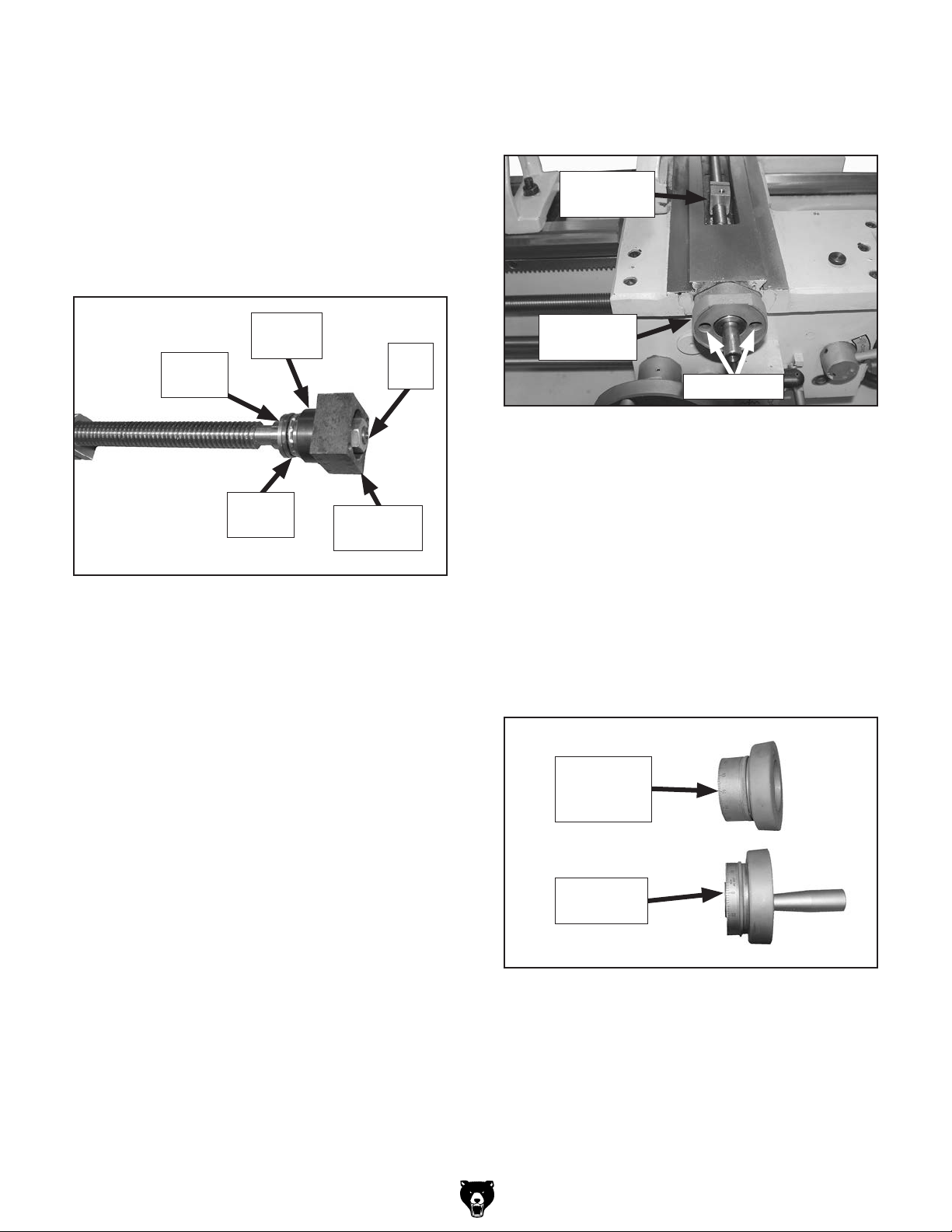

Box Contents (Figure 2): Qty

A. Slide Table & Body Assembly .....................1

B. Bed Clamp Rod ...........................................1

C. Bed Clamp Pivot Shaft w/Cap Screw ..........1

D. Work Lamp Extension Shaft .......................1

E. Handwheel Handle w/Shoulder Screw ........1

F. Alternate Leadscrew Rear Bracket ..............1

G. Bed Clamp Block w/Cap Screws .................1

H. Bed Clamp Bracket w/Cap Screw ...............1

I. Cross Feed Handwheel & Leadscrew

Assembly .....................................................1

J. Hardware Bag (Not Shown)

— Roll Pins 6 x 30mm ................................ 2

— Cap Screws M8-1.25 x 25 ...................... 2

— Cap Screws M8-1.25 x 16 ...................... 2

— Cap Screw M8-1.25 x 12 ........................ 1

— Cap Screws M6-1 x 25........................... 2

— Cap Screw M6-1 x 14............................. 1

Required for Setup

The items listed below are required to successfully set up and prepare this taper attachment for

operation. The installation is intended to be semipermanent and will take 1–2 hours.

Description Qty

• Another Person ...........................................1

• Safety Glasses .........................1 Per Person

• Cleaner/Degreaser ......................As Needed

• Disposable Shop Rags ................As Needed

• Oil Can w/General Machine Oil ...................1

• Grease NLGI#2 ...........................As Needed

• Drill & Drill Bit

• Bottoming Hand Tap M8-1.25 ......................1

• Precision Ruler ............................................1

• Phillips Screwdriver #0 ................................1

• Phillips Screwdriver #2 ................................1

• Wrench 14mm .............................................1

• Wrench & Socket 17mm .................... 1 Each

• Hex Wrench 2.5mm .....................................1

• Hex Wrench 4mm ........................................1

• Hex Wrench 5mm ........................................1

• Hex Wrench 6mm ........................................1

• Deadblow Hammer ......................................1

9

⁄32" ............................. 1 Each

Assembly & Installation

1. DISCONNECT LATHE FROM POWER!

2. Remove the back splash from the rear of

the lathe by removing the (4) Phillips head

screws and flat washers that secure it.

-2-

A

B

I

H

Figure 2. Shipping inventory.

C

G

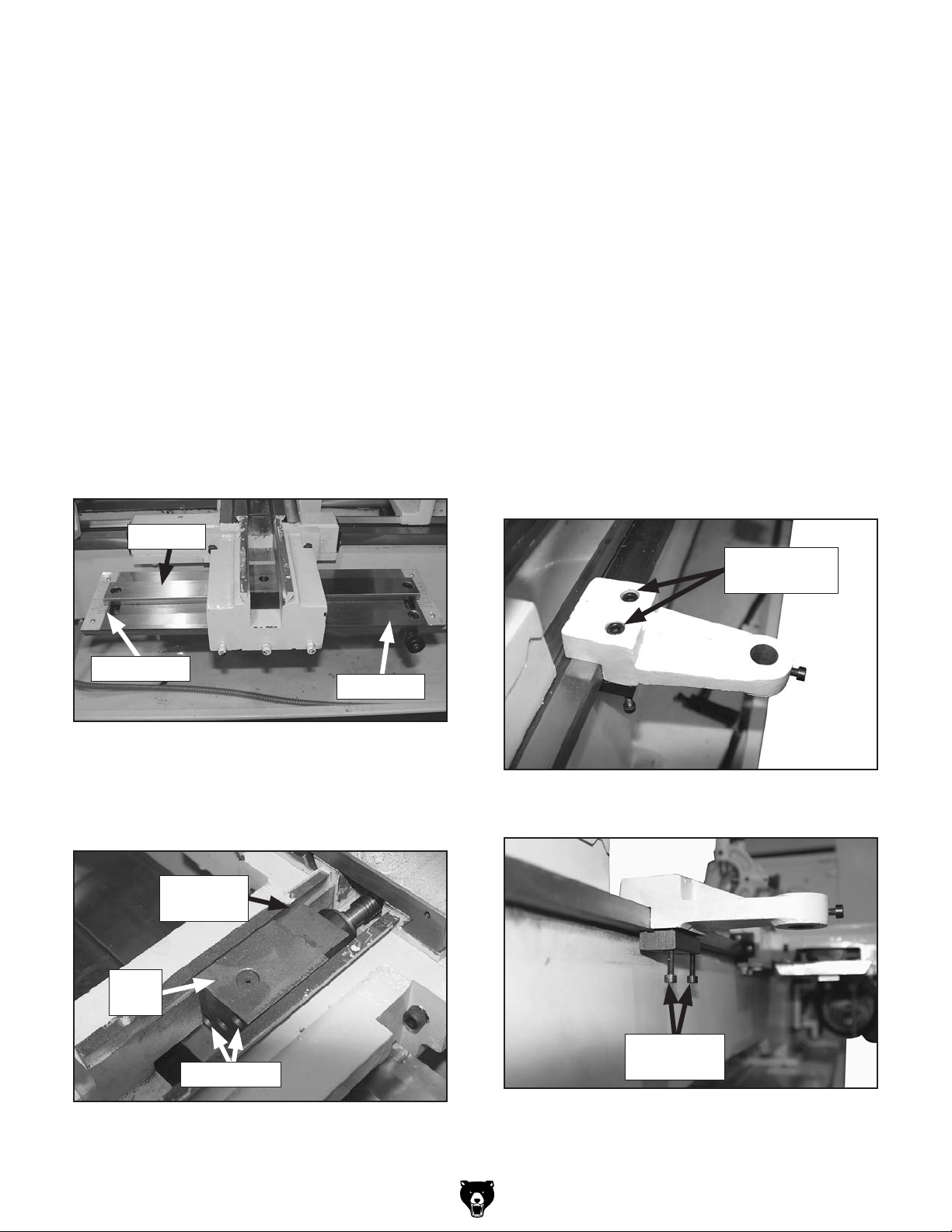

3. Remove the compound rest from the cross

slide by removing the (2) hex nuts shown in

Figure 3.

D

Hex Nuts

E

F

Figure 3. Hex nuts that secure the compound

rest.

T10502, T10556, T26300 (Mfg. Since 3/13)

Page 3

Keep track of fasteners removed. Some will

be needed for re-installing components.

4. Remove the cross slide rear cover by remov-

ing the (2) cap screws shown in Figure 4.

Rear

Cover

6. Rotate the cross slide handwheel clockwise until the leadscrew nut exits the rear

of the cross slide and can be removed (see

Figure 6).

Leadscrew

Nut

Leadscrew

Cap Screws

Figure 4. Cross slide rear cover location.

5. Remove the cap screw shown in Figure 5.

This cap screw secures the cross slide to the

leadscrew nut.

Cap Screw

Installation

Hole

Figure 6. Leadscrew nut removed from cross

slide leadscrew.

7. Loosen the set screw on the cross slide

handwheel retainer (see Figure 7), and rotate

the retainer counterclockwise to unthread

and remove it from the handwheel.

Handwheel

Retainer

Set

Screw

Figure 7. Handwheel retainer set screw location.

Figure 5. Cap screw removed that secures cross

slide to leadscrew nut.

T10502, T10556, T26300 (Mfg. Since 3/13)

-3-

Page 4

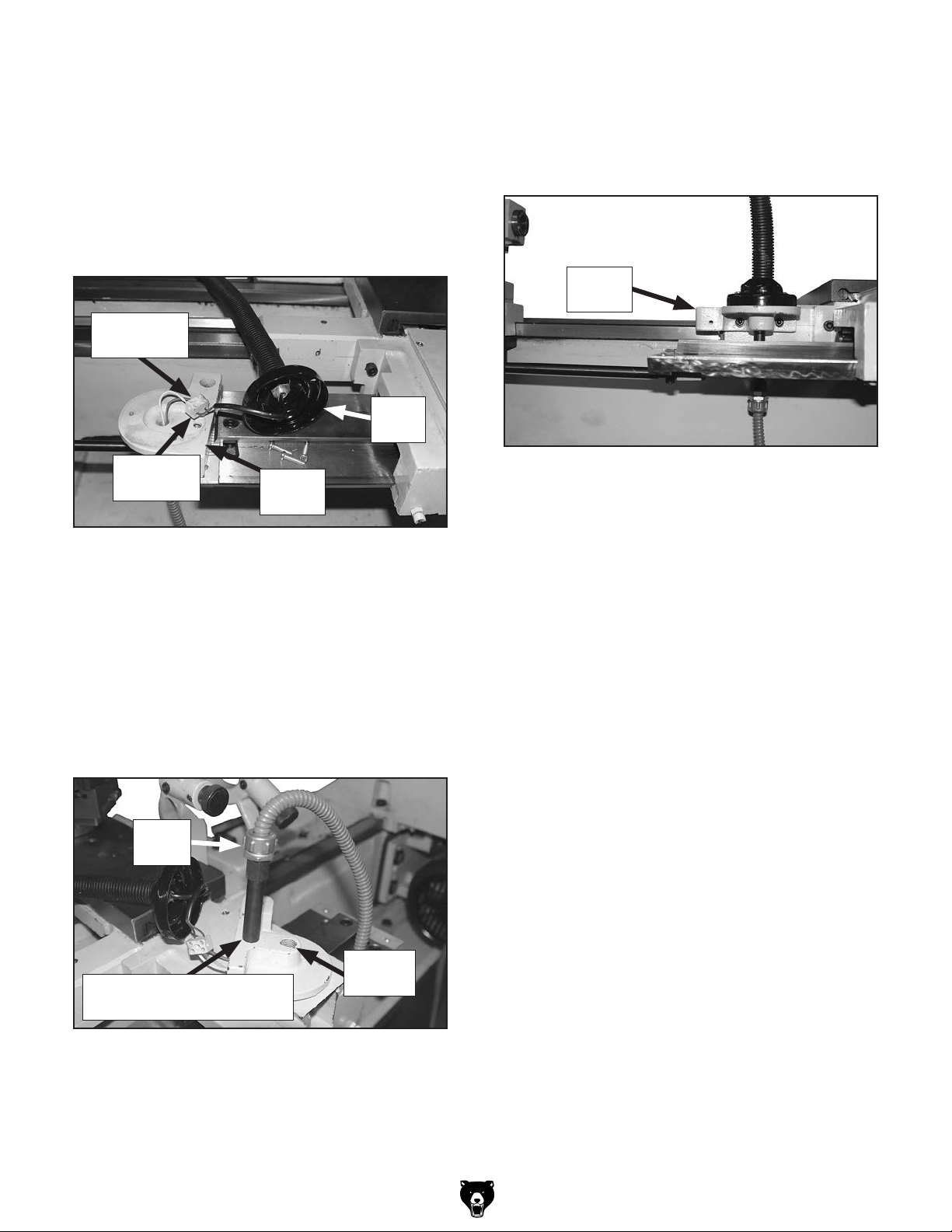

8. Slide the handwheel and graduated dial

assembly off the leadscrew, then remove the

two cap screws that secure the handwheel

bracket to the cross slide (see Figure 8).

Handwheel

Bracket

11. Remove the cross slide from the saddle by

sliding it off the dovetail way (see Figure 10).

Cap Screws

Figure 8. Handwheel bracket cap screw

locations.

9. Pull the handwheel bracket and leadscrew

assembly from the front of the cross slide

(see Figure 9).

Leadscrew

Assembly

Figure 9. Cross slide leadscrew assembly

removed.

10. Remove the work lamp and bracket assembly

from the rear of the saddle, and set it aside

for now. It is not necessary to disconnect the

wires at this time.

Figure 10. Cross slide removed from saddle.

12. Remove the top cover from the taper attach-

ment body (see Figure 11), the remove the

block assembly.

Slide

Table

Pivot

Bar

Figure 11. Top cover and block assembly

removed from taper attachment body.

Note: To accomplish this step, you may have

to loosen the block assembly with a deadblow hammer.

13. Slide the taper attachment body off the pivot

bar.

Top Cover

Block

Assembly

Taper Attachment Body

Note: For the Model G0709, the bracket

assembly also includes the coolant nozzle.

-4-

T10502, T10556, T26300 (Mfg. Since 3/13)

Page 5

14. Loosely re-install the top cover on the attachment.

15. Have another person align and hold the body

against the rear of the saddle, then use a

punch to mark the saddle through the attachment holes.

Note: The taper attachment body is properly

aligned when the sides of the internal ways

are evenly aligned with those of the saddle

and the top cover is flush with or slightly

lower than the saddle dovetail ways (see

Figure 12).

19. Loosen the (2) cap screws on the block

assembly you removed from the body in

Step 12, then separate the pivot and alignment blocks, as shown in Figure 13.

Pivot

Block

Alignment Block

Top Flush with Dovetail Ways Here

Attachment Holes

Figure 12. Taper attachment body properly

aligned with saddle.

16. Drill and tap holes at the two marks you made

in Step 15. The tapped holes should accept

M8-1.25 x 25 cap screws.

17. Mount the attachment body to the saddle, as

shown in Figure 12.

18. Remove the top cover from the taper attachment.

Cap Screws

Figure 13. Pivot and alignment blocks

separated.

20. If the alternate leadscrew rear bracket is

installed on the taper attachment leadscrew

(see Figure 14), then remove it now.

Important: Make a note of the order of the

components in front of and behind the bracket, and keep this information for future use.

If you remove the taper attachment later, the

taper attachment leadscrew and handwheel

can remain installed by re-installing the

bracket and the components in the same

order. The bracket is mounted to the saddle

in the same manner as the taper attachment

body.

Taper Attachment

Leadscrew

T10502, T10556, T26300 (Mfg. Since 3/13)

Alternate Leadscrew

Rear Bracket

Figure 14. Alternate leadscrew rear bracket on

taper attachment leadscrew.

-5-

Page 6

21. Keeping the component order on the end of

the taper attachment leadscrew the same as

it was shipped (minus the alternate bracket),

install the alignment block you removed in

Step 20 between the bearing cap and hex

nuts, as shown in Figure 15.

Note: Hand-tighten the first hex nut, then

tighten the second hex nut against the first to

secure the installation.

24. Slide the leadscrew assembly into the saddle

with the threaded hole in the leadscrew nut

facing up, as shown in Figure 16.

Leadscrew

Nut

Bearing

Cap

Flat

Washer

Thrust

Bearing

Figure 15. Alignment block installed on taper

attachment leadscrew.

22. Remove the handwheel and graduated dial

from the taper attachment leadscrew assembly in the same manner as instructed in

Steps 7–8.

23. Rotate the alignment block at the end of the

leadscrew (see Figure 15) so the orientation

of the threaded holes will match the orientation of the cap screws in the pivot block when

it is installed inside the taper attachment body

(see to Step 31 and Figure 20 on Page 7 for

orientation reference).

Alignment

Hex

Nuts

Block

Handwheel

Bracket

Cap Screws

Figure 16. Taper attachment leadscrew

assembly installed.

25. Secure the handwheel bracket in place with

(2) M8-1.25 x 16 cap screws.

26. Re-install the handwheel and graduated dial

assembly, then attach the handle.

Note: Be sure to install the handwheel

and graduated dial assembly that came

with the taper attachment. As shown in

Figure 17, there is a critical difference in

thickness between the two.

Taper

Attachment

Handwheel

Original

Handwheel

-6-

Figure 17. Handwheel comparison.

T10502, T10556, T26300 (Mfg. Since 3/13)

Page 7

27. Slide the cross slide back onto the saddle

dovetail.

28. Use the cross slide handwheel to position the

leadscrew nut so the hole in the cross slide

aligns with the threaded hole in the top of the

leadscrew nut.

32. Use the cross slide handwheel to extend the

end of the leadscrew into the taper attachment body so the alignment block is against

the pivot block, as shown in Figure 19.

33. Thread the cap screws through the pivot

block into the alignment block to secure it.

29. Secure the cross slide to the leadscrew nut

with the cap screw removed in Step 5.

Note: Only tighten the cap screw until it is

snug. Overtightening it could interfere with

cross slide movement.

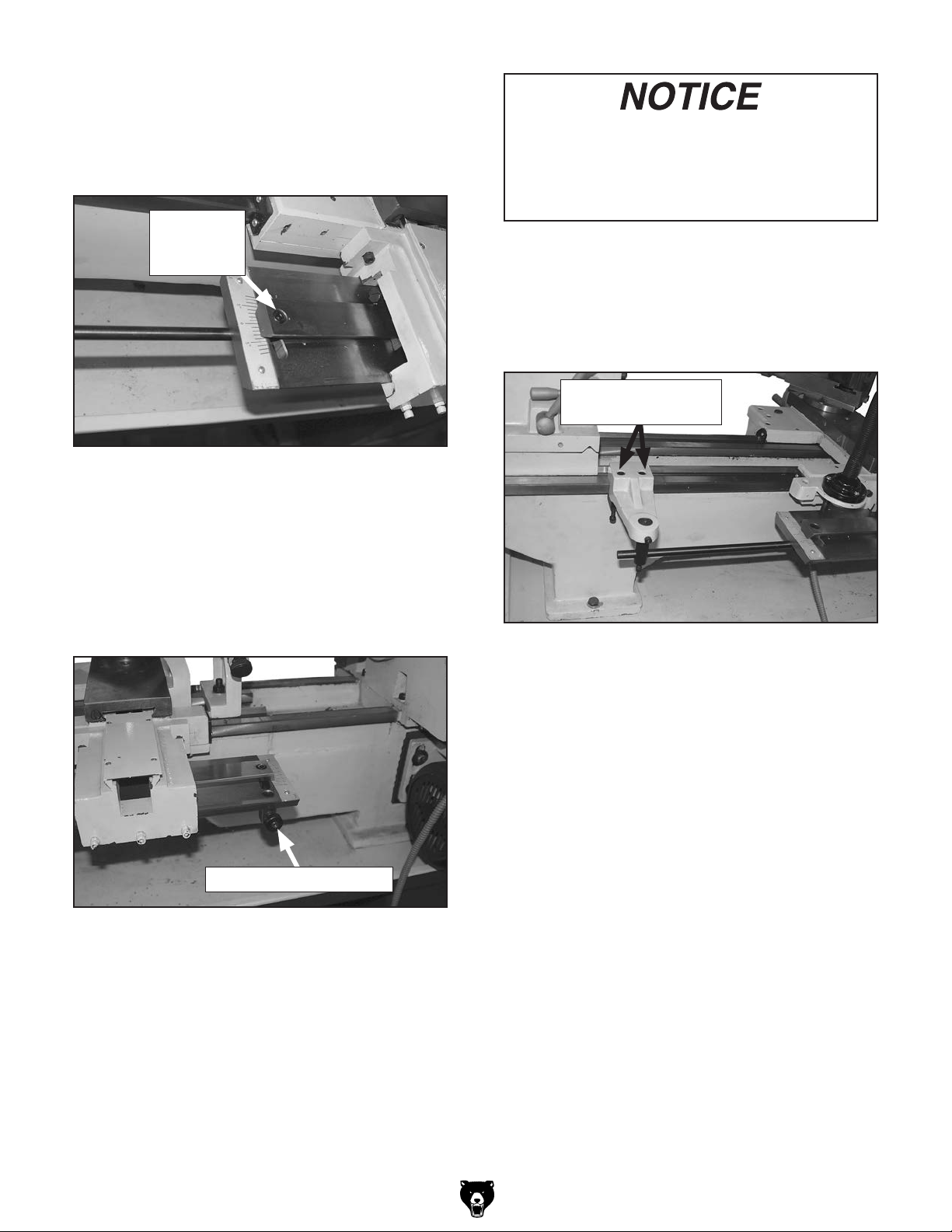

30. Orient the angle scale of the slide table

toward the tailstock, then slide the pivot bar

dovetail through the slide block underneath

the taper attachment body, as shown in

Figure 18.

Pivot Bar

Angle Scale

Slide table

34. Re-install the taper attachment top cover.

35. Attach the bed clamp bracket and bed clamp

block to the bedway between the tailstock

and taper attachment, using (2) M10-1.5 x 30

cap screws and (2) M6-1 x 35 cap screws, as

shown in Figures 20–21. Leave the bracket

loose enough on the bedway so that you

adjust its position.

Note: Use the bottom cap screws to bring the

bracket level with the bedway, then use the

top cap screws to secure the bracket in place.

M10-1.5 x 30

Cap Screws

Figure 18. Slide table re-installed.

31. Re-install the pivot block into the taper attach-

ment body so that you can access the cap

screws from the outside (see Figure 19).

Alignment

Block

Pivot

Block

Cap Screws

Figure 19. Pivot and alignment blocks

re-installed.

Figure 20. Bed clamp bracket and block

attached to bedway (top view).

M6-1 x 35

Cap Screws

Figure 21. Bed clamp bracket and block

attached to bedway (bottom view).

T10502, T10556, T26300 (Mfg. Since 3/13)

-7-

Page 8

36. Attach the flattened end of the bed clamp rod

to the underside of the slide table, as shown

in Figure 22, with (1) M6-1 x 20 cap screw.

Bed Clamp

Rod

40. Mount a dial indicator magnetic base on top

of the saddle so that the indicator needle is

resting on the pivot bar at the tailstock end,

as shown in Figure 24, then zero the indicator.

M6-1 x 20

Cap Screw

Figure 22. Bed clamp rod attached to slide table.

37. Insert the round end of the bed clamp rod

into the bed clamp pivot shaft, then insert the

pivot shaft into the bottom of the bed clamp

bracket, as shown in Figure 23.

Bed Clamp

Pivot Shaft

Bed Clamp Rod

Figure 23. Bed clamp pivot pin installed.

Pivot

Bar

Figure 24. Using a dial indicator to measure

slide table tilt.

41. Move the carriage toward the tailstock as far

as possible.

— If the indicator reading is 0.010" or less, the

tilt of the slide table is considered acceptable. Proceed to Step 36.

— If the indicator reading is greater than

0.010", proceed with the next step.

42. Loosen the cap screws that secure the taper

attachment body to the saddle, then rotate

the taper attachment assembly left or right to

correct the tilt. Retighten the cap screws and

repeat Step 41.

38. Tighten the bed clamp bracket cap screws to

secure it in position on the bedway.

39. Move the carriage toward the spindle as far

as possible.

Note: Adjust components as necessary to

expose as much of the pivot bar as possible

on the tailstock side of the taper attachment

body.

-8-

T10502, T10556, T26300 (Mfg. Since 3/13)

Page 9

43. Separate the lamp base from the lamp bracket, as shown in Figure 25.

Disconnect the wires at the lamp terminal

bar, on the side coming from the electrical

box.

Note: For the Model G0709, the coolant

nozzle position does not need changing.

Disconnect

Wires Here

Lamp

Base

46. Reconnect the wires to the lamp terminal bar,

re-attach the lamp base to the lamp bracket,

then re-attach the bracket to the saddle using

the (2) M6-1 x 10 cap screws removed in

Step 10, as shown in Figure 27.

Lamp

Bracket

Terminal

Bar

Figure 25. Lamp base and bracket separated.

44. Unthread the cable strain relief from the lamp

bracket, then feed the wires through the work

lamp extension shaft.

45. With the wires inserted through the bracket

hole and accessible from the top of the bracket, thread the extension shaft into the second

bracket hole, then reconnect the strain relief

(see Figure 26).

Strain

Relief

Lamp

Bracket

Figure 27. Lamp assembly reattached to saddle.

47. Re-install the compound rest and back splash

on the lathe to complete the taper attachment

assembly procedure.

Original

Extension Shaft Threaded

into Second Hole

Figure 26. Extension shaft threaded into second

hole of lamp bracket.

T10502, T10556, T26300 (Mfg. Since 3/13)

Hole

-9-

Page 10

Determining Amount of Taper

The amount of taper is expressed either in increments per length, such as 1" per foot, or degrees

of angle.

In Figure 28, the increments of taper per length

of the taper is calculated by subtracting the small

workpiece diameter (A) from the large diameter

(B) per the taper length (C).

C

Direction of Taper

The direction of taper is controlled by which way

you rotate the pivot bar.

For instance, if the headstock end of the pivot

bar is rotated toward the bedway, as shown in

Figure 30, the small end of the taper will be at the

tailstock end.

Headstock

B

Workpiece

A

Figure 28. Measuring increments per length of

taper.

For example, if

A = 2"

1

B = 3

⁄2 "

C = 12"

then the amount of taper would be calculated with

the formula B – A per C, as follows:

1

3

⁄2 " - 2" per 12", or 1 1⁄2 " per 12"

In this case, you would set the inches-per-foot

1

scale at ±1

⁄2 .

In Figure 29, the angular amount of taper is deter-

mined by the angular measurement between the

sides of the finished taper.

This End of

Pivot Bar

Rotated In

Small

End

Tailstock

Figure 30. Direction of taper in relation to pivot

bar rotation.

Operation

1. DISCONNECT LATHE FROM POWER!

2. Mount the workpiece between centers.

Angle of

Taper

Workpiece

Figure 29. Taper determined by angular

measurement.

In this case, the angular scale on the tailstock end

of the slide table would be set at the desired angle

of the taper.

-10 -

3. Loosen the bed clamp bracket cap screws

(see Figure 31), position the tooling at

approximately the center of the workpiece,

then retighten the cap screws.

Bed Clamp Bracket

Cap Screws

Figure 31. Location of bracket cap screws.

T10502, T10556, T26300 (Mfg. Since 3/13)

Page 11

4. Make sure each end of the bed clamp rod is

firmly secured.

5. Loosen the cap screw at each end of the

pivot bar (see Figure 32).

Pivot Bar

Cap Screw

(1 of 2)

Figure 32. Pivot bar cap screw

(1 of 2).

6. Determine the amount of taper (refer to the

previous page for more information).

There is always a certain amount of backlash in the taper attachment. To prevent

inconsistent turning results, always start

1

each pass with the tool approximately

⁄2"

behind the starting point on the workpiece.

To disengage the taper attachment:

1. Loosen the bed clamp bracket cap screws

(see Figure 34) so the bed clamp bracket

can freely travel along the bedway.

Bed Clamp Bracket

Cap Screws

7. Use the slide table scales and the taper

adjustment knob (see Figure 33) to adjust

the pivot bar for the desired taper.

Taper Adjustment Knob

Figure 33. Location of taper adjustment knob.

8. Retighten the cap screw on each end of the

pivot bar to secure the setting.

9. Move the carriage by hand to make sure

there is the proper amount of travel to turn

the taper. Make adjustments to the taper

attachment as necessary.

Figure 34. Location of bed clamp bracket cap

screws.

2. Loosen the cap screws at each end of the

pivot bar, rotate the taper adjustment knob

(see Figure 33) to center the bar on the

scales, then retighten the cap screws.

T10502, T10556, T26300 (Mfg. Since 3/13)

-11-

Page 12

Maintenance

To reduce risk of shock or

accidental startup, always

disconnect lathe from

power before adjustments,

maintenance, or service.

Lubricating Slide Table & Dovetail Ways

After cleaning the surfaces of the slide table and

pivot bar (see Figure 35), apply a thin coat of a

quality way oil to these surfaces (see Page 16

for an offering from Grizzly). Slide the attachment

body back and forth along the slide table to distribute the oil along the dovetail ways.

For optimum performance from the taper attachment, follow the maintenance schedule below and

follow specific instructions given in this section.

Daily

• Check/correct loose mounting fasteners.

• Clean debris and grime from all attachment

surfaces.

• Clean/lubricate unpainted surfaces of slide

table and dovetail ways.

• Correct any other unsafe condition.

Monthly

• Disassemble, clean, and lubricate pivot block,

alignment block, and internal ways inside the

attachment body.

Cleaning & Protecting

Typically, the easiest way to clean debris and

grime from the attachment is to use a wet/dry

shop vacuum that is dedicated for this purpose.

The small chips left over after vacuuming can

be wiped up with a slightly oiled rag. Avoid using

compressed air to blow off chips, as it may drive

them deeper into moving surfaces and could

cause sharp chips to fly into your face or hands.

To keep the unpainted surfaces of the slide table

and dovetail ways rust free and in top condition,

apply a thin coat of quality way oil after cleaning

them.

Pivot

Bar

Slide

Table

Figure 35. Slide table and pivot bar.

Lubricating Pivot Block, Alignment Block, &

Internal Ways

1. Remove the top cover from the attachment

body, disconnect the pivot block from the

alignment block, then remove the pivot block

(see Figure 36).

Alignment

Block

Pivot

Block

Internal

Ways

-12-

Figure 36. Internal lubrication points of taper

attachment body.

2. Clean the pivot block, alignment block, and

internal ways of the attachment body with

mineral spirits and shop rags.

3. When dry, apply a thin coat of NLGI#2 grease

to all surfaces of the blocks and internal

ways, then re-assemble the parts.

T10502, T10556, T26300 (Mfg. Since 3/13)

Page 13

Calibrating Scales

There is a small amount of side-to-side adjustment in the slide table angular and inch-per-foot

scales that allow for precise calibration with the

pivot bar (see Figure 37).

Pivot Bar

Indicator Mark

Figure 37. Pivot bar indicator mark and slide

table scale.

Tool Needed Qty

Phillips Screwdriver #2 .......................................1

Scale

Gib Adjustment

The goal of adjusting the gib screws is to remove

sloppiness or “play” from the ways without overadjusting them to the point where they become

stiff and difficult to move.

In general, loose gibs cause poor finishes and

inaccurate tapers; however, over-tightened gibs

cause premature wear and make it difficult to

move the carriage and cross slide.

Tool Needed Qty

Standard Screwdriver #2 ....................................1

Internal Gib

The internal gib is tapered and held in position by

a screw at each end (see Figure 38). To adjust

this gib, turn one screw

1

the other screw

⁄4 turn counterclockwise, so both

screws move in the same direction and the same

amount. Test the feel of the setting by moving the

carriage, and adjust the gib screws as necessary

to make it tighter or looser.

1

⁄4 turn clockwise and

To calibrate the slide table scales:

1. Adjust the pivot bar so that the indicator marks

aligns with the “0” marks on the scales.

2. Turn a length of round stock and measure the

amount of taper, if any, from one end to the

other.

— If there is no taper on the round stock and

the pivot bar indicator marks align with the

“0” mark on each scale, no further adjustment is required.

— If there is no taper on the round stock but

the pivot bar indicator marks do not align

with “0” mark on each scale, continue with

the next step.

— If there is a taper on the round stock, adjust

the pivot bar to remove the taper, then

repeat this step.

3. Loosen the Phillips head screws that secure

the scales, and shift them until the “0” marks

align with the pivot bar indicator mark, then

retighten the screws.

4. To recheck the settings, repeat Step 2.

Internal Gib

Adjustment Screw

(1 of 2)

External

Hex Nuts

Gib

& Cap Screws

Figure 38. Locations of gib components.

Tools Needed Qty

Wrench 10mm ....................................................1

Hex Wrench 5mm ...............................................1

External Gib

The external gib is wedge-shaped and is held in

position by three cap screws (see Figure 38). To

adjust this gib, loosen the hex nuts and turn the

cap screws in equal amounts. Test the feel of the

setting by moving the carriage, and adjust the cap

screws as necessary to make it tighter or looser.

When satisfied with the movement, retighten the

hex nuts to secure the setting.

T10502, T10556, T26300 (Mfg. Since 3/13)

-13-

Page 14

Parts Diagram

13

12

5

15

127

115

117

104

102

125

126

114

106

129

23

18

19

18

17

16

22

6

8

3

3

1

2

14

11

10

9

7

20

21

4

108

139

105

137

128

138

133

134

101

110

132

109

115

136

107

131

119

120

111

113

130

116

122

118

124

123

103

135

121

112

26

121

-14-

T10502, T10556, T26300 (Mfg. Since 3/13)

Page 15

Parts List

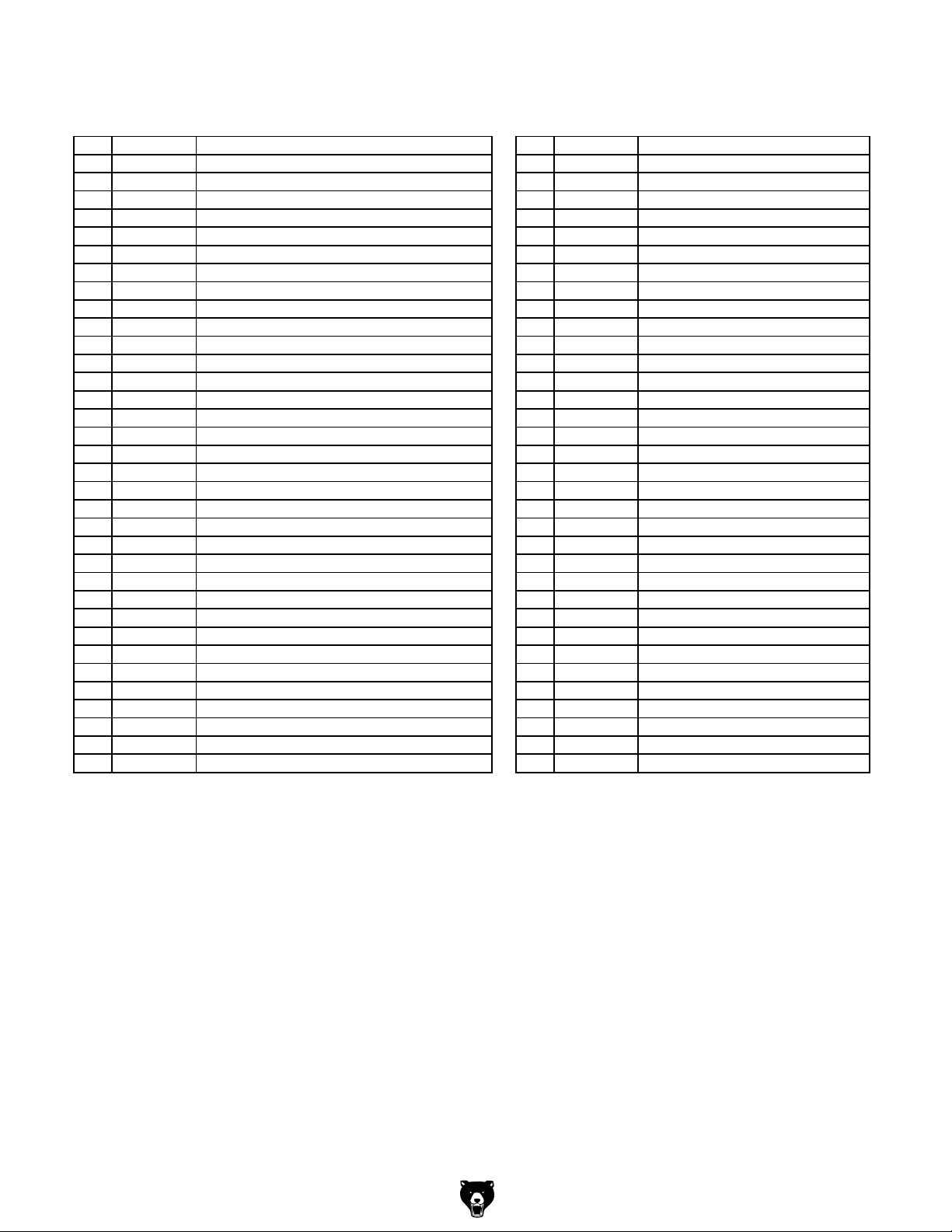

REF PART # DESCRIPTION REF PART # DESCRIPTION

1 PT10556001 HANDWHEEL BRACKET (T10556 & T26300) 105 PT10556105 TOP COVER

1 PT10502001 HANDWHEEL BRACKET (T10502) 106 PT10556106 SLIDE BLOCK

2 PCAP06M CAP SCREW M6-1 X 25 107 PT10556107 SLIDE TABLE

3 P51102 THRUST BEARING 51102 108 PT10556108 PIVOT BLOCK

4 PT10556004 GEAR SHAFT 13T (T10556) 109 PT10556109 GIB

4 PT10502004 GEAR SHAFT 19T (T10502) 110 PT10556110 CLAMP BAR

4 PT26300004 GEAR SHAFT 17T (T26300) 111 PT10556111 PIVOT SHAFT

5 PT10556005 CROSS SLIDE LEADSCREW (T10556 & T26300) 112 PT10556112 BED CLAMP PIVOT SHAFT

5 PT10502005 CROSS SLIDE LEADSCREW (T10502) 113 PT10556113 BED CLAMP ROD

6 PT10556006 ALIGNMENT KEY W/ONE HOLE 114 PT10556114 GIB ADJUSTMENT SCREW

7 PT10556007 HANDWHEEL (T10556 & T26300) 115 PCAP13M CAP SCREW M8-1.25 X 30

7 PT10502007 HANDWHEEL (T10502) 116 PT10556116 SHAFT MOUNTING BLOCK

8 PK06M KEY 5 X 5 X 10 117 PCAP11M CAP SCREW M8-1.25 X 16

9 PT10556009 HANDWHEEL RETAINER 118 PT10556118 KNURLED KNOB

10 PT10556010 COMPRESSION SPRING 0.7 X 5 X 10 119 PT10556119 TAPER ADJUSTMENT SHAFT

11 PSTB003M STEEL BALL 6MM 120 PRP02M ROLL PIN 3 X 16

12 PT10556012 HANDWHEEL HANDLE 121 PCAP01M CAP SCREW M6-1 X 16

13 PT10556013 SHOULDER SCREW M8-1.25 X 16 75L 122 PT10556122 BED CLAMP BLOCK

14 PT10556014 GRADUATED DIAL (T10556 & T26300) 123 PCAP45M CAP SCREW M8-1.25 X 45

14 PT10502014 GRADUATED DIAL (T10502) 124 PCAP48M CAP SCREW M6-1 X 35

15 PSS117M SET SCREW M5-.8 X 16 CONE-PT 125 PCAP72M CAP SCREW M10-1.5 X 30

16 PT10556016 THRUST WASHER 126 PRP05M ROLL PIN 5 X 30

17 PT10556017 SPACER 127 PFH27M FLAT HD SCR M4-.7 X 6

18 P51101 THRUST BEARING 51101 128 PCAP109M CAP SCREW M5-.8 X 50

19 PT10556019 ALIGNMENT BLOCK 129 PT10556129 PIVOT BLOCK PIN

20 PN50M HEX NUT M10-1.5 THIN 130 PT10556130 BED CLAMP ROD STOP BLOCK

21 PFH49M FLAT HD SCR M3-.5 X 6 131 PCAP02M CAP SCREW M6-1 X 20

22 PT10556022 CROSS SLIDE LEADSCREW NUT 132 PCAP06M CAP SCREW M6-1 X 25

23 PW06M FLAT WASHER 12MM 133 PN01M HEX NUT M6-1

26 PT10556026 WORK LAMP EXTENSION SHAFT 134 PSS134M SET SCREW M6-1 X 20 CUP-PT

101 PT10556101 BODY 135 PT10556135 TPF SCALE PLATE

102 PT10556102 PIVOT BLOCK 136 PS79M PHLP HD SCR M3-.5 X 8

103 PT10556103 BED CLAMP BRACKET (T10556 & T26300) 137 PT10556137 REAR COVER

103 PT10502103 BED CLAMP BRACKET (T10502) 138 PCAP03M CAP SCREW M5-.8 X 8

104 PT10556104 ALTERNATE LEADSCREW REAR BRACKET 139 PT10556139 ANGLE SCALE PLATE

T10502, T10556, T26300 (Mfg. Since 3/13)

-15-

Page 16

Accessories

order online at www.grizzly.com or call 1-800-523-4777

NOTICE

Refer to our website or latest catalog for

additional recommended accessories.

T23962—ISO 68 Moly-D Way Oil, 5 gal.

T23963—ISO 32 Moly-D Machine Oil, 5 gal.

Moly-D oils are some of the best we've found for

maintaining the critical components of machinery

because they tend to resist run-off and maintain

their lubricity under a variety of conditions—as

well as reduce chatter or slip. Buy in bulk and

save with 5-gallon quantities.

T24802—iGaging® Digital Indicator & Magnetic

Base Set

Includes iGaging

which has a range of 0–6"/150mm, and can read

and convert in inch, metric, and fractions. Fine

adjustment magnetic base has 85 lbs. of pull

power. Magnetic indicator back for position indicator on metal surfaces. Protective case included.

®

3-reading digital indicator,

T23962

Figure 39. ISO 68 and ISO 32 machine oil.

T23964—Armor Plate with Moly-D MultiPurpose Grease, 14.5 oz. (NLGI#2 Equivalent)

Armor Plate with Moly-D is a rich green moly

grease that provides excellent stability and unsurpassed performance under a wide range of

temperatures and operating conditions. Armor

Plate grease is entirely unique due to the fact that

the moly in it is solubilized which provides superior performance to other greases containing the

black solid form of molybdenum disulfide.

T23963

®

Figure 41. Model T24802 iGaging

Indicator & Magnetic Base Set.

G9766—29 Piece HSS Metric Drill & Tap Set

We offer a set of taps with all the drill bits necessary to produce perfectly tapped holes, Each size

has three tapes which include a starting taper

tap, a secondary intermediate tap, and a finishing

bottom tap. These are great taps for those hardto-tap materials. Sizes: M3-0.5, M4-0.7, M5-0.8,

M6-1.0, M8-1.25, M10-1.5, and M12-1.75. Includes

tap handle and storage case.

Digital

Figure 40. T23964 Armor Plate with Moly-D

Multi-Purpose Grease

Figure 42. Model G9766 Drill & Tap Set.

-16 -

T10502, T10556, T26300 (Mfg. Since 3/13)

Loading...

Loading...